Patents

Literature

37results about How to "Efficient cleaning operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

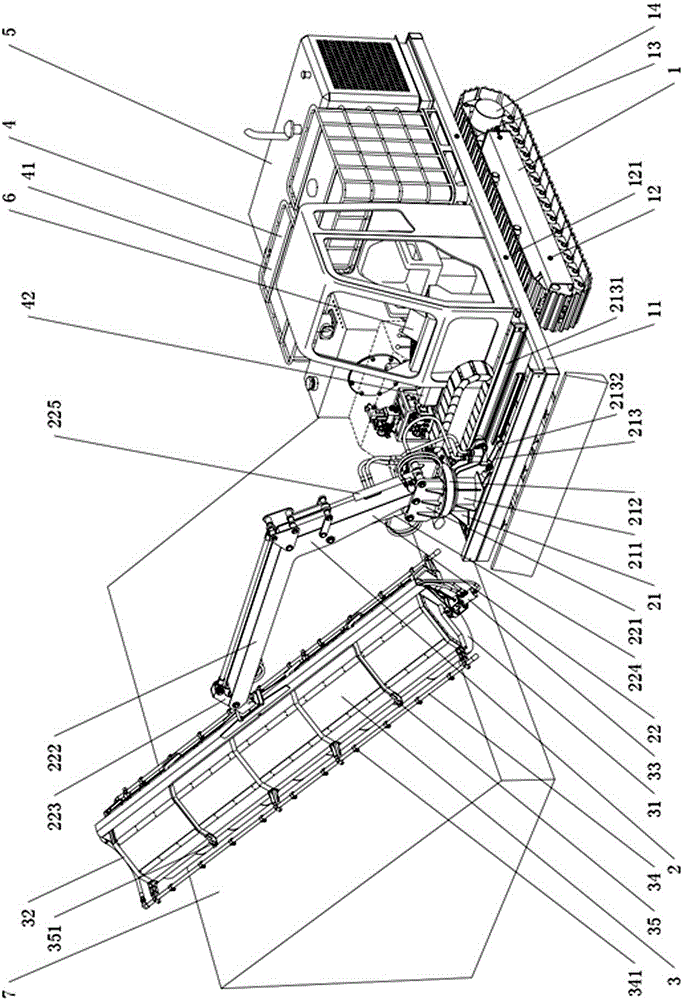

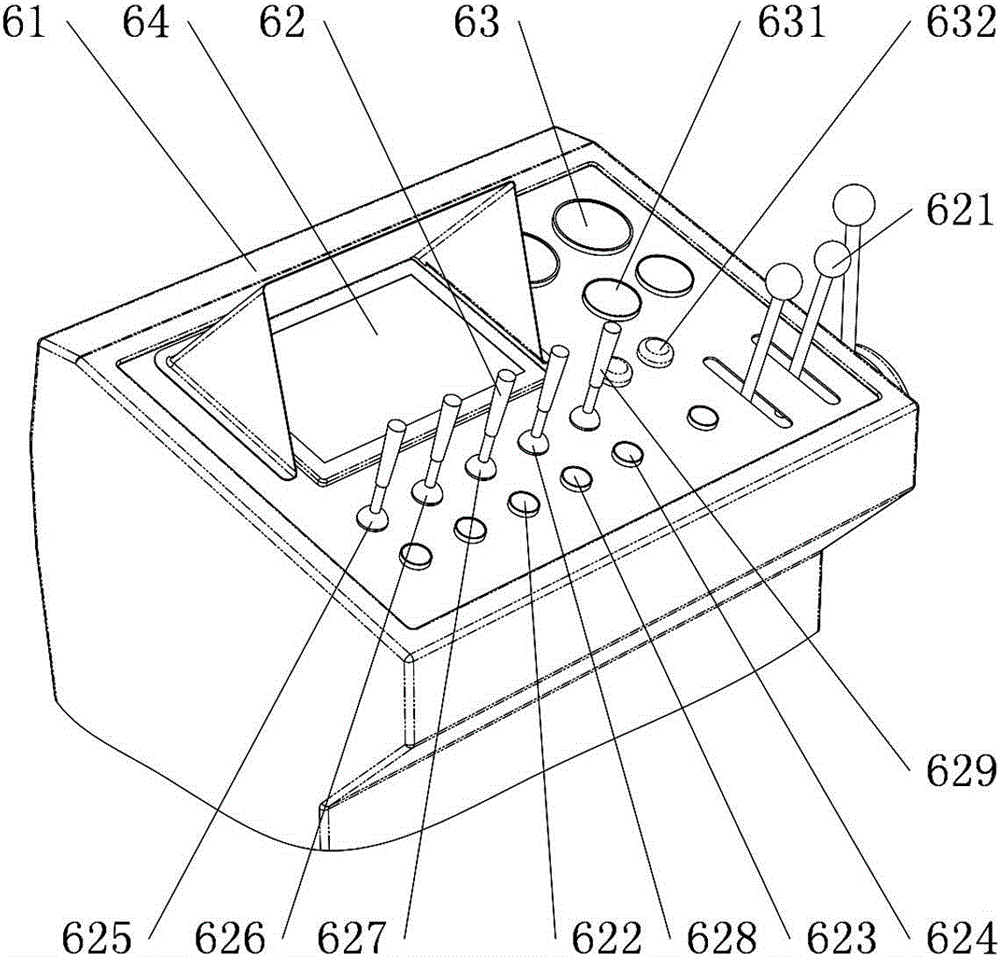

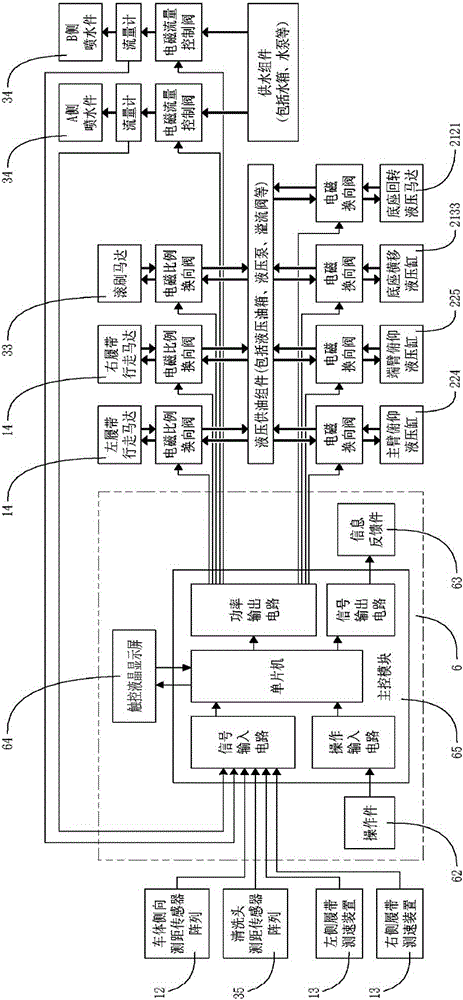

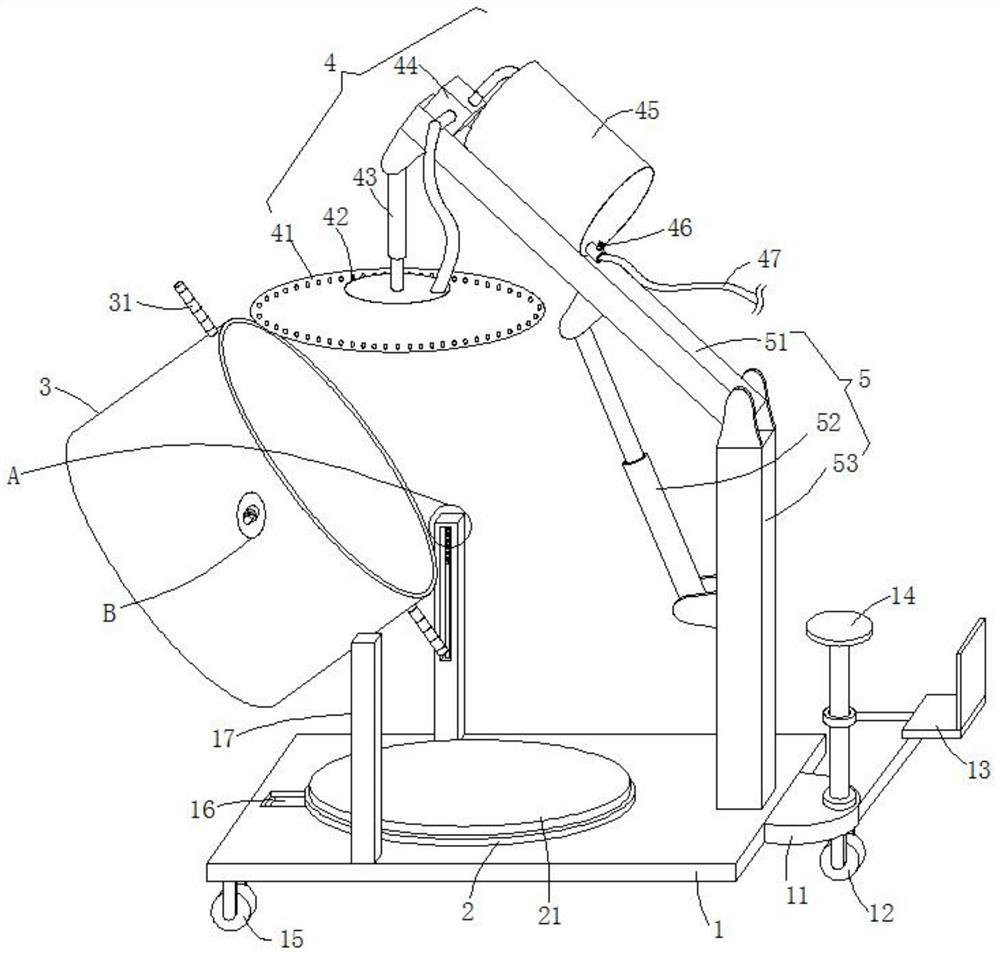

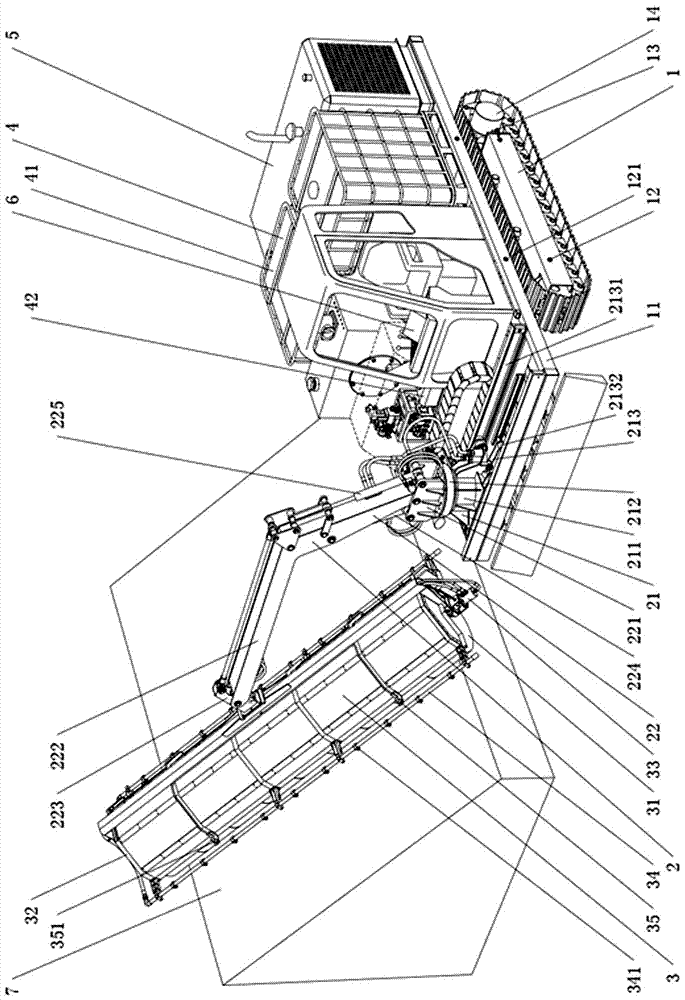

Photovoltaic array washing vehicle and photovoltaic array washing method thereof

ActiveCN105195488AUniform cleaning effectReduce consumptionSolar heating energyFlexible article cleaningComputer moduleEngineering

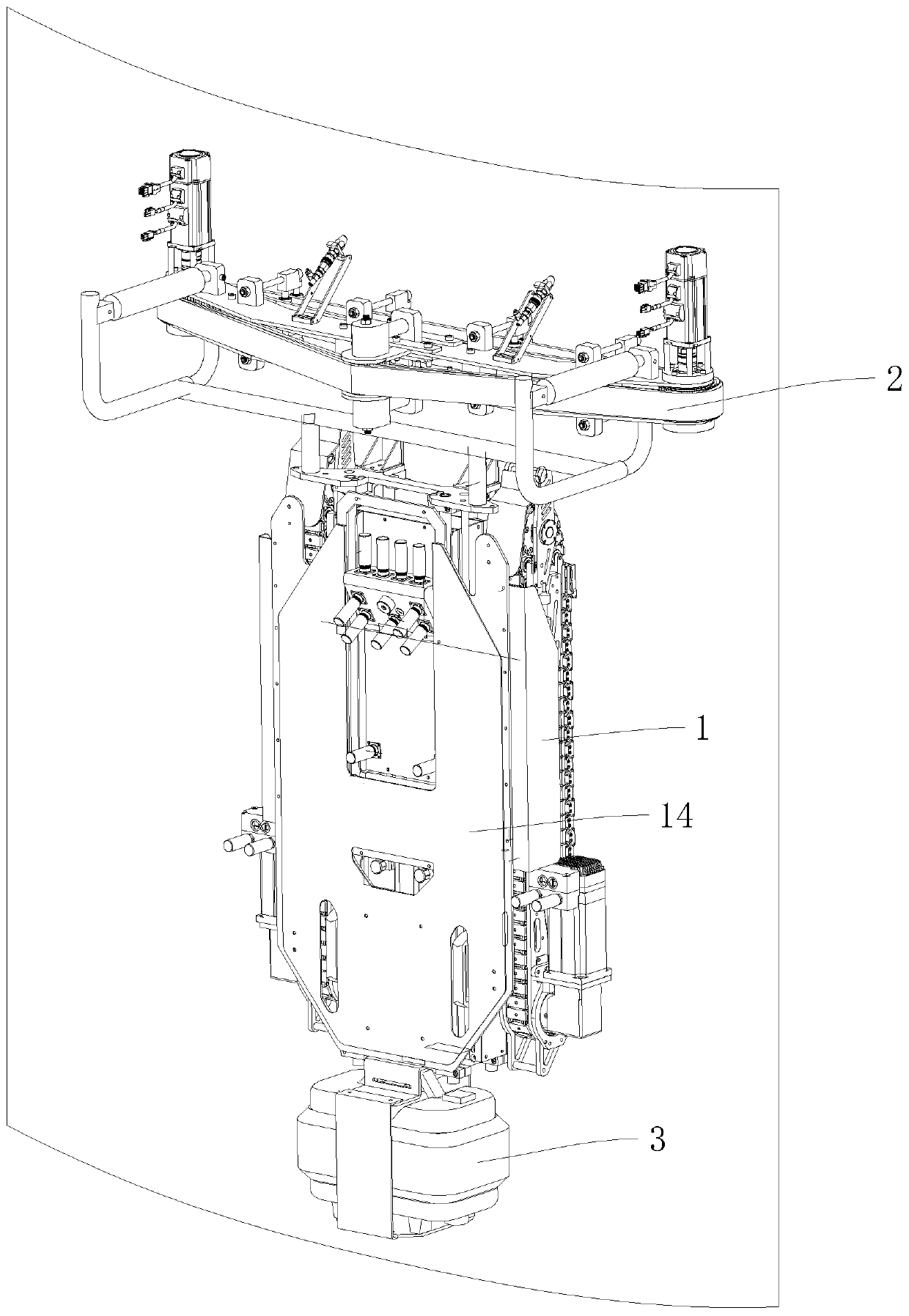

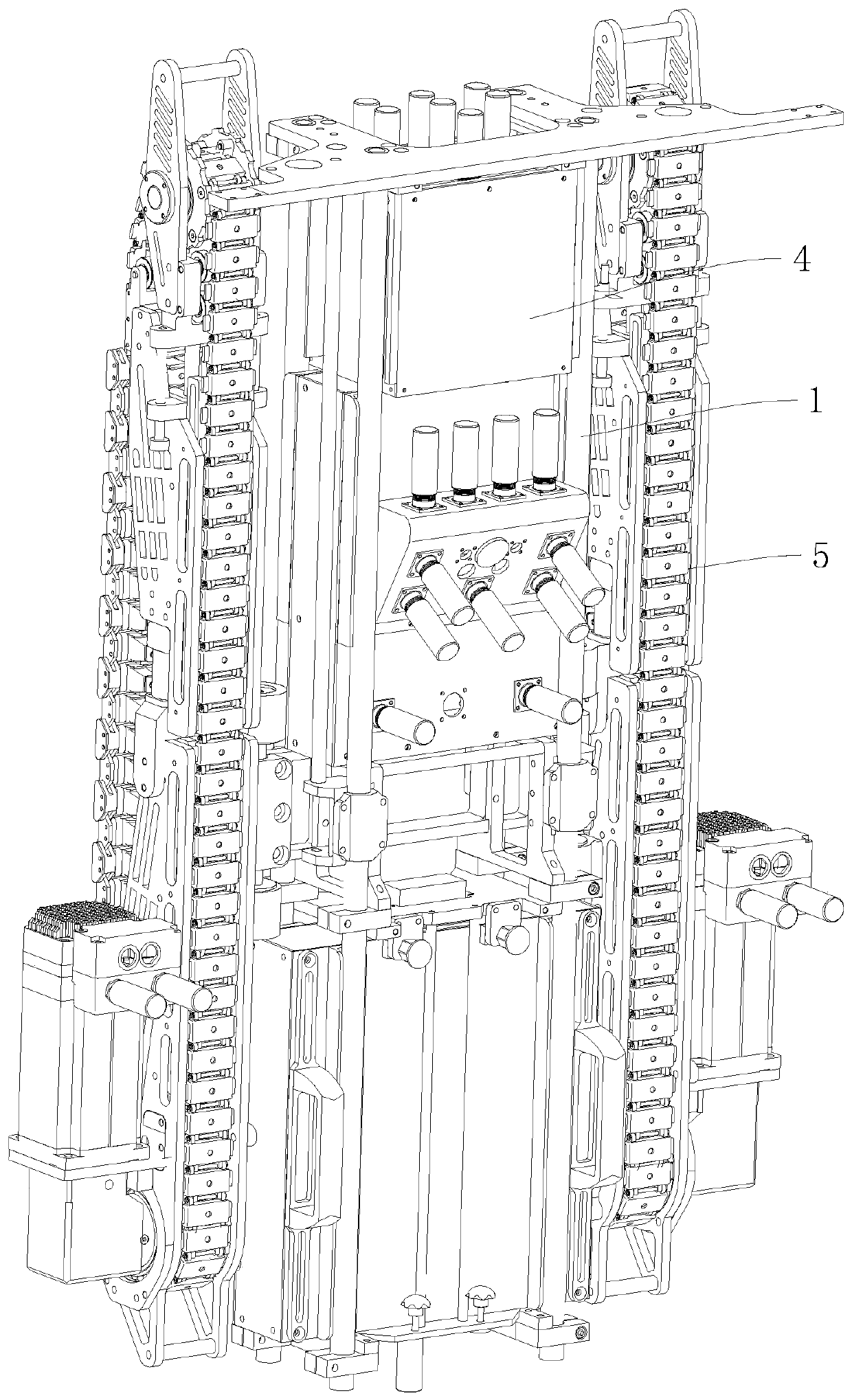

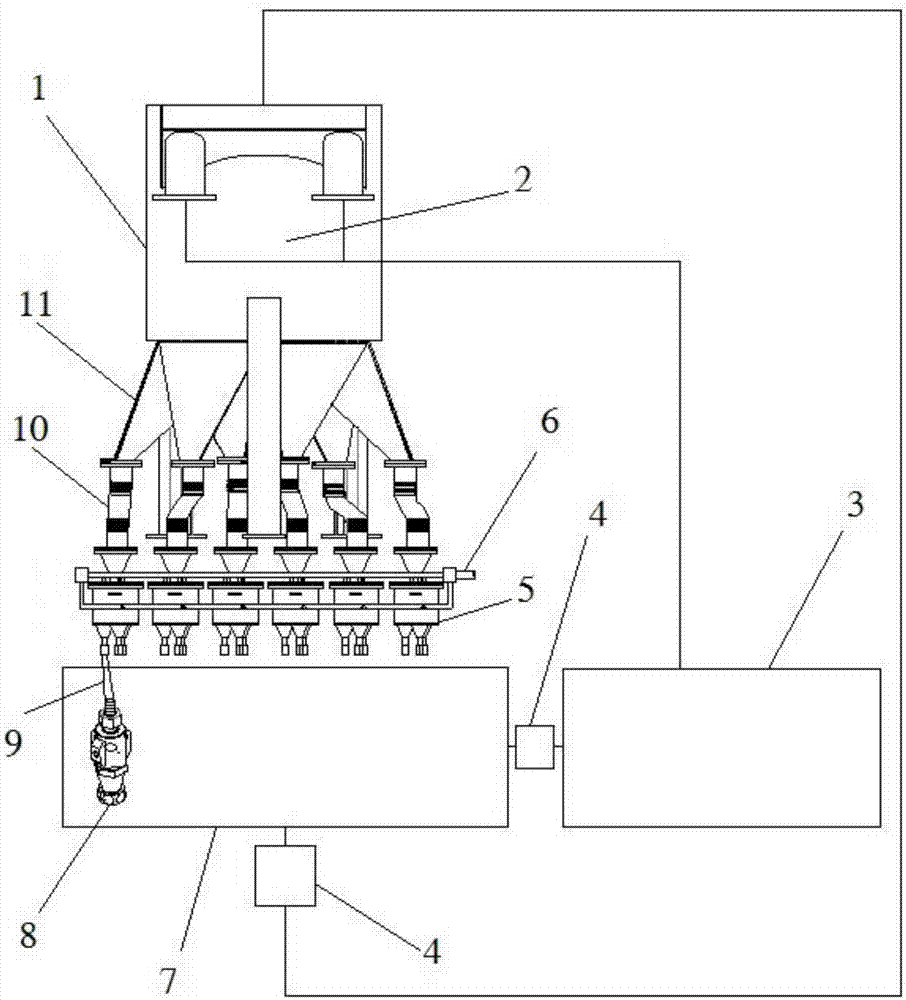

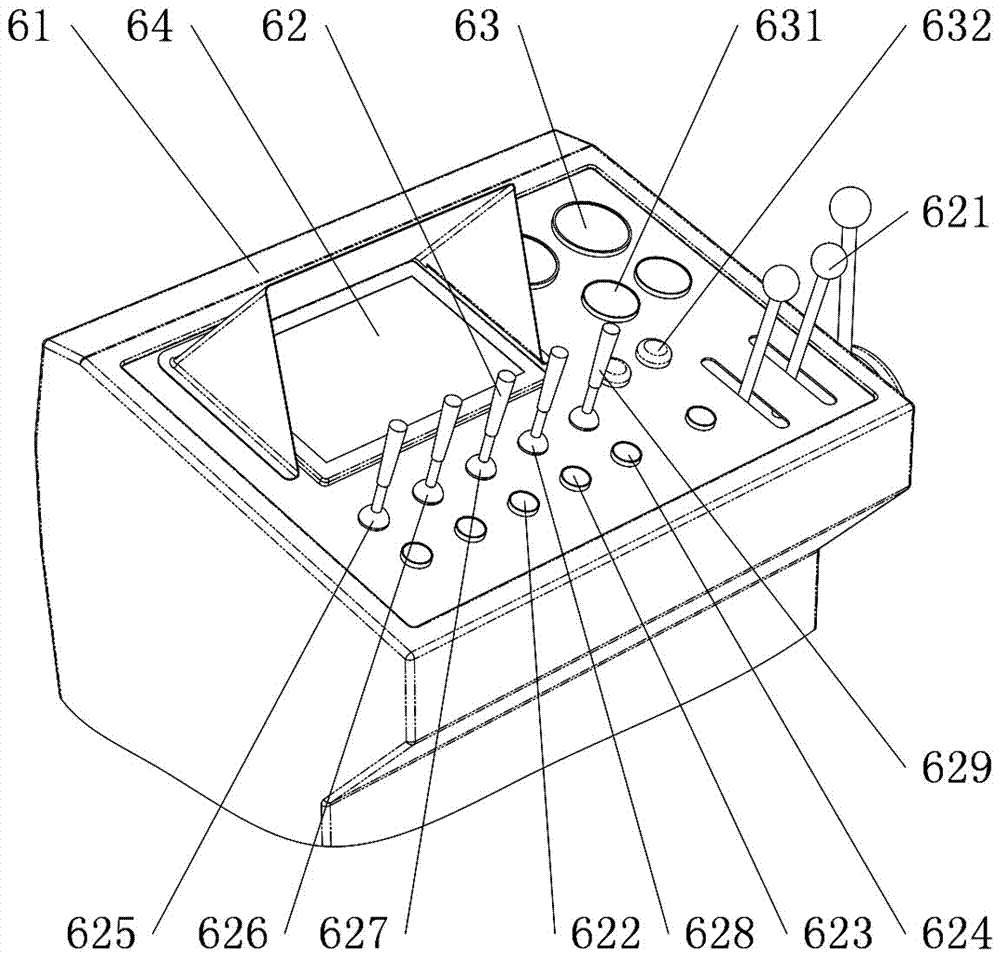

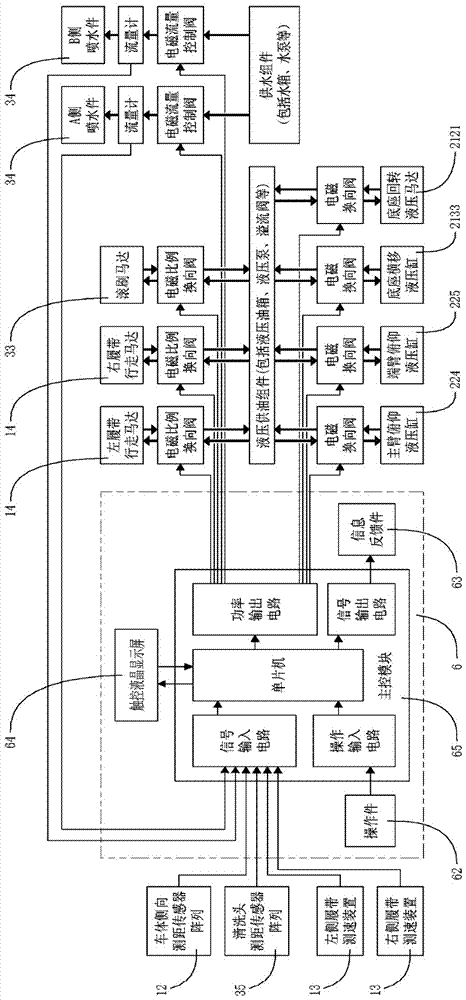

The invention discloses a photovoltaic array washing vehicle. The photovoltaic array washing vehicle comprises a proceeding chassis, a washing head supporting and positioning unit, a washing head unit, a water supply unit, an operation control unit and a vehicle body pose information collection device used for obtaining pose information of a vehicle body relative to the photovoltaic array, wherein a motion control component of a proceeding chassis steering system driving part is controlled by a main control module of the operation control unit; the washing head supporting and positioning unit comprises a movable base located at the head of the vehicle and a working arm set mounted on the movable base; the movable base comprises a rotation device and a transverse moving device; the working arm group comprises a main arm and an end arm capable of respectively pitching; the washing head unit comprises a washing brush, a water spraying part and a distance measuring sensor used for measuring the surface position and pose of a photovoltaic array board relative to the washing head unit; the main control module of the operation control unit takes a computer as the core of control. The invention also provides a method for washing the photovoltaic array by using the washing vehicle. The washing process is intelligent, efficient, flexible and safe, and is simple to operate, excellent in washing effect and low in usage cost.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

