Radiographic inspection robot

A radiographic inspection and robotics technology, applied in manipulators, material analysis using radiation, lifting devices, etc., to reduce the number of times entering the inspection room, speed up efficiency, and reduce missed work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

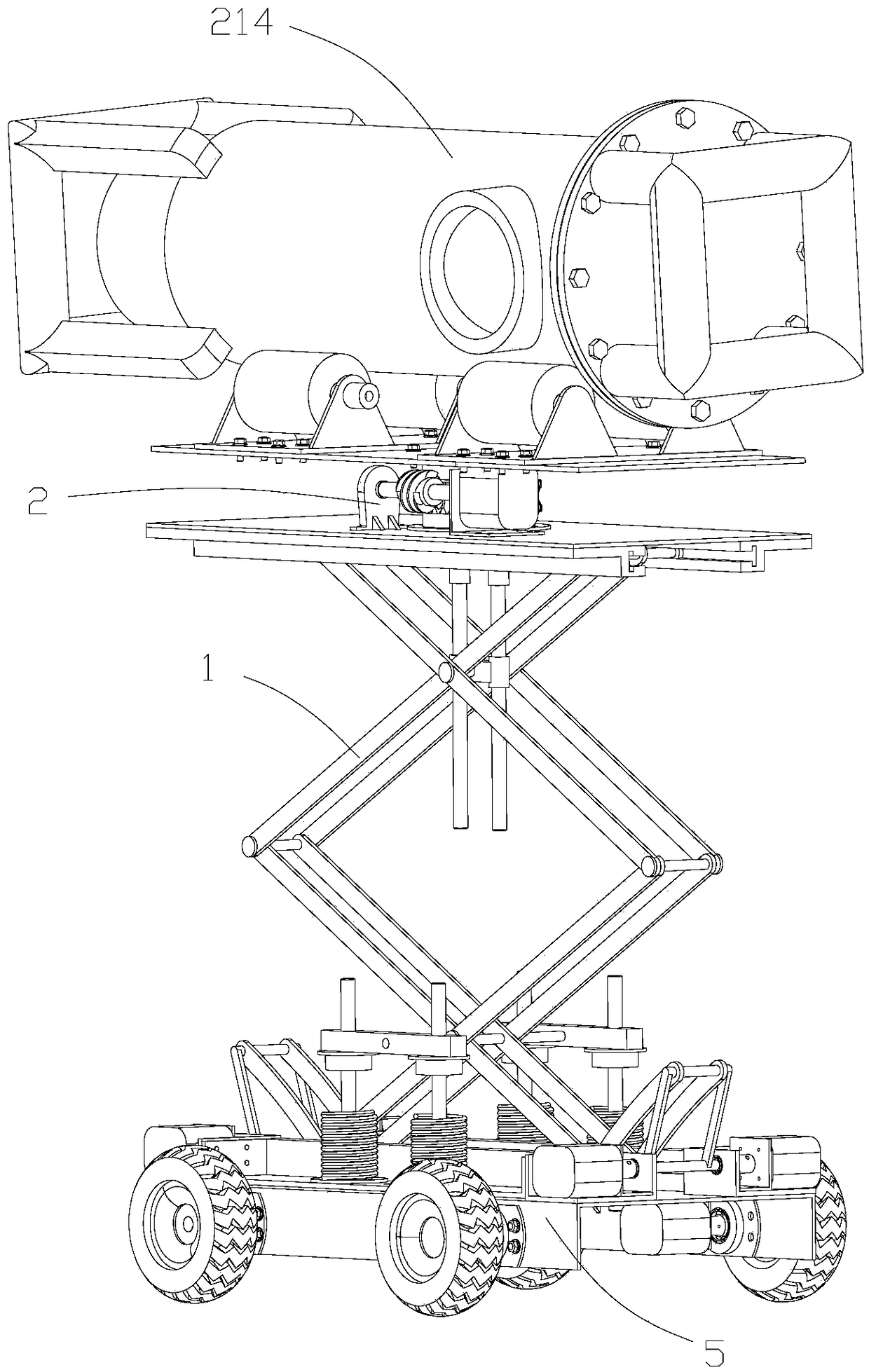

