Patents

Literature

196results about How to "Fully washed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

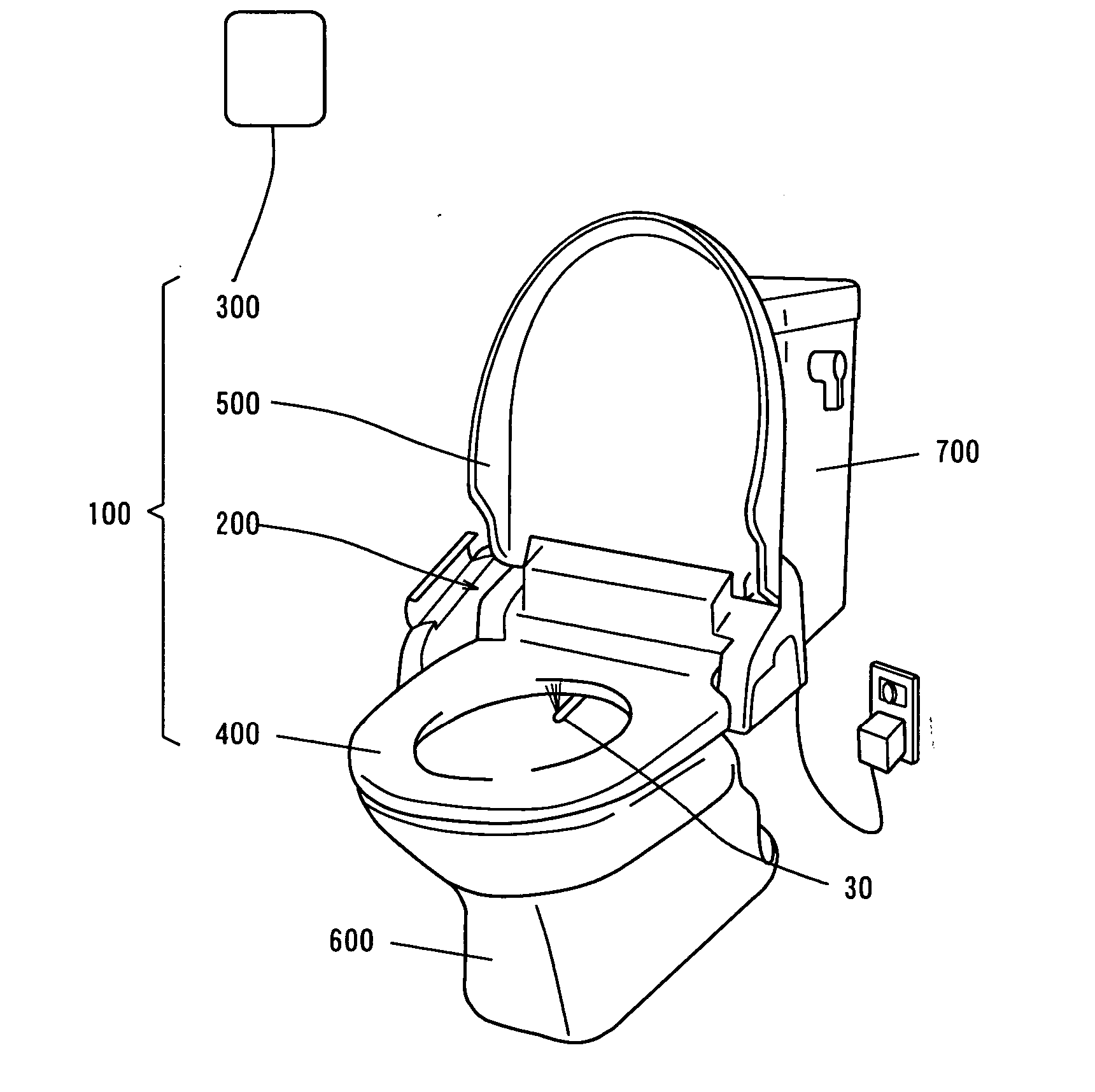

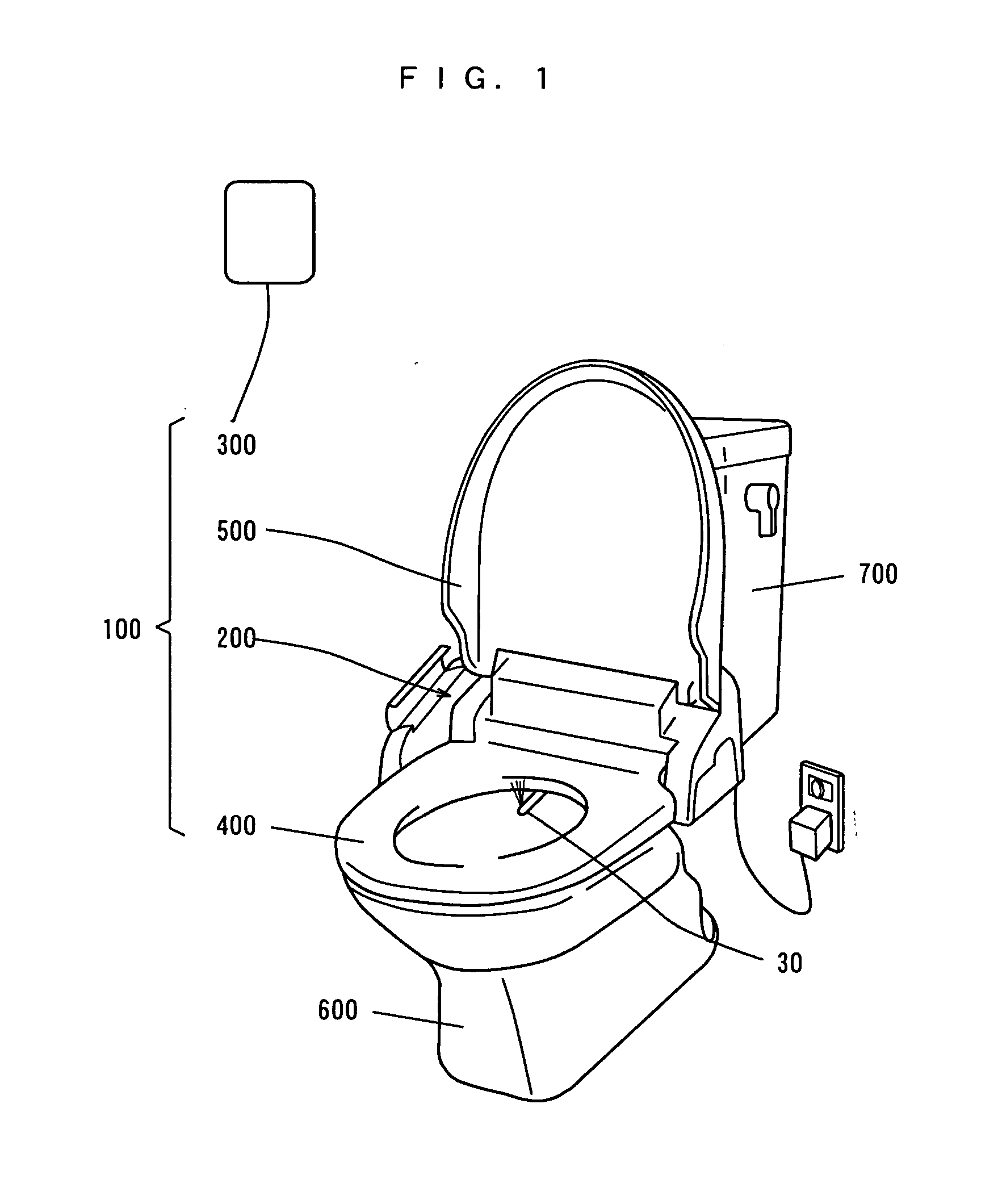

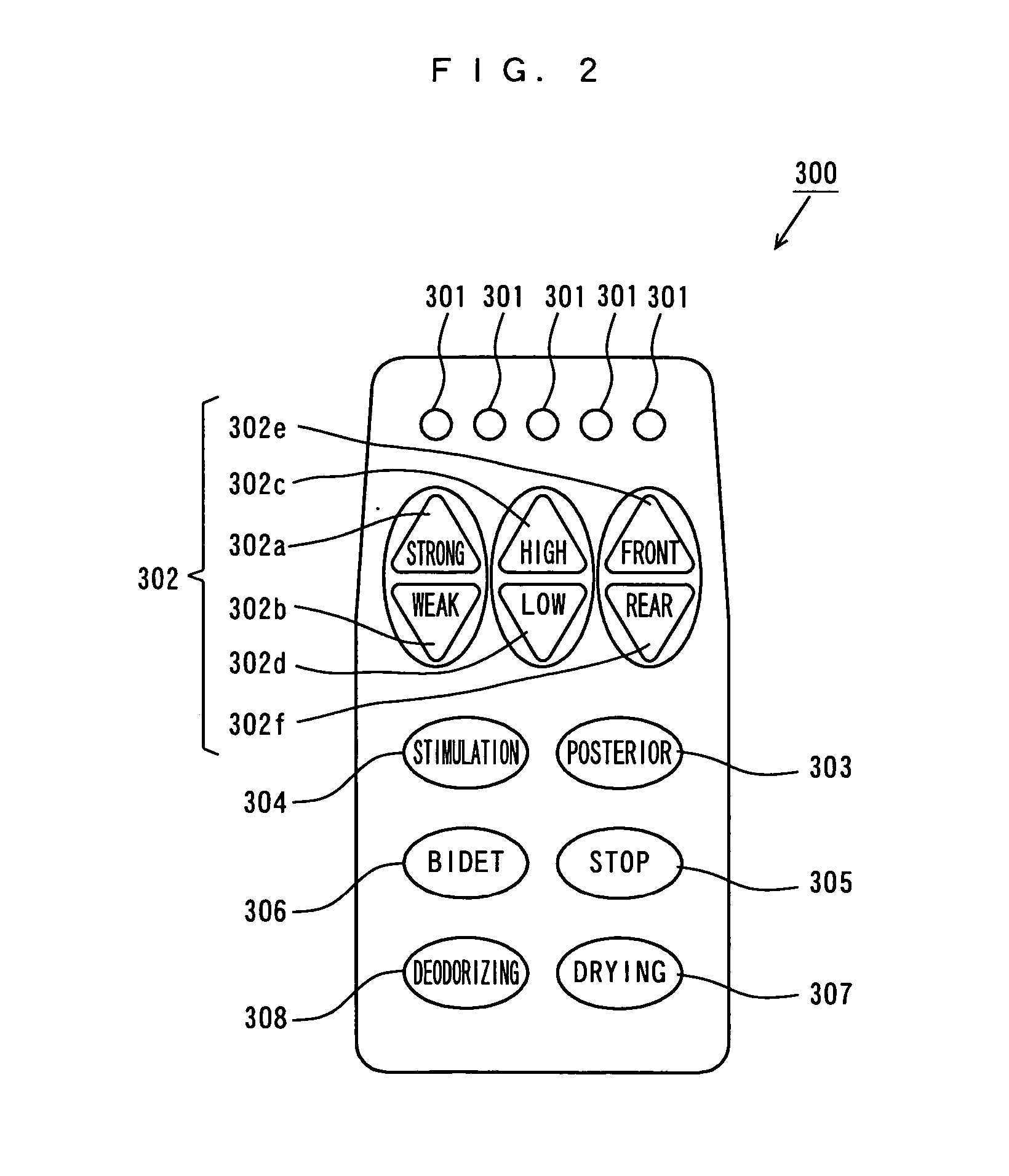

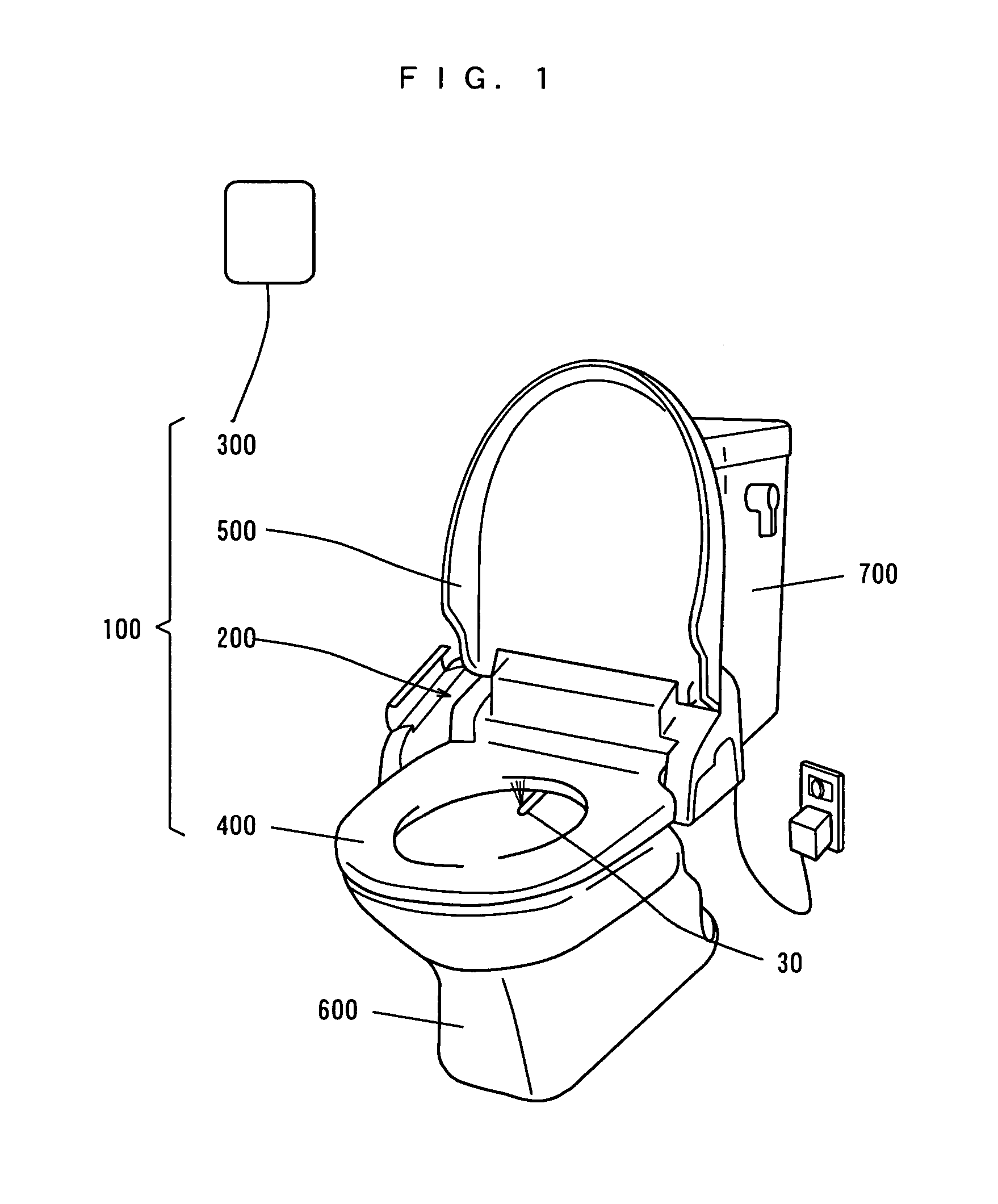

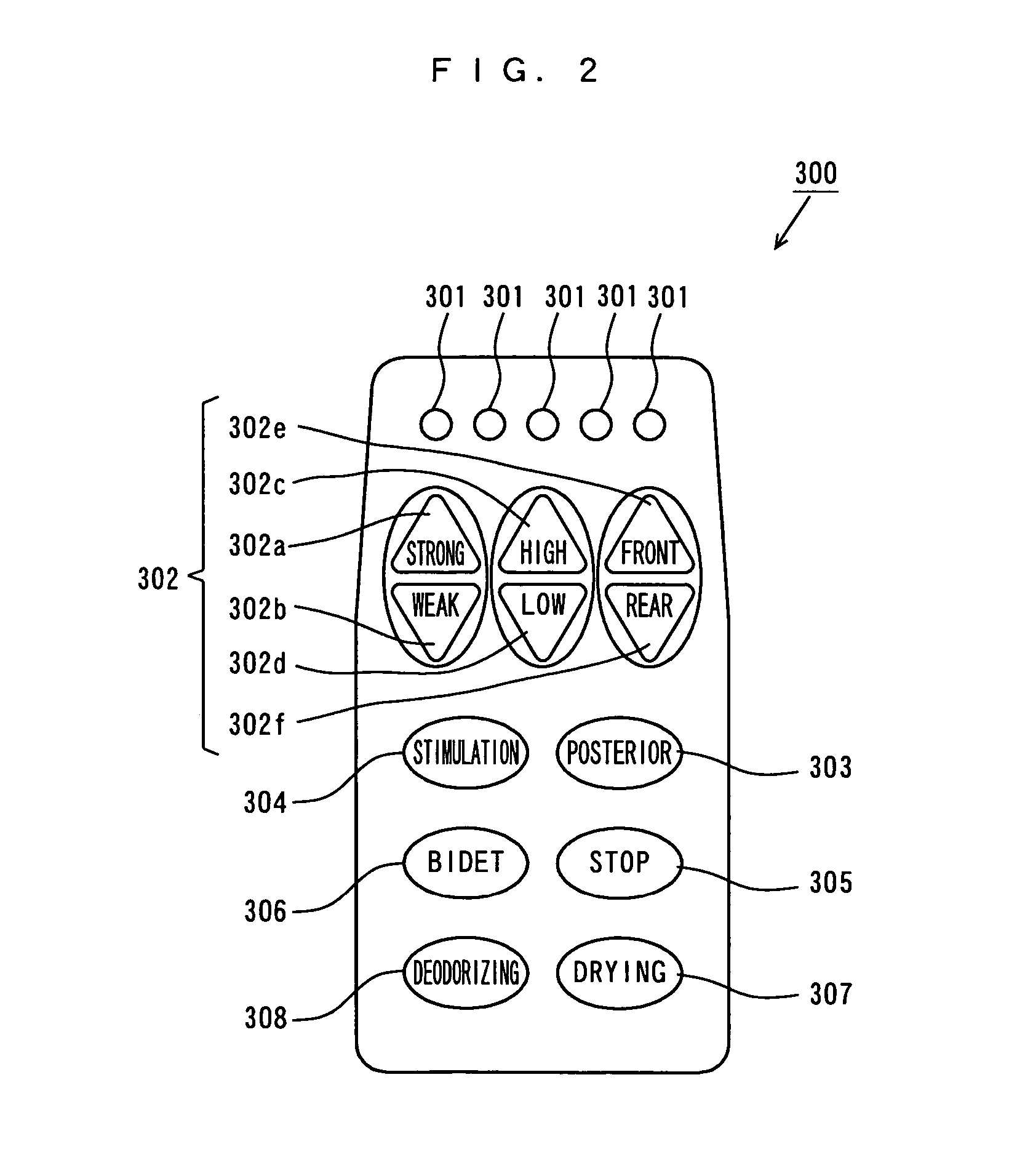

Nozzle device and hygienic washing device

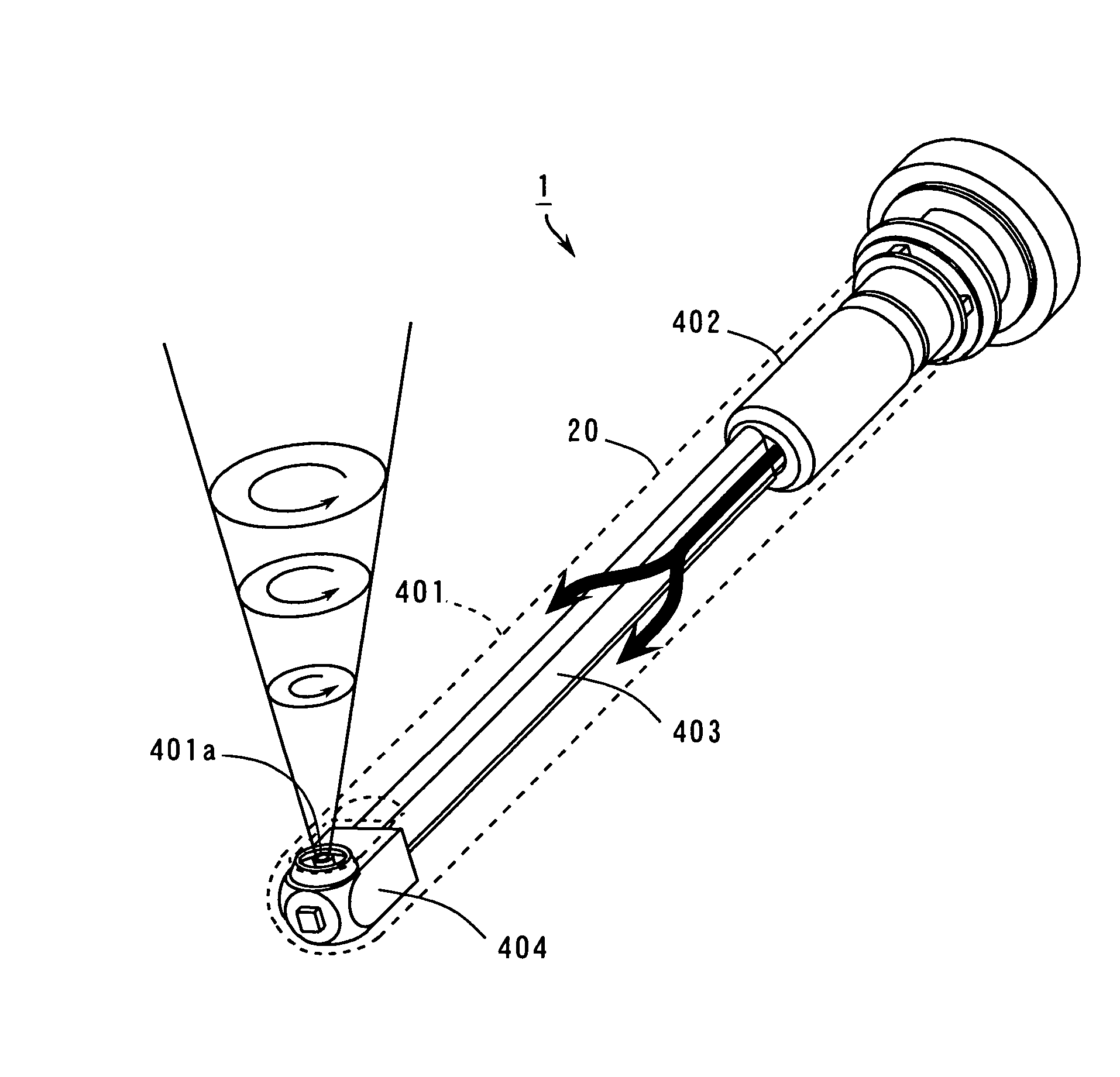

Since the inner diameter of a flow-contracting portion continuously decreases toward a cylindrical swirl chamber, the velocity of flow of washing water flowing in the flow-contracting portion continuously rises. Since the inner diameter of the flow-contracting portion continuously decreases toward a spray hole, the velocity of flow of the washing water flowing in the flow-contracting portion continuously rises. Washing water supplied to one of flow paths in a two-flow path pipe is supplied to a flow path merger through a one-flow path pipe. The washing water supplied to the other flow path in the two-flow path pipe is supplied to the flow path merger after passing through a space between the one-flow path pipe and a nozzle cover. Washing water sprayed from a nozzle cleaning hole flows out of an opening at a front end of a nozzle cleaning cylinder along an outer peripheral surface of a piston while being spirally swirled in a space between an inner wall of the nozzle cleaning cylinder and the outer peripheral surface of the piston. A position fixing member having a curved shape along an inner surface at a front end of the nozzle cover is formed at a front end of the flow path merger. While a posterior nozzle moves from a forward position to a backward position, dispersed spiral flow and linear flow are alternately sprayed.

Owner:PANASONIC CORP

Method for preparing ultrafine high-whiteness active barite powder

ActiveCN102616824AConserve waterFully washedCalcium/strontium/barium sulfatesOXALIC ACID DIHYDRATEHydrogen Sulfate

The invention relates to the field of mineral materials, in particular to a method for preparing ultrafine high-whiteness active barite powder. The method comprises the following steps of: (1) preparing pulp from 325-mesh barite powder, and performing wet ultrafine grinding until the particle size is less than 10mu m; (2) filtering the barite pulp subjected to wet ultrafine grinding, and drying; (3) adding mixed acid into the dried ultrafine barite powder, and performing oxidation leaching reaction with stirring, wherein the mixed acid is a mixed solution of sulfuric acid, hydrofluoric acid and oxalic acid; (4) filtering the barite powder subjected to oxidation leaching reaction by the mixed acid, and washing until the pH is 6 to 7; and (5) performing pressure filtration, and drying to obtain the ultrafine high-whiteness active barite powder. The preparation method is simple and controllable and easy to popularize, equipment can be localized completely, over 99 percent of prepared barite product has the particle size of -10mu m, and the whiteness is over 90 percent.

