Preparation method of slump-retaining reinforced fiber concrete

A fiber-reinforced, concrete-enhanced technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as low efficiency, large footprint, cumbersome process, etc., to stabilize the cleaning process and reduce Support work fatigue and improve cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technique of the present invention, the creation characteristics, the achievement and the efficiency are readily understood, and the present invention is further illustrated in connection with the present invention, and it is to be explained, and the embodiments in the present application are described below. The features in the examples can be combined with each other.

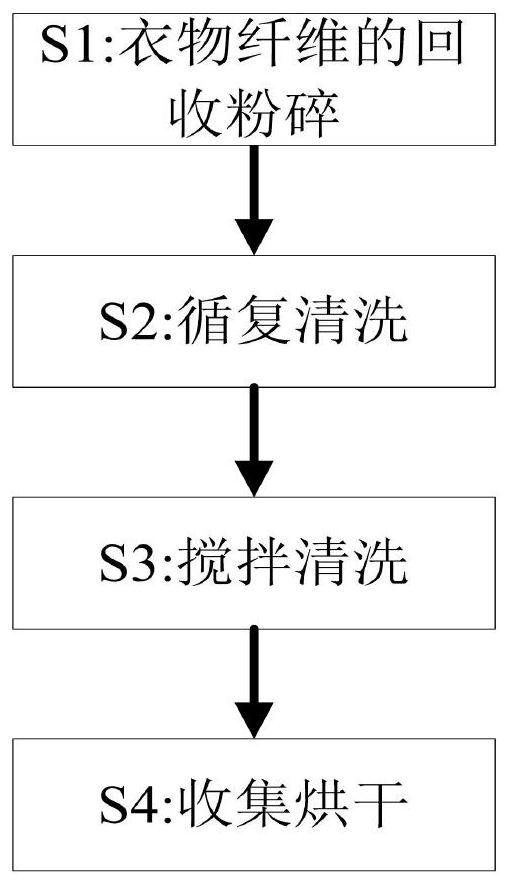

