Patents

Literature

110results about How to "Efficient cooperation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

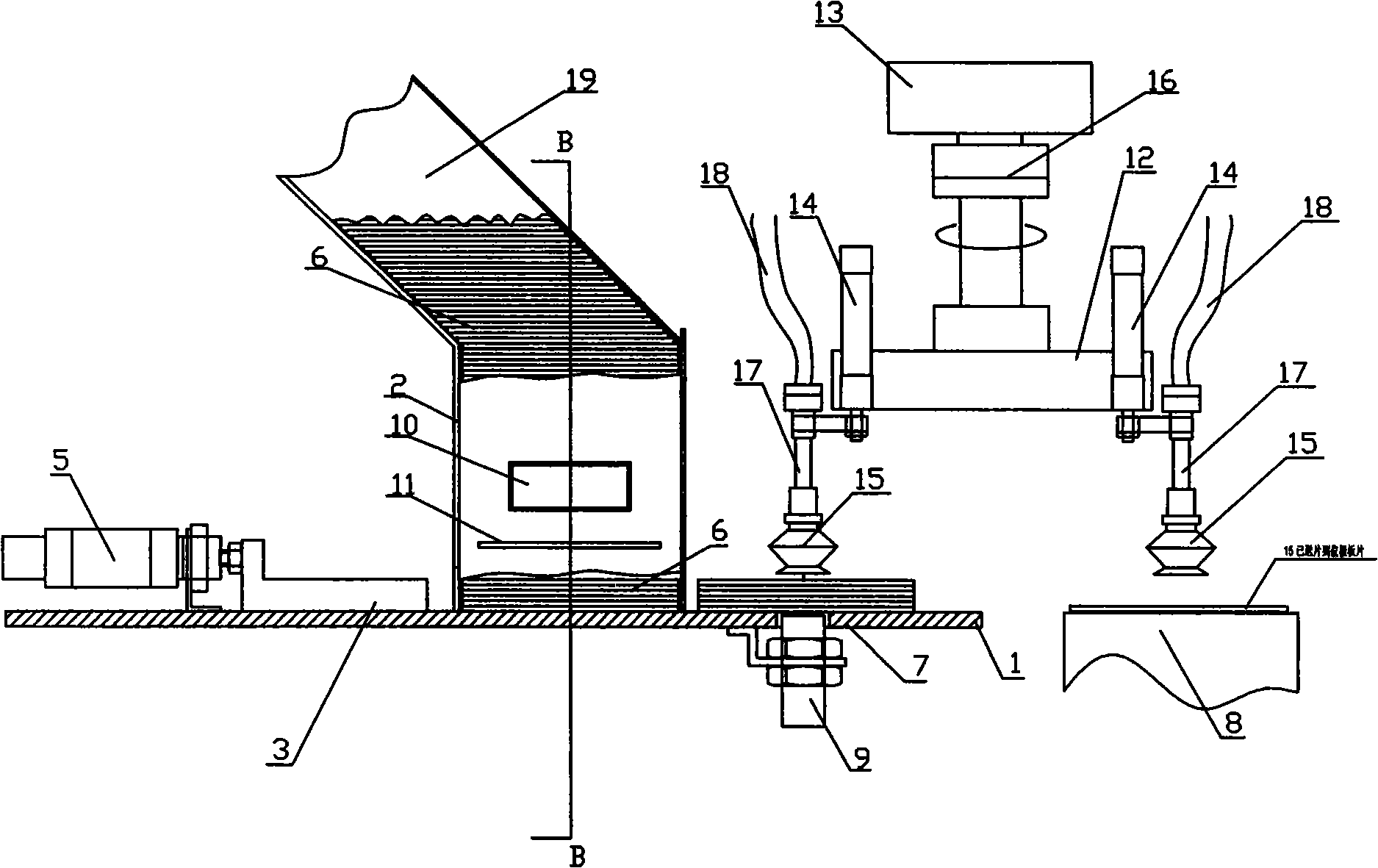

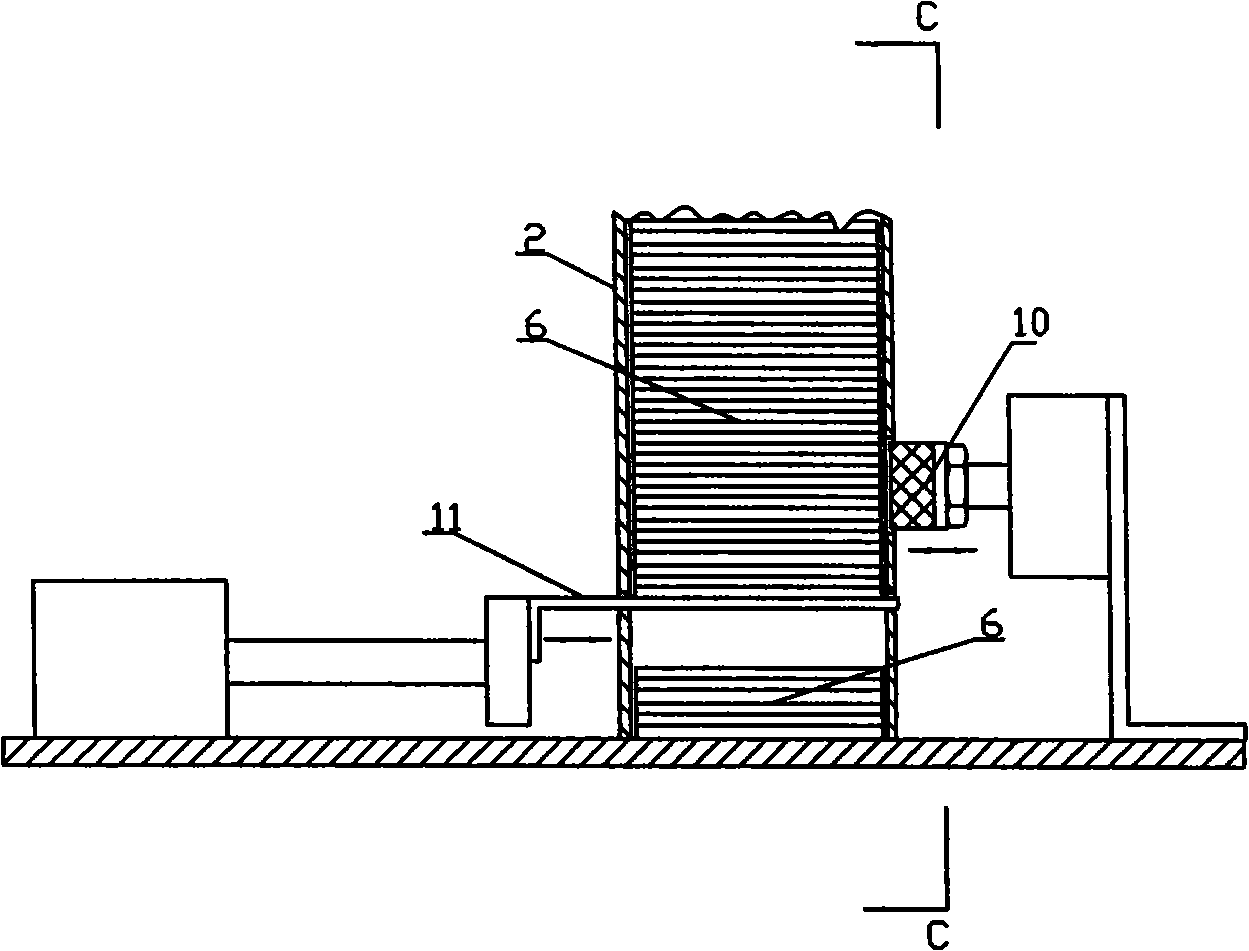

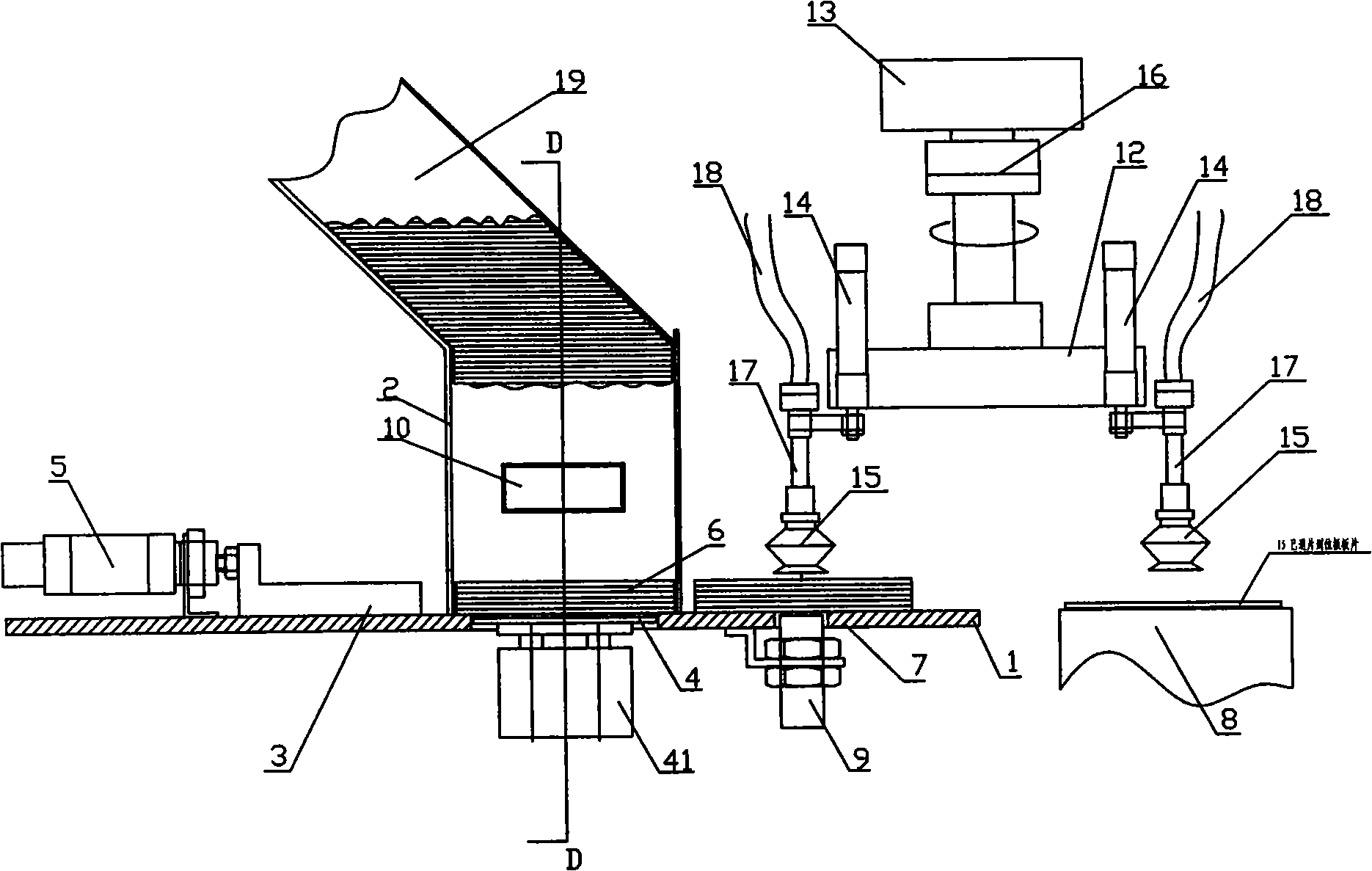

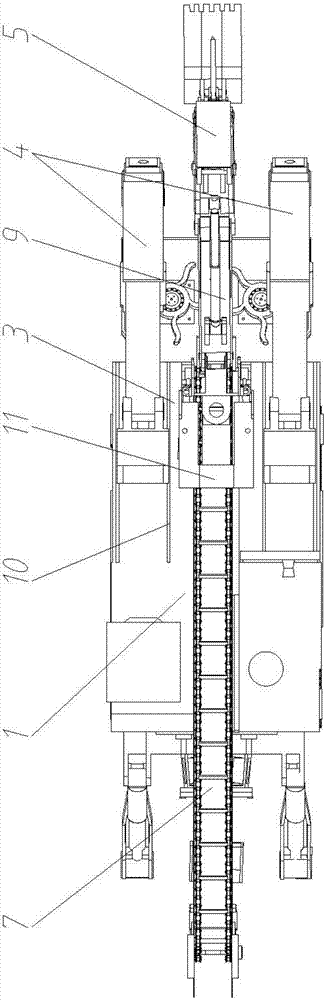

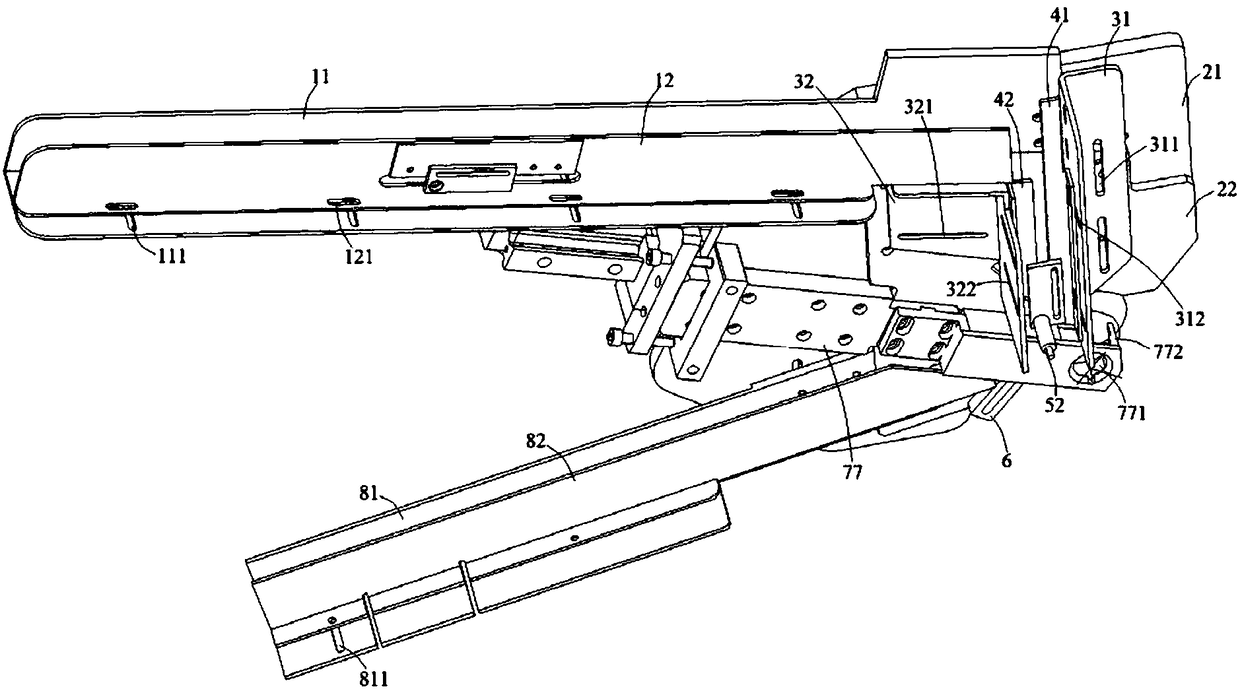

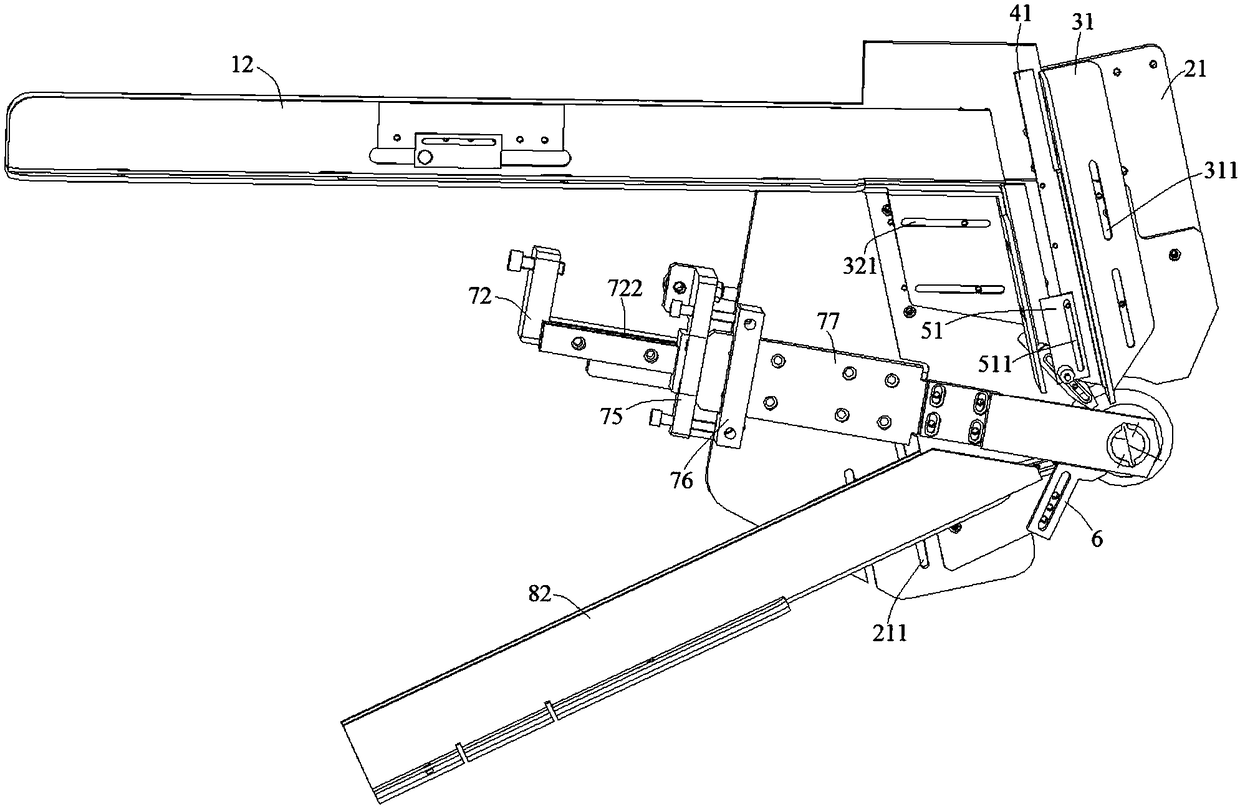

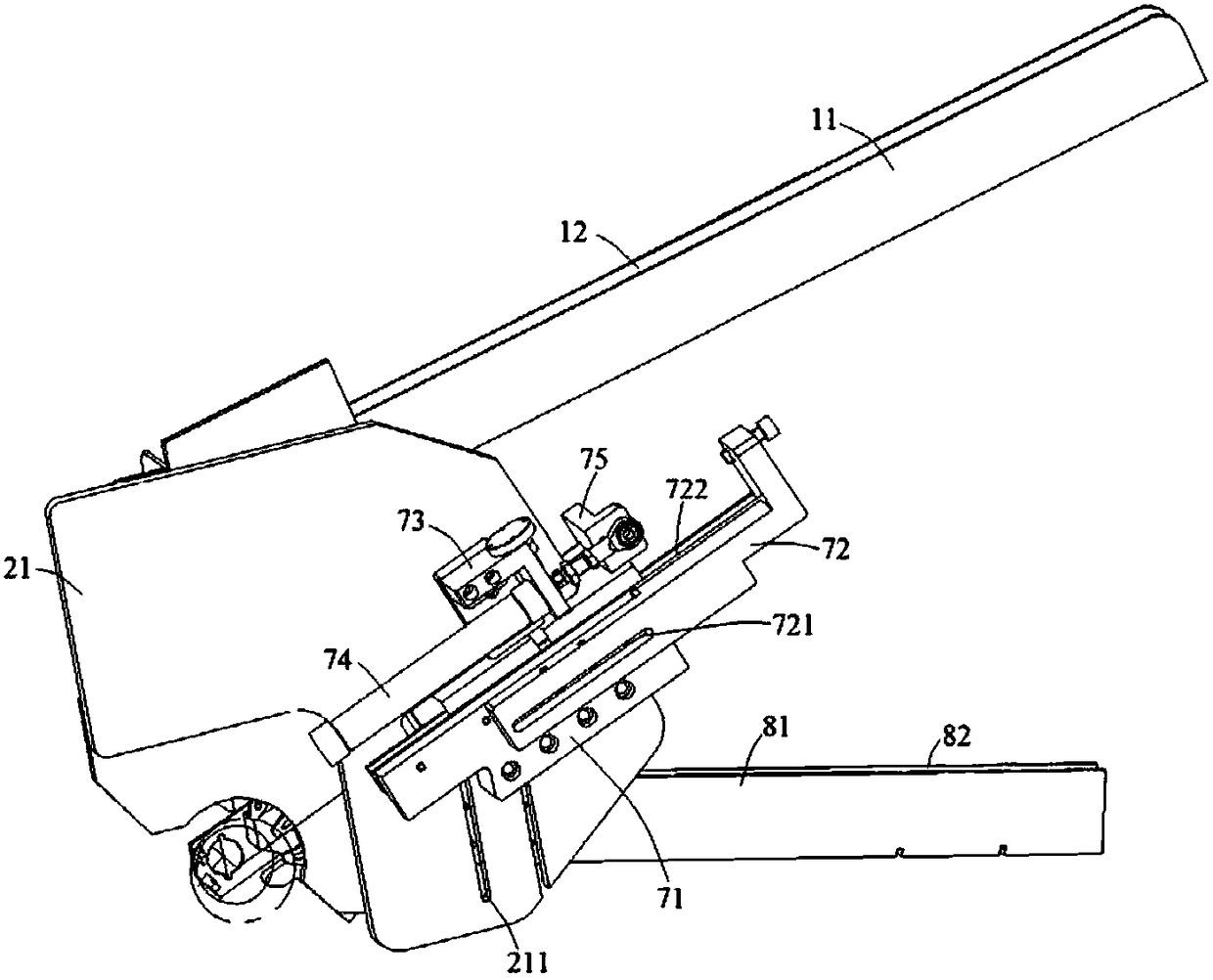

Feeding device of sorter of batteries plate

InactiveCN101357717ASimple structureCooperate wellGripping headsDe-stacking articlesBattery electrodeEngineering

The invention discloses a battery electrode sorting machine sheet conveying device, consisting of a material conveying platform, a vertical material bin, a material feeding pushing plate and a reciprocating swing sheet conveying mechanism; the vertical material bin is arranged above the middle part of the material conveying platform; the material conveying pushing plate is arranged at the rear part of the vertical material bin of the material conveying platform; the material conveying pushing plate is pushed by a material conveying cylinder and can slide forwards and backwards; the batter electrodes which are piled at the bottom of the vertical material bin are sent into the sheet taking positions of the reciprocating swing sheet conveying mechanism; the reciprocating swing sheet conveying mechanism is arranged above the front part of the material conveying platform; the battery electrodes piled at the sheet taking positions are sent to a feeding working position of the battery electrode sorting machine one after another. The battery electrode sorting machine sheet conveying device of the invention has simple structure, can quickly, exactly and safely send the battery electrodes into the inlet of the sorting machine one after another, and realizes the high-efficiency matching of the battery electrode sorting machine, thus ensuring that the battery electrode sorting machine sufficiently exerts the working efficiency.