Owner:WUHAN UNIV OF TECH

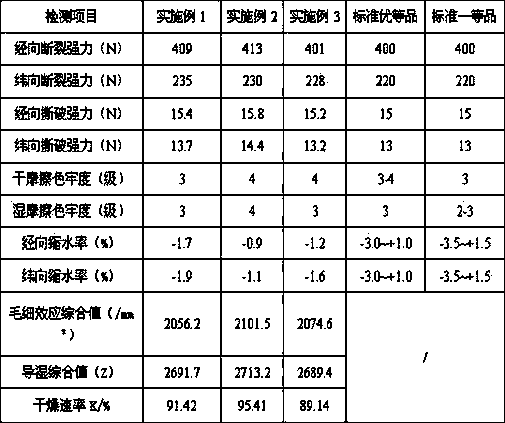

Polyester/cotton interwoven fabric dyeing and fishing process

InactiveCN103437213AImprove durabilityFully washedDry-cleaning apparatus for textilesBleaching apparatusReactive dyePolyester

The present invention discloses a polyester / cotton interwoven fabric dyeing and fishing process, which comprises cold stacking, washing and blanching, shaping, mercerizing, ammonia nitrogen emission-free environmental-protection type dispersing reactive printing, persistent moisture absorption and sweat releasing finishing, and stentering and anti-shrinking treating. According to the present invention, in the ammonia nitrogen emission-free environmental-protection type dispersing reactive printing, the color fixation method that baking soda and urea are added to a printing slurry after printing drying in the traditional process are abandoned, only a dye, a paste and other materials are added to a printing slurry, an alkali agent and gravy salt rapid steam color fixation method is adopted after printing drying to make color fixation of a reactive dye, the whole process does not adopt urea as the additive, no ammonia nitrogen exists in the discharged water, and characteristics of environmental protection and energy saving are provided; and the persistent moisture absorption and sweat releasing finishing process adopts a nano-scale moisture absorption rapid drying agent and a washing resistance fixing agent, and the used additives and fibers are subjected to cross-linking after high temperature baking so as to significantly increase function persistence.

Owner:SUNTEX

Nozzle device and hygienic washing device

In a nozzle device a spray hole for spraying washing water and a pipe forming a first flow path that introduces the washing water to the spray hole is provided. Further, the spray hole is provided in a cover that surrounds the pipe. The cover is integrally formed of a cylindrical metal whose front end is closed. A space between an outer surface of the pipe and an inner peripheral surface of the cover member forming a second flow path that introduces the washing water to the spray hole. Further, the second flow path surrounds surface of the pipe in a circumferential direction of the cover member.

Owner:PANASONIC CORP

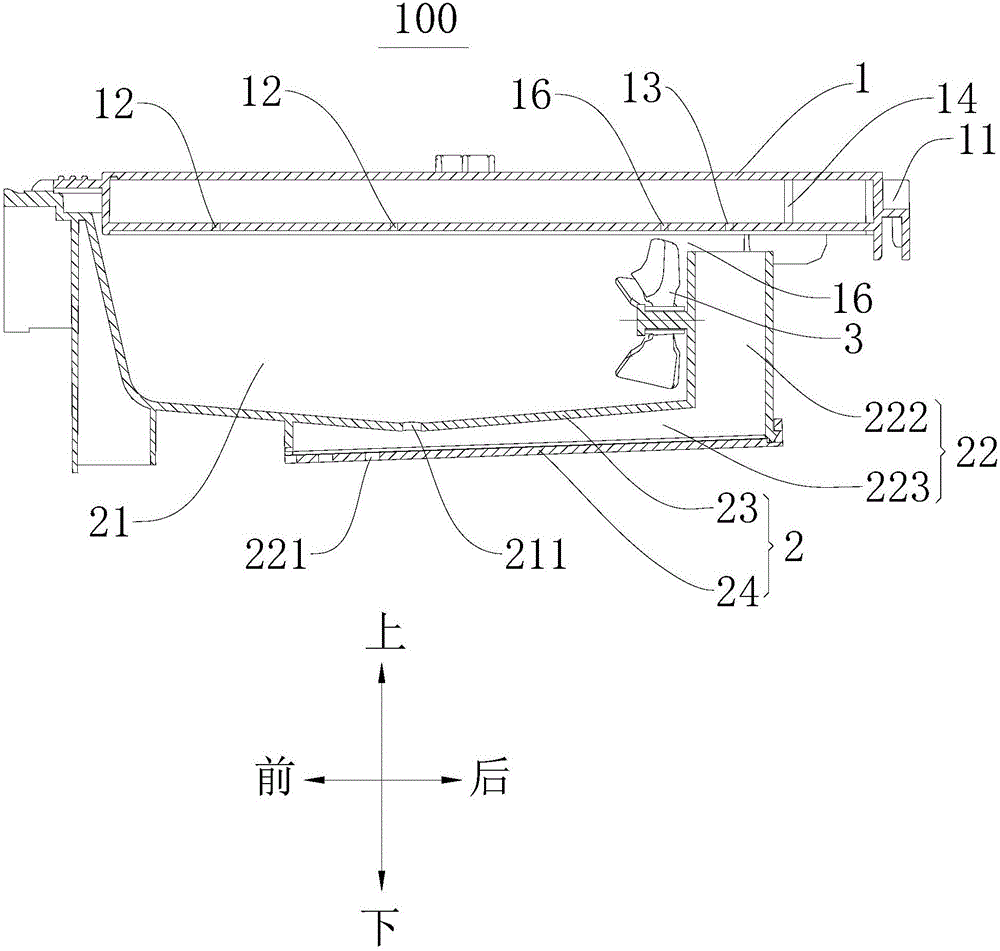

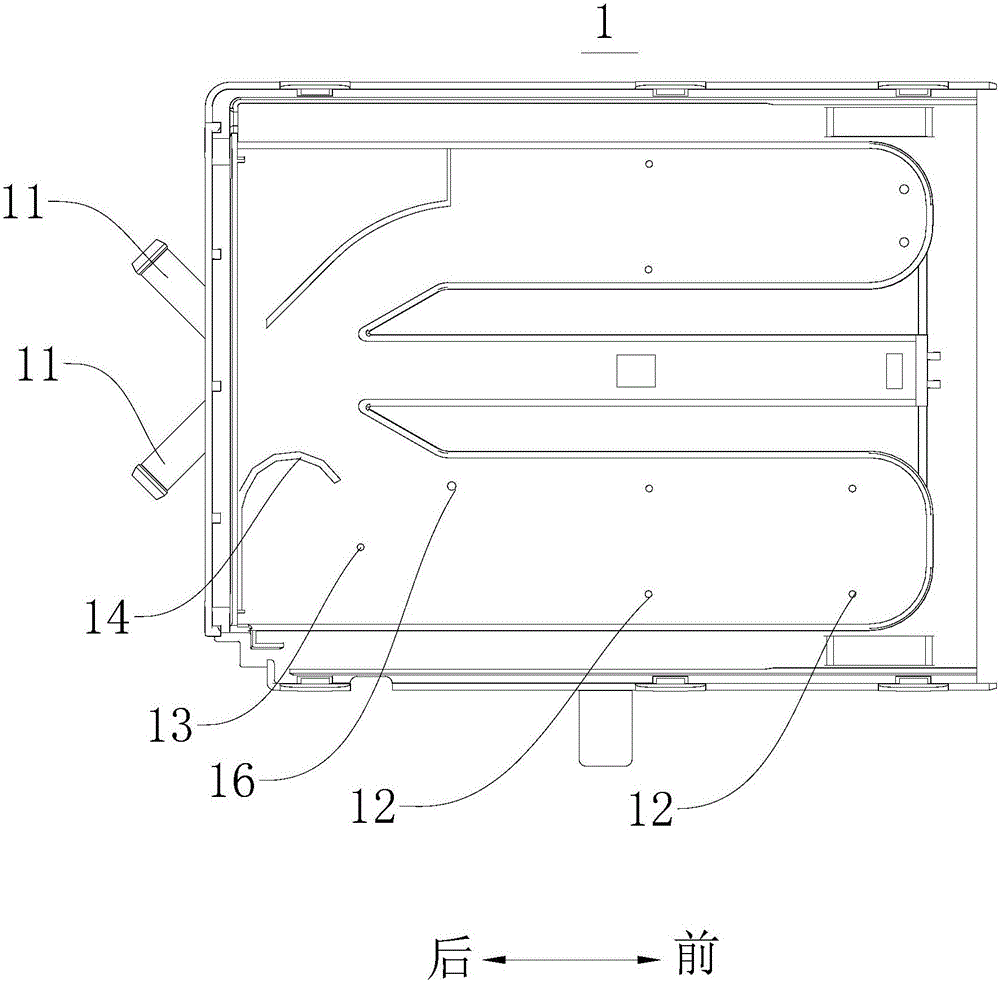

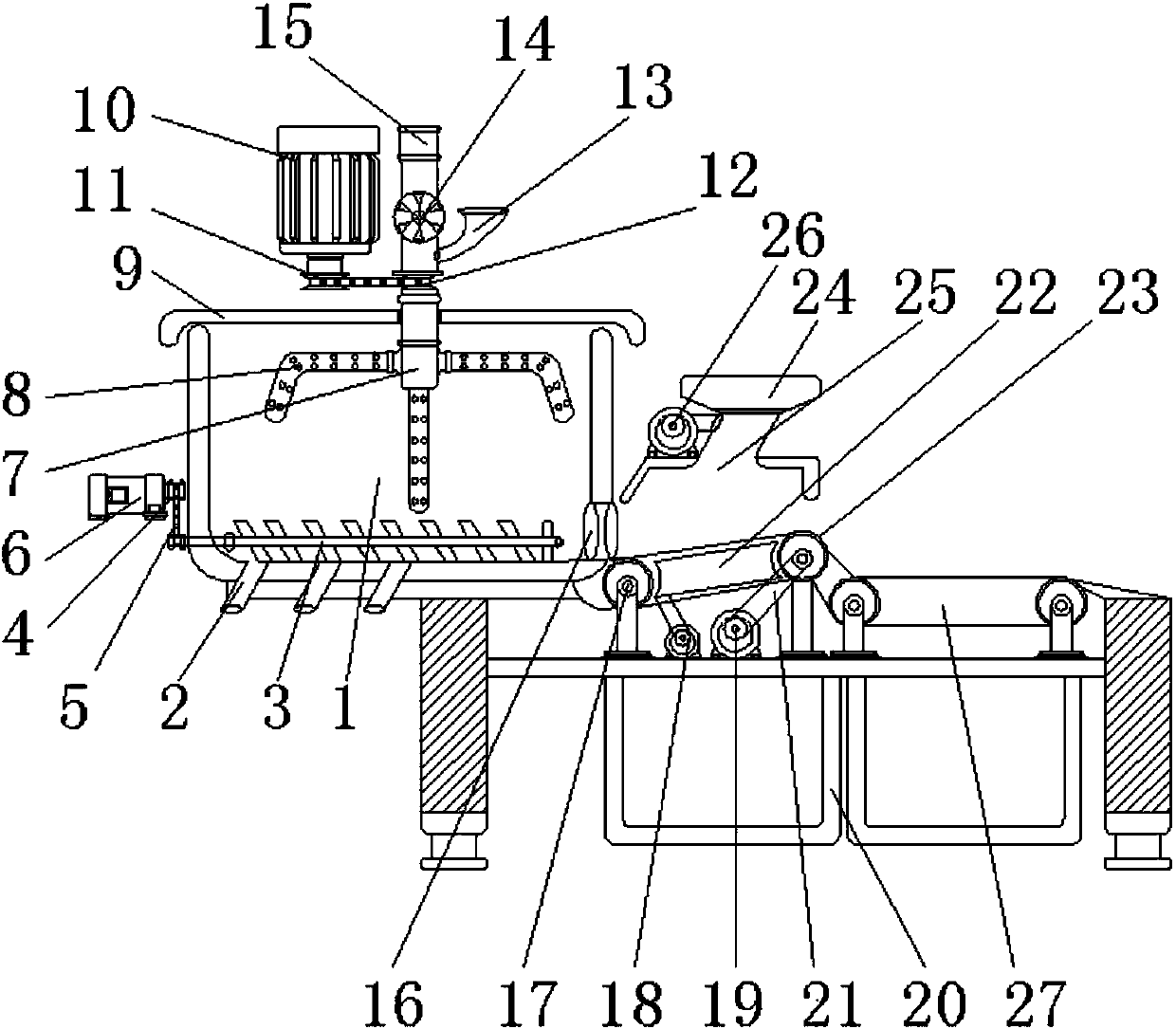

Dissolving device used for roller washing machine and roller washing machine with same

PendingCN106637833AImprove washing effectImprove solubilityOther washing machinesTextiles and paperImpellerWater discharge

The invention discloses a dissolving device used for a roller washing machine and the roller washing machine with the same. The dissolving device used for the roller washing machine comprises a water inlet case, a dissolving case and vane wheels, wherein the water inlet case is provided with a water inlet, a first water discharging port communicated with the water inlet, and a water flushing port communicated with the dissolving case, the dissolving case is arranged below the water inlet case, a first dissolving cavity which is communicated with the first water discharging port is defined in the dissolving case, the bottom wall of the first dissolving cavity forms an inverted conical shape and is provided with a first water outlet which is used for discharging water flow out, the vane wheels are rotationally arranged on the side wall of the dissolving case and is located at a degating position, and the water in the water inlet case rushes towards the vane wheels through the water flushing port so as to propel the vane wheels to rotate. According to the dissolving device used for the roller washing machine, sufficient dissolving of a detergent can be achieved, the dissolving efficiency of the detergent is improved, so that clothes are completely washed, and the washing effect of the washing machine is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

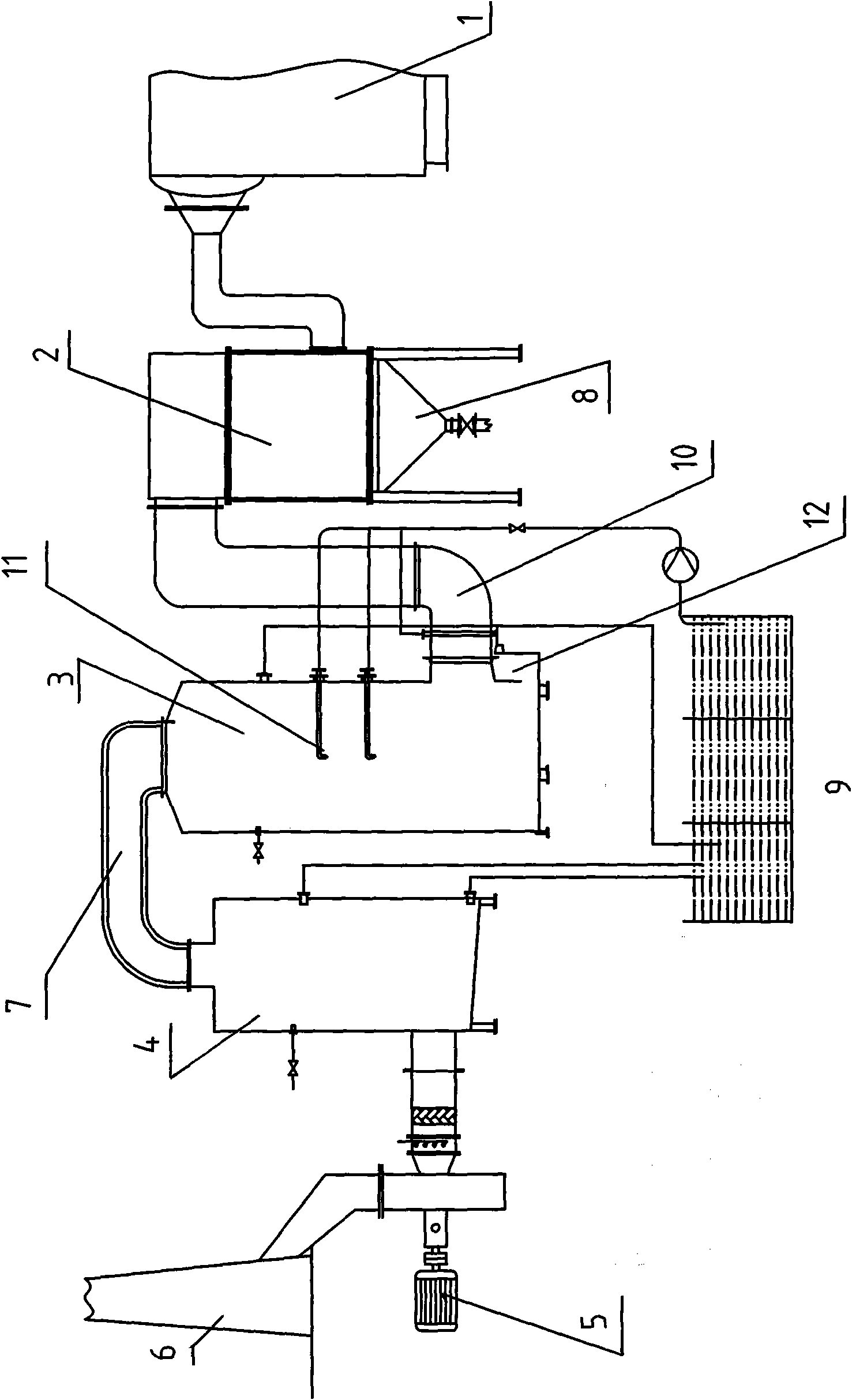

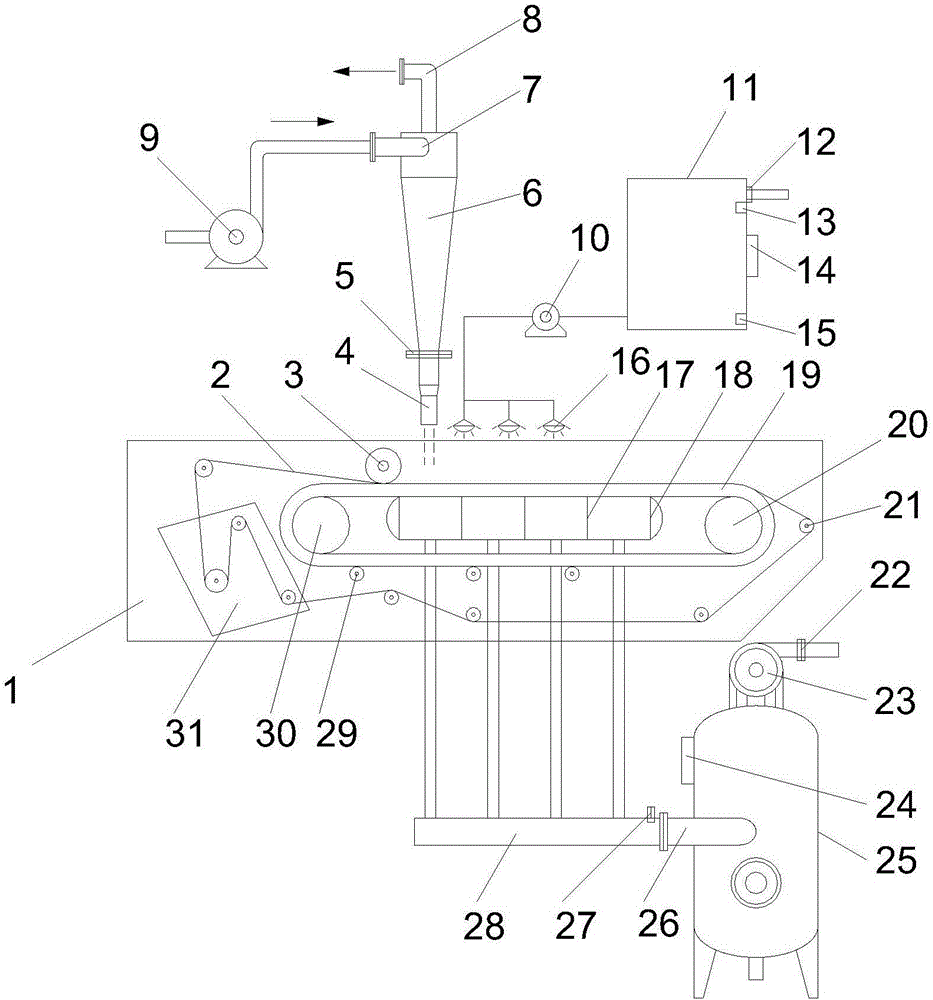

Combined three-stage efficient desulfurization dust-removal system and method thereof

The invention provides a combined three-stage efficient desulfurization dust-removal system and a method thereof. The system comprises a dry dust remover internally provided with a turboseparator, a desulfurization purification tower and a centrifugal hydroextractor which are arranged between a flue gas generating device and a chimney in sequence and are communicated by an connecting channel, wherein a venturi is arranged at the front of the tangential inlet of the desulfurization purification tower, and a draught fan is arranged between the centrifugal hydroextractor and the chimney. In the method, firstly about 90% dust particles are removed in the dry dust remover by dry dust removal, then wet desulphurization dust removal is carried out in the venturi and the desulfurization purification tower for many times, and finally dehydration, dehumidify and discharge are carried out in the centrifugal hydroextractor. The wear of flue gas on the device is reduced with high dust removal efficiency and the invention enjoys good desulfurization effect, stable property, long service life and easy operation, thus thoroughly overcoming the disadvantages of easy corrosive wear of other desulfurization dust-removal devices.