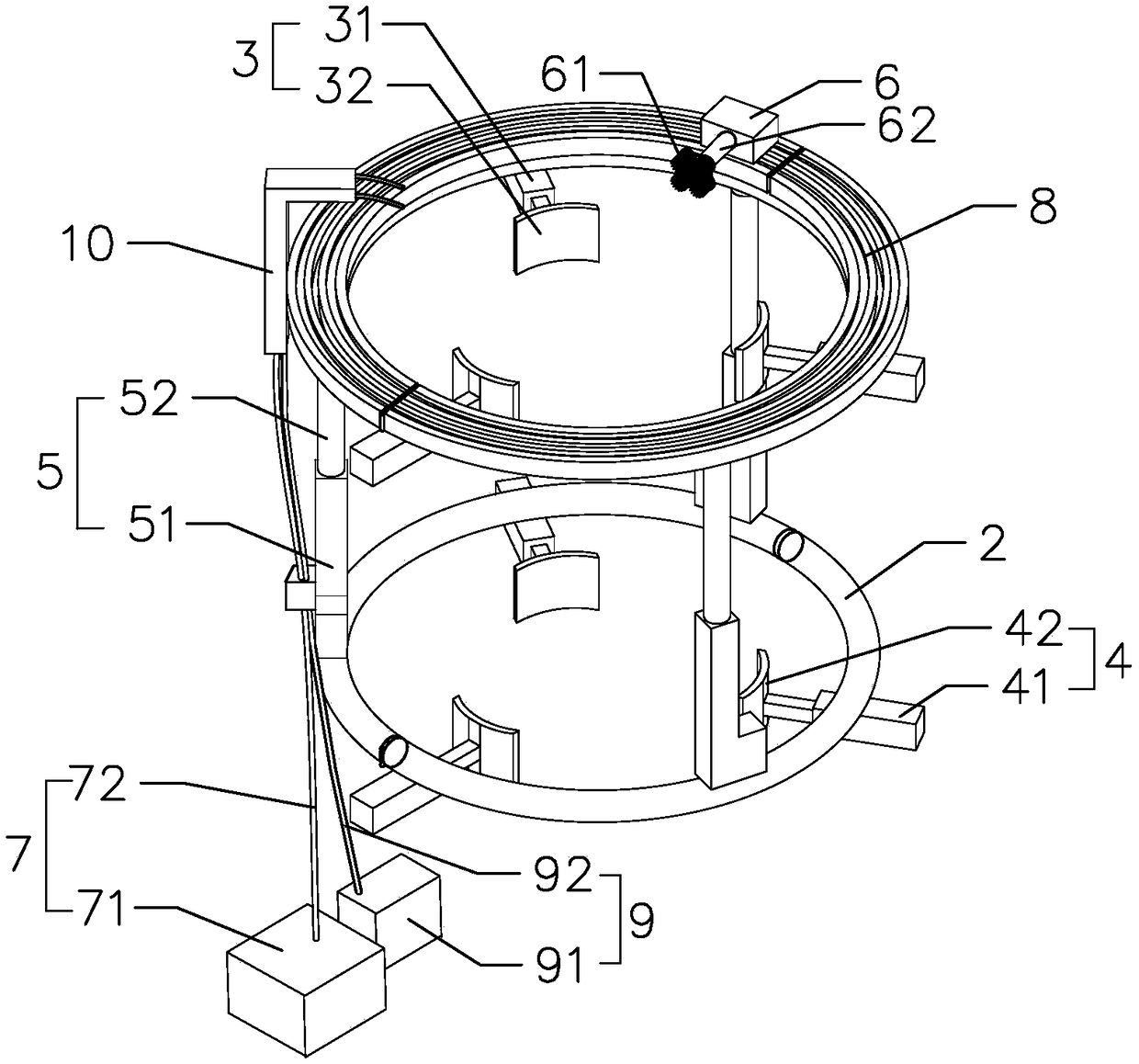

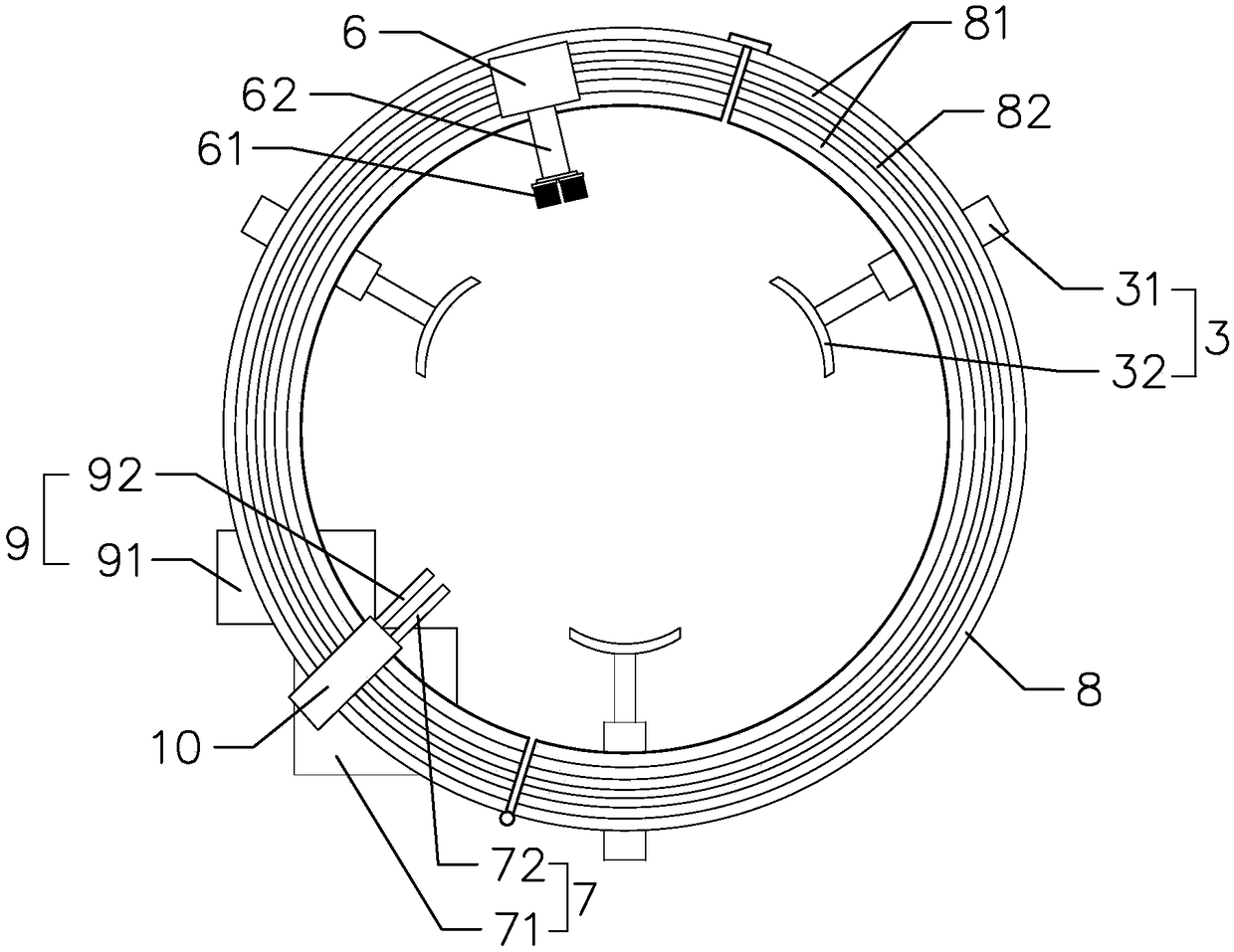

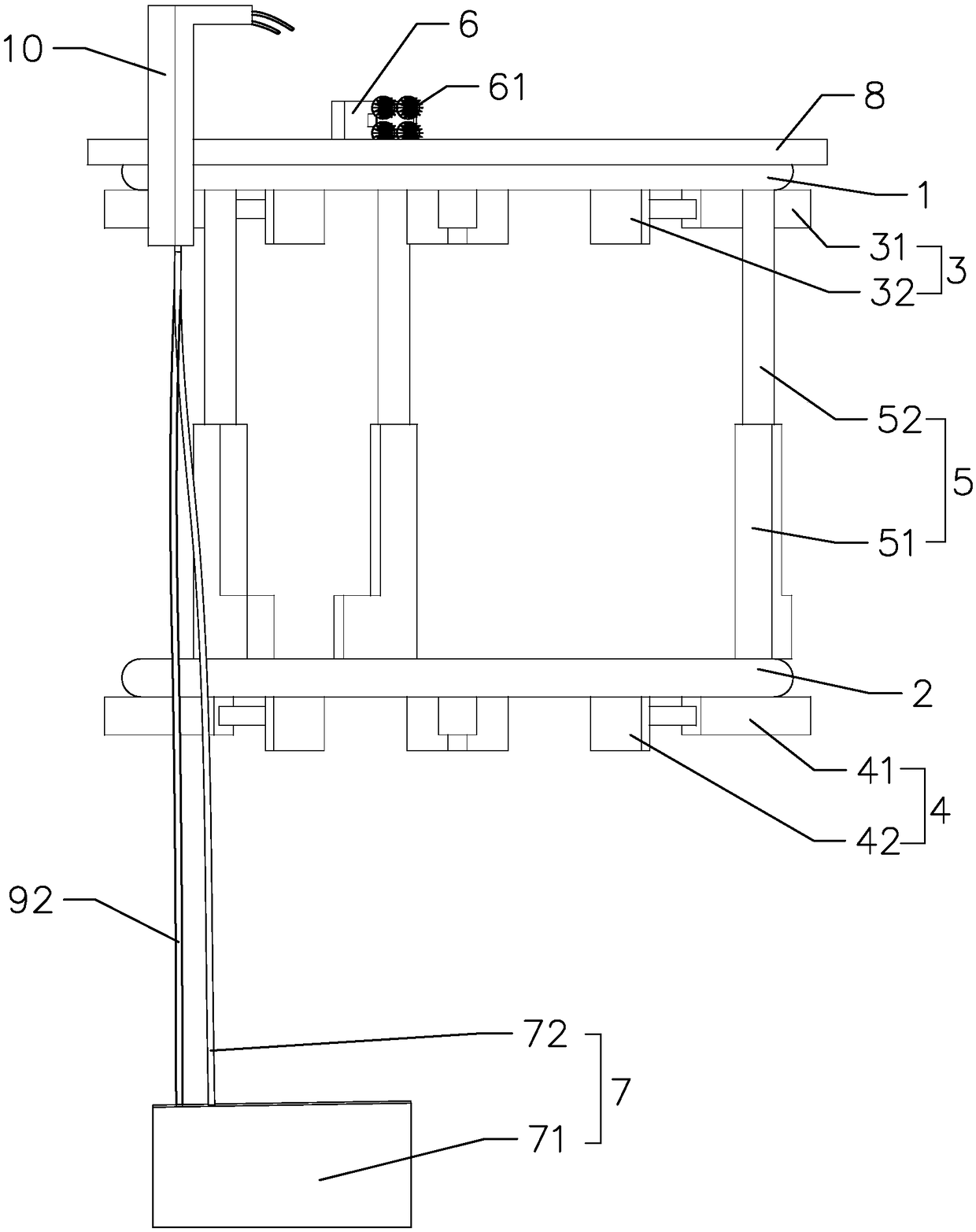

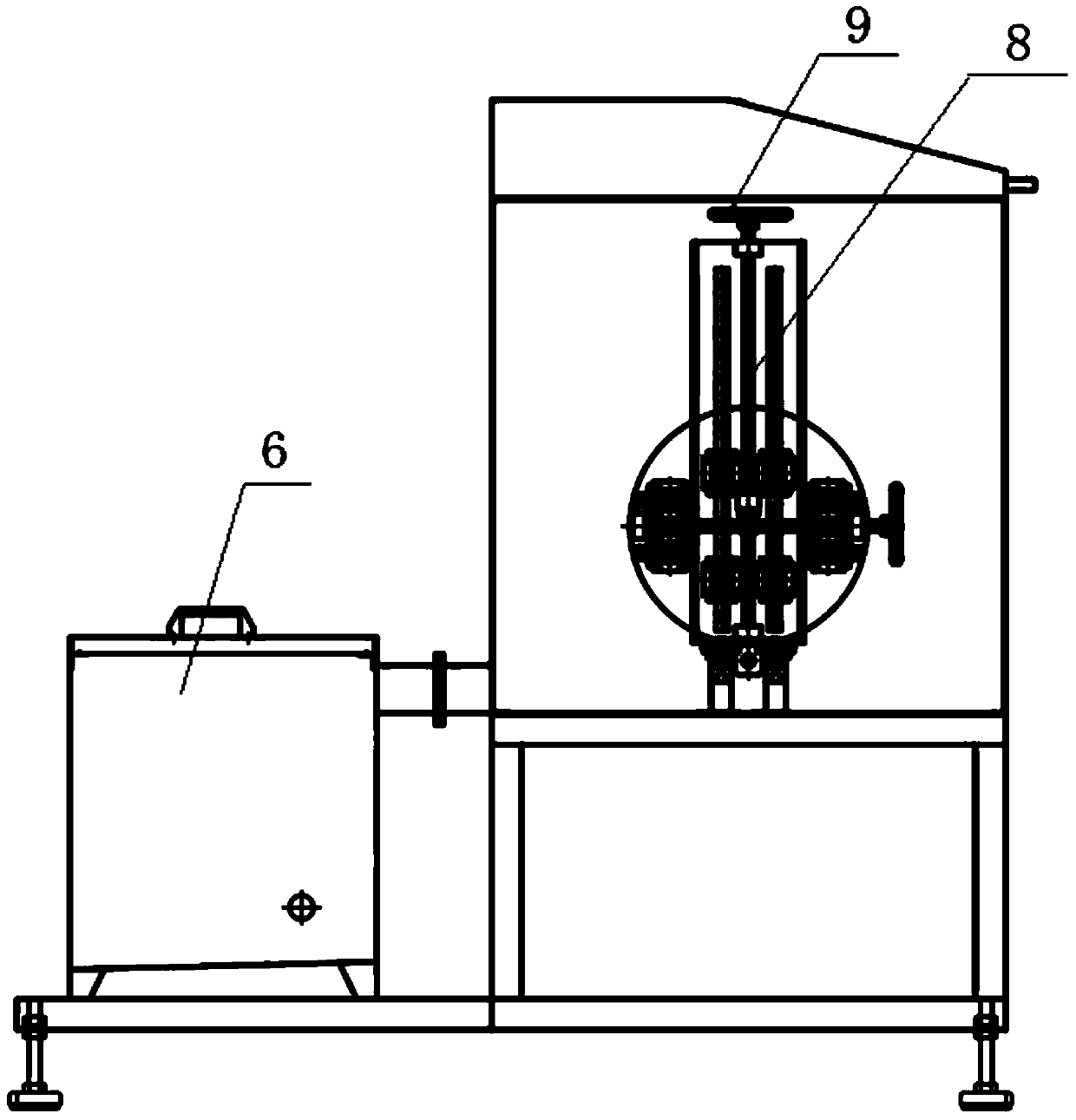

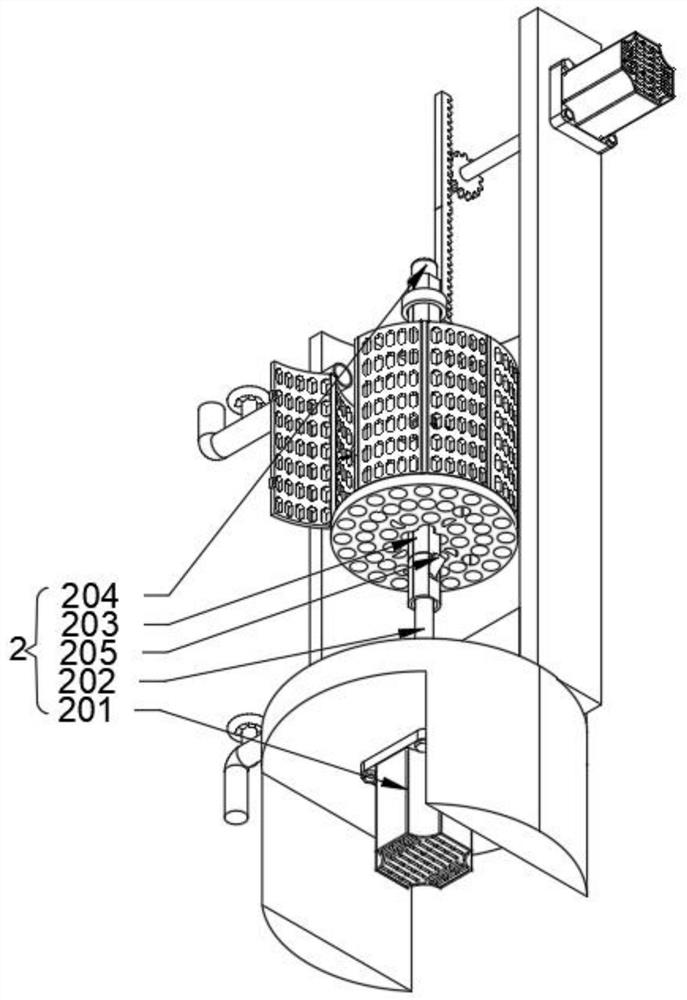

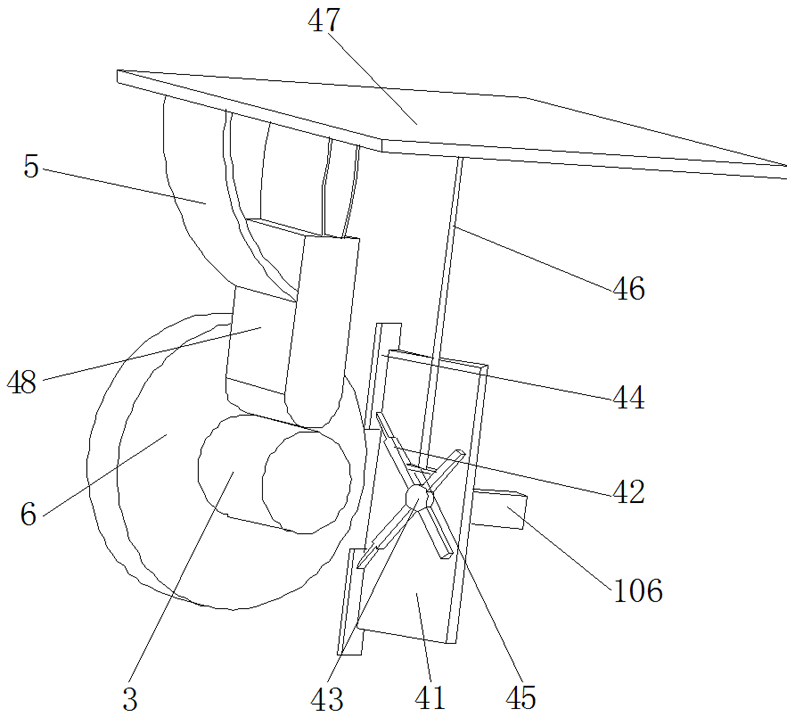

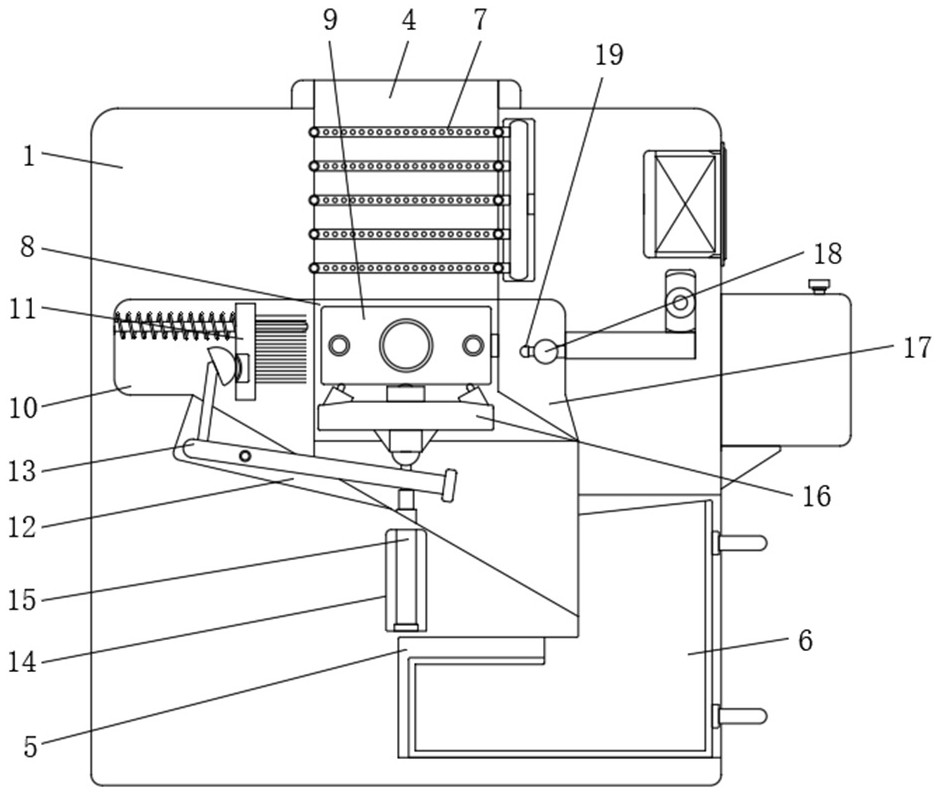

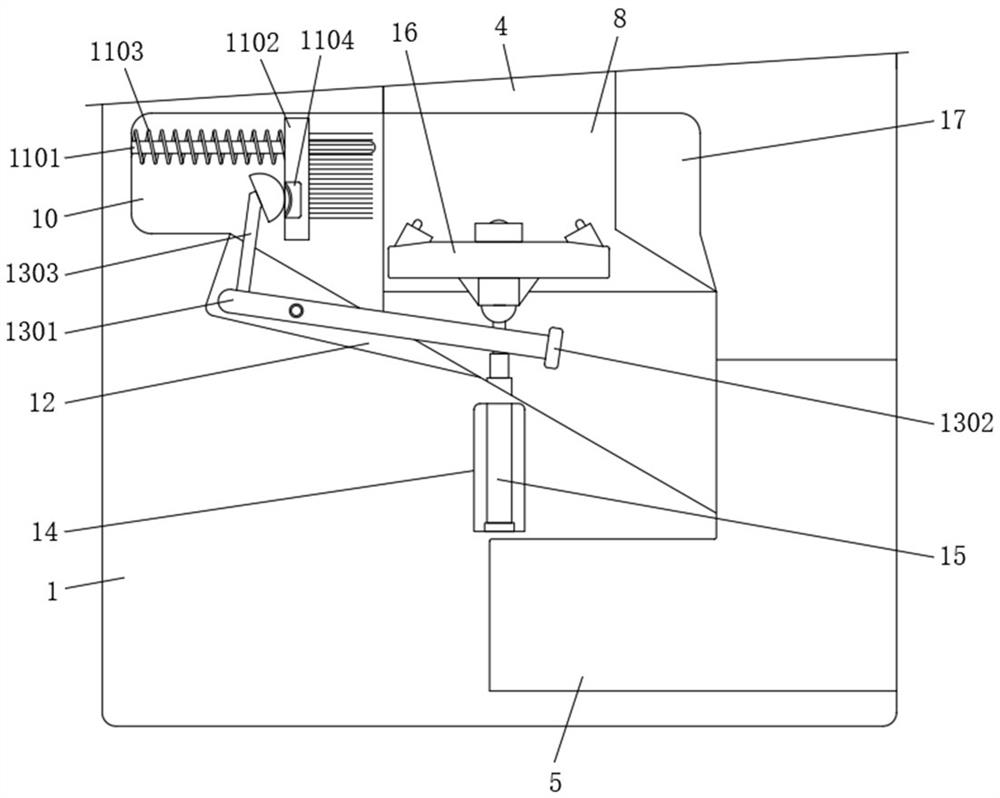

Integrated sweeping device for supporting insulator of transformer substation

InactiveCN109365365AEasy to disassemble and operateEfficient cleaning operationsDrying gas arrangementsCleaning using toolsTransformerEngineering

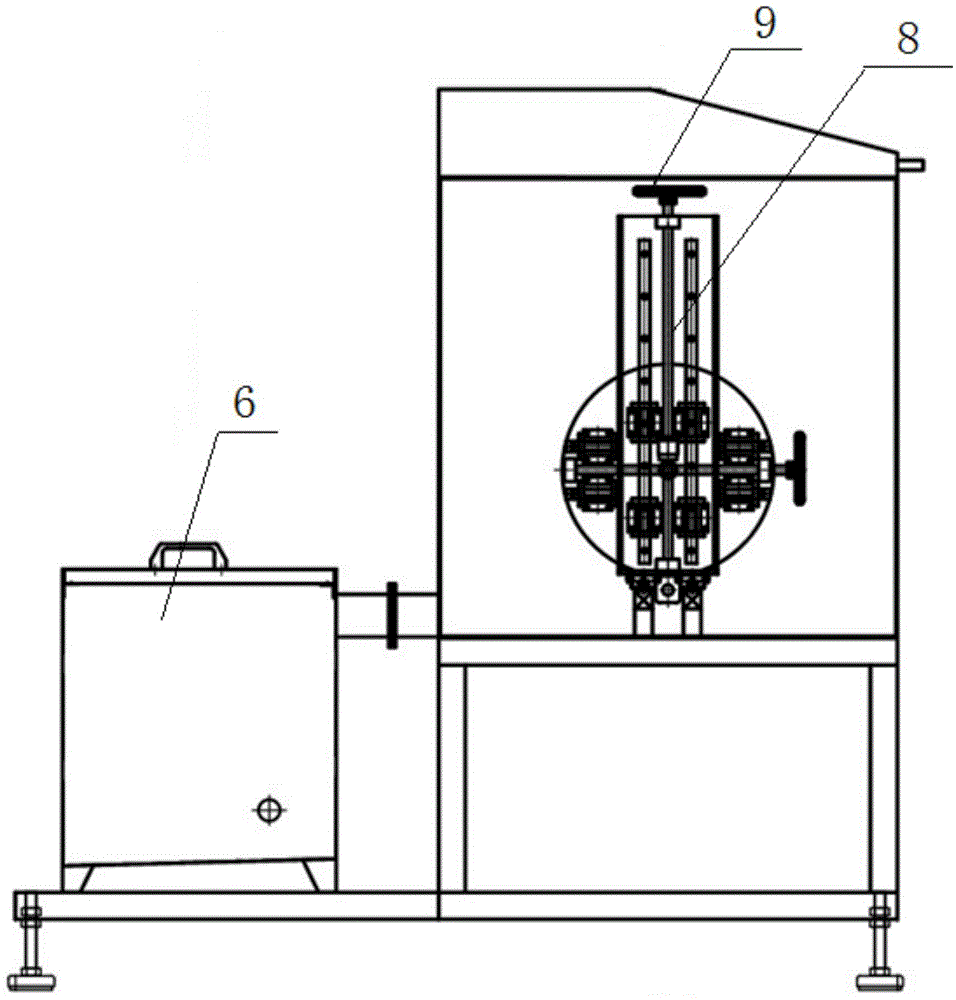

The invention provides an integrated sweeping device for a supporting insulator of a transformer substation. The integrated sweeping device comprises a clamping mechanism, a vertical telescopic mechanism and a sweeping mechanism, wherein the clamping mechanism comprises an upper embracing arm, a lower embracing arm and a clamping piece, the clamping piece comprises a first clamping piece and a second clamping piece, the first clamping piece is arranged on the upper s embracing arm, and the second clamping piece is arranged on the lower embracing arm; the vertical telescopic mechanism compriseselectric push rods which are connected with the upper embracing arm and the lower embracing arm, the sweeping mechanism comprises a brush, an air blowing device and a spraying device, an annular guide rail is arranged at the upper end of the upper embracing arm, an electric vehicle is arranged on the annular guide rail, and the brush is arranged on the electric vehicle; and the air blowing devicecomprises a fan and an air pipe, the spraying device comprises a water tank and a water pipe, and the outlet of the air pipe and the outlet of the water pipe are both fixed above the annular guide rail. By integrating the brush, the air blowing device and the spraying device on one device, the device can realize sweeping, soot blowing, liquid spraying and blow-drying functions only by using the device, and the cleaning operation of the supporting insulator of the transformer substation is simpler and more efficient.