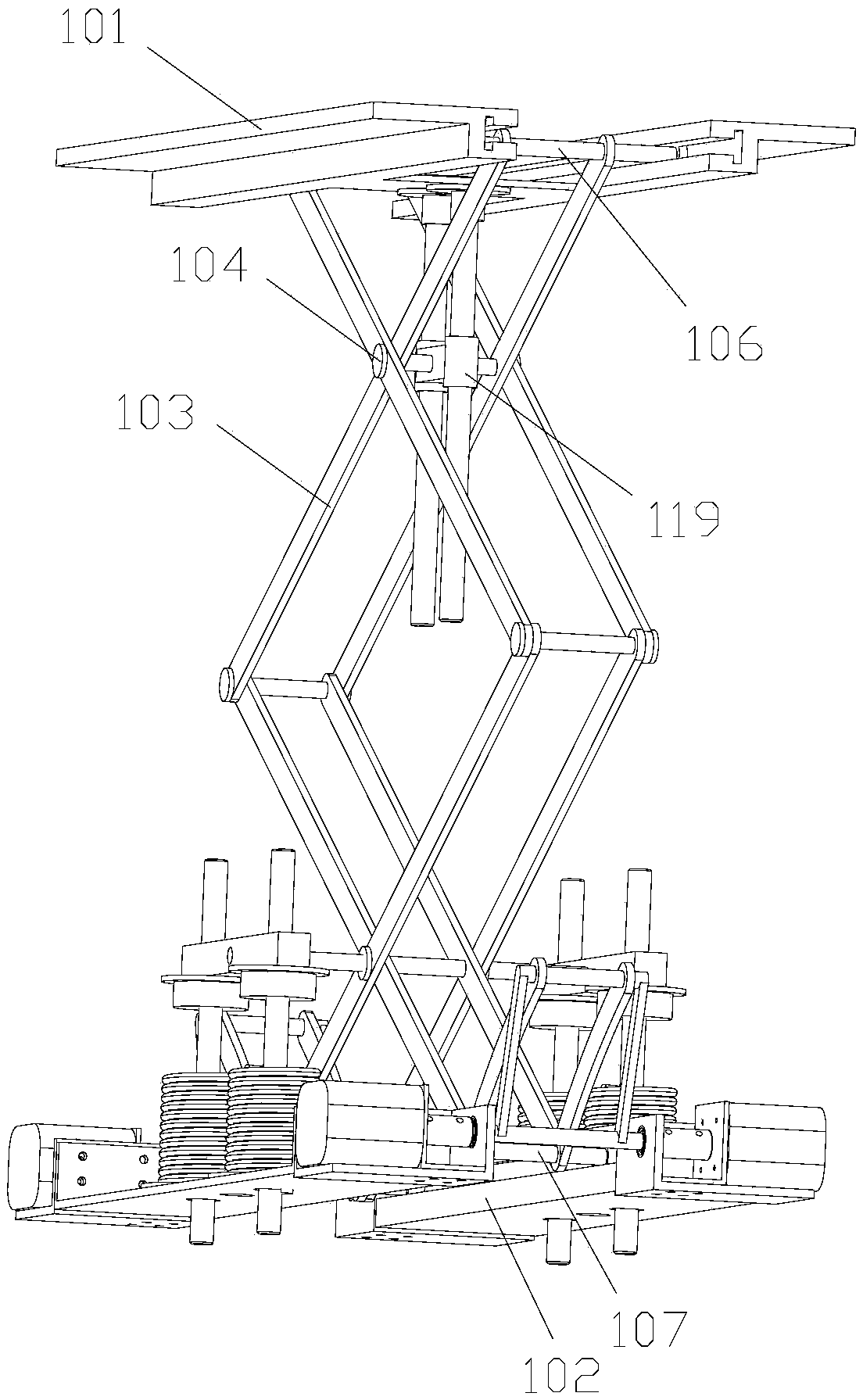

[0086] to combine figure 1 As shown, a radiographic inspection robot includes a traveling mechanism 5 , a lifting mechanism 1 and a rotating mechanism 2 . Wherein, the traveling mechanism 5, the lifting mechanism 1 and the rotating mechanism 2 are arranged in sequence from bottom to top.