Owner:BEIJING TONGMING ENVIRONMENTAL PROTECTION EQUIP FACTORY

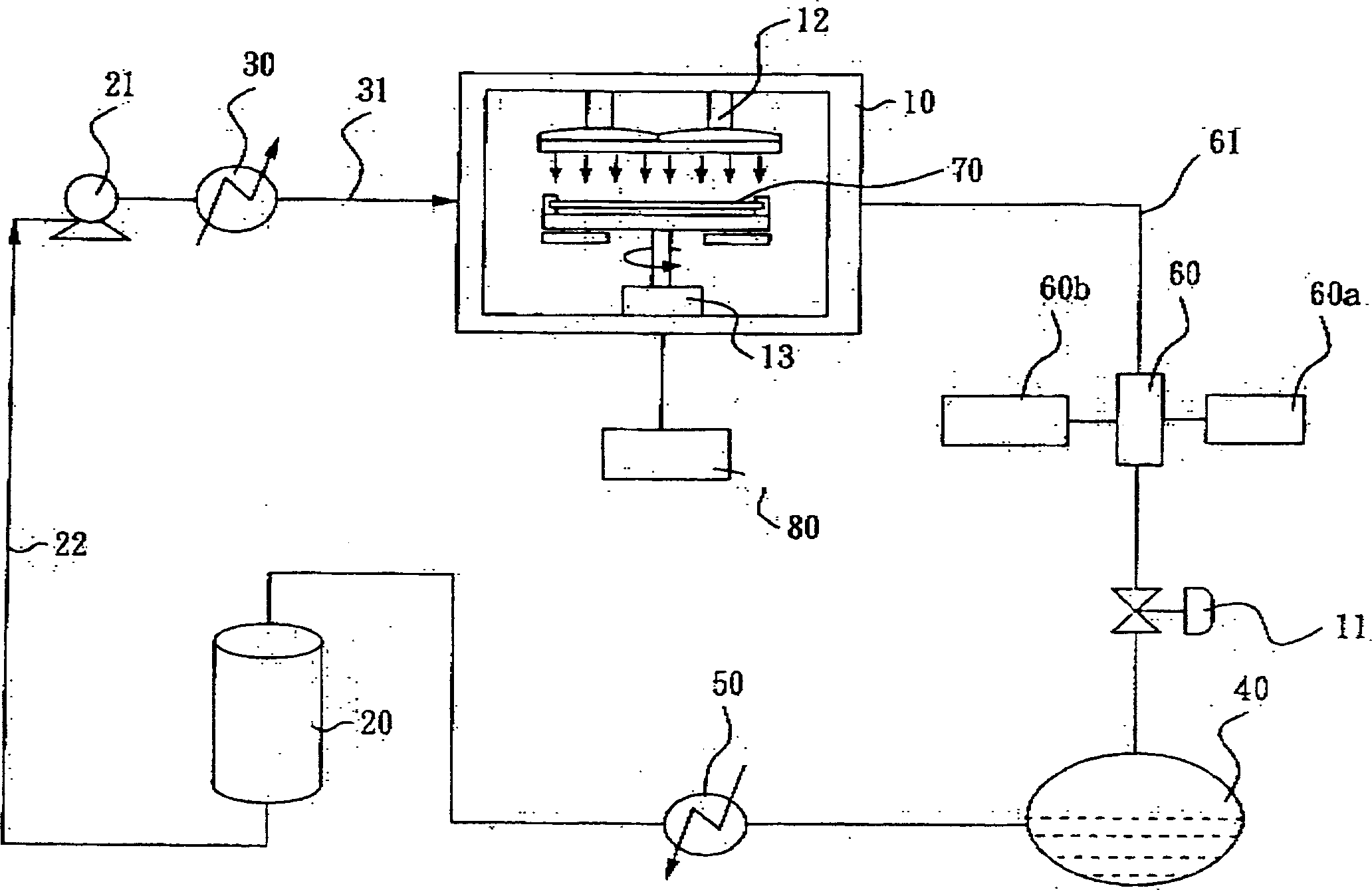

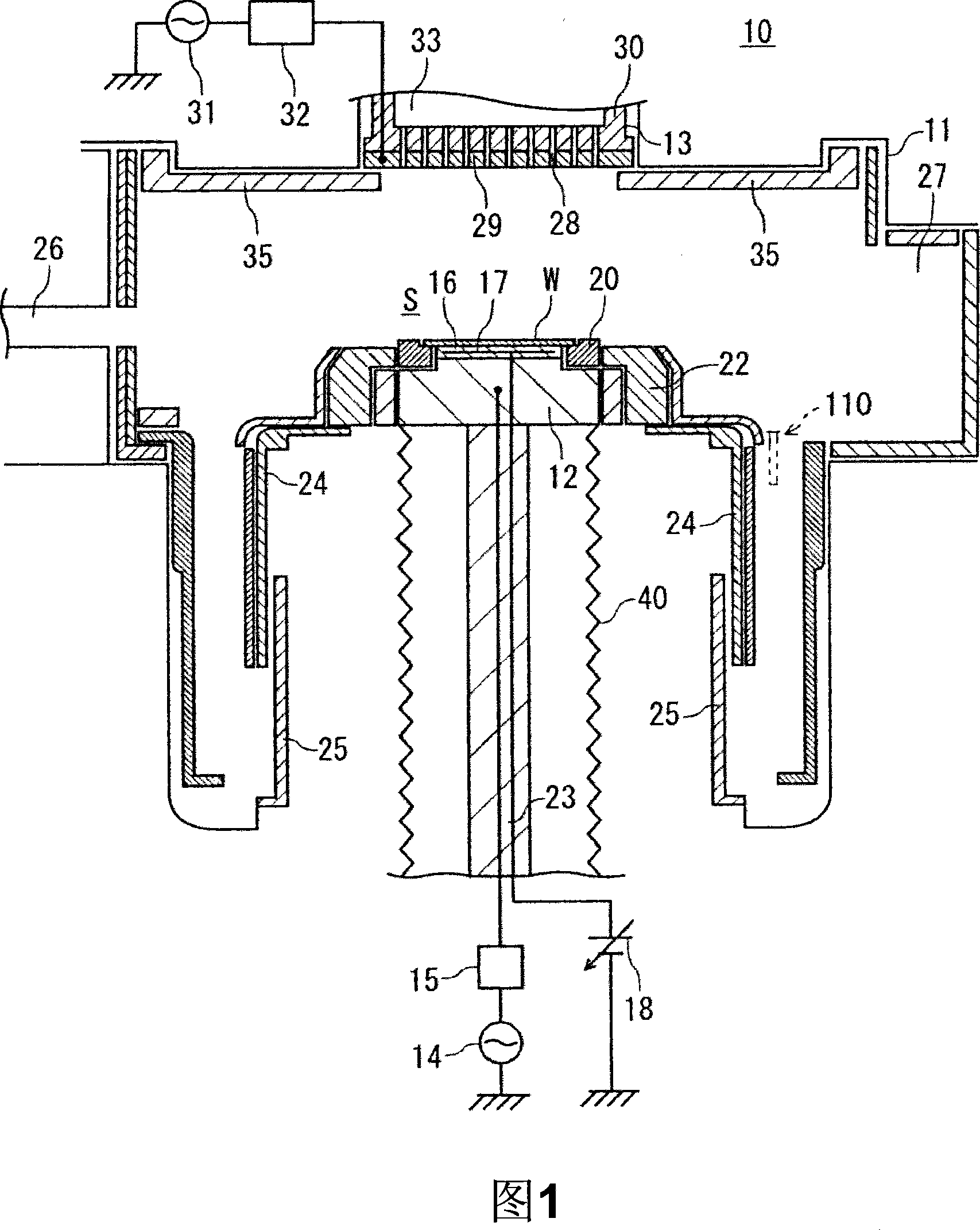

Basal plate cleaning system and method

InactiveCN1799710AReduce surface tensionLow viscosityCleaning using liquidsTemperature controlUltrasonic nozzle

The invention relates to a base plate cleaning system, comprising: a sealed cleaning chamber; a cleaning solution supply device; a carbon dioxide liquid storage device; a pressure controller; a temperature controller; and a online detector. Wherein, said cleaning solution supply device is connected to the carbon dioxide liquid storage device via a connection pipe; the carbon dioxide liquid storage device is connected to the pressure controller via a connection pipe; the pressure controller is connected to the temperature controller via a connection pipe which is connected to the sealed cleaning chamber via a through pipe to feed the above-critical carbon dioxide mixture into sealed cleaning chamber and utilize the ultrasonic nozzles in dual number to spray the mixture on the basic plate; and said online detector is connected to the sealed cleaning chamber via a sampling pipe.

Owner:IND TECH RES INST

Knitted fabric processing device

InactiveCN103774370AFast and even heatingProcessing quality is easyTextile treatment containersTextile treatment machine arrangementsWrinkle skinEngineering

The invention discloses a knitted fabric processing device. The knitted fabric processing device comprises a knitted fabric open-width padding device, a knitted fabric heat treatment device and a knitted fabric cylindrical open-width washing device, which are sequentially arranged, so that the knitted fabric can be sequentially processed in open-width padding, heat treatment and washing. The weaknesses in the prior art that the cylindrical open-width washing machine is non-uniform in washing, multiple indentation wrinkles exist and a great amount of water is consumed can be overcome, the weaknesses of a steaming method in the prior art that the consumption of steam is vast, the cost of equipment is high, the investment is large, the steaming process is difficult for controlling the temperature and humidity of the steam, the processing quality of the knitted fabric is difficult to control, the washing effect is poor and the crease is severe can be overcome, and the weaknesses of the prior art that the tension of a padding device is large, the knitted fabric is easy to crease in the transportation process, the indentation of the knitted fabric is severe, the liquid is non-uniform, the knitted fabric cannot adequately absorb the additives and dye and the contaminant on the knitted fabric cannot be removed can be overcome.

Owner:青岛元辰科技有限公司

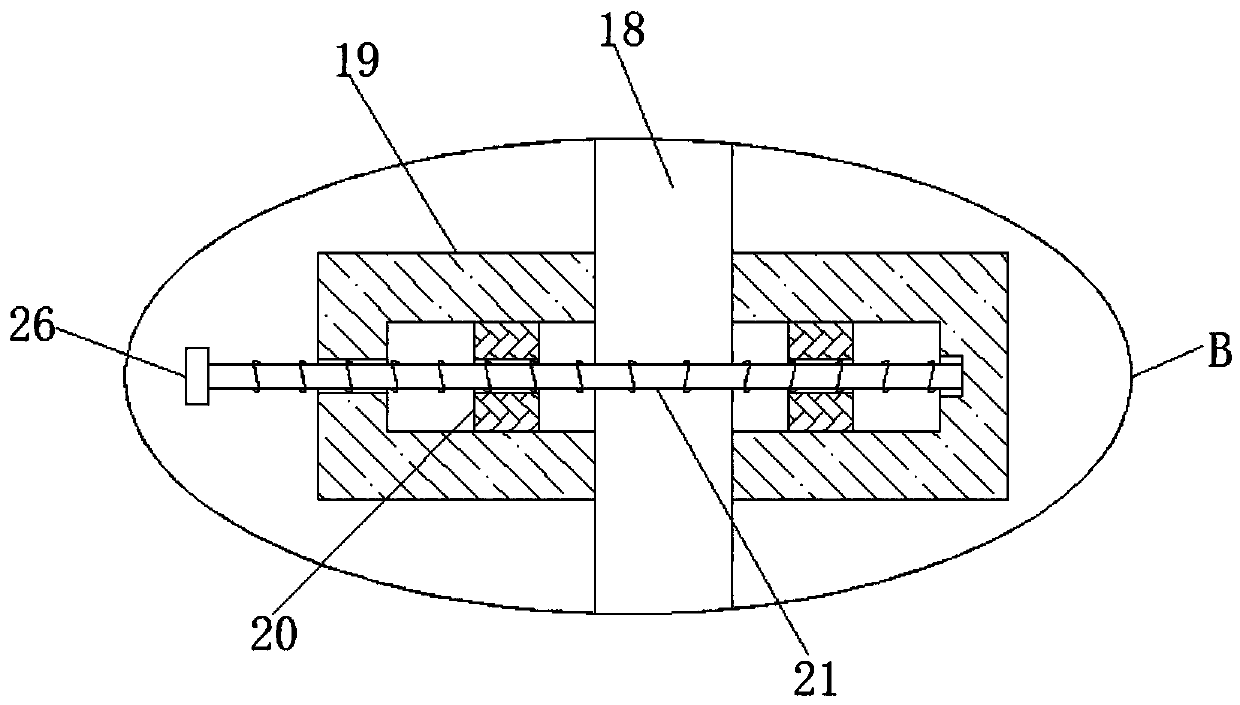

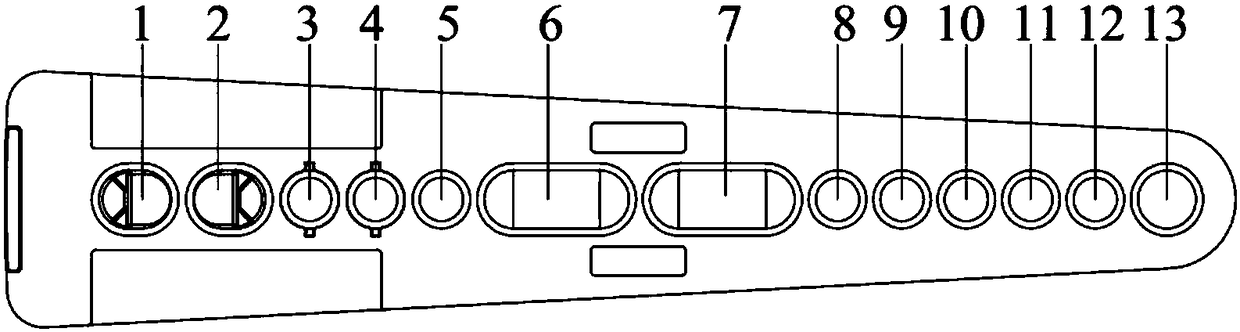

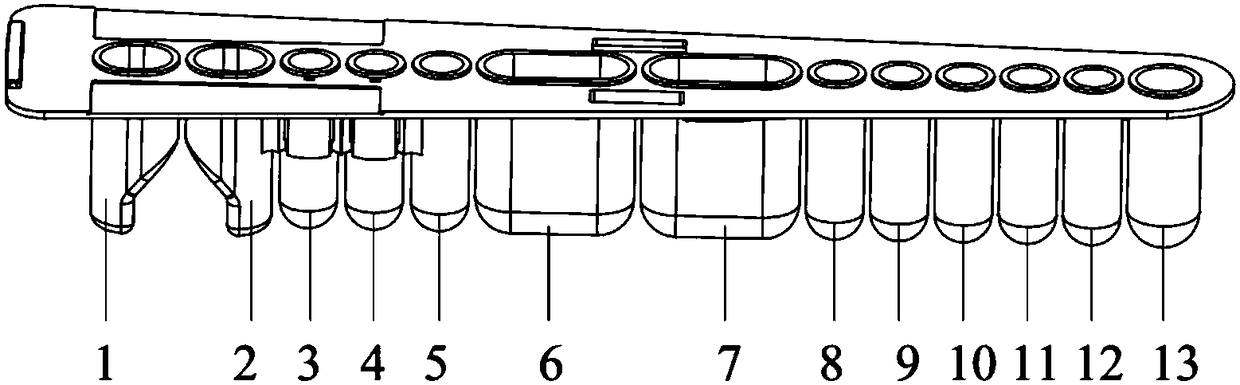

Magnetic rod pipe sleeves, multi-link assembly and nucleic acid extraction instrument

ActiveCN105062888AHigh yieldReduce manufacturing costBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadRotation velocity

The invention relates to magnetic rod pipe sleeves, a multi-link assembly and a nucleic acid extraction instrument. The nucleic acid extraction instrument comprises the multi-link assembly, a fixing device and a power mechanism, wherein the power mechanism drives the magnetic rod pipe sleeves to rotate and is connected with the fixing device. The magnetic rod pipe sleeves, the multi-link assembly and the nucleic acid extraction instrument have the beneficial effects that the magnetic rod pipe sleeves on the multi-link assembly are driven by the power mechanism to rotate at high speed relative to a support plate; the rotation speeds of the magnetic rod pipe sleeves can be adjusted by adjusting the speed of the power mechanism, so that the requirement of flow of high-viscosity magnetic beads can be met; stirring structures stir reagent liquid at high speed by driving the magnetic rod pipe sleeves to rotate at high speed, thus eliminating the phenomenon of splash of the reagent liquid, widening the uniformly mixed area, fully adsorbing, washing and eluting the magnetic beads, greatly increasing the nucleic acid yield and also reducing the nucleic acid extraction instrument production cost.

Owner:苏州东胜兴业科学仪器有限公司

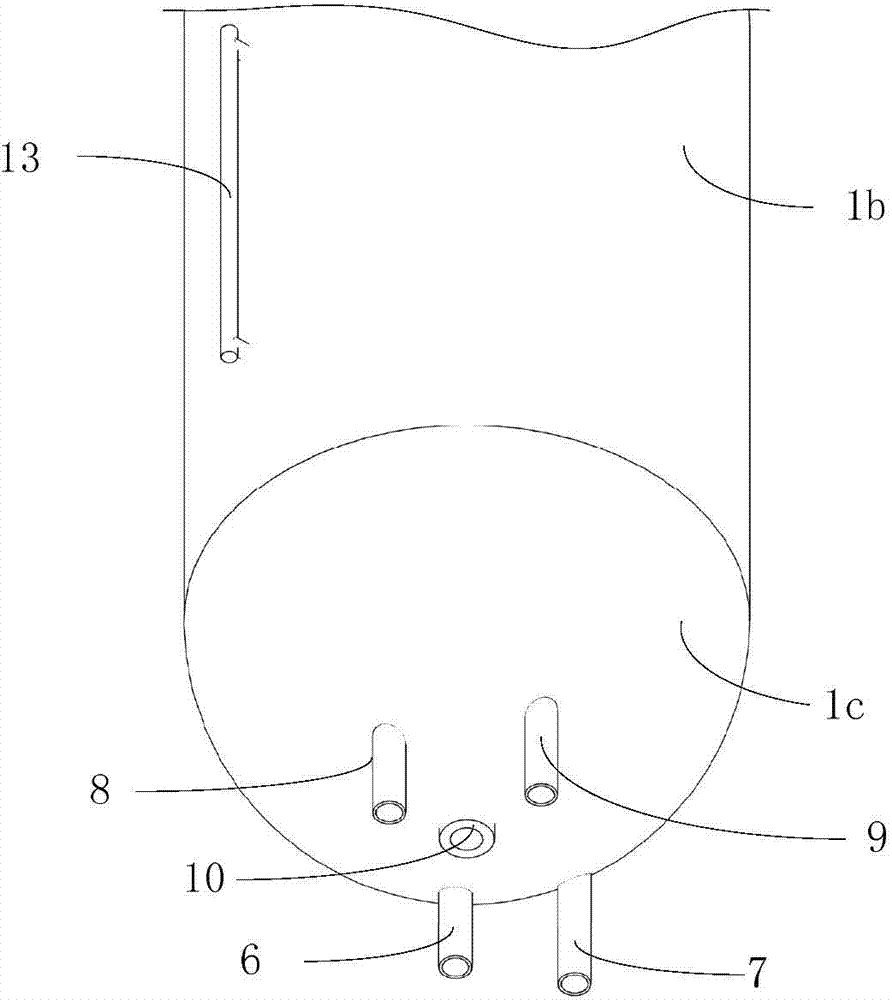

Production device and method of germinated rice

The invention relates to a production device of germinated rice. The production device comprises a hollow germinating container, wherein a first water inlet pipe, a first exhausting pipe and a feeding pipe are arranged on the top of the germinating container; the first exhausting pipe is used for exhausting air in the germinating container to generate negative pressure, the feeding pipe is used for leading unpolished rice into the germinating container under the action of the negative pressure, and the first water inlet pipe is used for spraying water; a filter plate is fixedly arranged in the germinating container to divide into a hollow space into a first containing chamber and a second containing chamber which are longitudinally adjacent to each other; the filter plate comprises a plurality of through holes, and the hole diameters of the through holes are smaller than the particle size of the unpolished rice; a second water inlet pipe, a second exhausting pipe, a draining pipe and an air inlet pipe are arranged at the bottom of the germinating container, and a discharging hole is formed in the bottom of the germinating container; the second water inlet pipe and the draining pipe are respectively used for feeding water and discharging water, the second exhausting pipe is used for exhausting air in the second containing chamber to generate negative pressure to drain residual water after the water is drained, and the air inlet pipe is used for supplying air into the second containing chamber to generate airflow to writhe the unpolished rice in the first containing chamber. The invention further relates to a production method of the germinated rice.

Owner:TONGHUA BAIAO JINSEN BIOTECH CO LTD

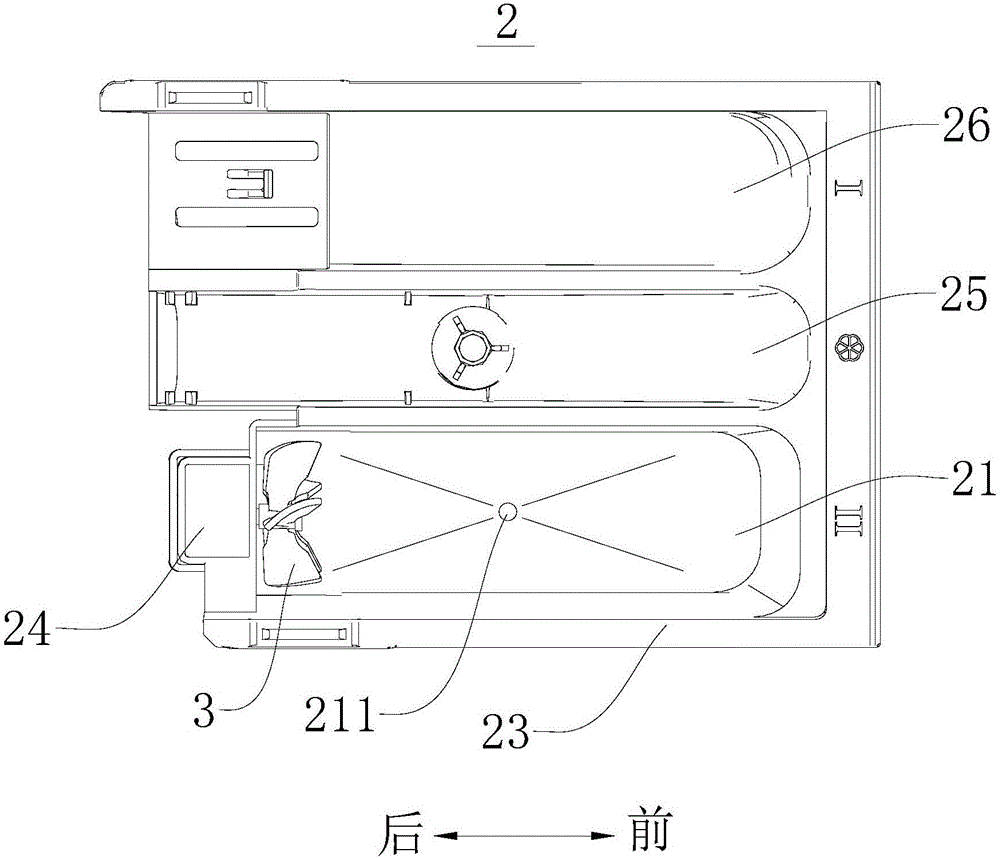

Filtering and lifting device and roller washing machine

ActiveCN108193444AFully washedPlay a filtering roleOther washing machinesTextiles and paperWater flowPulp and paper industry

The invention provides a filtering and lifting device and a roller washing machine, and relates to the technical field of household appliances. The problem that a roller washing machine is poor in washing effect in the prior art is solved. The filtering and lifting device comprises a shell with an inner cavity. The two opposite sides in the water flow passing direction of the shell are each provided with a water passing hole. A baffle is arranged beside each water passing hole. At least part of the area of the side face of each water passing hole and / or the corresponding baffle on the shell isprovided with a filtering structure. The baffles are pushed by water flow to swing toward the inner side of the shell so as to completely expose the water passing holes, and the baffles are pushed bywater flow to swing towards the outer side of the shell so as to cover the water passing holes, so water flows out of the inner cavity of the shell through the filtering structure. The filtering andlifting device is applied to the roller washing machine and used for filtering away hair and other sundries in an inner tub, and the washing effect of the roller washing machine is improved.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD +1