Owner:NANJING NORMAL UNIVERSITY

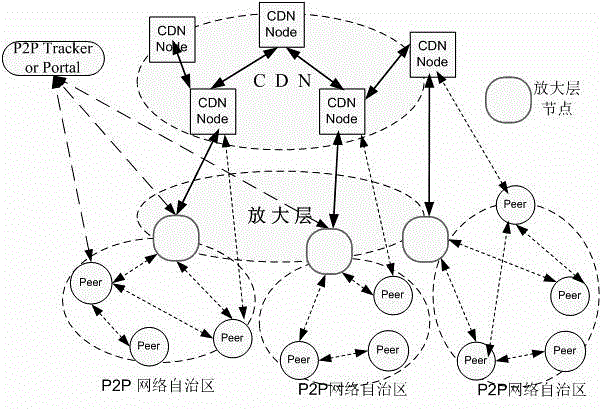

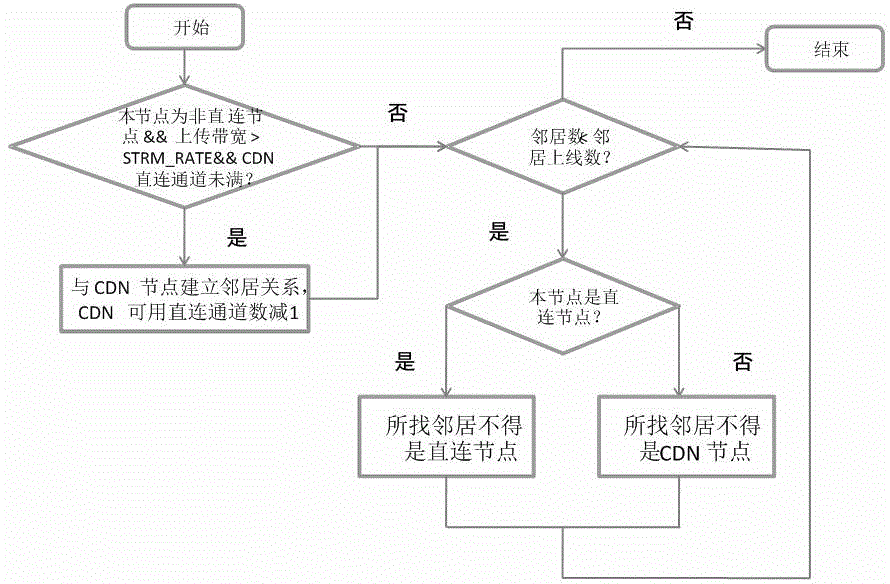

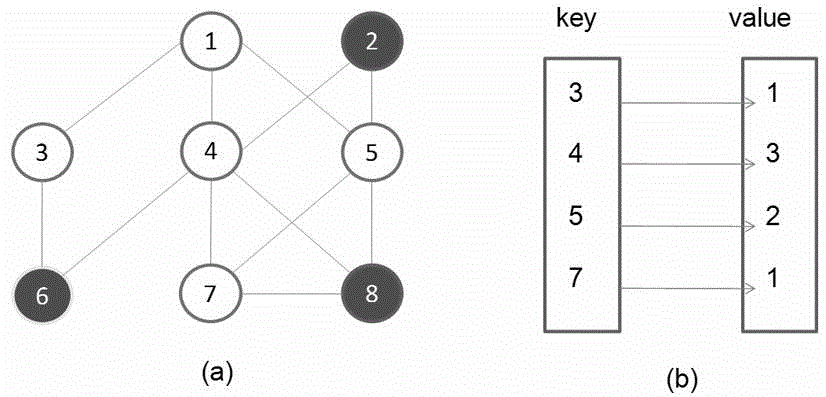

Method of CDN to actively select high quality nodes in advance to conduct optimizing content distribution service

InactiveCN102984279AEfficient disseminationEfficient cooperationTransmissionContent distributionVideo on demand

The invention belongs to the technical field of network multimedia, and particularly discloses a method of a CDN (content distribution network) to actively select high quality nodes in advance to conduct an optimizing content distribution service. The method comprises the steps that an amplification layer is added in an overlay network; a CDN server selects a certain number of high quality nodes through information obtained from peer nodes to serve as nodes of the amplification layer; when system performances are poor or service ability is limited, the CDN services the high quality nodes directly and preferentially but does not service common nodes blindly; and the high quality nodes service the common nodes continuously, so that stream media data is spread more efficiently. With the adoption of the mode, the CDN can cooperate with a P2P (Peer to Peer) system, a VOD (video on demand) system and the like more efficiently. The method operates stably after probation; a result proves that compared with the existing traditional CDN-P2P mixed architecture, the performance is improved by at least 10-25%; and experimental comparison indexes comprise start-up delay, play quality and play delay.

Owner:FUDAN UNIV

Soil conditioner prepared from sludge and preparation method thereof

InactiveCN106867544ASave landfill landResolve disposal issuesAgriculture tools and machinesOther chemical processesEcological environmentResource utilization

The invention belongs to the field of solid waste reclamation comprehensive utilization and particularly relates to a soil conditioner prepared from sludge and a preparation method thereof. The soil conditioner is prepared from river and lake bottom mud, conditioner, medium sand, agricultural and forestry residues, biological manure and plant ash, wherein the conditioner is 5% to 8% of the mass of the river and lake bottom mud, the medium sand is 5% to 10% of the mass of the river and lake bottom mud, the agricultural and forestry residues are 5% to 10% of the mass of the river and lake bottom mud, the biological manure is 1% to 5% of the mass of the river and lake bottom mud, and the plant ash is 1% to 3% of the mass of the river and lake bottom mud. The soil conditioner prepared from sludge disclosed by the invention achieves resource utilization of sludge, also fully utilizes sludge, tailings or river and lake sand, tailing sand, pipe network sand and agricultural and forestry residues at the same, achieves the purpose of treating waste through waste, avoids solid waste landfill, land occupancy and secondary pollution, reduces engineering cost of land reclamation, landscaping, forest land plant and the like and is beneficial to ecological environment; in addition, the river and lake sand, the tailing sand, the pipe network sand and the agricultural and forestry residues are separated and sorted from pipe network sludge.

