Patents

Literature

323results about How to "Meet cleaning needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shale gas development oil-base drilling fluid mud cake cleaning solution

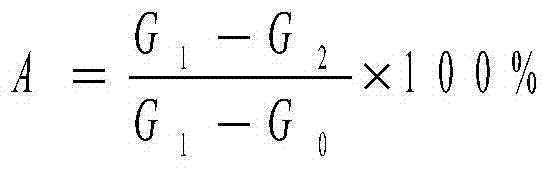

The invention relates to a shale gas development oil-base drilling fluid mud cake cleaning solution and belongs to the technical field of petroleum drilling engineering chemical agents. The shale gas development oil-base drilling fluid mud cake cleaning solution is characterized by comprising the following components in percentage by weight: 10 percent to 30 percent of a cleaning agent, 0 percent to 60 percent of a weighting agent and the balance of water, wherein the cleaning agent consists of nonionic surfactants and mutual solvents; the weight ratio of the nonionic surfactants to the mutual solvents is 1:9 to 9:1; the nonionic surfactants are polyoxyethylene ether, polyoxyethylene aliphatic ester, polypropylene oxide aliphatic ester and the like; the mutual solvents are methyl alcohol, ethanol, isopropanol and the like; the weighting agent is superfine iron ore powder and has density of 4.90 to 5.20 g / cm<3>. The cleaning solution disclosed by the invention has low viscosity, can form turbulence displacement, can effectively clear away oil-base slurry and mud cakes attached on a well wall and change the water wetting condition of the well wall, and has the characteristics that the density adjustable range is wide, the cleaning effect is good, and the shale gas development oil-base drilling fluid mud cake cleaning solution is beneficial to improving well cementing quality.

Owner:JINGZHOU JIAHUA TECH

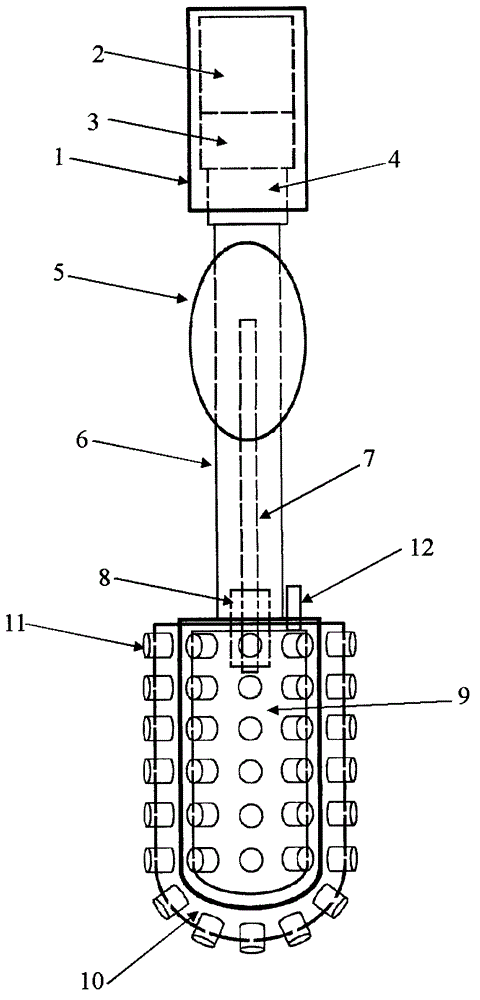

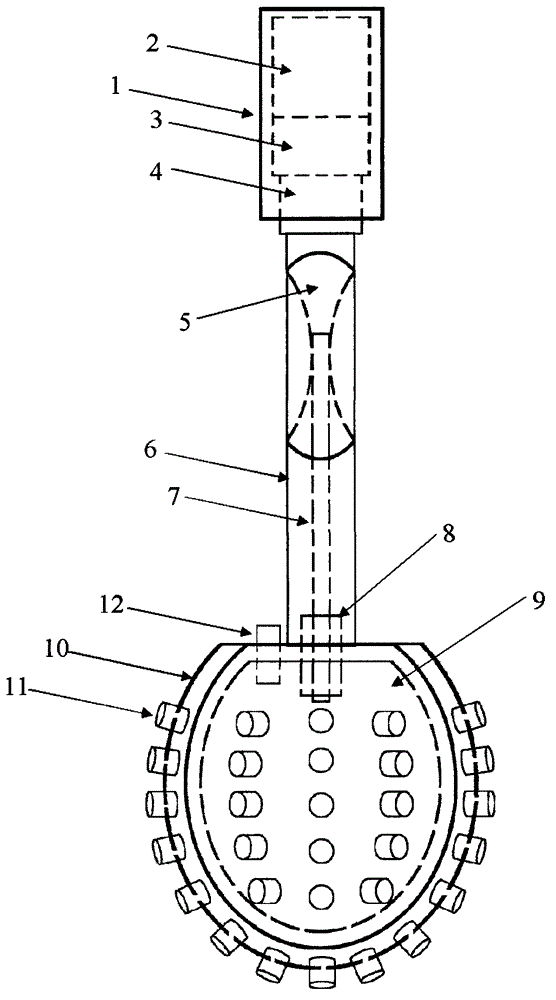

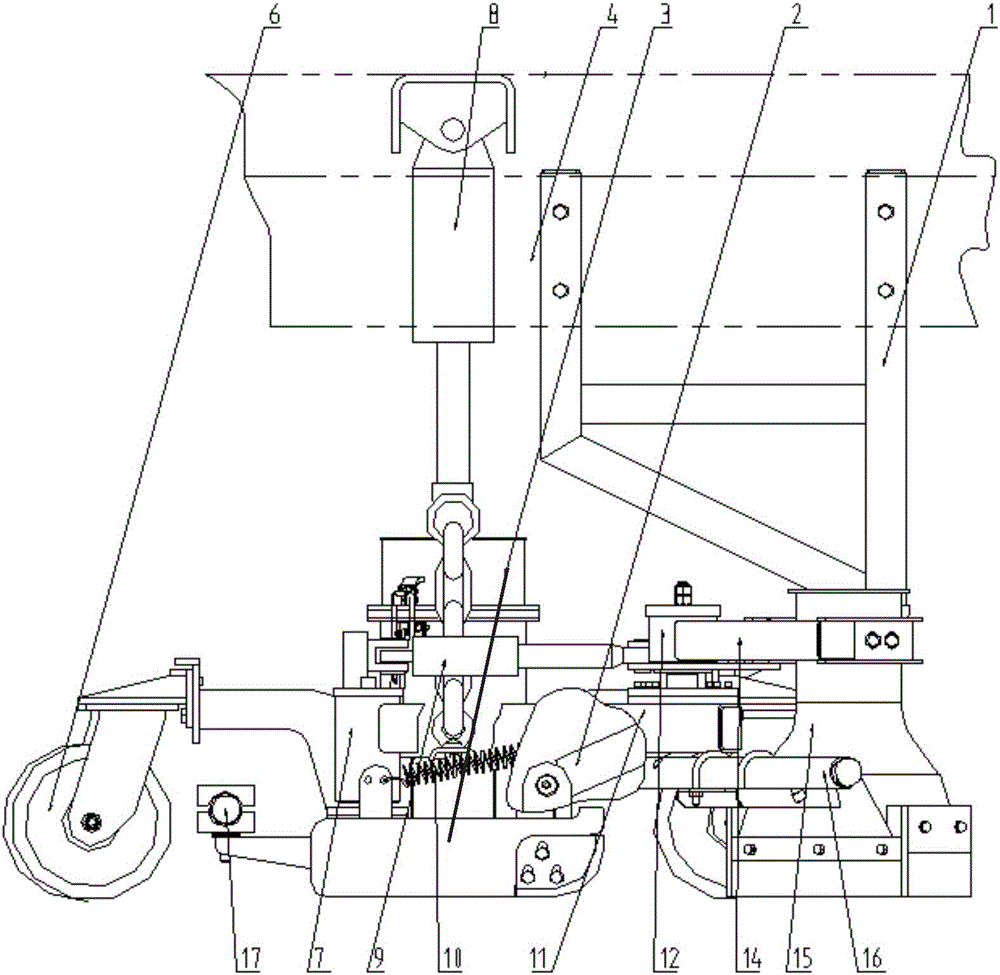

Power pipeline cleaning device

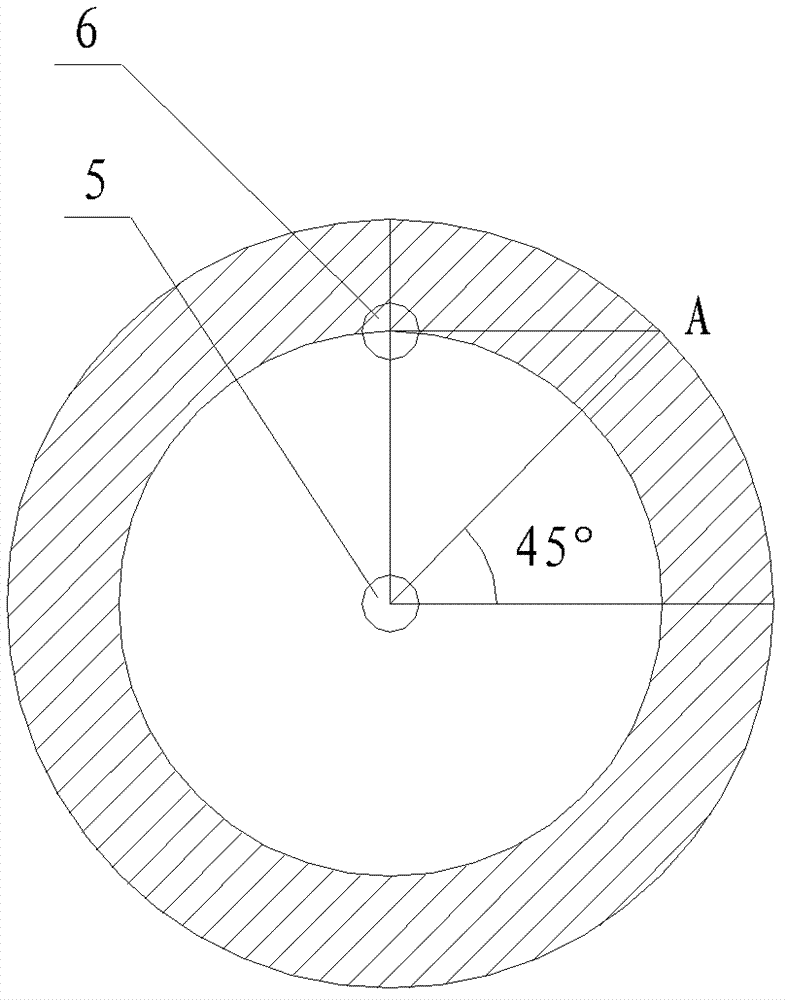

InactiveCN108080369AMeet cleaning needsImprove cleaning efficiencyHollow article cleaningRotational axisEngineering

The invention discloses a power pipeline cleaning device. The power pipeline cleaning device comprises a bolt fastening frame arranged at an opening of a power pipeline, an electric cylinder fixed onthe bolt fastening frame, a rotating motor connected with the electric cylinder and a rotating seat connected with the rotating motor; a push rod of the electric cylinder and a rotating shaft of the rotating motor are located on the central axis of the power pipeline, the front end of the push rod is connected to the end, opposite to the rotating shaft, of the rotating motor, and the front end ofthe rotating shaft is connected with one end of the rotating seat; and a supporting seat is arranged at the bottom of the rotating motor, rolling wheels are installed at the bottom of the supporting seat, a scraping plate is vertically arranged on the rotating shaft, cleaning brushes are connected to the rotating seat in the radial direction of the power pipeline, the other end of the rotating seat is connected with a liquid storage tank, and liquid spraying openings are formed in the two ends of the liquid storage tank in the radial direction of the power pipeline. According to the power pipeline cleaning device, the power pipeline is cleaned by rotating the cleaning brushes, the structure is simple, and the cleaning efficiency is high.

Owner:CHENGDU ZHONGAN ELECTRICAL

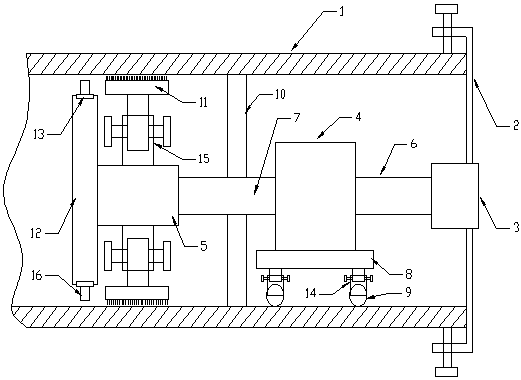

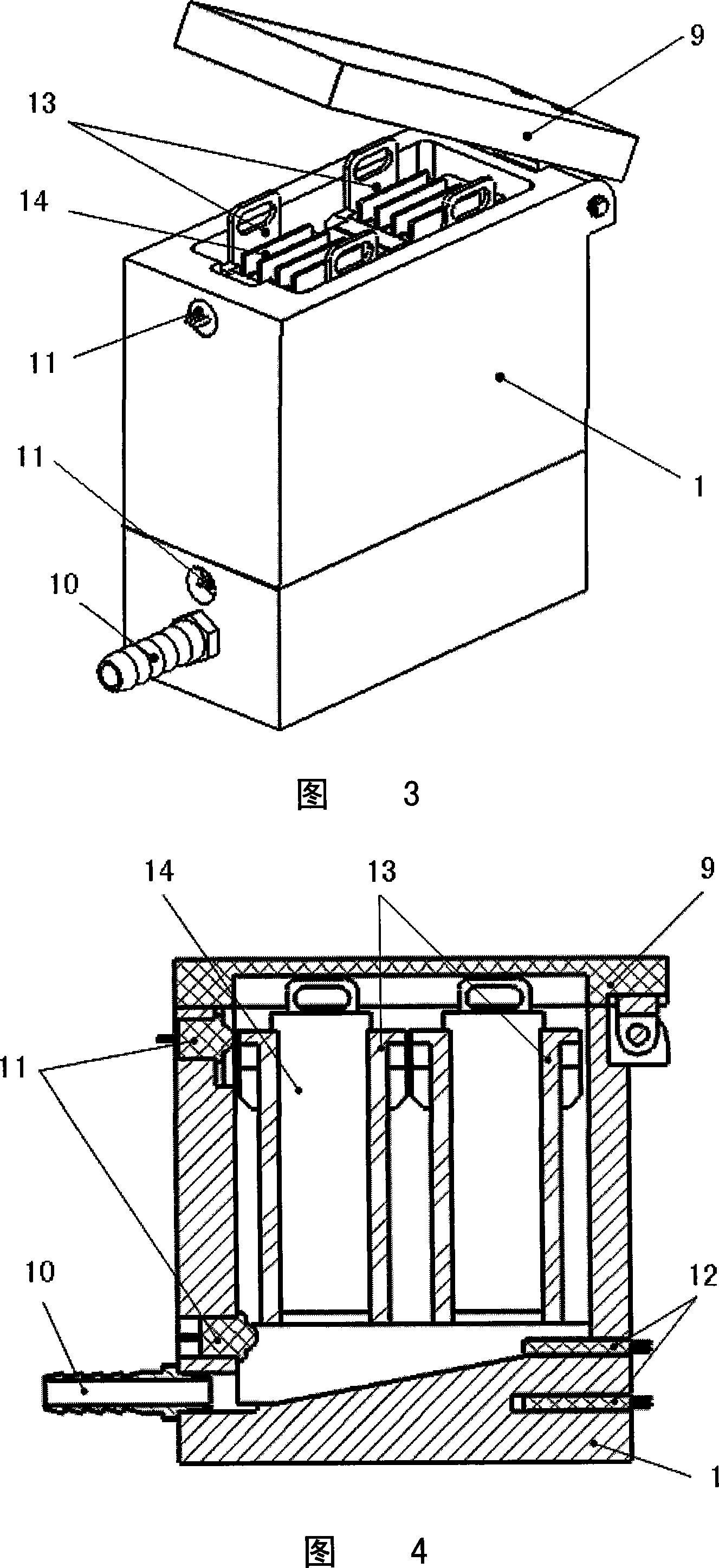

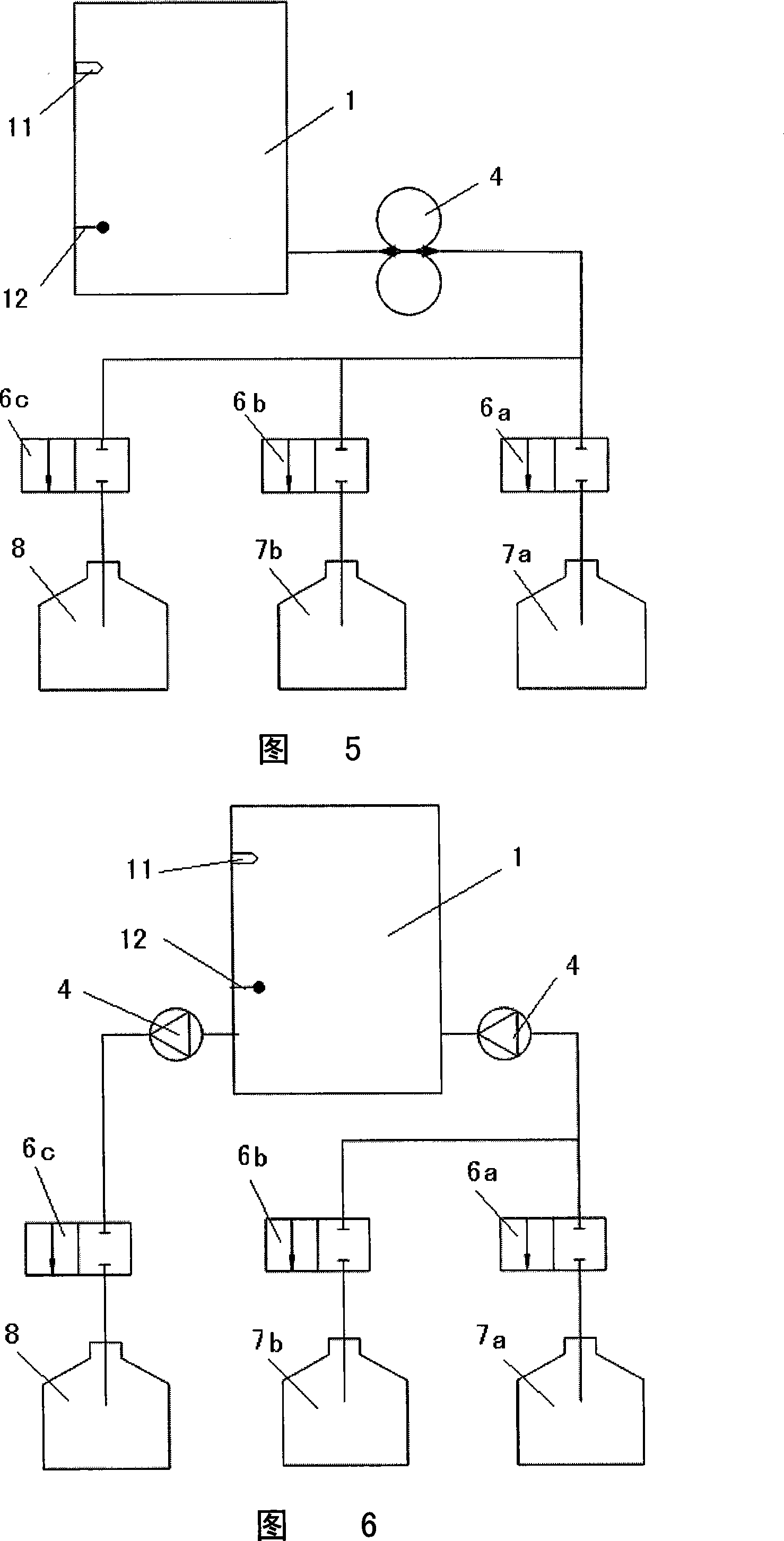

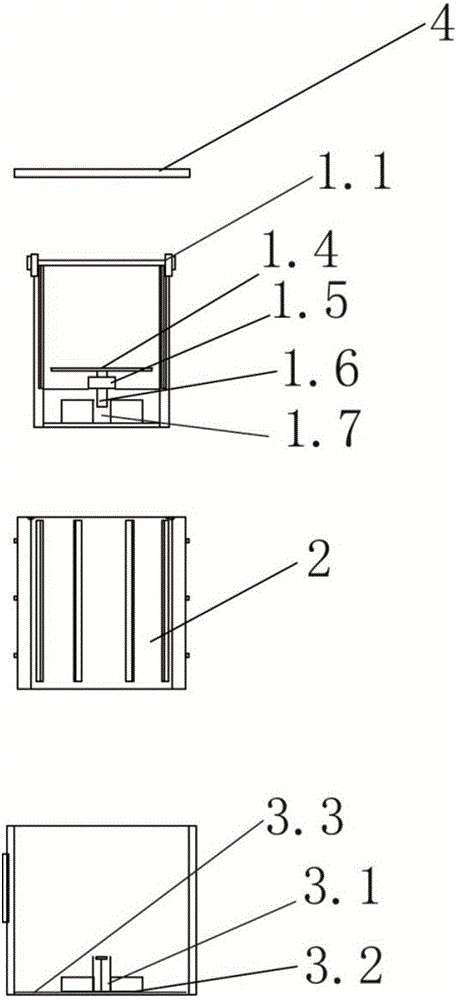

Washing method and device for biological chip

ActiveCN101196447AMeet cleaning needsImprove cleaning efficiencyPreparing sample for investigationBiological testingBiochipBottle

The invention relates to a cleaning method of biochip and device, which comprises the following procedures: firstly, a plurality of fixing grooves fixed with a biochip are arranged in a cleaning chamber; secondly, at least a pipeline to a liquid cleaning bottle and a pipeline to a waste liquid bottle are connected under the cleaning chamber, a liquid pump and a valve are arranged on the pipeline; thirdly, the valve to the waste liquid bottle is closed, the valve to the cleaning liquid is opened, through liquid pump, make the cleaning liquid pump in the cleaning chamber; fourthly, the valve to the cleaning liquid is closed and the valve to the waste liquid bottle is opened. Starts the liquid pump for / backward frequently, and makes the cleaning liquid pump in the cleaning chamber enter into the waste liquid bottle by pump. The invention has simple structure and lower cost, which realizes the automatic cleaning to biochip, avoids the error caused by manual operation, and is easier to realize automatic controlling and integrating.

Owner:BOAO BIOLOGICAL CO LTD +1

Cleaning tool

InactiveCN106694492AEasy to cleanProtect the internal structureHollow article cleaningEngineeringMechanical engineering

The invention discloses a cleaning tool comprising a handheld shell, a motor, a gas bag, a hollow structure, a gas vent and cleaning cloth. The handheld shell is conveniently held in hand while be used for protecting an inside structure; the motor is powered by a battery and drives a rotating shaft to rotate so as to drive a supporting rod and the hollow structure to integrally rotate for conveniently cleaning a vessel; the supporting rod is internally provided with a gas pipe which is connected with the hollow structure by a connection; gases are charged from the gas pipeto the hollow structure part by virtue of the joint by pressing the gas bag; the gas-charged hollow structure can expand and the hollow structure is made of a telescopic material; the gas vent is located at the hollow structure, and the gases in the hollow structure are discharged by the gas vent; and the outside of the hollow structure is wrapped with outer cleaning cloth, the surface of the cleaning cloth is provided with cleaning cotton heads, and the to-be-cleaned vessel can be gradually filled with the outer surface of the expanded hollow structure, so that dead angles in the vessel are conveniently cleaned when the motor is started for rotatably cleaning, and the cleaning requirements of people are met.