[0087] The traveling mechanism 5 in this embodiment is used to realize the forward, backward or turning actions of the radiographic inspection robot.

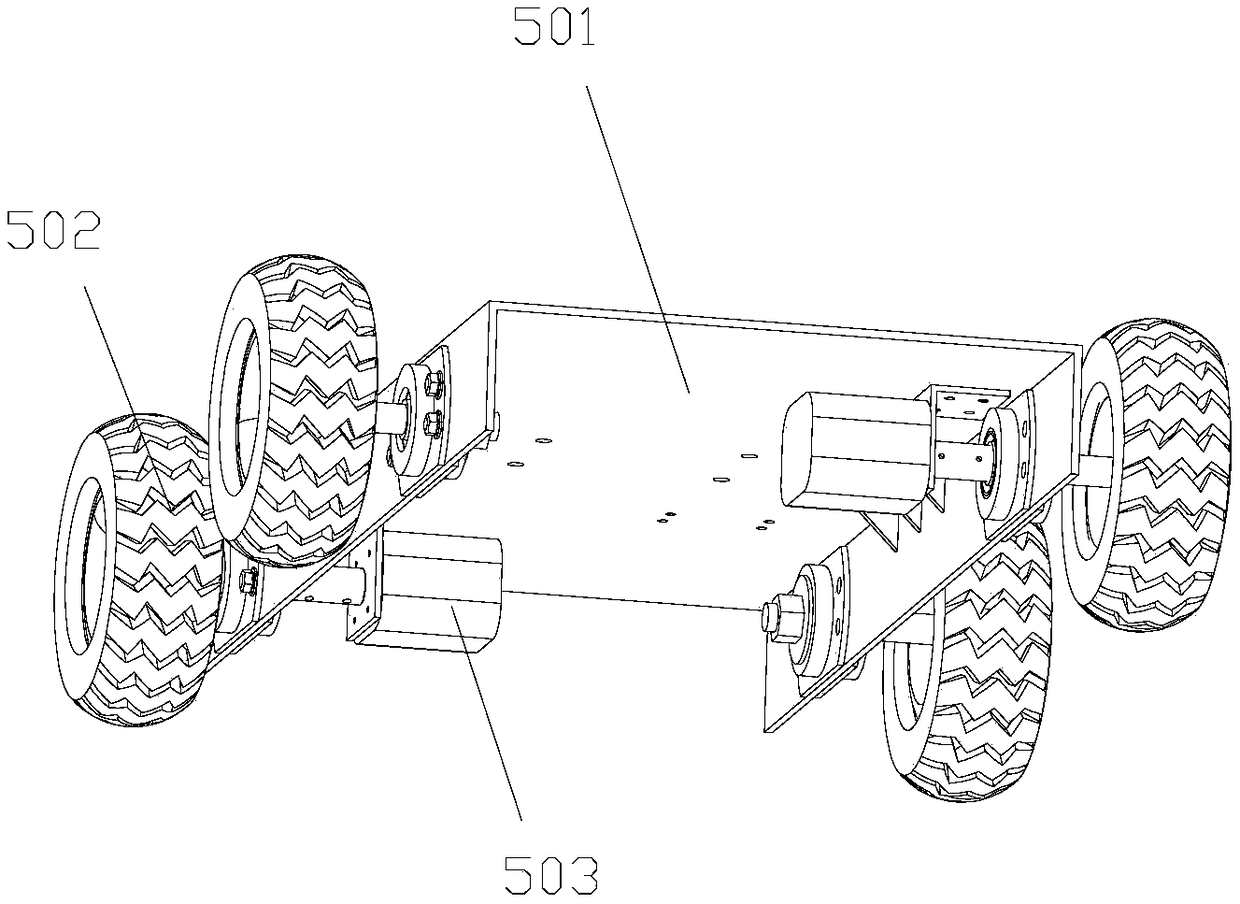

[0088] Such as figure 2 As shown, the traveling mechanism 5 includes a traveling mechanism mounting plate 501 and four traveling wheels, such as traveling wheels 502 . Wherein, two traveling wheels are driving wheels and are equipped with drive motors 503 respectively, and the other two traveling wheels are driven wheels.

[0089] Specifically, for example, the figure 2 The road wheel on the middle left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com