Owner:SAFECLEEN TECH

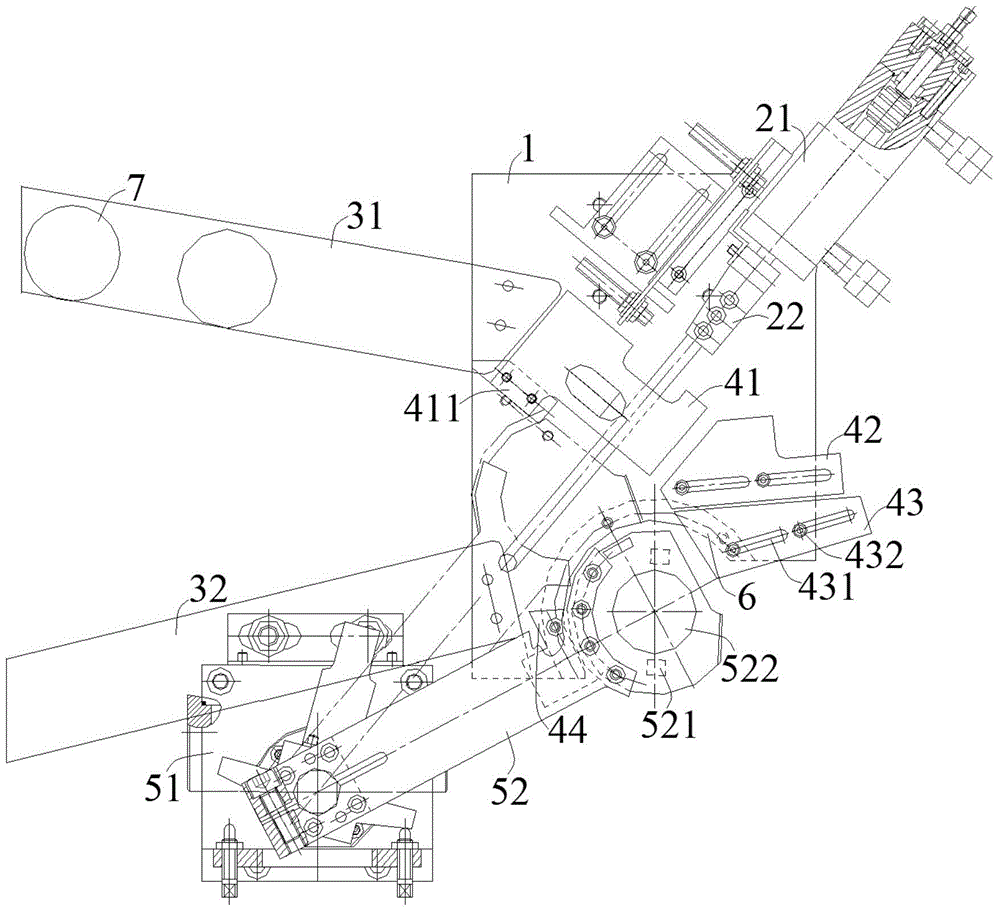

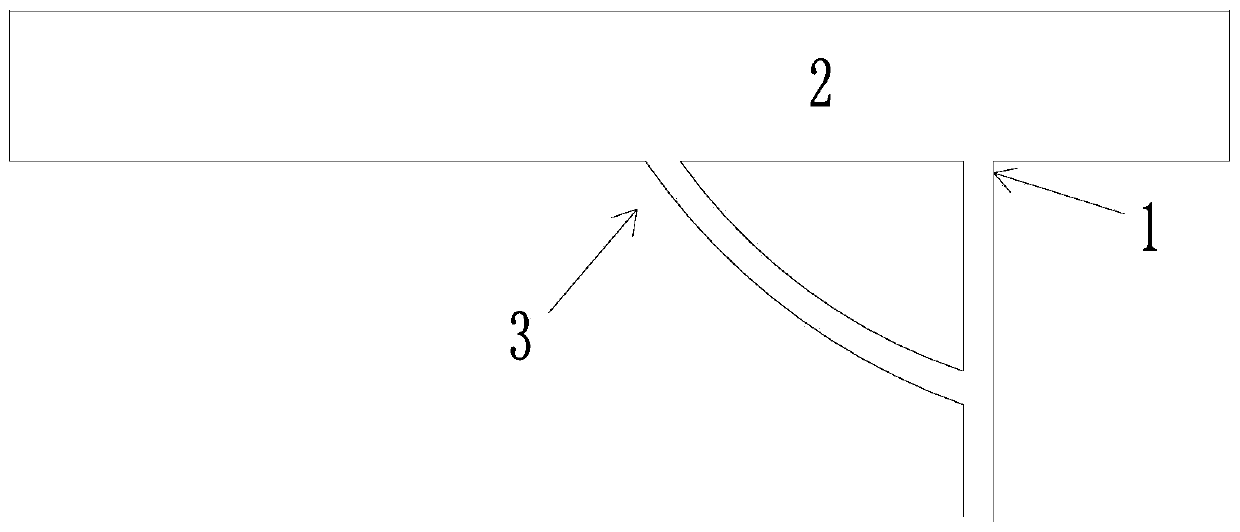

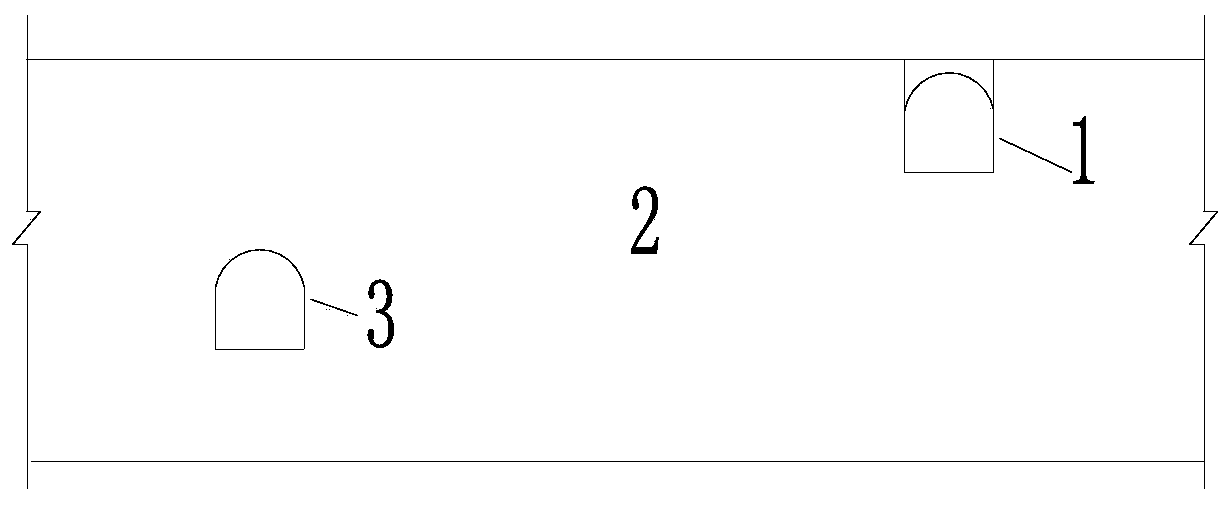

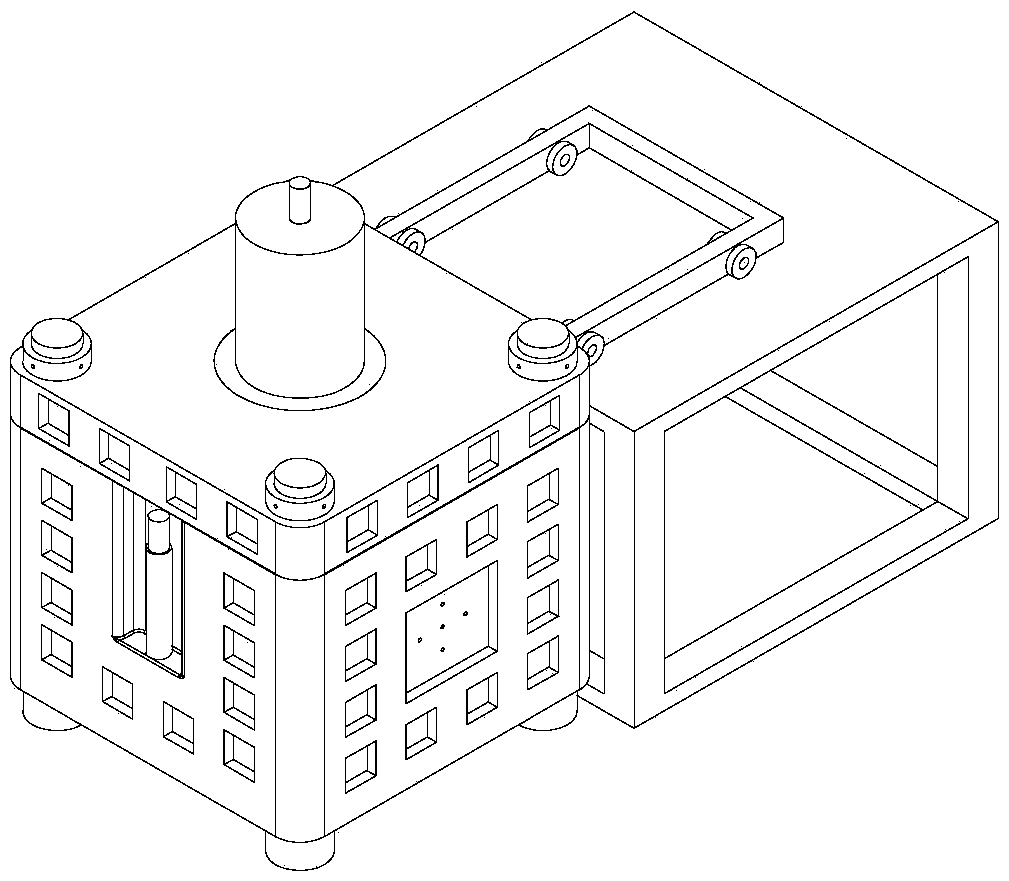

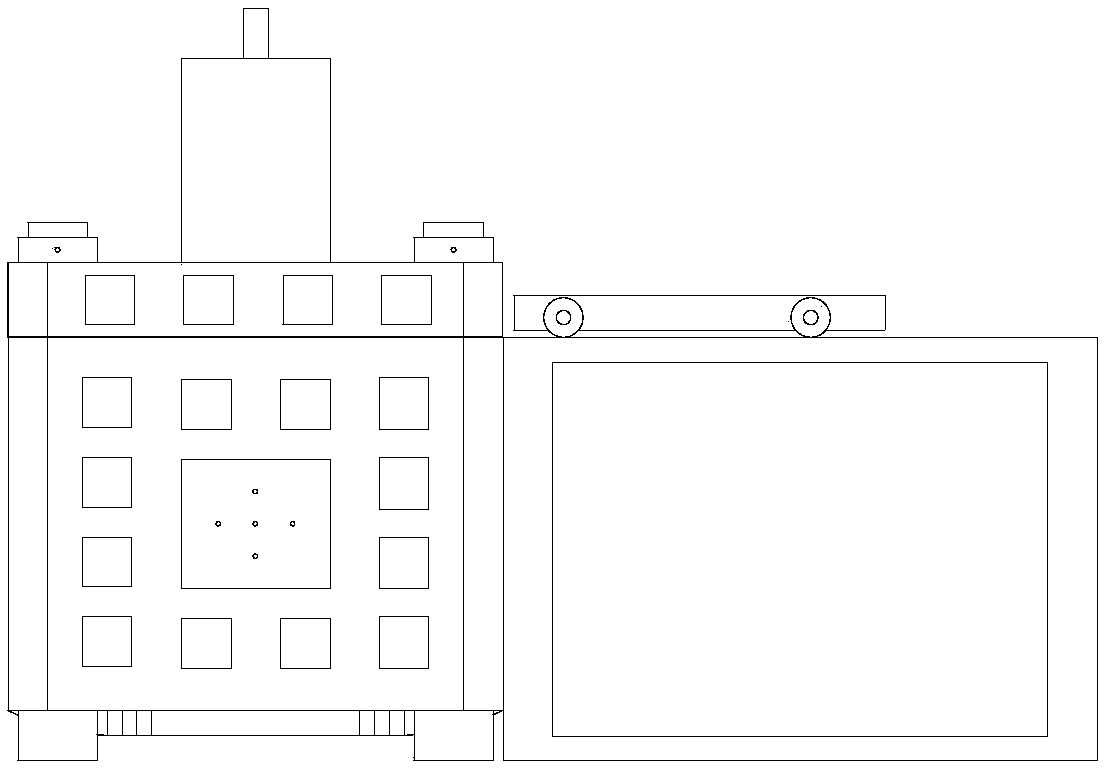

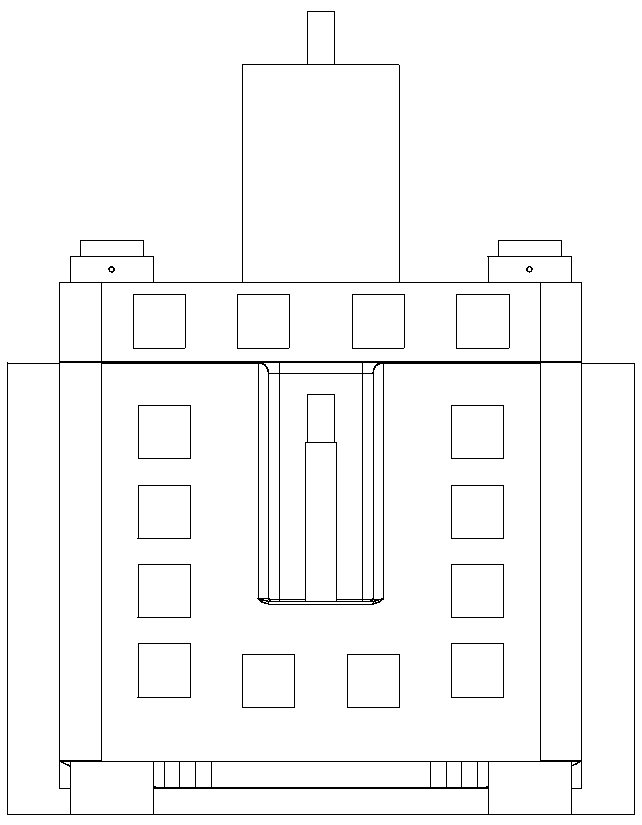

Automatic inner bore grinding device and automatic inner bore grinding method

ActiveCN104476340AImprove processing efficiencyEfficient cooperationRevolution surface grinding machinesEngineeringUltimate tensile strength

The invention discloses an automatic inner bore grinding device and an automatic inner bore grinding method and belongs to the technical field of processing of inner holes. The automatic inner bore grinding device comprises a feeding passage, a material saving mechanism, a pushing mechanism, a material blocking mechanism and a discharging passage, wherein the material saving mechanism is used for conveying to-be-ground pieces rolling in the feeding passage to the pushing mechanism, limiting the next to-be-ground piece when the previous to-be-ground piece is subjected to inner hole grinding until the previous to-be-ground piece is discharged through the discharging passage, and then conveying the next to-be-ground piece to the pushing mechanism; the pushing mechanism is used for rotating and pushing the to-be-ground pieces to processing stations for inner hole grinding; the material blocking mechanism is matched with the material saving mechanism and the pushing mechanism and used for limiting the to-be-ground pieces to move according to specified path. The feeding and discharging rhythm is controlled by virtue of up-and-down movement of a material saving rod; a manipulator is rotated to push the to-be-ground pieces to the processing stations, so that automatic feeding-processing-discharging circulation is realized, the whole processing process is free of manual intervention, the labor strength of working personnel is low and the inner hole processing efficiency is high.

Owner:MAANSHAN HENGLIDA MACHINE BLADE +1

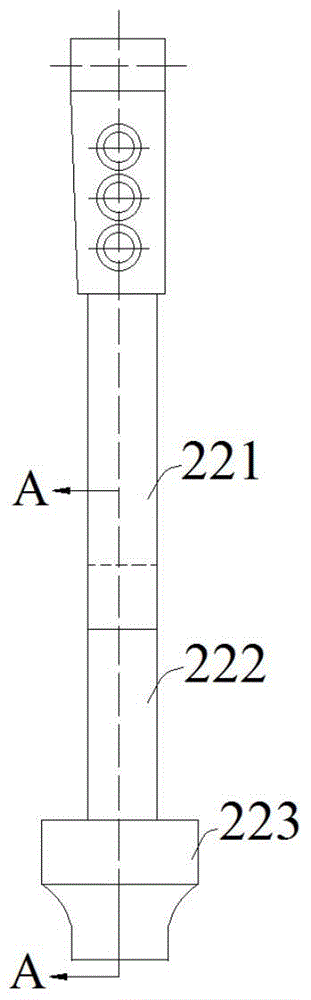

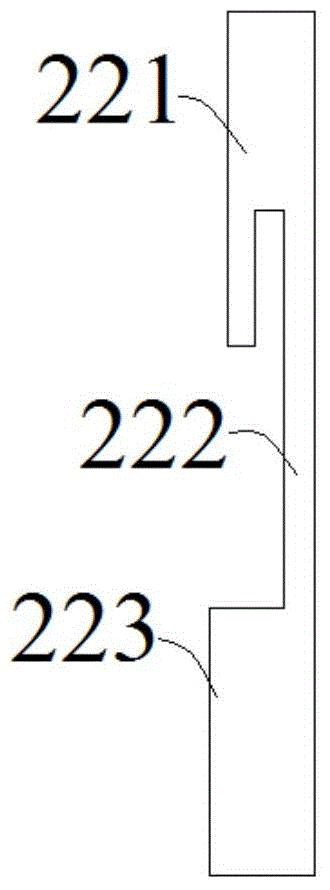

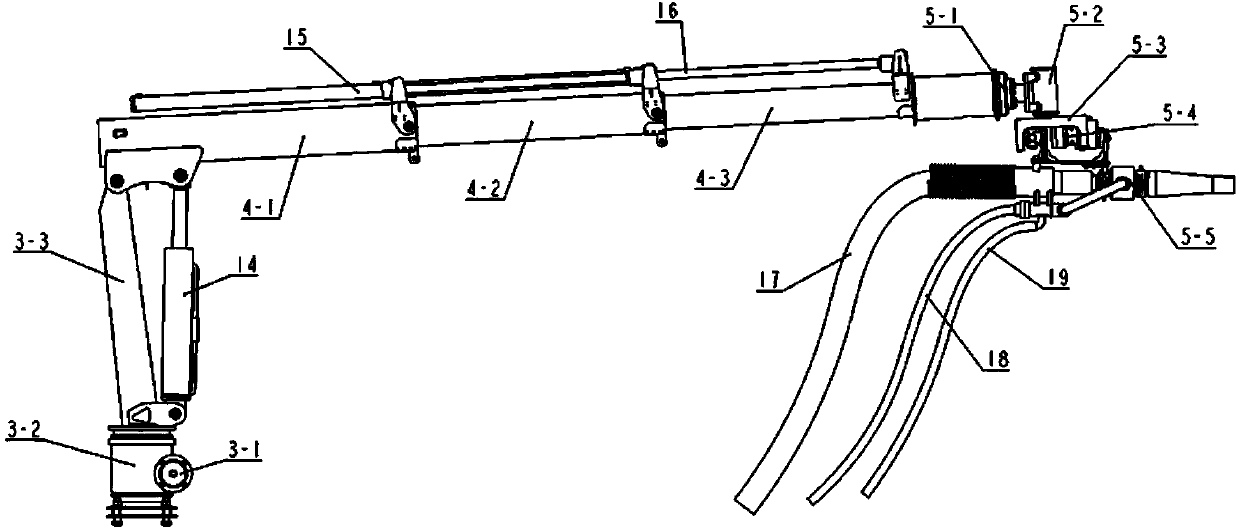

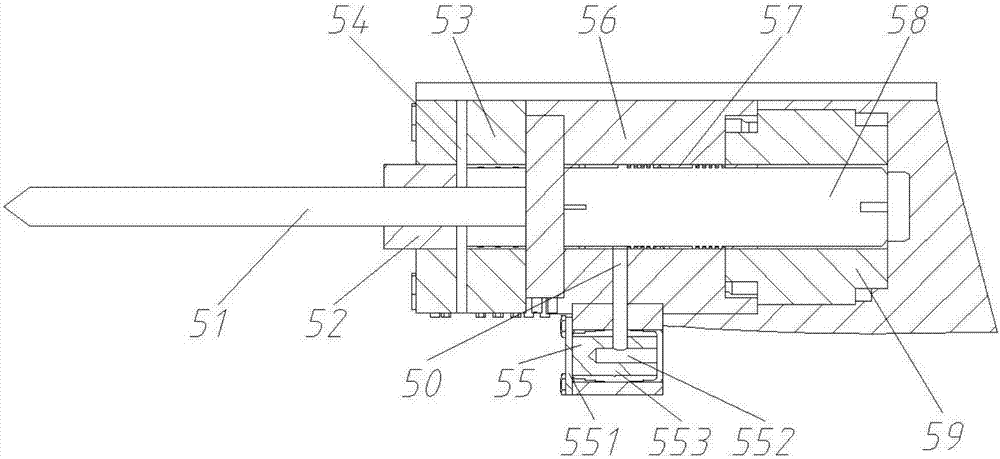

Grouting manipulator

InactiveCN103775103ACooperate wellConvenient for spraying workUnderground chambersTunnel liningManipulatorCompressed air

The invention relates to a grouting manipulator. The grouting manipulator comprises a chassis, a revolving mechanism, an arm support, a spray head device, a hydraulic system and an electric system, wherein the revolving mechanism, the hydraulic system and the electric system are arranged on the chassis; the arm support is hinged to the revolving mechanism, and can be driven to rotate relative to the chassis by using the revolving mechanism; the spray head device is arranged at the front end of the arm support, and is connected with a concrete conveying pipe, a compressed air conveying pipe and a setting accelerator conveying pipe of a wet sprayer; the electric system and the hydraulic system are used for controlling the actions of the arm support and the spray head device. By adopting the grouting manipulator, efficient matching with the wet sprayer is realized, operating personnel can carry out grouting work conveniently, the spray height and position can be adjusted conveniently, heavy labor work of manual holding of a spray head is liberated, the spray range is enlarged, and the construction quality is improved. Compared with a large-sized grouting vehicle, the grouting manipulator has the advantages of simple structure, small size, lower cost, suitability for construction of certain medium and small-section tunnels, and more extensive application occasions.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

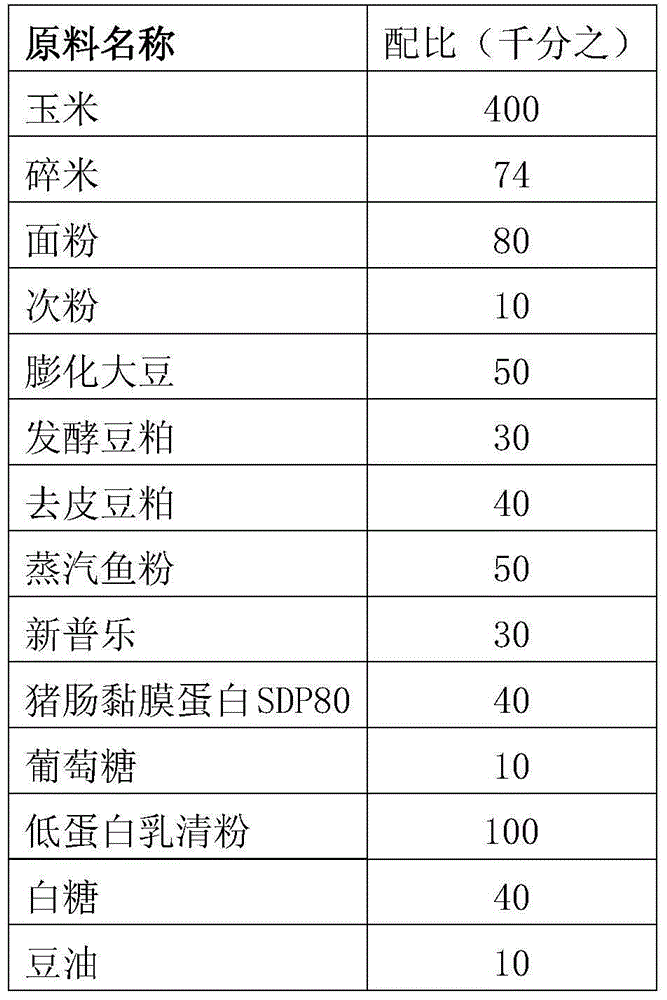

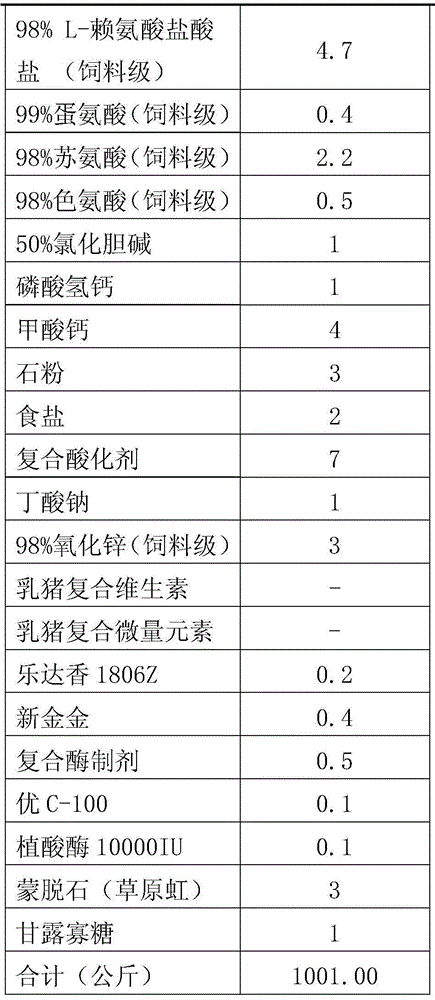

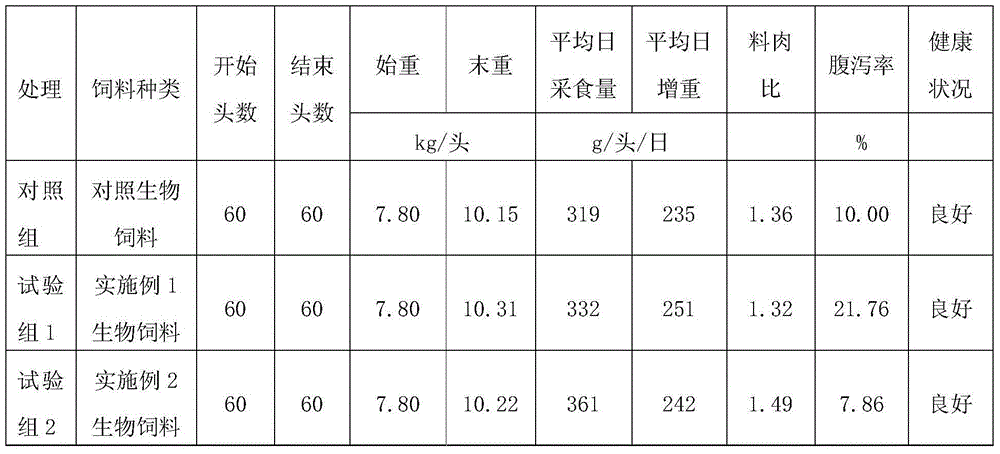

Safe low-copper biological compound feed free of antibiotics or plasma protein powder for suckling pigs

InactiveCN104543579AImprove immunityImprove palatabilityAnimal feeding stuffAnimal scienceFeed conversion ratio

The invention discloses a safe low-copper biological compound feed free of antibiotics or plasma protein powder for suckling pigs. The invention provides specific components and proportions of the biological feed, and application of the biological feed in improvement of daily gain, daily feed intake and / or feed conversion ratio. A biological composition free of the antibiotics or the plasma protein powder for the suckling pigs is developed from four aspects of improvement of the feed digestibility, improvement of the feed palatability, cultivation of intestinal flora and enhancement of the immunity of piglets according to the nutrient physiological characteristics of the suckling pigs; the selected raw materials are environmentally friendly and safe; a feeding experiment proves that the diarrhea rate is obviously reduced; the feed palatability is improved; the food intake and the daily gain are improved; and the biological compound feed disclosed by the invention is a safe, environment-friendly and efficient composition for the suckling pigs.

Owner:北京挑战牧业科技有限公司

A New Method to Control Membrane Fouling in Membrane-Bioreactor

InactiveCN102276055AReduce membrane foulingMitigation of membrane foulingSustainable biological treatmentBiological water/sewage treatmentDuplex systemChemistry

A new method for controlling membrane fouling in a membrane-bioreactor relates to a technology for controlling fouling of a membrane component in a membrane-bioreactor, and is suitable for treating water and waste water by a membrane-bioreactor. The invention forms a dual system of biofilm method and membrane-bioreactor by adding a certain amount of filler in the reactor as the carrier of the biofilm, thereby reducing the pollution rate of the surface of the membrane module; at the same time, the optimized aeration method can By controlling the metabolism of microorganisms to further slow down membrane fouling and reduce energy consumption. The method of the present invention does not require structural modification of the original membrane-bioreactor, only needs to add a certain amount of filler, and the method of the present invention can further reduce energy consumption, and is suitable for membrane-bioreactions in the form of various membrane modules It has strong practicability, wide application range, low operating cost, and convenient operation and management. The invention integrates the biofilm method and the membrane-bioreactor efficiently, and has an optimized aeration mode, can well control membrane pollution, reduce energy consumption, and realize long-term stable operation of the membrane-bioreactor.