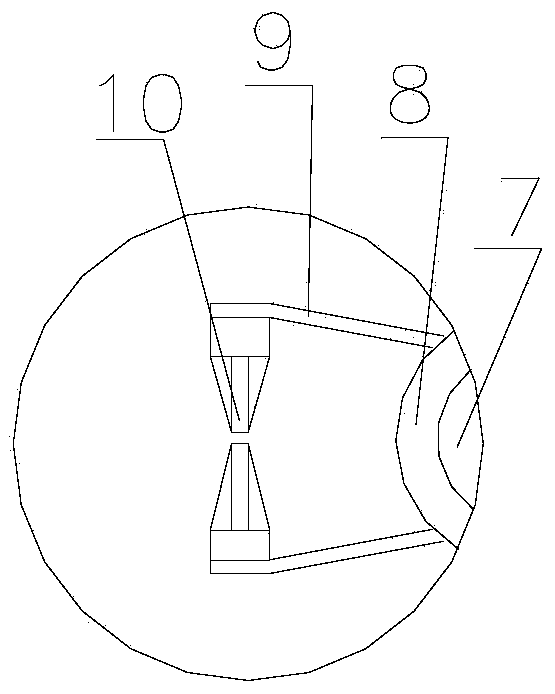

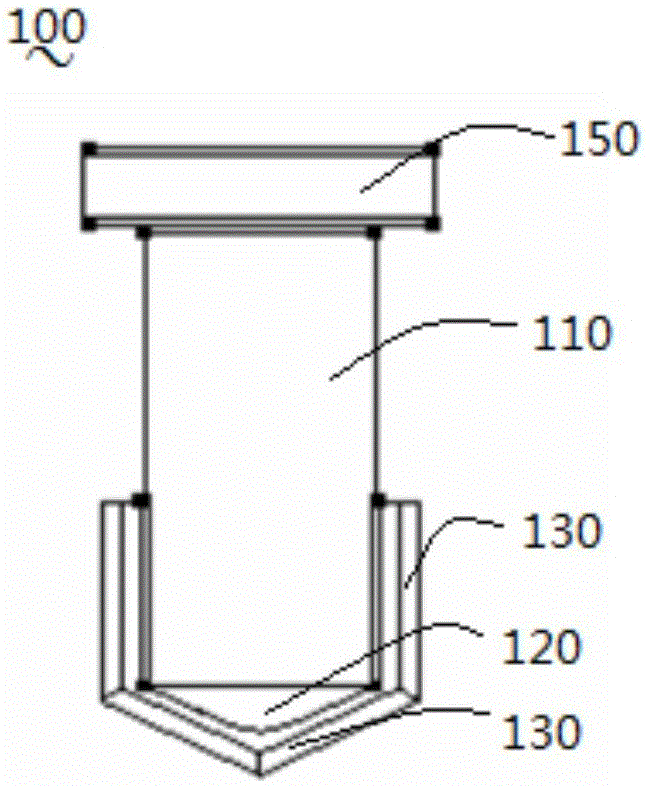

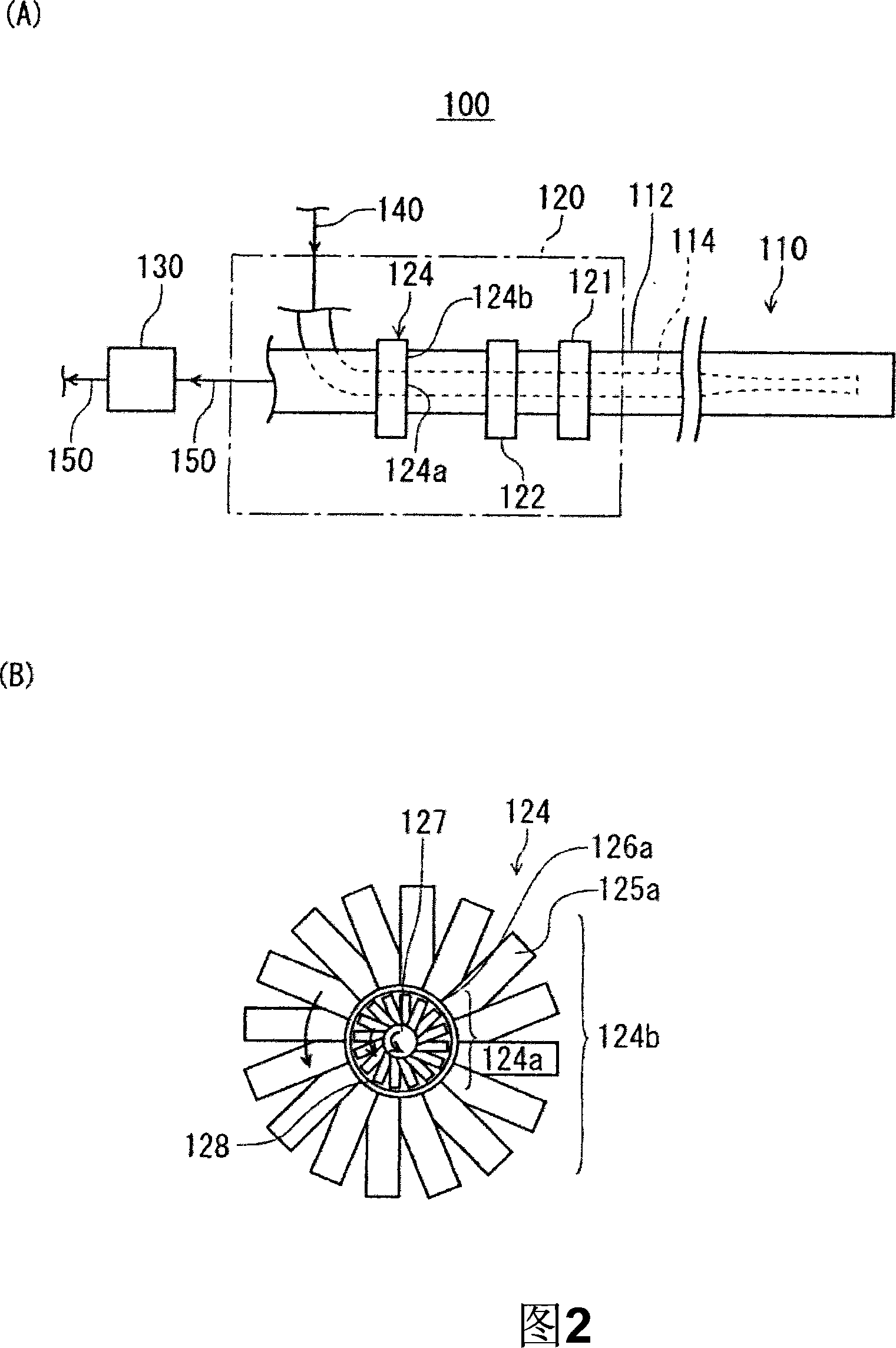

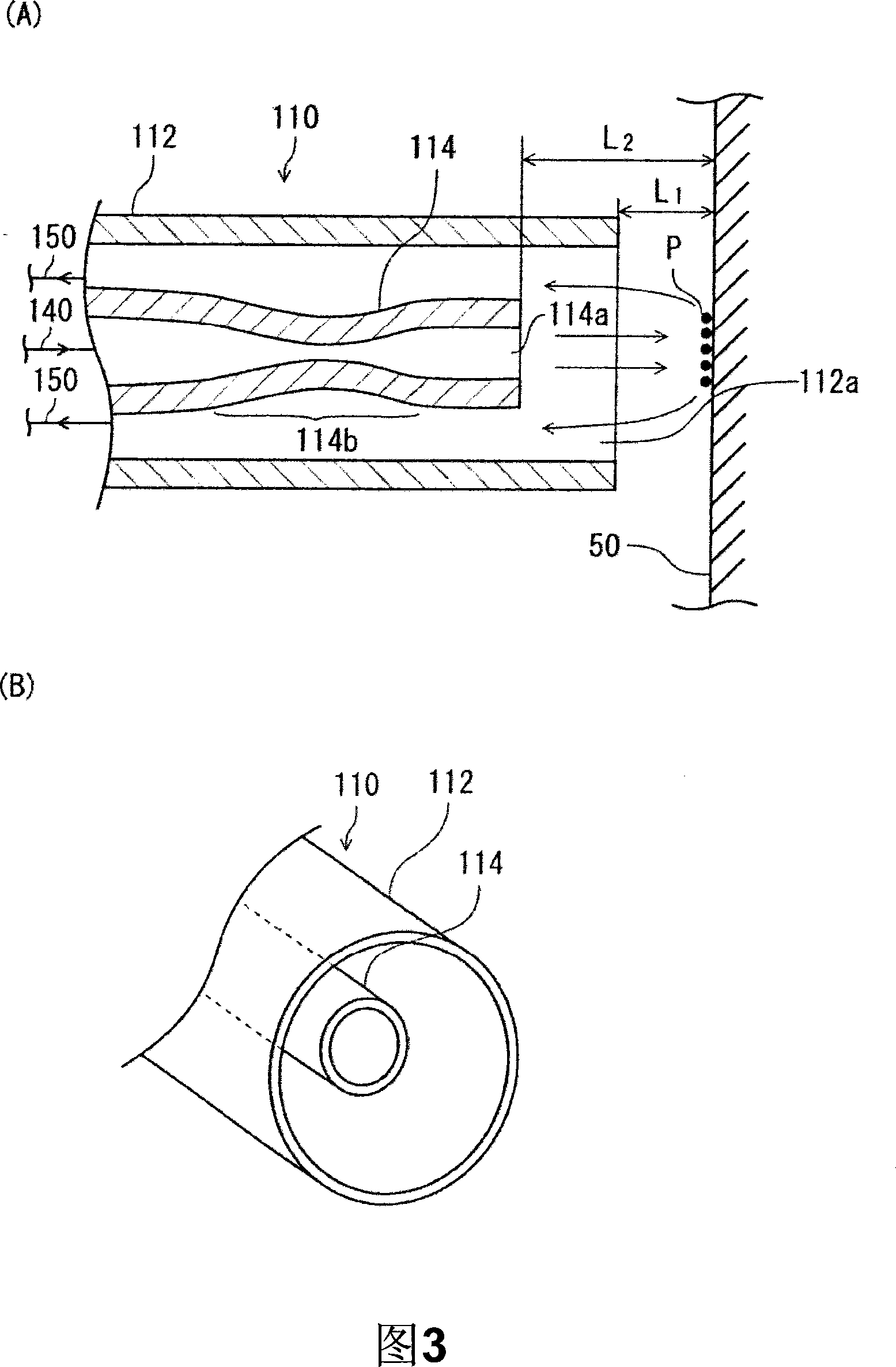

Cleaning apparatus and cleaning method

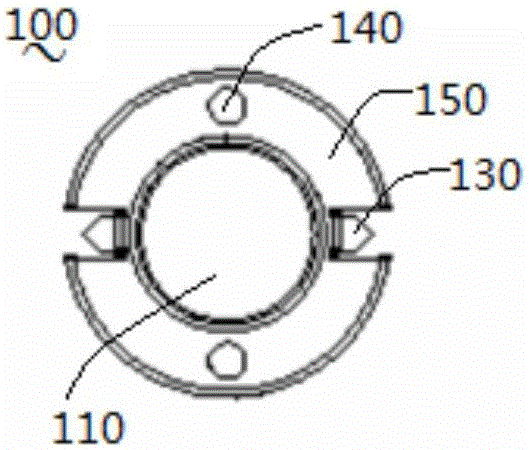

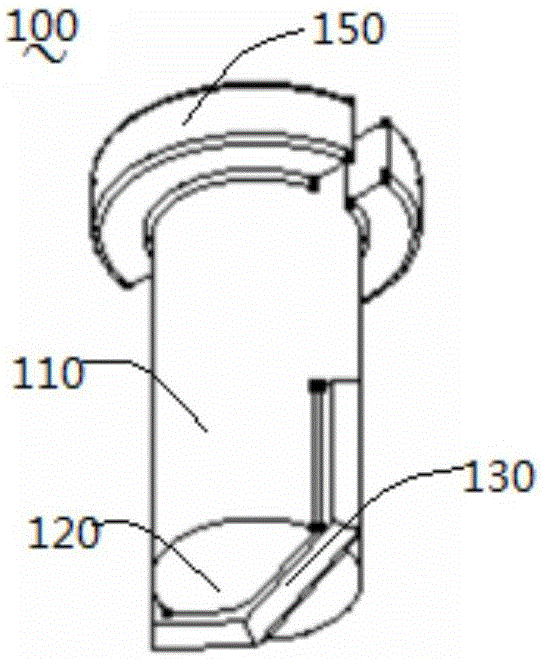

InactiveCN101134203AFully washedLow yieldSemiconductor/solid-state device manufacturingCleaning using liquidsEngineeringNozzle

A cleaning apparatus which can efficiently and satisfactorily clean component parts facing towards narrow spaces. A cleaning apparatus (100) is arranged with main body (120) and two-layer tube nozzle (110) extending freely from the main body (120). The two-layer tube nozzle (110) is arranged with ejecting tube (114) and suction catheter (112) surrounding the ejecting tube (112), the ejecting mouth (114a) of the ejecting tube (114) opens within the suction (112a) of the suction catheter (112). The ejecting tube (114) is arranged with reduced section (114b) by its ejecting mouth (114a), and accelerates the gas within the reduced section (114b). As a result, to gel part of gas, and the gas forms bow wave due to acceleration. Thus, the ejecting tube (114) ejects the bow wave containing the gas and air sol composed of material being same to the gas, towards particle (P) hanging to the surface of a construction (50).

Owner:TOKYO ELECTRON LTD

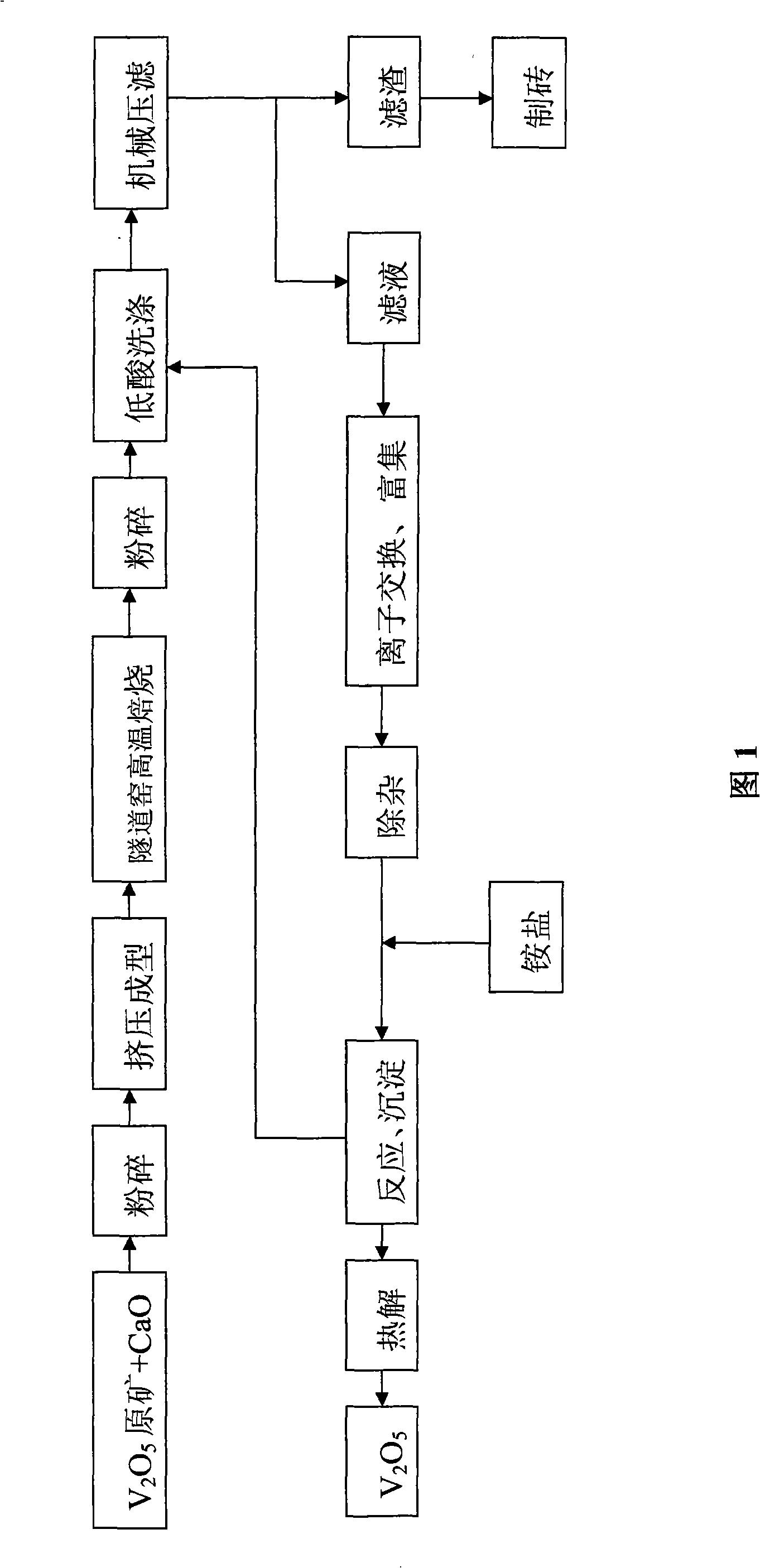

Technique for extracting vanadium pentoxide by tunnel kiln calcification roasting

InactiveCN101265522AEasy to stackReduce sulfur dioxide contentProcess efficiency improvementTunnel kilnBrick

The invention relates to a method for extracting vanadium pentoxide by calcification and calcination of tunnel kiln coal gas, which comprises the steps of: mixing mineral soil and calcium oxide at a proper proportion, crushing, squeezing to obtain bricks, stacking on a kiln cart, placing into a coal gas tunnel kiln, calcinating at a certain temperature, pulverizing the calcinated bricks with a ball mill, placing the obtained powder into a large stirring tank, leaching with low concentration sulphuric acid solution under stirring to obtain slurry, press filtering with a press filter, washing, separating, transferring the filtrate to a ion-exchange column for exchange and enrichment, purifying to obtain ammonium metavanadate, and performing thermal decomposition with an electrothermal burning furnace to obtain vanadium pentoxide. The inventive method has the advantages of low production equipment investment, convenient and accurate process condition control, low production operating cost, high product extraction yield (mean value about 75%), and high product purity (over 99%). The exhaust gas emission meets the standards, the waste water is recycled and reused without external discharge, and the waste residues are integrally utilized to produce bricks, so as to realize clean and environmentally friendly production.

Owner:闫国正

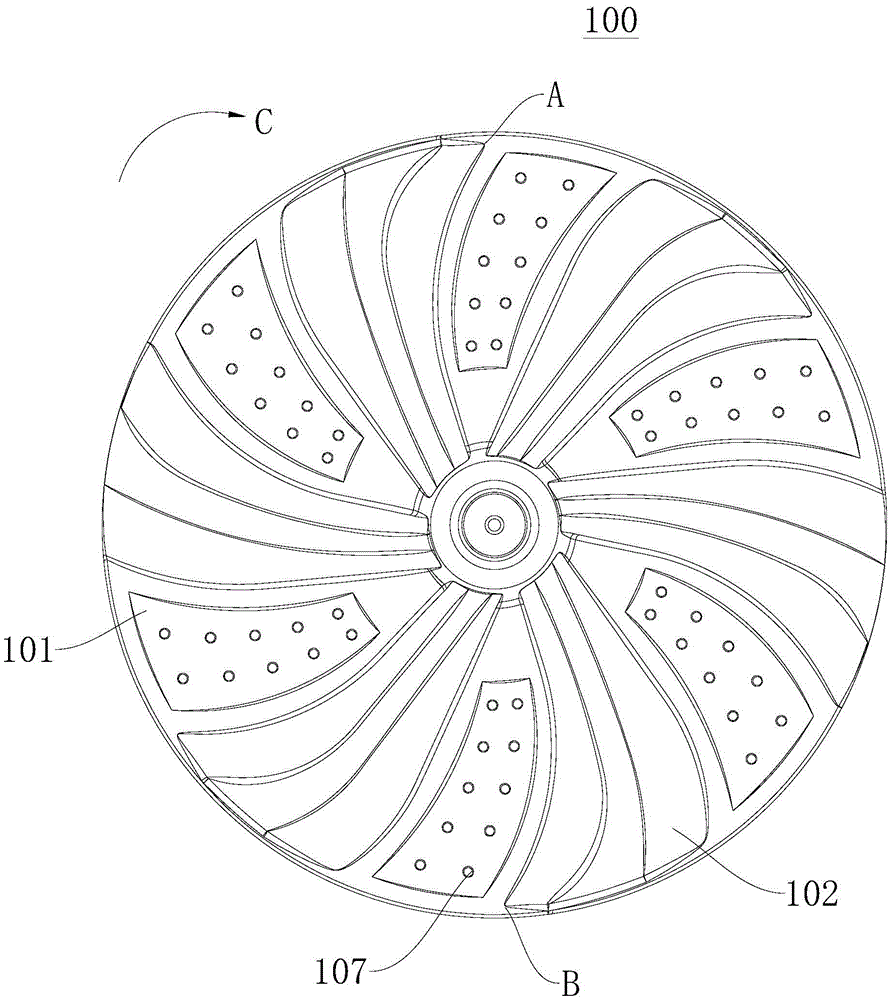

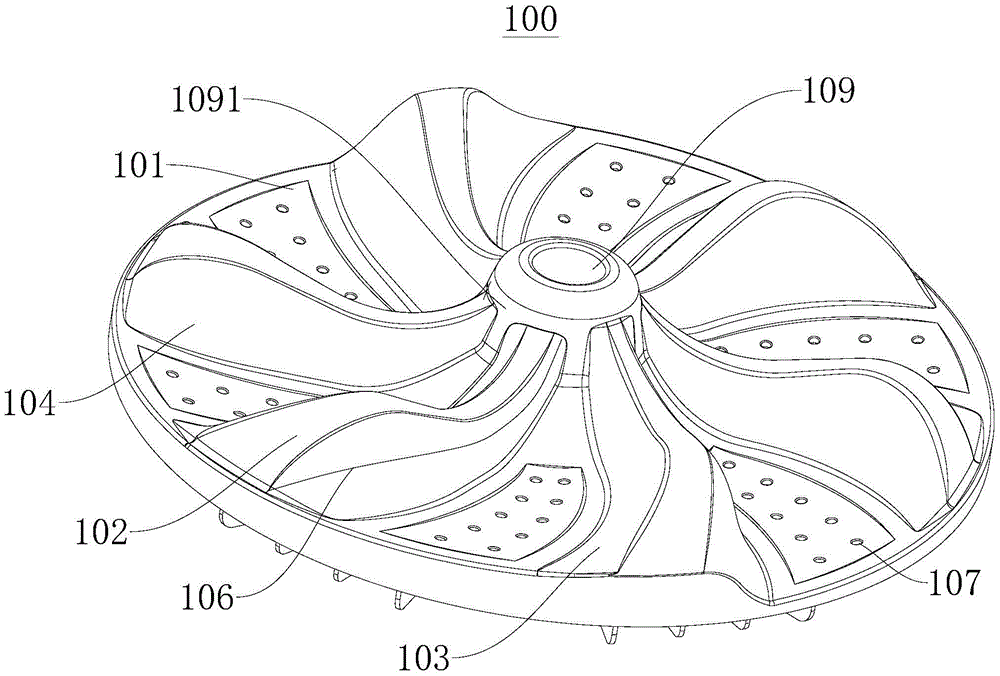

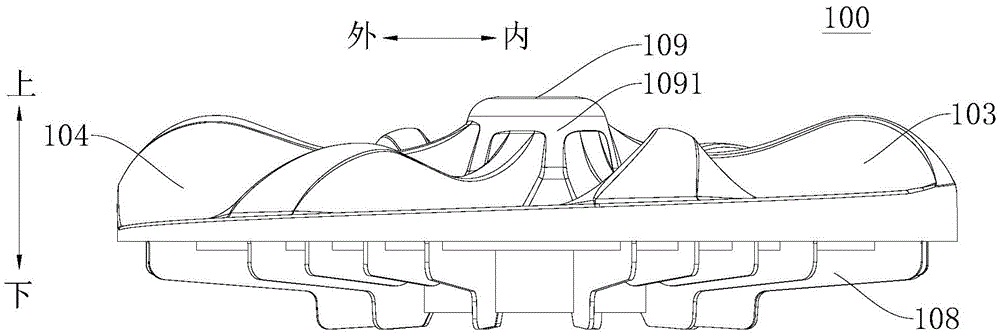

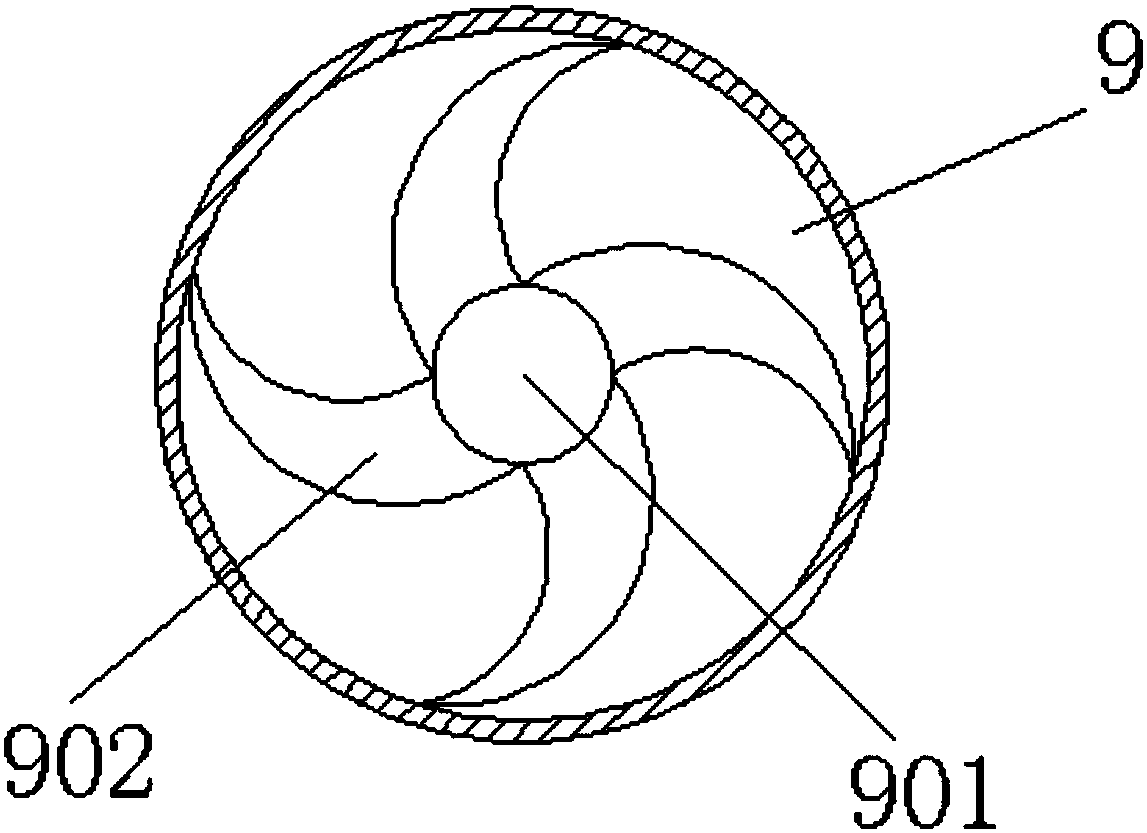

Impeller for washing machine

ActiveCN105483968AFully washedImprove cleanlinessWashing machine with receptaclesTextiles and paperImpellerEngineering

The invention discloses an impeller for a washing machine. At least one part of a disc face of the impeller is in a hook face shape of which the height is gradually increased in the first direction of the axis of the impeller. Water stirring ribs extending in the radial direction are arranged on the disc face of the impeller. According to the impeller, clothes participating in washing can rise and then fall when the impeller rotates under the stirring of the water stirring ribs, and therefore clothes can be more sufficiently washed, and the cleanness degree of clothes can be increased.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

