Large thin plate laser cutting clamp and machining method thereof

A technology of laser cutting and thin plate, which is applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of variable shape and difficult processing, and achieve the effect of reducing manufacturing cost, solving variable shape, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

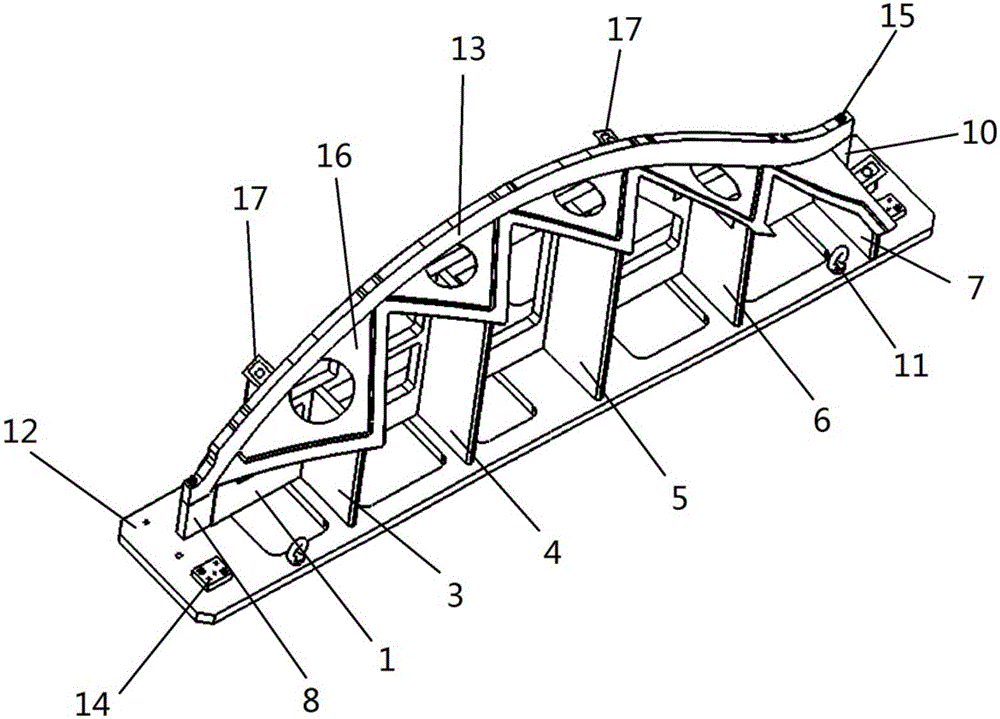

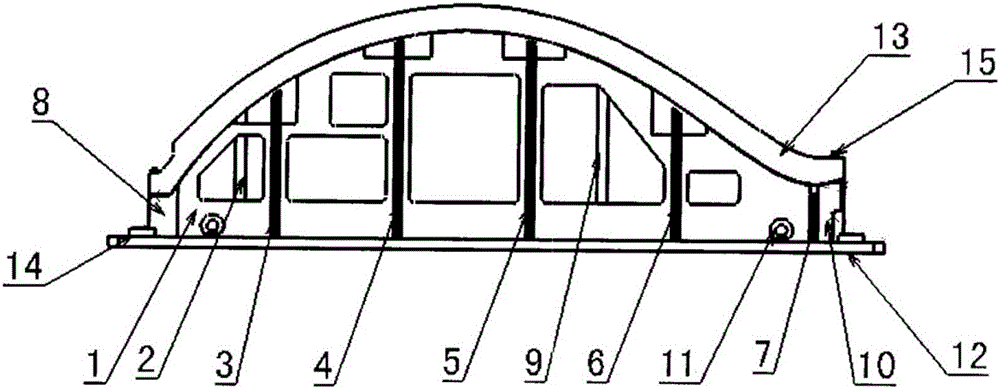

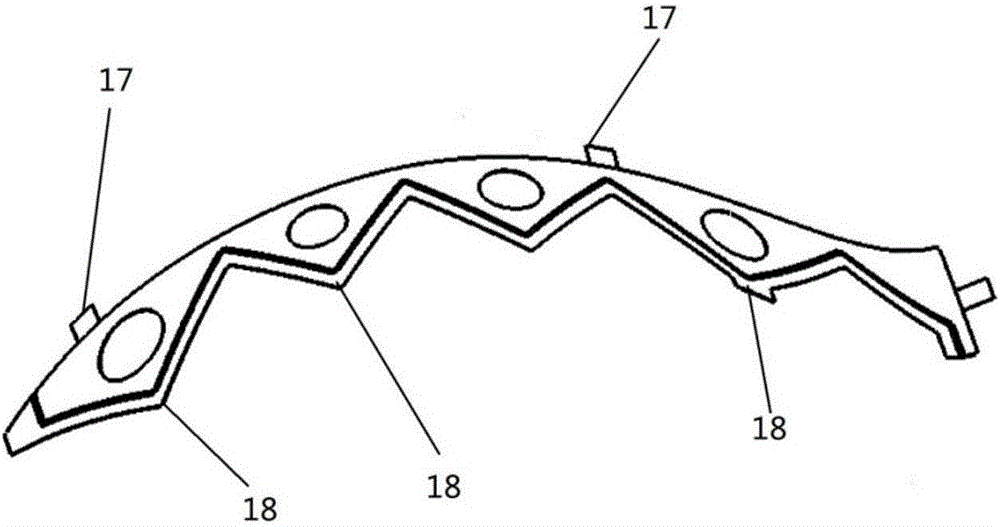

[0022] like Figure 1-2 A large thin plate laser cutting fixture is shown, which is used for clamping such as image 3 Shown aircraft skin part 16 has base plate 12 (thickness is 25mm), is provided with support frame 1 (thickness is 20mm) on base plate 12, and this support frame 1 is perpendicular to base plate 12, and the length of this support frame 1 and cover The lengths of the leather parts 16 are matched. The top surface of the support frame 1 is a curved surface I, and the curvature of the curved surface I matches the curvature of the skin part 16 .

[0023] On the bottom plate 12, there are five brackets I (thickness: 20mm) on one side of the support frame 1, which are respectively the first bracket I3, the second bracket I4, the third bracket I5, and the fourth bracket I6, and fifth bay I7. And the surface of the skin part 16 is supported by these five brackets I with different heights. The number of brackets I depends on the length of the skin part 16 and is adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com