Owner:PACIFIC WATER TREATMENT ENG +1

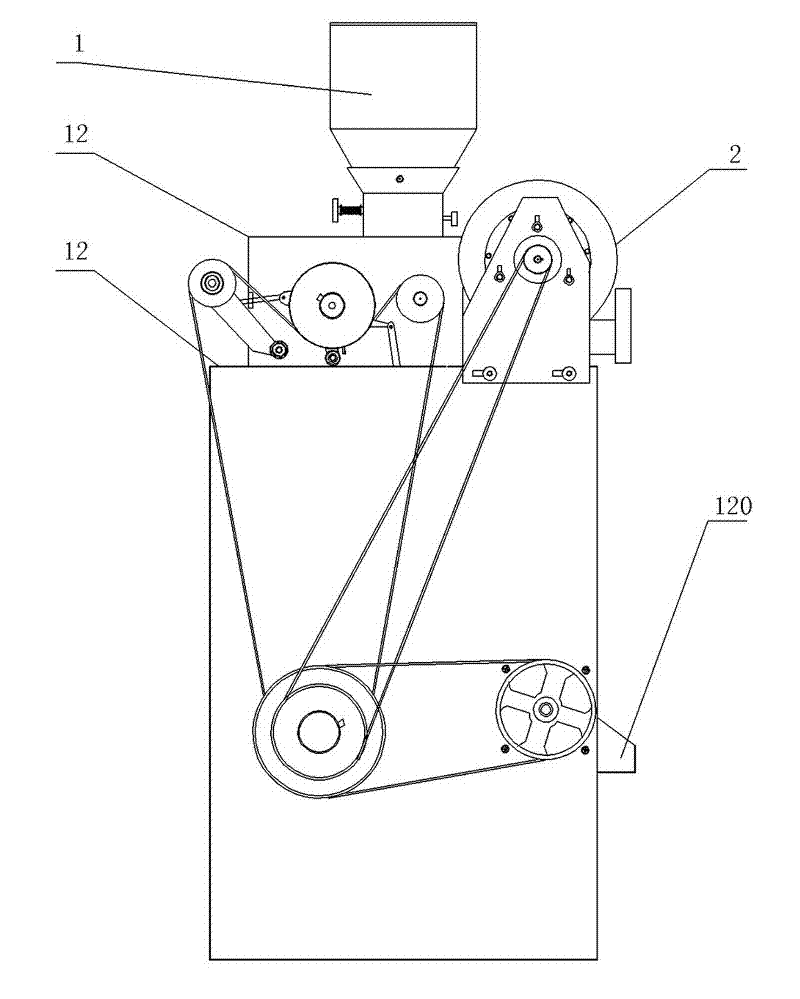

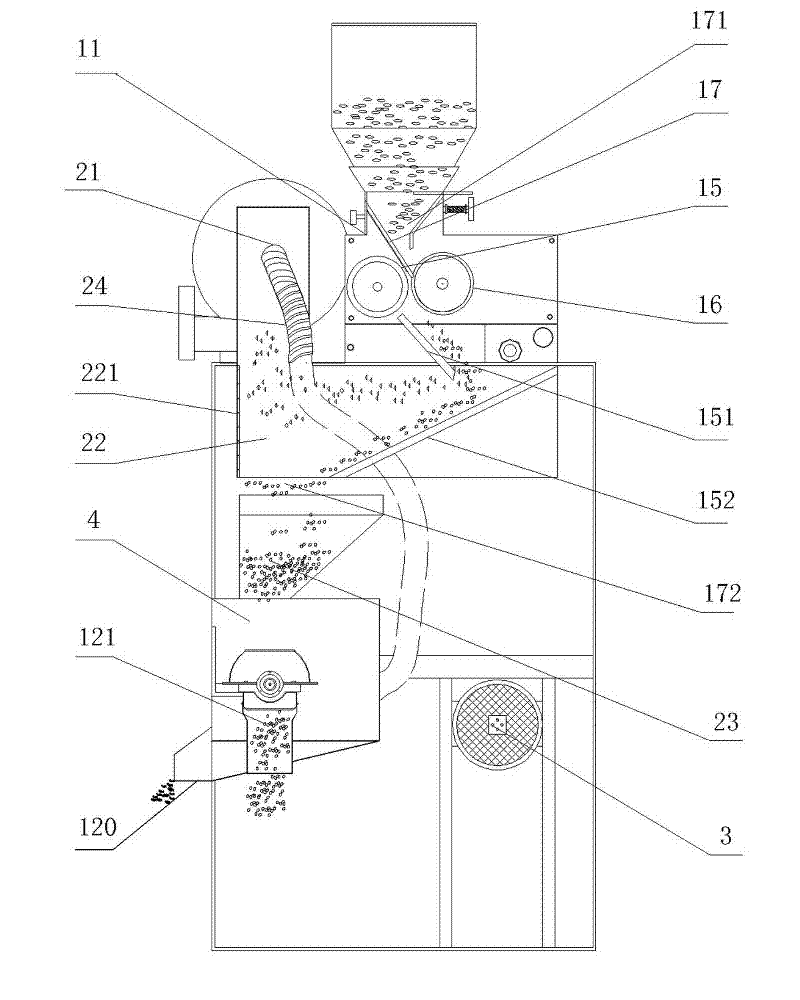

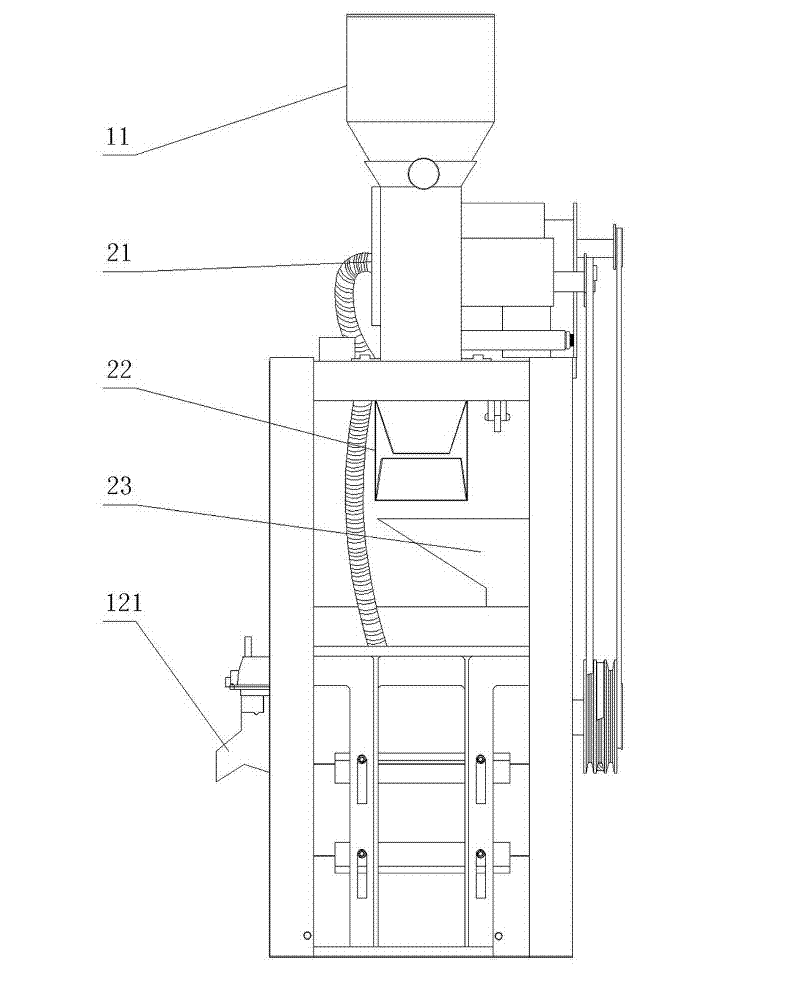

Compact type high-efficiency combined rice milling machine

InactiveCN102371198ACompact structureReduce volumeGrain huskingGrain polishingBroken riceAgricultural engineering

The invention relates to a compact type high-efficiency combined rice milling machine comprising a machine body and a motor. The top of the machine body of the compact type high-efficiency combined rice milling machine is provided with a rice hulling machine head and a fan, the top of the rice hulling machine head is provided with a feed hopper, a bran separator and a rice milling machine are arranged in the machine body from top to bottom, an air inlet at the bottom of the fan is connected with a bran outlet at the top of the bran separator, an unpolished rice outlet at the bottom of the bran separator is positioned above the feed hopper of the rice milling machine, and the bottom of the rice milling machine is provided with a fine bran hopper; according to the compact type high-efficiency combined rice milling machine, the functions of rice hulling, rice milling and fine processing are integrated; and the compact type high-efficiency combined rice milling machine has the characteristics of compact structure, small size, little energy consumption, short processing procedure, low processing cost, convenient operation and the like. According to the compact type high-efficiency combined rice milling machine, a rice milling chamber has a simple structure, a strip-shaped rice knife of a fixed screen mesh and a rice milling roller are matched with high efficiency, and the quickness and the cleanness of rice milling are ensured. A rice output regulating device can be used for regulating the magnitude of the frictional force of the rice milling of unpolished rice, and the rice output rate is high. By applying the device, the inherent defect of a traditional rice milling machine can be overcome, and the condition of obtaining rice with low broken rice rate and bright and integral rice grains becomes a normal state.

Owner:HUBEI JIALIANG MACHINERY

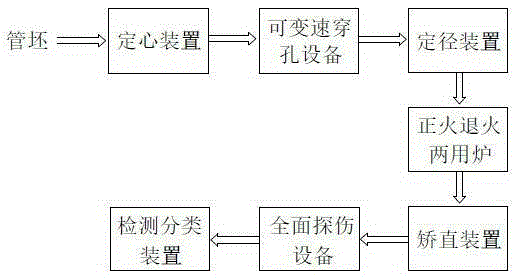

Steel pipe machining system

ActiveCN105268760ARealize a wide range of speed changesEfficient cooperationFurnace typesHeat treatment furnacesLow speedEngineering

The invention discloses a steel pipe machining system and belongs to the technical field of steel pipe machining. The steel pipe machining system comprises a centering device, variable-speed perforating equipment, a normalizing and annealing two-purpose furnace, a sizing device, a straightening device, comprehensive flaw detection equipment and a detection and classification device. Different rotating speeds are provided for the variable-speed perforating equipment through the cooperation of a high-speed motor, a low-speed motor and a reduction gearbox so that different types of steel pipes can be perforated. According to the normalizing and annealing two-purpose furnace, two heat treatment processes are achieved through one furnace body. The comprehensive flaw detection equipment integrates an eddy current flaw detection method and an ultrasonic flaw detection method, so that the detection quality of the steel pipes is guaranteed. According to the whole system, the efficiency of the steel pipe machining process is high, and the quality of the steel pipes is guaranteed.

Owner:ANJI PENGDA STEEL PIPE

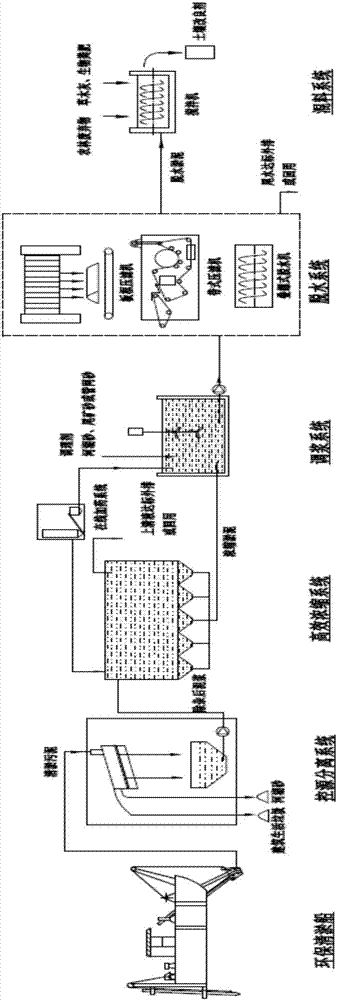

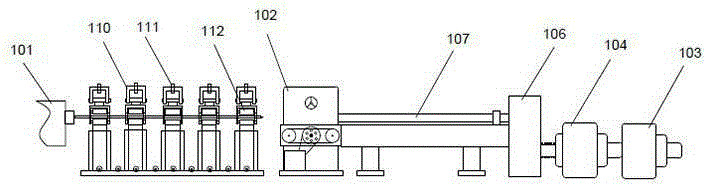

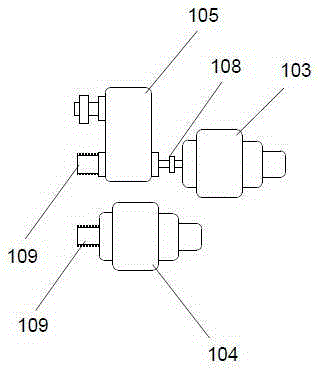

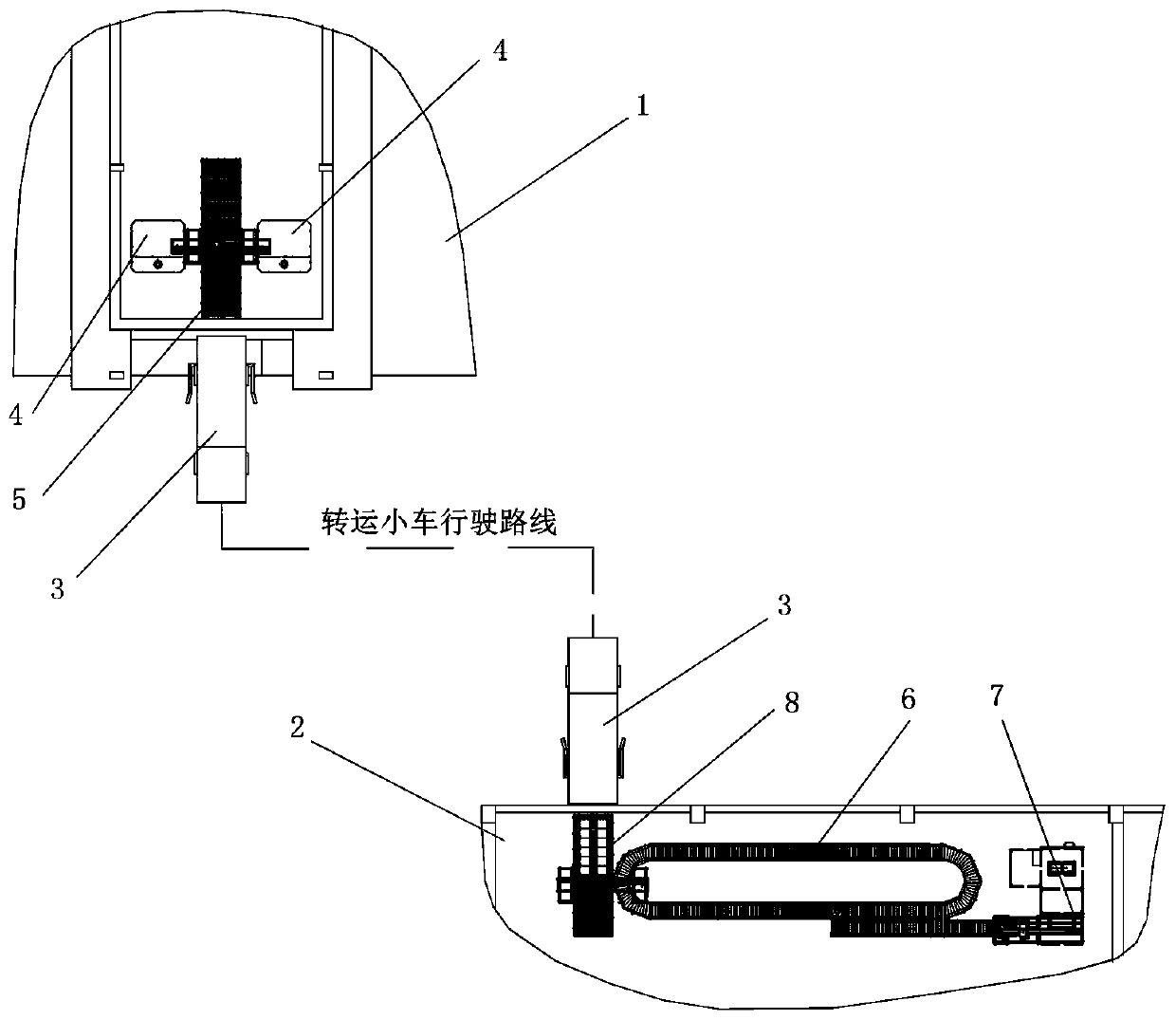

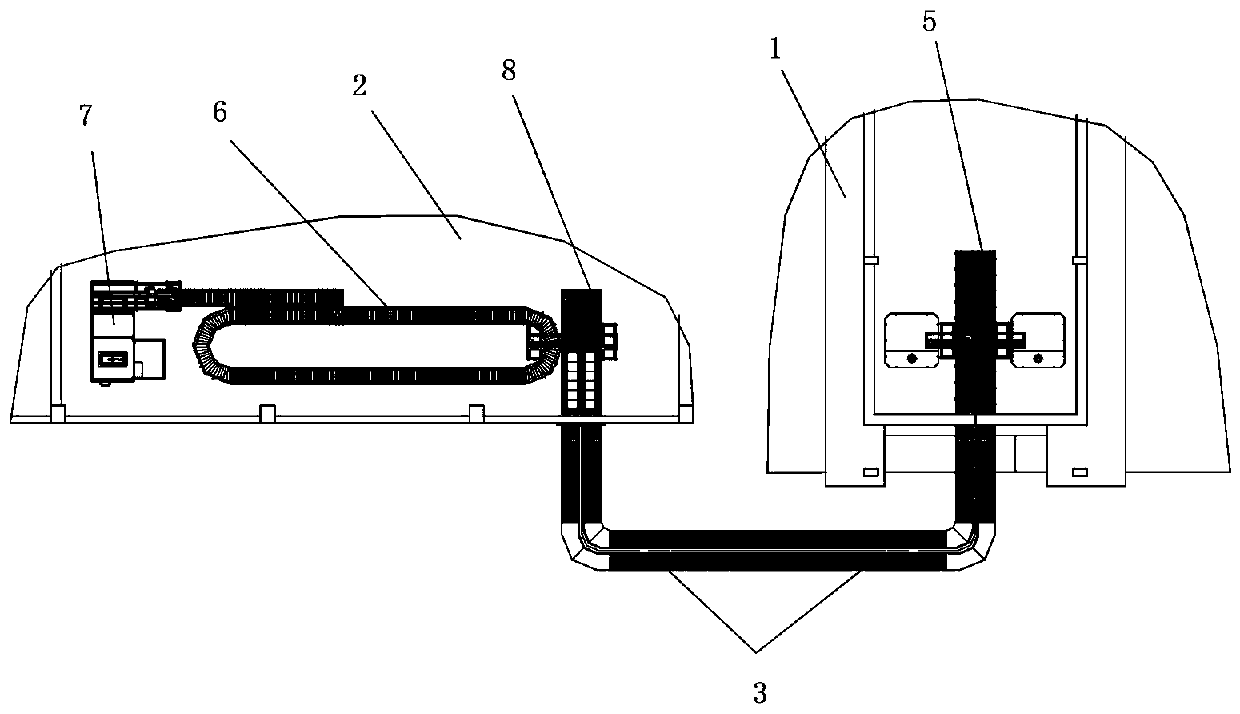

Sampling and sample preparation system used for samples

ActiveCN108045935AImprove automationImprove completenessWithdrawing sample devicesPreparing sample for investigationButt jointIn degree

The invention discloses a sampling and sample preparation system used for samples. The sampling and sample preparation system includes a sampling end and a sample preparation end. Butt joint conveyingis conducted between the sampling end and the sample preparation end through a butt joint conveying unit. The butt joint conveying unit is used for conveying a sample shipped sample barrel of the sampling end to the sample preparation end to conduct sample preparation, and conveying an empty sample barrel of the sample preparation end to the sampling end to conduct sample shipping. The sampling end is provided with an intelligent ore separator unit and a sampling end sampling barrel transshipment unit. The sample preparation end is provided with a sample batch unit, an automatic discharging unit, and a sampling end sampling barrel transshipment unit. The sampling and sample preparation system used for the samples has the advantages of being high in degree of automation and intelligence, high in security, capable of reducing manual labor intensity, and capable of keeping working continuity.