Owner:宁波恒晨电力建设有限公司 +2

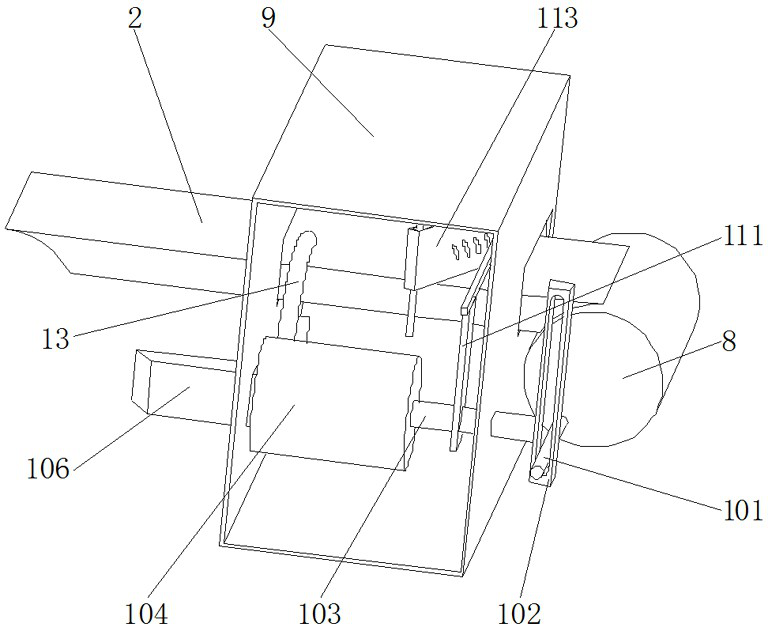

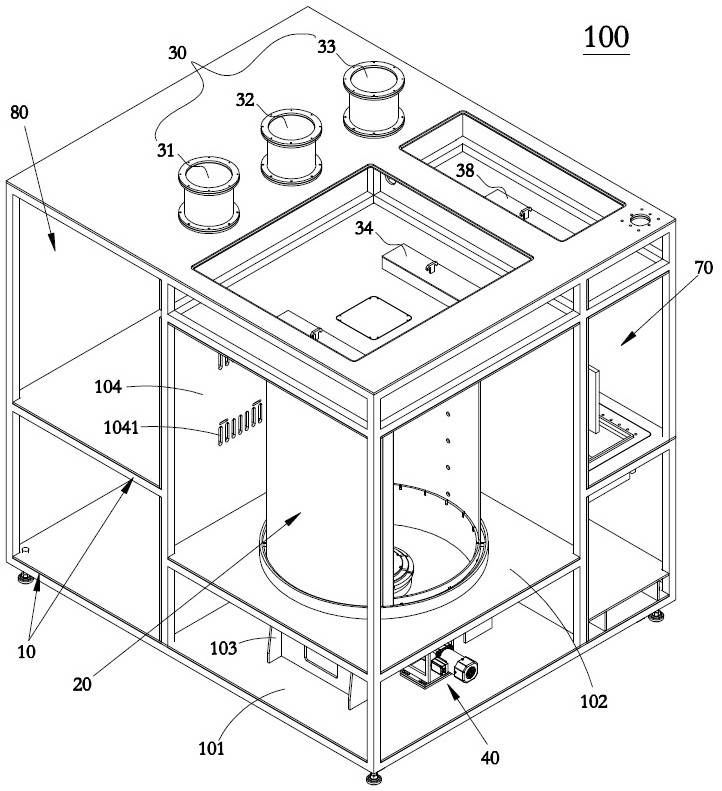

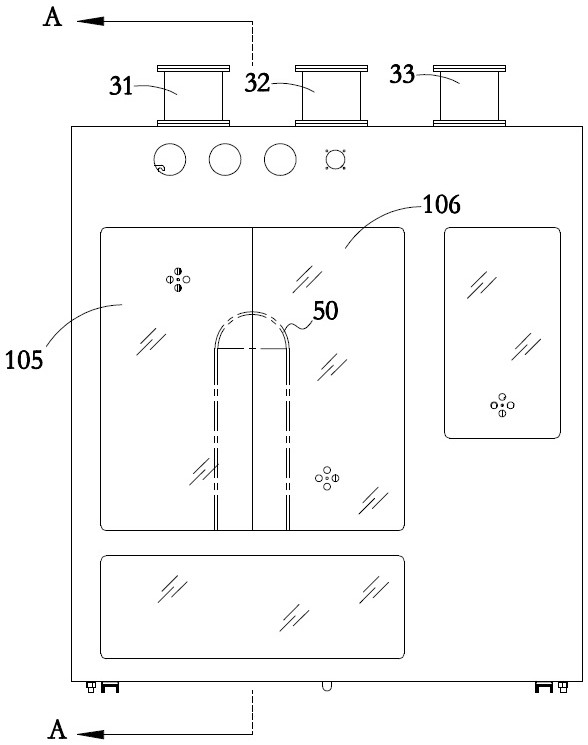

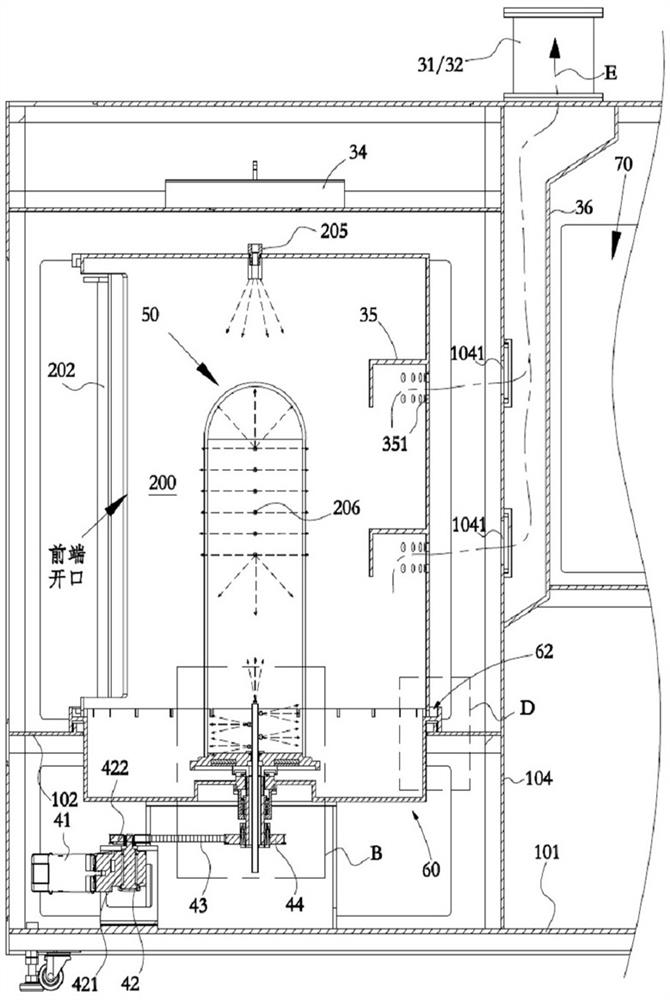

Quartz tube cleaning device and cleaning method

ActiveCN113500070AEfficient cleaning operationsSimple structureHollow article cleaningDrying gas arrangementsPhysical chemistryEngineering

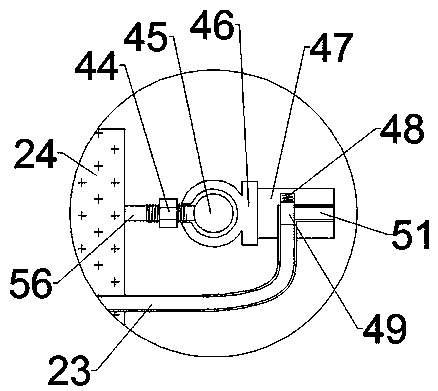

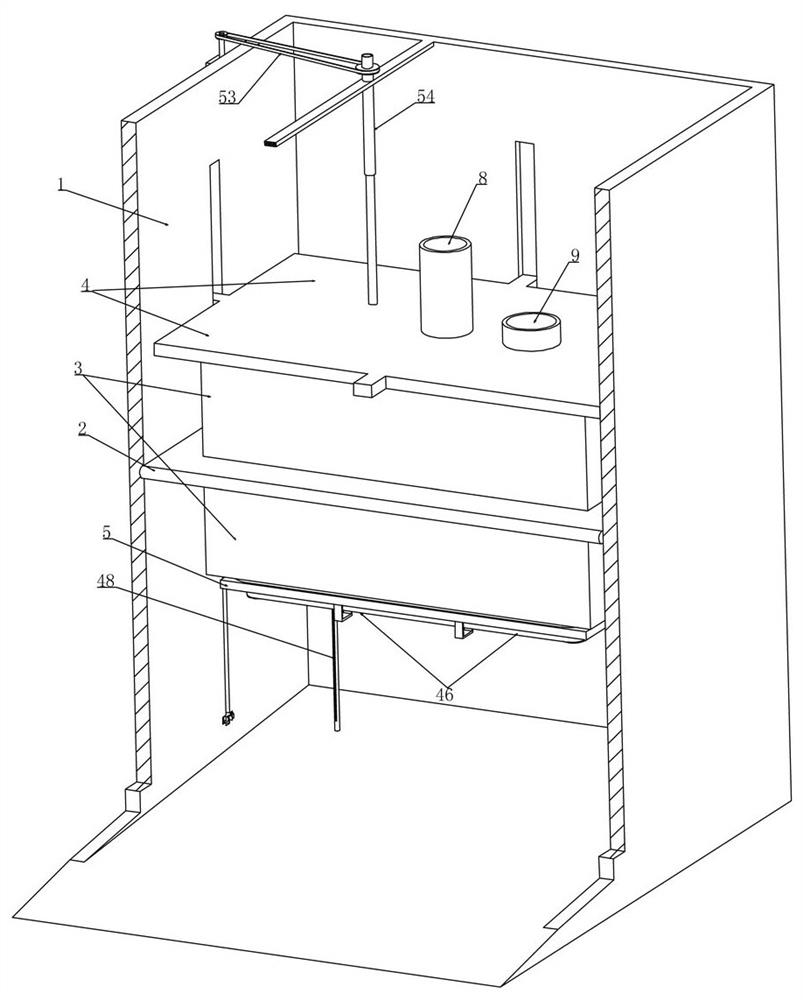

The invention provides a quartz tube cleaning device and cleaning method. The quartz tube cleaning device comprises a cleaning cover with an opening in the bottom, a base movably assembled with the cleaning cover in an inserted mode in the vertical direction, a bearing table arranged in the base and hooping a quartz tube, and a driving device. A first nozzle is arranged at the top of the cleaning cover, a plurality of second nozzles are vertically arranged on the side wall of the cleaning cover, an inner spray pipe is vertically arranged on the bearing table, and a plurality of third nozzles are arranged at the top and the side of the inner spray pipe above the bearing table; a rotary sealing device is embedded in the base, and the inner spray pipe continuously penetrates through the bearing table and the rotary sealing device in the vertical direction; the driving device drives the bearing table to rotate, and the inner spraying pipe is kept static in the rotating process of the bearing table. By means of the quartz tube cleaning device, efficient cleaning operation on the quartz tubes of various sizes is achieved, the requirement for cleaning the quartz tubes of different diameters can be met, the structure of the quartz tube cleaning device is simplified, the service life is prolonged, and the quartz tubes are prevented from being damaged in the cleaning process.

Owner:ZHICHENG SEMICON EQUIP TECH (KUNSHAN) CO LTD

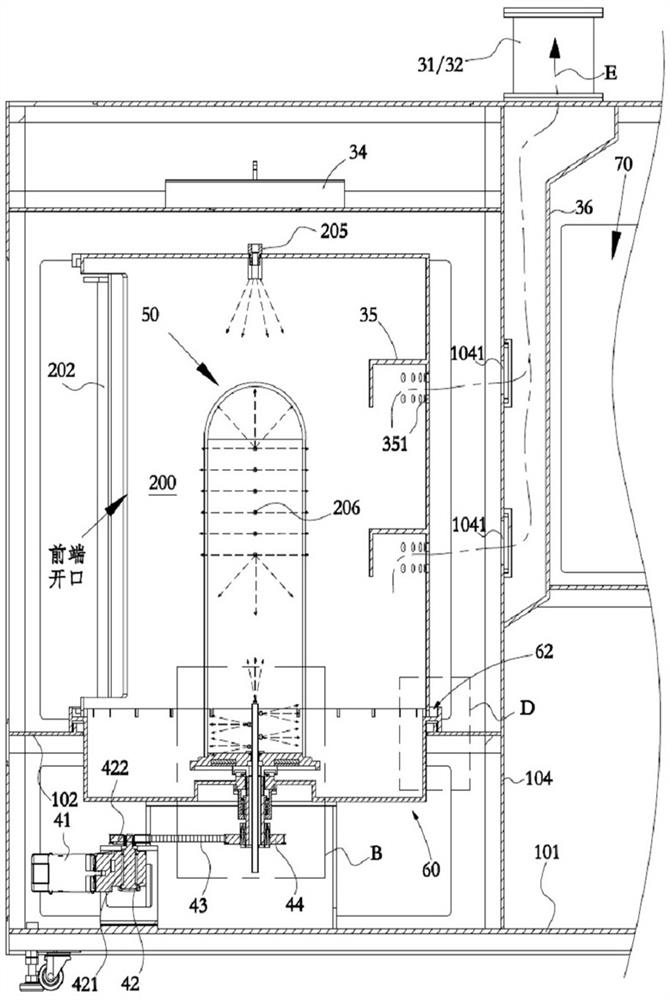

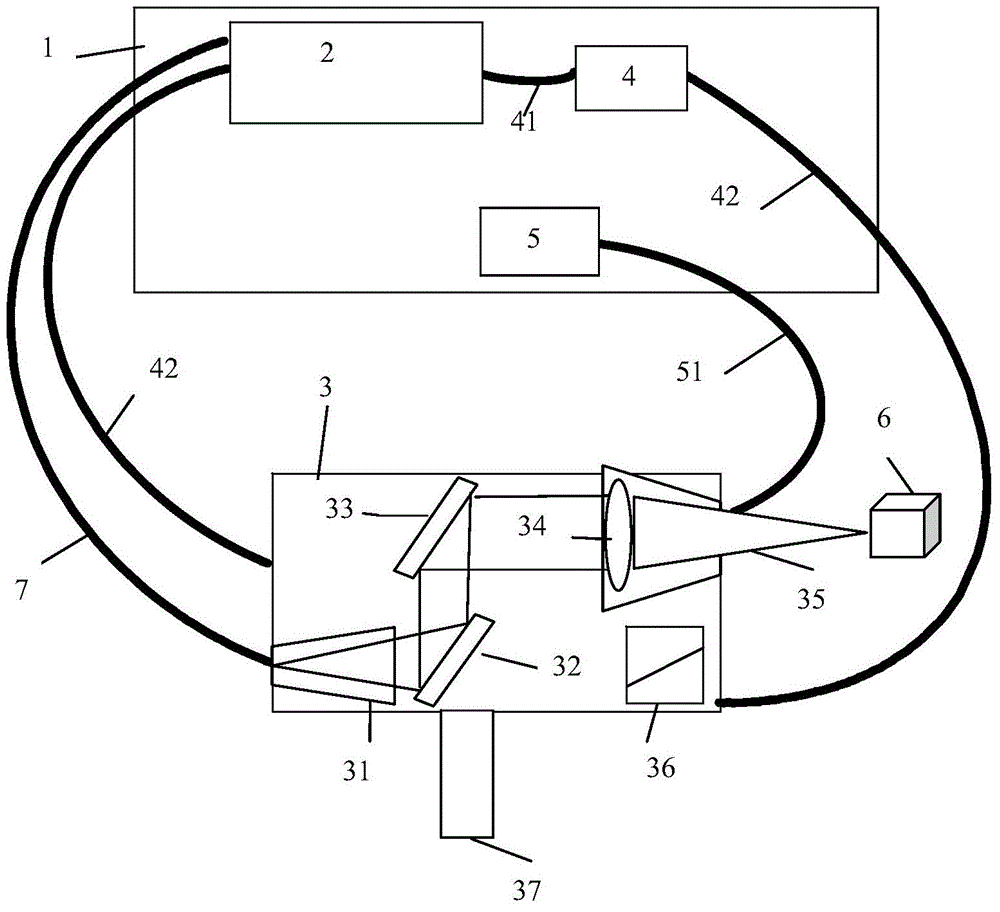

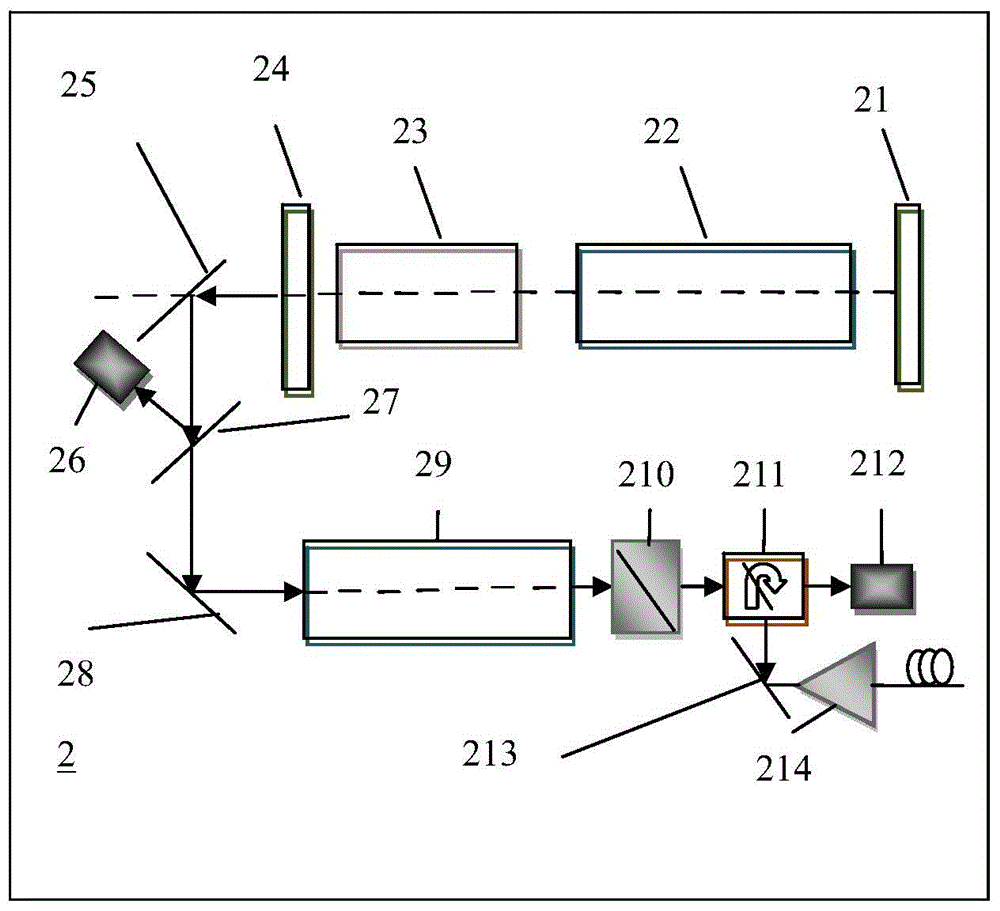

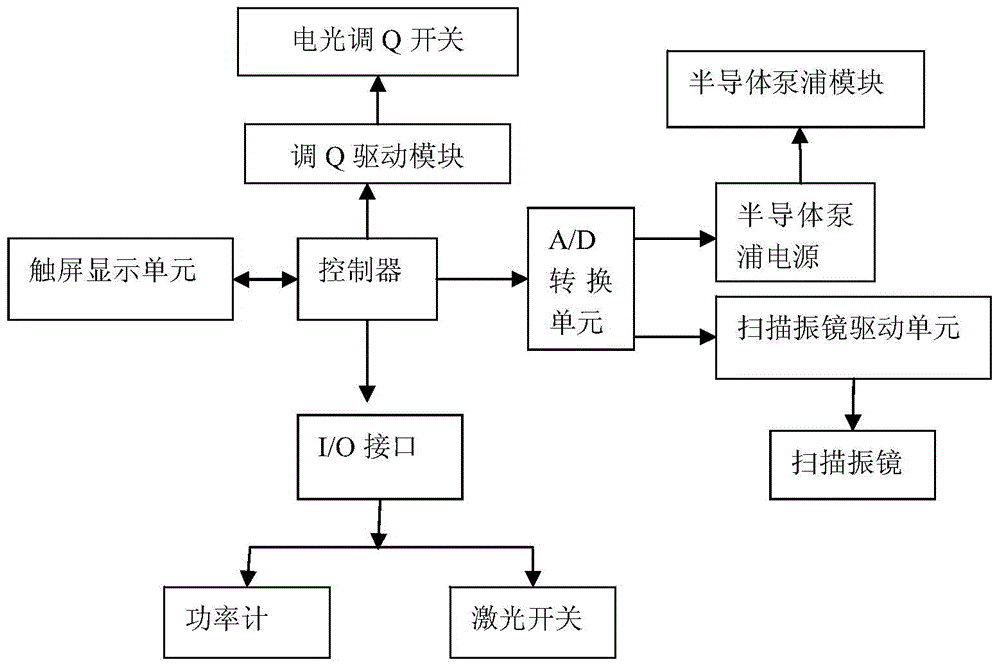

Airplane coated paint laser cleaning equipment

ActiveCN104438227AIncrease laser output powerImprove efficiencyDirt cleaningJet aeroplaneAutomatic control

The invention discloses airplane coated paint laser cleaning equipment which comprises a laser device 2 and a cleaning and processing head 3 connected with the laser device 2. A semiconductor pumping solid pulse laser device is adopted, and laser output power is improved by means of electro-optical modulation Q through an MOPA structure; optical fibers are coupled through a hollow cone, long-distance, large-range, long-time and stable cleaning is realized through optical fiber transmission, and no potential safety hazard is caused to an airplane body, so that cleaning cost is greatly lowered, pollution, of a paint stripper, to environment is reduced, and the airplane coated paint laser cleaning equipment can realize automatic control and is low in using cost and high in efficiency.