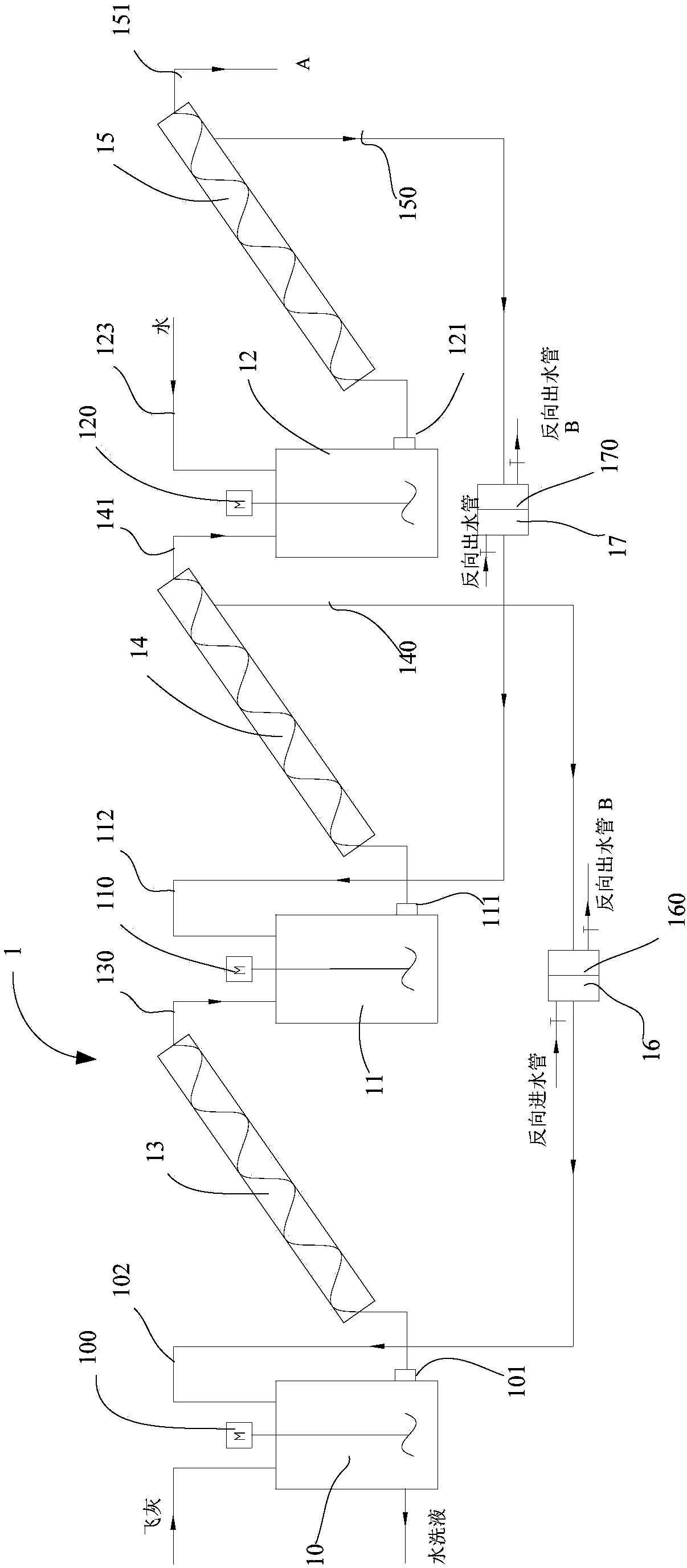

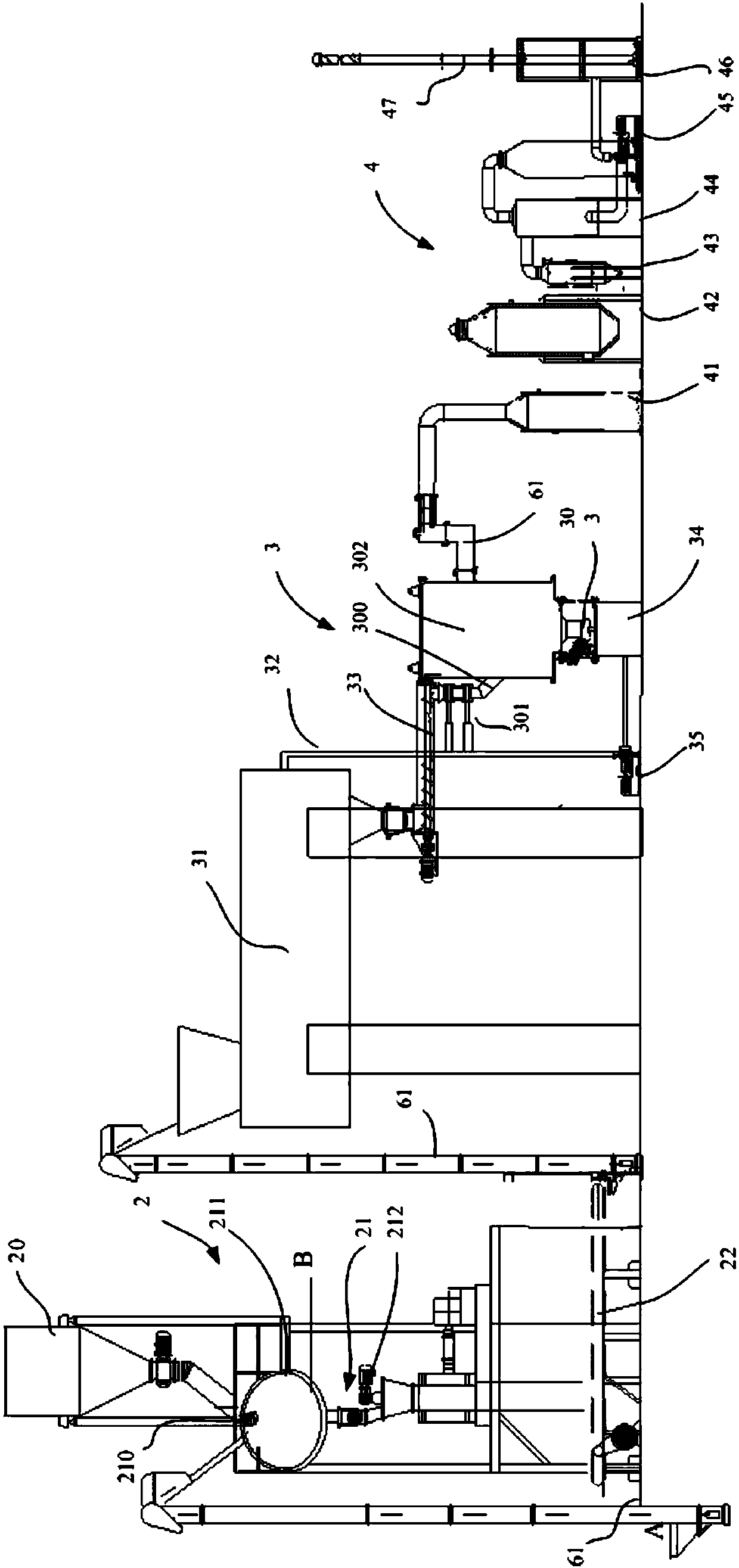

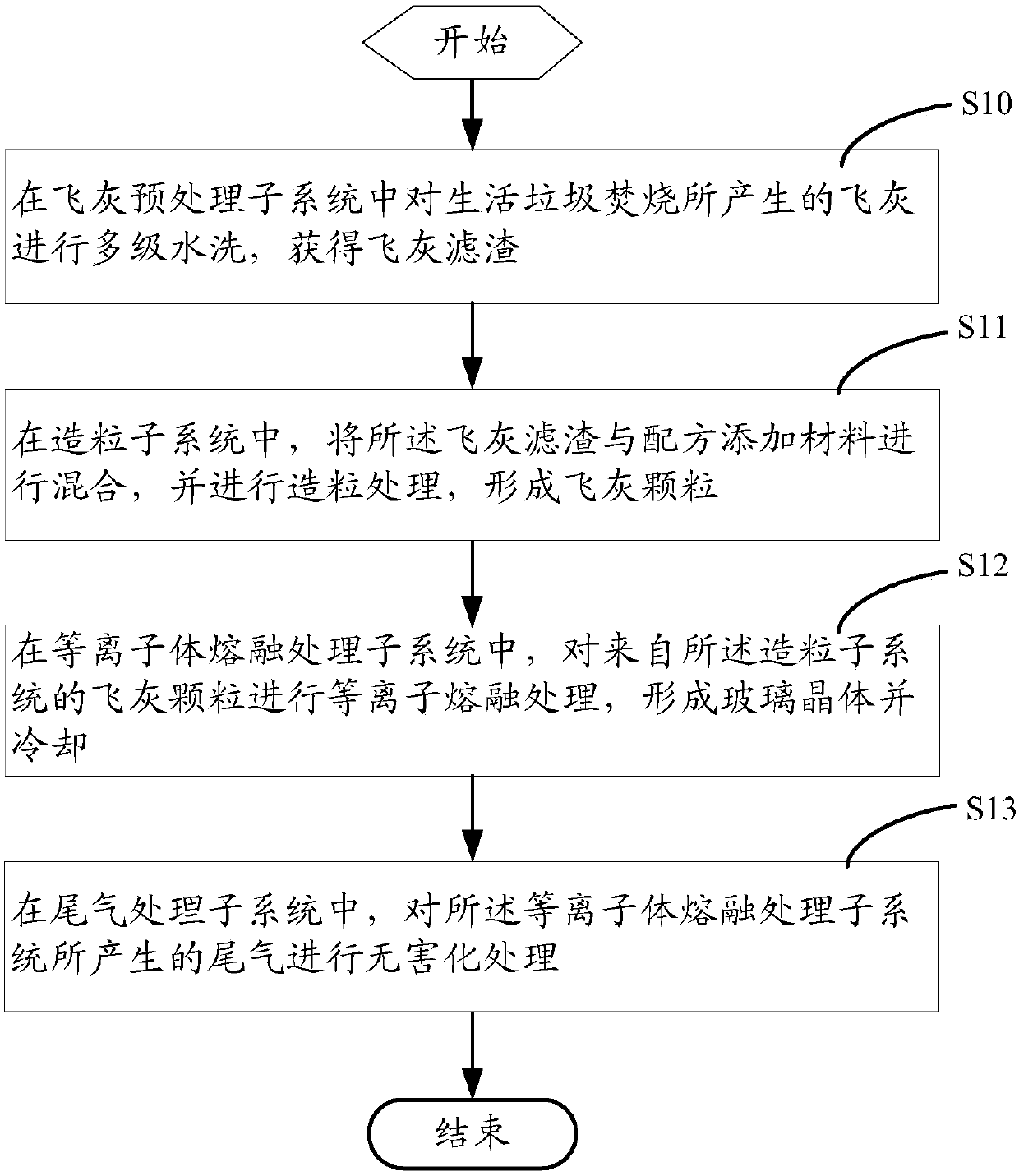

Innocent treatment system and method for household garbage incineration fly ash

PendingCN108043859AFully washedReduce corrosion rateSolid waste disposalTransportation and packagingLitterFly ash

The invention discloses an innocent treatment system for household garbage incineration fly ash at least comprising a fly ash pretreatment subsystem, a pelleting subsystem, a plasma melting treatmentsubsystem, and an exhaust gas treatment subsystem; the fly ash pretreatment subsystem is used for multi-stage washing fly ash produced by household garbage incineration, and fly ash residues are obtained; the pelleting subsystem is used for mixing the fly ash residues with formula additive materials, and pelleting treatment is carried out to form fly ash particles; the plasma melting treatment subsystem is used for performing plasma melting treatment for the fly ash particles from the pelleting subsystem, and glass crystals are formed and cooled; and the exhaust gas treatment subsystem is usedfor performing innocent treatment for exhaust gas produced by the plasma melting treatment subsystem. The invention also discloses a corresponding method. The implementation of the innocent treatmentsystem and the method for household garbage incineration fly ash can realize disposal of harness, stabilization and recycling of the incineration fly ash.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Method for improving filtering performance of ferrous sulfate

The invention discloses a method for improving filtering performance of ferrous sulfate. The method comprises the following concrete operations: taking a clear titaniferous solution obtained by a titanium dioxide production technology employing a sulfuric acid method, wherein the clear titaniferous solution contains ferrous sulfate; adding an accelerant to the clear titaniferous solution and evenly mixing; putting the clear titaniferous solution mixed with the accelerant into ice water to crystallize; keeping stirring in the crystallization process, and crystallizing until the temperature of the clear titaniferous solution is smaller than or equal to 20 DEG C, so as to obtain a crystallized titaniferous solution; taking the crystal titaniferous solution, and filtering under the condition of negative pressure, so as to obtain a filter cake of ferrous sulfate crystal containing the titaniferous solution; and washing when filtering, so as to wash out the titaniferous solution in the filter cake. By adopting the method, the accelerant is added to the clear titaniferous solution, a crystallization center is provided for crystallization of the ferrous sulfate, and generation of iron vitriol is facilitated, so that the crystallization speed of the ferrous sulfate is greatly improved, so as to shorten the crystallization time. In addition, the ferrous sulfate crystal particles are uniform in size, and large in particle size, washing of the filter cake is facilitated, the content of residue titanium in the filter cake can be reduced, and the yield of titanium is improved.

Owner:PANZHIHUA DONGFANG TITANIUM IND +1

Lifting rotating spray-washing device

InactiveCN101069628ASimple structureImprove performanceTableware washing/rinsing machinesKitchen utensilsSpray nozzle

The present invention relates to a kind of lifting-falling rotary spray-washing equipment, belonging to the field of washing technology. It includes the following several portions: machine body, lifting-falling rotary spray-washing device and its spray nozzle, conveying device and control device, said control device is connected with the lifting-falling rotary spray nozzle. Said invention is simple in structure, and can be extensively used for washing kitchen utensils.

Owner:TIANJIN DIEQIAO PACKAGING & FOOD MACHINERY INST

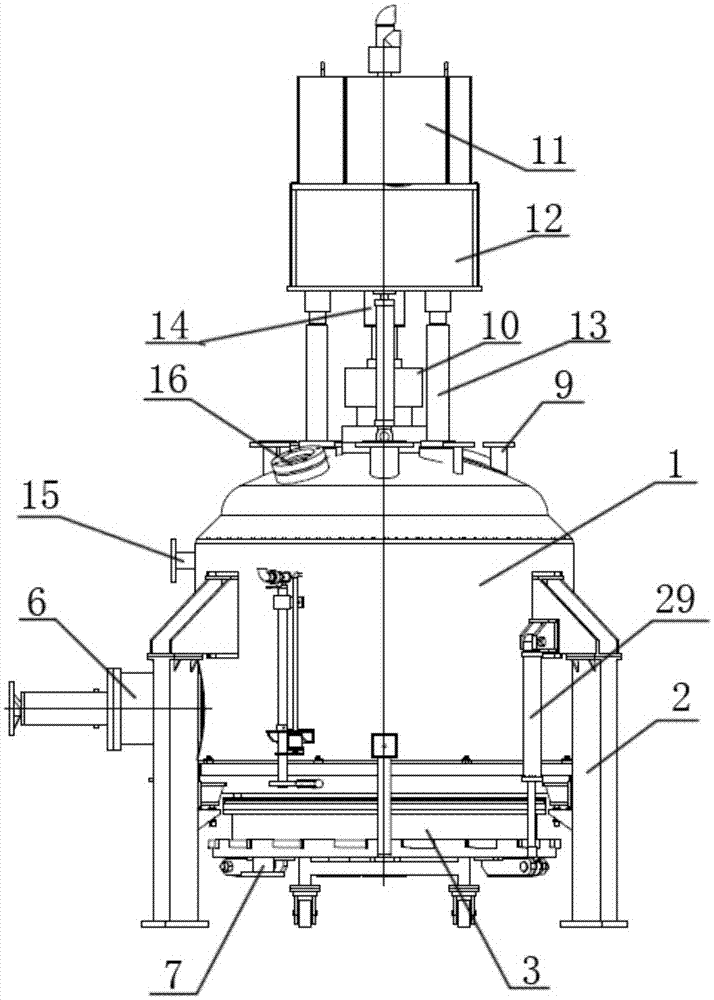

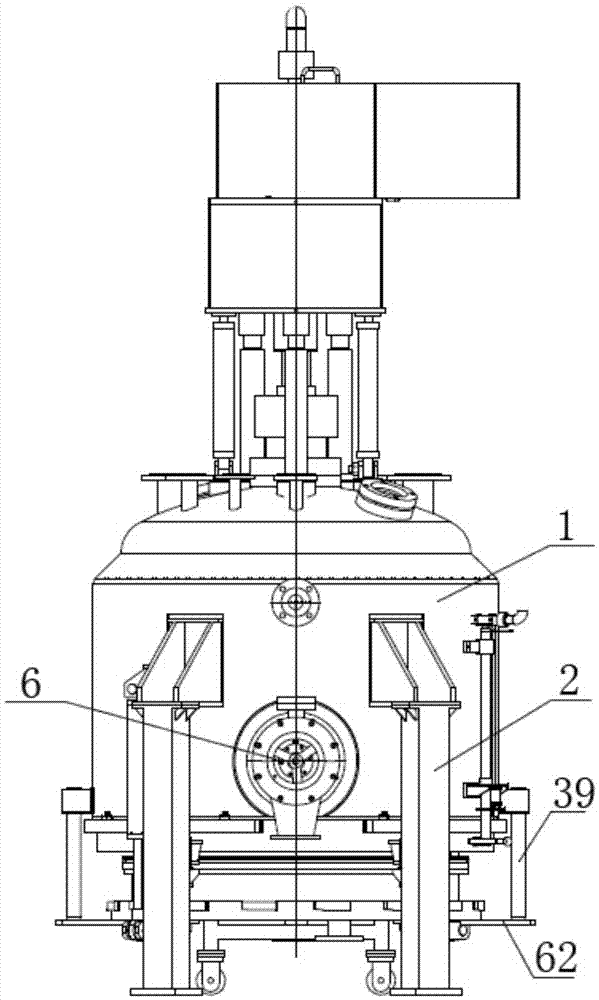

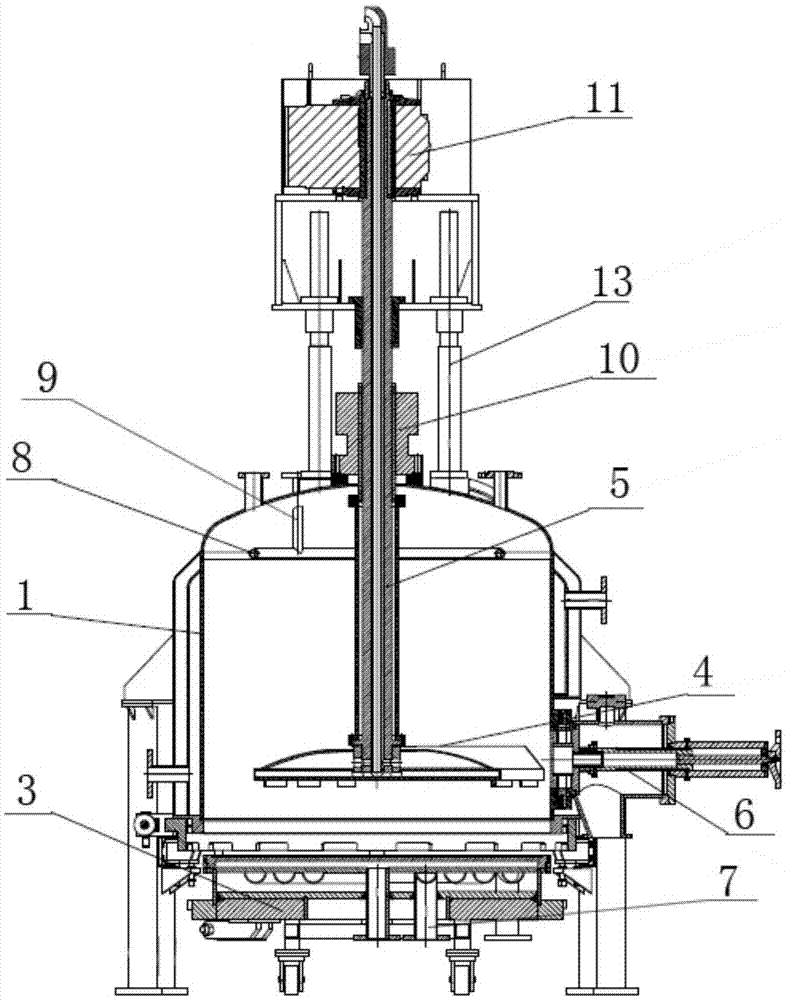

Three-in-one kettle structure

InactiveCN105435502AImprove filtration efficiency and qualityImprove heat transfer coefficientMembrane filtersStationary filtering element filtersFiltrationWater source

The invention provides a three-in-one kettle structure. According to the three-in-one kettle structure, internal cleaning and material slurry washing can be realized in a container, when materials are dried, the turning distance is short, the crystal destruction is less, the agglomeration is difficult, and the heat transfer coefficient is high. The three-in-one kettle structure comprises a kettle body, wherein a plurality of vertically arranged support legs are arranged on the outer side of the kettle body, a lower end cover is arranged just below the bottom end surface of the kettle body, a stirring blade is arranged in the kettle body, a stirring shaft penetrates through the top of the kettle body and then is fixedly connected to the center of the stirring blade, and a discharging mechanism is arranged on the middle lower part of the kettle body. The three-in-one kettle structure is characterized in that a suction filtration opening is formed in the lower end cover which is a filter heating chassis, a spray device is arranged on the upper part of an inner cavity of the kettle body, the spray device is externally connected with an external water source through a connecting pipe, a sealing device is arranged between the stirring shaft and the top of the kettle body, a stirring motor is externally connected to the top of the stirring shaft, and the stirring motor is supported on a motor base.

Owner:MIYOU GROUP

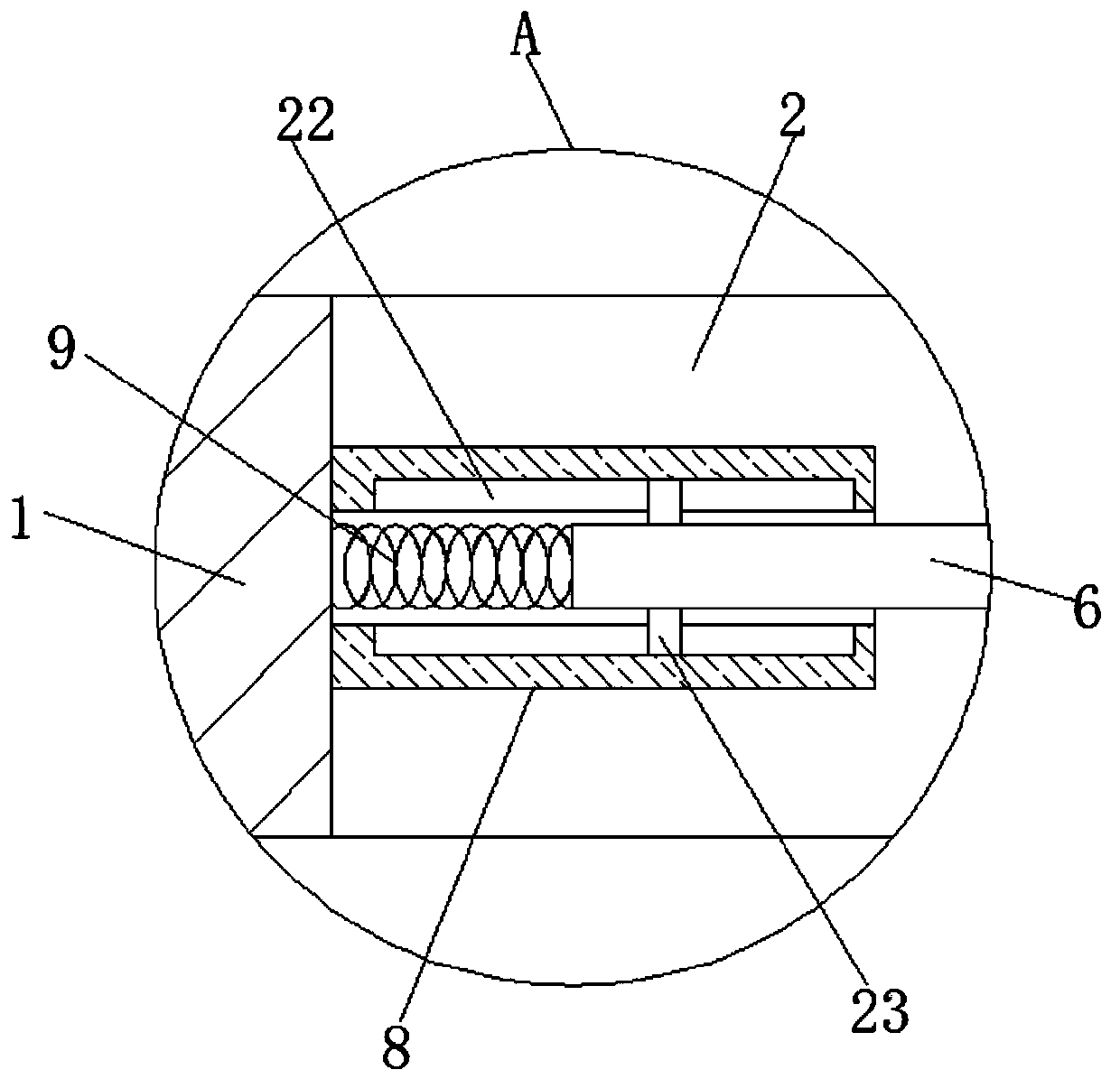

Water washing mechanism for stone processing system

InactiveCN109092753AFully washedWater recyclingUsing liquid separation agentCleaning using liquidsSurface mountingArchitectural engineering

The invention discloses a water washing mechanism for a stone processing system, comprising a crusher shell, a through groove is formed in the top of the crusher shell, a water guide pipe matched withthe through groove is inserted in the through groove, and the water guiding pipe is in movable connection with the through groove. One end of the water guide pipe fixedly communicates with a water guide plate, and a plurality of evenly distributed nozzles are mounted on the lower surface of the water guide plate. The water guide plate is located in the inner cavity of the crusher shell, and the outer side wall of the water guide pipe is symmetrically fixedly connected with a sliding rod and a protruding rod. A position, corresponding to the sliding rod, at the inner wall of the through grooveis fixedly connected with a sleeve matched with the sliding rod, and one end, away from the water guide pipe, of the sliding rod is inserted in the sleeve and fixedly connected with a spring, the sliding rod is in slidable connection with the sleeve, and the other end of the spring is fixedly connected to the bottom in the sleeve. The water washing mechanism disclosed by the invention makes stonewashing more fully in a processing process, and water after washing can be recycled to avoid waste of water resources.