Owner:HUNAN SUNDY SCI & TECH DEV

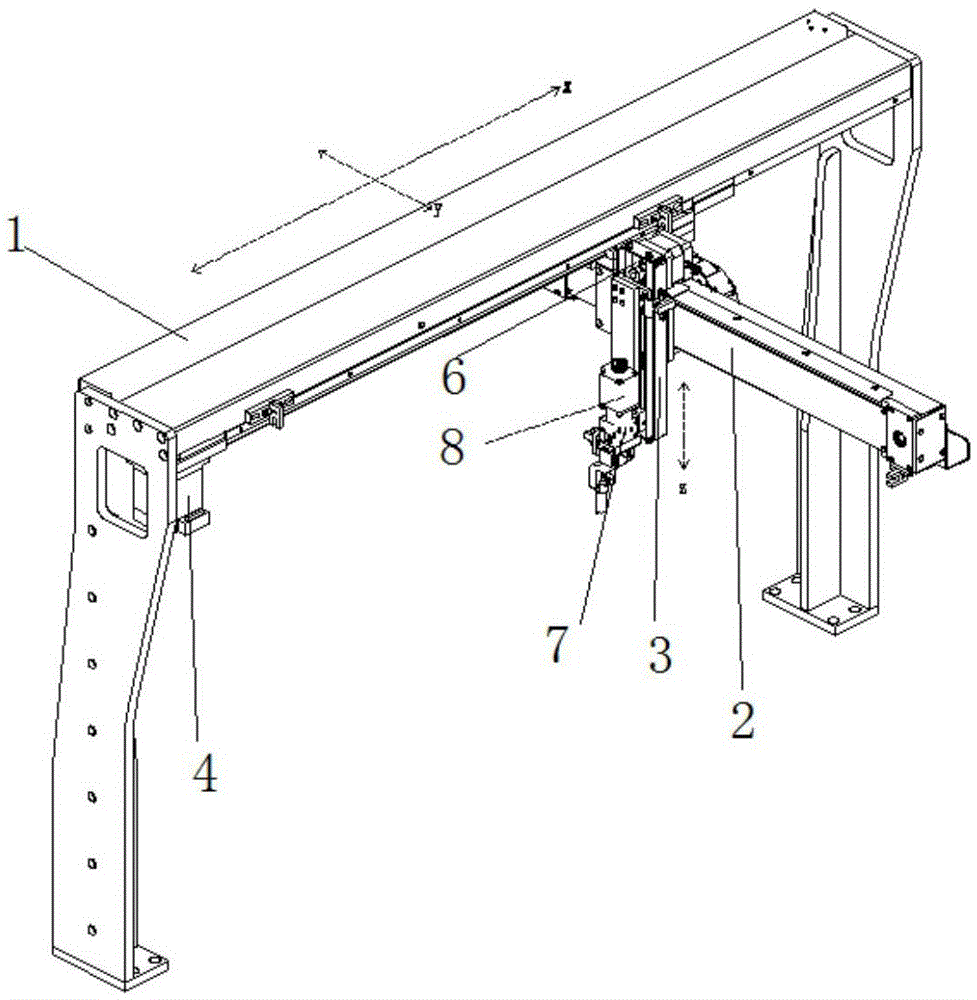

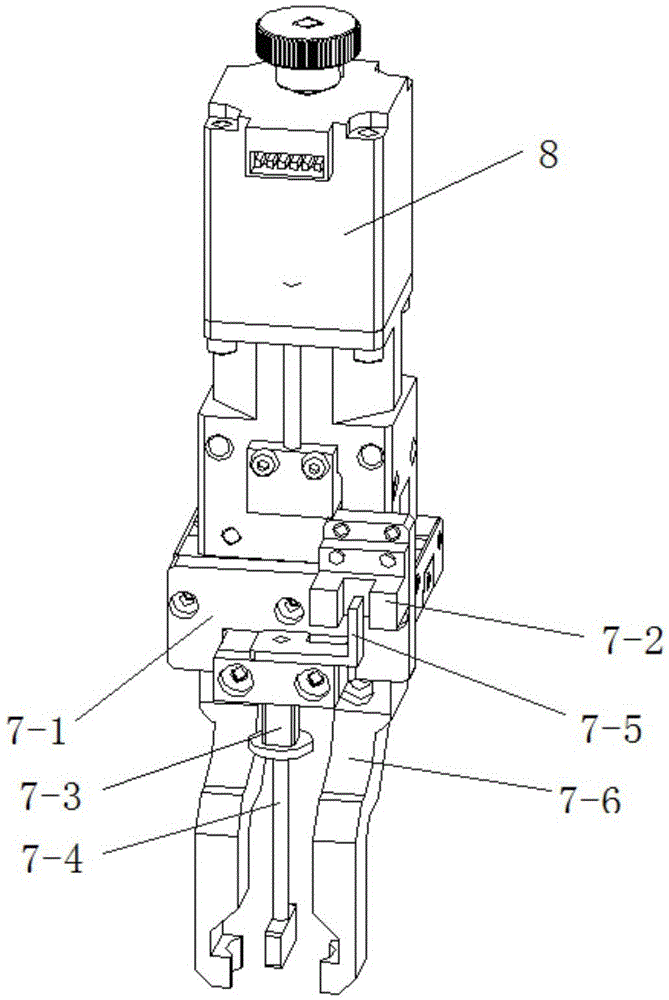

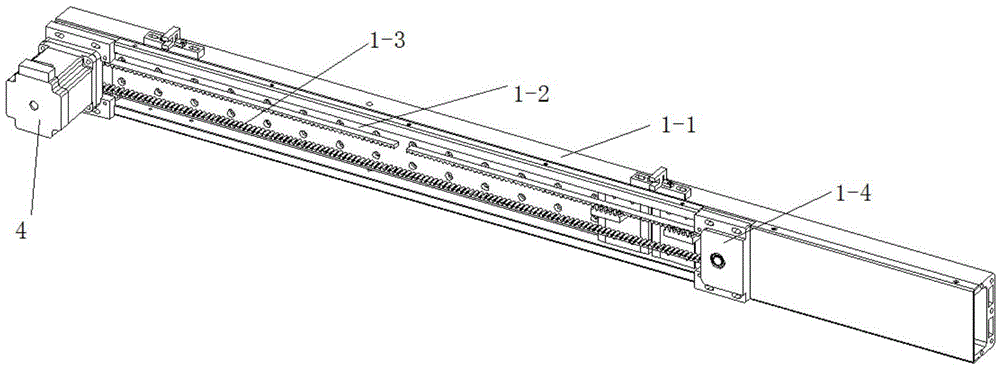

Mechanical arm

The invention discloses a mechanical arm, and belongs to the field of chemiluminescence measurement. The mechanical arm comprises an X-axis guide rail assembly, a Y-axis guide rail assembly, a Z-axis guide rail assembly, an X-axis motor, a Y-axis motor, a Z-axis motor, a mechanical gripper and a mechanical gripper motor. The X-axis guide rail assembly is connected with the X-axis motor. The Y-axis guide rail assembly is connected with the Y-axis motor. The Z-axis guide rail assembly is connected with the Z-axis motor. The mechanical gripper is connected with the mechanical gripper motor. The Y-axis guide rail assembly is arranged on the X-axis guide rail assembly. The Z-axis guide rail assembly is arranged on the Y-axis guide rail assembly. The mechanical gripper is arranged on the Z-axis guide rail assembly. The mechanical gripper comprises a clamping jaw and a detection device, and the detection device is arranged above the clamping jaw. The mechanical arm can run in three-dimensional space flexibly and stably, and can detect whether a reaction cup is clamped or not.

Owner:NANJING NORMAN BIOLOGICAL TECH

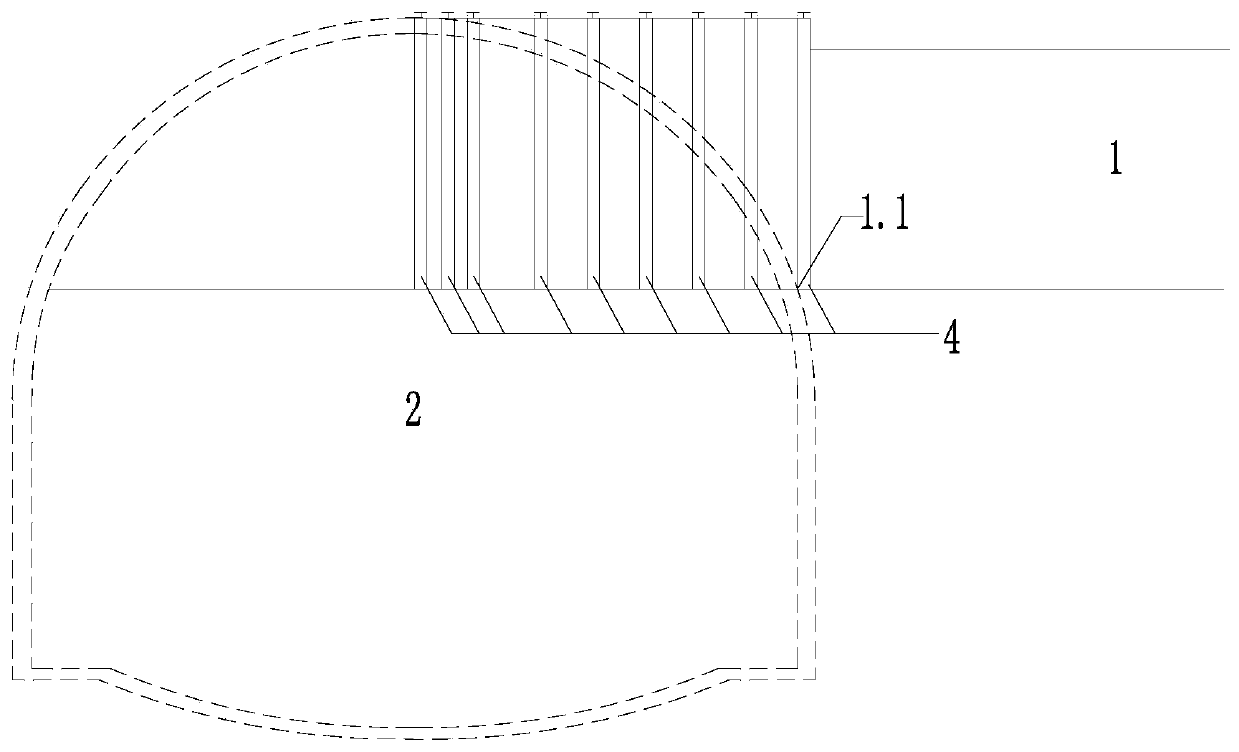

Method for excavating and supporting subway station tunnel by adopting underground excavation construction channel

InactiveCN110905524AReduce construction difficultyReduce the number of temporary supportsUnderground chambersTunnel liningArchitectural engineeringSubway station

The invention discloses a method for excavating and supporting a subway station tunnel by adopting an underground excavation construction channel, relates to the technical field of tunnel construction, and mainly aims to solve the problems of complicated conversion procedures, high risk, high temporary support consumption and the like in a station tunnel construction method. The method comprises the steps of conversion construction of a main construction channel and a station tunnel, conversion construction of an auxiliary construction channel and the station tunnel and excavation support of the station tunnel; the top of the main construction channel is lifted to be flush with an arch crown of the station, and parallel station entering and portal steel arch frame support are adopted; andthe auxiliary construction channel adopts footage from the station tunnel, relates to the station excavation construction step sequence in the range of the conversion section and support at the connection position of the station tunnel and the auxiliary construction channel. The method aims to solve the problems of complicated construction steps, large construction risk of key sections and more temporary supports in the traditional construction method so as to expect the underground station tunnel construction to achieve safer and more efficient purposes.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD +1

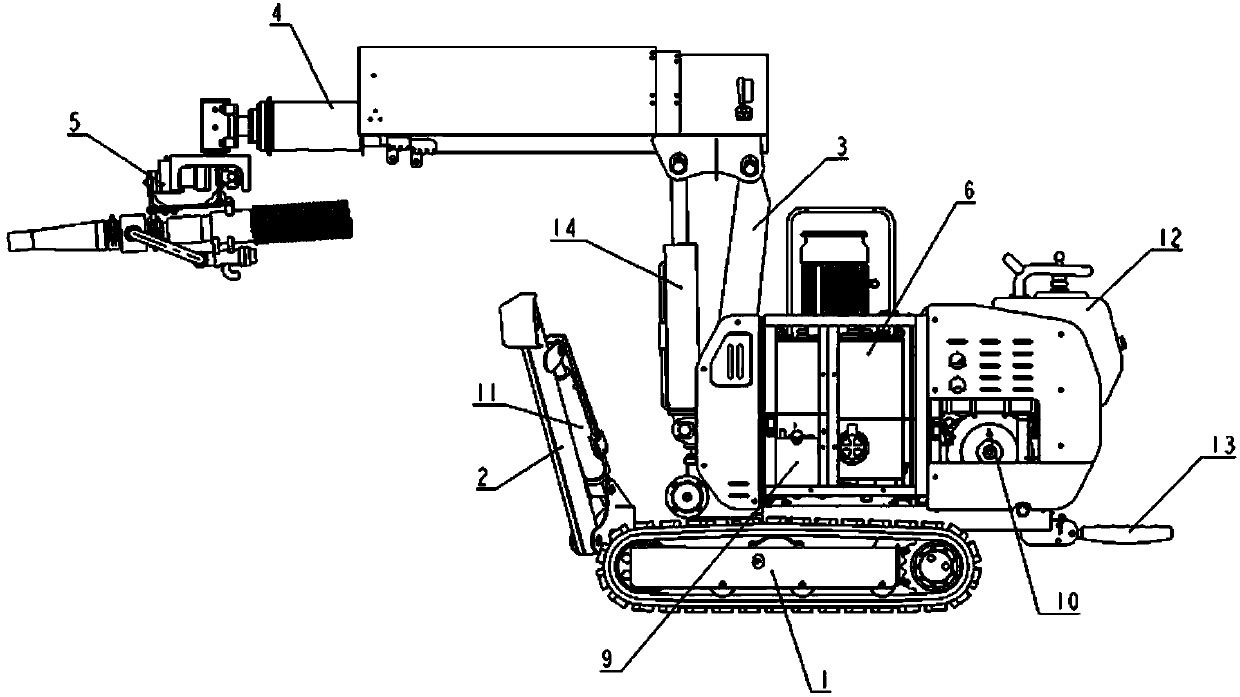

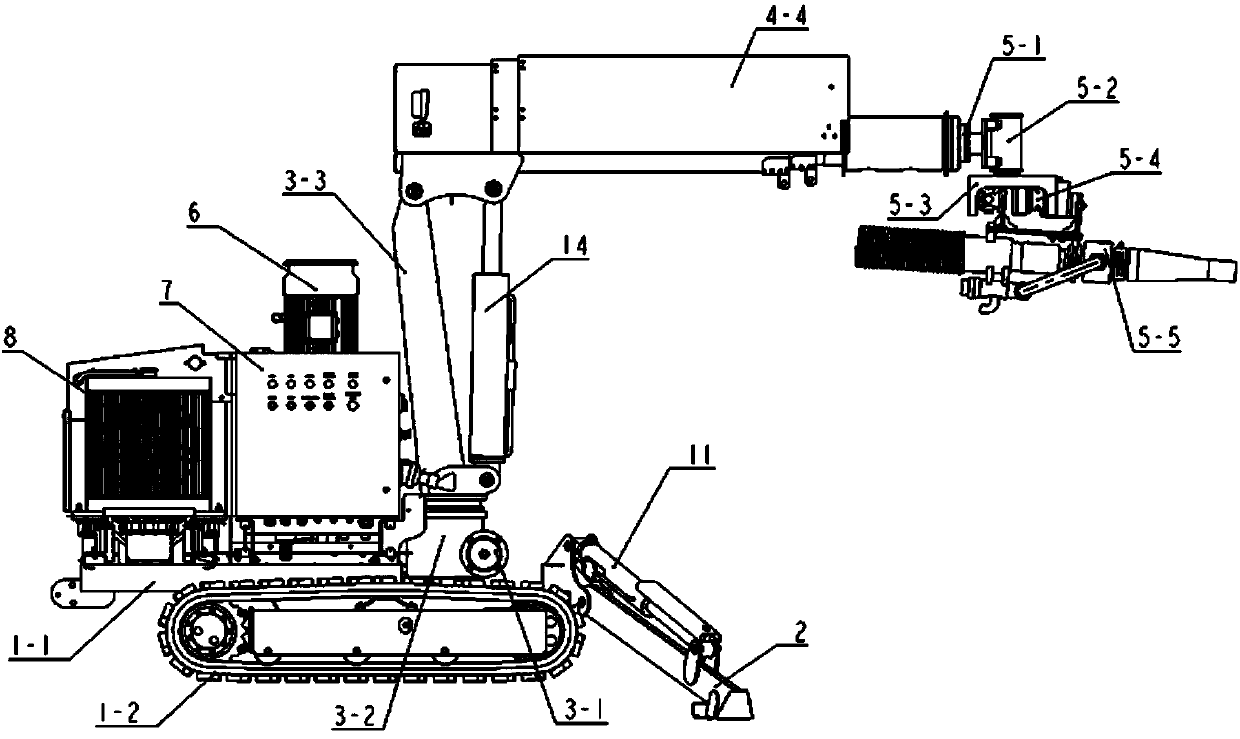

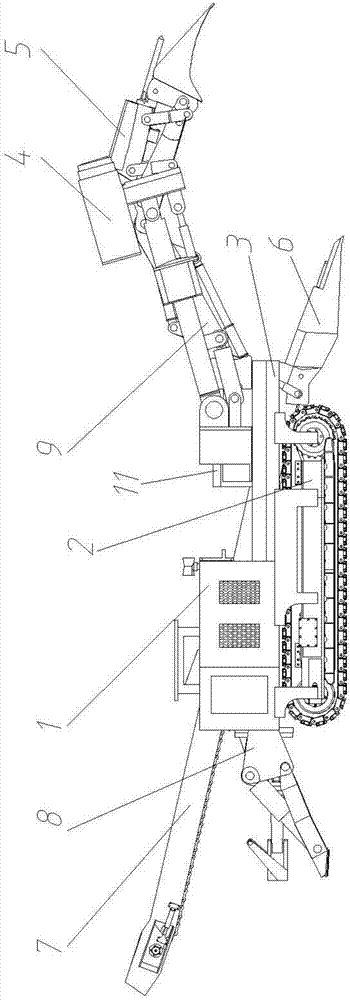

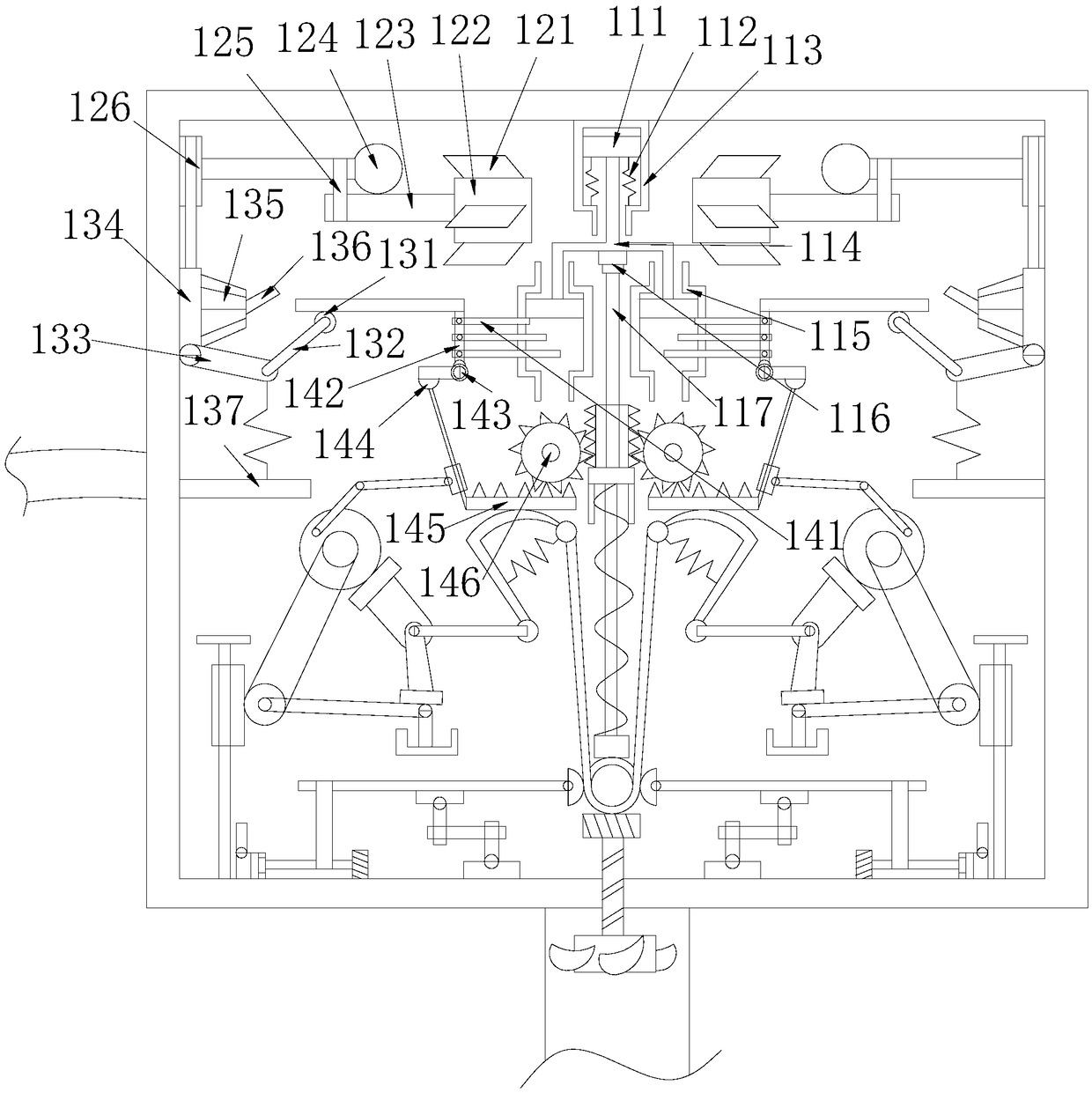

Mining underground drilling, anchoring and rock breaking integrated excavation type loader

