Precision forging and plastic molding process for inner toothed ring of winch

A technology of plastic forming and internal gear ring, applied in the field of metal forging and pressing, can solve the problems of high processing cost, low production cost, long production cycle, etc., and achieve high tooth surface strength and precision, high comprehensive mechanical performance, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

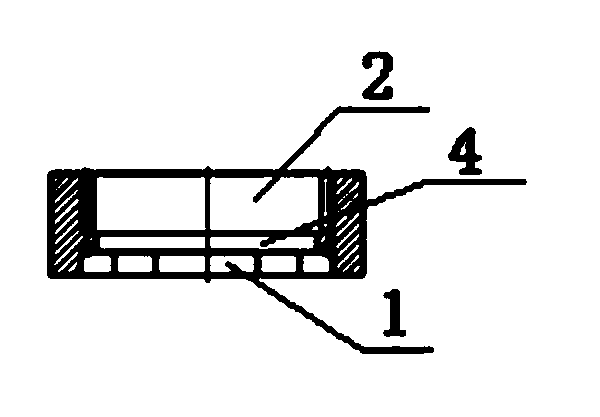

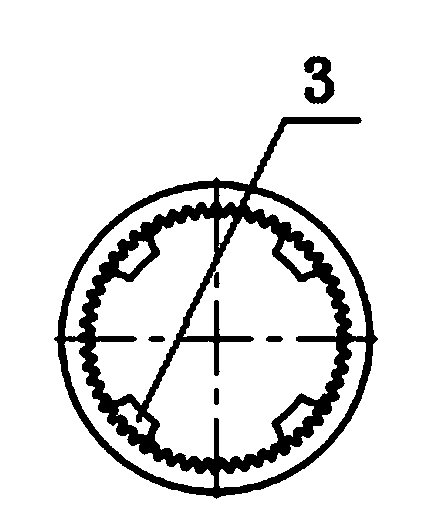

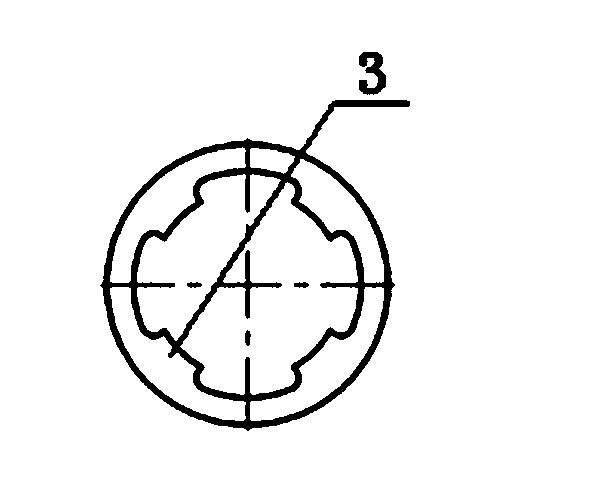

[0021] see figure 1 , figure 2 and image 3 As shown, a capstan internal gear ring includes an assembly end 1 and an internal gear ring 2, and a coupling portion 4 is also provided between the assembly end 1 and the internal gear ring 2, and the assembly end 1, the coupling portion 4 and the internal gear The ring 2 is an integral structure, and the positioning inner cavity of the assembly end 1 has a convex-convex geometry that cooperates with the assembly body. The positioning inner cavity of the assembly end 1 is a ring-shaped inner wall with four protrusions 3 evenly distributed on the inner wall of the assembly end. The inner diameter of the tooth top of the ring 2 is smaller than the inner diameter of the annular assembly end and larger than the inner diameter of the top of the corresponding protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com