Owner:TIANJIN POLYTECHNIC UNIV

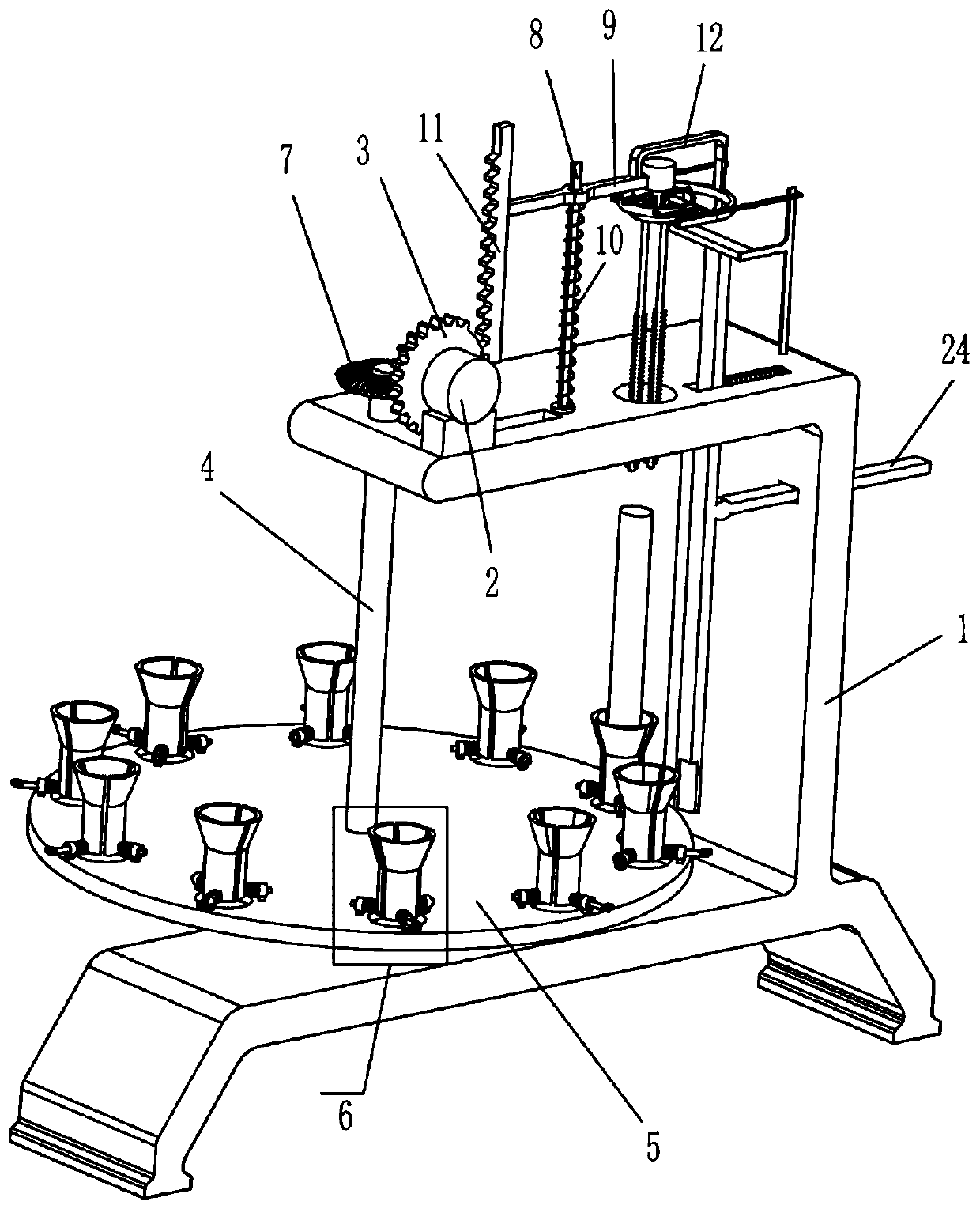

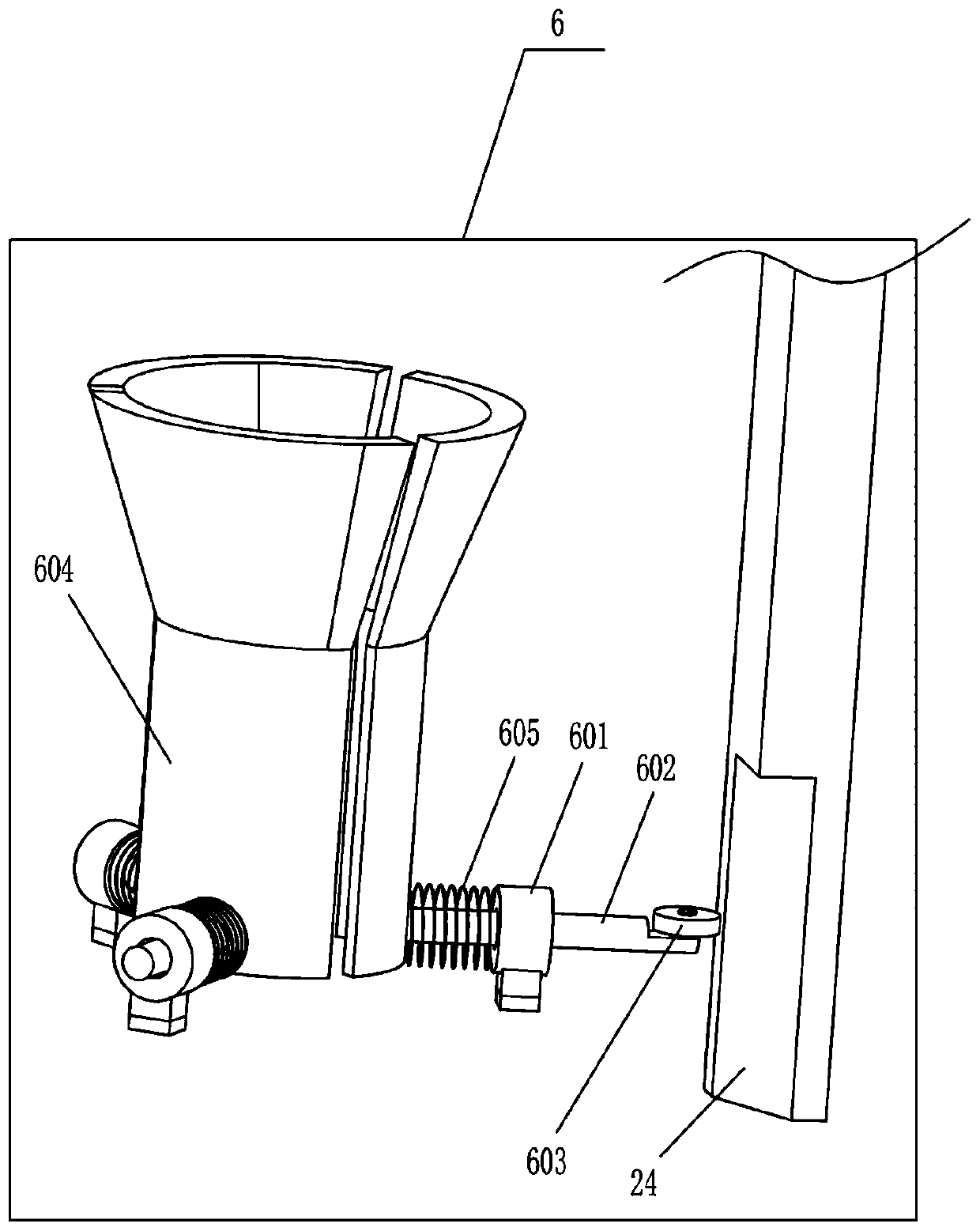

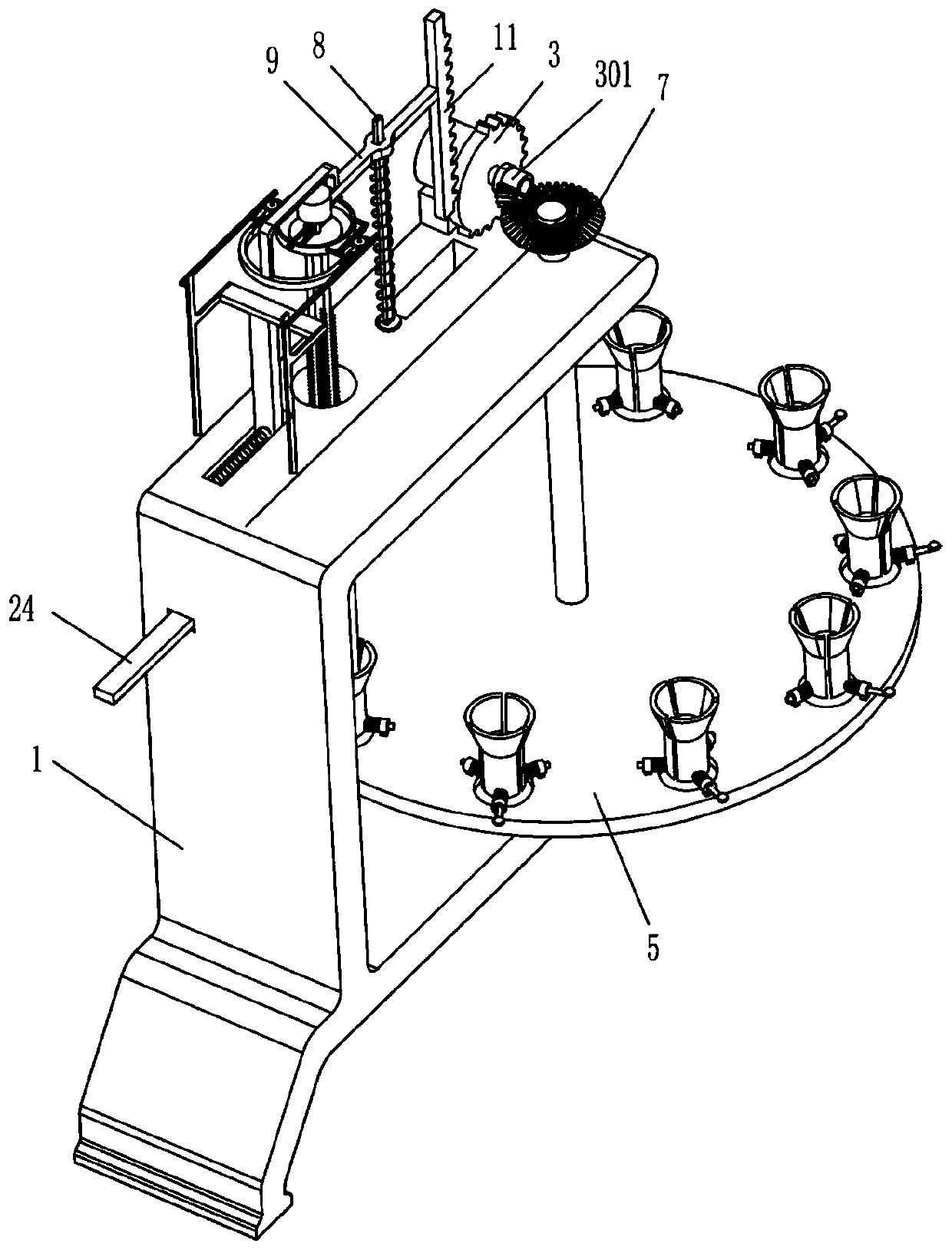

Cleaning device suitable for interiors of test tubes of different sizes

ActiveCN111451233AAchieve mechanical cleaningSolve cleaningHollow article cleaningGear wheelElectric machinery

The invention relates to the technical field of test tube cleaning, in particular to a cleaning device suitable for interiors of test tubes of different sizes. The invention aims to provide the test tube interior cleaning device which can be used for quickly and thoroughly cleaning test tubes, is high in cleaning efficiency and good in effect and can meet the cleaning requirements of the test tubes with different inner diameters. According to the technical scheme, the cleaning device suitable for the interiors of the test tubes of different sizes comprises a support, a transmission motor, a sector gear, a tooth-missing bevel gear, a rotating shaft and the like; and the transmission motor is fixedly installed on one side face of the support, the sector gear is installed on an output shaft of the transmission motor, the tooth-missing bevel gear and the sector gear are coaxially arranged, and the rotating shaft is installed on the support through a bearing and penetrates through the support. According to the cleaning device, mechanical cleaning of the test tube is achieved, and the problems that due to the fact that the test tube is too long, cleaning is inconvenient and not thoroughwhen the test tube is manually cleaned through a hairbrush are solved; and the cleaning requirements of the interiors of test tubes with different thicknesses can be met, the application range is wide, and practicability is high.