ActiveCN107130656AAchieve brokenEfficient cooperationMechanical machines/dredgersWork periodIntegrated operations

The invention discloses a mining underground drilling, anchoring and rock breaking integrated excavation type loader, and relates to an excavation type loader used underground. The loader comprises a walking portion, a machine body and a machine frame. The rear end of the machine frame is connected with the front end of the machine body. The middle of the machine body and the middle of the machine frame are provided with lifting mechanisms correspondingly. The upper portions of the lifting mechanism are provided with a connection frame fixed between the machine body and the machine frame. The connection frame is provided with a slagging-off mechanism. The front end of the slagging-off mechanism is provided with a rock braking mechanism. The lower portion of the front end of the machine frame is connected with a front shovel portion. The rear end of the machine body is connected with a rear support. The left side and the right side of the slagging-off mechanism are each provided with a sliding rail installed on the machine frame. Anchoring rod mechanisms are installed on the sliding rails and can slide on the sliding rails. Excavation and anchoring integrated operation can be achieved in a narrow roadway, working time is greatly shortened, and safety of underground work is improved.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

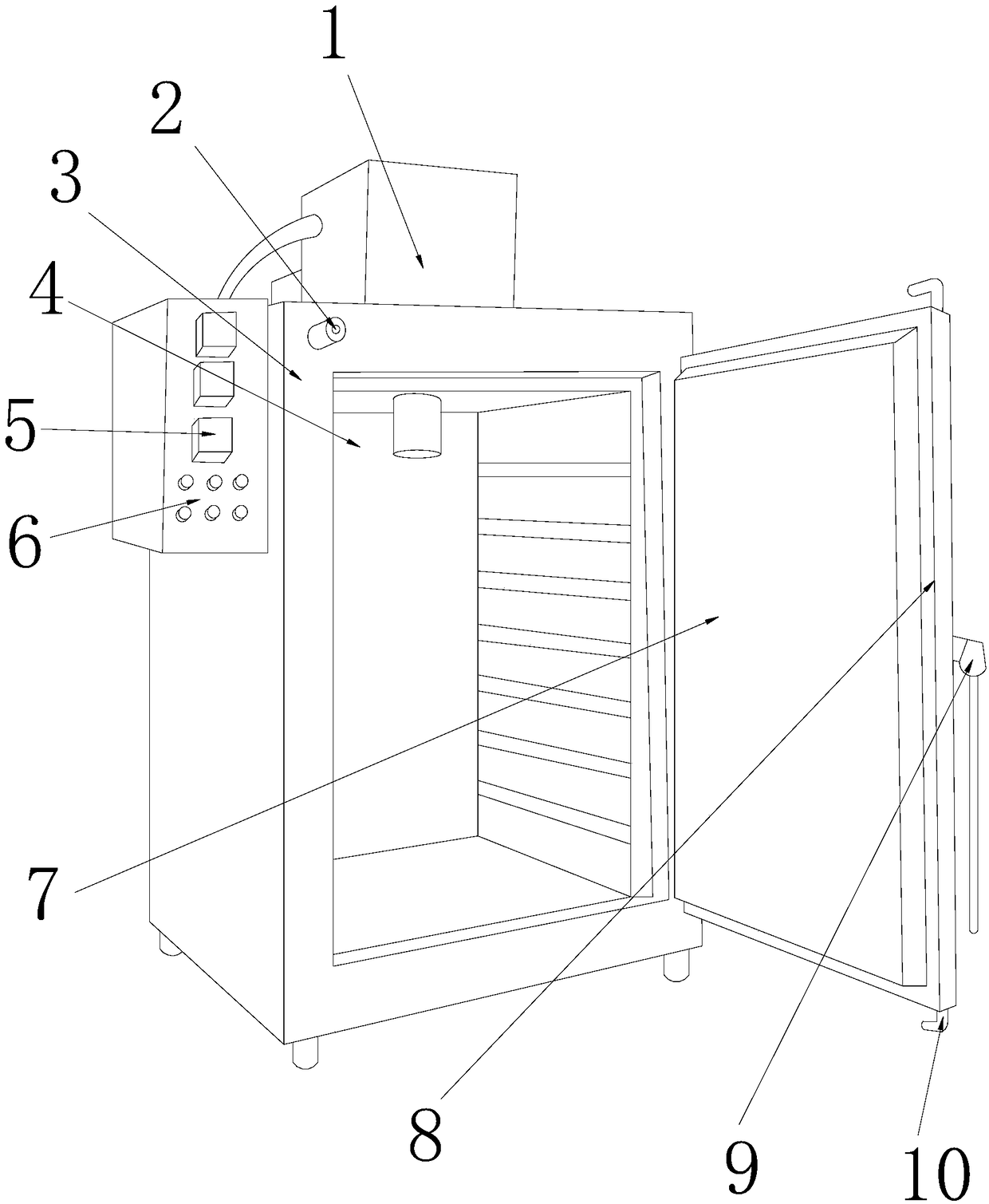

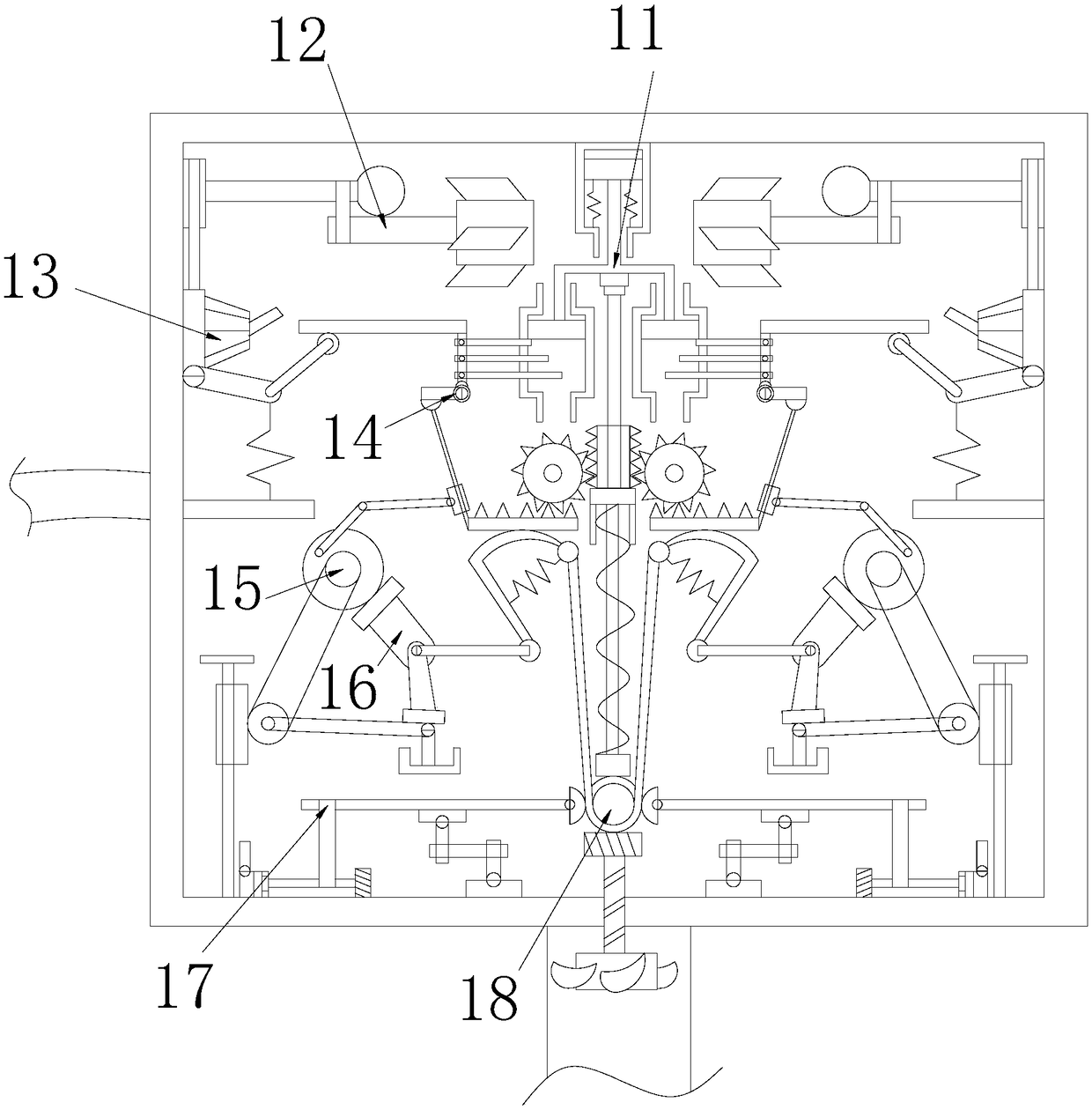

Circulating drying oven for leather products

InactiveCN108626980AFlexible shiftGood effectDrying gas arrangementsMachines/enginesPropellerContinuous use

The invention discloses a circulating drying oven for leather products. The circulating drying oven for the leather products structurally comprises a jet engine, an exhaust column pipe, an alloy shell, a leather product drying oven groove, encoding controllers, an integrated electric control box, a rubber sealing plate, a drying oven door plate, an oven door hand dragging rod and L-shaped plug pincolumns. A propeller of the jet engine is inserted into the axis of the leather product drying oven groove in an embedded mode, and the leather product drying oven groove is embedded into the alloy shell in a sleeved mode. The jet engine comprises a jet piston cylinder set, fan rotating mechanisms, mechanical switch supporting bases, separating plate transverse movement devices, conveying belt pulley sets, lug plate supporting devices, shaft rod transmission mechanisms and a turbine spiral device. The purpose that the effect of jet type gear-shifting heating of a mechanical structure of the circulating drying oven is enhanced is achieved, mechanical and flexible gear shifting is achieved, and a piston rod conducts jacking push heating; the processing quality of a whole belt is improved through gradual temperature increase and decrease of leather product drying, and the working efficiency is also improved; and after the internal environment is cooled through wind power, the internal environment is continuously used, the working efficiency is improved, and the whole mechanical integrity cooperation is efficient.

Owner:莆田市鸿事达商贸有限公司

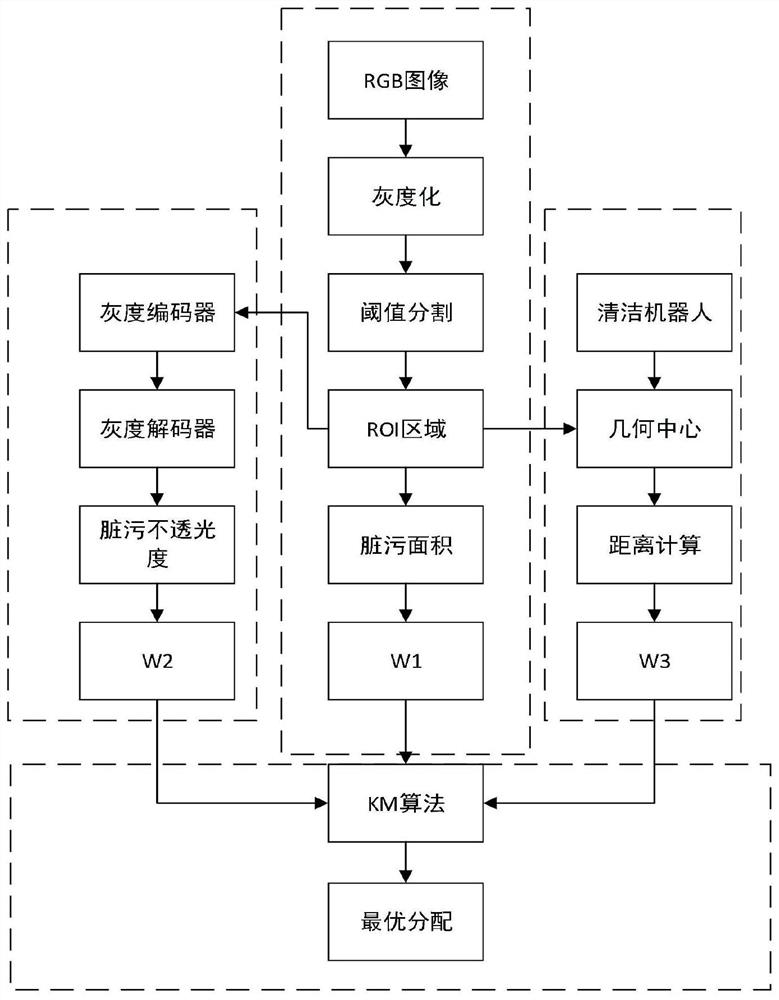

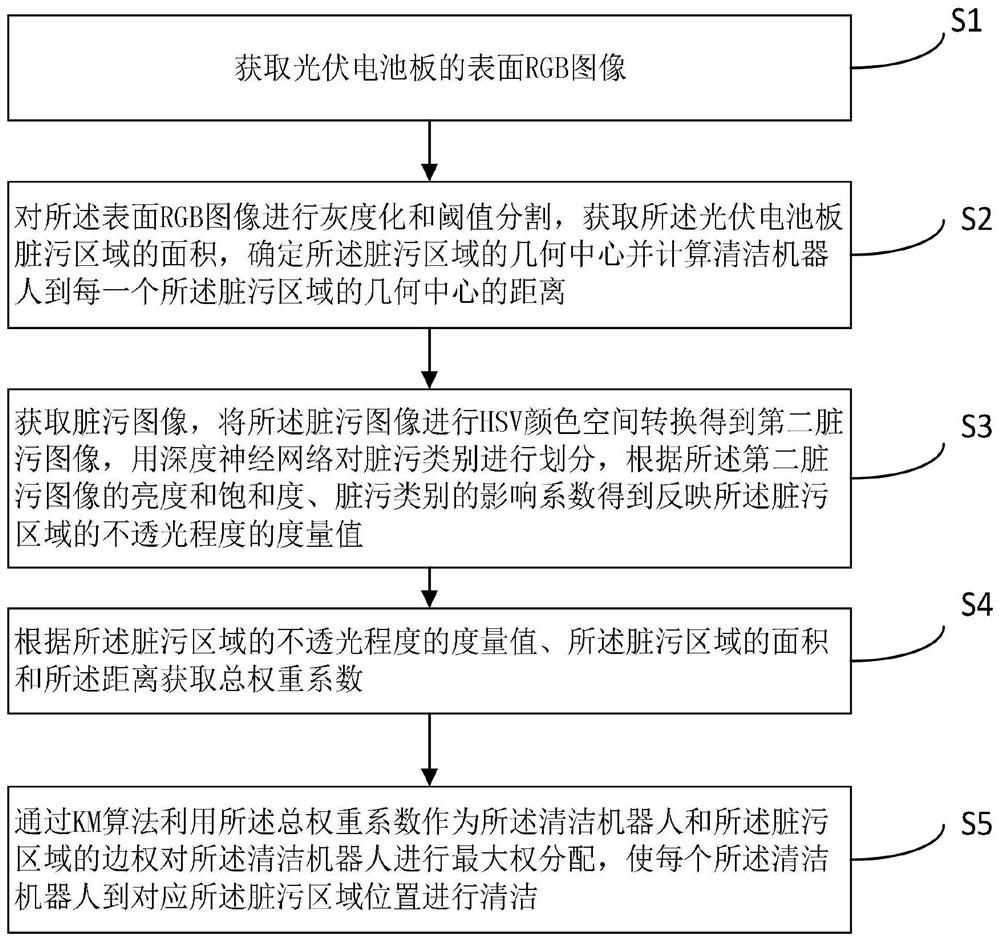

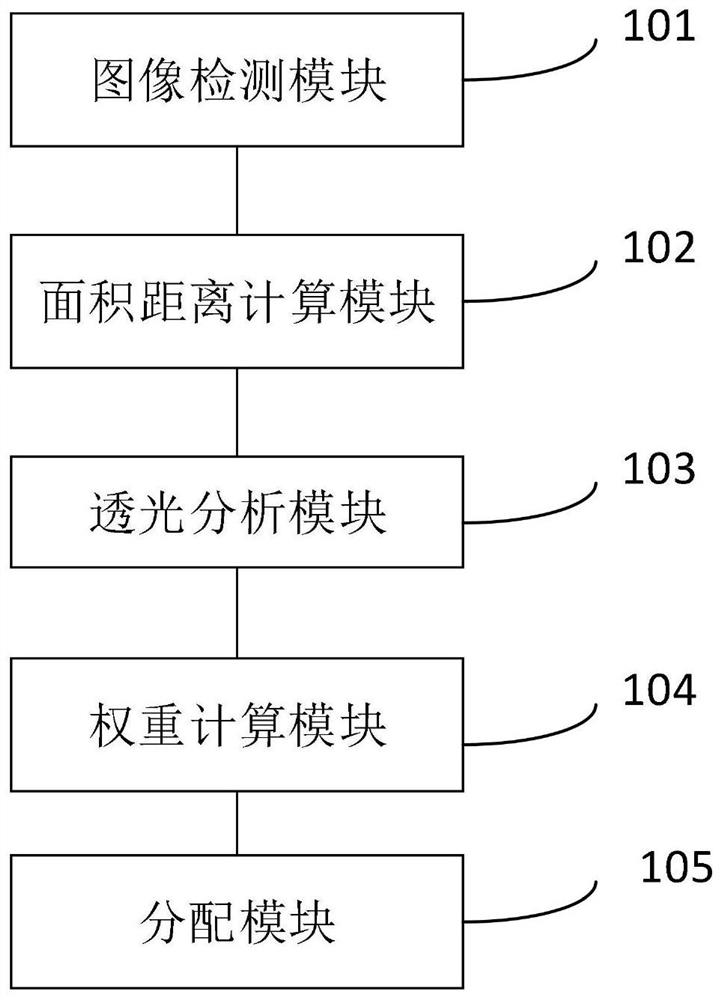

Multi-robot cooperative cleaning method and device on photovoltaic module based on artificial intelligence

InactiveCN112588764AEfficient cooperationTo achieve the purpose of cleaningImage enhancementImage analysisCells panelAlgorithm

The invention relates to the technical field of artificial intelligence, in particular to a multi-robot cooperative cleaning method and device on a photovoltaic module based on artificial intelligence. The method comprises the following steps of acquiring a surface RGB image of a photovoltaic cell panel, performing graying and threshold segmentation, acquiring the area of a smudgy area of the photovoltaic cell panel, and calculating the distance; acquiring a smudginess image, performing HSV color space conversion to obtain a second smudginess image, dividing smudginess categories, and obtaining a measurement value reflecting the light-proof degree according to the brightness and saturation of the second smudginess image and the influence coefficient of the smudginess categories; acquiringa total weight coefficient according to the measurement value of the light-proof degree of the smudgy area and the area and the distance of the smudgy area; and using the total weight coefficient as the edge weight of the cleaning robot and the smudgy area to carry out maximum weight distribution on the cleaning robot, so that each cleaning robot can reach the corresponding position to carry out cleaning. According to the multi-robot cooperative cleaning method and device on the photovoltaic module based on artificial intelligence provided by the invention, task area route distribution can becarried out on the smudgy area, so that the cleaning robot can be guided to carry out cleaning efficiently and rapidly.

Owner:李振环

Anti-reflection displacement and multiphase seepage flow physical simulation experiment system and method for coal containing methane

The invention discloses an anti-reflection displacement and multiphase seepage flow physical simulation experiment system and experiment method for coal containing methane. The system comprises a model counter-force and sealing system for coal and rock specimen manufacturing and loading experiments, a stress loading system used for exerting axial pressure, a fluid injection system used for performing anti-reflection and displacement treatment on a specimen and a numerical control system used for monitoring physical and mechanics parameters inside the specimen. The anti-reflection measures suchas blasting fracturing and hydraulic fracturing and displacement measures such as injection of CO2, N2 and the like of deep methane adsorbed coal can be simulated; and the physical and mechanics parameters such as the coal stress, the strain, the temperature and the gas pressure can be monitored in real time by sensors arranged inside the specimen, so that the rules and mechanisms of adsorption and desorption, seepage and migration of the methane in the coal and rock under the condition of high crustal stress can be studied.