Owner:安龙县喜莱莹建材装饰有限公司

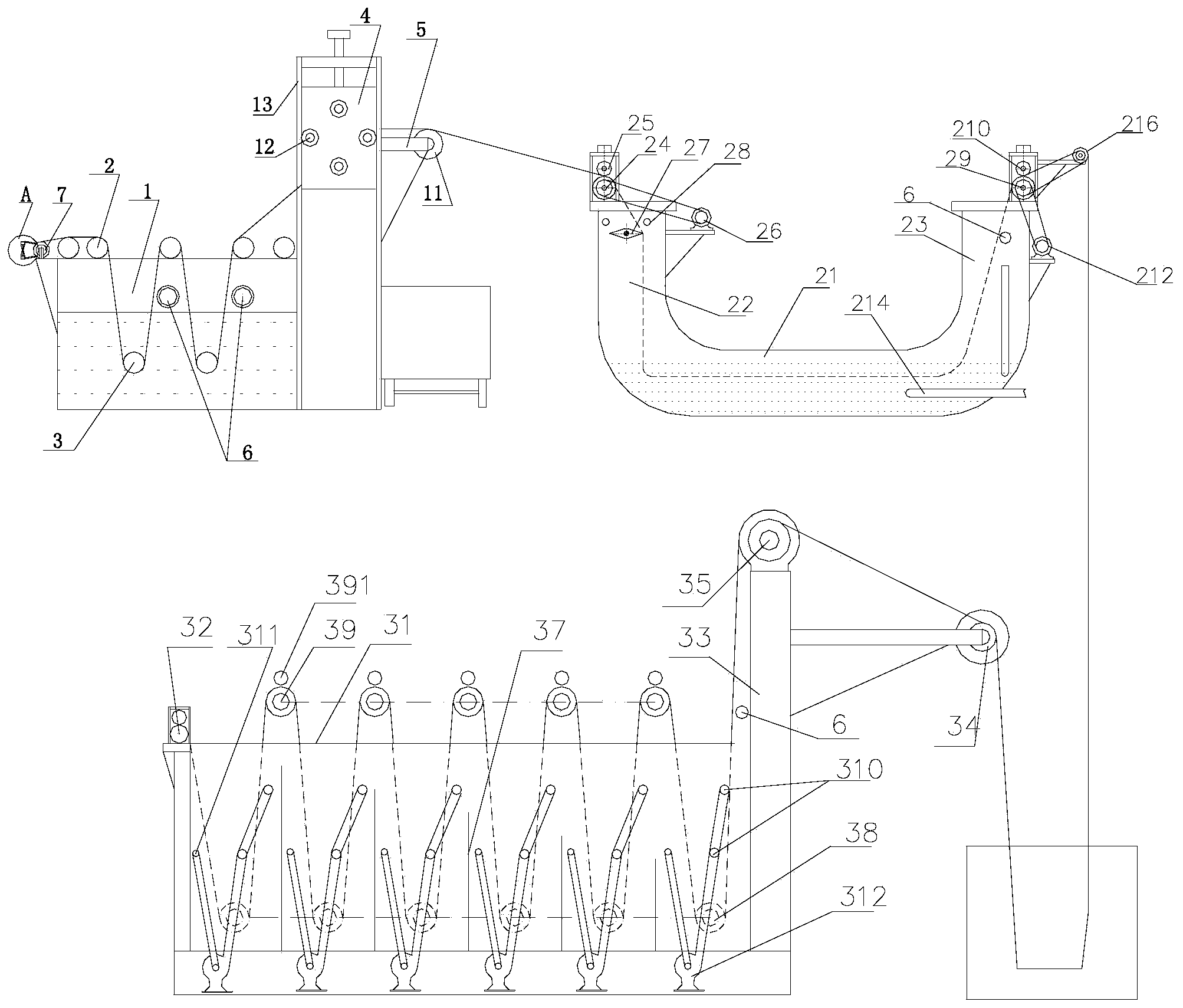

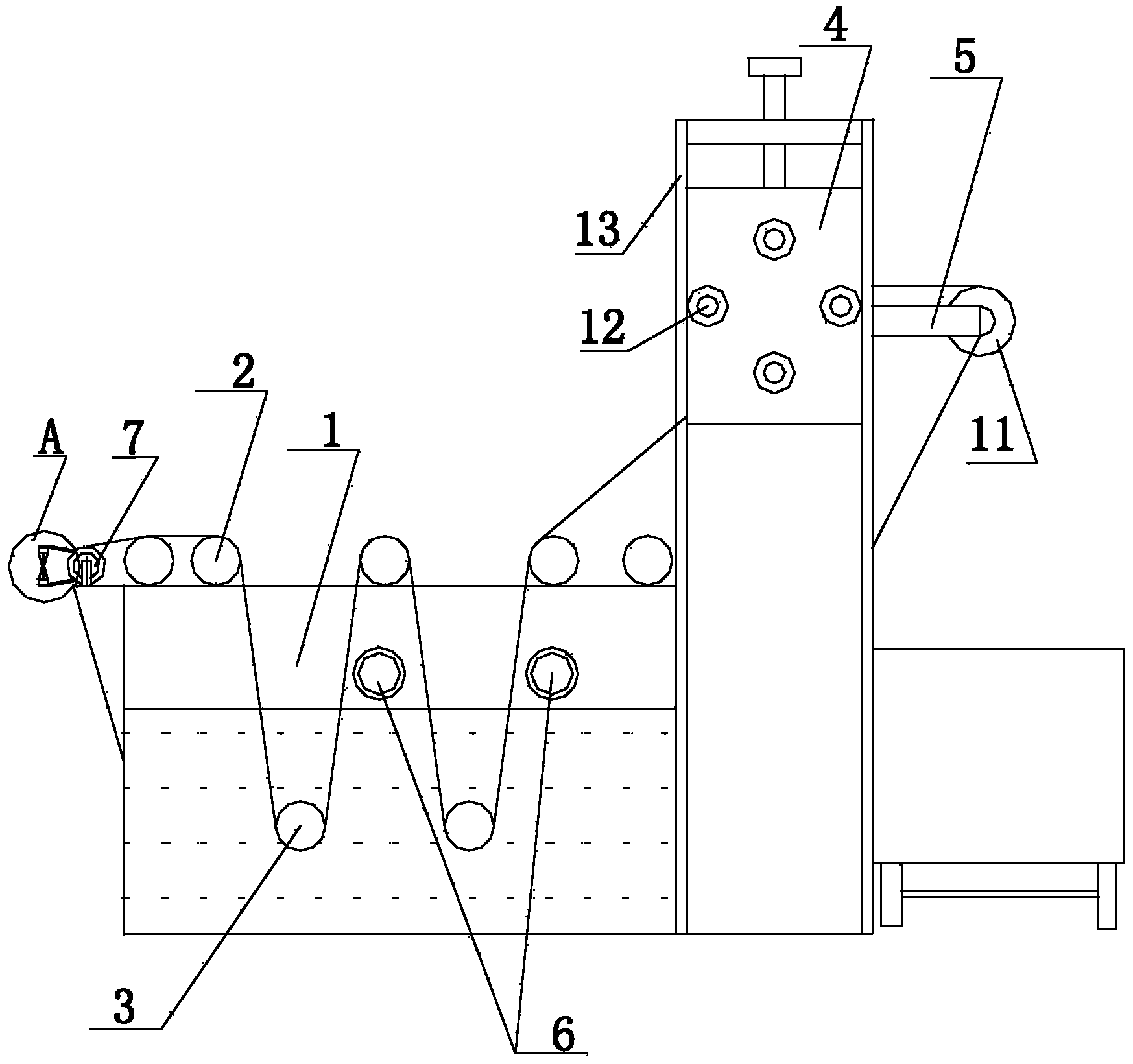

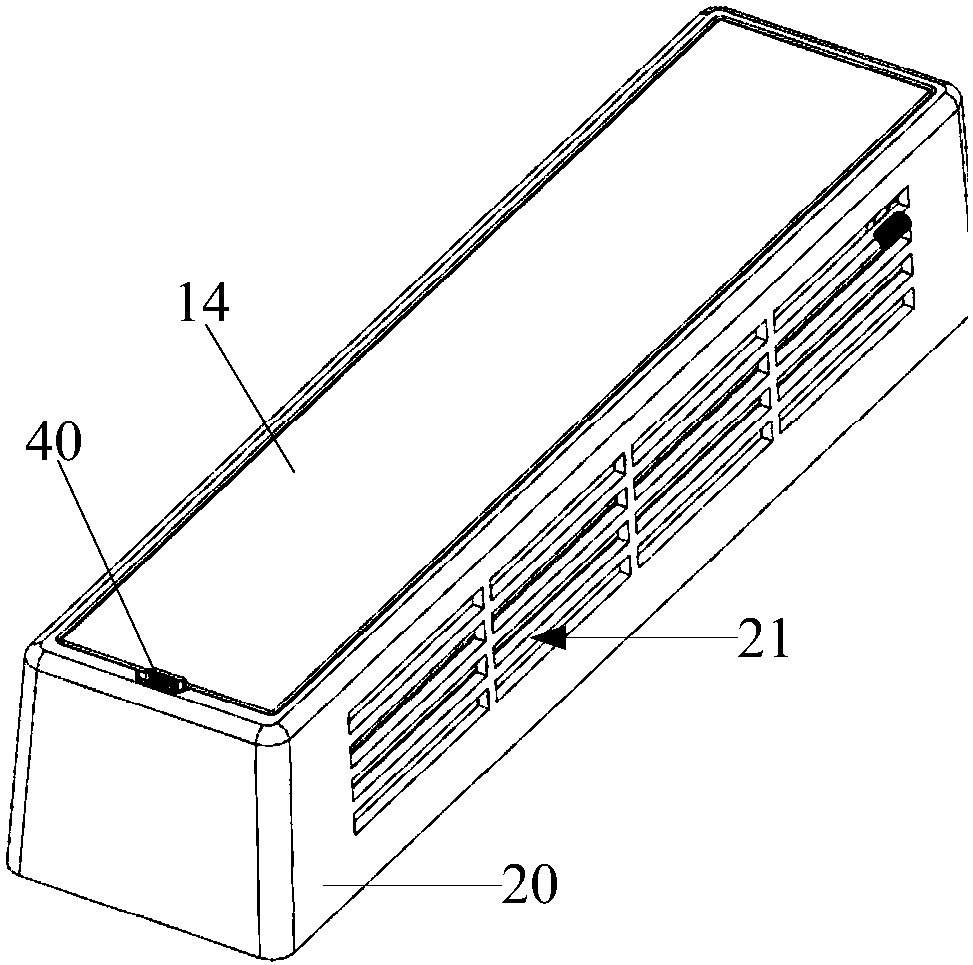

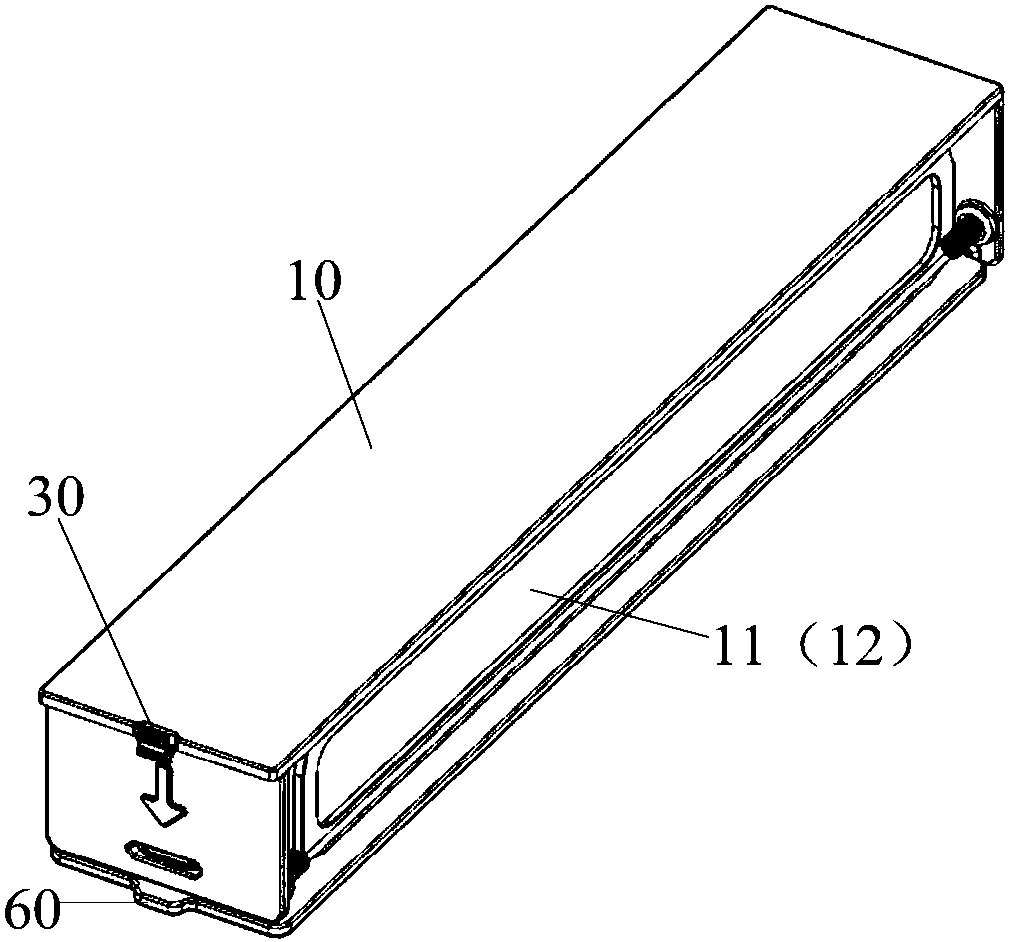

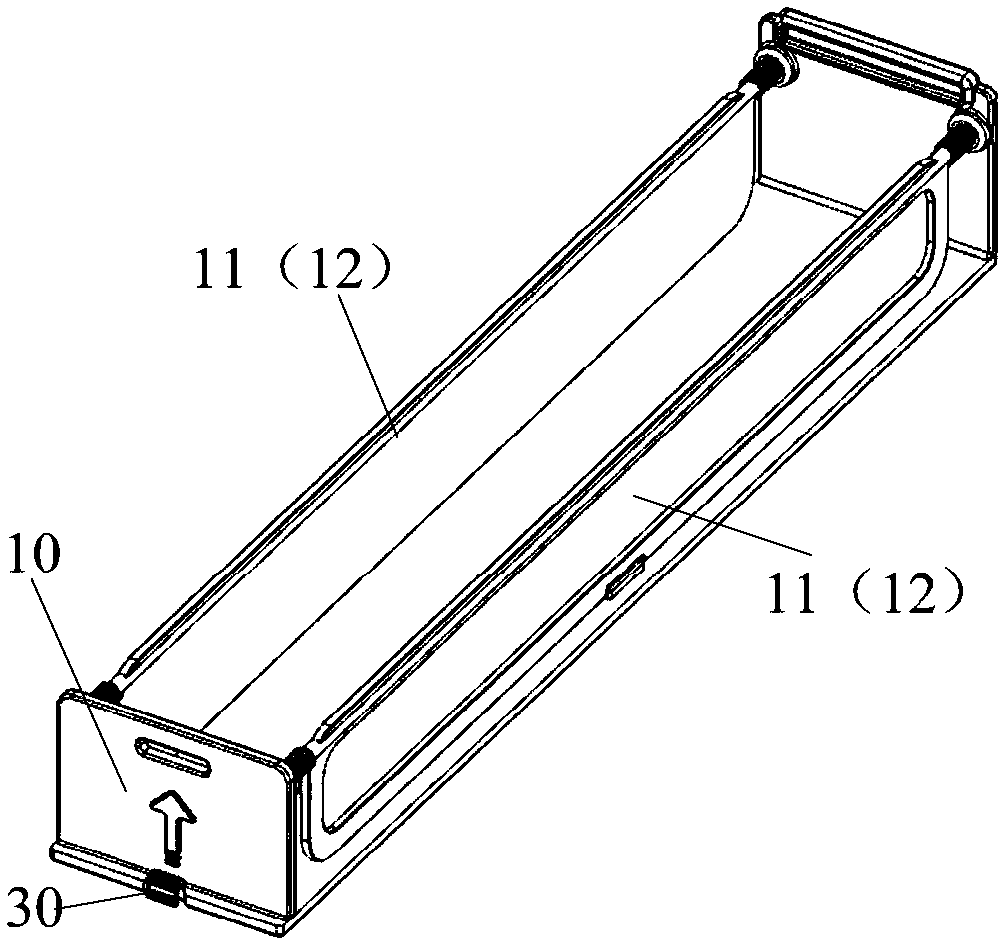

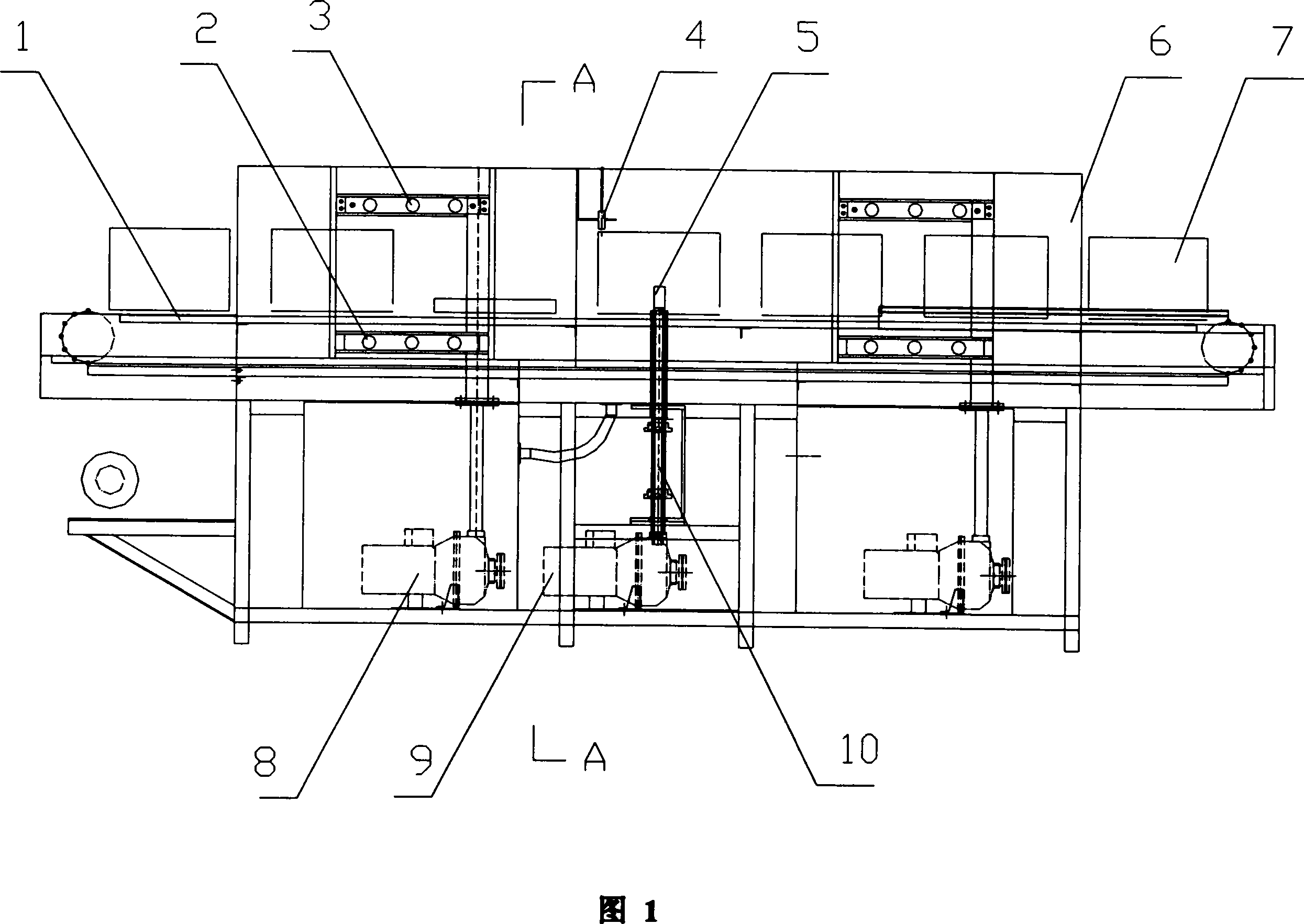

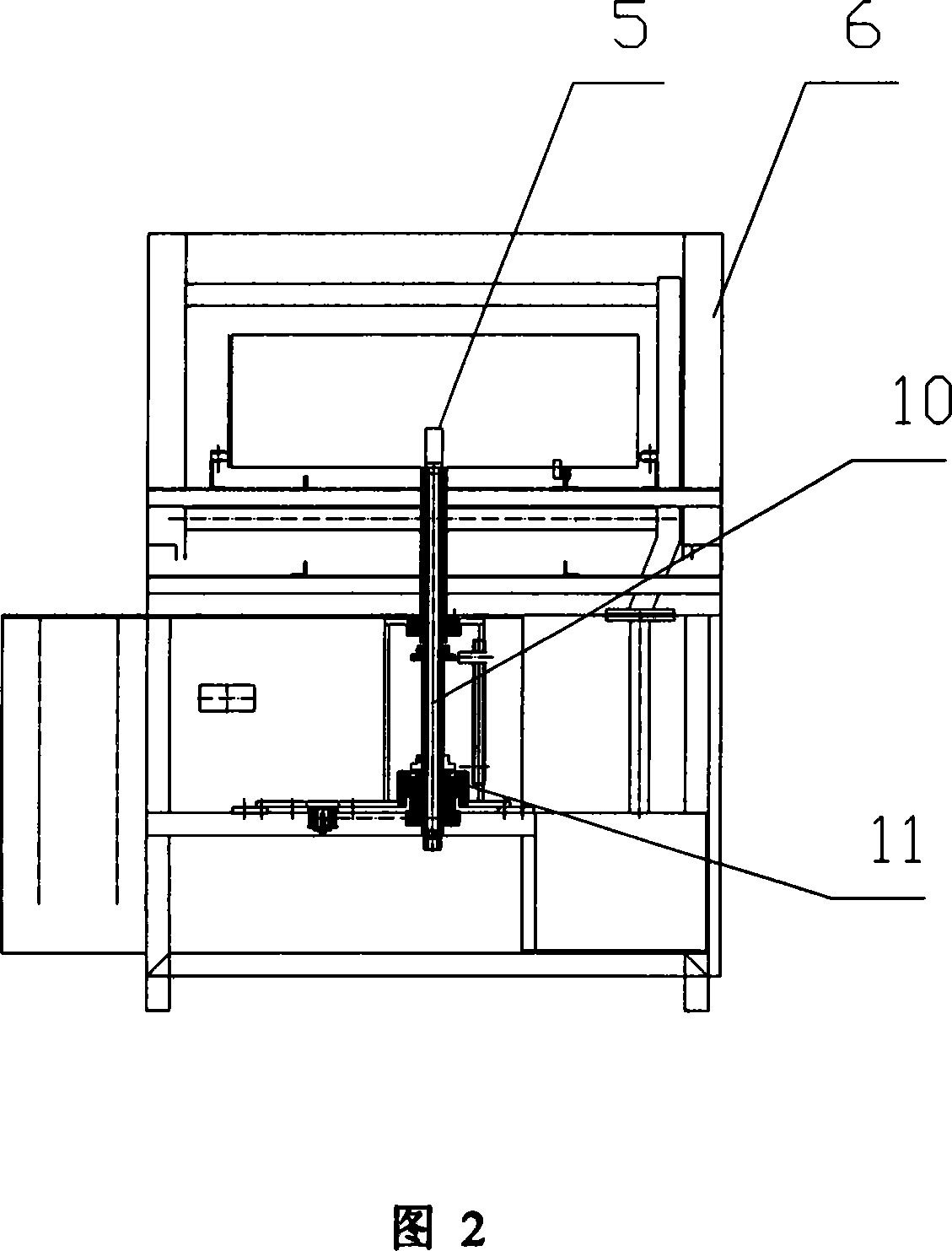

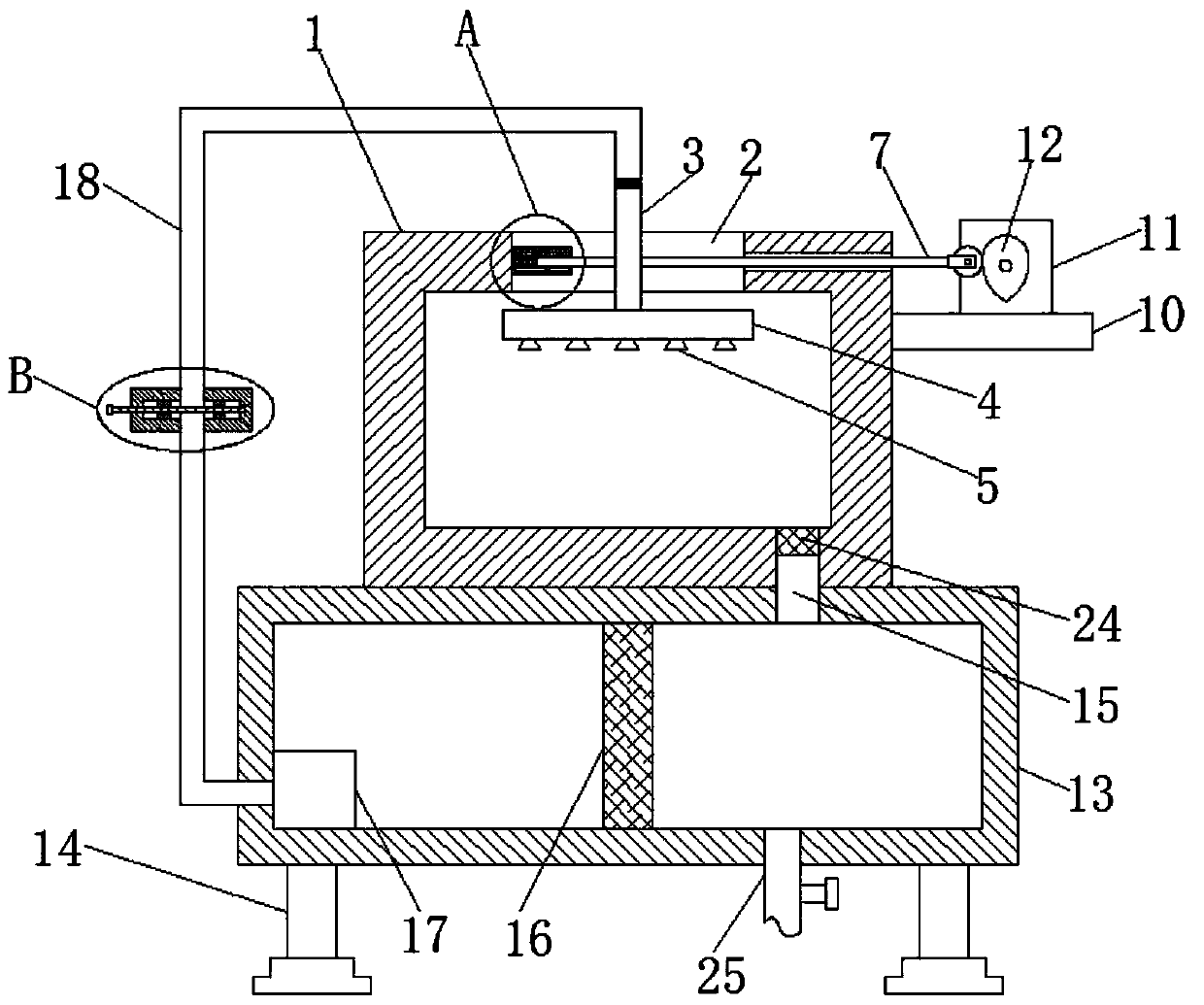

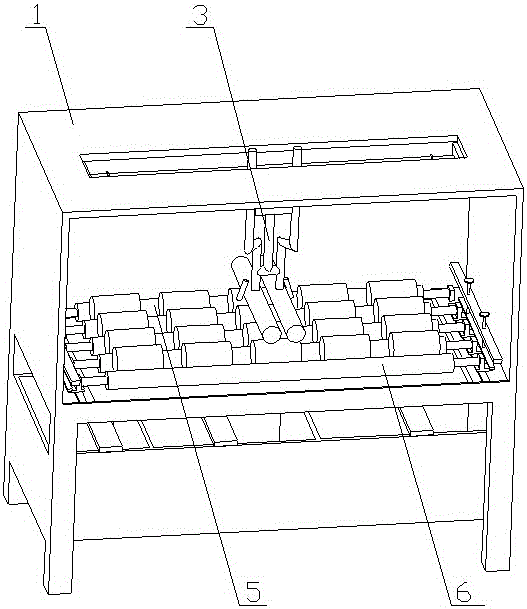

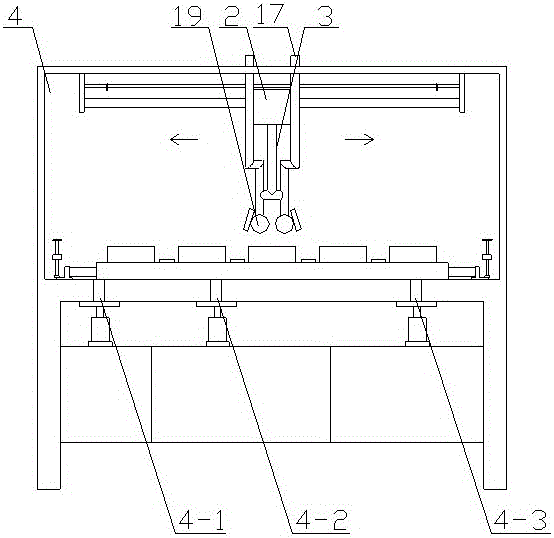

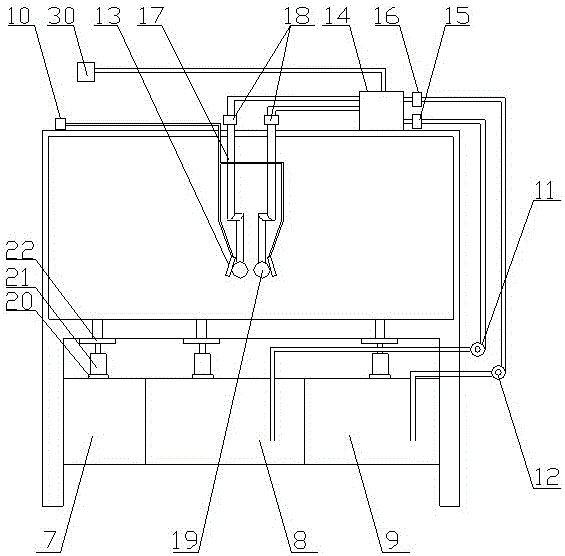

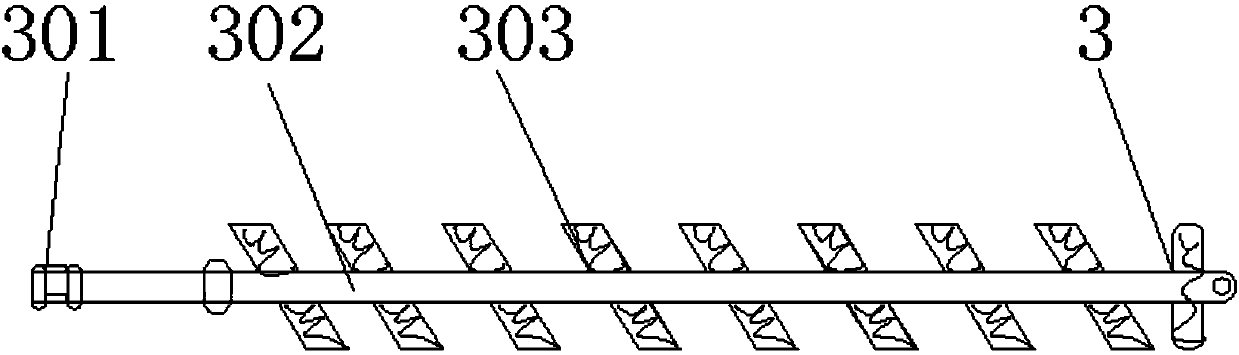

Full automatic cleaning machine for vacuum switch tubes

A full automatic cleaning machine for vacuum switch tubes is characterized by comprising a rack (1), a single-axis reciprocating machine (2), a fixed hanging rod (3), a transmission supporting mechanism and a circulatory spraying system. The transmission supporting mechanism comprises a driving roller (5), a set of driven rollers (6) and a motor. The circulatory spraying system comprises a waste water groove (7), an acid water groove (8), an alkali water groove (9), a high-pressure pump (10), an acid water pump (11), an alkali water pump (12), a pair of spraying nozzles (13), a multi-channel joint (14), an acid solenoid valve (15), an alkali solenoid valve (16), a pair of water outlet pipes (17), a pair of water outlet solenoid valves (18), a pair of stored water spraying pipes (19) and three switch mechanisms. The full automatic cleaning machine for the vacuum switch tubes has the advantages that the cleaning machine has the functions of water washing, acid washing and alkali washing, wherein the acid water and the alkali water can be recycled, so that the production cost is reduced; the cleaning machine can control the washing order and process of the water washing, the acid washing and the alkali washing by the solenoid valves, so that the cleaning requirements of the ceramic vacuum switch tubes in different production stages can be met and the degree of automation is high.

Owner:HUBEI XINSHIQI ELECTROCERAMICS TECH CO LTD

Corn kernel processing impurity removing machine

InactiveCN107695026ASimple device structureImprove production qualityGas current separationGranular material dryingNozzleVibration motor

The invention discloses a corn grain processing and removing machine, which comprises a cleaning box, a first motor, a three-way pipe, a cover, a transmission wheel and a wind cover. A water outlet hole is arranged on the left side of the bottom of the cleaning box. The first motor The first bearing and the first chain are respectively rotatably connected to the screw rod, the second motor is installed above the cover, the second motor is rotatably connected to the second bearing through the second chain, and the top of the three-way pipe is respectively installed There is a water valve and a water injection port, a discharge port is provided at the lower right corner of the cleaning box, a third motor is installed on the right side of the vibration motor, and a first conveyor belt and a second conveyor belt are respectively installed between the transmission wheels. A sundry collection box is installed above the wind shield, and the wind shield is located above the first conveyor belt. The corn kernel processing impurity removal machine can quickly clean and remove corn kernels, and can also screen corn kernels to further improve the quality of corn production.