Owner:惠州帝恩科技有限公司

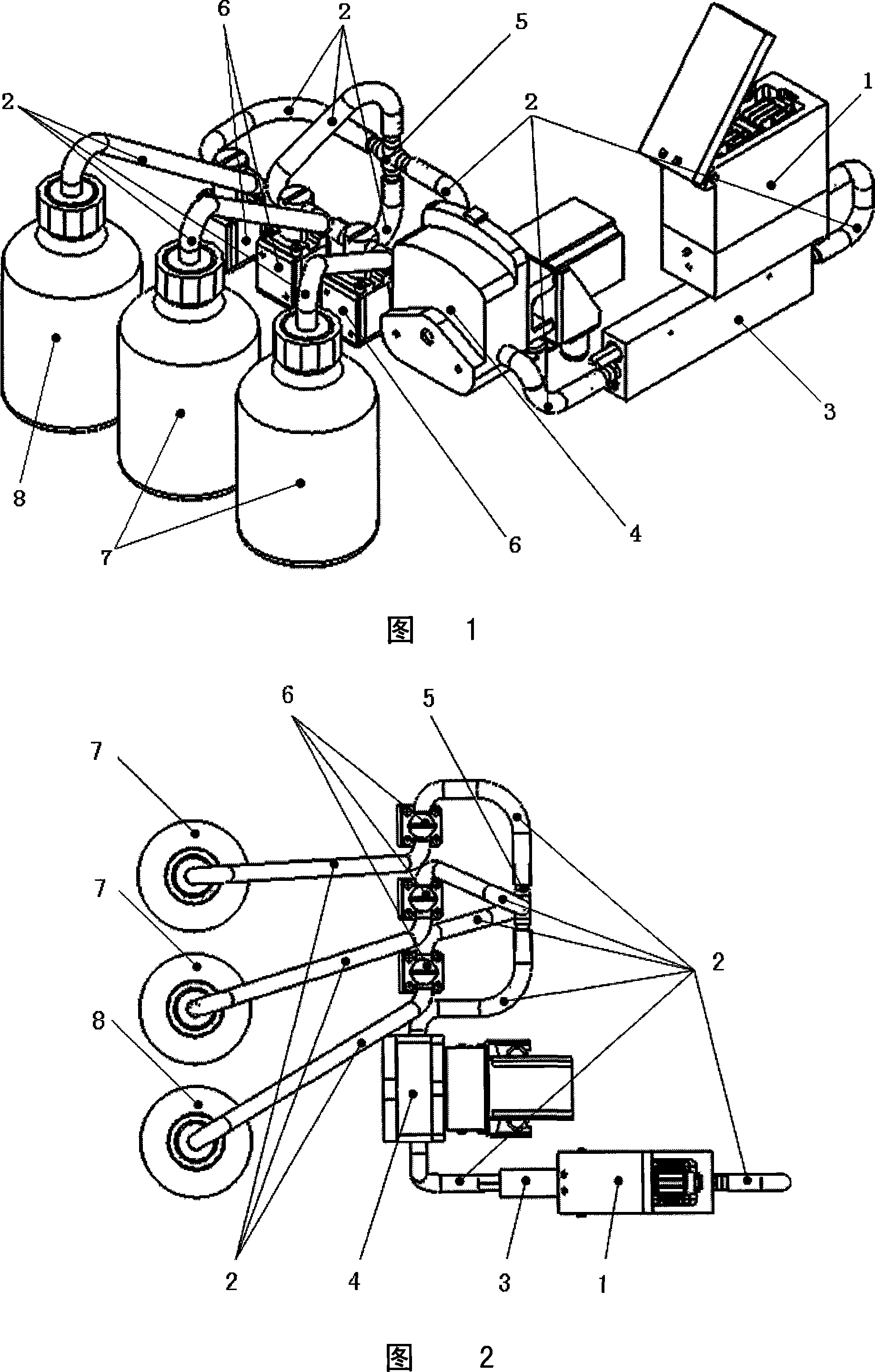

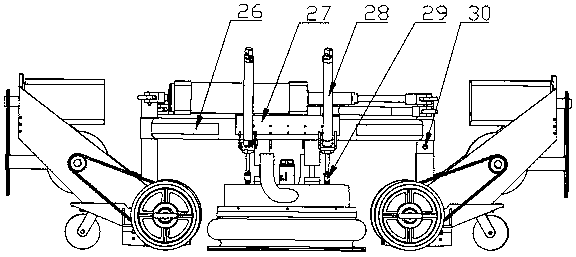

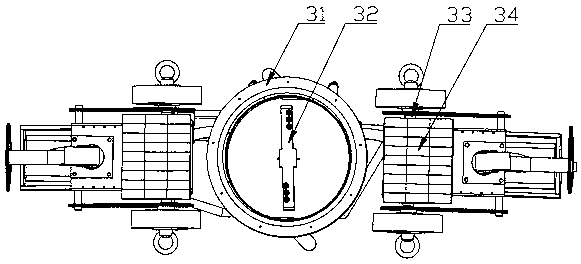

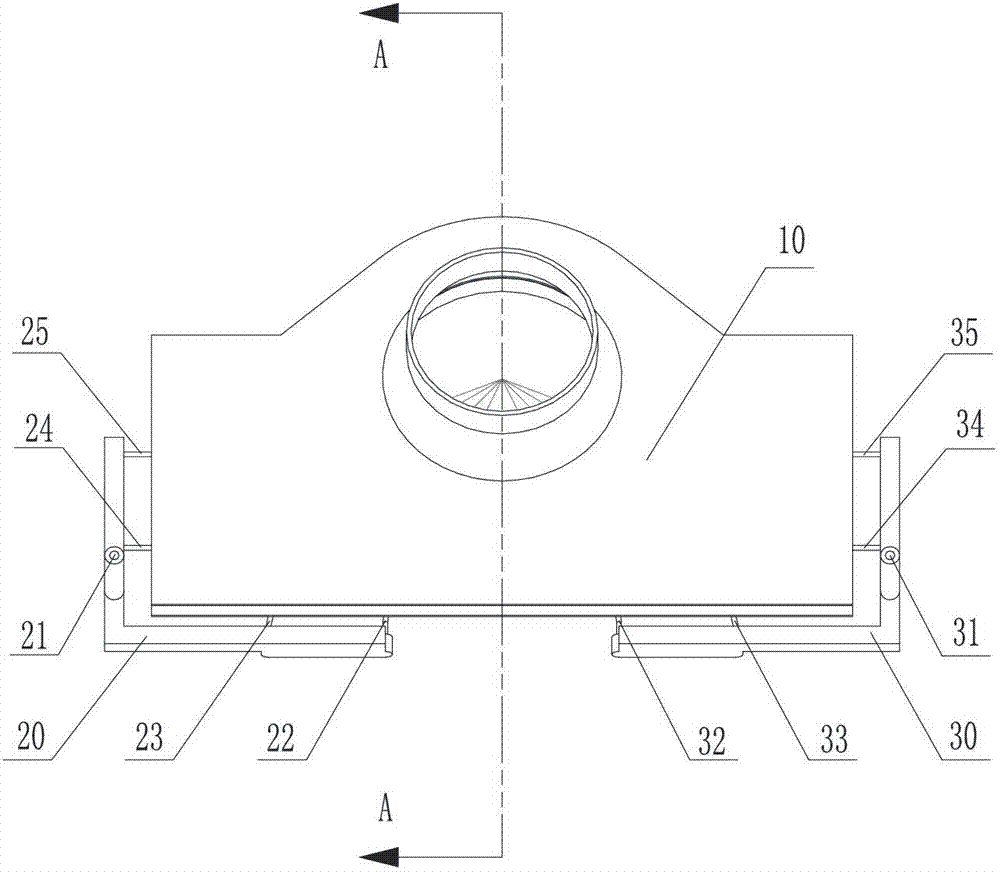

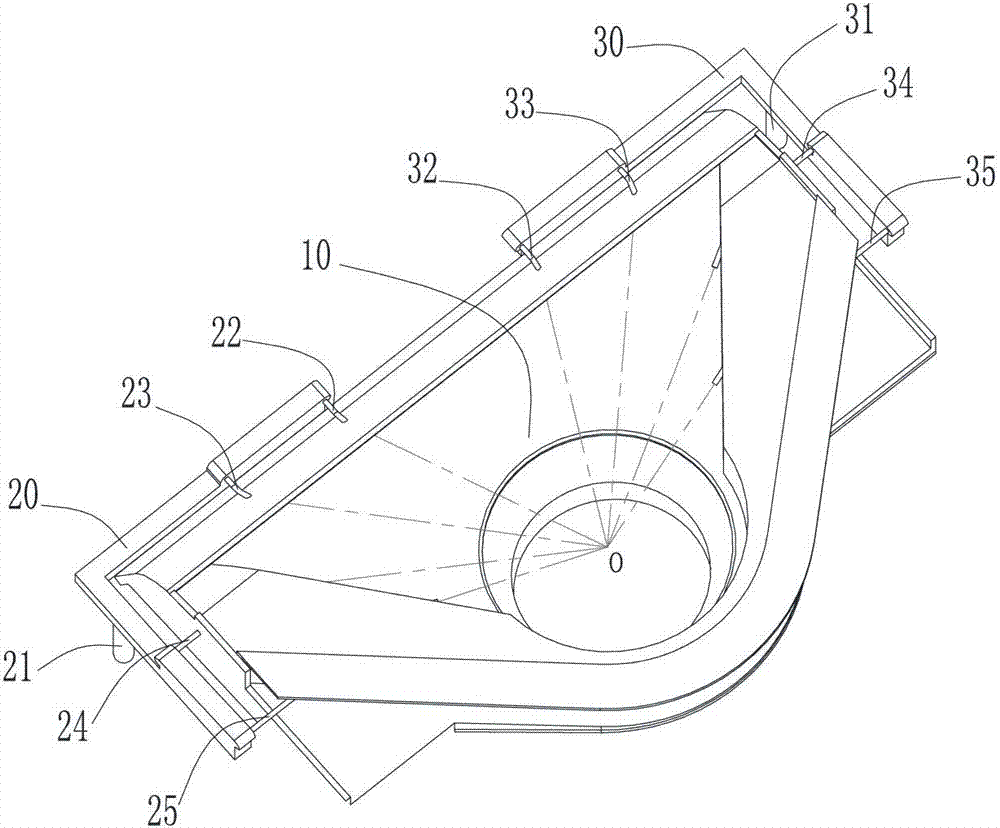

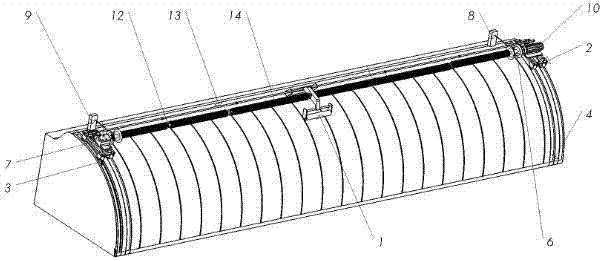

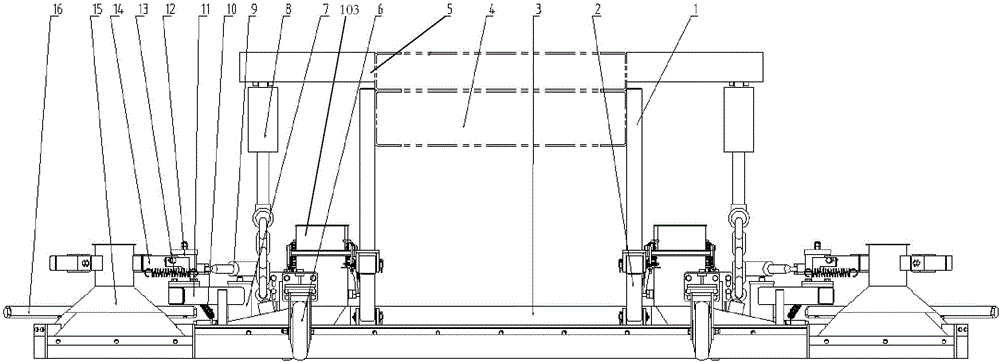

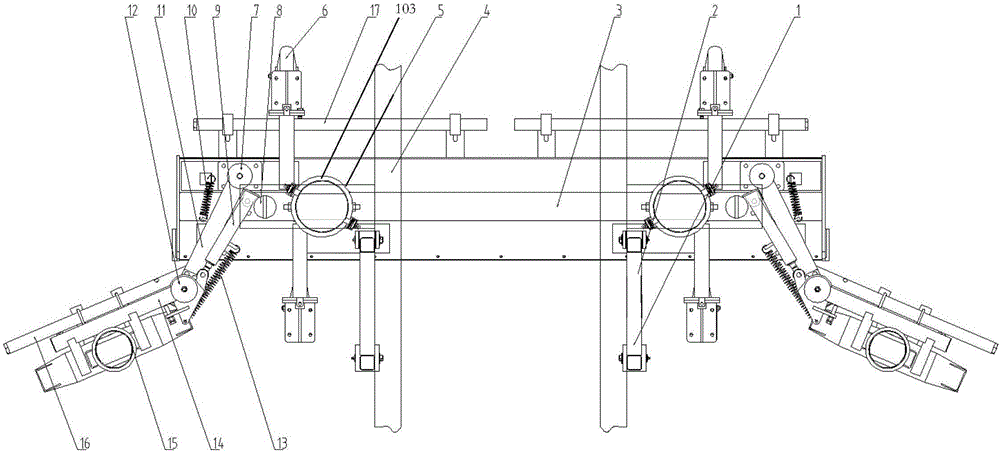

Curved surface wall-climbing robot for surface cleaning

PendingCN108500997AImprove working environmentImprove workabilityManipulatorVehiclesSurface cleaningHigh pressure water

The invention discloses a curved surface wall-climbing robot for surface cleaning. The robot comprises a front wheel driving mechanism, a rear wheel driving mechanism, a posture adjusting mechanism and a cleaning and derusting mechanism; the front wheel driving mechanism and the rear wheel driving mechanism are the same in structure; a steering motor in the posture adjusting mechanism drives a front wheel rotating claw and a rear wheel connecting claw to rotate, then a connecting rod is driven to move, so that the front wheel driving mechanism and the rear wheel driving mechanism are divertedin opposite directions; a guide air driver and an air cylinder in the cleaning and derusting mechanism are fixed to the side face of a transverse beam through a mounting frame, by controlling the posture of a cleaning disc, the cleaning disc can swing; a soft rubber gasket is fixed on the lower side of the cleaning disc, and can tightly press a working wall surface; and a rotator nozzle is fixed to the center of the upper surface of the cleaning disc, is connected with a high-pressure water pipe, and sprays high-pressure water outwards through a spraying rod. The robot can climb on a curved surface with a large curvature, the operation environment and the operation capability of the robot are expanded, and meanwhile, the cleaning requirements under different postures can be met.

Owner:ZHEJIANG UNIV

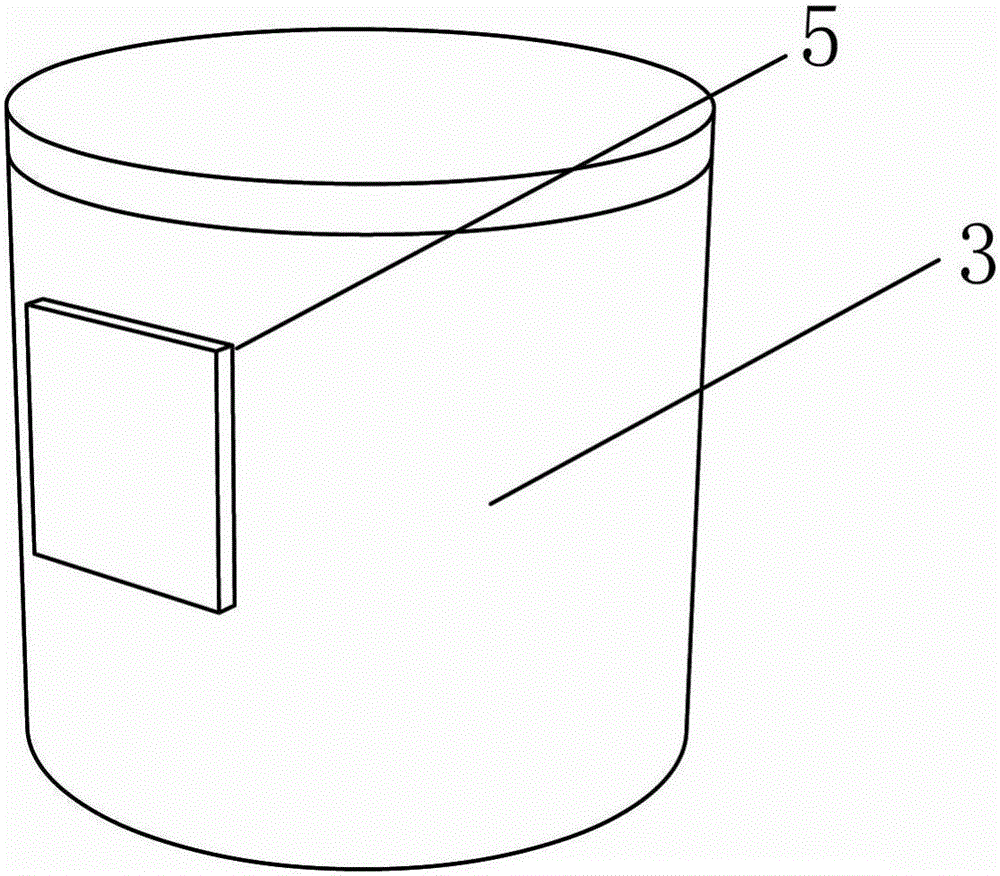

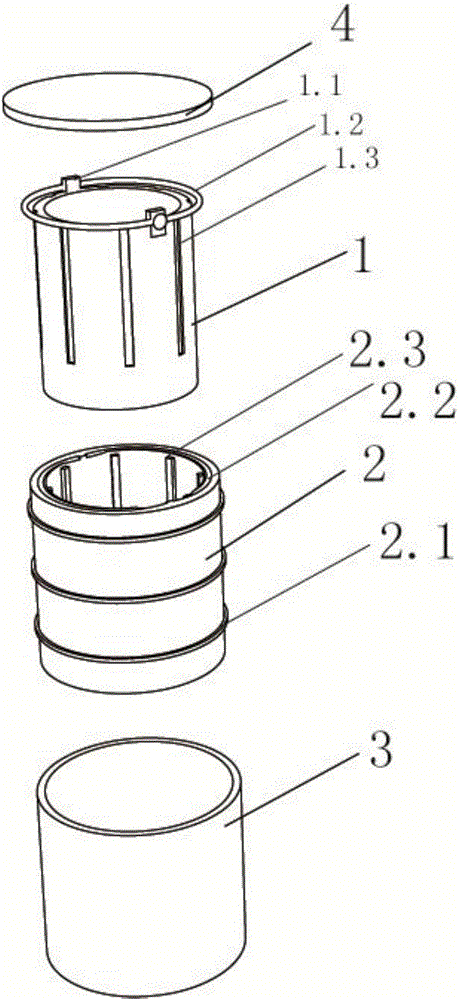

Split washing machine for the aged

InactiveCN105780388ASimple structureLow production costOther washing machinesTextiles and paperIndustrial designEngineering

The invention discloses a split washing machine for the aged. The split washing machine for the aged comprises an outer barrel and a rotary lining barrel arranged inside the outer barrel. The split washing machine is characterized in that the rotary lining barrel is matched with an inner lining barrel which can be used as a bucket, and when the inner lining barrel is nested in the rotary lining barrel, the inner lining barrel is fixedly connected with the rotary lining barrel through a fixing part, and rotates inside the outer barrel with the rotary lining barrel. The split washing machine for the aged is simple in structure, low in cost, suitable for a specific customer group, conformable with design psychology in industrial design, and capable of being widely applied to the elderly group. In addition, by means of functions of automatic drainage and automatic identification of match between the inner lining barrel and the rotary lining barrel, use safety of the washing machine is guaranteed.

Owner:HUBEI UNIV OF TECH

Cleaning agent of airplane carpets and in-cabin trimming parts

InactiveCN101638614AImprove performanceSafe and thorough cleaningInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsJet aeroplaneSodium metasilicate

The invention relates to a cleaning agent of airplane carpets and in-cabin trimming parts. The cleaning agent comprises the following components in percentage by weight: 7-13 percent of surface activeagent, 0.18-0.3 percent of inhibiter, 0.65-0.75 percent of anhydrous sodium metasilicate, 0.4-0.6 percent of water purification agent and the balance of water, wherein the surface active agent consists of dodecylbenzene sulfonic acid and nonylphenol polyoxyethylene ether. The cleaning agent of airplane carpets and cabin trimming parts can effectively clean the inner surfaces of an airplane body and various trimming part surfaces and textiles in the cabin, has the characteristic of universal use of various airplane types, has high safe dilution ratio without damaging rubber pieces and polyethylene plastic pieces of the airplane and breaking the fire resistance of the airplane carpets, and has low cost.

Owner:长沙艾森设备维护技术有限公司

Aqueous cleaning agent for liquid crystal display

InactiveCN1865420AEliminate residueImprove the finishOrganic detergent compounding agentsNon-ionic surface-active compoundsIonChemistry

The invention discloses a LCD water-based abluent of amine alkali and non-ion surface activator, which comprises the following parts: 20-70 percent amine alkali, 5-40 percent JFC, 5-20 percent non-ion surface activator and deionized water. The invention is beneficial to remove the surface residues, which improves the surface finishment of product.

Owner:HEBEI UNIV OF TECH

Cable ladder device for building rescue

This invention is tower rescue cable ladder device, it is fixed at floor and window of tower, and it can be remote controlled on ambulance. It includes cable rolling device, damping airbag and dragging cable capstan. The device is three way to supply power, automatic switch inside and outside of tower control system. It can be parted as floor rescue ladder, floor tank ladder, floor widow type ladder and other types. Firefighters can be quickly lifted up and safely evacuate persons in tower. It also can be used to cleaning of tower wall, quickly downhill exercise and lift big object.

Owner:周路定

Quartz tube cleaning device and cleaning method

ActiveCN113500070AEfficient cleaning operationsSimple structureHollow article cleaningDrying gas arrangementsPhysical chemistryEngineering

The invention provides a quartz tube cleaning device and cleaning method. The quartz tube cleaning device comprises a cleaning cover with an opening in the bottom, a base movably assembled with the cleaning cover in an inserted mode in the vertical direction, a bearing table arranged in the base and hooping a quartz tube, and a driving device. A first nozzle is arranged at the top of the cleaning cover, a plurality of second nozzles are vertically arranged on the side wall of the cleaning cover, an inner spray pipe is vertically arranged on the bearing table, and a plurality of third nozzles are arranged at the top and the side of the inner spray pipe above the bearing table; a rotary sealing device is embedded in the base, and the inner spray pipe continuously penetrates through the bearing table and the rotary sealing device in the vertical direction; the driving device drives the bearing table to rotate, and the inner spraying pipe is kept static in the rotating process of the bearing table. By means of the quartz tube cleaning device, efficient cleaning operation on the quartz tubes of various sizes is achieved, the requirement for cleaning the quartz tubes of different diameters can be met, the structure of the quartz tube cleaning device is simplified, the service life is prolonged, and the quartz tubes are prevented from being damaged in the cleaning process.

Owner:ZHICHENG SEMICON EQUIP TECH (KUNSHAN) CO LTD

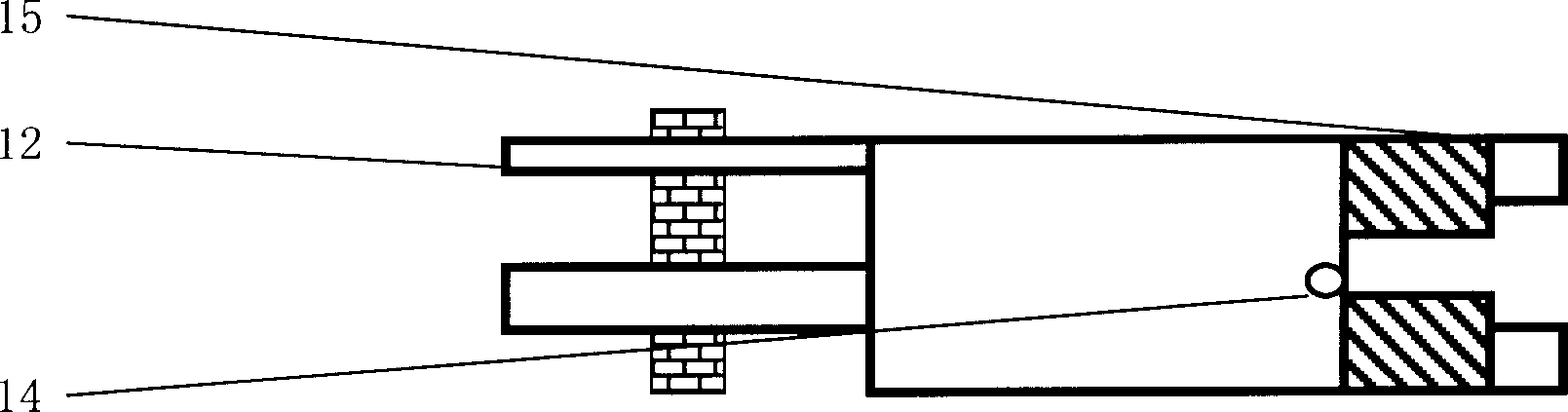

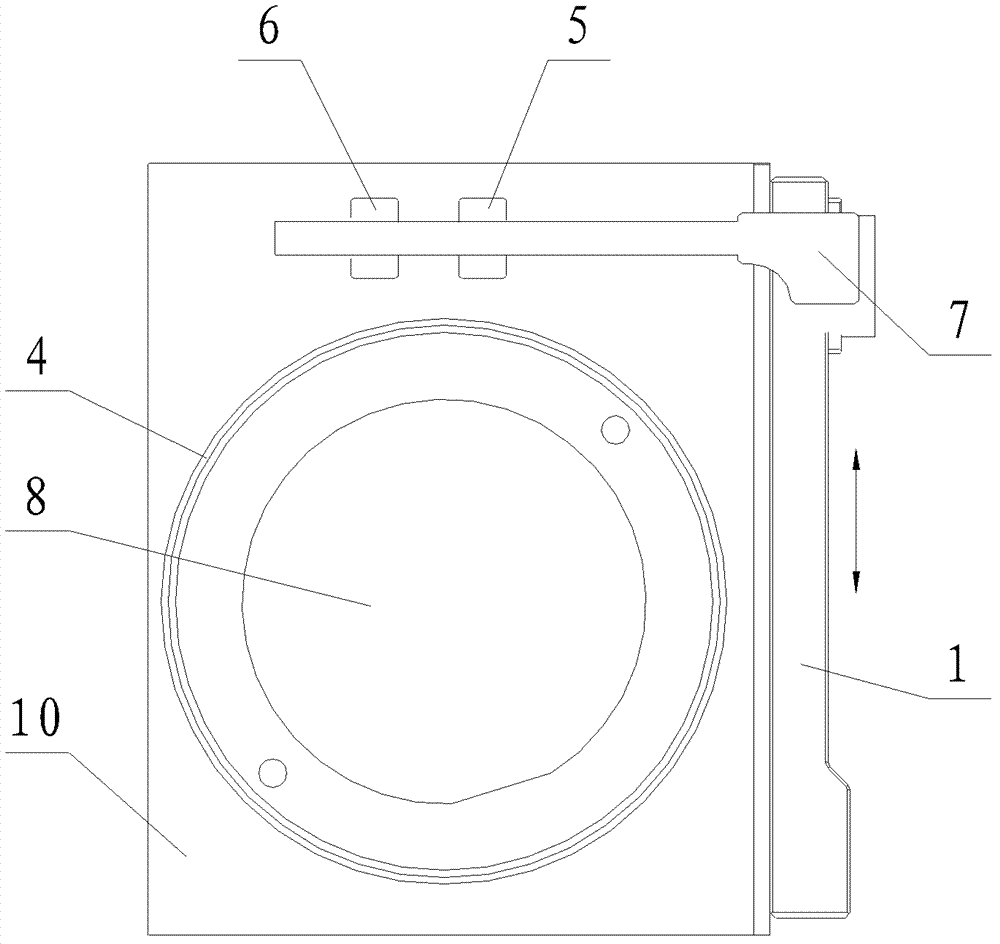

Quartz glass cleaning device

InactiveCN108655144ARealize automatic adjustmentMeet cleaning needsFlexible article cleaningCleaning using toolsBristleDrive shaft

The invention discloses a quartz glass cleaning device. The device comprises a machine frame, wherein a water retaining box is installed at the upper end of the machine frame, and a limiting mechanismis installed on the inner wall of the machine frame; a cleaning motor is installed on the back side of the machine frame, a driving shaft and a driven shaft are installed in the middle of the machineframe, and the driving shaft is fixedly connected to the cleaning motor; a driving gear is installed at the end of the driving shaft, a driven gear is installed at the end of the driven shaft, and the driving gear is meshed with the driven gear; and the outer side of the driving shaft and the outer side of the driven shaft are provided with cleaning brushes respectively. The quartz glass cleaningdevice has the beneficial effects that the quartz glass cleaning device can be fixed and limited through the limiting mechanism in the conveying and cleaning process, the inclination of the quartz glass is prevented, so that collision damage is caused; and the elasticity of an adjusting spring can be utilized, soft bristles can be lifted along with a lifting column, the cleaning distance can be automatically adjusted, so that the soft bristles are always in contact with the quartz glass, and the cleaning requirements of the quartz glass with different thicknesses can be met.

Owner:LIANYUNGANG QIQING OPTO ELECTRONICS LIGHTING

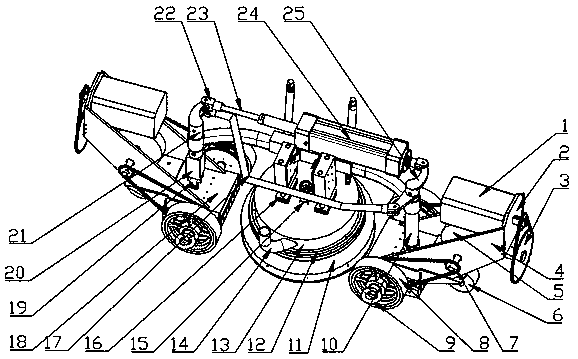

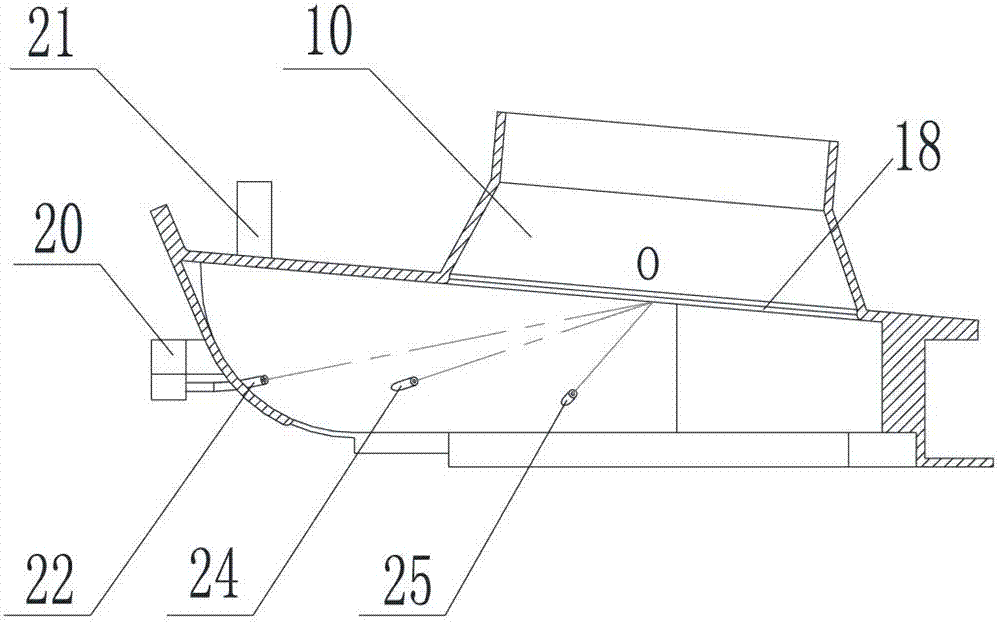

Suction nozzle and pulse gas path control system and sweeping car comprising same

ActiveCN103031818AImprove negative pressure suction abilityMeet cleaning needsRoad cleaningControl systemNozzle

The invention relates to a suction nozzle, a pulse gas path control system comprising the same and a sweeping car comprising the same. The suction nozzle comprises a suction nozzle body, wherein the suction nozzle also comprises a pulse jet device which is arranged on the suction nozzle body, and the pulse jet device is used for jetting a pulse gas flow along the suction-in direction of the suction nozzle body. The pulse gas path control system comprises the suction nozzle, an induction unit used for monitoring the distribution of waste on the surface of a working road, and a control platform used for controlling the on / off of the pulse jet device of the suction nozzle according to the monitoring information fed from the induction unit. According to the technical scheme of the invention, the pulse jet device can jet a pulse gas flow along the suction-in direction of the suction nozzle body, so that a local high negative pressure region is formed at the periphery of the pulse gas flow to effectively improve the negative pressure suction capacity of the suction nozzle within a short time period, so as to meet the cleaning need for severe working conditions and ensure the cleanness rate of the road surface.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Glass plate automatic cleaning device in mechanical field

ActiveCN106734015AMeet cleaning needsImprove cleaning efficiencyFlexible article cleaningCleaning using toolsBristleElectric machinery

A glass plate automatic cleaning device in the mechanical field comprises a bottom plate, a supporting device, a support device, a brushing washing device, a motor device, a water storage device, an extruding device and a water distributing device; universal wheels, a recycling box and a first positioning block are arranged on the bottom plate; the supporting device comprises a first filter screen, a second positioning block, a first vertical plate, a first cross rod, a first fixing rod and a first supporting rod; the support device comprises a second supporting rod, a second fixing rod, a first spring, a second cross rod and a third fixing rod; the brushing washing device comprises a rotating rod, a second spring, a fourth fixing rod, a telescopic rod, a brushing washing wheel, bristles and a connecting ring; the motor device comprises a first support, a first rolling wheel, a motor, an output shaft and a stay wire; the water storage device comprises a water storage frame, a second support, a first connecting rod and an inclined plate; the extruding device comprises a third support, an electric cylinder, a pushing rod, a pushing plate and a sponge block; and the water distributing device comprises a water distributing frame. The glass plate automatic cleaning device in the mechanical field can clean two side faces of a glass plate at the same time, and is high in cleaning efficiency.