Owner:SHANDONG UNIV +1

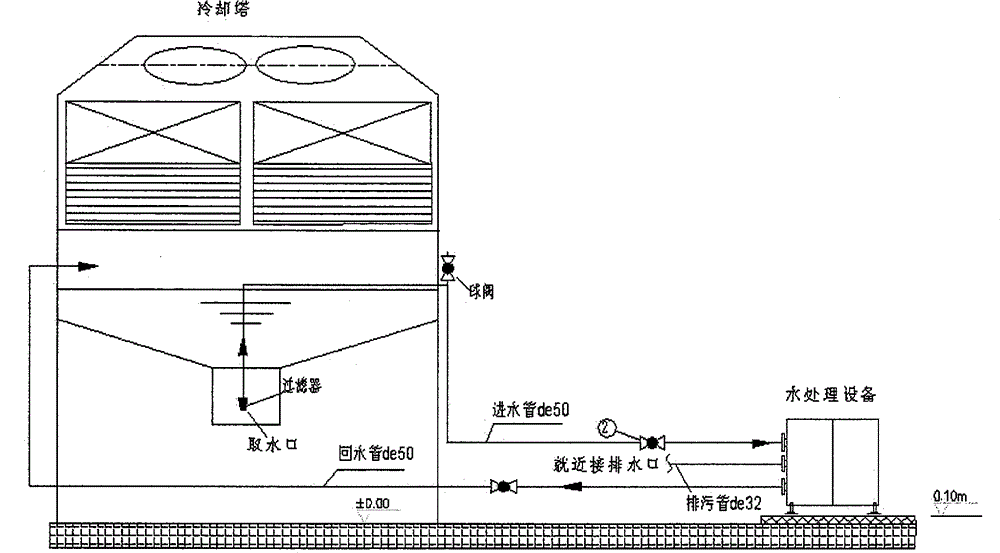

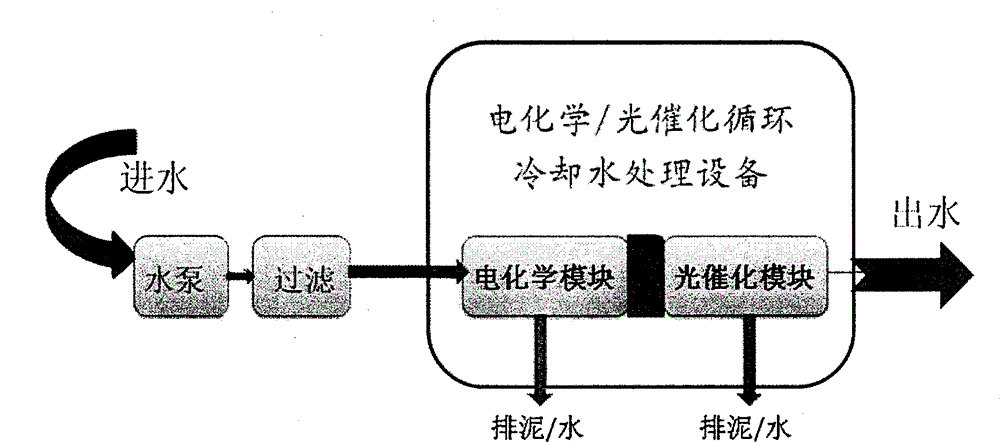

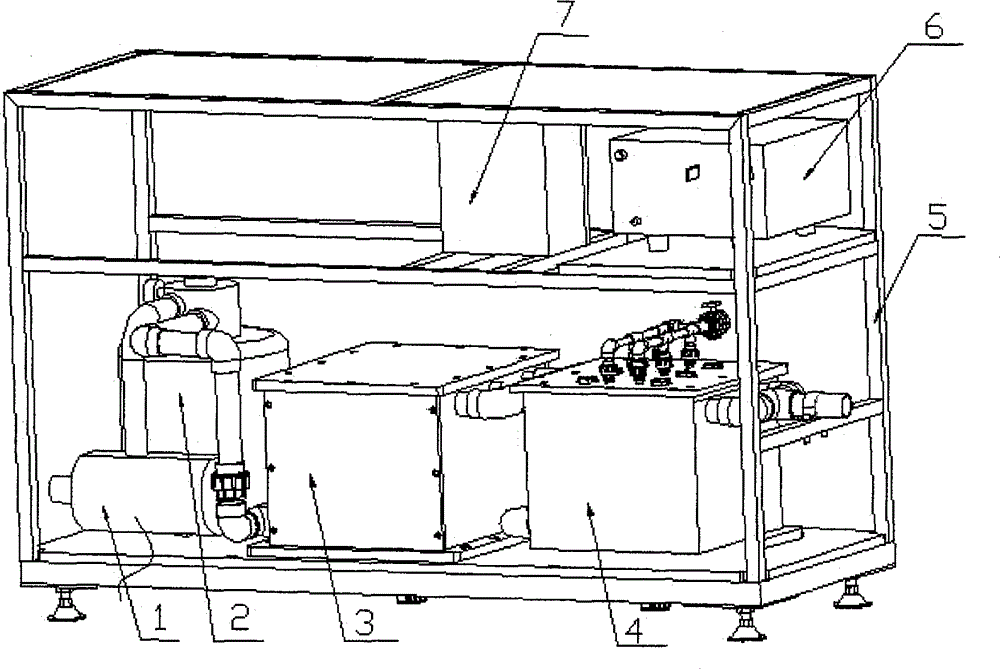

Novel electrochemical/photocatalysis circulating cooling water treatment device

ActiveCN104787842AProlong photocatalytic treatment timeLarge specific surface areaWater/sewage treatment by irradiationElectrolysisElectrochemistry

The invention relates to a novel electrochemical / photocatalysis circulating cooling water treatment device used for treating circulating cooling water and device self cleaning, and belongs to the field of water treatment. The novel electrochemical / photocatalysis circulating cooling water treatment device mainly comprises an electrolysis unit and a photocatalytic unit. The electrolysis unit is capable of removing ions in the circulating cooling water via electrochemical electrolysis technology, and preventing scaling and removing scale, wherein scaling is easily caused by the ions; the photocatalytic unit possesses high efficiency sterilization and algae extermination performance on circulating cooling water via photocatalysis technology. Innovations of the novel electrochemical / photocatalysis circulating cooling water treatment device are that: 1, organic combination of advantages of two water treatment technologies, including electrochemistry and photocatalysis, is realized, complementary performance of the two technologies is fully used, equipment comprehensive water treatment effect is improved, and a problem that comprehensive performance of single utilization is poor is solved; 2, polarities of the cathode and the anode of an electrode module are switched, cathode surface automatic descaling is realized under low current intensity in a short time; a rapid flow water washing nozzle arranged on the top of a photocatalysis box body can be used for washing pollutants on photocatalysis nets and ultraviolet lamps.

Owner:广州贝特缪斯能源科技有限公司

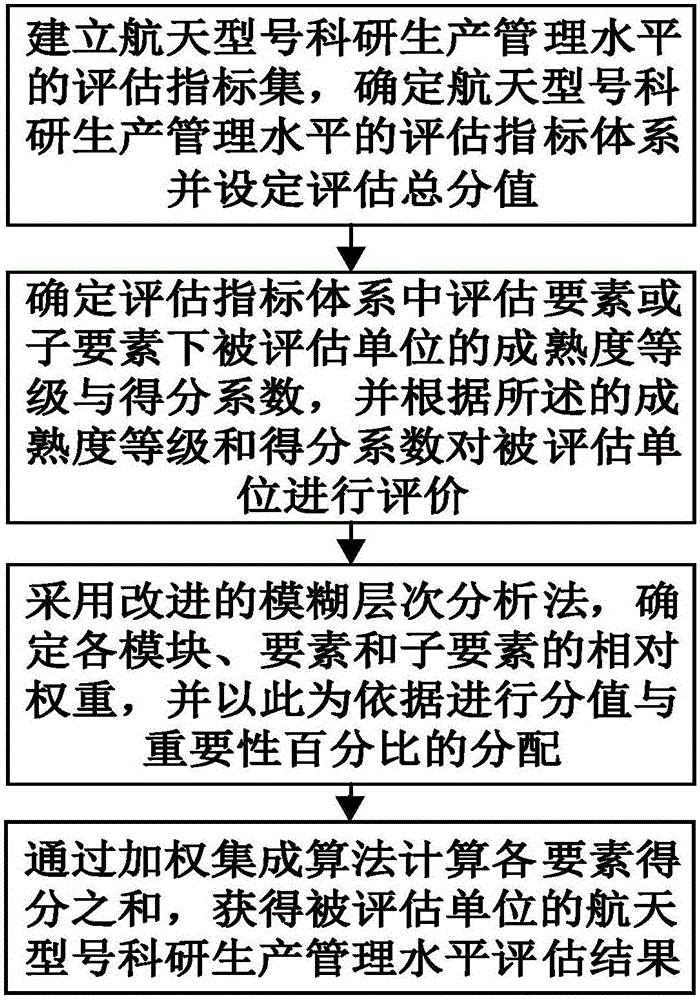

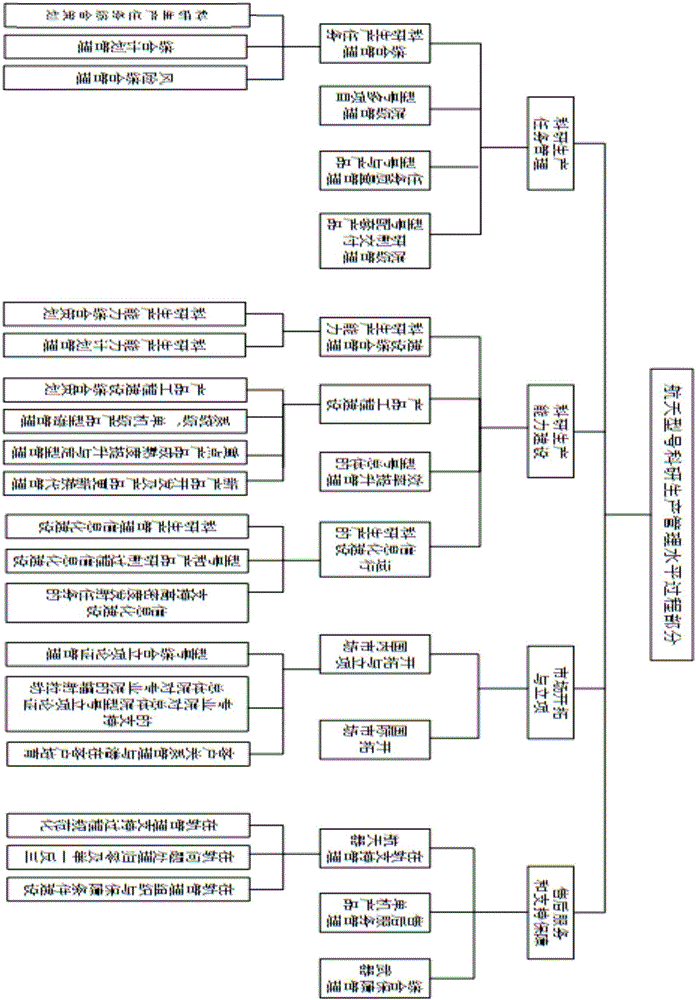

Fuzzy information-based aerospace model scientific research and production management level evaluation method

InactiveCN105976099AScientific research and production management level is accurateAccurate quantitative evaluationResourcesQuantitative assessmentAssessment methods

The invention discloses a fuzzy information-based evaluation method for the management level of scientific research and production of aerospace models, comprising: step 1, establishing an evaluation index set U of the management level of scientific research and production of aerospace models, and determining an evaluation index system for the management level of scientific research and production of aerospace models, And set the total assessment score P; step 2, determine the maturity level D and score coefficient ρ of the assessed unit under the assessment elements or sub-elements in the assessment index system, and evaluate the value of the assessed unit according to the maturity level and score coefficient The unit evaluates; step 3, adopts the improved fuzzy analytic hierarchy process to determine the relative weight of each module, element and sub-element, and assigns the score and importance percentage based on this; step 4, calculates the weight of each module through the weighted integration algorithm The sum of the element scores is used to obtain the evaluation results of the evaluation unit's scientific research and production management level of aerospace models. The invention realizes the accurate, objective and quantitative evaluation of the scientific research and production management level of aerospace models.

Owner:CHINA AEROSPACE STANDARDIZATION INST

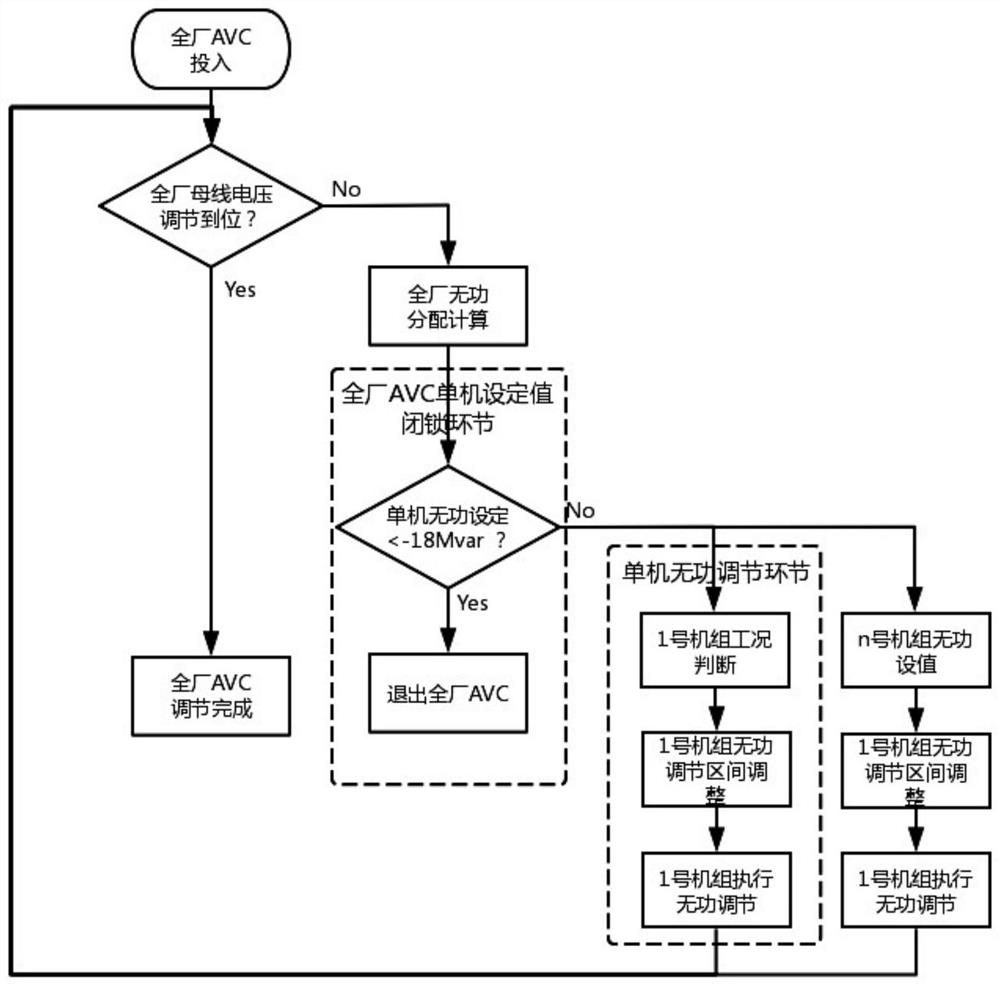

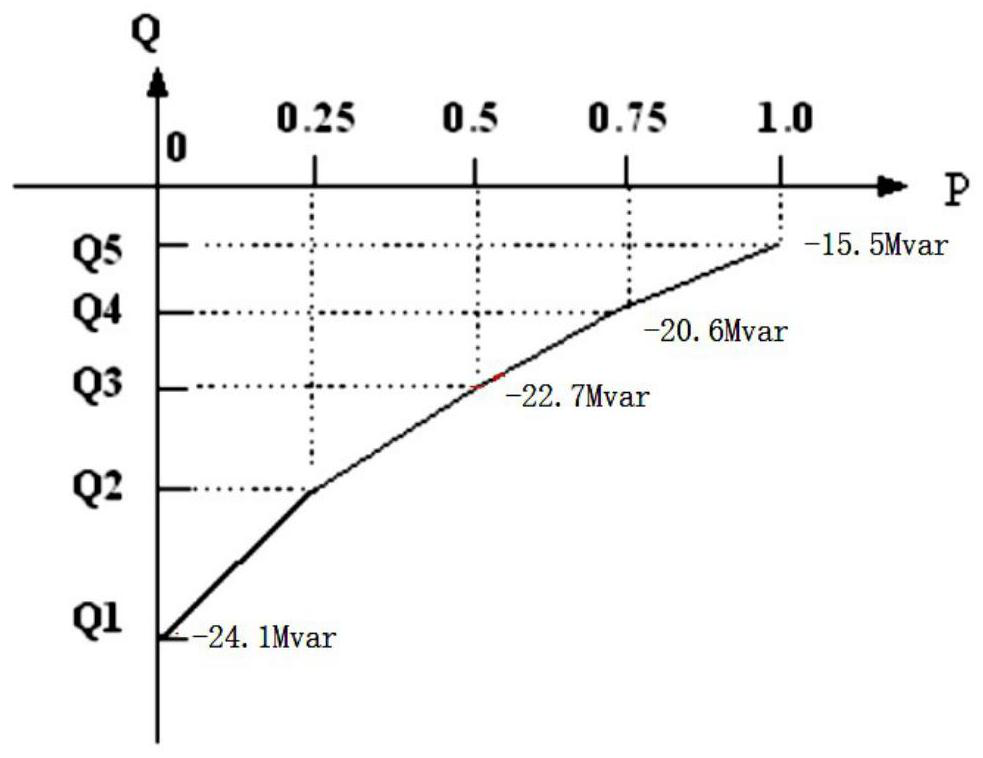

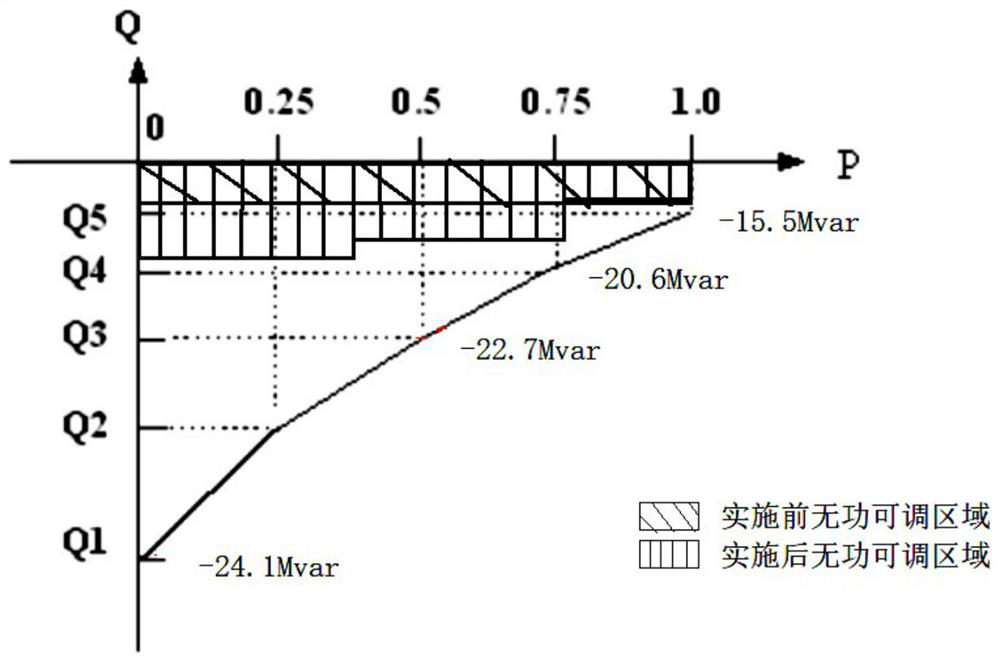

Variable adjustment interval whole-plant AVC-unit reactive power combined control method and system

PendingCN112366719AReasonable cooperationImprove operating rateSingle network parallel feeding arrangementsAc network voltage adjustmentControl engineeringPlant

The invention discloses a variable adjustment interval whole-plant AVC-unit reactive power combined control method and system, so as to solve the problem that the whole-plant AVC commissioning rate ofa power plant is low and overcome the defects caused by the low commissioning rate, and belongs to the technical field of hydroelectric generation. The method comprises the following steps: 1, a linkof judging bus voltage of a whole plant and performing reactive power distribution of the whole plant; 2, a whole-plant AVC single-machine set value locking link: setting a single-machine reactive power distribution value lower limit to be locked, automatically exiting the whole-plant AVC when the reactive power distribution value lower limit exceeds the limit value, and giving an alarm; 3, a single-machine reactive power regulation link: dividing the operation conditions of the unit into three types, judging which working condition the unit is in, automatically regulating the reactive powerregulation interval of the unit, enabling the reactive power regulation interval of the unit to better adapt to the operation conditions of the unit, completing reactive power regulation, and responding to a single-machine reactive power set value issued by AVC of the whole plant. On the premise of ensuring the safety of the unit, the reactive power adjustable interval of the unit is dynamically adjusted according to different operating conditions of the unit, so that the reactive power adjusting capacity of the unit is reasonably and fully exerted.