Owner:陈银芳

Vacuum belt filter for carbendazim production

InactiveCN106178661AReduce moisture contentImprove working conditionMembrane filtersMoving filtering element filtersBelt filterPulp and paper industry

The invention discloses a vacuum belt filter for carbendazim production. The vacuum belt filter comprises a machine frame, a filter cloth, a rubber belt, a driving roller and a driven roller, wherein the filter cloth, the rubber belt, the driving roller and the driven roller are arranged on the machine frame. One end of the machine frame is provided with the driving roller, the other end of the machine frame is provided with the driven roller, and the rubber belt is in sleeved connection between the driving roller and the driven roller. A vacuum tank is arranged in the machine frame, an annular friction belt is arranged between the upper edge of the periphery of the vacuum tank and the rubber belt, the vacuum tank is divided into a plurality of vacuum partition cavities through partition plates in the rubber belt material-conveying direction, an ascending portion of the filter cloth is pressed and overlaid on the upper end face of the ascending portion of the filter cloth through a cloth pressing roller, and the filter cloth is sequentially connected with a discharging roller, a filter cloth conveying roller, a filter cloth tensioning device and the cloth pressing roller. A feeding device and a leaching device are sequentially arranged on the right side of the cloth pressing roller and located above the filter cloth in the filter cloth material-conveying direction. The vacuum belt filter is simple in structure, improves product quality, is good in filtering effect, effectively protects the filter cloth and intelligently controls vacuum degree.

Owner:ANHUI DONGZHI GUANGXIN AGROCHEMICAL CO LTD

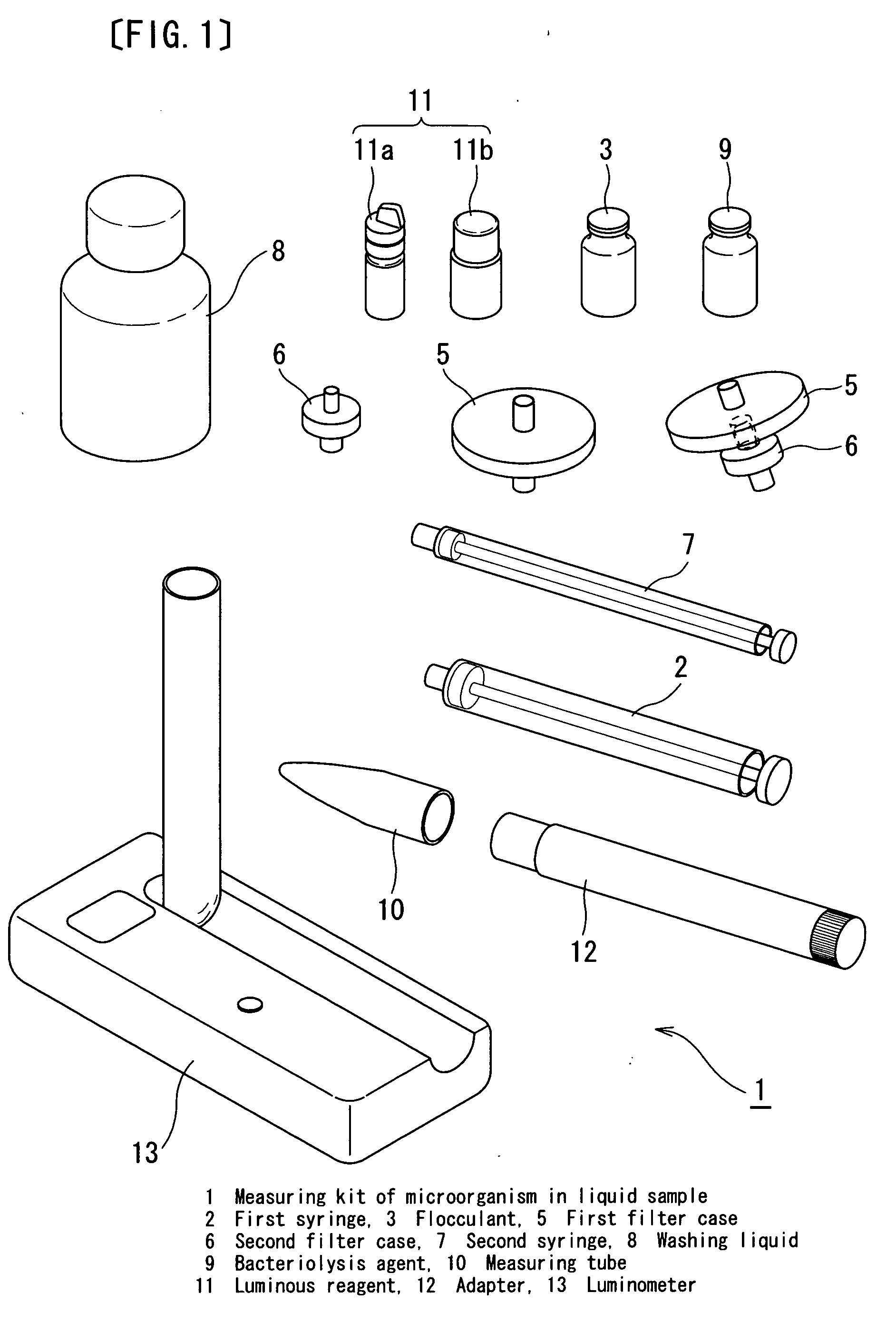

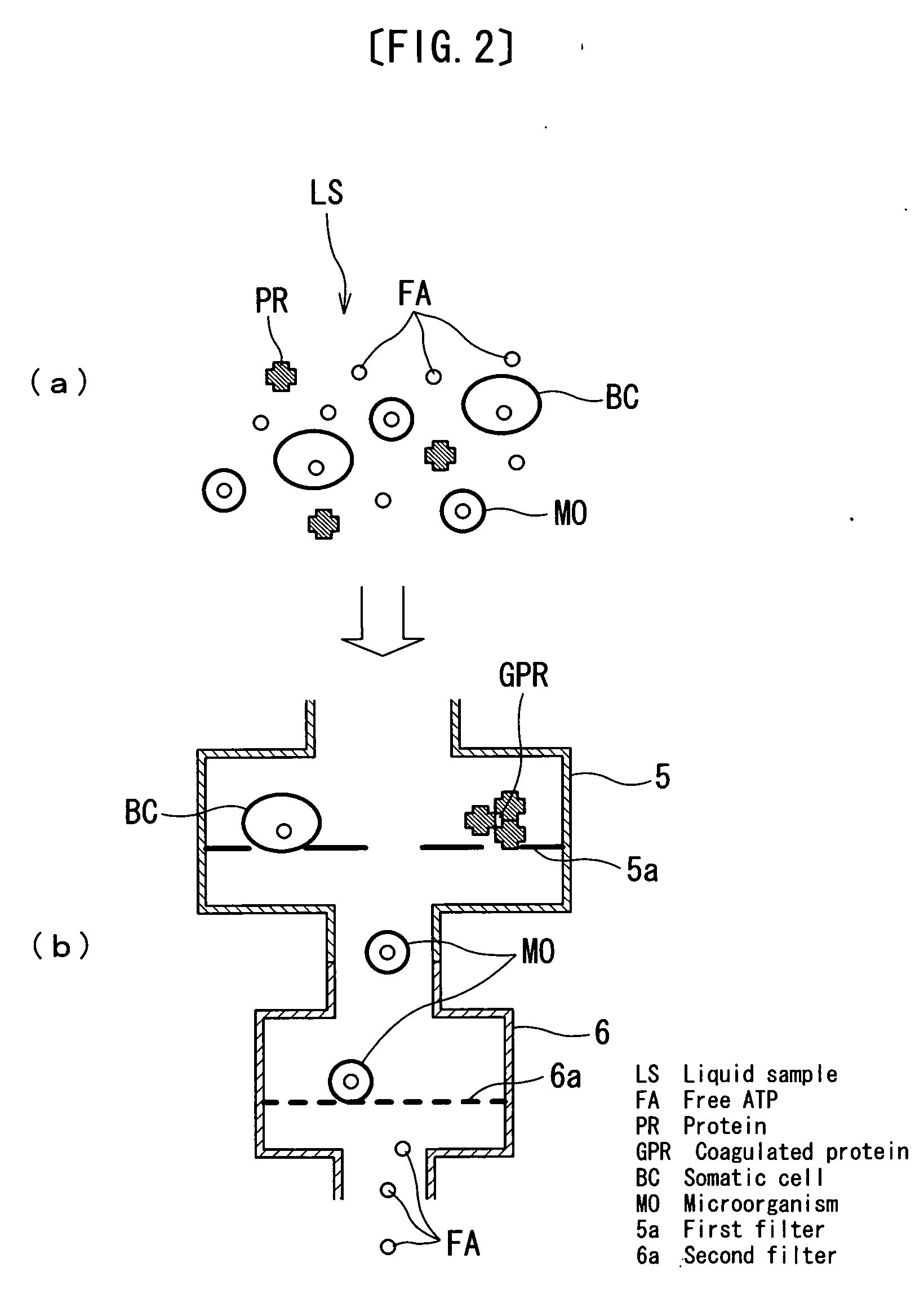

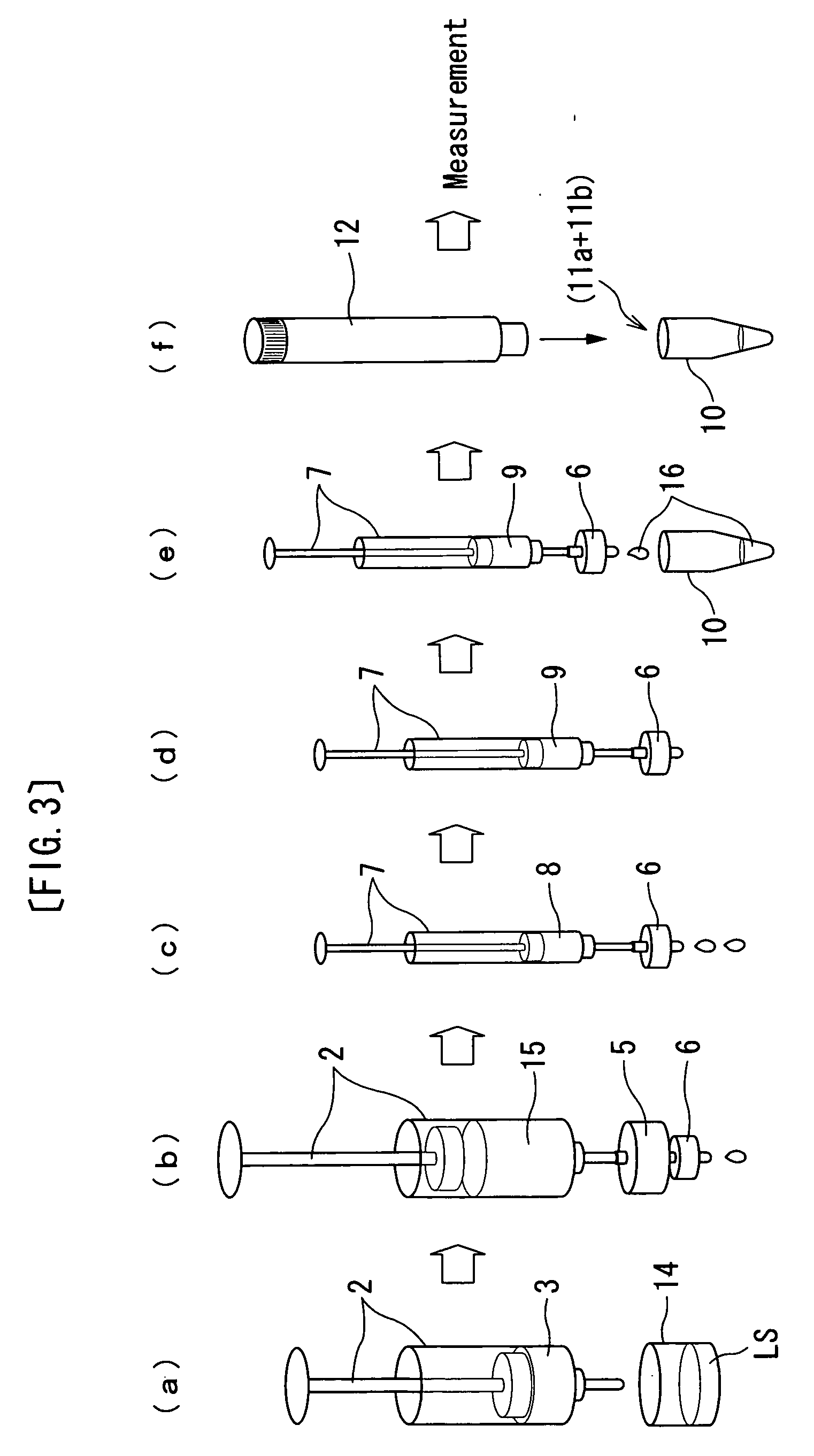

Measuring kit, measuring method and measuring apparatus of microorganism in liquid sample

InactiveUS20060263773A1Fully washedImprove reliabilityMicrobiological testing/measurementPush outChromatography

To be able to easily and rapidly remove free ATP, extract ATP from trapped microorganisms and measure extracted ATP, that loses less microorganisms in a sample, that does not require skill and that can measure the microorganisms in the sample stably and high-sensitively. A flocculant 3 is kept sucked beforehand in a first syringe 2. Then, a liquid sample LS is sucked and agitated. Then, a first filter case 5 and a second filter case 6 are attached immediately to a leading end. Then, this mixture liquid 15 is filtered. Then, only the second filter case 6 is detached and a washing liquid 8 is kept sucked by a second syringe 7 so as to wash the second filter case 6. Next, a bacteriolytic agent 9 is filled in the second filter case 6 and reacted for about 30 seconds. Then, a reacted liquid 16 is pushed out to a measuring tube 10. Then, a luminous reagent (11a+11b) that is prepared beforehand is added. Thereafter, an adapter 12 is attached. Then, it is agitated lightly. Then, a luminous quantity is measured by a luminometer at once.

