Environment-friendly nano calcium carbonate carbonation method

A technology of nano-calcium carbonate and carbonation, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, nanotechnology, etc., can solve the problems of solid particle pollution, poor effect, high dust content in tail gas, etc., and achieve good economy and Social benefits, simple production control process, and the effect of prolonging the escape time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

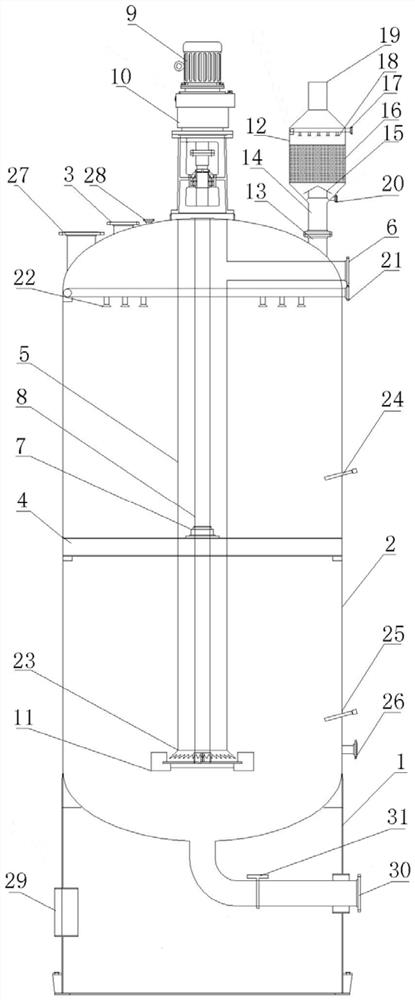

[0038] A kind of environment-friendly nano-calcium carbonate carbonation method, comprises the following steps:

[0039] S1: Preparation of seed crystals: In the initial state, the slurry discharge valve 31 of the reaction kettle is closed; the slurry inlet valve is opened, and the lime slurry with a temperature of 15°C enters the kettle body 2 from the slurry inlet pipe 3, and the stirring motor 9 is started, and the slurry is passed through the reducer 10 Drive the agitator shaft 8 to drive the agitator 11 to rotate for stirring. The rotation speed of the agitator 11 is 2m / s; the ultrasonic level gauge interface 28 is connected to the liquid level gauge to control the amount of slurry entering. When the amount of slurry entering reaches the reaction kettle When the volume is 1 / 5, close the slurry inlet valve, stop the feeding, adjust the speed of the agitator 11 to 6m / s at the same time, open the water inlet valve I, and the drain valve to connect the water inlet pipe I17 and...

Embodiment 2

[0042] A kind of environment-friendly nano-calcium carbonate carbonation method, comprises the following steps:

[0043] S1: Preparation of seed crystals: In the initial state, the slurry discharge valve 31 of the reaction kettle is closed; the slurry inlet valve is opened, and the lime slurry with a temperature of 10°C enters the kettle body 2 from the slurry inlet pipe 3, and the stirring motor 9 is started, and the slurry is passed through the reducer 10 Drive the agitator shaft 8 to drive the agitator 11 to rotate for stirring, and the rotation speed of the agitator 11 is 3m / s; the ultrasonic level gauge interface 28 is connected to the liquid level gauge to control the amount of slurry entering, when the amount of slurry entering reaches the reaction kettle When the volume is 3 / 10, close the slurry inlet valve, stop feeding, adjust the speed of the agitator 11 to 8m / s at the same time, open the water inlet valve I, and connect the water inlet valve I17 and the drain pipe 2...

Embodiment 3

[0046] A kind of environment-friendly nano-calcium carbonate carbonation method, comprises the following steps:

[0047] S1: Seed crystal preparation: In the initial state, the slurry discharge valve 31 of the reaction kettle is closed; the slurry inlet valve is opened, and the lime slurry with a temperature of 5°C enters the kettle body 2 from the slurry inlet pipe 3, and the stirring motor 9 is started, and the slurry is passed through the reducer 10 Drive the agitator shaft 8 to drive the agitator 11 to rotate for stirring, and the rotation speed of the agitator 11 is 4m / s; the ultrasonic liquid level gauge interface 28 is connected to the liquid level gauge to control the amount of slurry entering, when the amount of slurry entering reaches the reaction kettle When the volume is 2 / 5, close the slurry inlet valve, stop feeding, adjust the speed of the agitator 11 to 10m / s at the same time, open the water inlet valve I, and the drain valve to connect the water inlet pipe I17 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com