Owner:HIGO TECH (SUZHOU) CO LTD

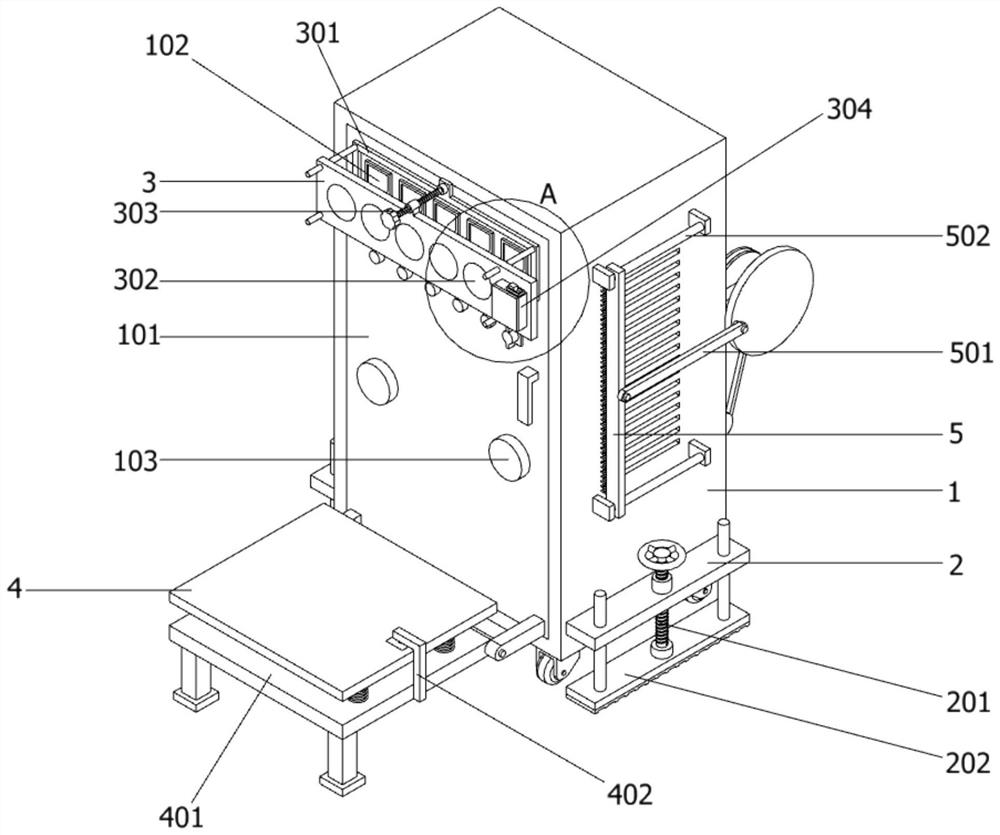

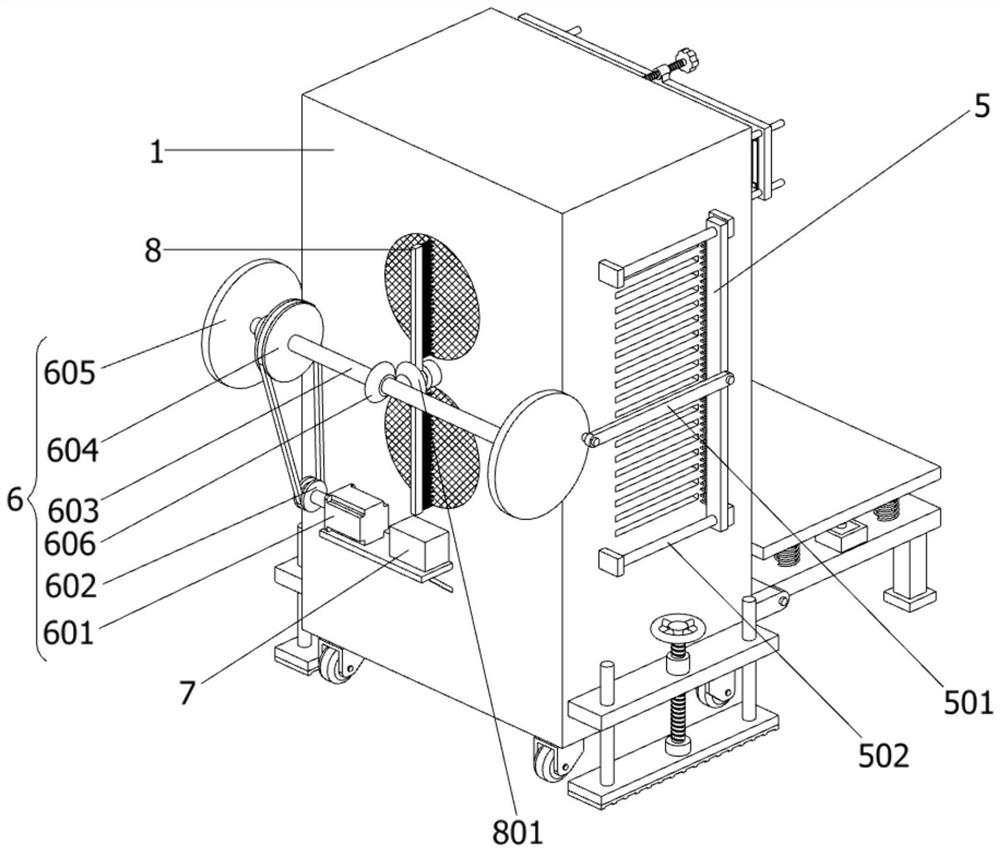

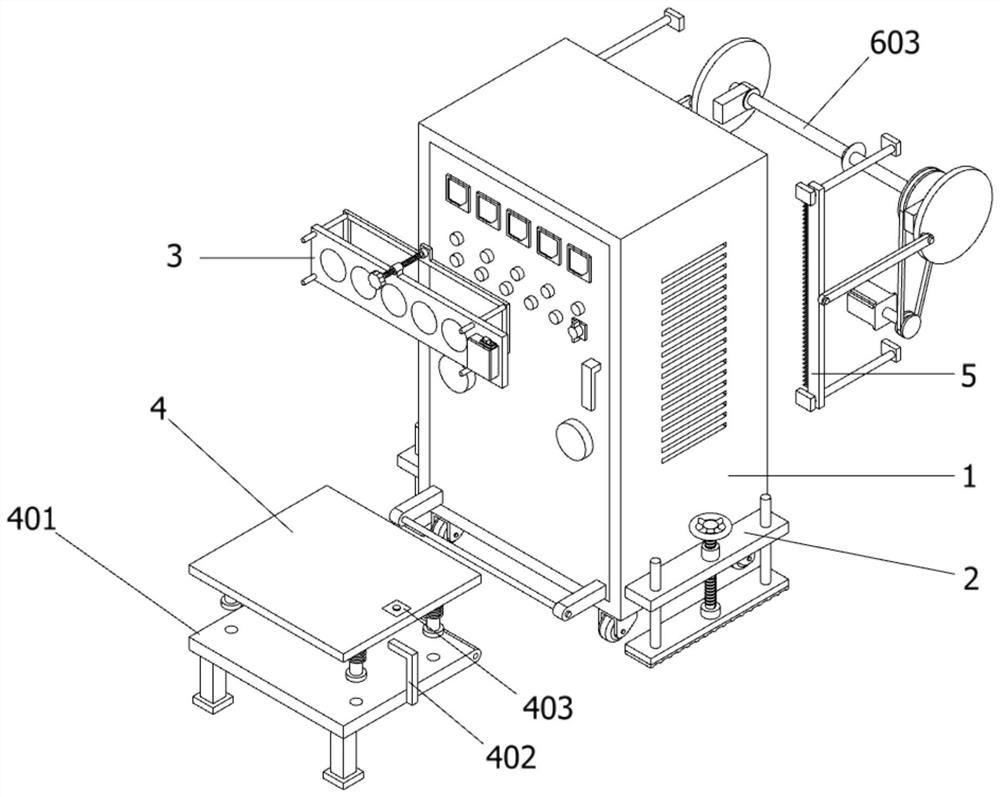

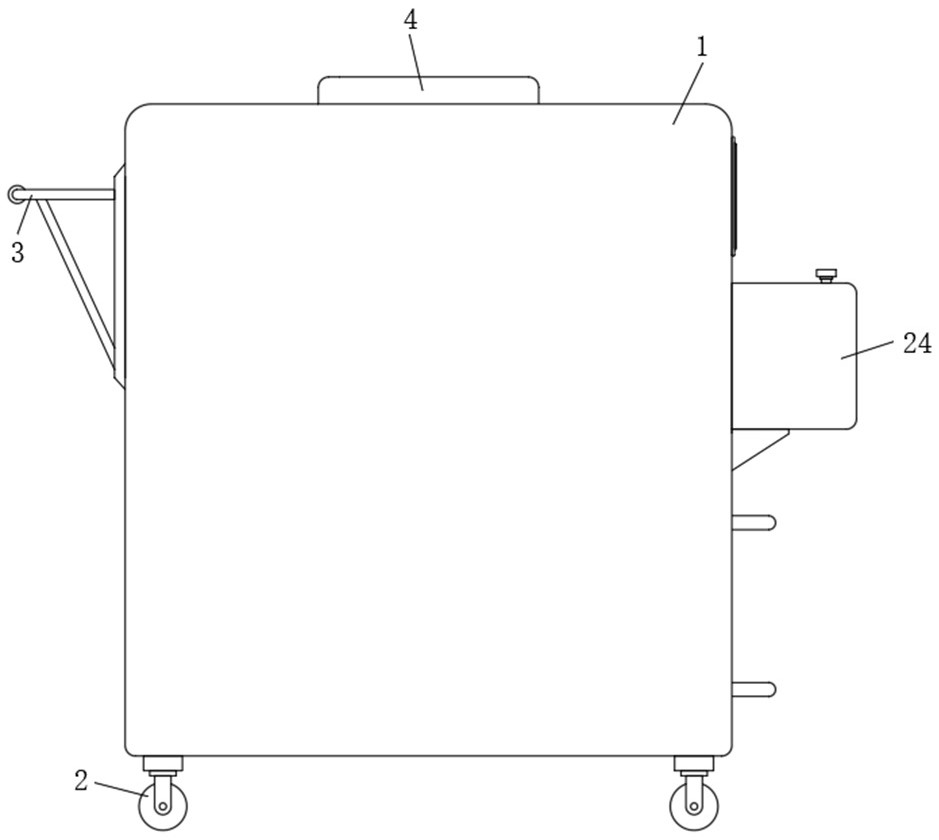

Electronic information technology anti-interference device convenient to move

InactiveCN112399753AEasy to cleanEfficient cleaning operationsElectric circuit arrangementsLighting elementsInterference resistanceElectric machinery

The invention provides an electronic information technology anti-interference device convenient to move, belongs to the technical field of anti-interference devices, and aims to solve the problem thatthe ventilation effect of an air inlet and an air outlet in the anti-interference device is reduced due to the lack of the effective automatic cleaning structures at the air inlet and the air outletin the outer wall of an existing anti-interference device. The device comprises a main body, and supporting mechanisms are fixedly and respectively connected to the lower portions of the left and right end faces of the main body. A pressing mechanism is treaded to move downwards under the action of gravity, so that a button on a starting switch is pressed, then a driving motor is started through acontroller, then a driving mechanism drives the two reciprocating cleaning pieces to reciprocate front and back, and then a first bevel gear drives a second bevel gear to rotate, therefore, a rotarycleaning piece drives a brush to rotate at a filter screen on the rear end face of a main body, impurities at the filter screen and on the rear end face of the main body are effectively cleaned, and the ventilation effect of the air inlet and the air outlet in the anti-interference device is improved.

Owner:宿州吾君信息服务有限公司

Reagent bottle cleaning method, reagent bottle reagent recycling method and reagent bottle cleaning system

InactiveCN107583925AEfficient removalEfficient cleaning operationsDispersed particle separationHollow article cleaningRecovery methodCondensation temperature

The invention relates to a reagent bottle cleaning method, a reagent bottle reagent recycling method and a reagent bottle cleaning system, and belongs to the technical field of container cleaning. Thereagent bottle cleaning method comprises the steps that a reagent bottle is subjected to reagent flushing and inert gas sweeping in sequence, and a cleaning operation can be conducted on the reagentbottle rapidly and efficiently. The invention further provides a reagent bottle reagent recycling method. The reagent bottle reagent recycling method comprises the steps that reagent flushing and inert gas sweeping are conducted on the reagent bottle in sequence, exhaust is obtained and collected, and then the reagent is subjected to condensation recycling, wherein the condensation temperature ranges from -10 DEG C to 0 DEG C. The reagent bottle which is practically used for repeated washing is obtained through the reagent bottle reagent recycling method; according to the method, operation iseasy, the cost is low, safety and high efficiency are achieved, and the problems that a traditional reagent bottle cleaning method is high in cost, high in pollution and unstable in reagent bottle cleaning quality can be avoided. The invention further provides the reagent bottle cleaning system.

Owner:HUBEI ENG UNIV

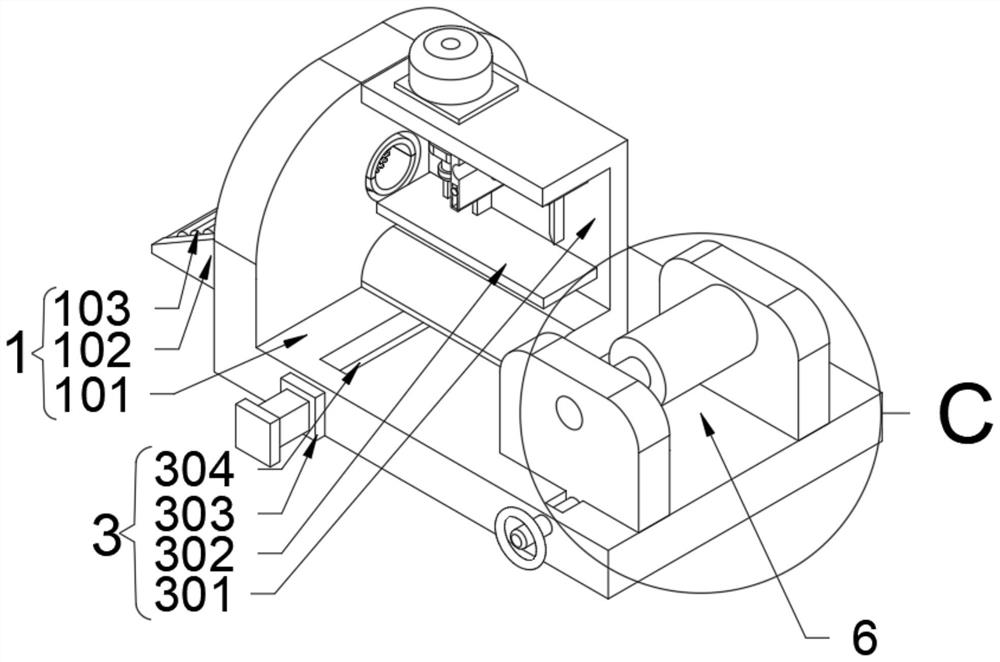

Walking and dredging mechanism device based on barrel-shaped pipeline dredging robot

InactiveCN111705913AEfficient cleaning operationsConvenient crushing operationSewer cleaningDomestic plumbingDrive wheelControl engineering

The invention discloses a walking and dredging mechanism device based on a barrel-shaped pipeline dredging robot, and relates to the field of cleaning robot devices. In the walking and dredging mechanism device, a fifth drive power device is mounted on the end side of a second telescopic connecting rod mechanism; a drive wheel is mounted on the fifth drive power device; a walking wheel structure is mounted on the end side of a third telescopic connecting rod mechanism; multiple fourth rotating power devices are fixedly mounted at the open position of the end side of a crushing inner guide cavity; and an external connection flow baffle structure is connected to an output shaft of each fourth rotating power device. Multiple stirring blades are driven through a first rotating power device tocarry out sediment crushing operation from outside to inside, and clearing operation is efficiently carried out on blocked pipelines; and the drive wheel structure is arranged on the dredging robot, the corresponding walking wheel structure is arranged, and therefore drive and walking wheel supporting and adjusting operation can be carried out according to pipe diameters of pipelines, and power isprovided for advancing and retreating operation of the dredging robot.

Owner:泉州台商投资区钗旺机械设备设计室

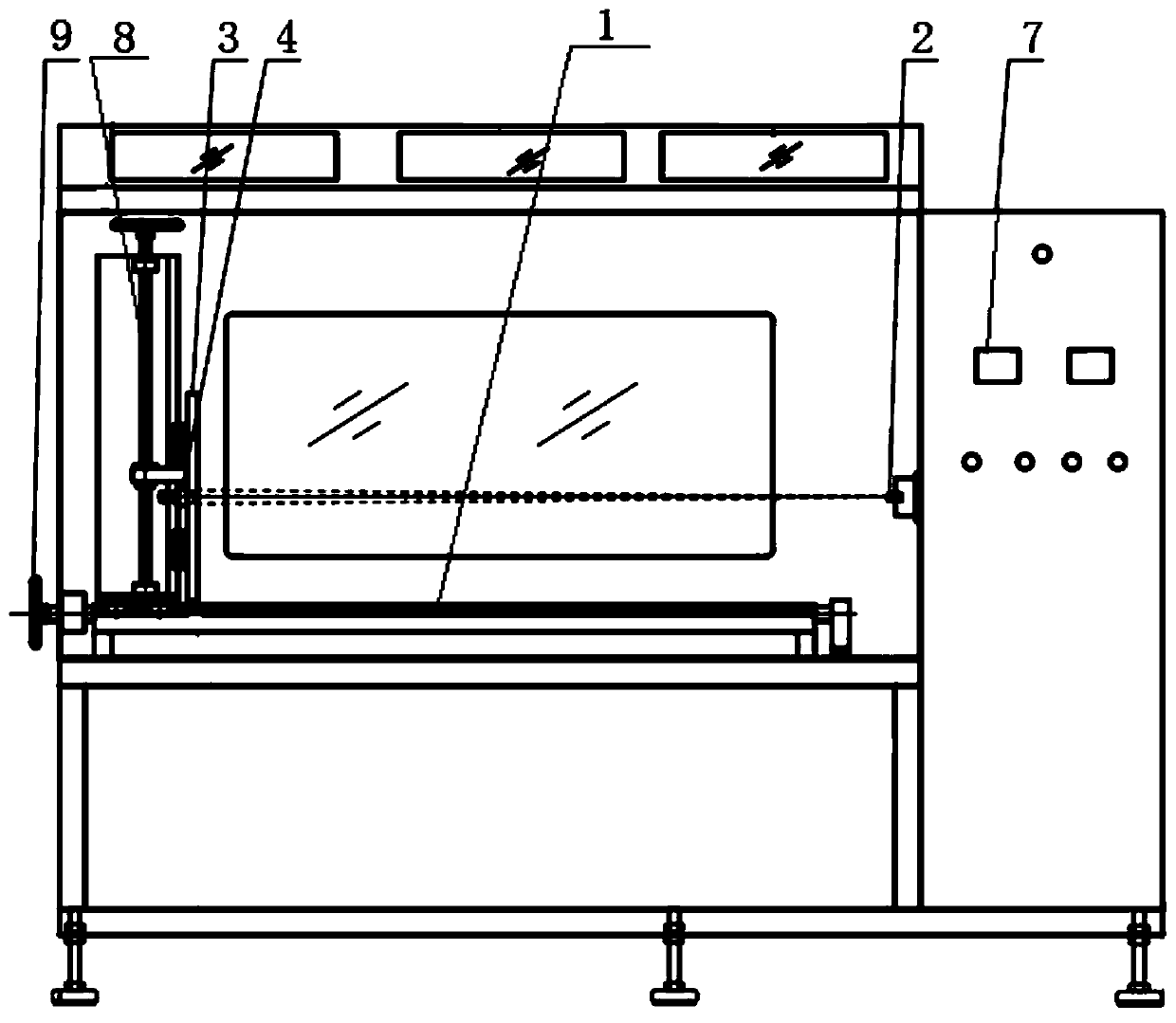

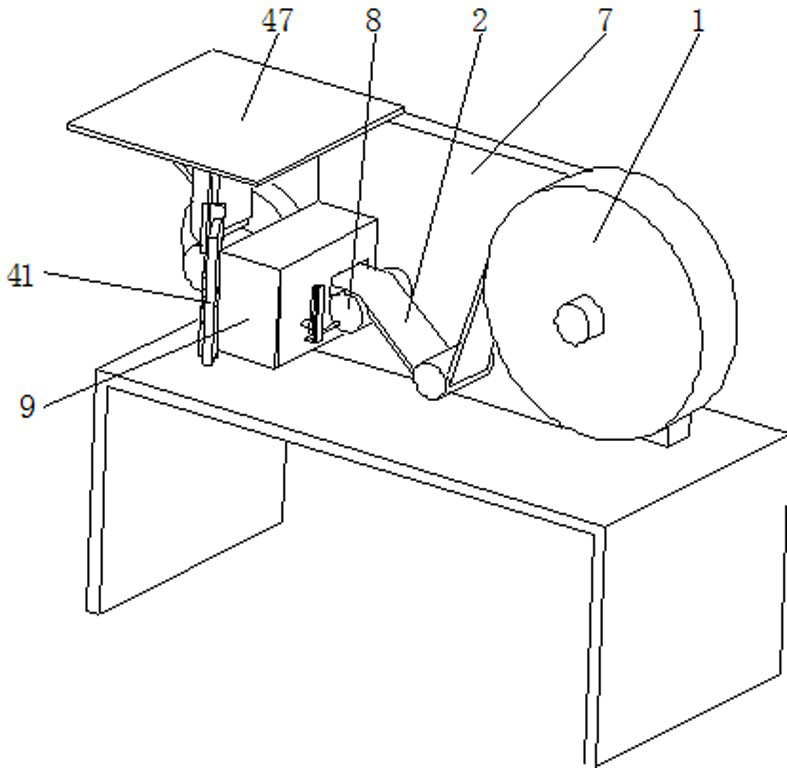

Special high-pressure water jet washing machine for industrial mechanical parts

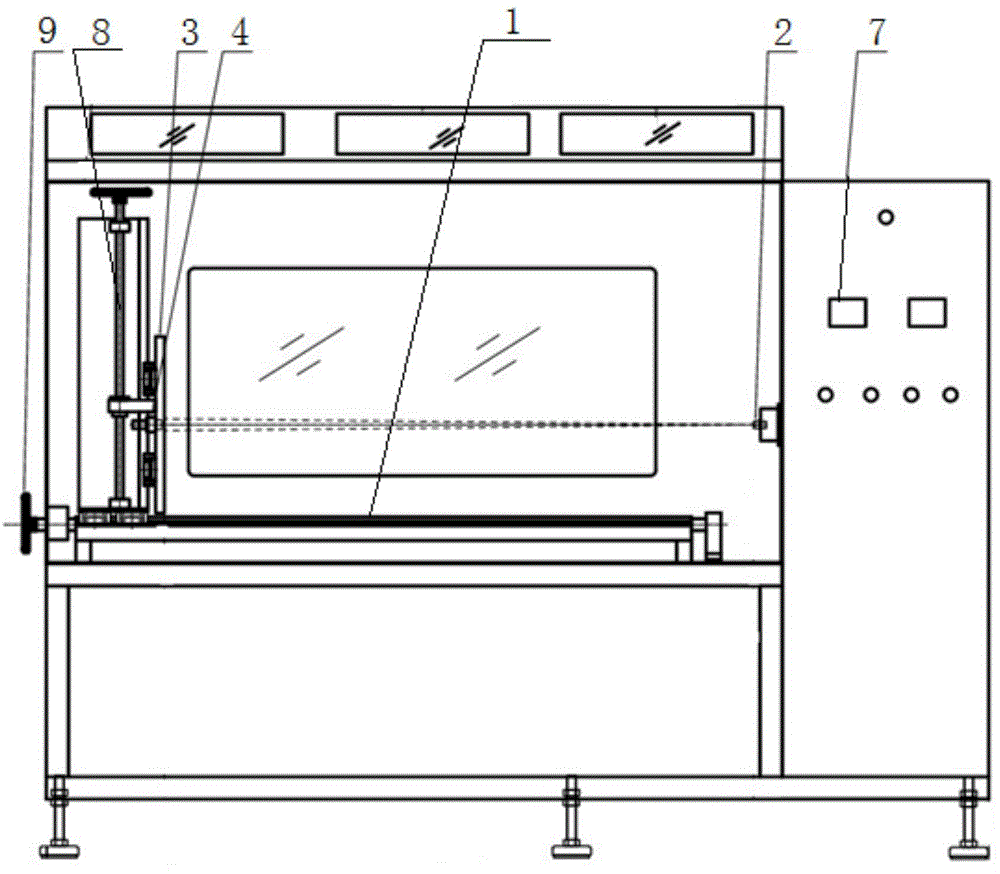

ActiveCN103752553AImprove cleaning efficiencyImprove cleaning qualityCleaning using liquidsSpray nozzleEngineering

The invention discloses a special high-pressure water jet washing machine for industrial mechanical parts. The high-pressure water jet washing machine comprises a washing platform, wherein a high-pressure nozzle is installed in one side face of the washing platform, a moving target surface device capable of moving vertically and horizontally and moving front and back is arranged on the other opposite side of the washing platform, the moving target surface device is provided with a pressure sensor capable of measuring water flow pressure and a clamping element capable of clamping the parts needing to be washed, the high-pressure nozzle is communicated with a high-pressure jet pump through a pipeline, the high-pressure jet pump pumps water in a water tank, a backflow pipe returning to the inside of the water tank is arranged on the lower portion of the washing platform, and the high-pressure jet pump is connected with control switches on one side of the washing platform through wires. The high-pressure water jet washing machine can remove dirt or rusting layers on the surfaces of the parts quickly and efficiently, washing cost can be effectively reduced, the washing speed and washing quality can be effectively improved.