Owner:DML

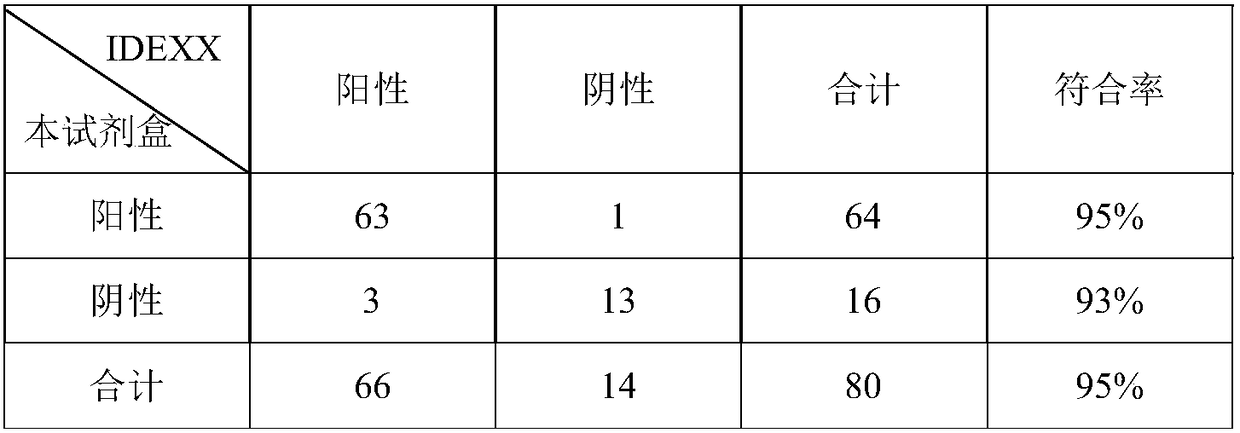

Magnetic micro particle immunofluorescence kit for quantitatively assaying classical swine fever virus antibody

InactiveCN108152509AImprove responseImproving immunogenicityBiological testingAntigenPositive control

The invention discloses a magnetic micro particle immunofluorescence kit for quantitatively assaying classical swine fever virus antibody, which consists of classical swine fever E2 antigen immunomagnetic beads, fluorescent substance-labeled goat anti-pig antibody, detergent, enhancement solution, negative control serum and positive control serum. Compared with the RT-PCR (reverse transcription-polymerase chain reaction) method and the ELISA (enzyme-linked immunosorbent assay) method, the magnetic micro particle immunofluorescence kit for quantitatively assaying classical swine fever virus antibody which is disclosed by the invention is easy to operate and suitable for assaying different numbers of samples, and has high assay speed (a result can be obtained in about 20 minutes); and compared with the colloidal gold immunochromatographic strip, the kit has the advantages of higher sensitivity, wider linear range, capability of realizing accurate quantification and the like. The assay result of the kit can accurately reflect the change law of anti-CSFV (anti-classical swine fever virus) serum IgG antibody of the body in the process of vaccination and provide scientific and reasonabletechnical support for pig farmers in preventing and controlling CSF (classical swine fever).

Owner:GUANGZHOU BIOKEY HEALTH TECH CO LTD

Method for degumming raw silk and fabric thereof by recomposing papain and reagent N

InactiveCN101858041AImprove degumming effectEasy to controlBiochemical fibre treatmentAnimal fibresReagentChemistry

The invention discloses a method for degumming raw silk and fabric thereof by recomposing papain and a reagent N, which improves, prolongs and stabilizes the enzymatic activity through enzyme recomposition, thereby improving the degumming effect of enzyme, being beneficial to controlling the process of degumming and decontaminating and reducing the working procedures. Comparing with the method only using an enzyme treated sample contrast, the decrement rate of the complex enzyme treaded sample is 1.5-2.30 times of that of the contrast; compared with the method only using a reagent N treated sample contrast, the decrement rate of the complex enzyme treaded sample is 120-185 times of that of the contrast, thereby greatly saving the enzyme reagent, reducing the degumming and refining cost and keeping the deserved strengthen of the degummed silk and the fabric thereof.

Owner:SOUTHWEST UNIVERSITY

Novel process for purifying and washing ultra-fine silicon dioxide by employing membrane separation technology

InactiveCN101224889AImprove washing efficiencyShorten the timeSilicon compoundsSeparation technologyUltra fine

The invention provides a new technology for washing and purifying superfine silicon dioxide with an applied membrane separation technology, and discloses a new method for the efficient washing and purification and the solid-liquid separation and concentration of the superfine silicon dioxide powder, which effectively improves the phenomena of long washing cycle, low efficiency and poor product quality of traditional washing methods like a plate and frame filter press and a centrifuge. The superfine substance separation technology is based on the membrane filtering effect of a porous ceramics medium, and adopts an efficient 'cross flow' filtering type, which leads the superfine silicon dioxide powder suspending liquid to be treated with sufficient washing, solid-liquid separation and realize the purification purpose of the powder. The method is an ideal method for the moment for efficiently washing and purifying the superfine silicon dioxide powder.

Owner:HUNAN JINMA NEW MATERIAL TECH CO LTD

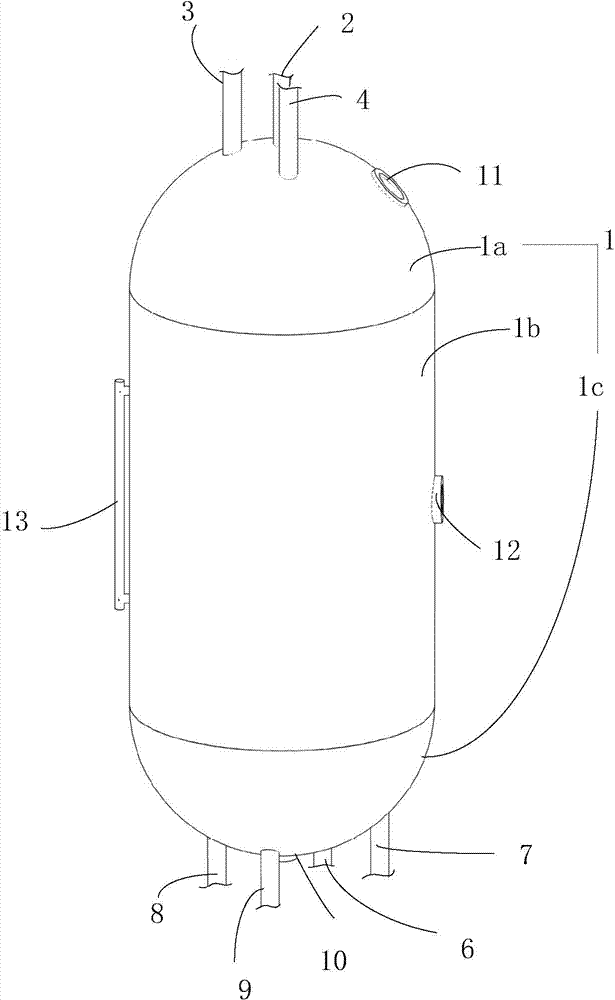

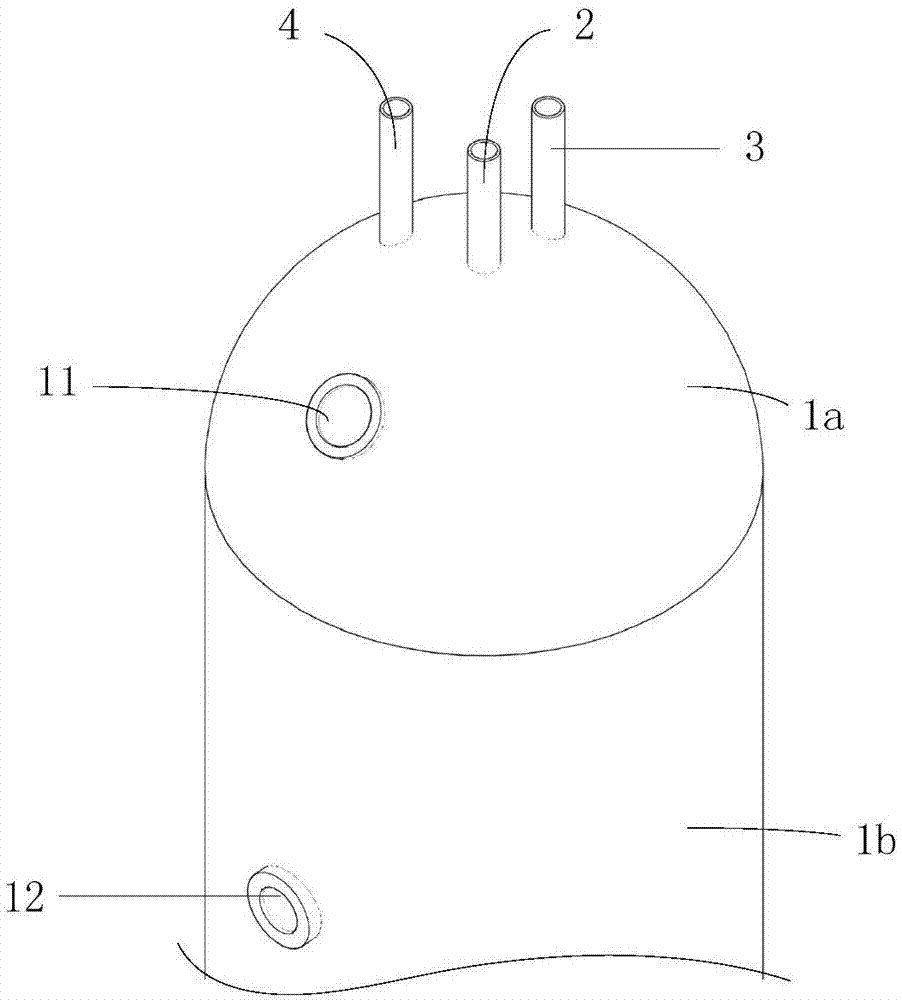

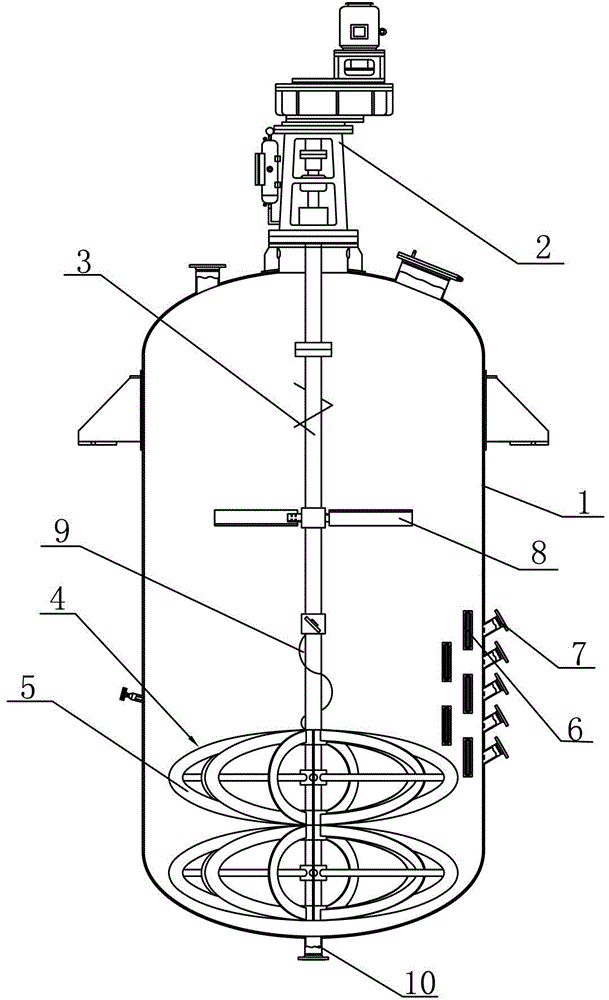

Novel coagulation washing kettle used for preparation of carbon dioxide-epoxy propane copolymer

InactiveCN103055787AHigh yieldQuality improvementChemical/physical/physico-chemical stationary reactorsEpoxyEngineering

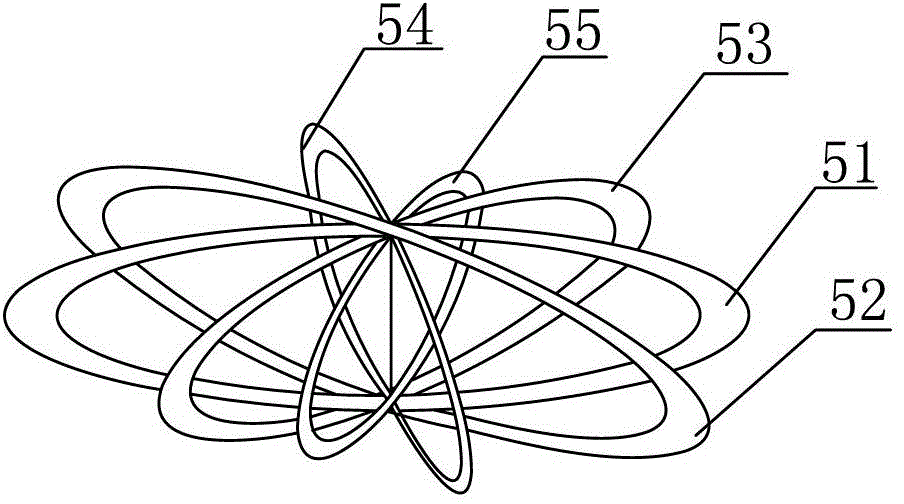

The invention discloses a novel coagulation washing kettle used for preparation of a carbon dioxide-epoxy propane copolymer. The washing kettle comprises a cylindrical kettle body which is vertically arranged. A central rotating shaft connected with an outer motor is longitudinally arranged in the kettle body. The washing kettle is characterized in that the lower end of the central rotating shaft is equipped with a plurality of ellipsoidal stirrers in a parallel manner longitudinally, the ellipsoidal stirrers are surrounded by a plurality of hollow oval stirring frame blades arranged on the central rotating shaft, a filter device is arranged on the side wall of the interior of the kettle body, a washing solution discharge pipe is arranged on the part, corresponding to the filter device, of the outer wall of the kettle body, the distance of the angle of the adjacent oval stirring frame blades is the same, the horizontal diameters of the oval stirring frame blades are different, and the height of the oval stirring frame blade is 1 / 8-1 / 6 of the length of the central rotating shaft. The novel coagulation washing kettle has advantages that the unreacted reaction material adhered to the surface of a solid polymer is completely separated from the solid polymer, and a polymer is collected through a material outlet, so that the yield and quality of the solid polymer are improved.

Owner:SEDIN NINGBO ENG

Process for preparing trisodium phosphate from glyphosate mother liquid

ActiveCN103693631ASimple production processEase of industrial applicationPhosphorus compoundsSodium acid carbonateGlyphosate

The invention provides a process for directly preparing trisodium phosphate from glyphosate mother liquid in order to effectively recover phosphorus resources from the mother liquid for producing trisodium phosphate. The process is characterized by comprising the following steps: oxidizing the glyphosate mother liquid through catalytic air, oxidizing organic phosphine in the mother liquid into orthophosphate ions, adding sodium hydroxide or sodium carbonate into the mother liquid to adjust the pH value to be 9-10, cooling to be -5 DEG C to 8 DEG C while stirring, crystallizing, separating, washing, and drying to obtain trisodium phosphate. The process is simple and easy for industrialization applications, the obtained trisodium phosphate is wide in application range, difficulty in enabling the glyphosate mother liquid subjected to terminal treatment to reach the emission standard is lowered, and treated solid waste is reduced.

Owner:福华通达化学股份公司

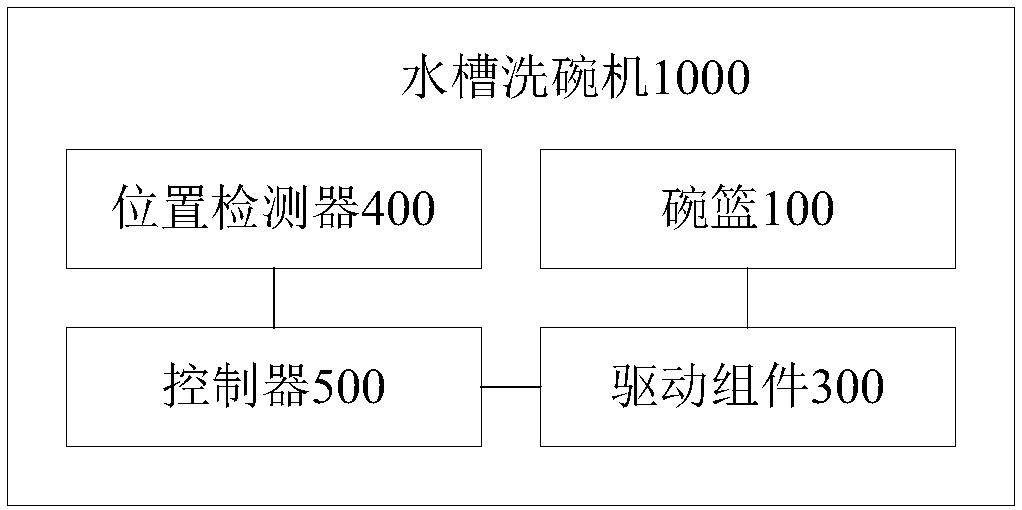

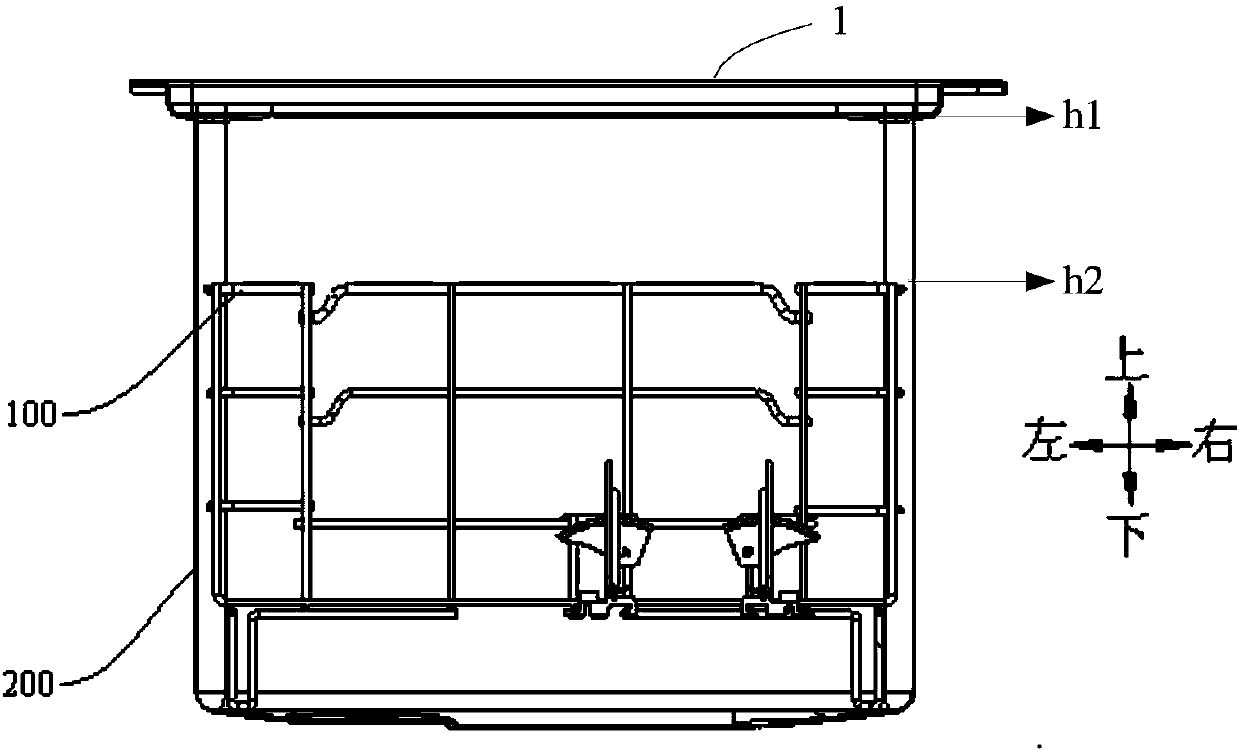

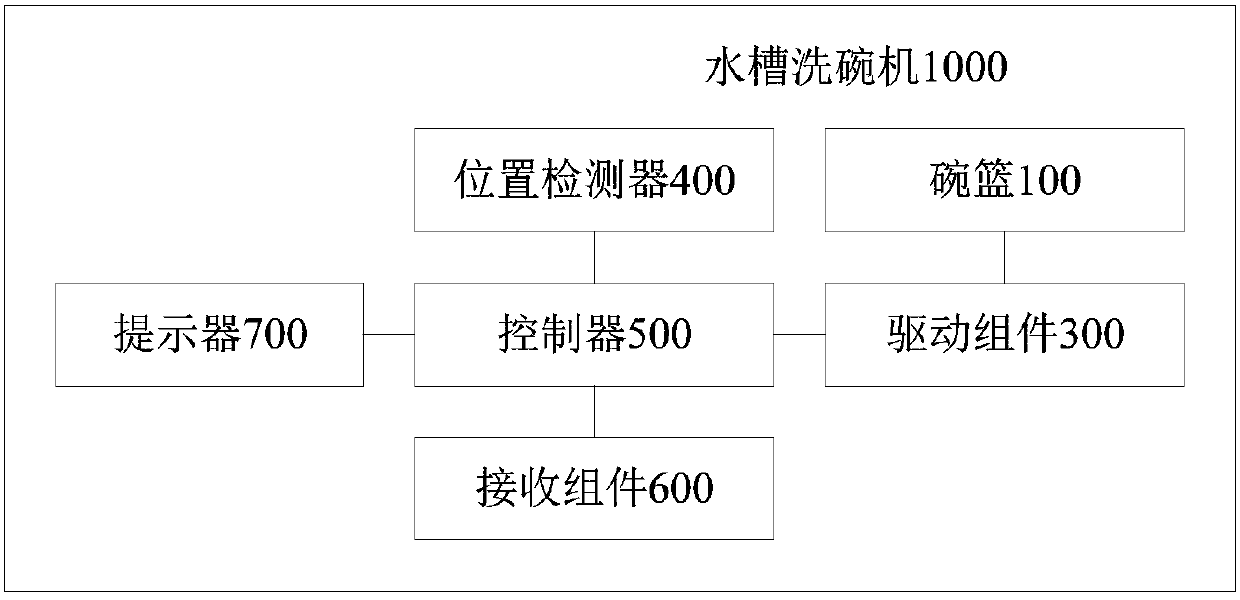

Sink-type dishwasher and bowl basket driving method thereof

InactiveCN107854089AEasy to placeEasy accessTableware washing/rinsing machine detailsControl engineeringStructural engineering

The invention provides a sink-type dishwasher and a bowl basket driving method thereof. The sink-type dishwasher comprises a sink piece, a bowl basket, a driving assembly, a position detector and a controller; the sink piece is of a general cuboid structure with an open top; the bowl basket is arranged in the sink piece, and the shape of the bowl basket is matched with that of the sink piece; thedriving assembly is connected with the bowl basket and used for driving the bowl basket to achieve lifting movement between a first position and a second position; the position detector is used for detecting the actual position of the bowl basket; the controller is connected with the position detector and the driving assembly separately and controls the driving assembly according to the actual position of the bowl basket to drive the bowl basket to be located at the first position or the second position. The sink-type dishwasher can achieve the lifting control over the bowl basket and is convenient for a user to use.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

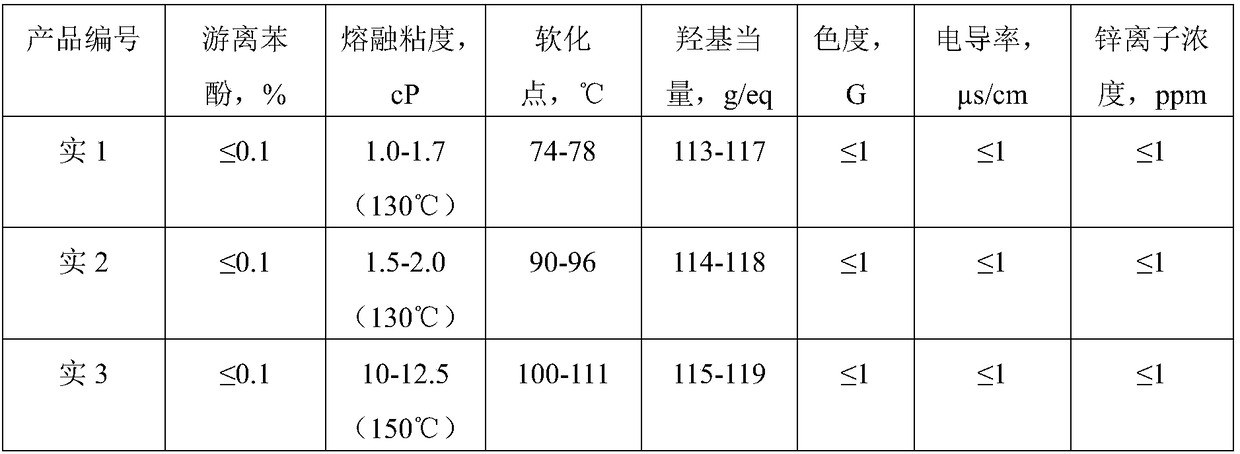

Preparation method of high-ortho-position electronic grade phenolic resin with high hydroxyl content

The invention relates to a preparation method of high-ortho-position special phenolic resin with high hydroxyl content. The preparation method is characterized in that zinc salt is adopted to performcatalysis, alkylphenol is adopted to replace phenol, the molar ratio of phenolic reaction is greater than 1, and after the reaction is finished, special deionized water washing and steam purging processes are adopted to effectively reduce the contents of impurity ions, volatile components and free phenols in the resin. The resin prepared by the preparation method provided by the invention has thecharacteristics of high electric insulativity, high cohesiveness, high thermal stability, high mechanical properties, low viscosity, low curing temperature, low dielectric constant, low thermal expansion coefficient, low hygroscopicity, low stress and the like, and can be widely applied to high and new technology fields of electronics, foundry industry, aerospace and the like.

Owner:SUZHOU XINGYE MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com