Owner:滁州尚诺自动化设备有限公司

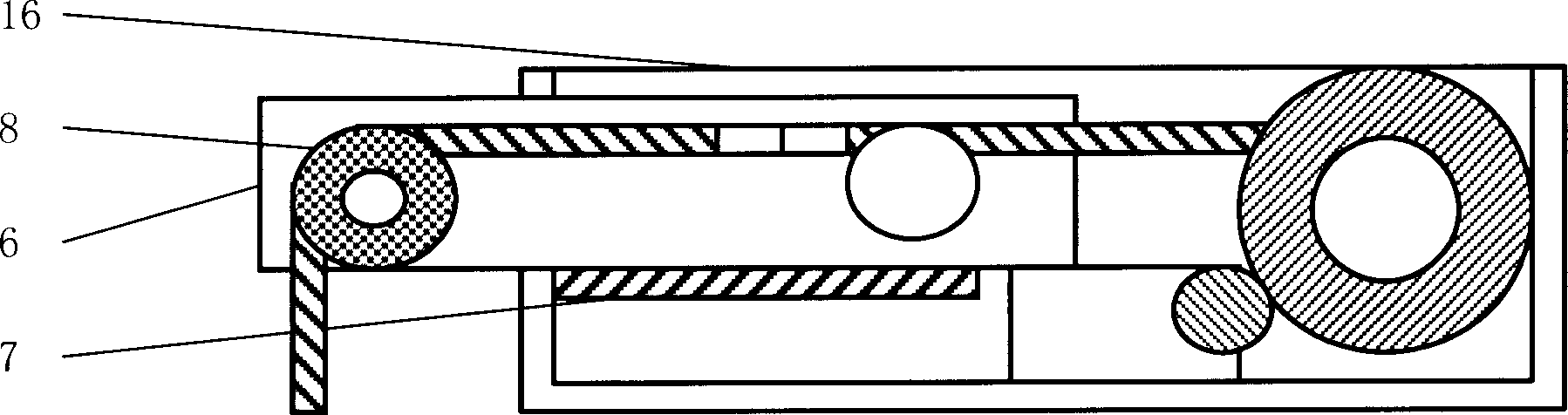

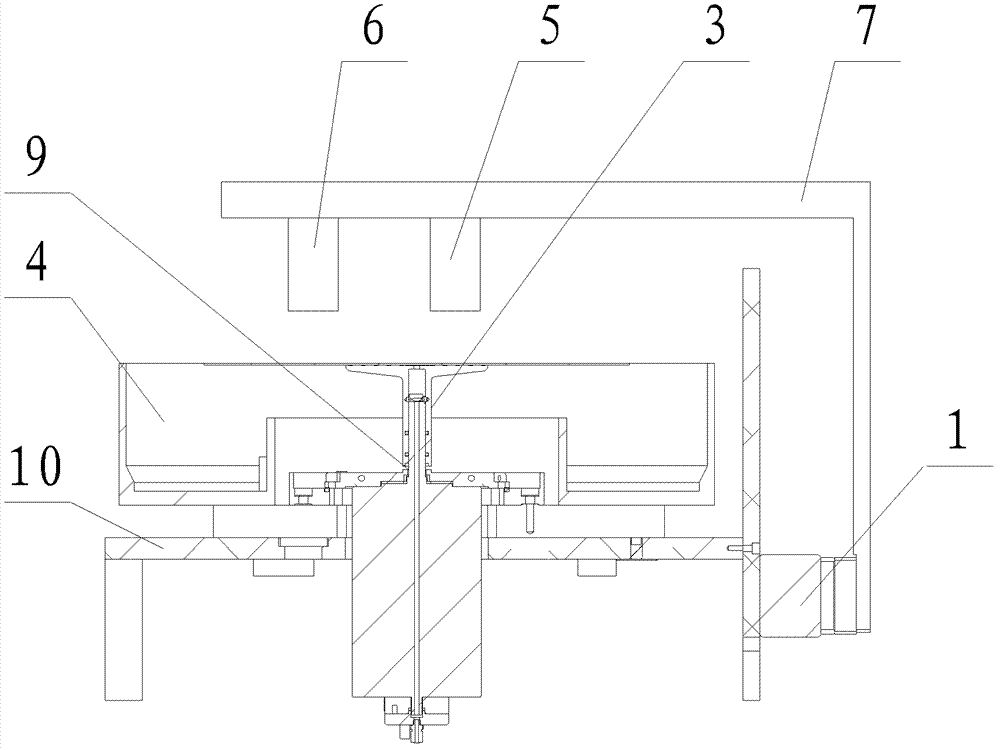

Cleaning machine with twin-jet nozzle

ActiveCN103094148AMeet cleaning needsTo achieve the purpose of cleaningSpraying apparatusSemiconductor/solid-state device manufacturingReciprocating motionSemiconductor chip

The invention relates to the equipment which is used for cleaning the chip in the workpiece process of semiconductor chips, in particular to a cleaning machine with a twin-jet nozzle used for optimizing the washing of the surface of the chip. The cleaning machine comprises a nozzle electric cylinder, a spindle motor, a supporting stage, a shell body, a nozzle arm, a spindle and a workbench. The spindle motor is installed on the workbench and one end of the spindle is connected with an output end of the spindle motor and the other end of the spindle motor is installed inside the shell body of the workbench. The other end of the spindle is connected with the supporting stage used for fixing and rotating the chip. The nozzle electric cylinder is installed on one side of the workbench and one end of the nozzle arm is connected with the nozzle electric cylinder and is in reciprocating motion through the drive of the nozzle electric cylinder. The other end of the nozzle arm is located above the chip and the other end of the nozzle arm is provided with the twin-jet nozzle corresponding to the chip. The cleaning machine with the twin-jet nozzle can meet the cleaning demand to the hilt through the control of the position of the nozzle and the characteristic of the rotation of the chip in the cleaning process and achieve the cleaning goal that all particles on the surface of the chip are cleared away.

Owner:SHENYANG KINGSEMI CO LTD

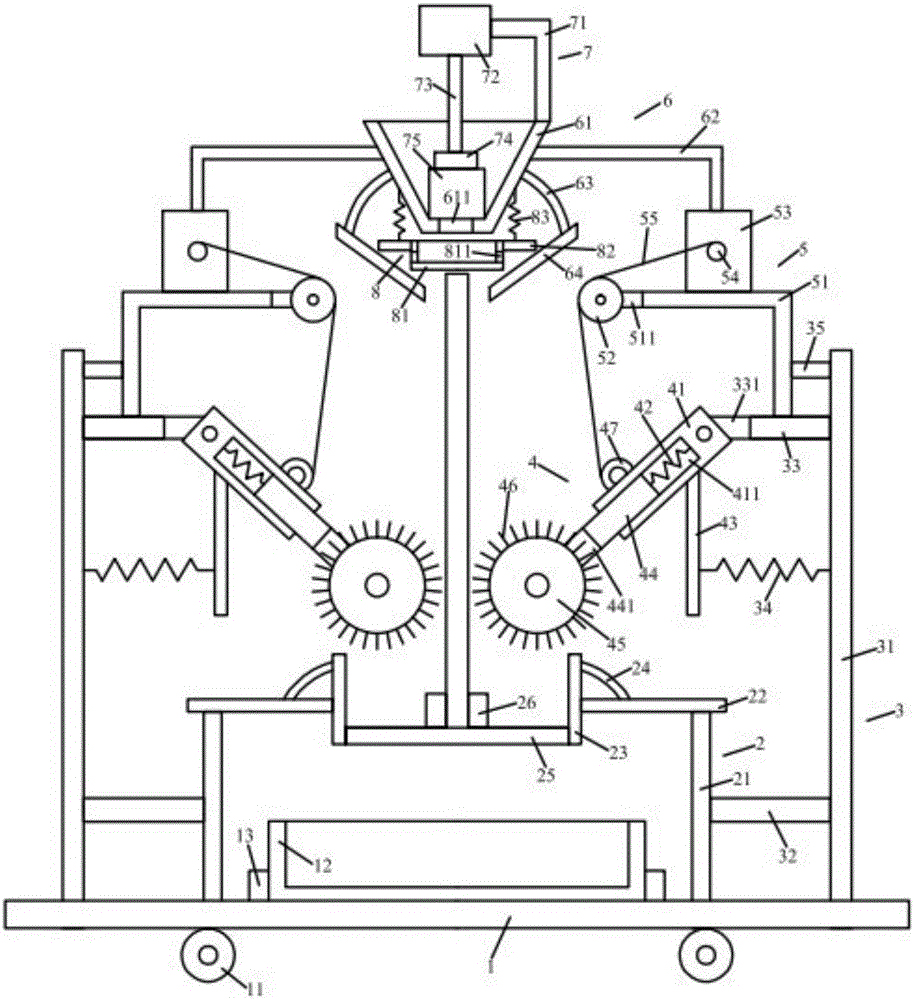

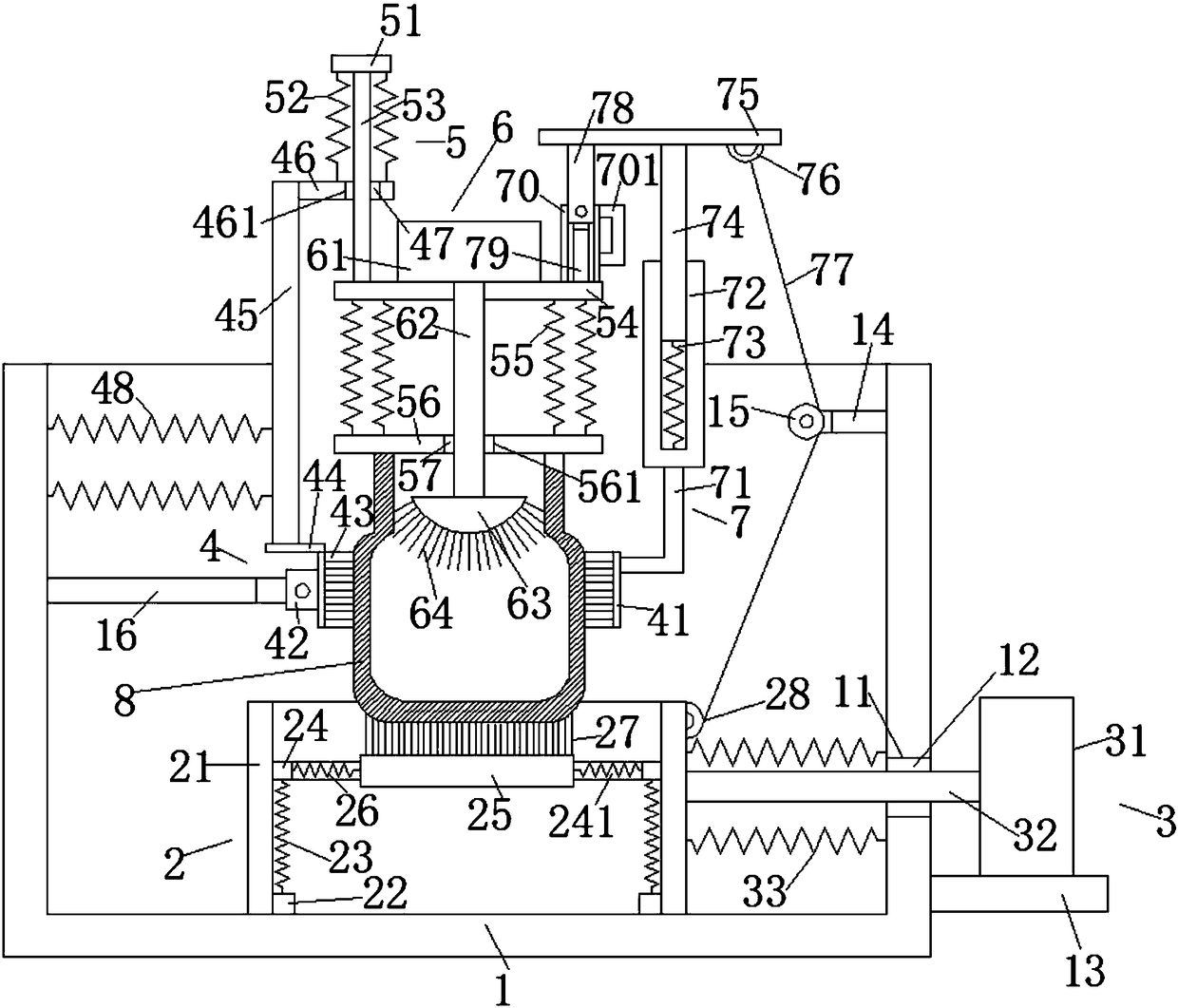

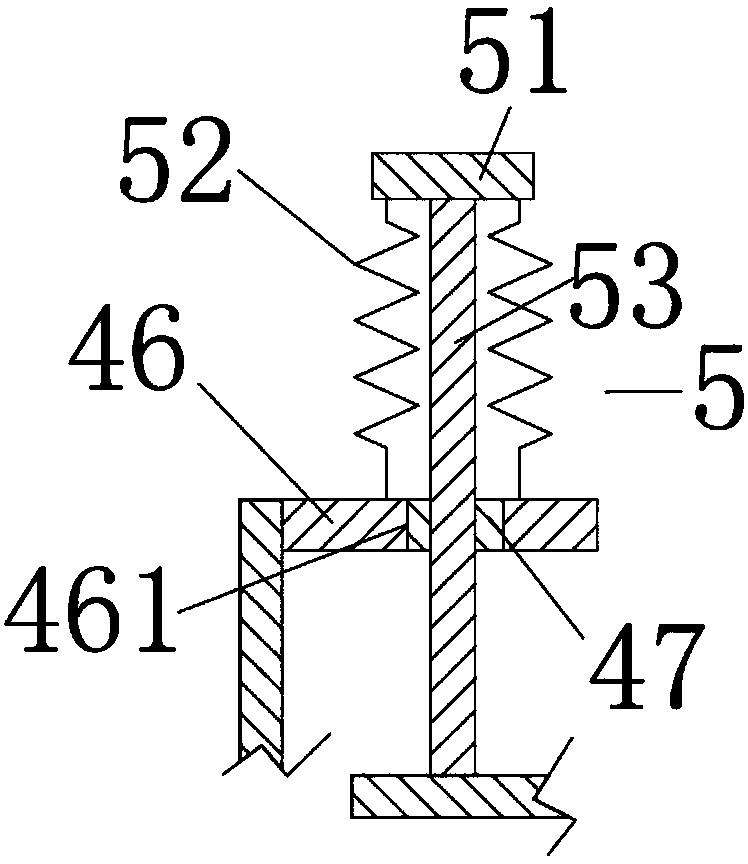

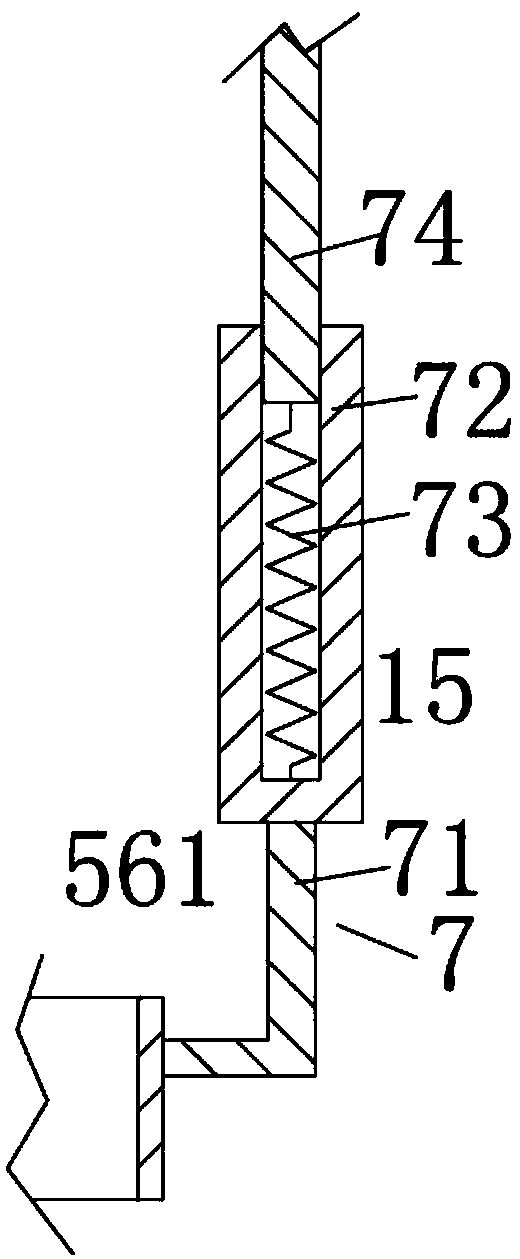

Feeding bottle cleaning equipment for gynaecology and obstetrics

InactiveCN108262322AMeet the needs of cleaningWashed away in timeHollow article cleaningBristleBiochemical engineering

The invention relates to feeding bottle cleaning equipment for gynaecology and obstetrics. The feeding bottle cleaning equipment comprises a frame body, a filtering frame device, a pushing device, a positioning device, a support device, a motor device and a pressing device, wherein the filtering frame device is arranged in the frame body, and the pushing device is arranged on the frame body; the positioning device is positioned above the pushing device, and the support device is arranged on the positioning device; the motor device is arranged on the support device; and the pressing device is arranged on the motor device. The feeding bottle cleaning equipment can clean the inner surface and the outer surface of a feeding bottle at the same time, the cleaning efficiency is high, and the cleaning effect is significant. Even if the inner surface and the outer surface of the feeding bottle have dirt that is harder to clean, the feeding bottle cleaning equipment can clear the dirt. The feeding bottle cleaning equipment has the advantages of low labor intensity, simple operation and convenience in use, can realize that the feeding bottle inclines and constantly sway from side to side, realizes full contact of the feeding bottle with water, is beneficial to washing away the dirt brushed away by first bristle, second bristle and third bristle in time, and can effectively meet the demandof cleaning the feeding bottle.

Owner:QINGDAO WOMEN & CHILDREN HOSPITAL

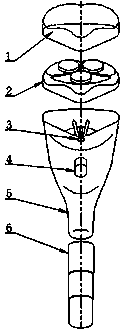

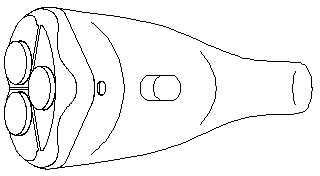

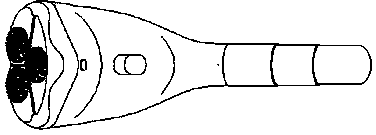

Human body cleaning device

InactiveCN104367248AMeet cleaning needsMeet various tactile requirementsBathroom accessoriesEngineeringControl switch

The invention relates to a human body cleaning device and belongs to the field of daily supplies. The human body cleaning device comprises a machine body, a protective cover, a head assembly releasing button and a control switch of a washable floating type three-head electric razor, and a brush head assembly, wherein the structure of the brush head assembly is the same as that of the head assembly of the floating type three-head electric razor and is connected with the machine body in a buckling mode, when the brush head assembly and the machine body are combined, the lower end of a brush head root fixing part of the brush head assembly is in butt joint with a universal head mechanism of the machine body in an embedded mode, the brush head assembly can be mounted and dismounted through the head assembly releasing button, and an adjustment rod is arranged at the bottom of the machine body and connected with the tail of the machine body spirally. Based on people-friendly functions like skin-attaching adjustment and correction and portable dismounting and mounting principle of the floating type three-head electric razor, the cleaning capacity and comfort degree can meet the needs of vast man and woman application crowds, various adaptive brush head assemblies are suitable for various skin qualities and various touch sense needs, and the human body cleaning device can be used for face washing, bathing and the like.

Owner:XIAOGAN QISIMIAOXIANG CULTURAL MEDIA

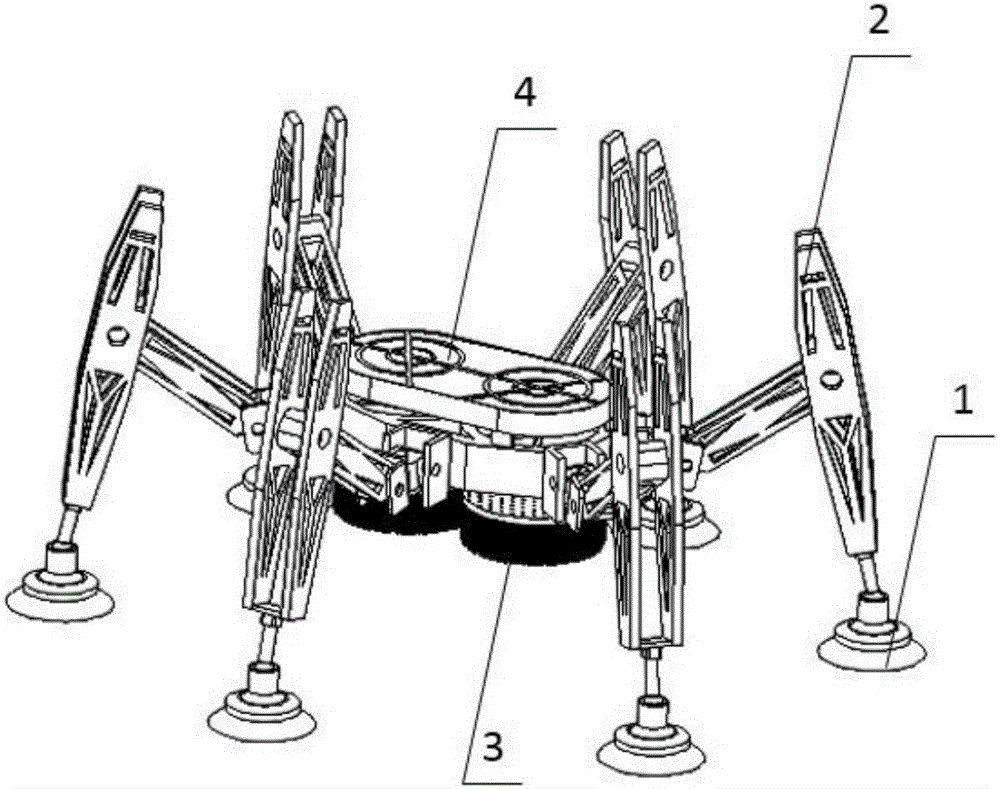

High-altitude glass curtain cleaning robot

InactiveCN106108761AMeet cleaning needsSimple structureCarpet cleanersFloor cleanersEngineeringElectrical and Electronics engineering

The invention discloses a high-altitude glass curtain cleaning robot. The high-altitude glass curtain cleaning robot is characterized by comprising foot fixing mechanisms, leg bionic mechanisms, a body connecting mechanism, and a dust cleaning and collecting mechanism; each foot fixing mechanism is movably connected with the lower end of the corresponding leg bionic mechanism; the leg bionic mechanisms are distributed on the periphery of the body connecting mechanism to simulate the leg forms of an ant to walk and are movably connected with the body connecting mechanism; the dust cleaning and collecting mechanism is arranged in the body connecting mechanism. The high-altitude glass curtain cleaning robot has the beneficial effects that the high-altitude glass curtain cleaning robot is simple in structure, safe and reliable, and can meet the current requirement on glass curtain cleaning; the manpower cost is greatly reduced; automatic cleaning operation is realized; the work efficiency is improved.