Owner:SHANDONG UNIV

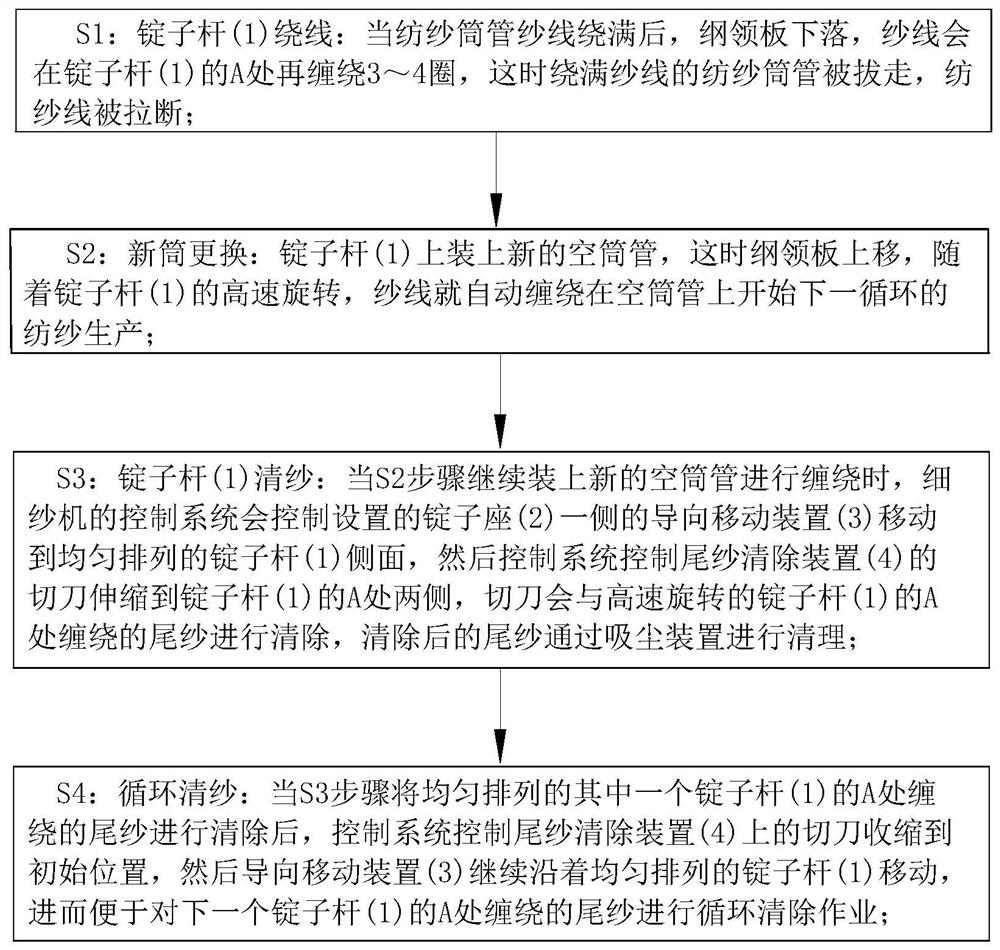

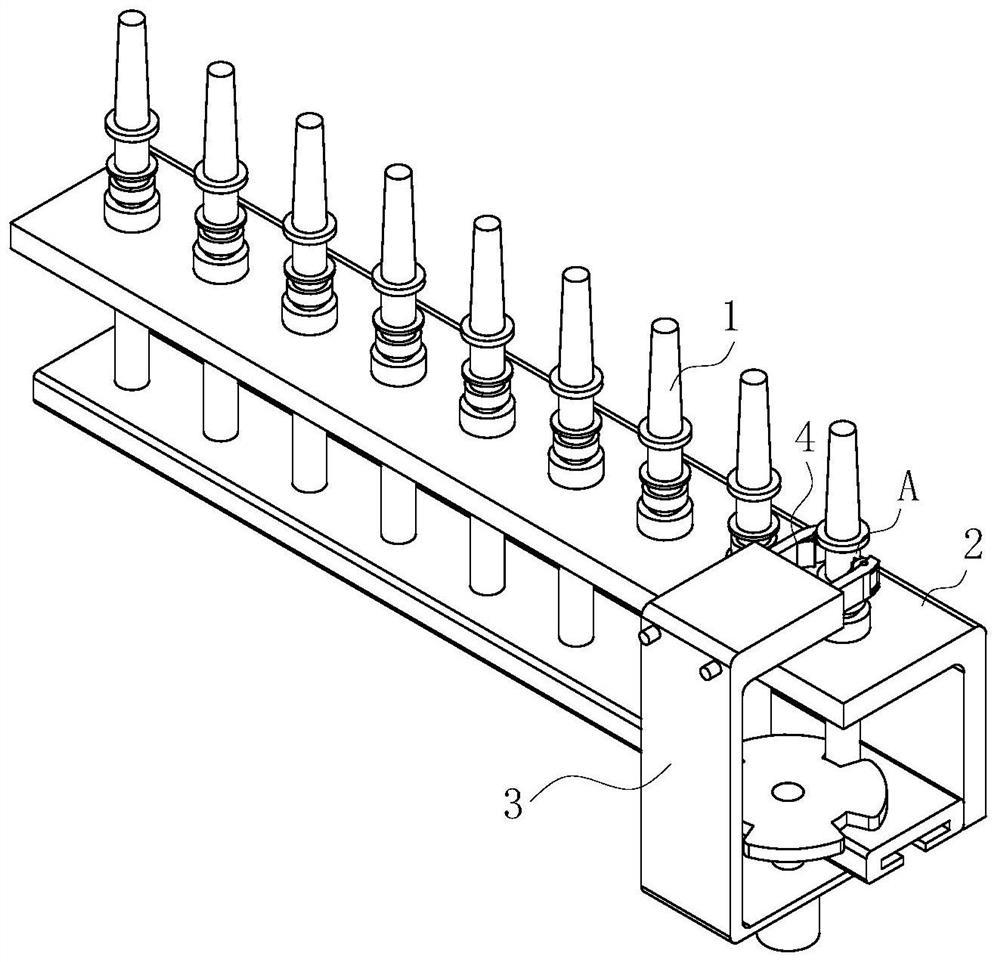

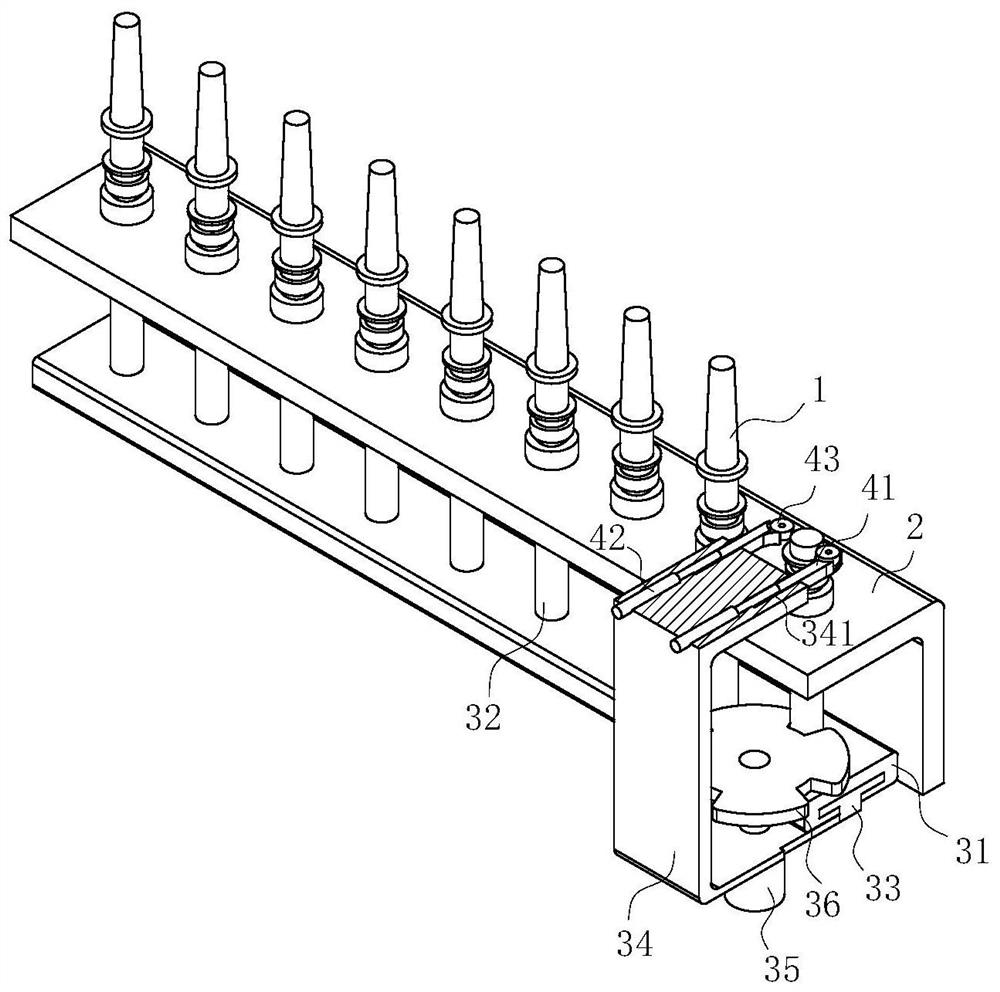

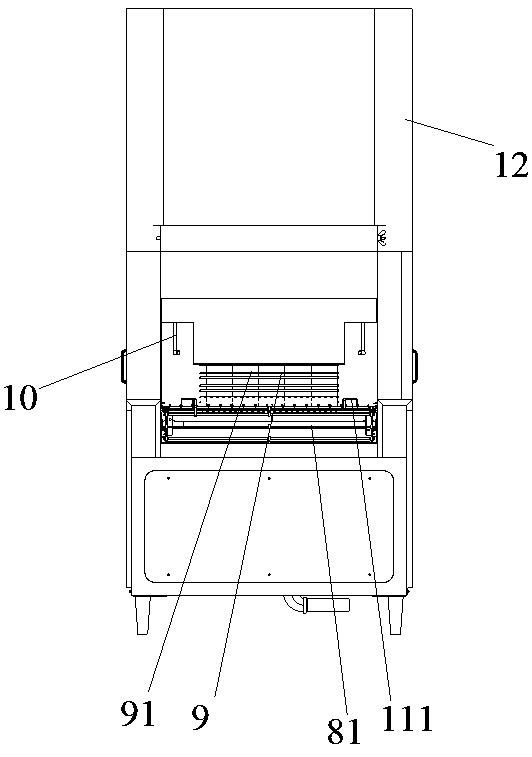

Automatic clearing method and automatic clearing device of spinning frame

PendingCN111850756AEfficient cleaning operationsSmall footprintTextiles and paperElectric machineryEngineering

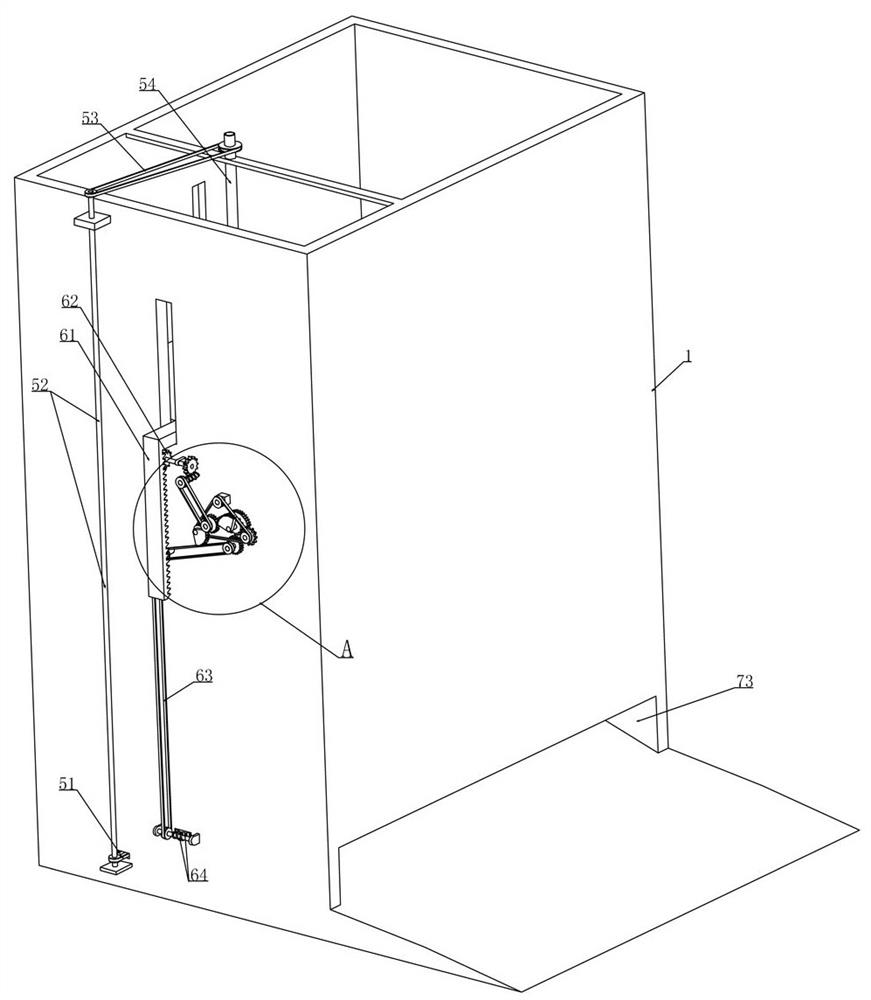

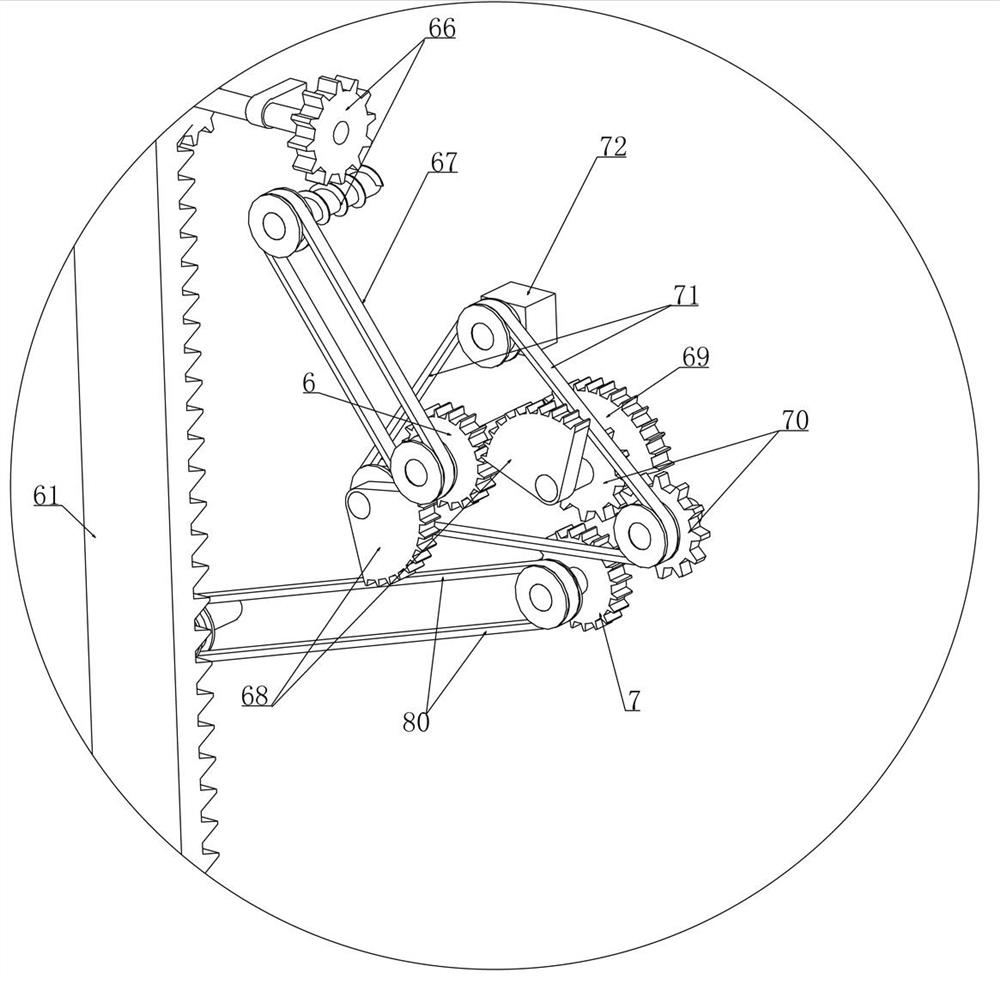

The invention belongs to the technical field of ring spinning, in particular to an automatic clearing method and an automatic clearing device of a spinning frame. Spindle connecting rods are evenly fixed to the upper end face of a guide sliding rail, and the spindle connecting rods are rotationally connected with the bottom ends of spindle rods. A sliding block is arranged inside the guide slidingrail in a sliding manner. An installation base is fixed to the side wall of the sliding block. A miniature motor is installed on the bottom end face of the installation base. A rotary wheel disk is in engagement with the spindle connecting rods which are evenly arranged. Sliding chambers are symmetrically formed in the upper-end side wall of the installation base. Sliding supporting strips are rotationally installed in the sliding chambers respectively. One end of each sliding supporting strip is connected to a telescopic end of an electric telescopic rod. Clearing barrels are fixed to the ends of the sliding supporting strips which are arranged in the shape of arcs through fixing columns. A cutter is fixedly arranged on the side wall of each clearing barrel. The automatic clearing devicecan carry out stable and efficient clearing operation on the spindle rods which are evenly arranged; and because a guide movement device is arranged on the side face of a spindle base, the space occupied by the automatic clearing device is reduced.

Owner:ANQING NORMAL UNIV

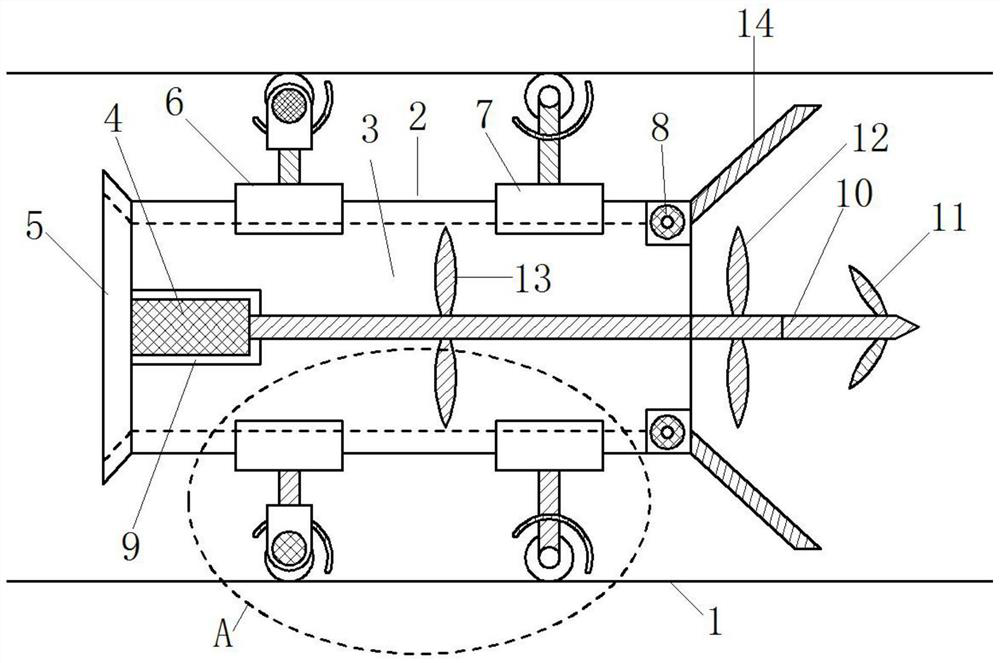

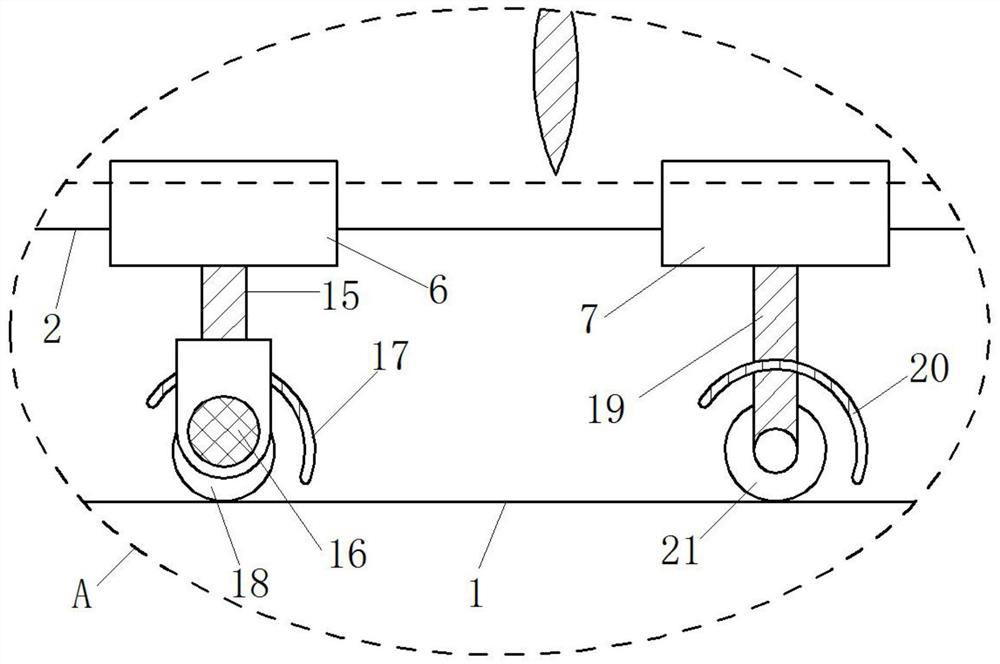

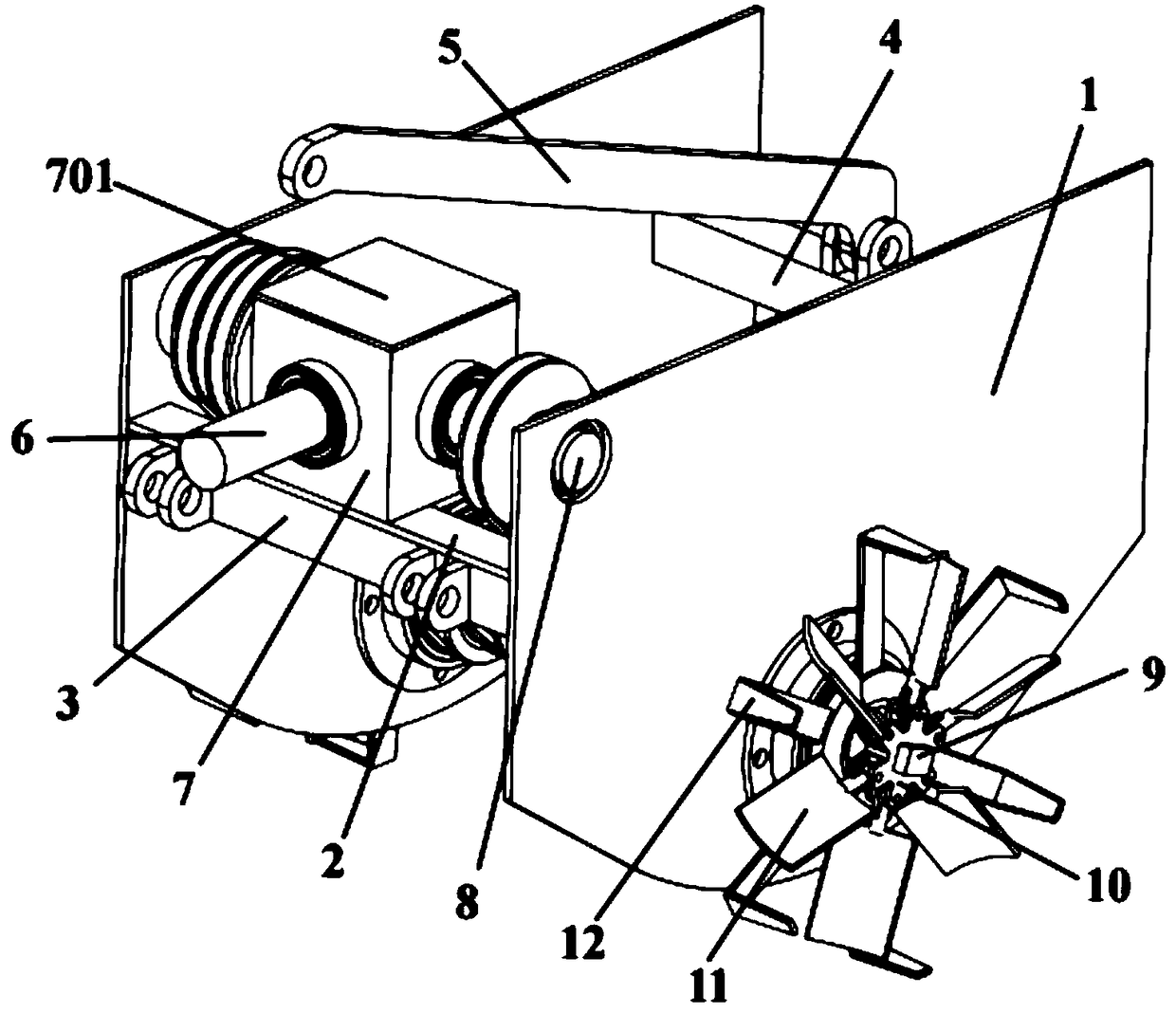

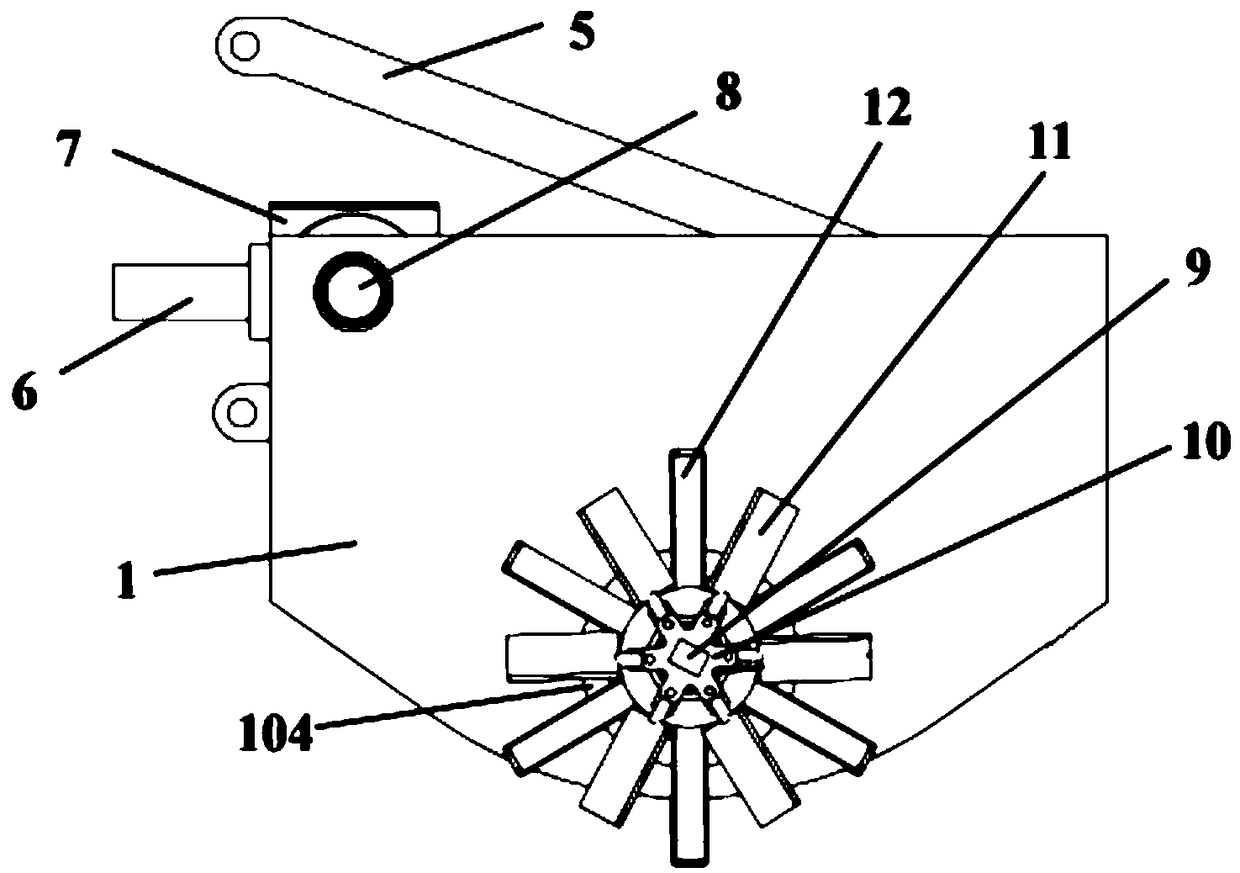

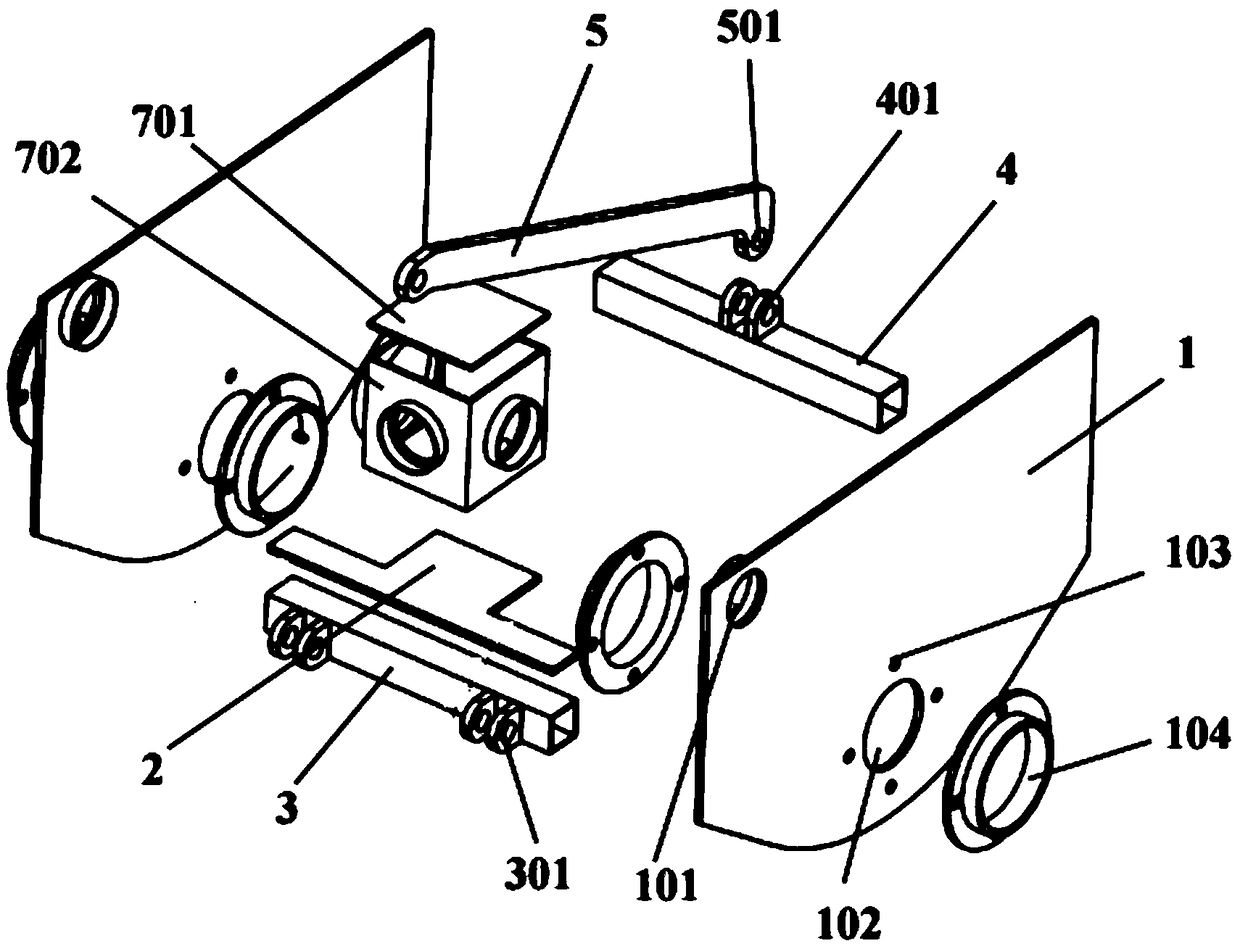

Elastic plate out-throwing type seed belt arranging and cleaning for wheat after rice

ActiveCN109196976AEasy to cleanReduce adhesionAgricultural machinesTilling equipmentsAgricultural engineeringHigh intensity

The invention an elastic plate out-throwing type seed belt arranging and cleaning device for wheat after rice, and belongs to the technical field of agricultural machines. The arranging and cleaning device is composed of an attachment device, a transmission device, a seed belt arrangement device and an elastic plate out-throwing device mounted on a frame, the arrangement device is connected to a suspension device and a traction device of a tractor via the attachment device, power of the tractor is transmitted to the seed belt arrangement device and the elastic plate out-throwing device via thetransmission device, and the seed belt arrangement device and the elastic plate out-throwing device rotate coaxially in the reverse directions respectively. An L-shaped arraignment cutter of the seedbelt arrangement device implements high-speed rotary cutting to cut residual roots and stalks in the seed belt and cut soil in the shallow layer, a high-intensity rubber arched elastic plate of the elastic plate out-throwing device rotates coaxially in the reverse direction relative to the L-shaped cutter, soil and straws attached to the seed belt arranging and cleaning device are removed by scraping, the seed belt is arranged and cleaned in a wheat after rice field, the whole structure is simple and compact, the seed belt arranging and cleaning effect is good, less soil and fewer straws areattached to the device, and high-efficiency seed belt arranging and cleaning of wheat after rice is realized. The elastic plate out-throwing type seed belt arranging and cleaning device is suitable for sowing and cultivating of wheat after rice.

