Shale gas development oil-base drilling fluid mud cake cleaning solution

An oil-based drilling fluid and cleaning fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as difficulties, affect cementing quality, and cementing failures, and achieve changes in water wetting conditions and improve The effect of cementing quality and wide adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

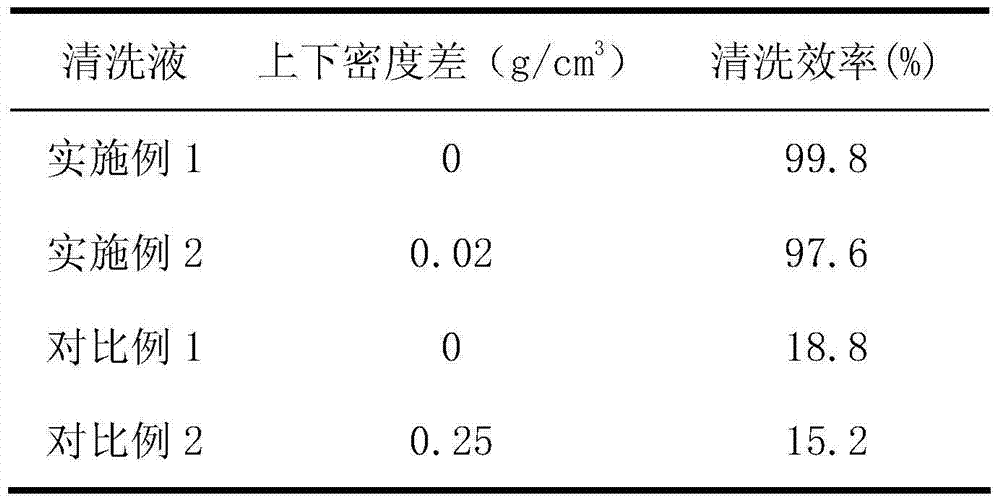

Embodiment 1

[0021] A shale gas development oil-based drilling fluid mud cake cleaning solution provided by the present invention, wherein the weight percentage of each component is: cleaning agent: 20%; water: 80%;

[0022] Described cleaning agent is made up of nonionic surfactant and mutual solvent, and the weight ratio of nonionic surfactant and mutual solvent is 1:3;

[0023] The nonionic surfactant is a combination of fatty acid polyoxyethylene ether and alkylphenol polyoxyethylene ether, and the weight ratio is 1:1;

[0024] The mutual solvent is used in combination of methanol and diethylene glycol monobutyl ether, and the weight ratio is 1:1.

Embodiment 2

[0026] A shale gas development oil-based drilling fluid mud cake cleaning solution provided by the present invention, wherein the weight percentage of each component is: cleaning agent: 10%; weighting agent: 40%; water: 50%;

[0027] Described cleaning agent is made up of nonionic surfactant and mutual solvent, and the weight ratio of nonionic surfactant and mutual solvent is 1:1;

[0028] The non-ionic surfactant is a combination of allyl alcohol polyoxyalkyl ether, fatty acid polyoxyethylene ester, and stearic acid polyoxyethylene ester, and the weight ratio is 1:1:1;

[0029] Described mutual solvent is the composite use of methanol, isopropanol, and weight ratio is 1:1;

[0030] The weighting agent is ultrafine iron ore powder with a density of 5.02g / cm 3 , the particle size is 1200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com