Owner:WUHAN UNIV OF TECH

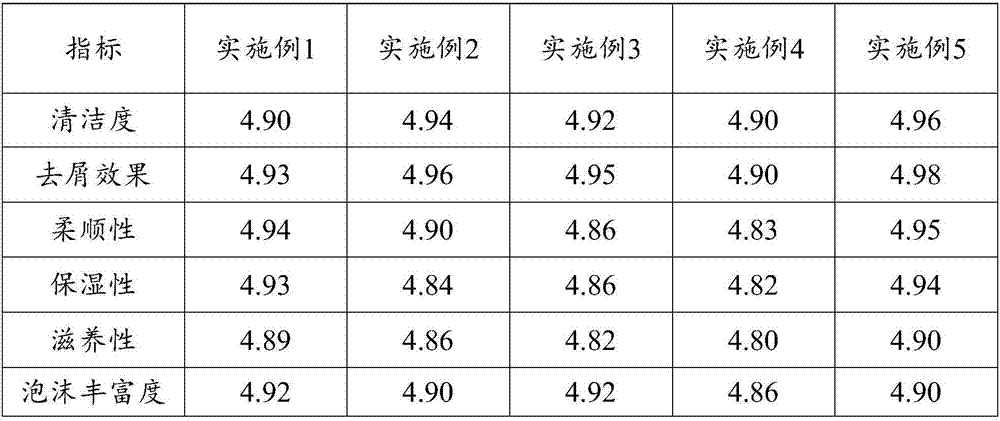

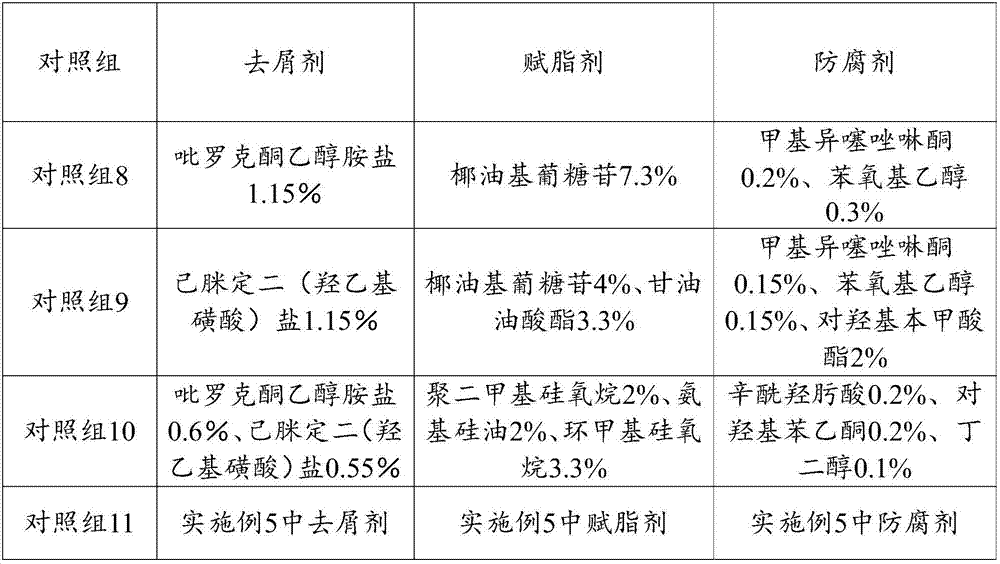

Ginseng oil-control anti-dandruff and silicone oil-free shampoo and preparation method thereof

InactiveCN107375066APromote circulationMeet the needs of cleaningCosmetic preparationsHair cosmeticsPiroctone olaminePhytosterol

The invention discloses a ginseng oil-control anti-dandruff and silicone oil-free shampoo, which comprises at least one of an anti-dandruff agent, a fatting agent and a preservative. The anti-dandruff agent consists of piroctone olamine, hexamidine diisethionate and a plant anti-dandruff agent; the fatting agent comprises phytosterol macadamiate, C12-13 alcohol lactate, coco-glucoside, olive oil PEG-6 polyglycerol-6 ester, dipentaerythityl tetraisostearate, glyceryl oleate and tri-C12-13 alkyl citrate; the preservative includes caprylhydroxamic acid, p-hydroxy acetophenone, glycerol octanoate and butylene glycol. At the same time, the invention discloses a preparation method of the ginseng oil-control anti-dandruff and silicone oil-free shampoo. The shampoo provided by the invention can reach the effects of deep oil control dandruff removal, meet the cleaning needs of people, effectively promote blood circulation and provide scalp nutrients, also can repair broken hair, split hair and improve hair quality, makes hair black, shiny and smooth, and also is mild and non-irritating, safe and healthy.

Owner:曾万祥

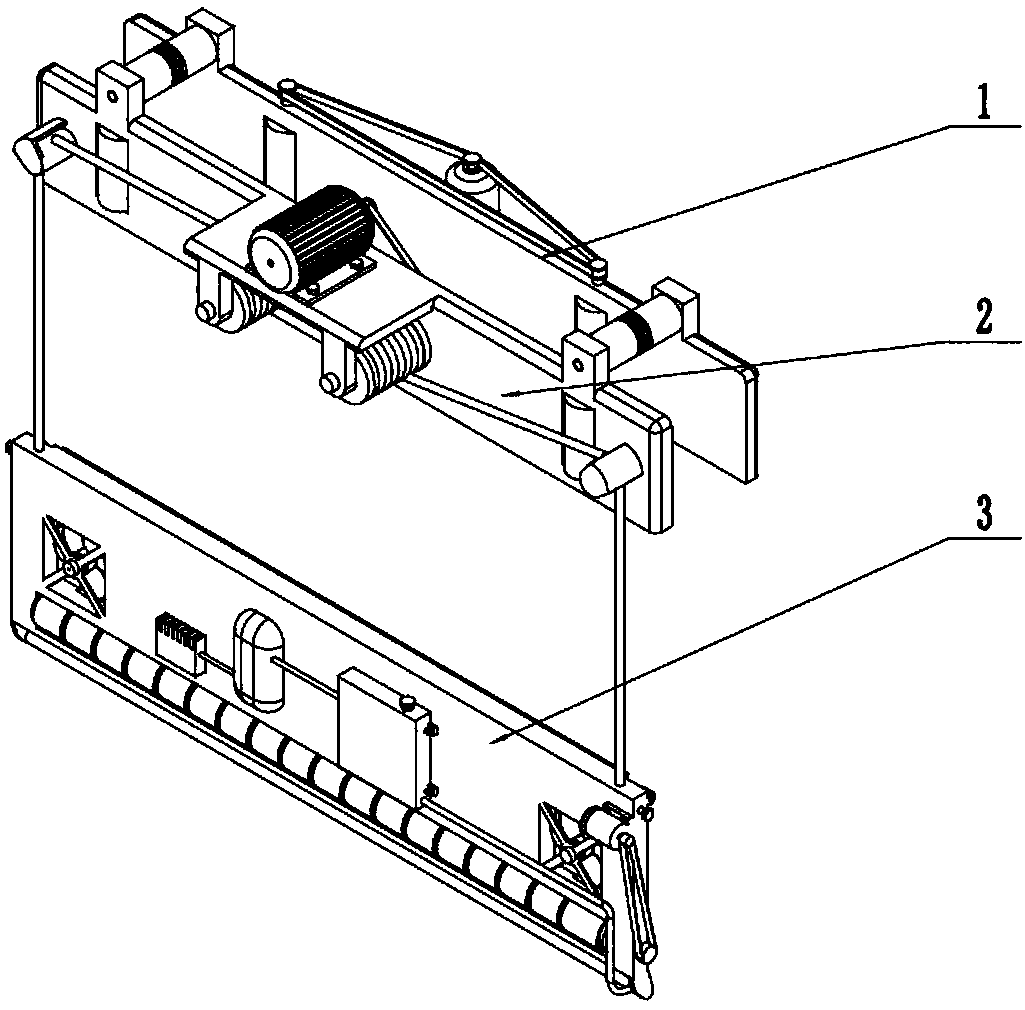

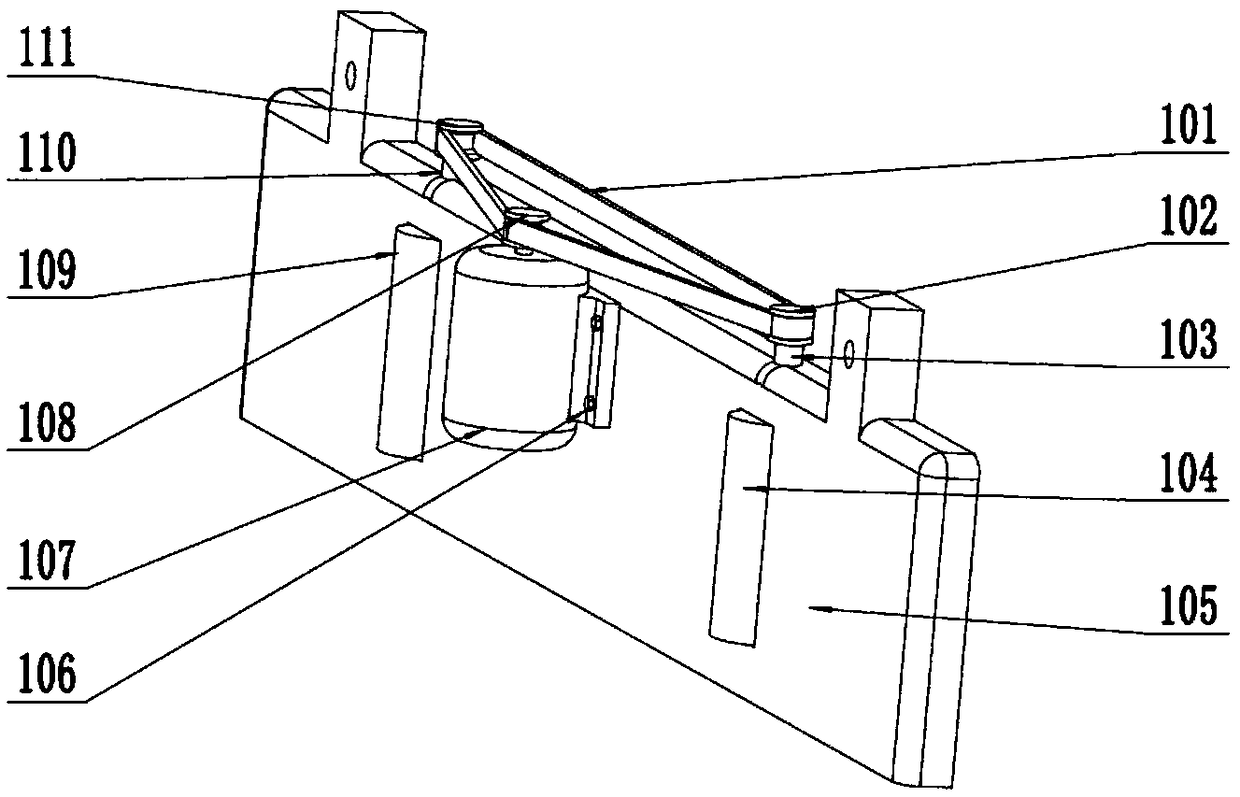

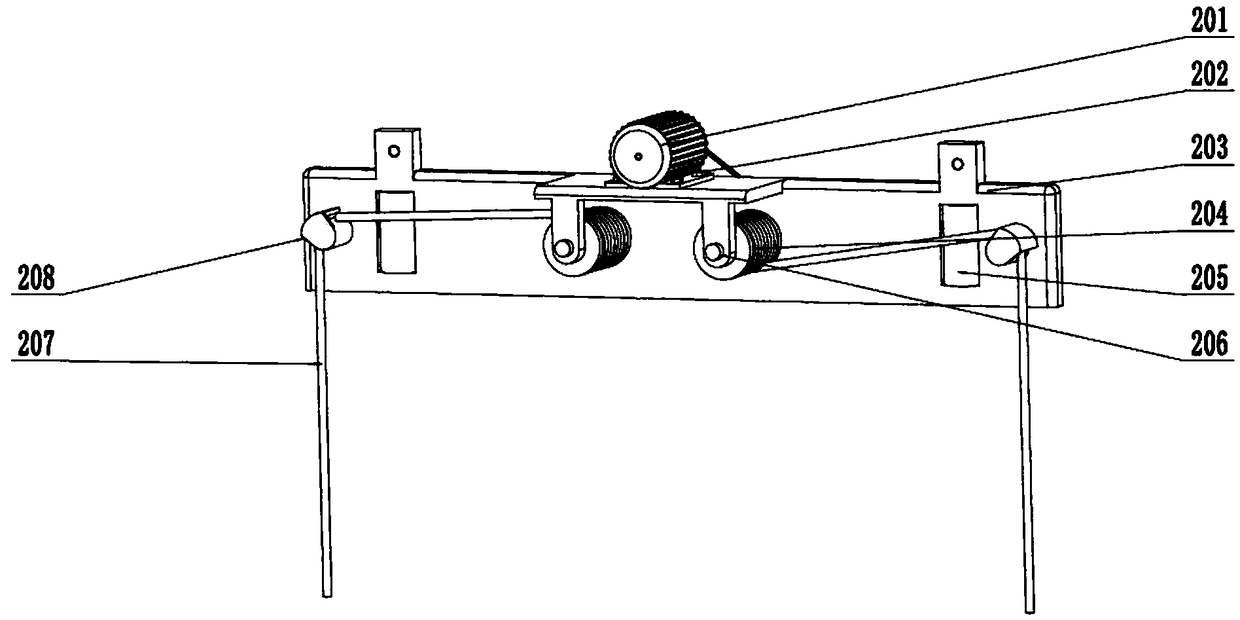

Cleaning device for outdoor wall

ActiveCN108338734AReduce laborExpand the scope of cleaningDrying solid materials without heatBuilding repairsEngineeringEnergy conservation

Provided is a cleaning device for an outdoor wall. The device is composed of a transverse move assembly, a lifting assembly and a cleaning assembly, wherein the transverse move assembly is arranged atone side of the lifting assembly, a transverse move body frame of the transverse move assembly is provided with two through holes, two supporting wheel fixed shafts of the lifting assembly penetratethrough the through holes of the transverse move body frame to be fixed, a transverse move motor is arranged at the outer side of the transverse move assembly, the lifting assembly is inserted into two countersinks of the cleaning assembly through metal cables, and cable fixing nuts fix the metal cables. The cleaning device for the outdoor wall can automatically clean the outdoor wall, the amountof labor of cleaners is reduced, after the wall is cleaned by a roller brush, a sponge block can be used for the secondary wiping and water absorption treatment on the wall, the cleaning range is larger, the cleaning can be performed with a width of two meters by each lifting operation, after vertical cleaning is completed, transverse translation can be directly performed, the efficiency is high,and the energy sources are saved.

Owner:林红英

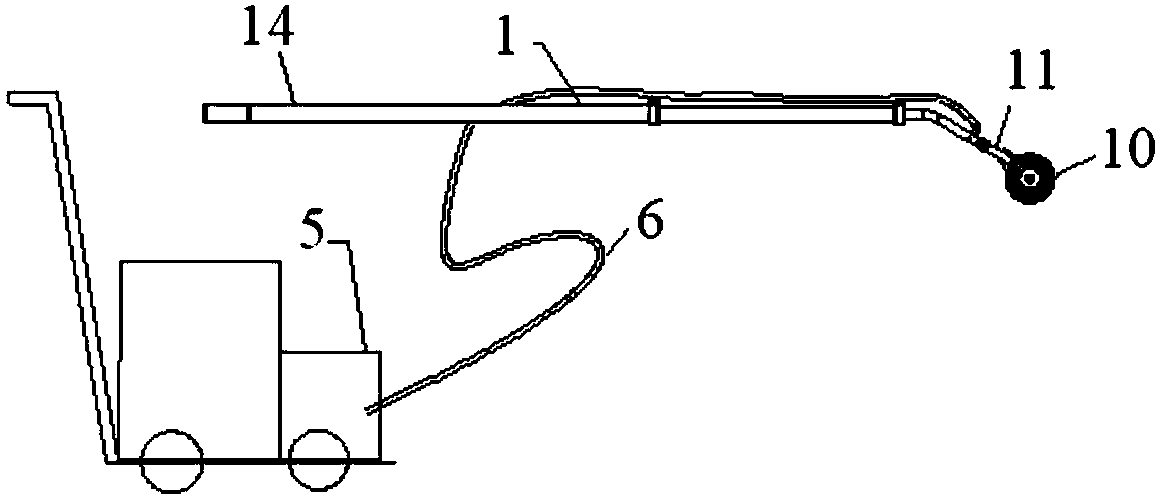

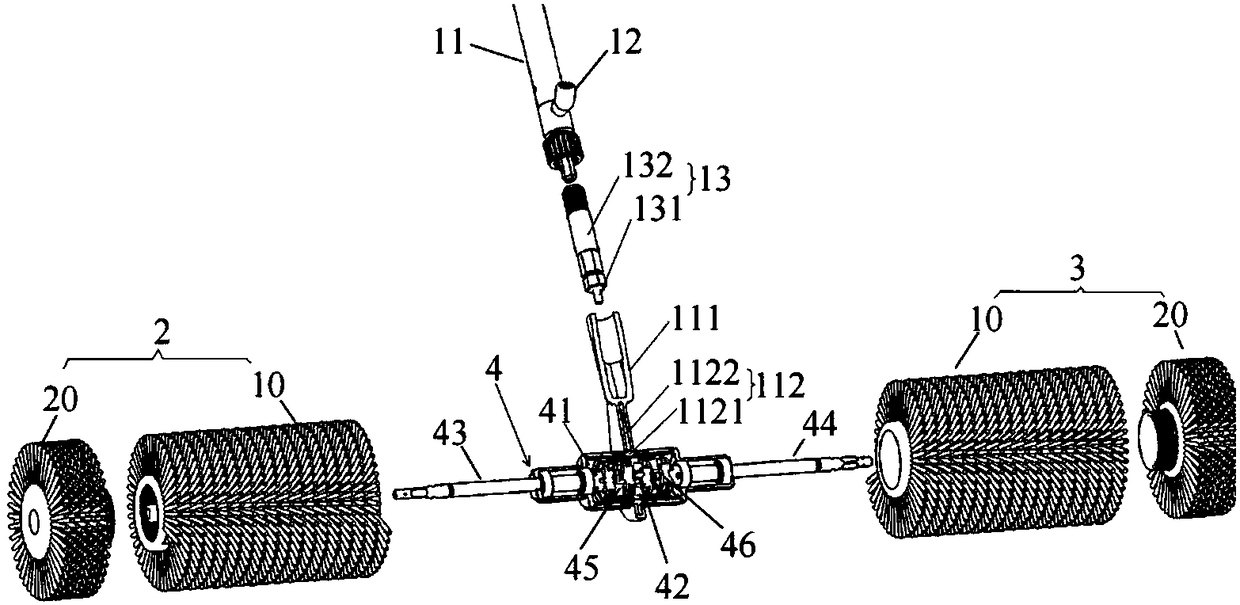

High-efficient cleaning machine for sunlight greenhouse film

PendingCN106914436ASimple and safe operationReduce manufacturing costClimate change adaptationCleaning using toolsMotor driveEngineering

The invention relates to a high-efficient cleaning machine for sunlight greenhouse film. The machine comprises a cleaning shaft, wherein the cleaning shaft is arranged along the length direction of a greenhouse; a hairbrush is fixed on the surface of the cleaning shaft; one end of the cleaning shaft is connected with a forward-reversing motor which is connected with a side wall of the greenhouse through a base in a sliding manner; the other end of the cleaning shaft is rotatably connected with a bracket which is connected with the other side wall of the greenhouse in the sliding manner; at least two rope rolling wheels further fixedly sleeve the cleaning shaft; each rope rolling wheel is wound with a rope of which one end is fixedly connected with a traction bracket fixed on the rear wall of the greenhouse. The high-efficient cleaning machine provided by the invention has the advantages that the forward-reversing motor drives the cleaning shaft to clean dust on the surface of the film of the greenhouse, so that the operation is simple and safe, and the cleaning efficiency is improved; when the cleaning shaft rotates, the rope rolling wheels rotate with the rotation of the cleaning shaft, and the extending length of each rope varies with the rotation of the corresponding rope rolling wheel, so that the position of the cleaning shaft is changed, and the film of the greenhouse can be comprehensively cleaned from top to bottom.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Special suction port for washing and sweeping vehicle

ActiveCN106120614ASatisfy the scope of cleaningMeet cleaning needsRoad cleaningTraction frameEngineering

The invention provides a special suction port for a washing and sweeping vehicle. Each traction frame comprises a crossbeam and a supporting truss. The top of each supporting truss is fixed to the washing and sweeping vehicle, the bottom of each supporting truss is hinged to one end of a rod-shaped traction arm, the other end of each traction arm is used for fixing a suction port body, a water spray pipe is fixed through the corresponding crossbeam, main suction ports are fixed to the positions, in front of each water spray pipe, on the two sides of the suction port body, walking trundles are fixed in front of and behind the suction port body, first avoidance rotary shafts are symmetrically and vertically arranged on the left side and the right side of the suction port body, supporting arms are fixed along the first avoidance rotary shafts, second avoidance rotary shafts are vertically arranged at the other ends of the supporting arms, one ends of square pipe swing arms are fixed in the radial direction of the second avoidance rotary shafts, side water suction ports are formed in the swing arms downwards, and the axial direction of side push oil cylinders is parallel to the second avoidance rotary shafts. Through side suction devices, the problems that the ground on the outer side of a vehicle body is not provided with the water suction ports, redundant water left after sanitation work is too much and is accumulated on the ground, and washing adsorption is not thorough are solved.

