Process lubrication optimization method aiming at stable rolling under large deformation of DCR unit

A technology of process lubrication and optimization method, which is applied in the direction of workpiece lubrication device, design optimization/simulation, roll, etc., can solve the problem of high front slip and rolling pressure, reduce the incidence of strip instability, and affect the rolling of the unit Stability and other issues, to achieve the effect of improving stability and uniform cooling capacity of emulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

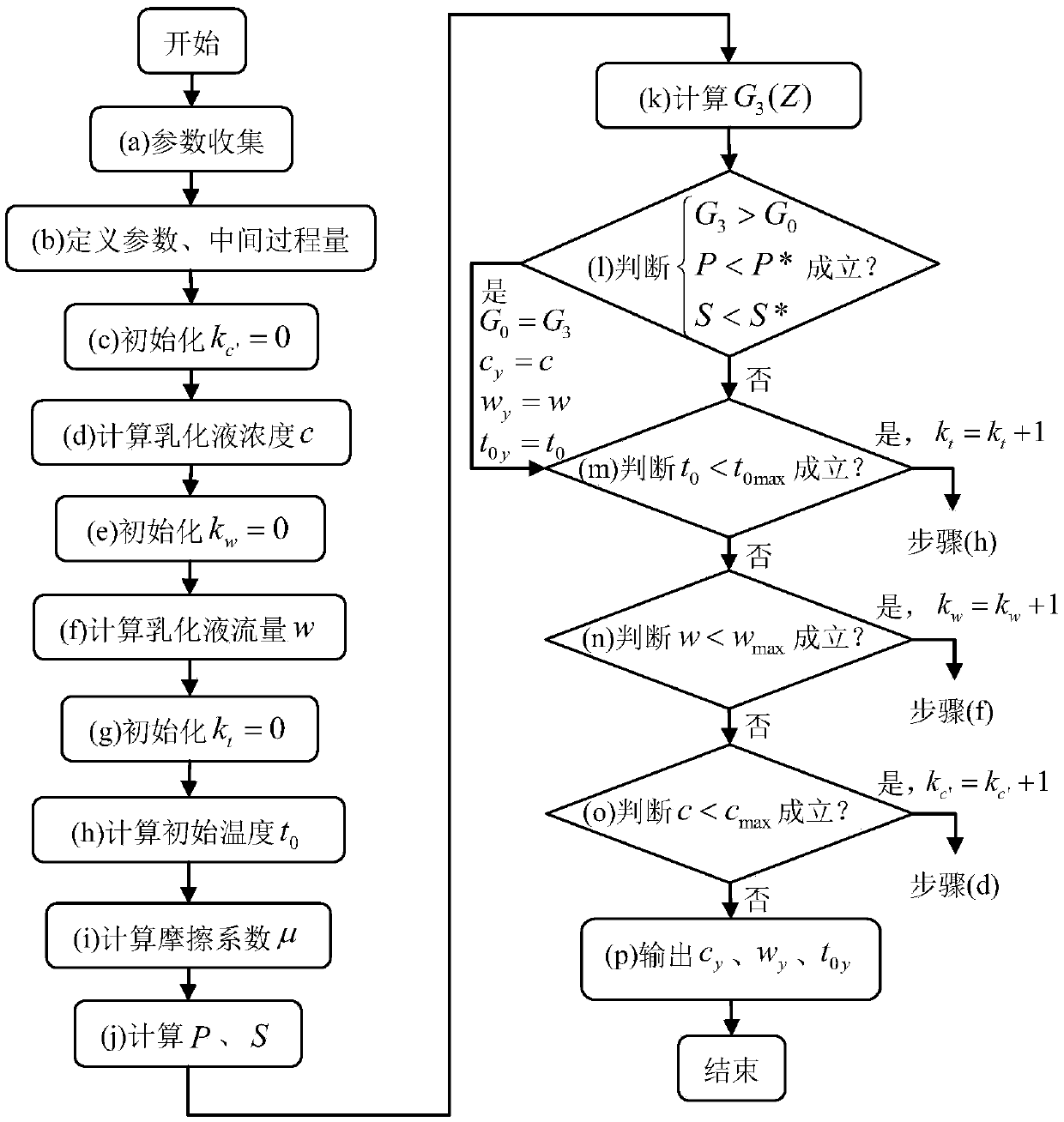

Method used

Image

Examples

Embodiment 1

[0032] (a) Collect the main equipment and process parameters of the secondary cold rolling unit, mainly including the following steps:

[0033] a1) Collect the roll process parameters of the cold rolling mill, mainly including: work roll diameter D=435mm; original surface roughness Ra r0 =0.52μm, the modulus of elasticity E=210GPa of the work roll, the Poisson's ratio v=0.27 of the work roll;

[0034] a2) Collect the relevant rolling process parameters of the secondary cold rolling unit, mainly including: the average deformation resistance K of the strip M =475MPa and yield strength σ s =500MPa, strip width B=908mm, incoming material thickness h 0 = 0.276mm, reduction rate ε = 46.8%, normal rolling speed V = 230m / min, rolling pressure setting value P = 401t, front tension T 1 =250MPa, back tension T 0 =300MPa, unit front tension σ 1 =21.1MPa, unit back tension σ 0 =12.7MPa;

[0035] a3) Collect process lubrication system parameters, mainly including dynamic viscosity of...

Embodiment 2

[0053] (a) Collect the main equipment and process parameters of the secondary cold rolling unit, mainly including the following steps:

[0054] a1) Collect the roll process parameters of the cold rolling mill, mainly including: work roll diameter D=435mm; original surface roughness Ra r0 = 0.52 μm, the elastic modulus E of the work roll = 210GPa, the Poisson’s ratio of the work roll v = 0.27; a2) Collect the relevant rolling process parameters of the secondary cold rolling unit, mainly including: the average deformation resistance K of the strip m =475MPa and yield strength σ s =500MPa, strip width B=908mm, incoming material thickness h 0 = 0.276mm, reduction rate ε = 47.5%, normal rolling speed V = 230m / min, rolling pressure setting value P = 4650KN, front tension T 1 =200MPa, back tension T 0 =250MPa, unit front tension σ 1 =20.3MPa, unit back tension σ 0 =12.7MPa;

[0055] a3) Collect process lubrication system parameters, mainly including dynamic viscosity of emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com