Wall cleaning robot for cleaning fan tower drum

A wall-climbing robot and wind tower technology, applied in the direction of wind power engines, machines/engines, engines, etc., can solve the problems of tower structural strength and life reduction, tower surface corrosion and rust, and affect the appearance of wind turbines, etc., to ensure The effect of safety and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

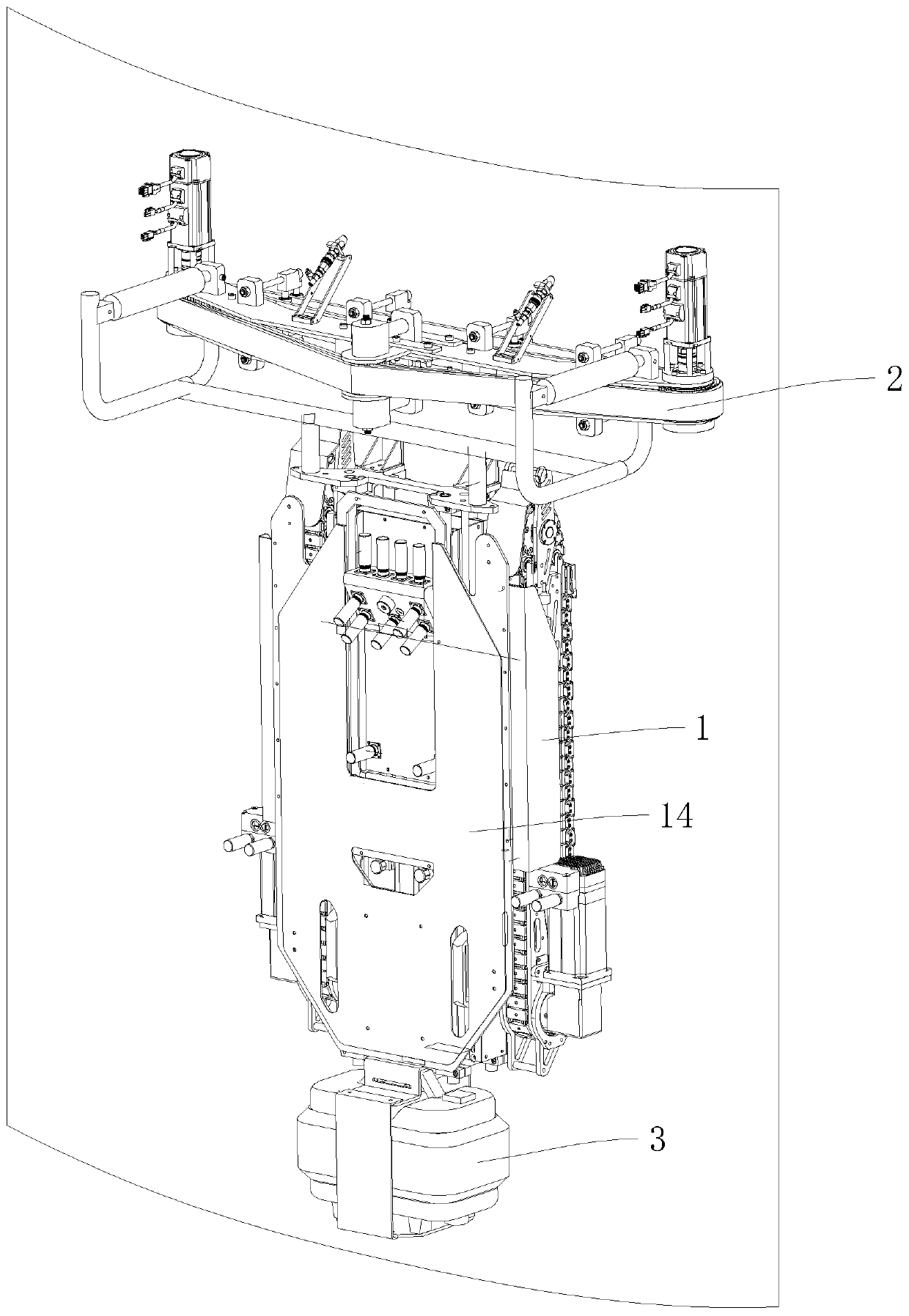

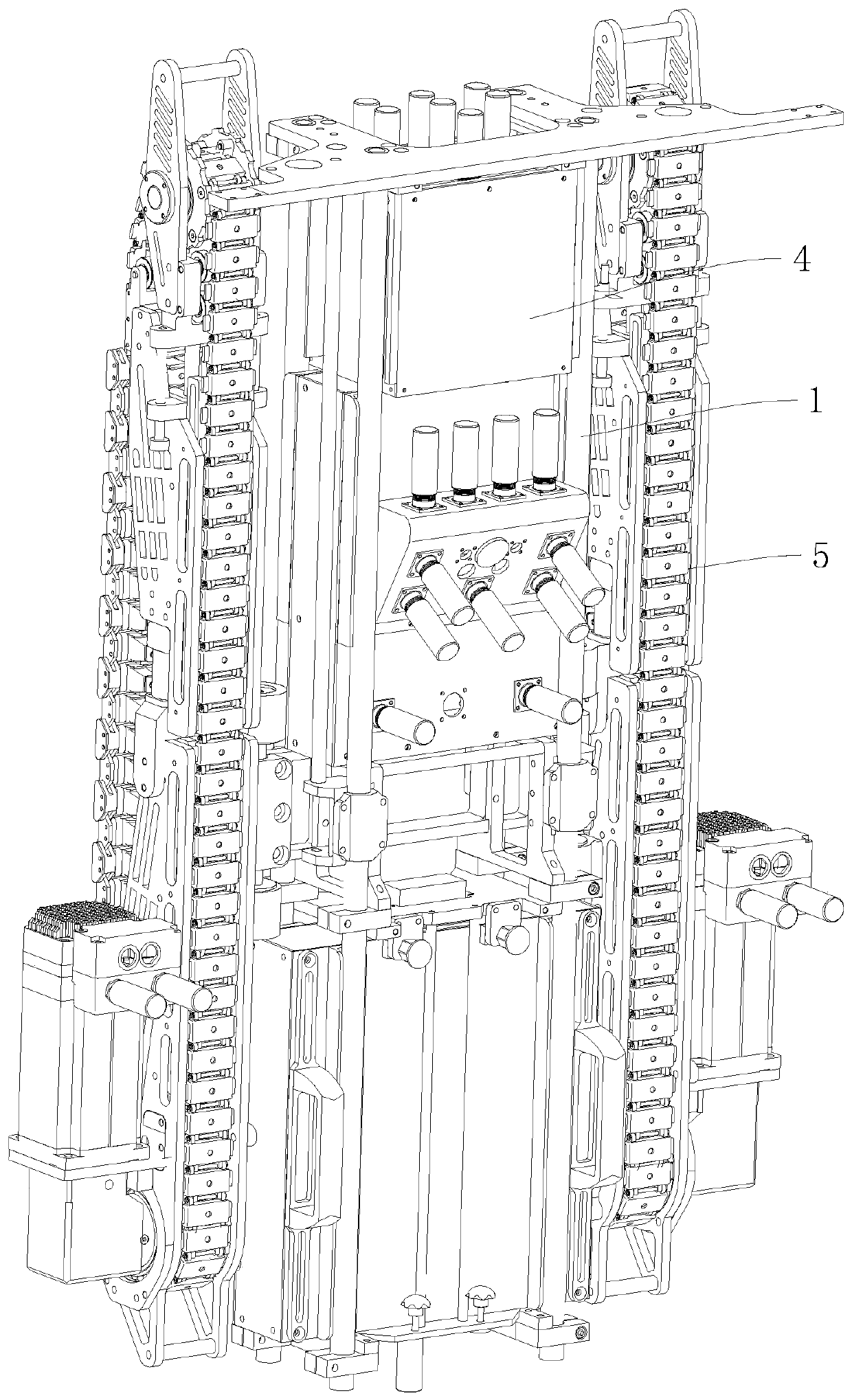

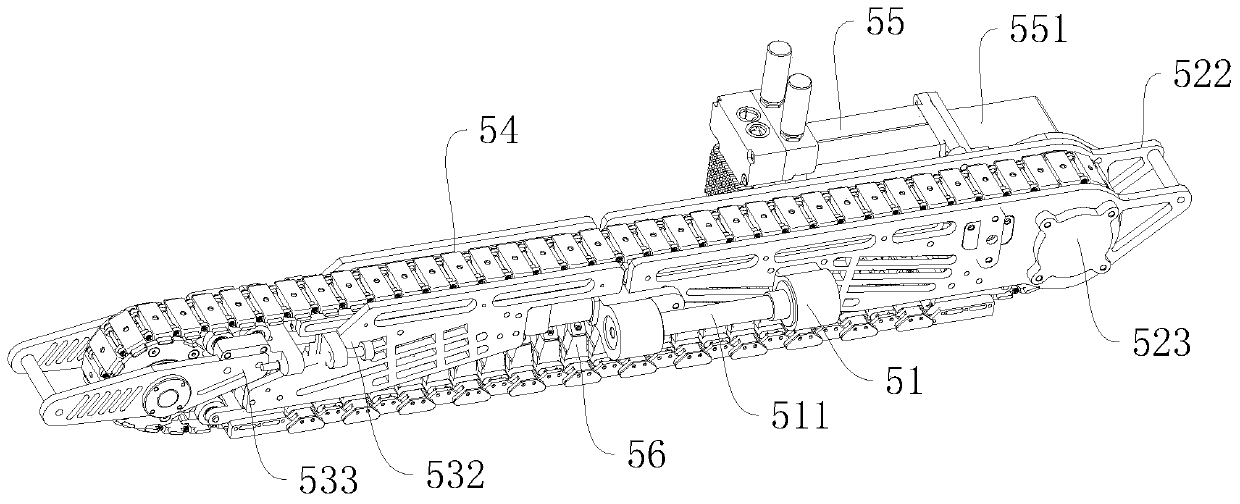

[0030] Such as Figure 1-Figure 2 Shown is a wall-climbing robot for fan tower cleaning strip brush of the present invention, comprising: mounting bracket 1, strip brush cleaning device 2 arranged on mounting bracket 1, water tank assembly 3, central control system 4, permanent magnet crawler drive Device 5, the mounting bracket 1 outside the central control system 4 is provided with a housing 14 for the protection of internal components; the strip brush cleaning device 2 is located above the mounting bracket 1; the water tank assembly 3 is suspended on the bottom of the mounting bracket 1 , connected to the strip brush cleaning device 2 through pipelines to provide cleaning liquid; the permanent magnet crawler drive device 5 includes a left permanent magnet cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com