Owner:BEIJING ENVIRONMENT SANITATION ENG GRP CO LTD +2

Process of carrying out low-temperature chemical cleaning passivation on thermal power plant boiler by utilizing EDTA (Ethylene Diamine Tetraacetic Acid)

InactiveCN102425778AIncrease pHAdjust pH valueBoiler cleaning apparatusMetallic material coating processesEthylene diamineEngineering

The invention relates to a low-temperature chemical cleaning method for a thermal power plant boiler and in particular relate to a process of carrying out low-temperature chemical cleaning passivation by utilizing EDTA (Ethylene Diamine Tetraacetic Acid). The process comprises the following steps: A. connecting a chemical cleaning platform with a system which needs to be cleaned to form a cleaning system, and flushing with circulating water after the connected cleaning system is subjected to a hydraulic test until effluent is transparent and is free from impurities; B. heating the cleaning system cyclically; C. carrying out alkali wash, and flushing; washing by use of EDTA; and passivating. The process has the following characteristics: energy is saved, the consumption is reduced, the cleaning period is shortened, the cleaning cost is reduced, and the boiler can be cleaned and passivated in one step. After the thermal power plant boiler is cleaned by the EDTA at low temperature, a passivation process is added. An alkali substance is added into EDTA cleanout fluid to regulate the pH value of the EDTA cleanout fluid so as to passivate the cleaned boiler. The cleaning process disclosed by the invention is suitable for boilers of various specifications and is beneficial to implementation and popularization on site.

Owner:NINGXIA ELECTRIC POWER RES INST

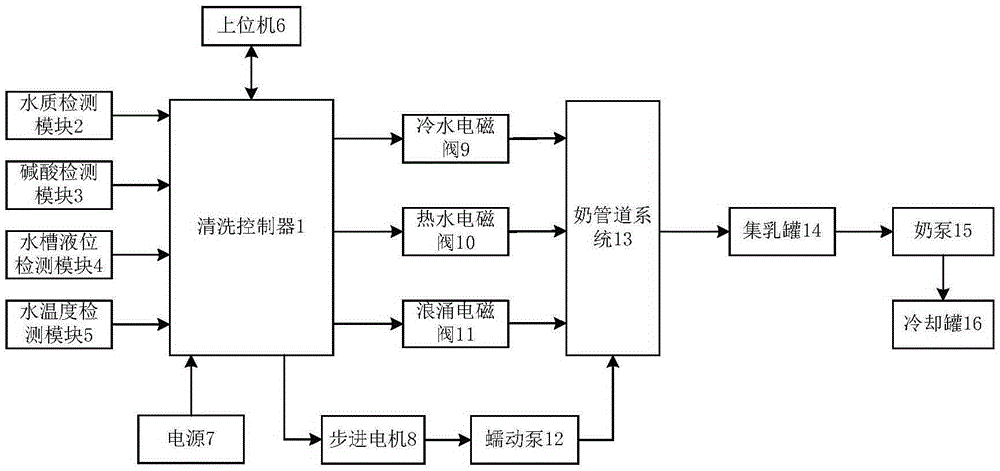

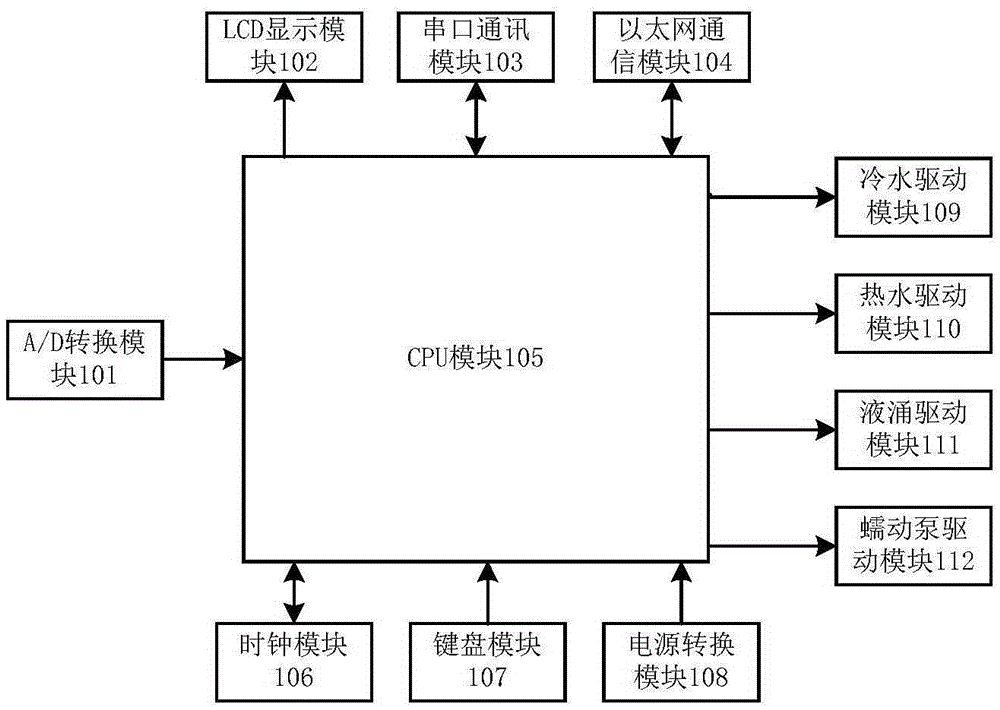

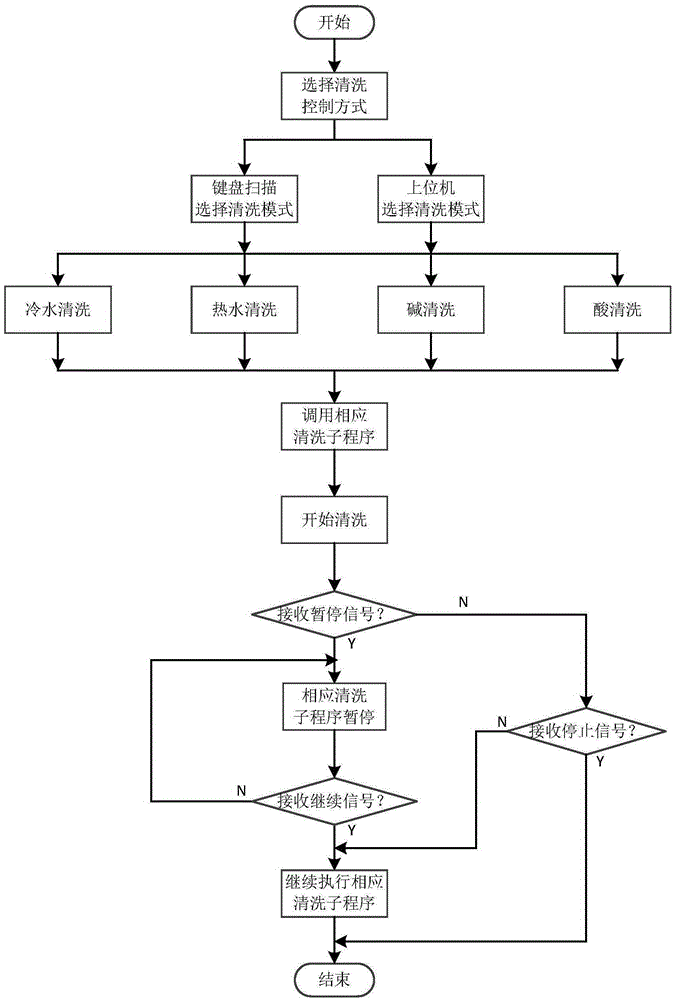

Full-automatic detection cleaning controller for milking machine, and control method of full-automatic detection cleaning controller

InactiveCN105353810ACheck cleaning qualityImprove cleaning qualitySimultaneous control of multiple variablesMilking devicesEngineeringThermal water

Aiming at the effective cleaning of milking equipment before and after milking, the invention provides a controller, and the controller has a function of automatic detection of cleaning quality, has a function of memorizing a characteristic programmable mode, has adjustable parameters, has functions of automatic detection, quick and convenient checking and communication with an upper computer, employs a surge cleaning mode, and has modes: cold water cleaning, hot water cleaning, alkali cleaning and acid cleaning. After cleaning, a system automatically cuts off the power, and the mode can be called as a one-key cleaning mode. The controller is suitable for various types of milking equipment, can improve the cleaning quality of the milking equipment and the quality of raw milk, can alleviate the labor intensity of a worker, reduces the unnecessary cleaning time, and saves the energy.