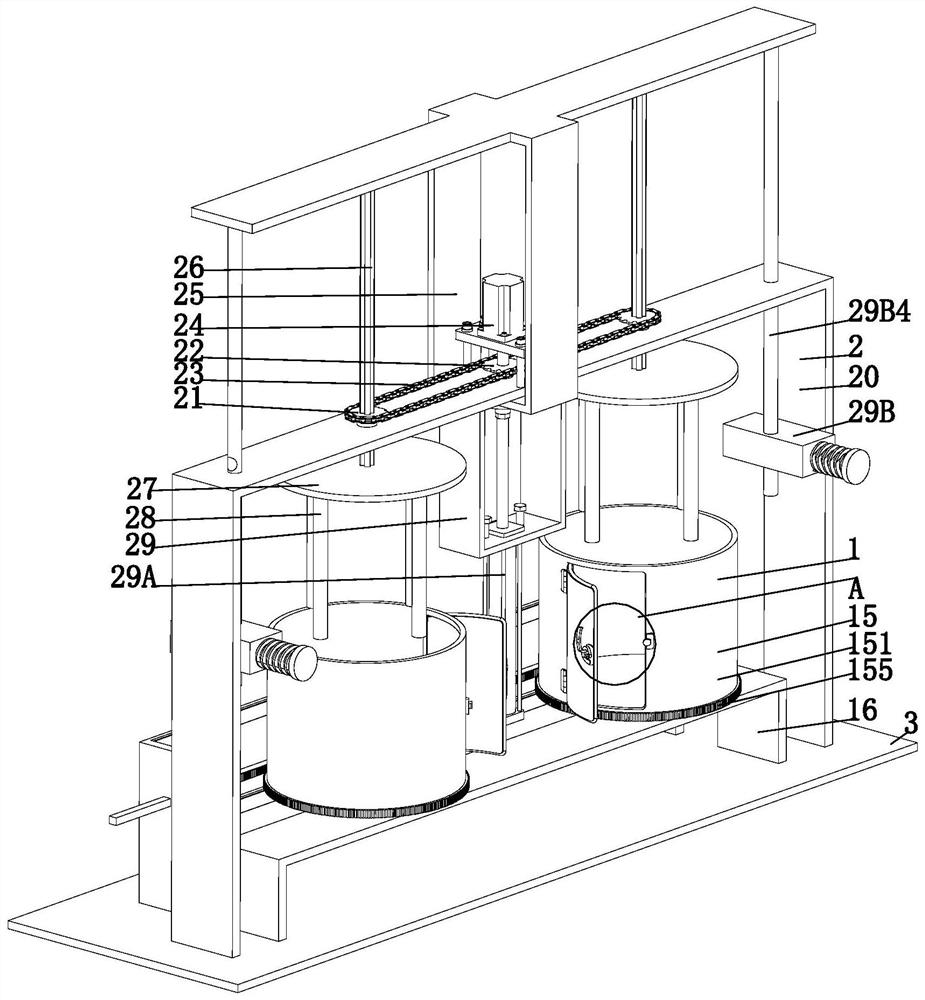

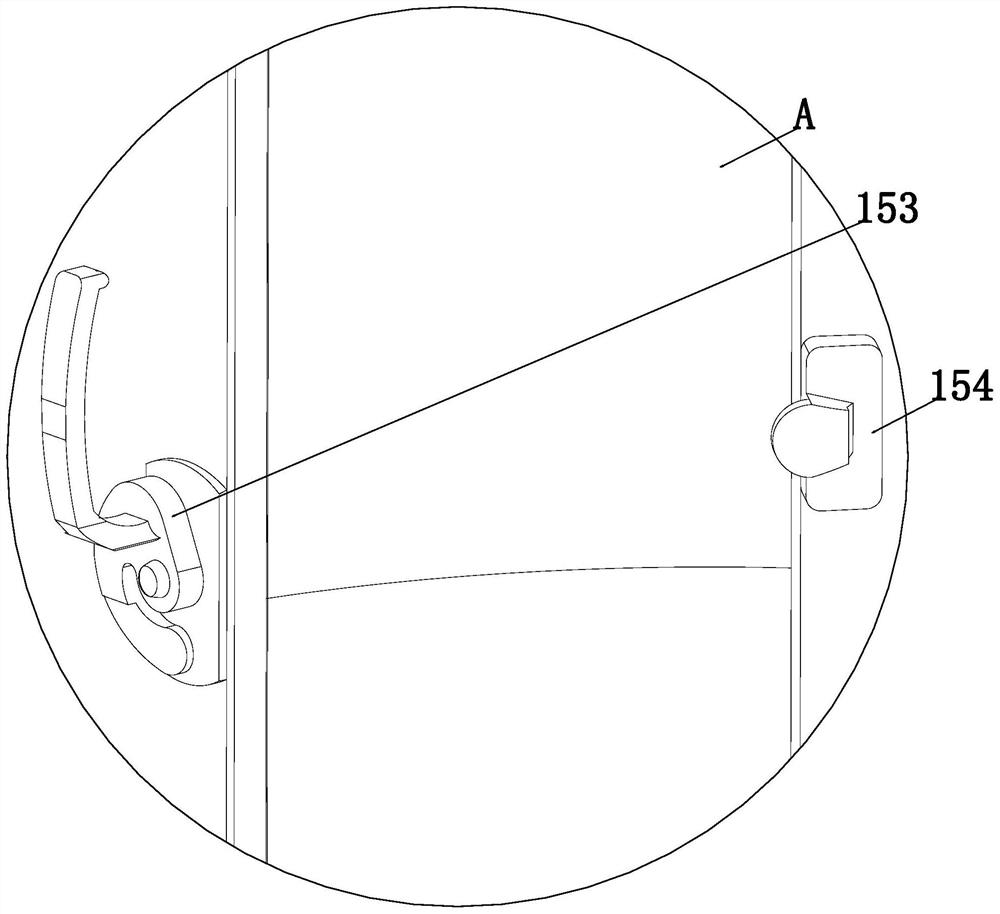

[0032] Such as Figure 1 to 9 As shown, a collapsed reinforced fiber concrete preparation method is used, which uses a collapsed reinforced fiber concrete production apparatus, which includes a burst cleaning mechanism 1, a stirring mechanism 2, and a bottom plate 3, and the above-described manufacturing equipment The specific method of cleaning fibers in fiber concrete is as follows:

[0033] S1, the recovery of clothing fibers: The recovered waste laundry is concentrated by pulverizing means to make the laundry becomes a cranked fiber material;

[0034] S2, burst cleaning: By fluidizi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com