Owner:CHINA AGRI UNIV

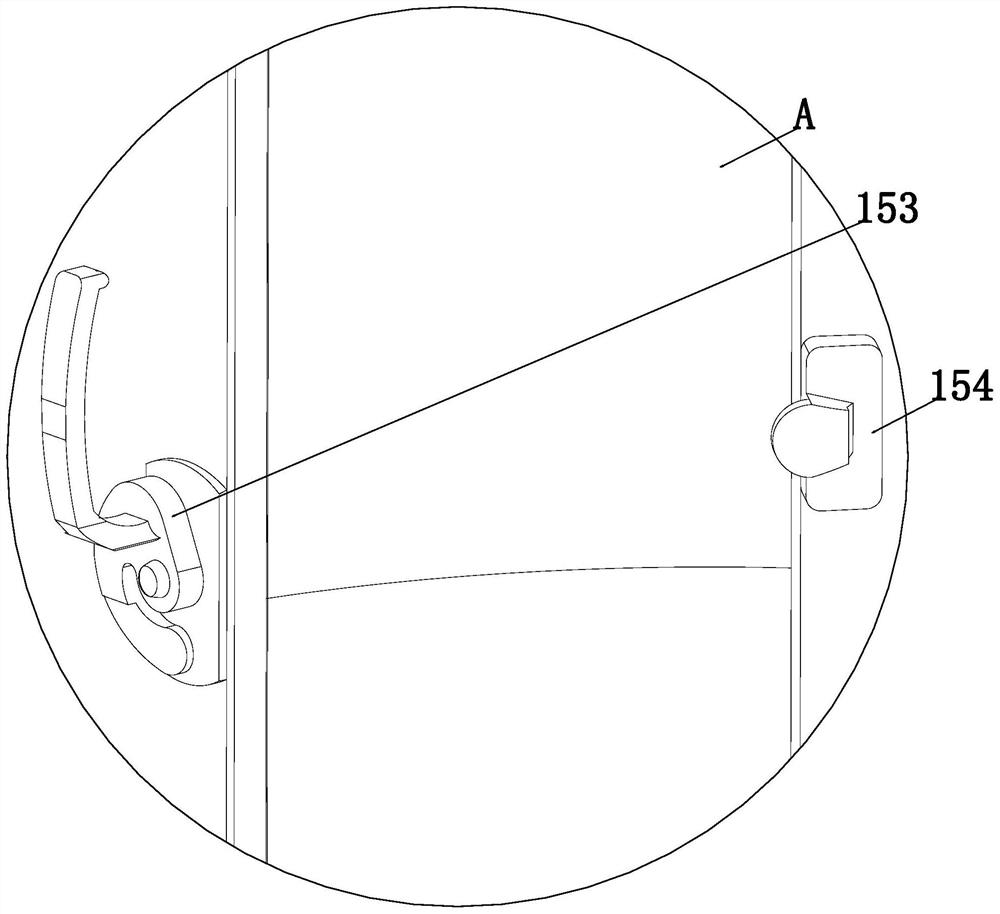

Switching mechanism with cable winding type extrusion locking structure

ActiveCN112700925APlay the role of guiding transportEfficient cleaning operationsApparatus for feeding conductors/cablesFilament handlingClassical mechanicsEngineering

The invention provides a switching mechanism with a cable winding type extrusion locking structure, and relates to the technical field of cable production. The problems that in the actual application process of an existing cable winding device, the outer skin of a cable cannot be effectively cleaned in advance when the cable is wound, so that the cable is damaged during winding due to the fact that impurities exist in the cable, and the problem that effective printing operation cannot be conducted according to different machined cable brands, so limitation exists in use are solved. The switching mechanism comprises a cable cleaning mechanism, and the cable cleaning mechanism is fixedly connected to the inner position of a bearing material guiding mechanism. When a cable moves to the inner side of the cable cleaning mechanism, two jackets can clamp the cable under the elastic force effect of clamping rods, so that the brushes make contact with the surface of the cable, and the purpose of effectively cleaning the outer skin of the cable is achieved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY

Cleaning and disinfecting device for medical instruments in nephrology department

PendingCN113500040AEfficient cleaning operationsFull cleaningDiagnosticsSurgeryBiomedical engineeringApparatus instruments

The invention provides a cleaning and disinfecting device for medical instruments in nephrology department, relates to the technical field of the medical instruments in the nephrology department, and solves the problems that in the actual application process of an existing cleaning device, because disinfectant contained in the medical instruments cannot be rapidly cleaned after the medical instruments are cleaned, and the disinfectant is carried on the medical instruments, cross infection is caused in later use, and it cannot be ensured that the medical instruments cannot collide with one another to be damaged while the batch instrument cleaning work is achieved. The cleaning and disinfecting device comprises a driving mechanism, wherein the driving mechanism installed at the inner position of a bearing mechanism. According to the cleaning and disinfecting device, movable plates in a containing mechanism are connected with fixed plates in an inserted manner through elastic insertion blocks installed at one ends of the movable plates, and through grooves are formed in the fixed plates, the movable plates and a base, so that during cleaning operation, internal medical instruments can be protected, and effective cleaning operation can be conducted.

Owner:刘道明

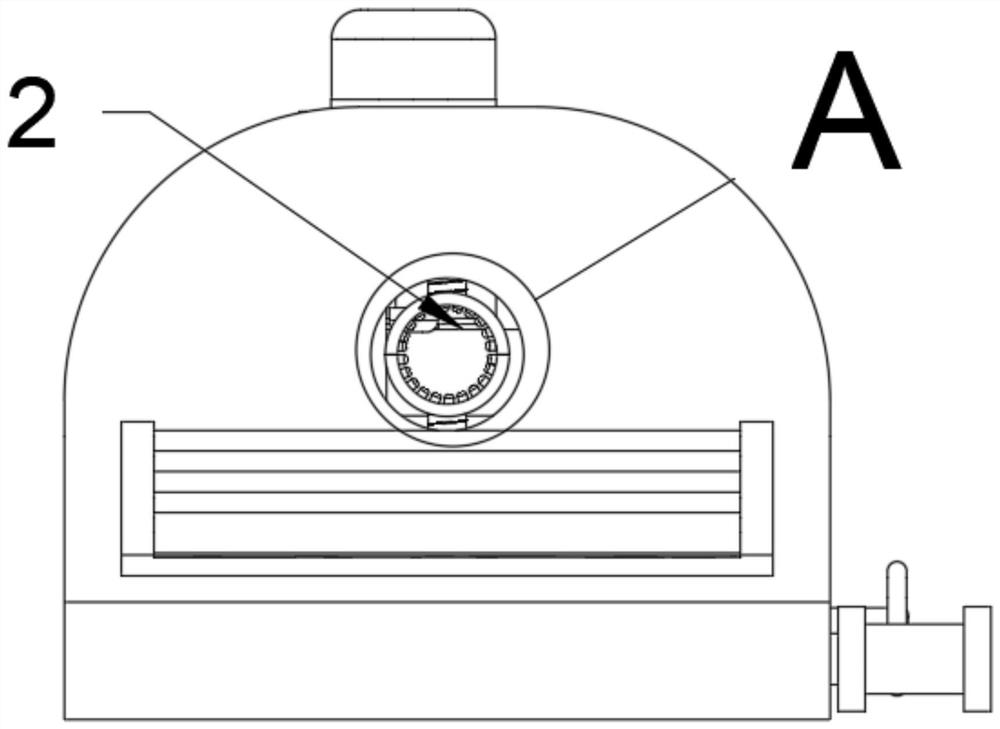

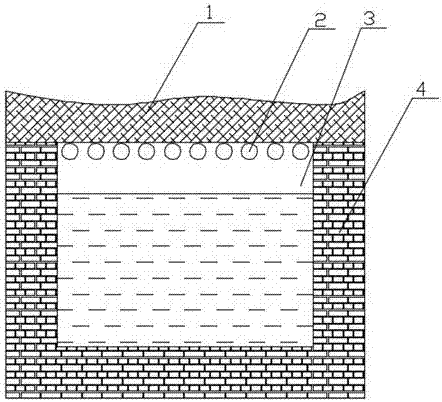

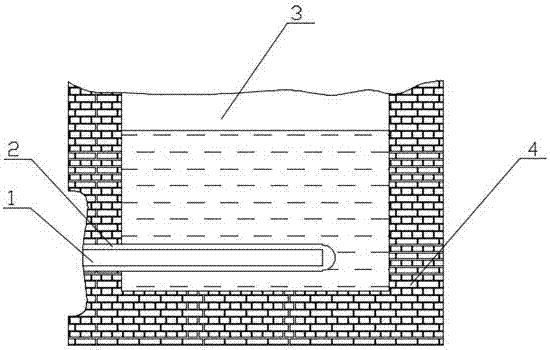

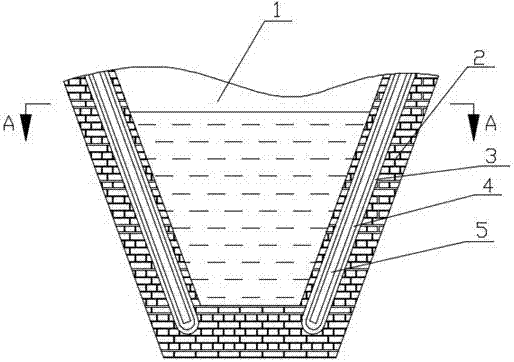

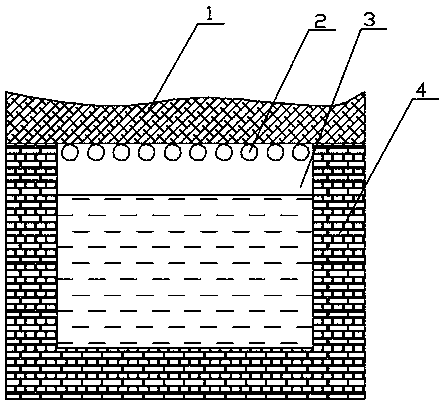

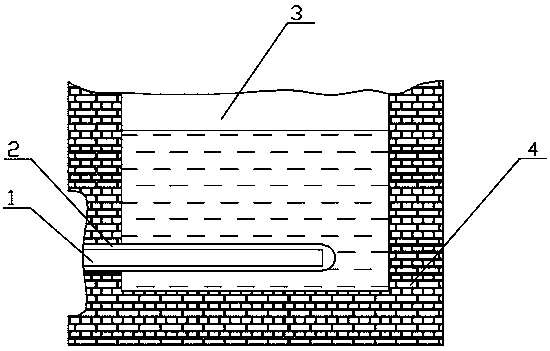

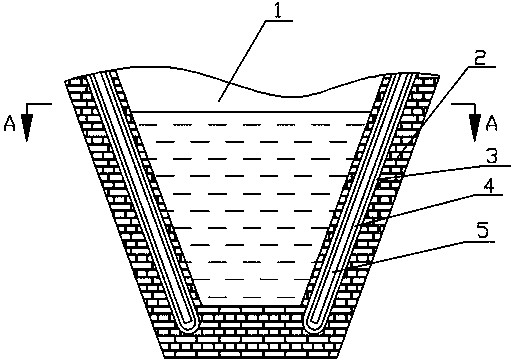

Heating and heat preservation method of aluminum alloy melt

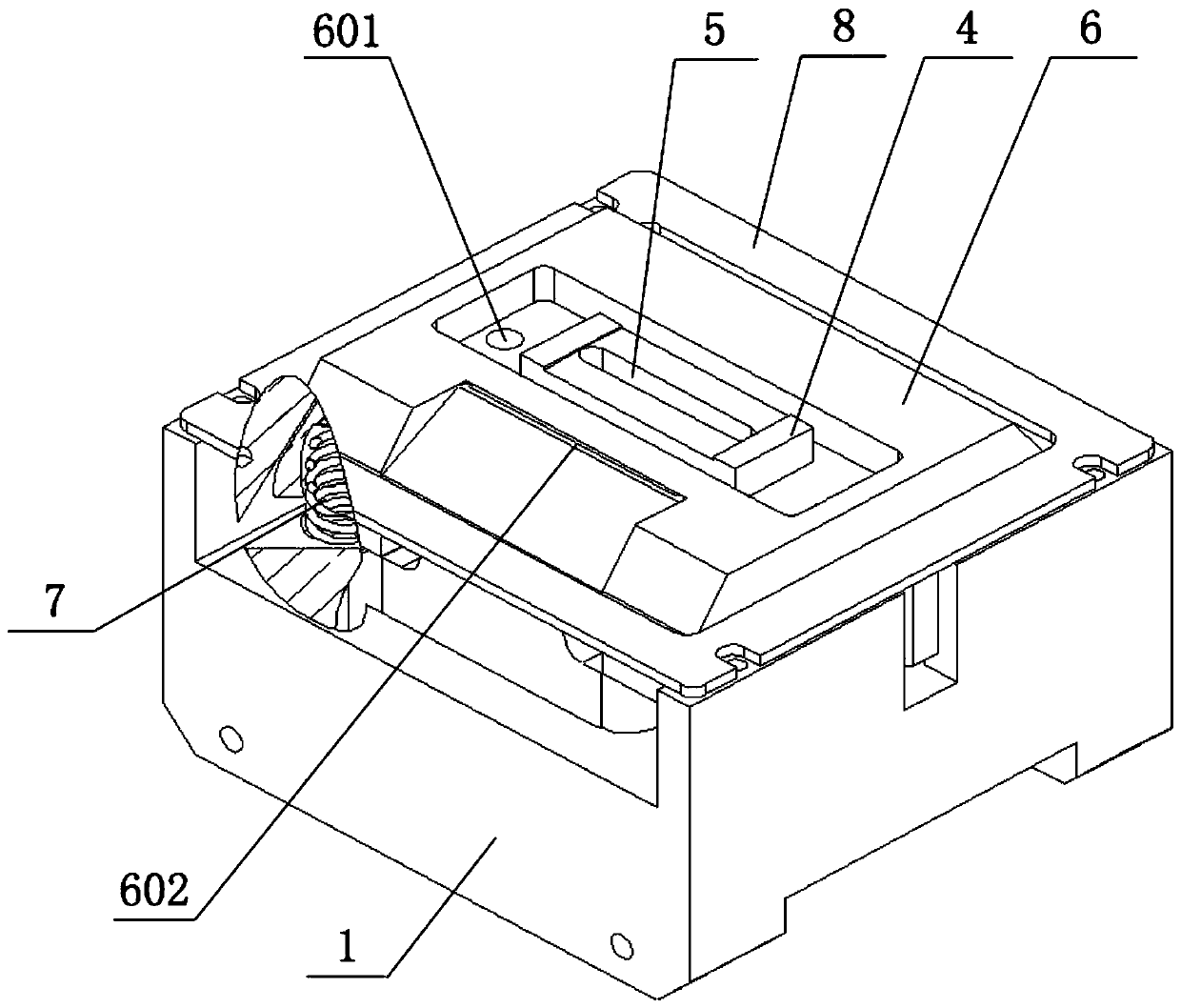

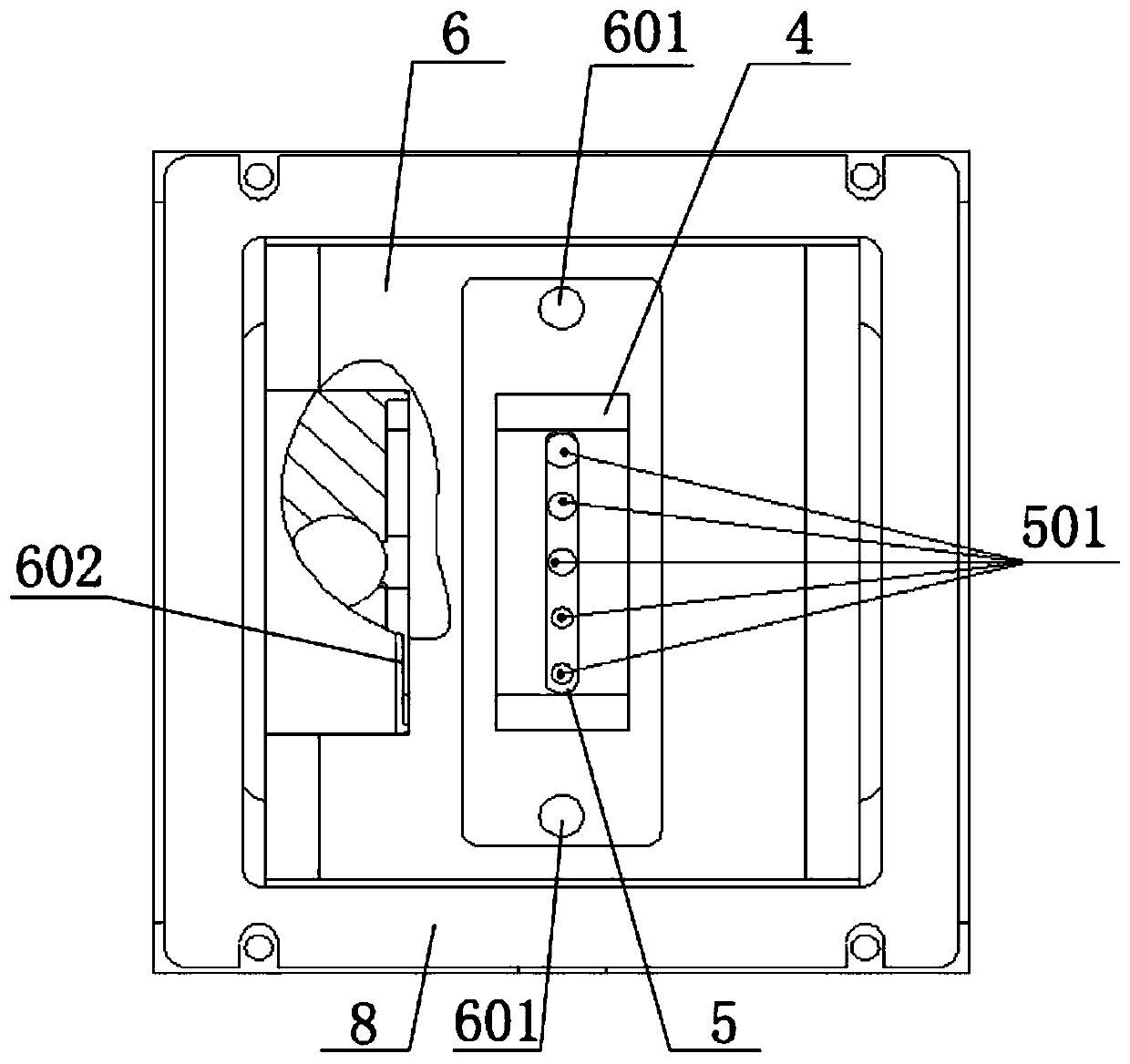

InactiveCN106914609AIncrease volumeFacilitate slag removalMelt-holding vesselsMelt temperatureElectric heating

The invention discloses a heating and heat preservation method of an aluminum alloy melt. The heating and heat preservation method comprises an aluminum alloy melt heating and heat preservation step, wherein in the step, an aluminum alloy melt heating and heat preservation device is used for carrying out heating and heat preservation on the melt; the aluminum alloy melt heating and heat preservation device comprises a furnace body, an electric heating element, a temperature controller and a temperature sensor; a containing cavity is formed in the furnace body; the containing cavity forms a melt temperature adjusting furnace chamber; the temperature sensor is mounted on the furnace body; the heating and heat preservation method is characterized in that the aluminum alloy melt heating and heat preservation step further comprises an indirect heating step; the indirect heating step comprises the step of forming a heating surface by utilizing an inner side face of a furnace lining of the furnace body; the heating surface is used for heating the aluminum alloy melt in the melt temperature adjusting furnace chamber. The heating and heat preservation method of the aluminum alloy melt, provided by the invention, has the advantages of simplicity and convenience for construction, uniform heating and uniform temperature distribution of a melting pool, easiness of mounting and replacing the electric heating element, convenience for cleaning molten slag of the melting pool and safety and reliability.

Owner:CHONGQING UNIV +1

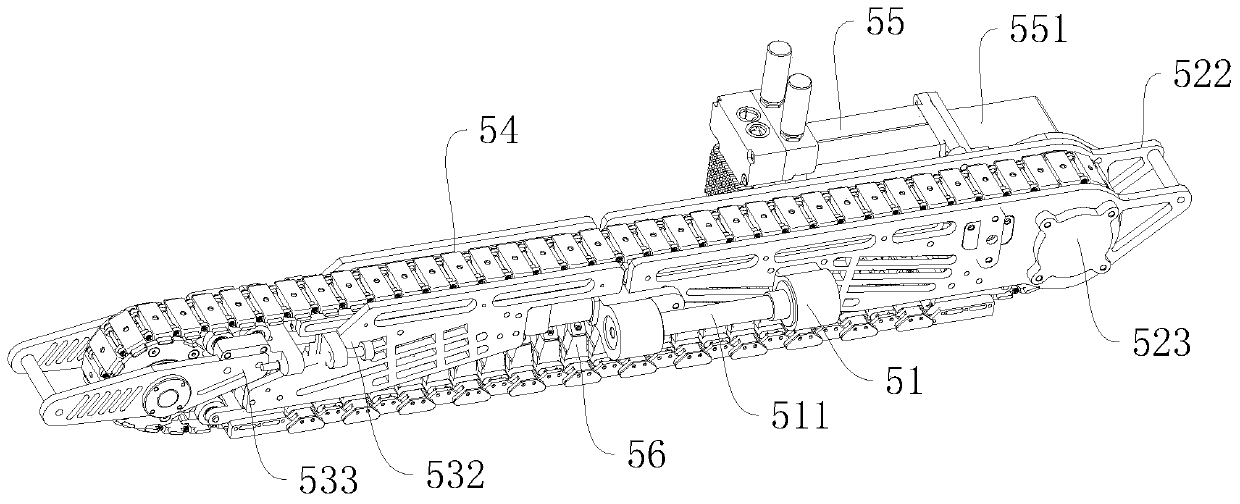

Wall cleaning robot for cleaning fan tower drum

PendingCN110454337AAdsorption is reliableAchieve cleaningMachines/enginesWind energy generationControl systemSewage

The invention discloses a wall cleaning robot for cleaning a fan tower drum. The wall climbing robot comprises a mounting bracket, a strip brush cleaning device, a water tank assembly, a central control system and permanent magnet crawler driving devices, wherein the strip brush cleaning device, the water tank assembly, the central control system and the permanent magnet crawler driving devices are arranged on the mounting bracket; the strip brush cleaning device is positioned above the mounting bracket, and the water tank assembly is connected with the strip brush cleaning device through a pipeline for providing cleaning liquid; the left permanent magnet track driving device and the right permanent magnet track driving device are respectively arranged on the two sides of the mounting bracket and are electrically connected with the central control system so as to form a chassis structure driven by a double-crawler belt, and a sewage suction sponge is arranged below the strip brush cleaning device to be used for adsorbing sewage so as to prevent the permanent magnet crawler driving devices and the central control system from being polluted. According to the technical scheme, the oilsludge cleaning operation on the surface of a tower barrel can be efficiently finished, manual cleaning is not needed, the labor cost is saved, and meanwhile, the safety is ensured.