Owner:CHINA AGRI UNIV

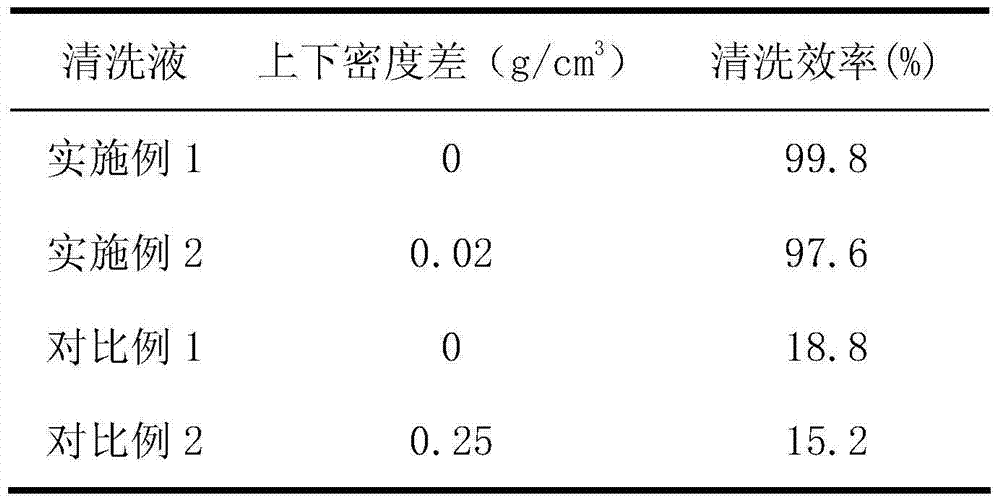

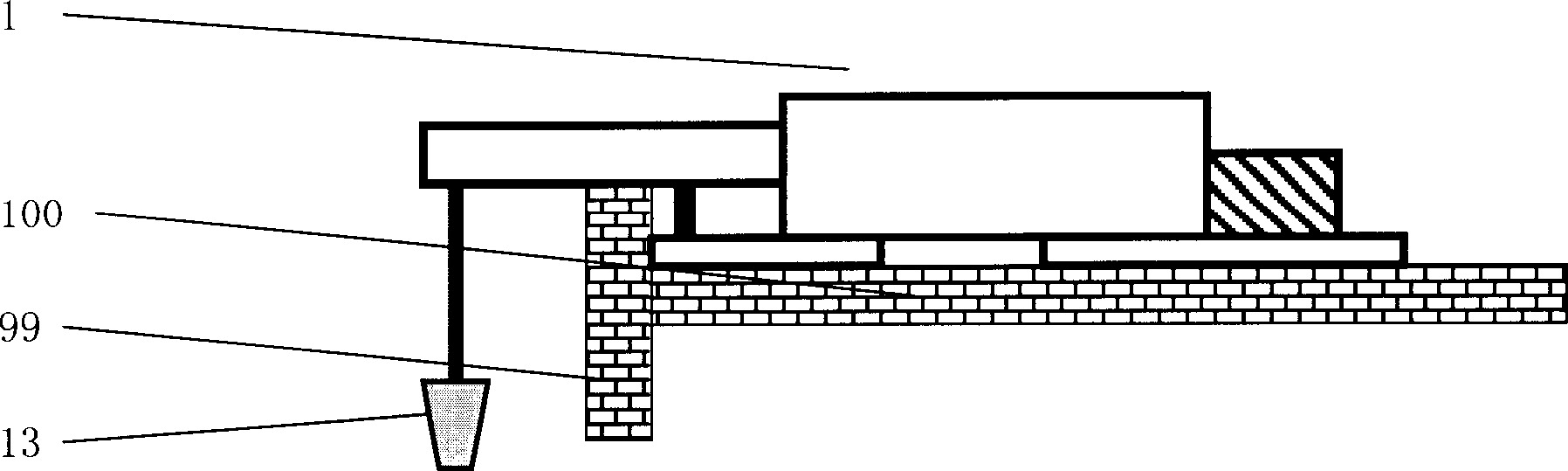

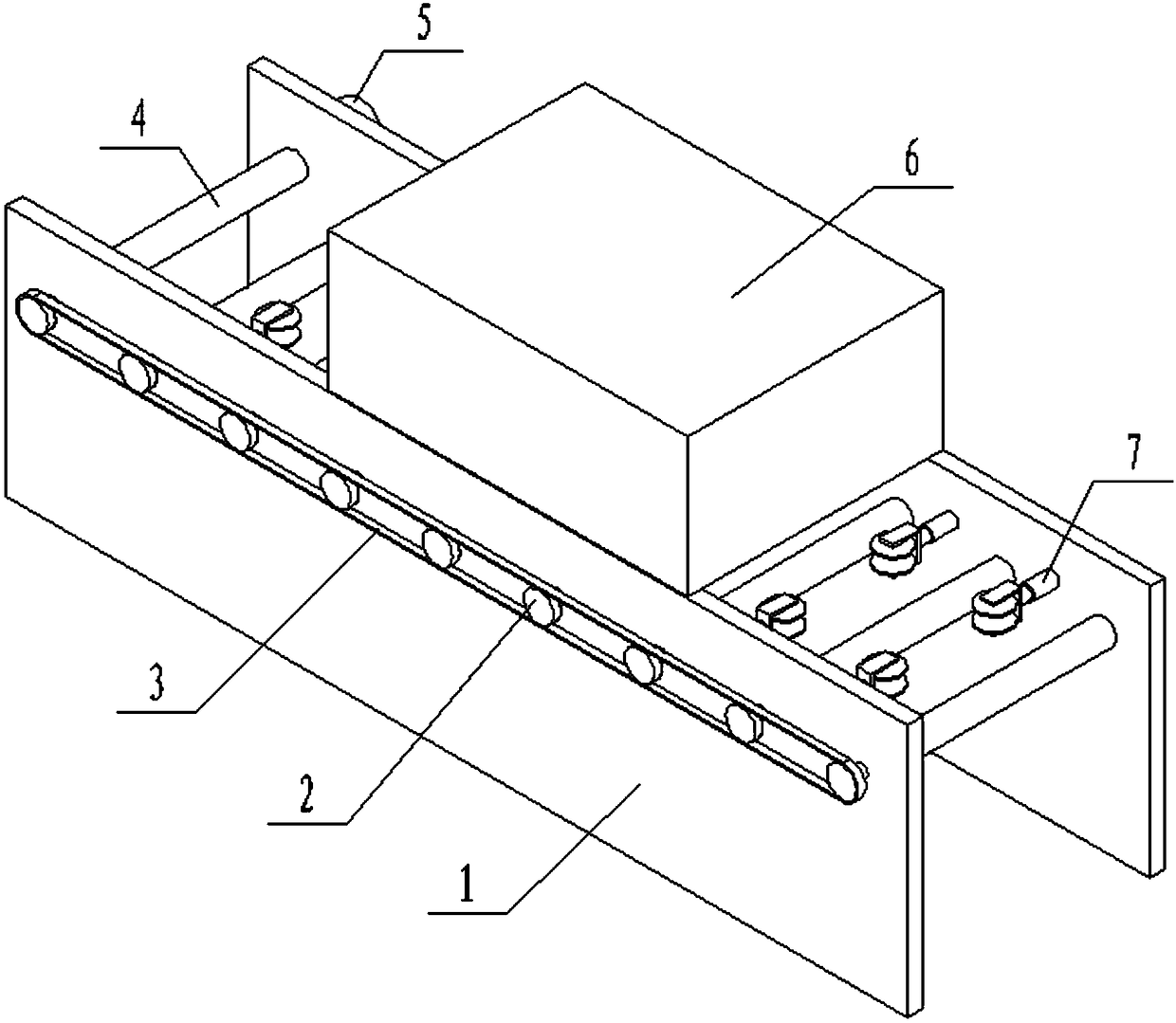

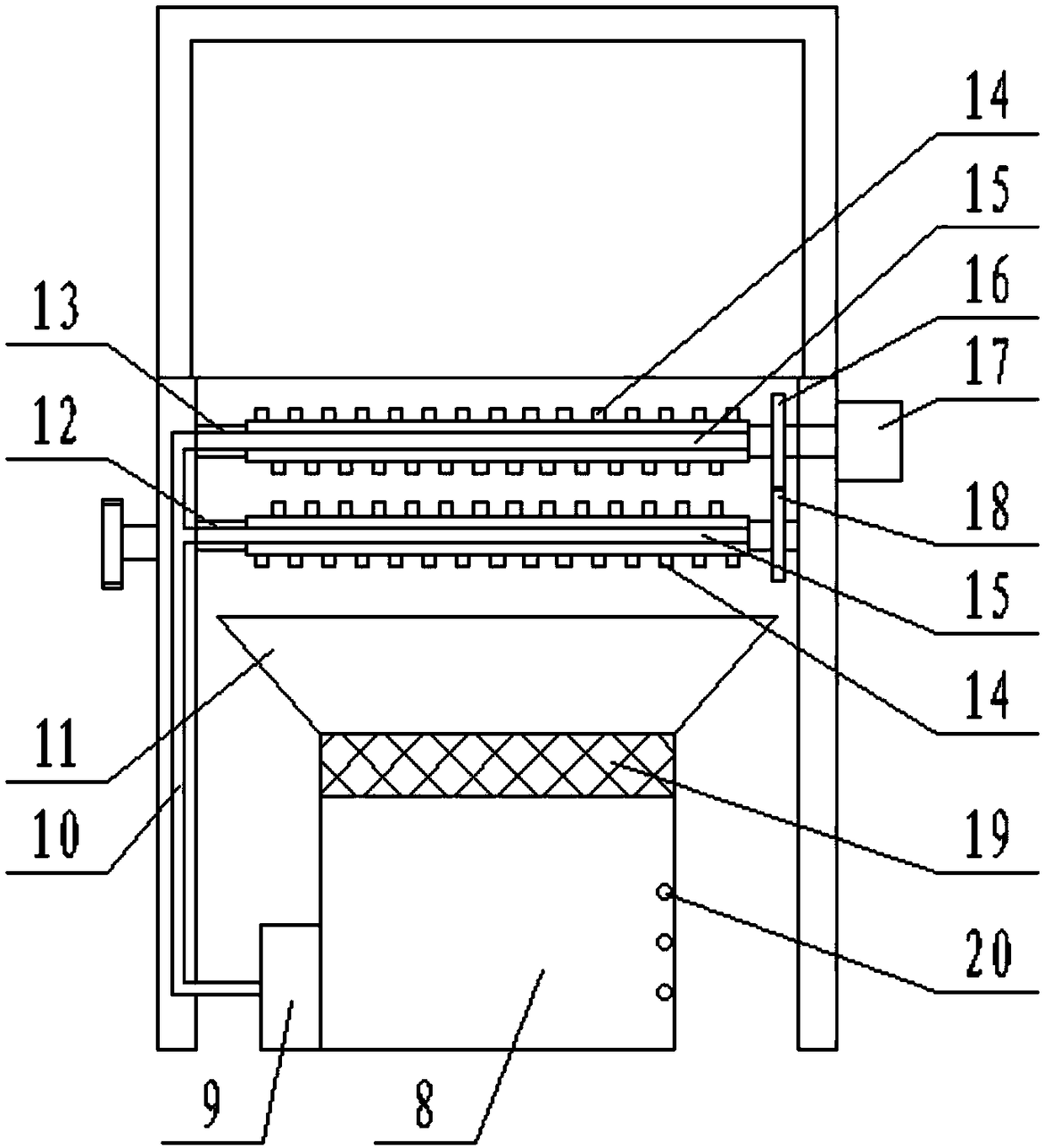

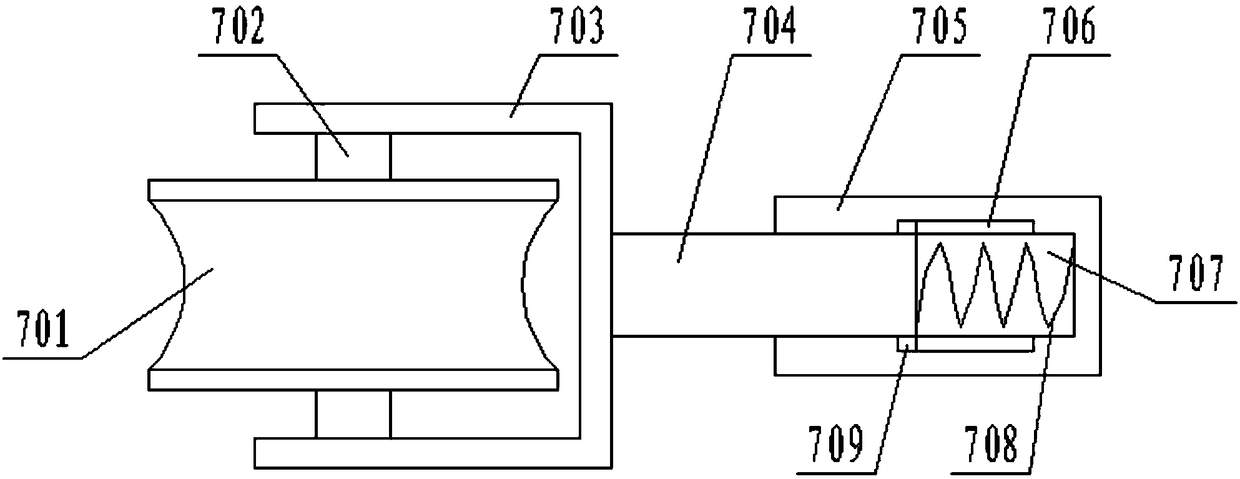

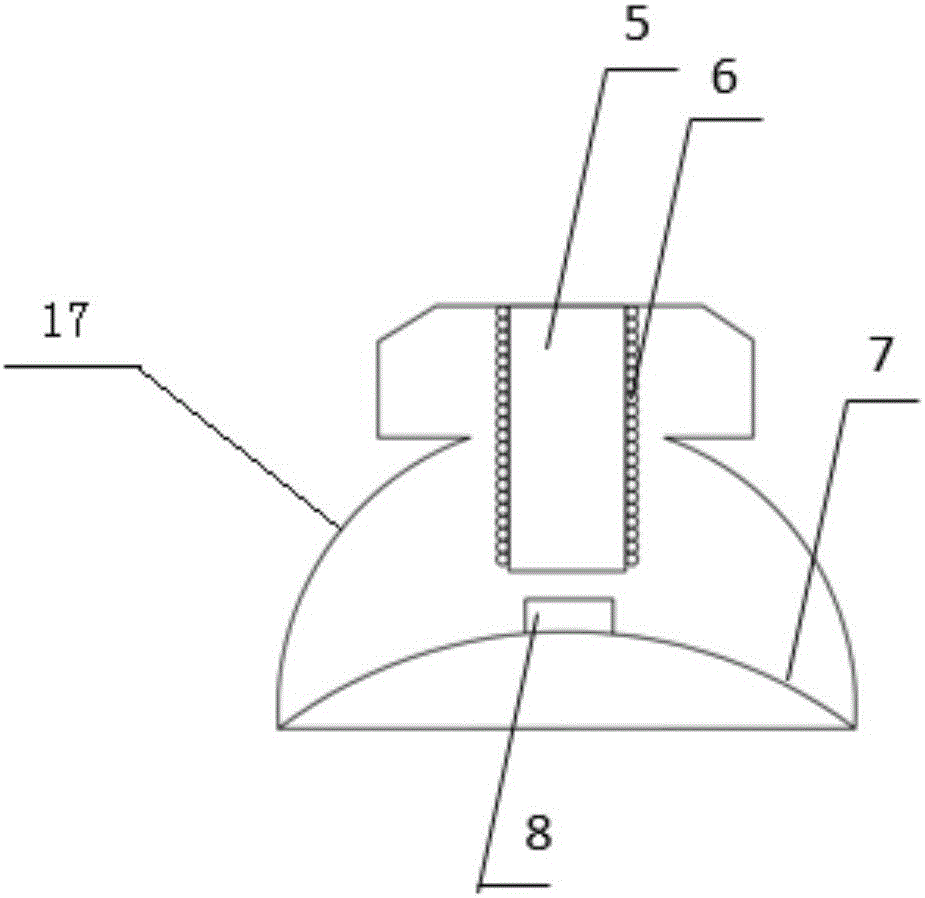

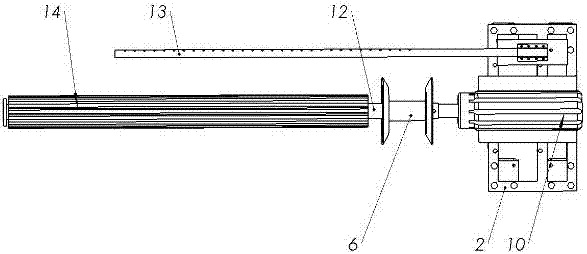

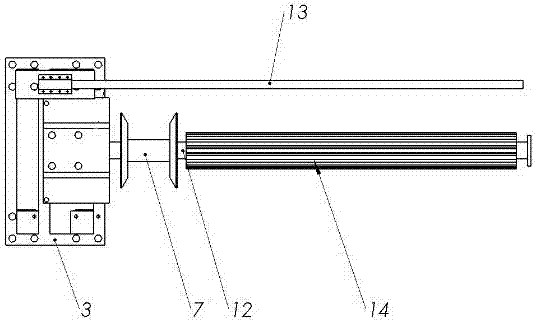

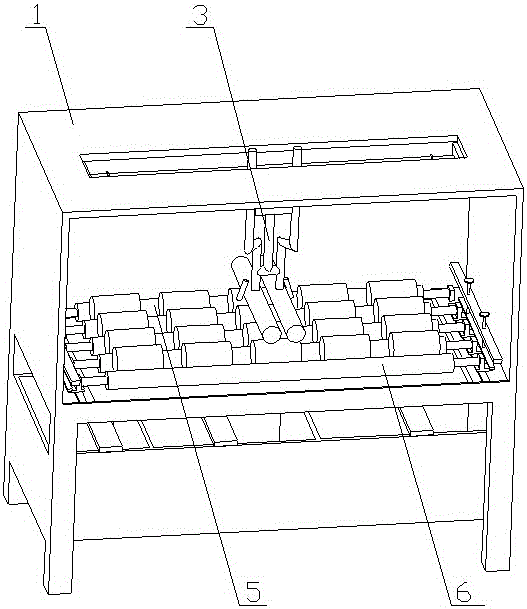

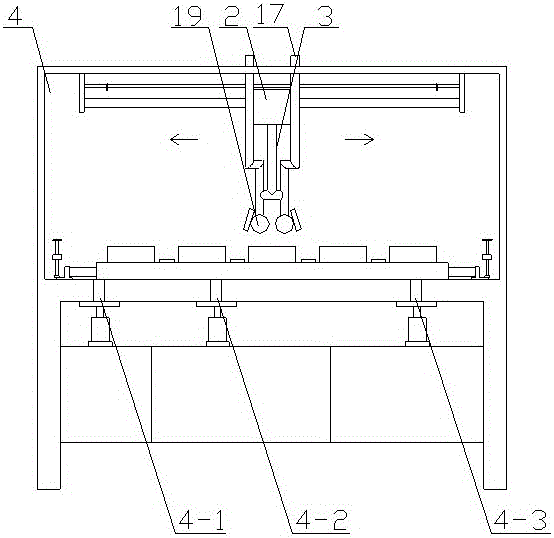

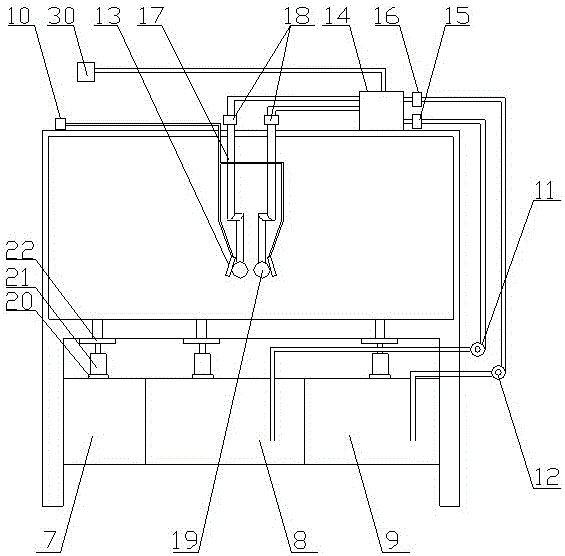

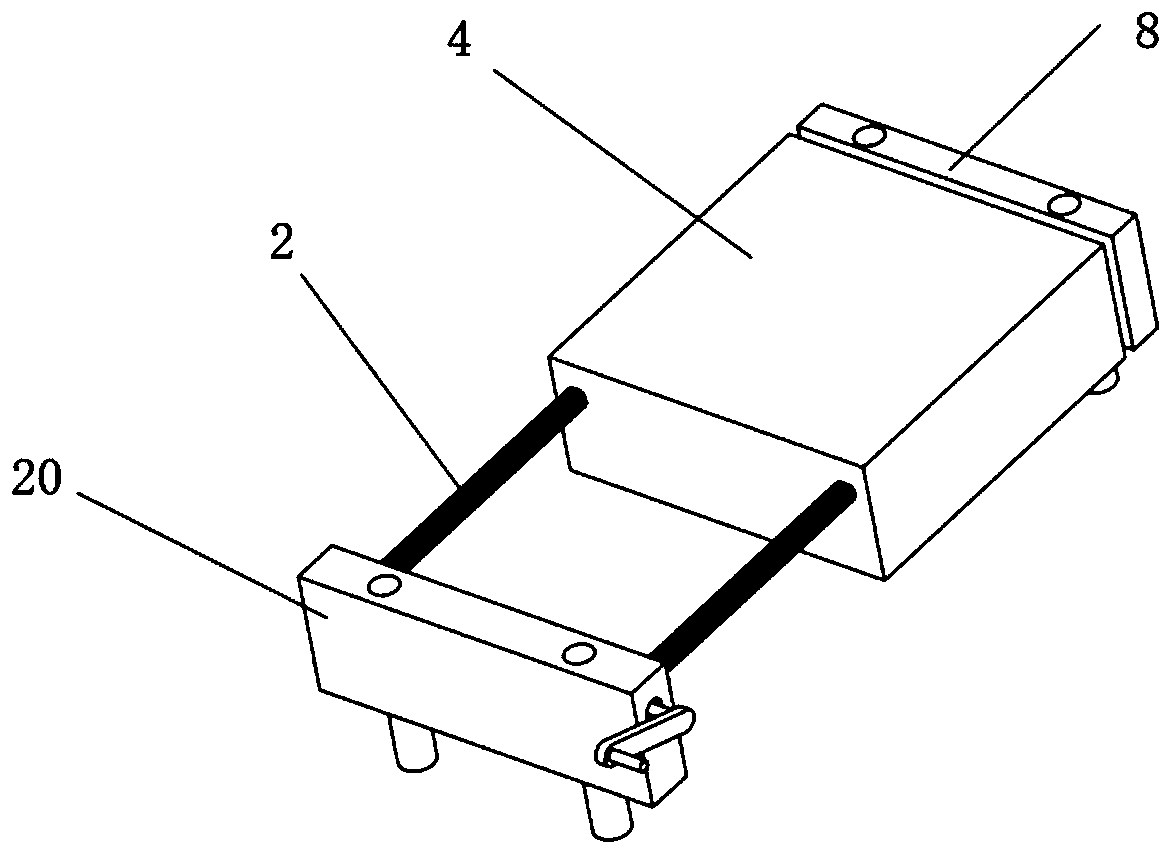

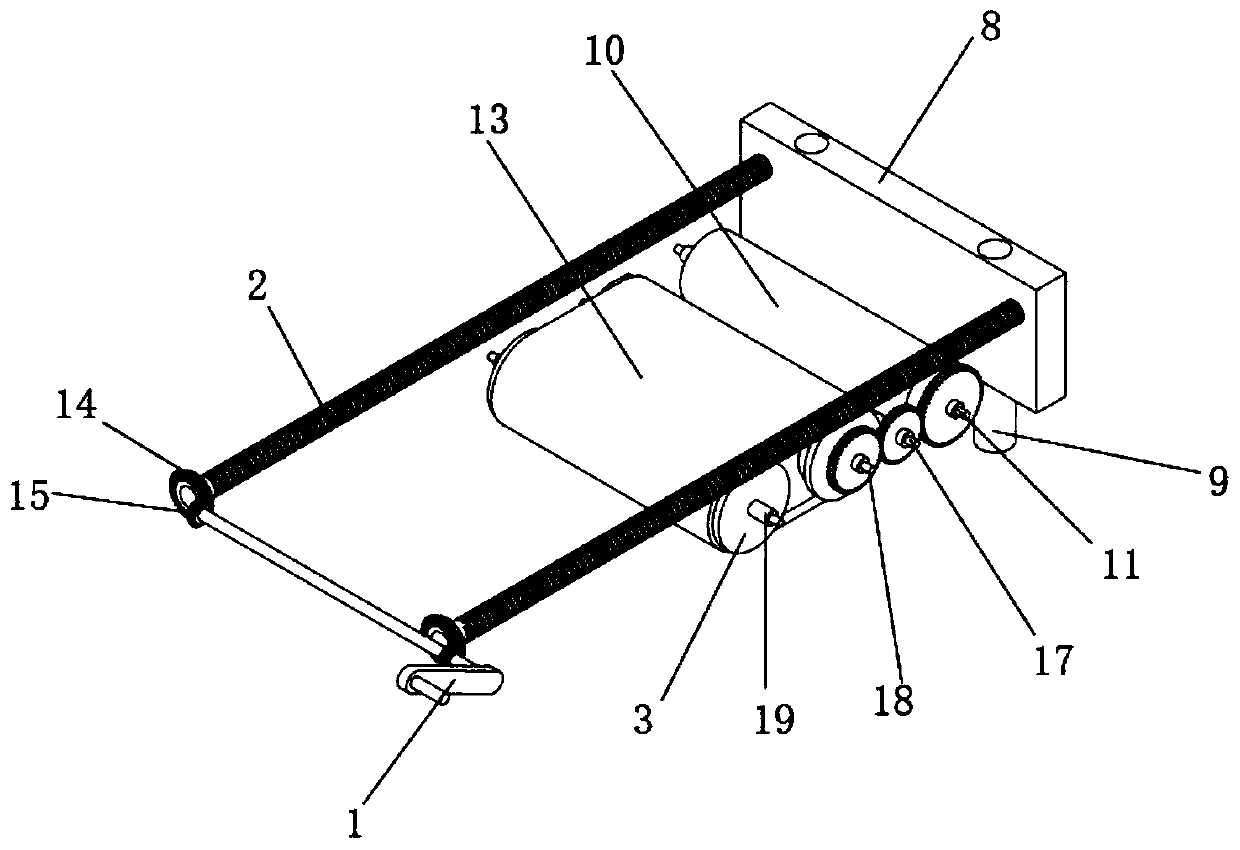

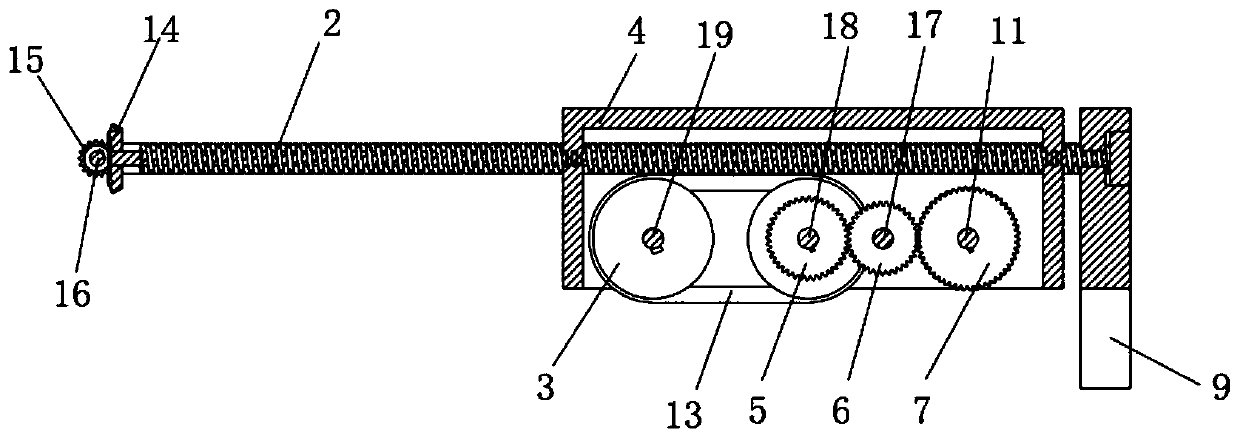

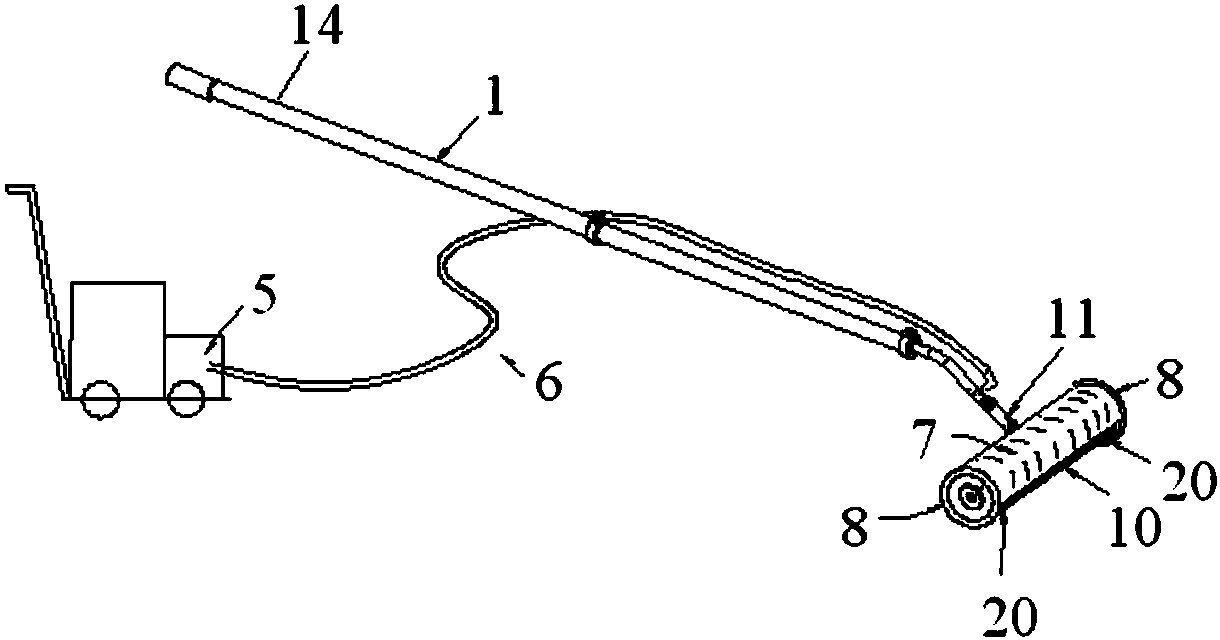

Full automatic cleaning machine for vacuum switch tubes

A full automatic cleaning machine for vacuum switch tubes is characterized by comprising a rack (1), a single-axis reciprocating machine (2), a fixed hanging rod (3), a transmission supporting mechanism and a circulatory spraying system. The transmission supporting mechanism comprises a driving roller (5), a set of driven rollers (6) and a motor. The circulatory spraying system comprises a waste water groove (7), an acid water groove (8), an alkali water groove (9), a high-pressure pump (10), an acid water pump (11), an alkali water pump (12), a pair of spraying nozzles (13), a multi-channel joint (14), an acid solenoid valve (15), an alkali solenoid valve (16), a pair of water outlet pipes (17), a pair of water outlet solenoid valves (18), a pair of stored water spraying pipes (19) and three switch mechanisms. The full automatic cleaning machine for the vacuum switch tubes has the advantages that the cleaning machine has the functions of water washing, acid washing and alkali washing, wherein the acid water and the alkali water can be recycled, so that the production cost is reduced; the cleaning machine can control the washing order and process of the water washing, the acid washing and the alkali washing by the solenoid valves, so that the cleaning requirements of the ceramic vacuum switch tubes in different production stages can be met and the degree of automation is high.

Owner:HUBEI XINSHIQI ELECTROCERAMICS TECH CO LTD

Dry-cleaning and water-washing hybrid solar panel cleaning device

PendingCN109731829ANovel structural designEasy to operateUsing liquid separation agentPhotovoltaicsDrive shaftWater resources

The invention discloses a dry-cleaning and water-washing hybrid solar panel cleaning device. According to the specific structure of the dry-cleaning and water-washing hybrid solar panel cleaning device, two driving bevel gears are arranged on a transverse shaft; two screw rods are parallel; transmission bevel gears are fixed at the front ends of the screw rods; the driving bevel gears and the transmission bevel gears are perpendicular and meshed mutually; through holes are formed in front and rear plates of a tank body; four nuts matched with the screw rods are arranged in the through holes; adriving shaft, a driving gear shaft, a water pipe and a gear shaft are sequentially fixed on left and right side plates of the tank body from front to back; friction wheels are correspondingly fixedat both ends of the driving gear shaft and the driving shaft; a strip sponge used for friction driving is arranged on the friction wheels; a rolling brush is fixed on the gear shaft; and a plurality of atomizing nozzles are fixed on the water pipe. The dry-cleaning and water-washing hybrid solar panel cleaning device disclosed by the invention is novel in structural design as well as simple and convenient to operate; the dry-wet dual cleaning process is achieved and the cleaning effect is good; the energy consumption is low and the recycling of water resources is achieved; and meanwhile, the cleaning requirements of photovoltaic panels of various sizes, heights and inclinations are met.

Owner:SOUTHWEST JIAOTONG UNIV

Cleaning device for solar photovoltaic panels

PendingCN108515067AIncrease the cleaning areaMeet cleaning needsFlexible article cleaningCleaning using toolsHigh pressure waterHigh pressure

The invention provides a cleaning device for solar photovoltaic panels. The cleaning device is simple and exquisite in structure and capable of being manually operated easily and can effectively cleanthe solar photovoltaic panels. The cleaning device comprises a handheld rod, a first rolling brush and a second rolling brush. The head end of the handheld rod is rotatably connected with a hydraulicshaft. The hydraulic shaft extends in the direction to intersect with the handheld rod and is provided with a shell cavity communicating with high-pressure water. The first rolling brush and the second rolling brush are respectively connected and fixed to the two ends of the hydraulic rod in a sleeving mode and are provided with water spray holes communicating with the shell cavity. According tothe cleaning device, the rolling brushes are mounted at the head ends of the handheld rod, users can clean the solar photovoltaic panel by holding the handheld rod, and the cleaning device accords with the home distribution characteristics of the solar photovoltaic panels and well meet the cleaning requirement of the solar photovoltaic panels; and the cleaning device has the advantages of being easy to operate, simple in structure, small in size and the like.

