Adsorbing transferring device for glass processing

A transfer device and glass technology, applied in the direction of transportation and packaging, lighting and heating equipment, conveyor objects, etc., can solve the problems of difficulty in movement, influence on processing links, inconvenient position adjustment, etc., achieve clear working principles, improve production efficiency, Adsorption is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

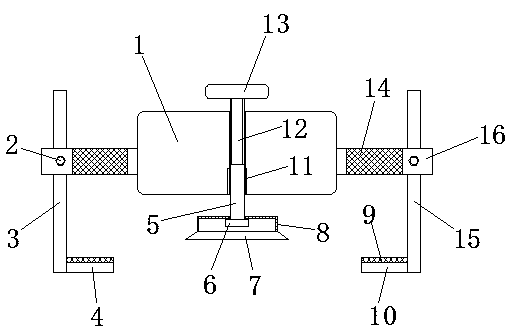

[0015] Such as figure 1 As shown, an adsorption transfer device for glass processing is composed of a frame 1, a support rod 16, a left moving rod 3, a right moving rod 15, a central rotating rod 5 and a suction cup 7; the middle part of the frame 1 is provided with a central through hole , the lower end of the central through hole is provided with an internal threaded hole 11, the central rotating rod 5 is pierced in the central through hole, the rotating disk 13 is arranged on the top of the central rotating rod 5, the suction cup 7 is arranged on the bottom of the central rotating rod 5 and passes through the limit The bump 6 is fixed in position, and the shaft of the central rotating rod 5 is provided with an external thread 12, and both sides of the frame 1 are connected with a support rod 16, and the support rod 16 is provided with a left moving rod 3 and a right movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com