Owner:湖南沄耀中创科技有限公司 +1

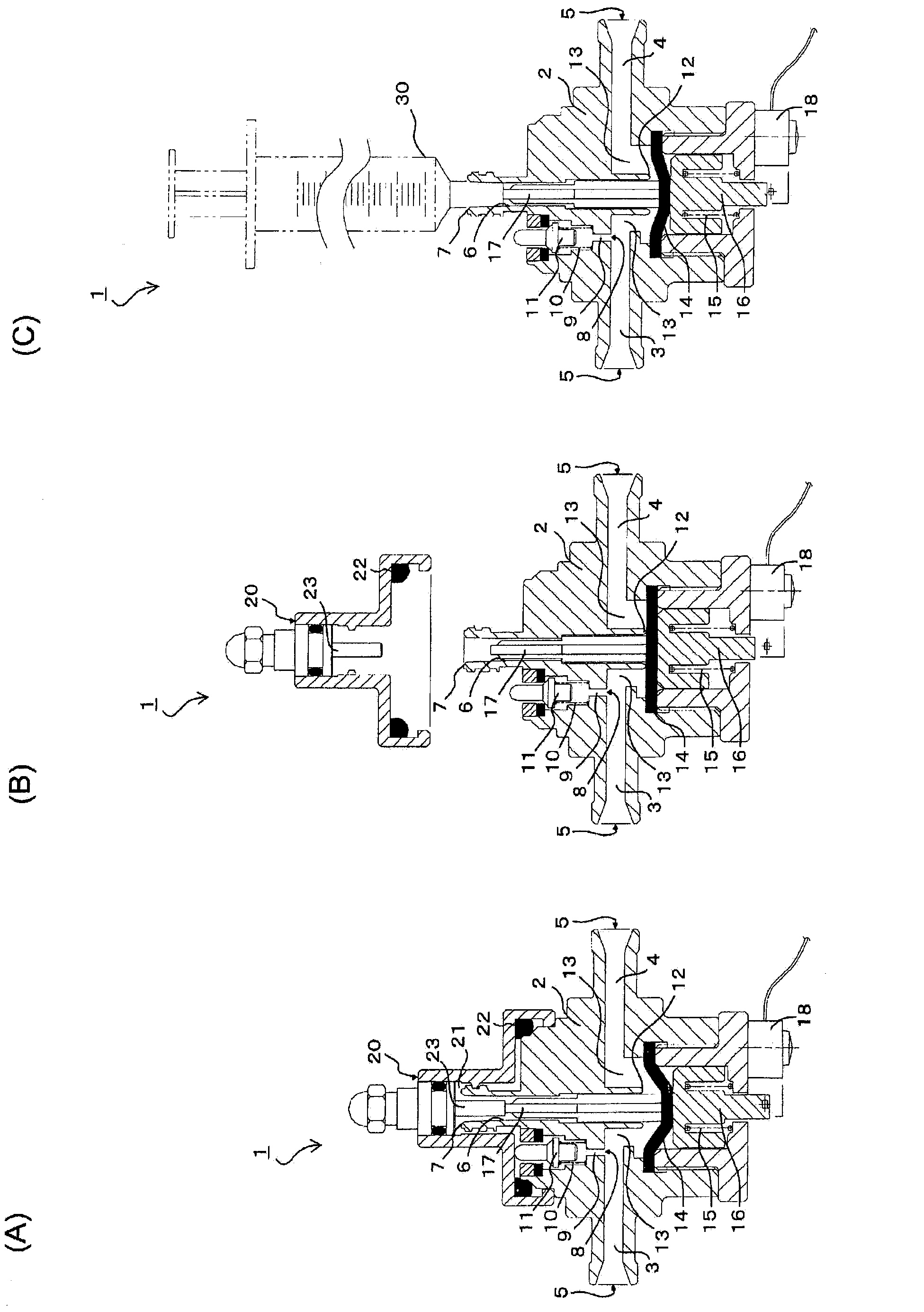

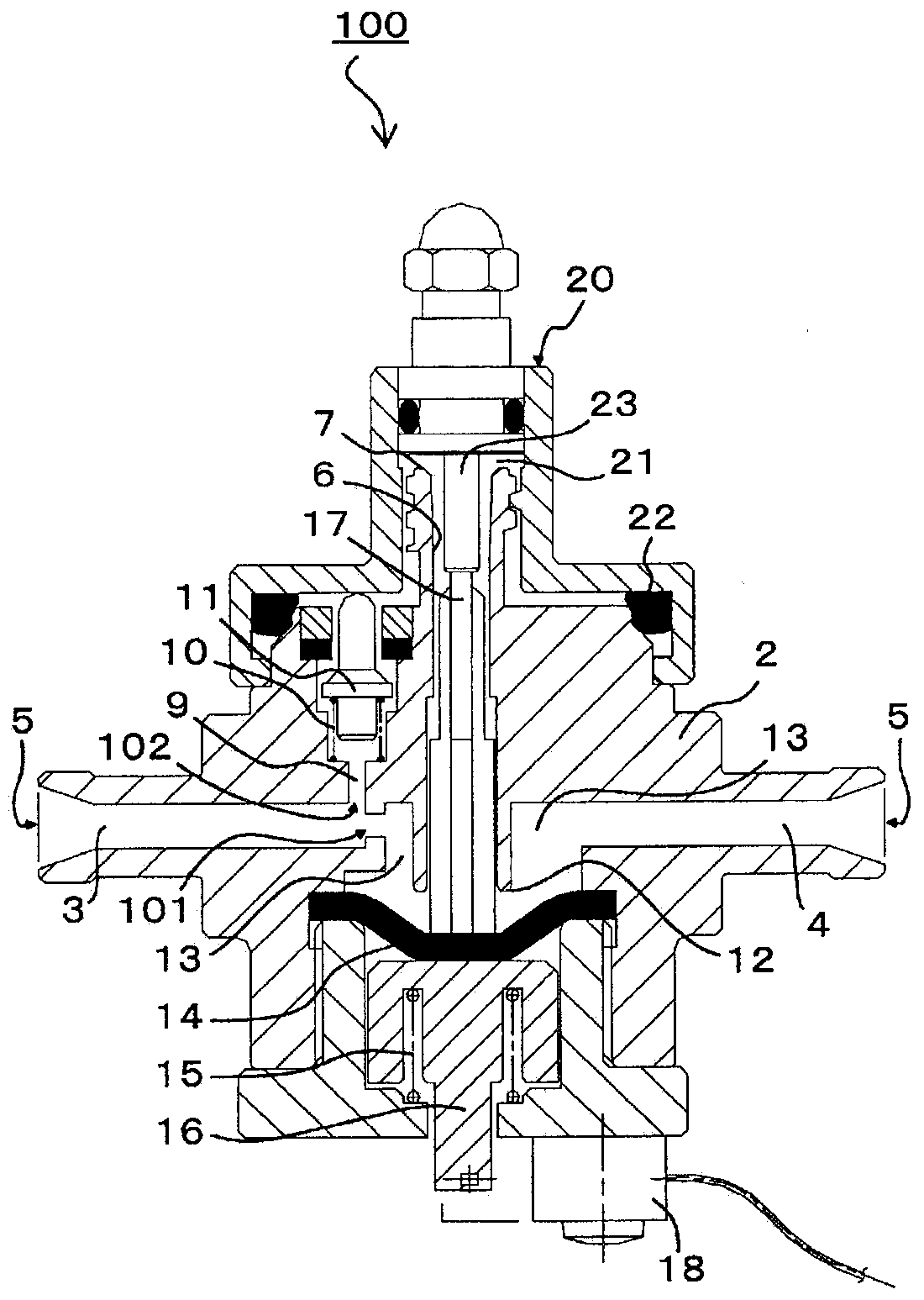

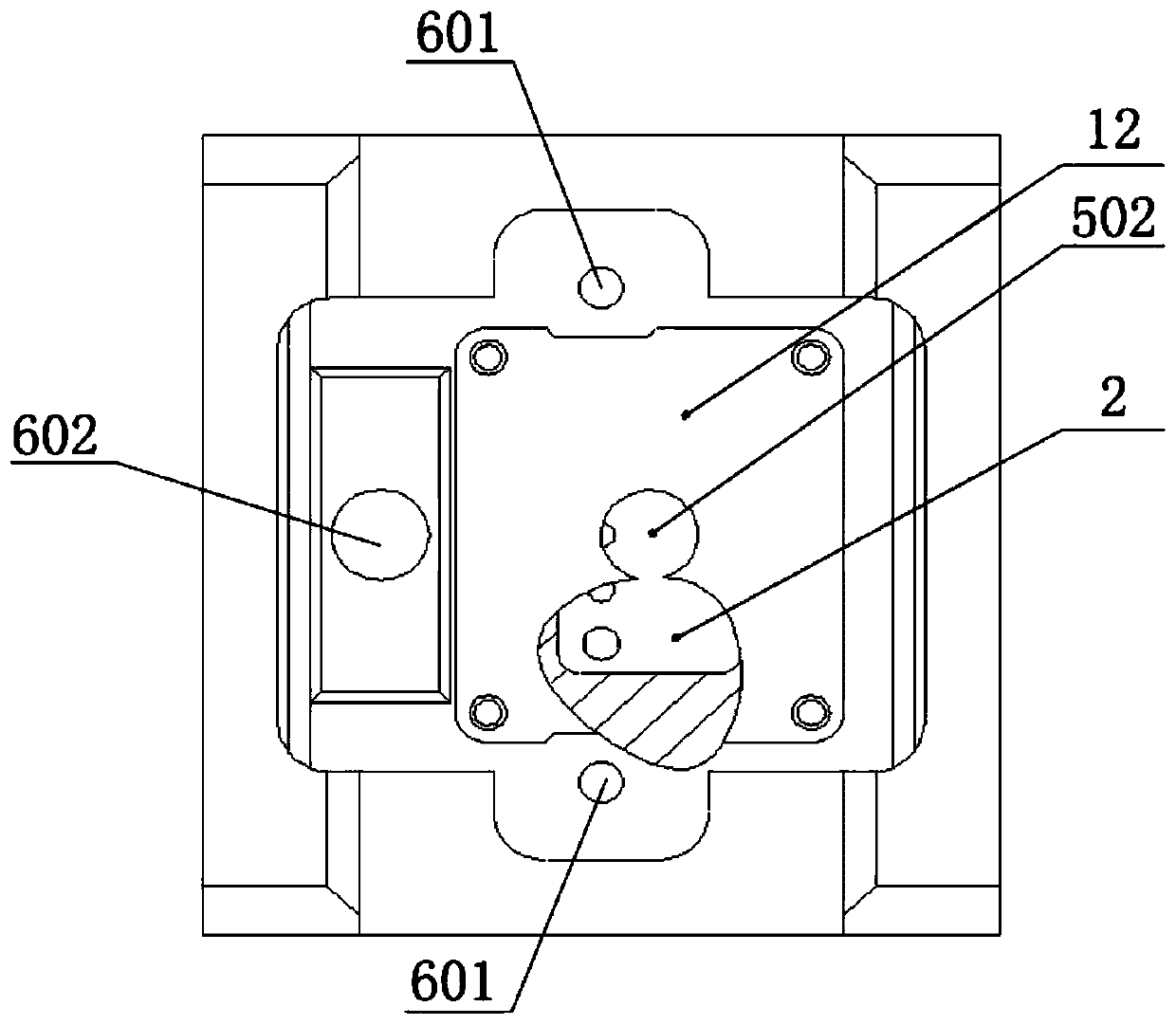

Branching port

ActiveCN103491991AImprove cleanlinessAvoid pollutionDiaphragm valvesEngine diaphragmsBiomedical engineering

Owner:TORAY MEDICAL

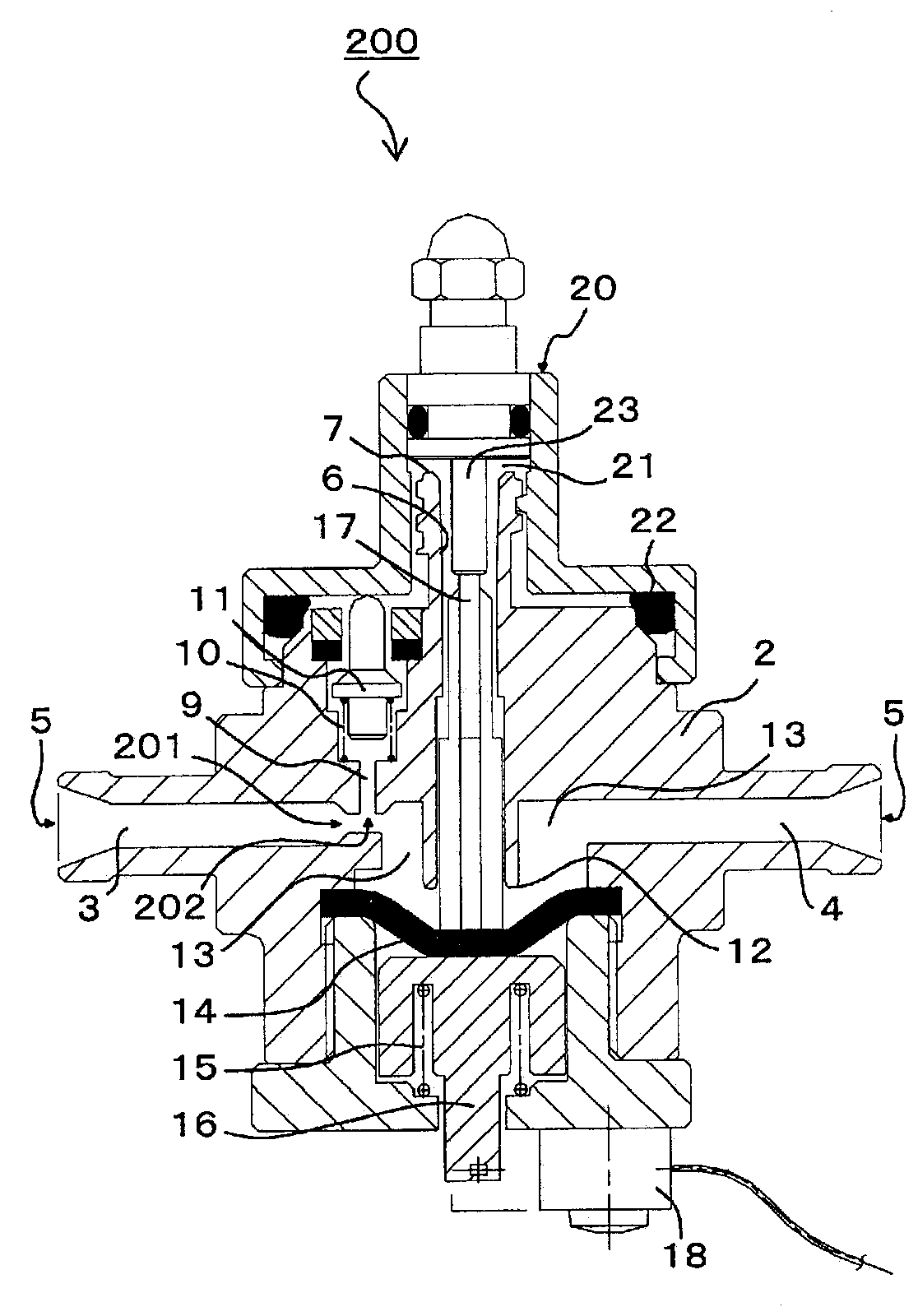

Multifunctional tableware cleaning machine

PendingCN109512356AAchieve divisionRealize the division and set the conveying area adjustment on the conveyor beltTableware washing/rinsing machine detailsEngineeringMechanical engineering

The invention provides a multifunctional tableware cleaning machine. The machine is used for solving the problems that different kinds of tableware cannot be classified and large tableware cannot be cleaned efficiently when existing tableware cleaning devices are used for cleaning the tableware. The multifunctional tableware cleaning machine comprises a rack and a conveying mechanism, and a cleaning chamber and a washing chamber are sequentially formed in the conveying direction of the conveying mechanism; a cleaning spraying system is arranged in the cleaning chamber, and a cleaning water tank is arranged at the lower portion of the cleaning chamber. A washing spraying system is arranged in the washing chamber, and a washing water tank is arranged in the washing chamber. The conveying mechanism comprises a conveying belt and a conveying belt driving mechanism, at least one side guide plate is arranged above the conveying belt, and a conveying area adjusting mechanism is arranged on the conveying belt. According to the multifunctional tableware cleaning machine, a conveying area of the conveying belt is adjusted, so that different kinds of tableware are placed in different areas, classified cleaning operation of the tableware can be achieved, the cleaning space is effectively utilized, and efficient cleaning operation of the tableware is achieved.

Owner:Xiamen ShenYing Technology Co Ltd

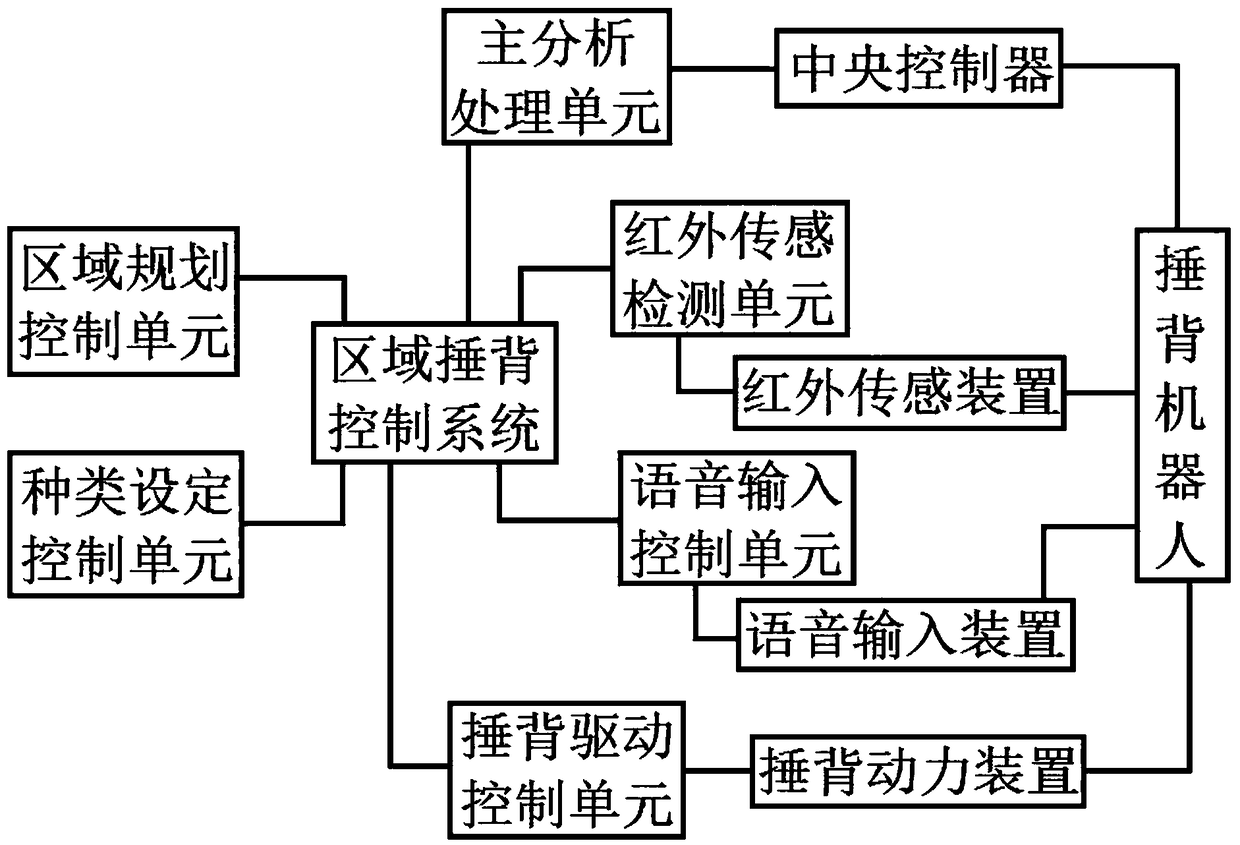

Mousetrap robot control system based on morphological analysis

InactiveCN108719263AEfficient cleaning operationsImprove the home environmentProjectileCharacter and pattern recognitionAnesthesia needleHome environment

The invention discloses a mousetrap robot control system based on morphological analysis, and relates to the field of graphic analysis and intelligent control systems. A main processing control unit transmits the corresponding data information / signal to an image processing and analyzing unit through a data information / signal transmission module; the main processing control unit is connected to aninformation matching driving unit through the information / signal transmission interactive mode; the main processing control unit transmits the corresponding driving information / signal to an anesthesiadriving control unit through the information / signal transmission module. By means of interactive analysis of the image processing and analyzing unit and an image database, the current object physicalform and the active state are effectively analyzed, and the anesthesia driving control unit is utilized to drive an anesthesia launching device to launch an anesthesia needle to a mouse-like object to effectively clear mice in domestic life and ensure a good home environment.

Owner:ANHUI SANDI ELECTRONICS TECH CO LTD

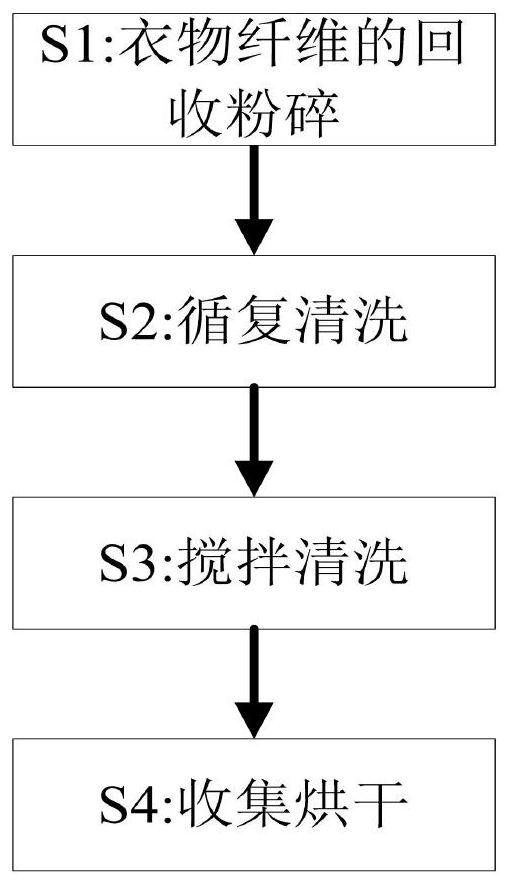

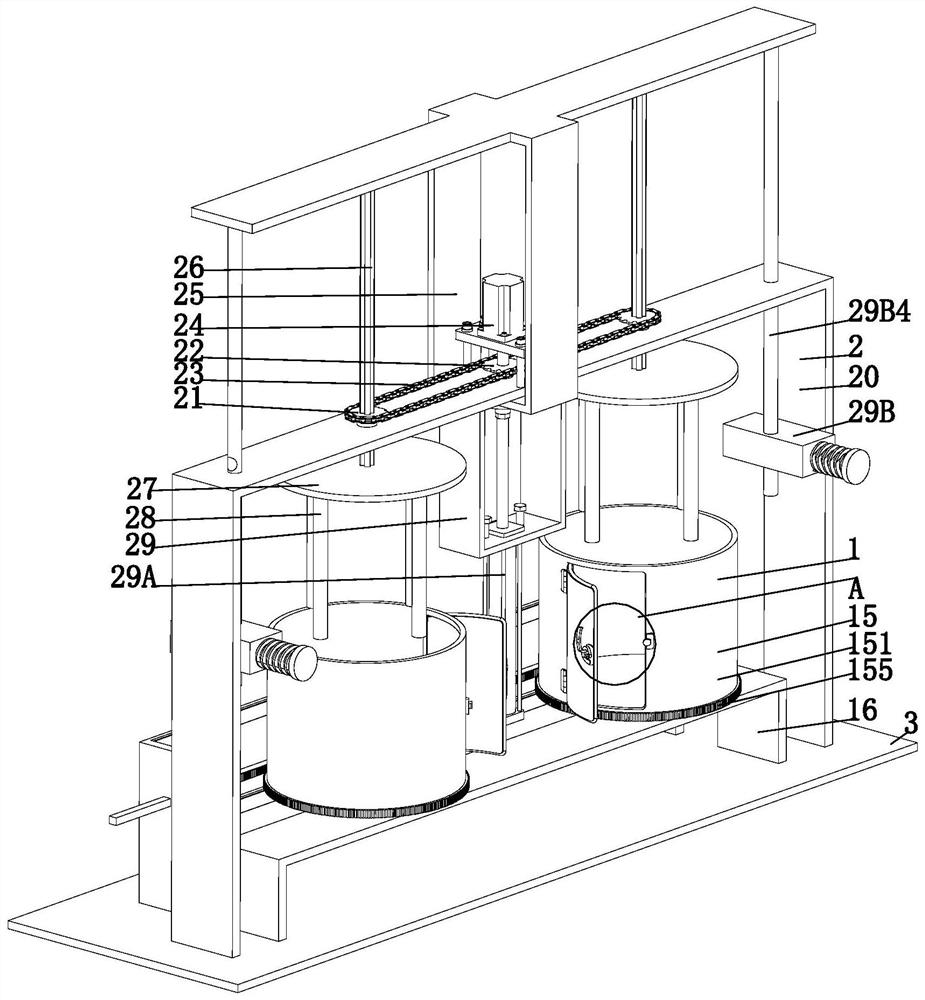

Preparation method of slump-retaining reinforced fiber concrete

InactiveCN113021685ATo achieve the purpose of cleaningAchieve sealingPlastic recyclingMechanical material recoveryFiberArchitectural engineering

The invention provides a preparation method of slump-retaining reinforced fiber concrete. The method involves a circulating cleaning mechanism, a stirring mechanism and a bottom plate, wherein the circulating cleaning mechanism is mounted on the bottom plate, the stirring mechanism is arranged over the circulating cleaning mechanism, and the stirring mechanism is mounted on the bottom plate. The method solves the problems that at present, fiber materials are cleaned manually, the process is tedious, the efficiency is low, stains on the fibers cannot be effectively removed, the fibers affect the strength and slump retaining performance of concrete, follow-up application of slump-retaining reinforced fiber concrete preparation is affected, and the actual use requirements cannot be met.