Owner:SHANDONG HAOWO ELECTRICAL CO LTD

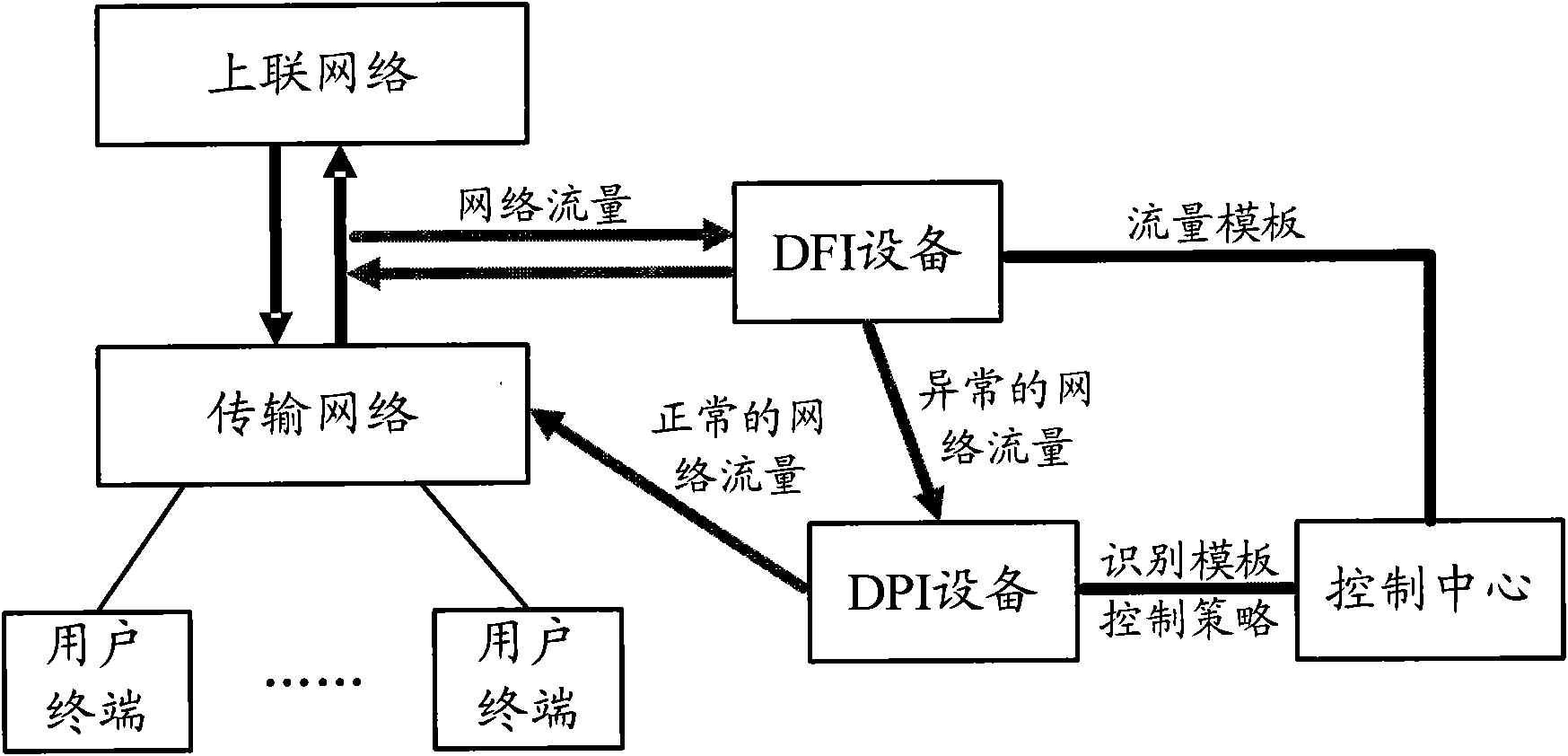

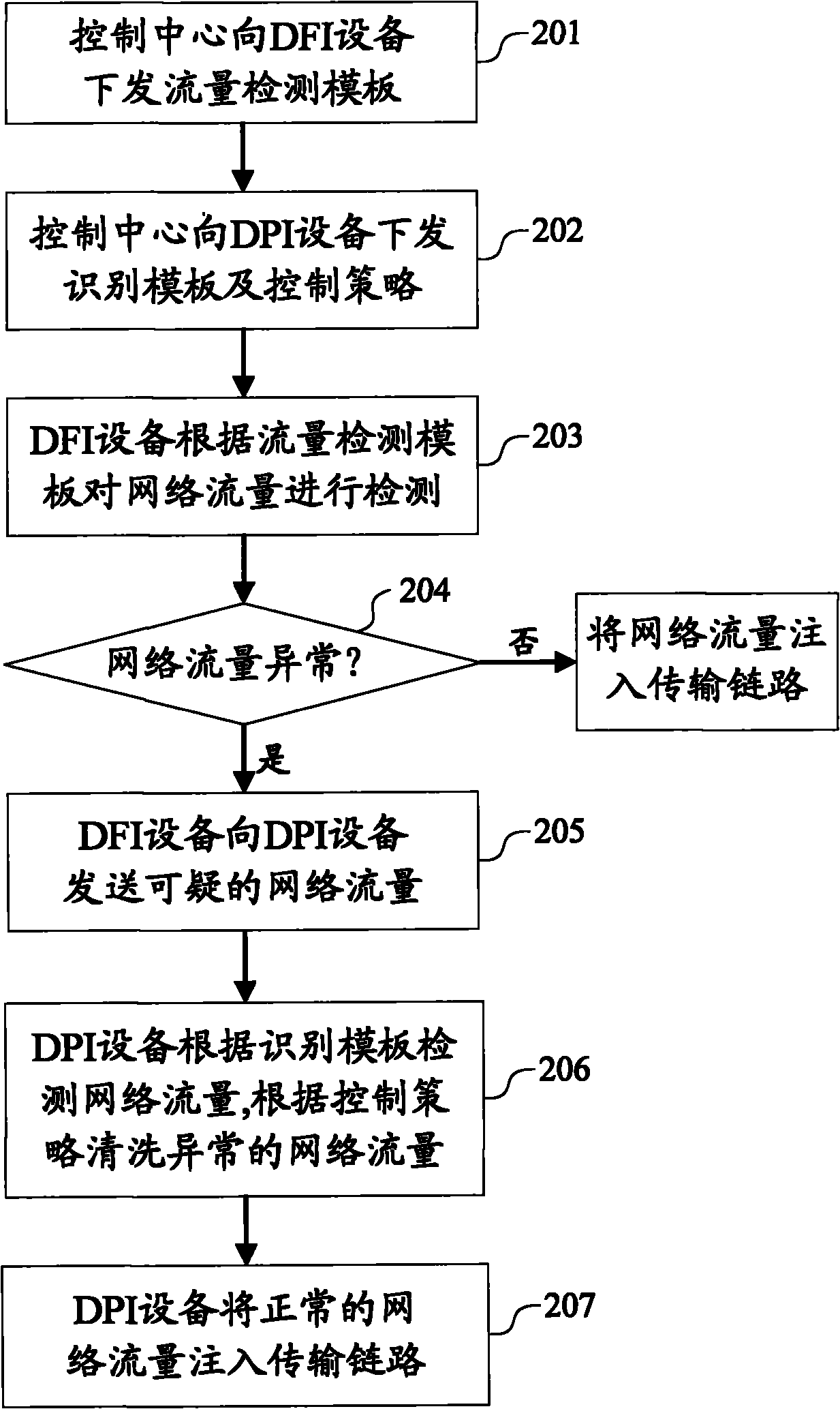

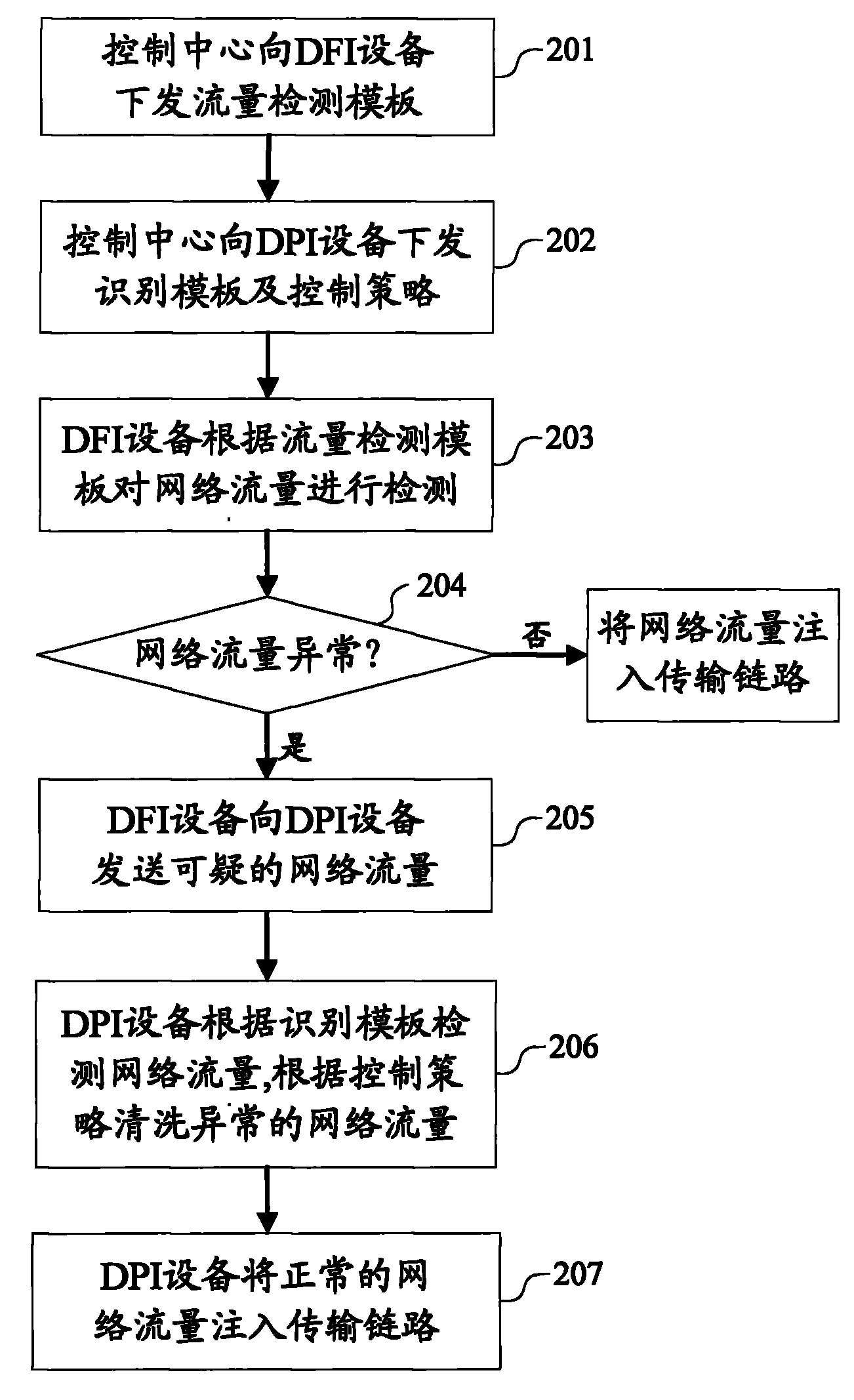

Method and system for realizing network flow cleaning

InactiveCN101986609AResolve integritySolve efficiency problemsData switching networksStreamflowDistributed computing

The invention discloses a method and a system for realizing network flow cleaning. In the scheme adopted by the invention, data field identifier (DFI) equipment detects network flow according to a flow detection template and transmits suspicious network flow to data processing installation (DPI) equipment; and the DPI equipment detects the suspicious network flow according to an identification template and cleans abnormal network flow according to a control policy. In the scheme adopted by the invention, DFI technology and DPI technology are combined, the contradiction between the completeness of the detection and cleaning efficiency in the network flow cleaning is well solved, the detection efficiency and accuracy are both taken into consideration, the network flow cleaning needs of mass data can be satisfied, and the network flow cleaning efficiency is improved considerably.

Owner:ZTE CORP

LCD water-base cleaning liquid

InactiveCN101121913AHigh ultrasonic cavitation efficiencyNot dangerous to healthCationic surface-active compoundsDetergent compounding agentsOrganic filmOil and grease

The invention relates to a LCD water-base rinse-solution, a condensation substance (JFC) - a mixture of organic base, oxirane and high-grade fatty alcohol, surfactant and deionized water), the weight ratio of the components is: organic base (5 to 20 percent), JFC (1 to 10 percent), surfactant (1 to 10 percent), and the remained is deionized water; wherein, the surfactant takes at least one of teramethyl ammonium chloride, ethyoxylated nonyl amber-acid semi-ester sodium salt, triethanolamine oleate soap, SDBS or amine oxide OA. The invention has the advantages that the organic base has certain decomposing function, the active agent and organic are mutually soluble, and the double effects can better remove the residue on the product surface; the rinse-solution is non-toxic, not harmful to the health of workers, inflaming retarding, explosion-free and safe; the formulate of the rinse-solution is very flexible, capable to meet specific requirements of cleaning, and has sound effect on LCD and organic film cleaning and as well as removal of oil and grease, and so on.

Owner:天津晶岭电子材料科技有限公司

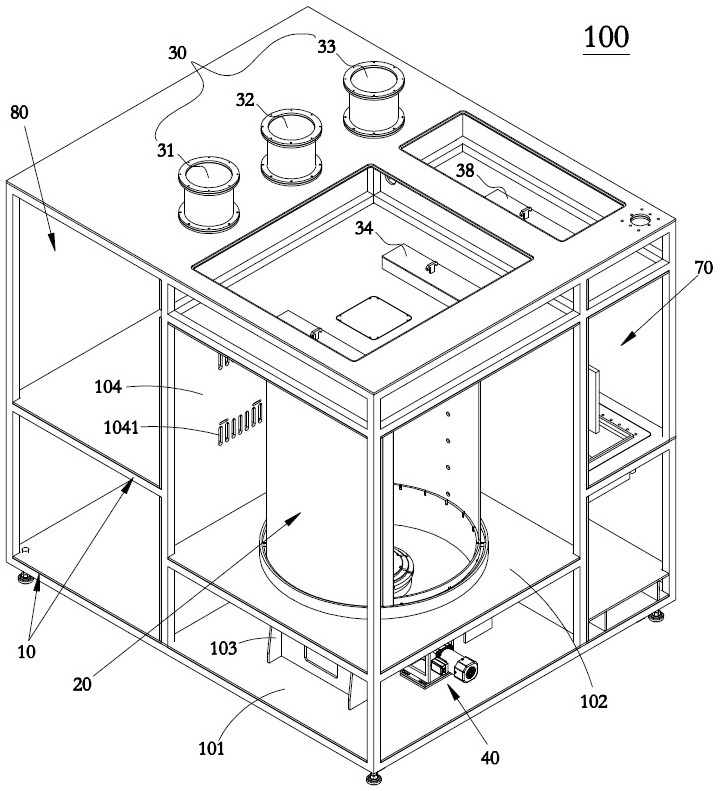

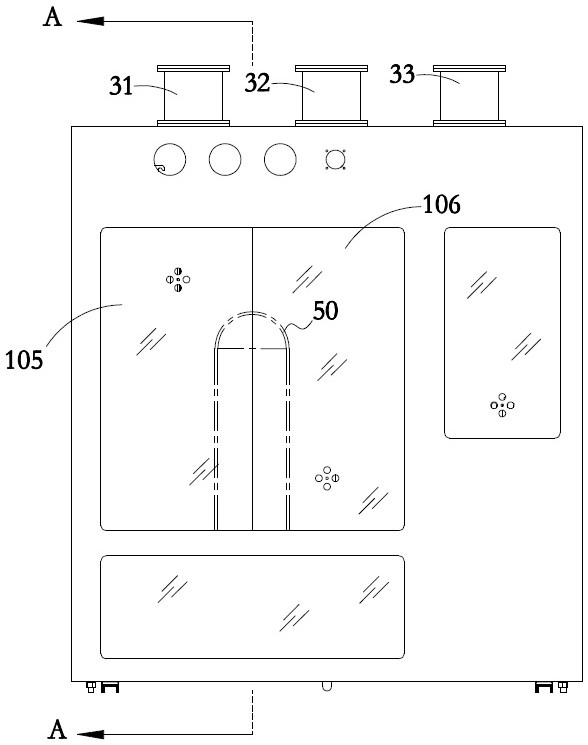

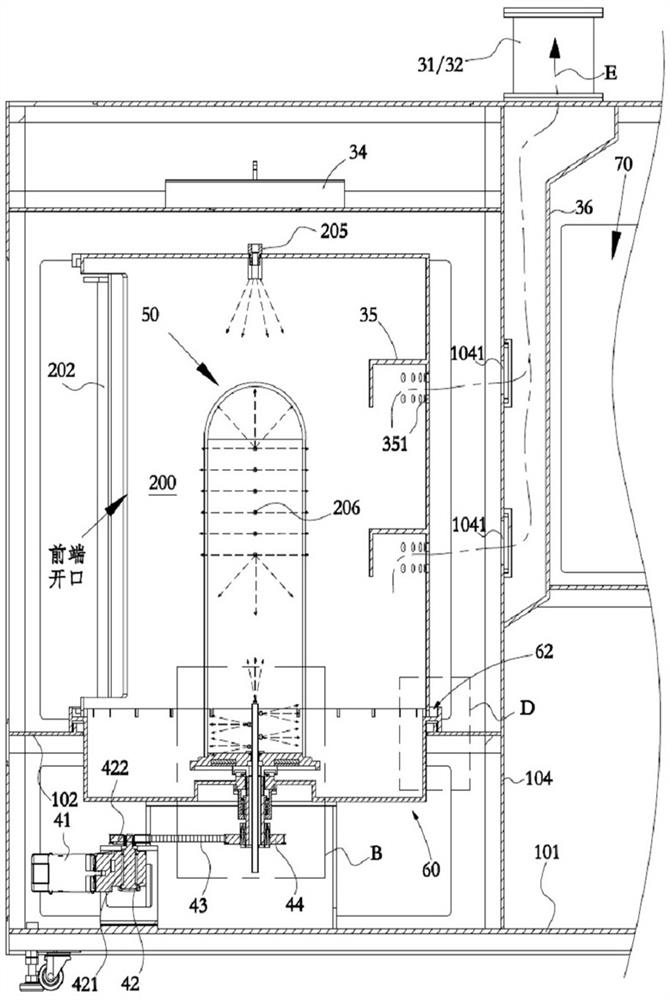

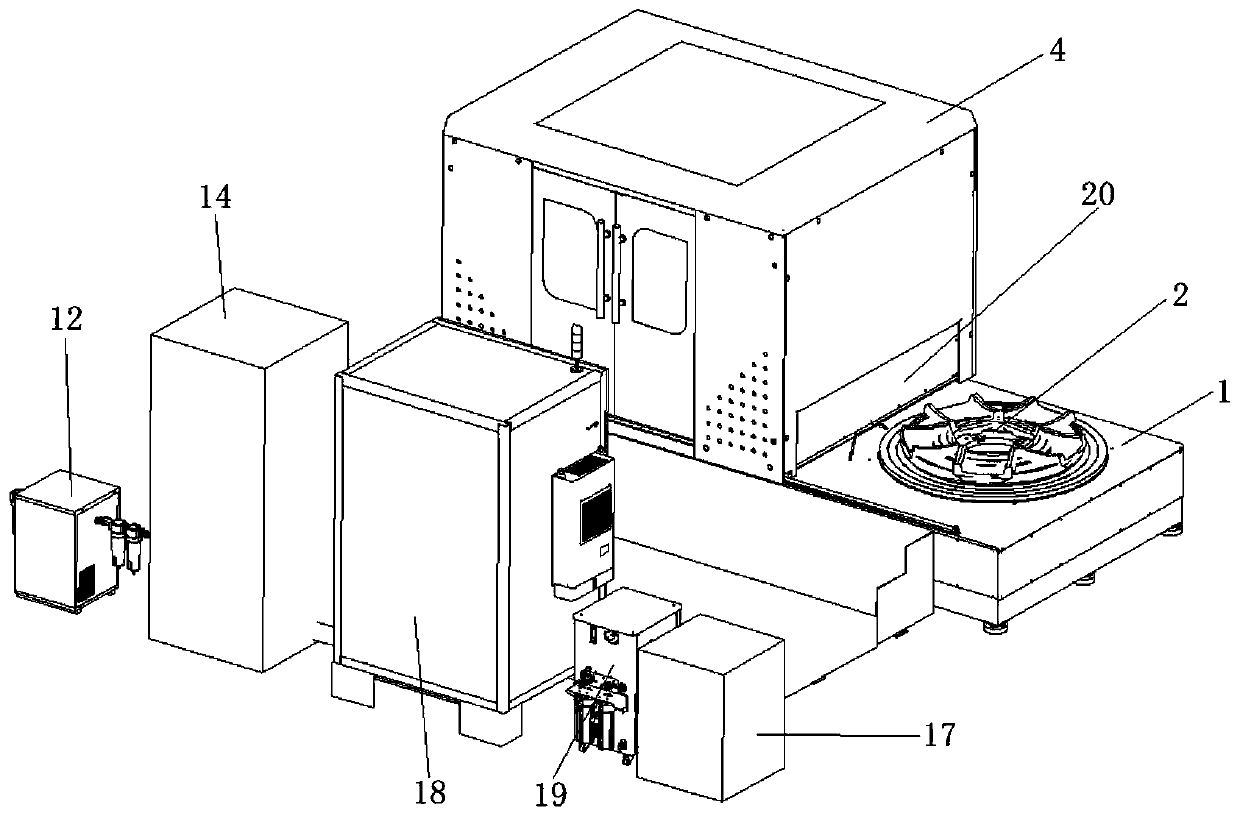

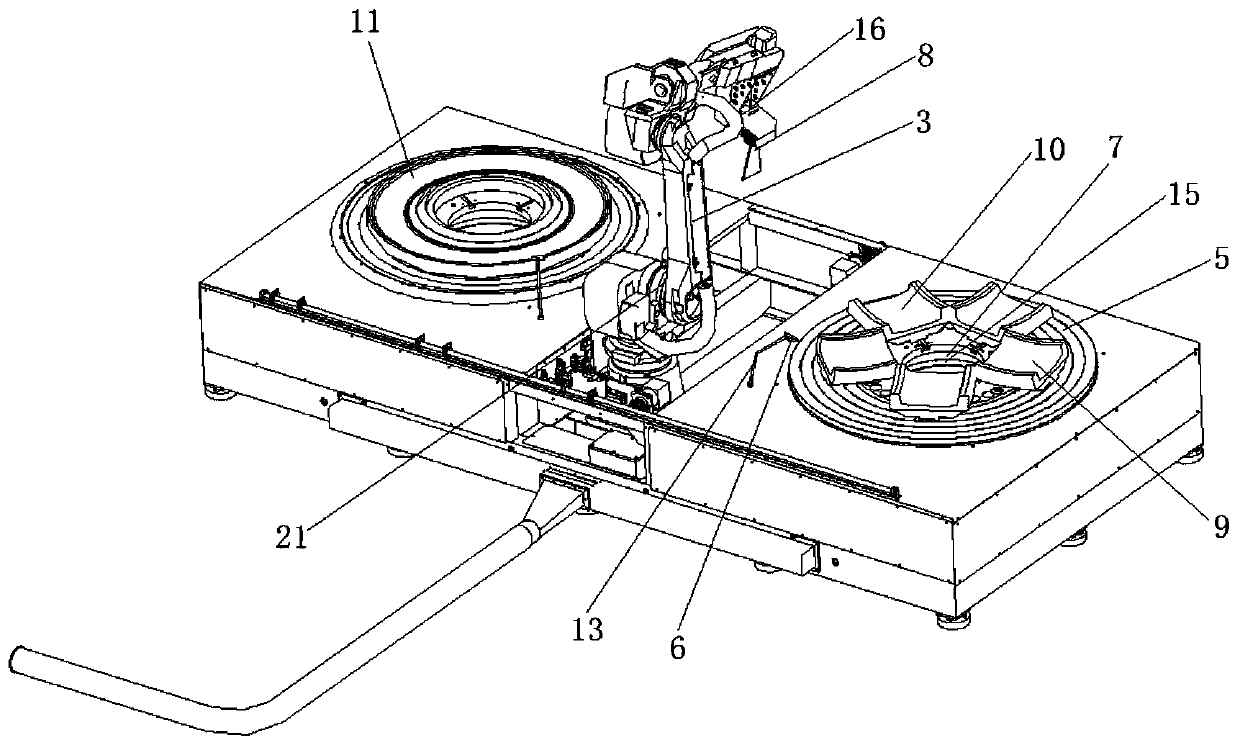

Double-station laser cleaning device

PendingCN110227688ANice appearancePrevent splashing and hurting peopleDirt cleaningCleaning stationPetroleum engineering

The invention belongs to the technical field of laser cleaning equipment, and particularly relates to a double-station laser cleaning device. The double-station laser cleaning device comprises a worktable, cleaning stations, a cleaning mechanism and a protective cover. The two cleaning stations are distributed on the work table in a left and right symmetrical manner, each cleaning station includes a rotating platform deck, each cleaning station is provided with an air blowing mechanism and an air pumping mechanism, and the cleaning mechanism is arranged between the two cleaning stations; thecleaning mechanism includes laser cleaning heads capable of moving and rotating above the cleaning stations; and the protective cover covers the outer sides of one cleaning station and the cleaning mechanism, the protective cover is slidably connected with the work table, and the protective cover can be moved from one cleaning station to the other cleaning station. The double-station laser cleaning device greatly improves the work efficiency, reduces the production cost and has the advantages of being simple and reasonable in structure, convenient to operate, high in work efficiency, safe, reliable and the like.

Owner:南京集萃激光智能制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com