Full automatic cleaning machine for vacuum switch tubes

A technology for fully automatic cleaning and vacuum switching tubes, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of complex cleaning process, many cleaning steps, unqualified products, etc. The effect of high washing quality, high degree of automation and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

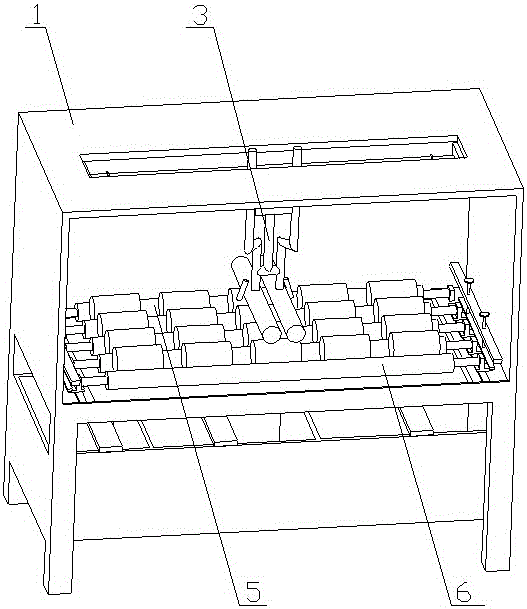

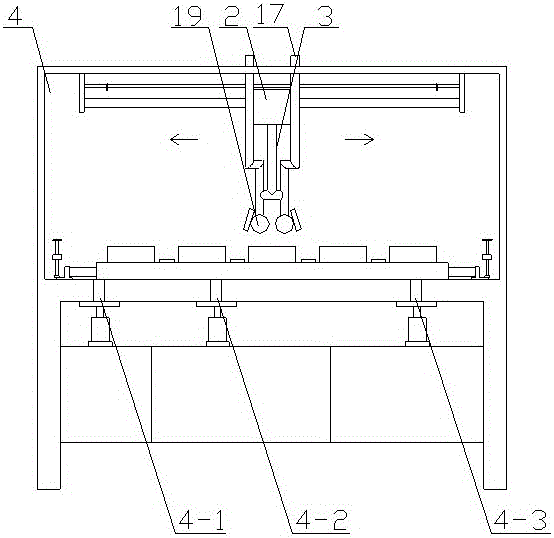

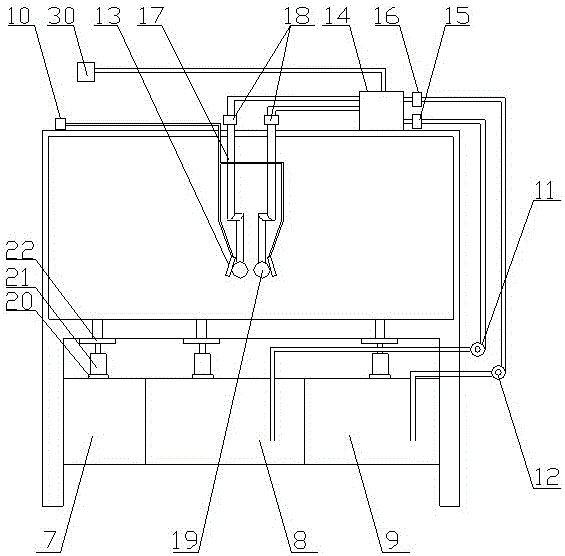

[0021] Such as Figure 1-6 As shown, the present invention includes: a frame 1, a single-axis reciprocating machine 2, a fixed hanging rod 3, a transmission support mechanism and a circulating spraying system, the upper part of the frame 1 is provided with a spraying area 4, and the bottom of the spraying area 4 is respectively There are waste water outlet 4-1, acid water outlet 4-2 and alkaline water outlet 4-3, the single-axis reciprocating machine 2 is installed on the frame 1, and one end of the fixed hanging rod 3 is installed on the single-axis reciprocating machine 2 The bottom of the running mechanism, the transmission support mechanism includes a driving roller 5, a set of driven rollers 6 and a motor, and the two ends of the driving roller 5 and a group of driven rollers 6 are respectively installed on the spray At both ends of the bottom of zone 4, one end of the driving roller 5 is connected to the power output shaft of the motor. The driving roller 5 and a set of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com