Owner:张俊豪

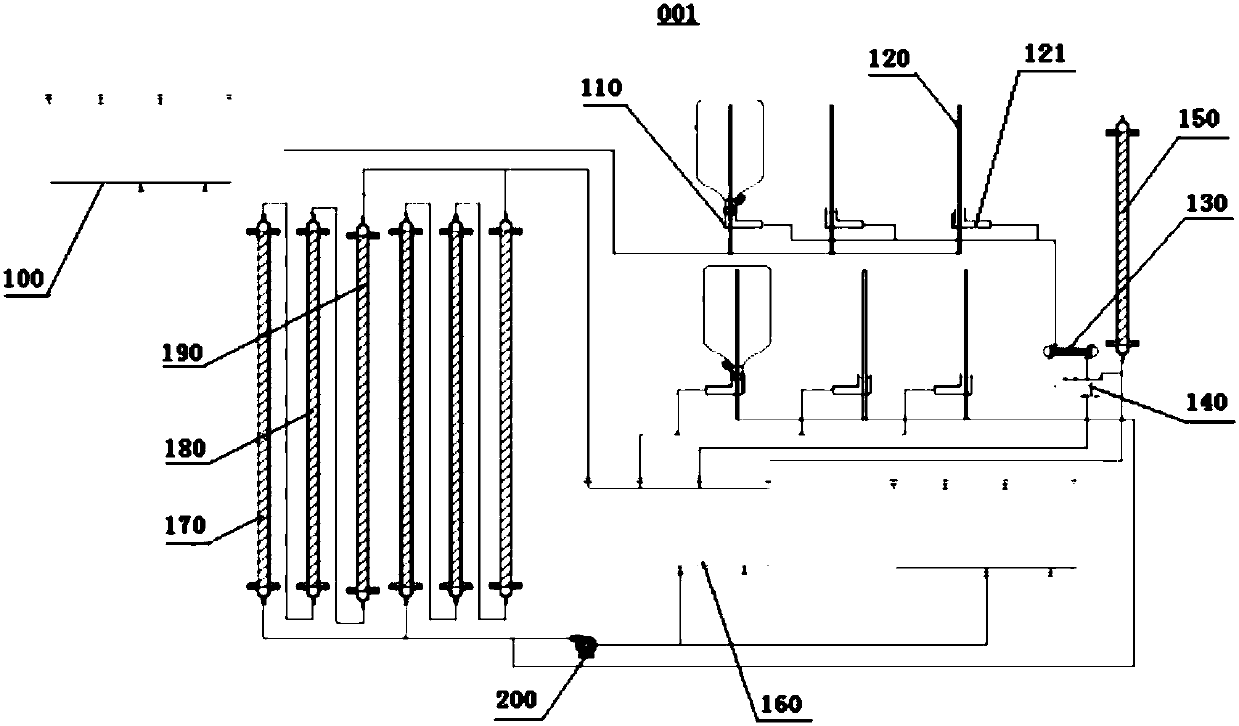

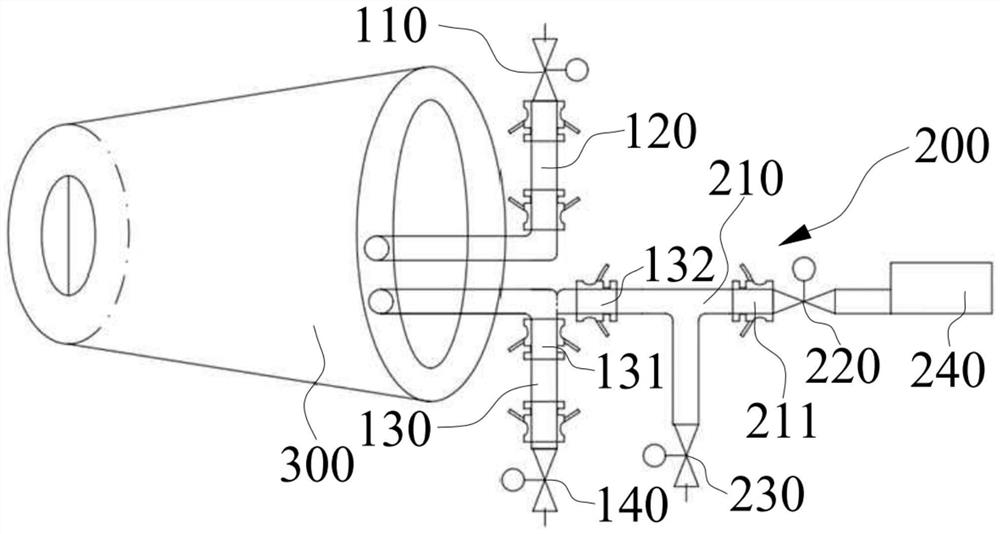

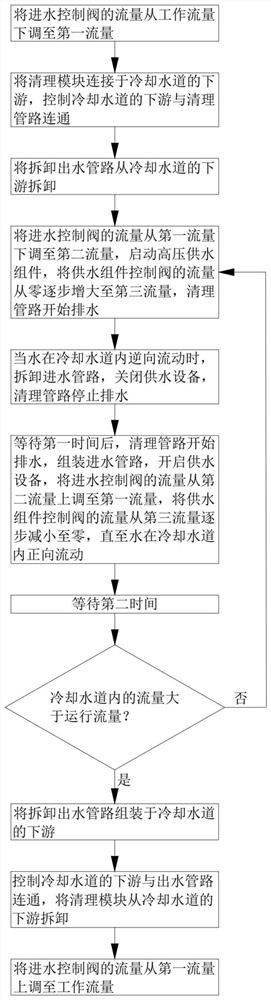

Cooling water channel system and maintenance method thereof

ActiveCN114657299AEasy to disassemble and operateEasy to controlTuyeresCooling devicesStream flowWater flow

The invention relates to the technical field of blast furnace cooling, and particularly discloses a cooling water channel system and a maintenance method thereof. The system is applied to a cooling water channel of a blast furnace tuyere sleeve and comprises a water inlet pipeline, a water outlet pipeline for draining water and a cleaning module comprising a cleaning pipeline, the upstream of the cooling water channel is sequentially communicated with a water inlet control valve and water supply equipment through a water inlet pipeline; the water inlet control valve is used for controlling the flow of the water supply equipment; the downstream of the cooling water channel selectively communicates with the water outlet pipeline or the cleaning pipeline, the cleaning pipeline can selectively drain water, the cleaning pipeline sequentially communicates with a water supply assembly control valve and a high-pressure water supply assembly, and the water supply assembly control valve is used for controlling the flow of the high-pressure water supply assembly. By means of the structure, cleaning operation of the cooling water channel and replacement operation of the water inlet pipeline and the water outlet pipeline can be completed by changing the water flowing path in the cooling water channel under the condition that the cooling water channel runs, maintenance efficiency is improved, and production loss is reduced.

Owner:SGIS SONGSHAN CO LTD

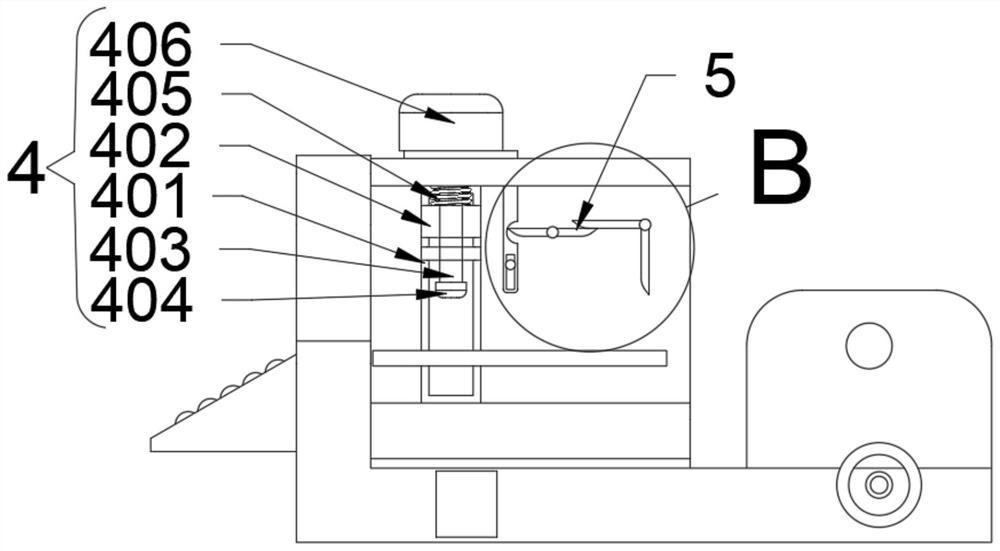

An intelligent garbage cleaning vehicle

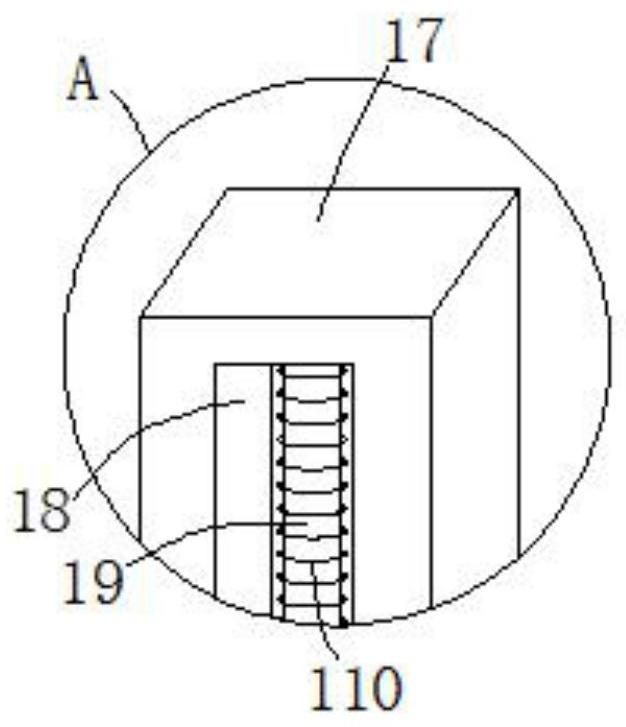

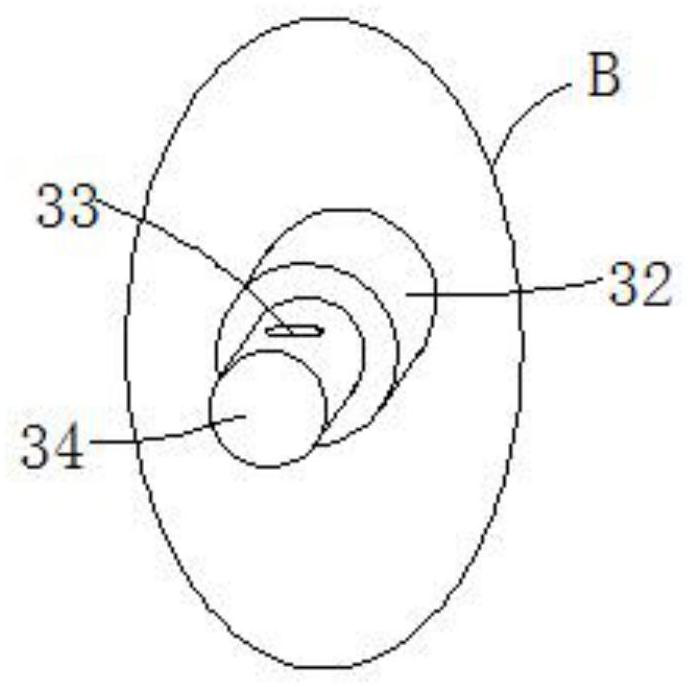

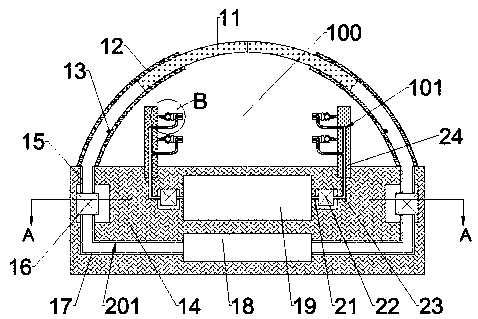

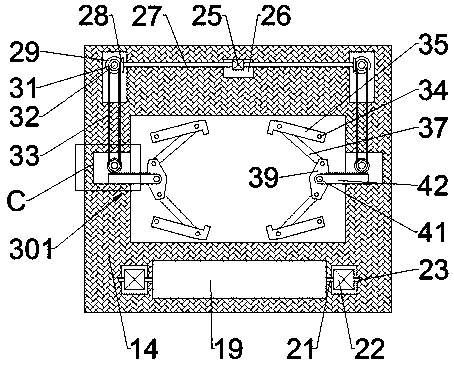

ActiveCN111717575BQuick clean upEfficient cleaning operationsRefuse vehiclesStructural engineeringMechanical engineering

The invention discloses an intelligent garbage cleaning vehicle, which comprises a vehicle body. Traction wheels used for driving module driving are provided on the left front and rear sides of the bottom end face of the vehicle body, and a semicircular extension block is arranged in the middle of the right end face of the vehicle body. The bottom end surface of the semicircular extension block is rotated on the right side with a universal wheel, and the top surface of the semicircular extension block is rotated and inserted with a rotating rod for controlling the rotation of the universal wheel. There are vertical columns at both ends, a collection cylinder is arranged between the two columns, the inner cavity of the collection cylinder is a hollow structure, and there is no upper and lower cover. There is a hoisting mechanism in the middle section on the right side of the top surface of the hoisting mechanism, and a compaction mechanism for compacting garbage is hoisted under the tip of the hoisting mechanism. It is convenient to quickly clean up the turnover garbage, to effectively clean the inner cavity of the collection cylinder, and to reduce the speed of bacterial growth.

Owner:安徽江田环卫设备股份有限公司

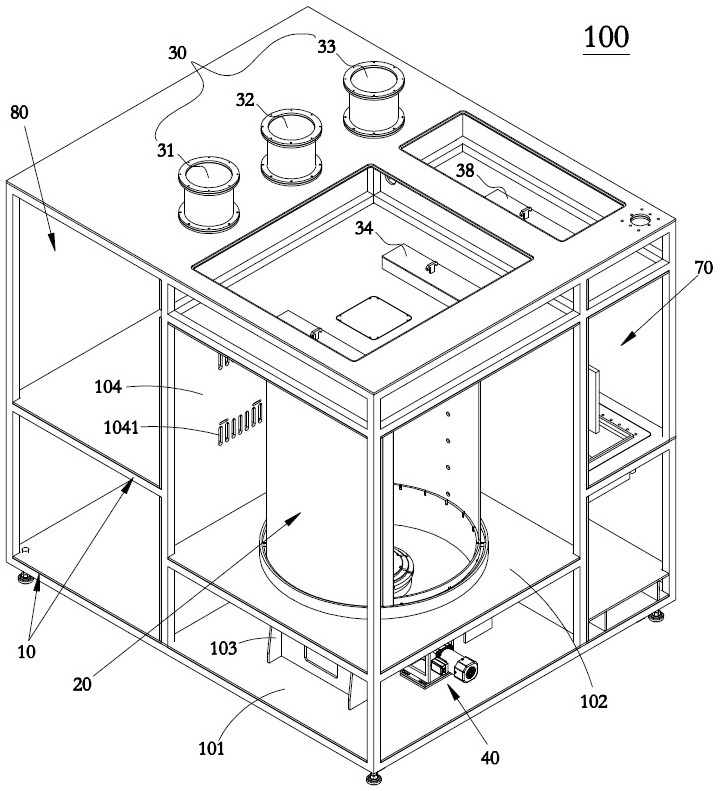

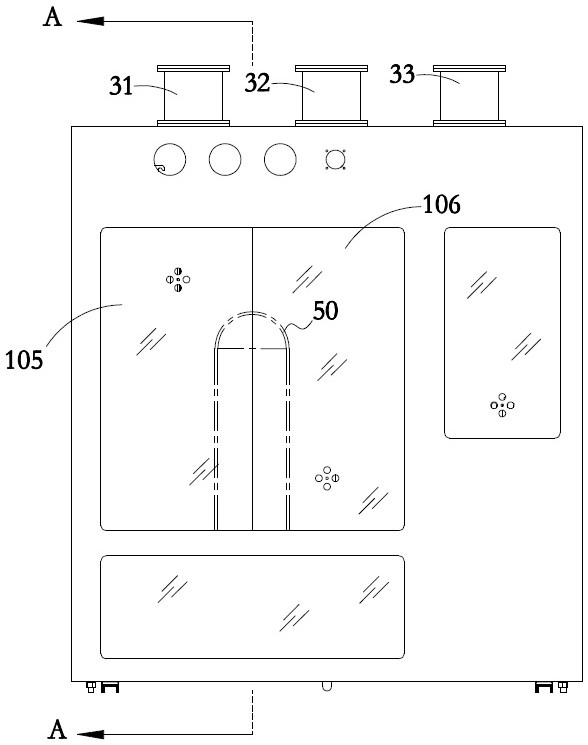

A maintenance and cleaning device for a turbine

ActiveCN110813879BEasy to cleanEfficient cleaning operationsMachines/enginesEngine componentsStructural engineeringTurbine

The invention discloses a maintenance and cleaning device for a turbine. The maintenance and cleaning device comprises a cleaning platform, wherein protective covers are fixedly arranged on the upperwall surface of the cleaning platform in a left-right symmetry mode; slidable protective plates are arranged in the protective covers; and limiting blocks are fixedly arranged on the inner wall surfaces of the protective covers. The maintenance and cleaning device is simple in structure, convenient to maintain and convenient to use, the turbine can be automatically cleaned, the turbine can be efficiently cleaned in all directions through a built-in movable spray head, so that the cleaning efficiency of the turbine is greatly improved, moreover, through a high-pressure water spraying valve, dead corners which cannot be cleaned manually can be completely and thoroughly cleaned, and the maintenance and cleaning device is worthy of commercial popularization.

Owner:溧阳市华顺机械配件有限公司

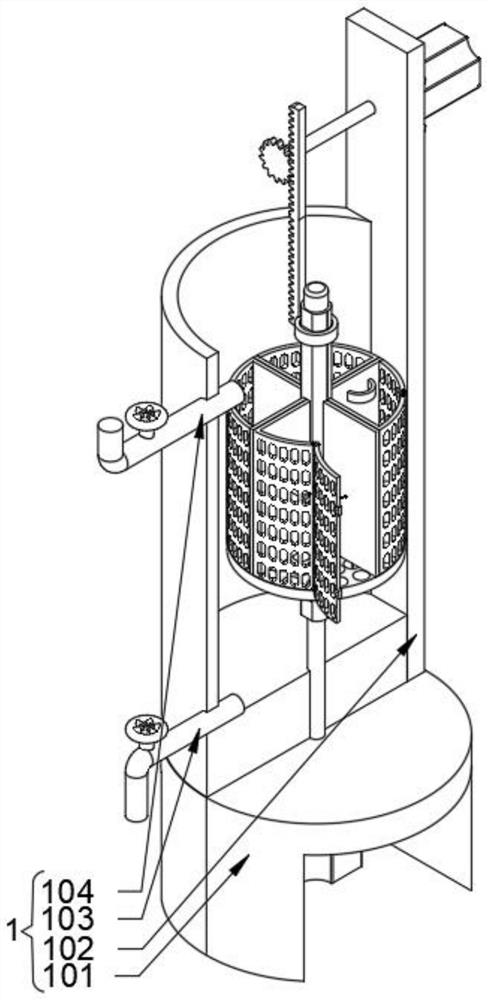

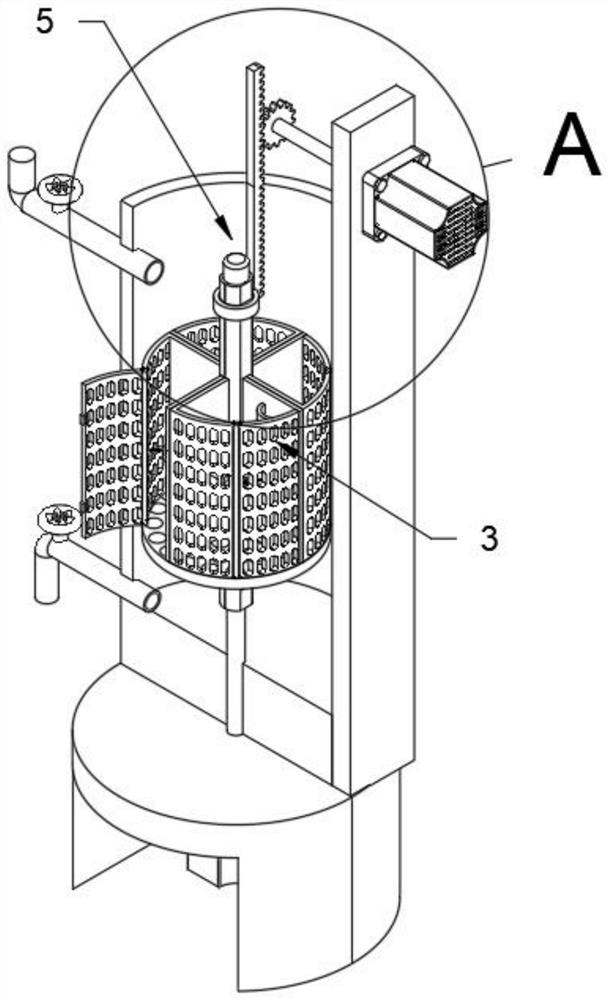

Traditional Chinese Medicine Heat Therapy Nursing Device

ActiveCN112058828BReduce workloadImprove heat therapy efficiencyHollow article cleaningBathing devicesNursing careHyperthermia Treatment

The invention relates to a traditional Chinese medicine hyperthermia nursing device. The invention effectively solves the existing problems of large workload and low efficiency of medical staff when performing traditional Chinese medicine hyperthermia care; the technical solution includes: the traditional Chinese medicine hyperthermia care device There are two heating boxes, which can automatically realize the dumping and cleaning of the remaining traditional Chinese medicine, and while cleaning the used heating box, it does not prevent the other heating box from performing hyperthermia for the next patient, which greatly improves the thermal treatment. While improving efficiency, it also reduces the workload of medical staff.

Owner:HENAN PROVINCE HOSPITAL OF TCM THE SECOND AFFILIATED HOSPITAL OF HENAN UNIV OF TCM

Zero-approach terminal abrasive material delivering system

PendingCN107322490ACompact structureShorten the conveying distanceAbrasive feedersAbrasive machine appurtenancesStructural engineeringProcess engineering

The invention discloses a zero-approach terminal abrasive material delivering system. The system comprises a material collection tank, a feed inlet is formed in the top of the material collection tank, an overflow opening is formed in the lateral part of the material collection tank, a discharging opening is formed in the bottom of the material collection tank, one or more mixing bins are arranged in the discharging opening, power liquid connectors are arranged on the mixing bins, an abrasive material collection box is arranged below the material collection tank, a water inlet is formed in the lateral part of the abrasive material collection box, a water outlet is formed in the bottom of the abrasive material collection box, the feed inlet is communicated with the water outlet, the water inlet is communicated with a pond, delivering pumps are arranged between both the feed inlet and the water outlet and between the water inlet and the pond, one or more nozzles are arranged in the abrasive material collection box, and the nozzles are connected with the mixing bins. By means of the zero-approach terminal abrasive material delivering system, the problem that abrasive materials cannot be effectively utilized when the surface of metal is cleaned through abrasive material water jet is solved.

Owner:侯亚康

High-pressure water jet cleaning machine for industrial machinery parts

ActiveCN103752553BImprove cleaning efficiencyImprove cleaning qualityCleaning using liquidsTarget surfaceWater flow

The invention discloses a special high-pressure water jet washing machine for industrial mechanical parts. The high-pressure water jet washing machine comprises a washing platform, wherein a high-pressure nozzle is installed in one side face of the washing platform, a moving target surface device capable of moving vertically and horizontally and moving front and back is arranged on the other opposite side of the washing platform, the moving target surface device is provided with a pressure sensor capable of measuring water flow pressure and a clamping element capable of clamping the parts needing to be washed, the high-pressure nozzle is communicated with a high-pressure jet pump through a pipeline, the high-pressure jet pump pumps water in a water tank, a backflow pipe returning to the inside of the water tank is arranged on the lower portion of the washing platform, and the high-pressure jet pump is connected with control switches on one side of the washing platform through wires. The high-pressure water jet washing machine can remove dirt or rusting layers on the surfaces of the parts quickly and efficiently, washing cost can be effectively reduced, the washing speed and washing quality can be effectively improved.

Owner:SHANDONG UNIV

Winding equipment for motor stator core

ActiveCN113644791BEffective coolingNo wasteCleaning using toolsManufacturing stator/rotor bodiesWinding machineElectric machine

The invention discloses a winding device for a stator iron core of a motor, which relates to the technical field of machinery. It includes a winding machine and a stator core, and an automatic adjustment mechanism is arranged outside the stator core, and the automatic adjustment mechanism includes a ventilation plate, a telescopic rod, a rotating column, a slide plate, a pull plate, a pull rod, a support plate and a pressing block, The telescopic rod penetrates and is slidably mounted on a rotating column, the rotating post is rotatably mounted on the ventilation plate, the top of the telescopic rod is rotatably mounted on a slide plate, and the slide plate is slidably mounted on the air outlet end of the ventilation plate. The winding equipment for the stator core of the motor can effectively dissipate heat from the wound silicon steel sheet and the stator core by setting an automatic adjustment mechanism outside the stator core without causing waste of wind power resources, and at the same time Through the cleaning mechanism inside the cleaning box, impurities such as engine oil on the surface of the silicon steel sheet can be effectively scraped and cleaned to improve the adhesion of the silicon steel sheet.

Owner:NANTONG HUDA MASCH EQUIP CO LTD

A photovoltaic array cleaning vehicle and a photovoltaic array cleaning method thereof

ActiveCN105195488BUniform cleaning effectReduce consumptionSolar heating energyFlexible article cleaningEngineeringWater spray

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

Non-contact type gas-liquid comprehensive cleaning device applied to digital printing machine

PendingCN110667256ARealize the cleaning operationAvoid direct physical contactPrintingEngineeringDigital printing

The invention discloses a non-contact type gas-liquid comprehensive cleaning device applied to a digital printing machine, The non-contact type gas-liquid comprehensive cleaning comprises a base, a water storage cavity, a cleaning pump, a mounting seat, a mounting groove and a water outlet, wherein the water storage cavity is formed in the base and used for temporarily storing cleaning liquid, thecleaning pump communicates with the water storage cavity and used for pumping the cleaning liquid into the cleaning pump, the mounting seat is arranged on the surface of the base and used for abutting against the bottom surface of a printing spray head, the mounting groove is formed in the surface of the mounting seat and used for mounting a printing area on the printing spray head, and the wateroutlet is formed in the bottom surface of the mounting groove, communicates with the water storage cavity and is used for spraying the cleaning liquid on the printing area on the printing spray head.Therefore, the printing area on the printing spray head can be effectively prevented from being damaged in the cleaning operation due to the fact that a water outlet of a core cleaning part is not indirect physical contact with the printing area on the printing spray head, and meanwhile the cleaning liquid is automatically sprayed through the power of the cleaning pump, so that the cleaning operation on the printing spray head of the digital printing machine can be conveniently and efficiently completed.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

Quartz tube cleaning device and cleaning method

ActiveCN113500070BEfficient cleaning operationsSimple structureHollow article cleaningDrying gas arrangementsStructural engineeringTube cleaning

The invention provides a quartz tube cleaning device and a cleaning method. The quartz tube cleaning device includes a cleaning cover with an open bottom, and a base that is movably plugged and assembled with the cleaning cover along the vertical direction, and is arranged in the base to hold the quartz tube. The bearing platform, and the driving device; the top of the cleaning cover is provided with a first nozzle, the side wall of the cleaning cover is vertically provided with several second nozzles, and the bearing platform is vertically provided with an inner nozzle pipe, and the inner nozzle pipe is located at the top and side above the bearing platform A number of third nozzles are provided; the base is embedded with a rotary sealing device, and the inner nozzle pipe runs through the carrier platform and the rotary sealing device continuously in the vertical direction; the driving device drives the carrier platform to rotate, and the inner nozzle tube remains stationary during the rotation process of the carrier platform. Through the application, efficient cleaning of quartz tubes of various sizes has been realized, which can meet the cleaning needs of quartz tubes with different diameters, simplifies the structure of the quartz tube cleaning device and improves the service life, and avoids the quartz tubes from being damaged during the cleaning process. damage.

Owner:ZHICHENG SEMICON EQUIP TECH (KUNSHAN) CO LTD

A kind of aluminum alloy melt heating insulation method

Owner:CHONGQING UNIV +1

An automatic cleaning device for sports basketball

ActiveCN113633943BAutomatic cleaning operationComprehensive and effective cleaning operationsBall sportsEngineeringMechanical engineering

The invention relates to the technical field of basketball cleaning devices, and discloses an automatic cleaning device for sports basketballs, which solves the problems of slow speed and low efficiency of manual cleaning operations on basketballs. The four corners of the bottom are equipped with moving brake wheels, the upper part of one side of the equipment housing is equipped with a moving handle, the top of the equipment housing is provided with a through cavity, and the bottom of the other side of the equipment housing is provided with a placement groove, the through cavity The bottom of the tank is connected with the placement tank, the inside of the storage tank is equipped with a cleaning liquid collection box, and the upper part of the through cavity is equipped with an air-drying end; this basketball cleaning device can automatically clean the basketball, and can comprehensively and effectively clean the basketball. Disinfection and air-drying improve the efficiency and speed of basketball cleaning. At the same time, the basketball cleaning device is simple and convenient to use and operate, and can meet people's needs for basketball cleaning.

Owner:CHONGQING TECH & BUSINESS UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com