Owner:桑河二级水电有限公司

Fully-automatic numerical control composite inner surface grinding machine

PendingCN108340243AIngenious structural designSimple structureGrinding drivesGrinding machinesSurface grindingMotor drive

The invention discloses a fully-automatic numerical control composite inner surface grinding machine, and belongs to the technical field of composite grinding machines. The fully-automatic numerical control composite inner surface grinding machine comprises a machine body, a servo driving mechanism and a workpiece conveying mechanism, and the workpiece conveying mechanism comprises a feeding channel, a material stopping channel, a workpiece pushing assembly and a discharging channel; workpieces pass through the feeding channel and the material stopping channel and reach a grabbing station of the workpiece pushing assembly, the workpiece pushing assembly pushes the workpieces to a machining station for being ground; the ground workpieces are output through the discharging channel, and the feeding channel, the material stopping channel and the discharging channel are formed by enclosing of baffles, and the positions of the baffles can be adjusted; and the servo driving mechanism comprises a workpiece feed motor, a drag plate, a magnetic chuck and a grinding wheel, the magnetic chuck is arranged on the drag plate, the workpiece feed motor drives the drag plate to move in the horizontal direction, the magnetic chuck moves to the workpiece machining station, and the workpieces are adsorbed and fixed. The fully-automatic numerical control composite inner surface grinding machine canrealize automatic circulation of the whole process of feeding, machining and discharging, the material channels can be conveniently adjusted to adapt to the conveying requirement of the workpieces with the different sizes, and the good adaptability is achieved.

Owner:马鞍山市恒永利机械科技有限公司

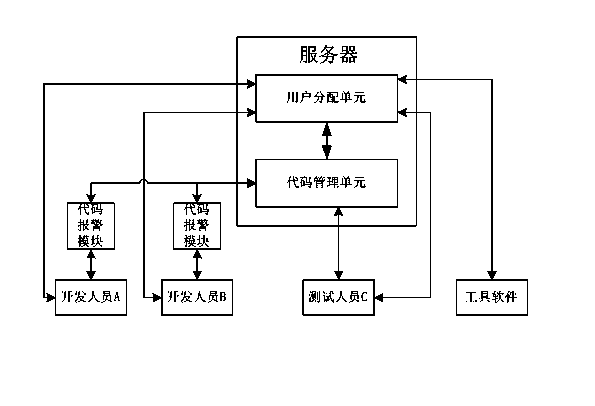

System and method for managing multi-people cooperative project in program development

The invention discloses a system and a method for managing a multi-people cooperative project in program development. The system comprises a code management unit and a user distribution unit, wherein the user distribution unit comprises a project role management module for distributing all roles in the project to specific people of the project, and an authority management module for setting corresponding authorities according to the roles of the people; the code management unit comprises a code storage module for completely storing codes submitted by development people, a code downloading module for downloading the codes to development people or testing people, a code alarm module for alarming and reminding if the development people do not store the codes within a set time interval and further for compulsively executing the code storage module if the alarm is made twice continuously, so as to prevent the situation that the testing people cannot test the latest codes as the development people forget to store the latest codes. By adopting the system and the method, under the condition that a program is developed by multiple people, the codes can be stably stored in time, and the cooperation of staff is simple and efficient.

Owner:JIANGSU MINGTONG TECH

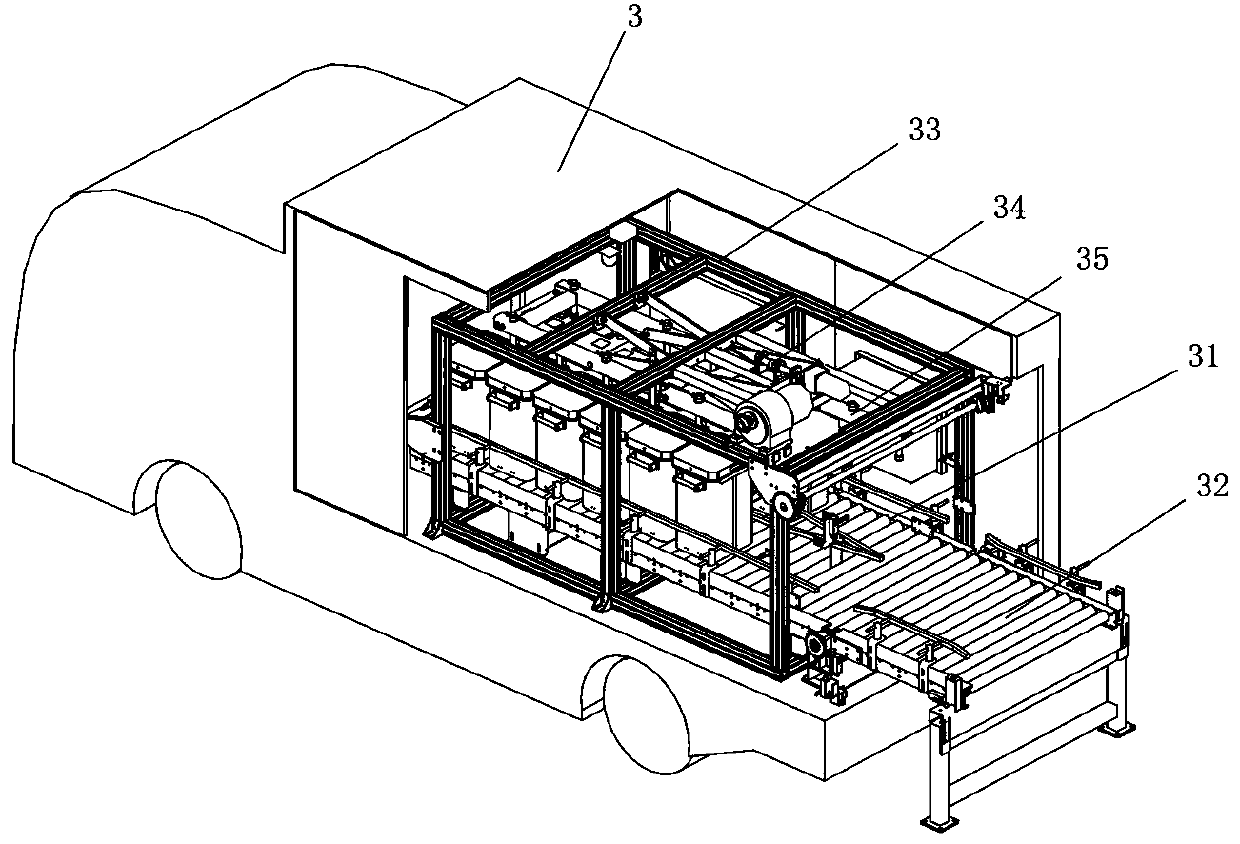

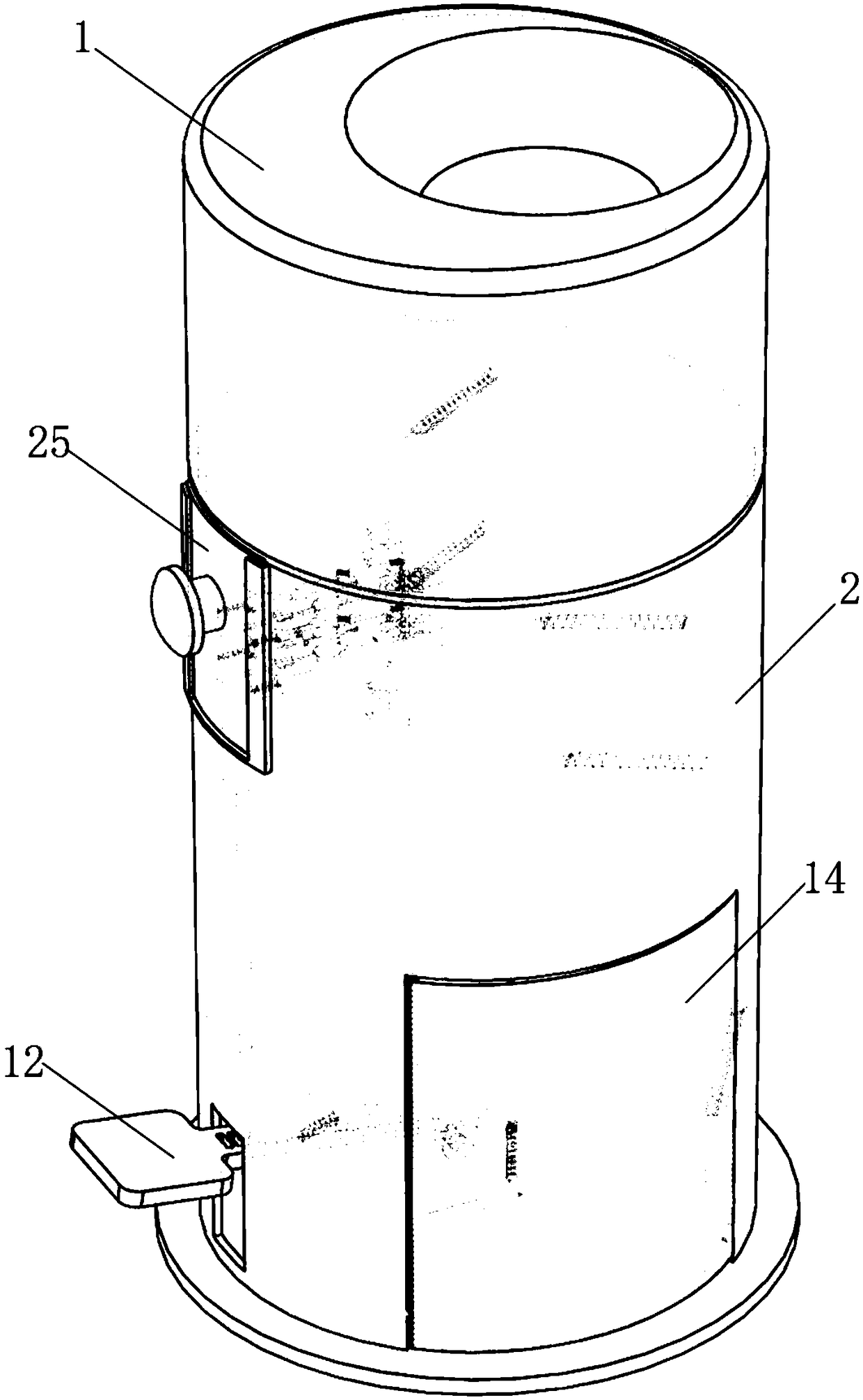

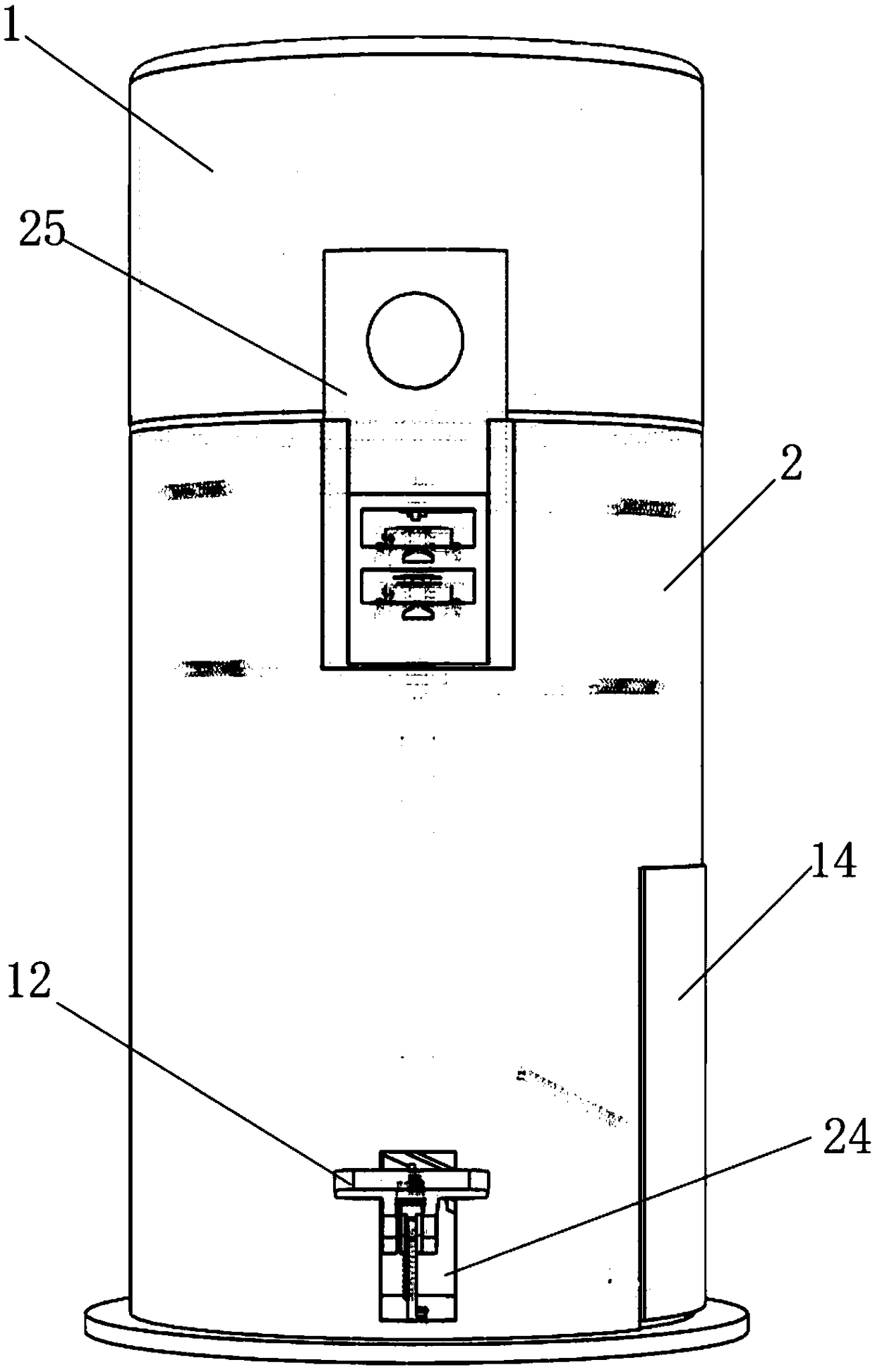

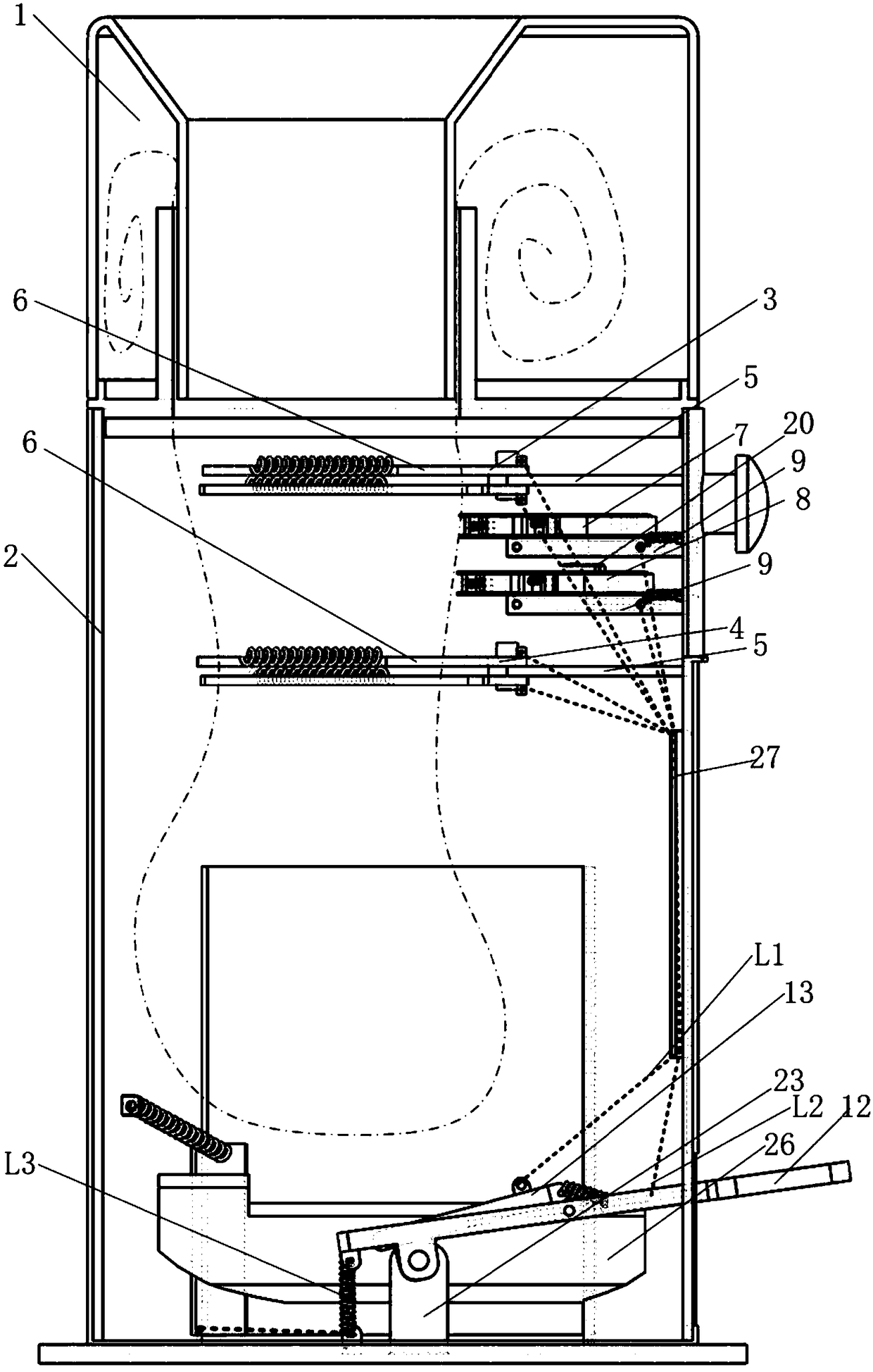

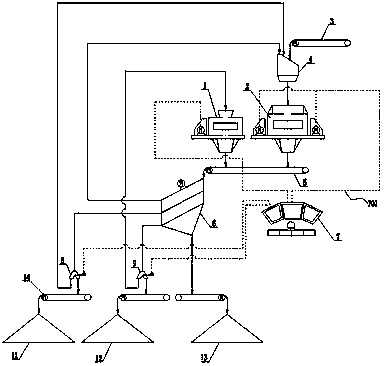

Vehicular continuous packaging garbage can

PendingCN109264247AEnsure reasonable exerciseEasy dischargeVehicle arrangementsRefuse receptaclesWire ropePlastic bag

The invention relates to a vehicular continuous packaging garbage can which comprises a main cylinder, a garbage bag storage mechanism, a transmission mechanism, a door opening mechanism, a cutting mechanism, a binding mechanism and sealing mechanisms. The garbage bag storage mechanism comprises an auxiliary cylinder and an upper cover and is used for storing long-cylinder plastic bags without hotcutting, the transmission mechanism is mounted at the bottom of the main cylinder and comprises an outer pedal and an inner pedal, power is transmitted to mechanisms through three groups of steel wire ropes, the binding mechanism and the sealing mechanisms are mounted in the main cylinder according to a set sequence, the cutting mechanism are mounted in the middle of the two sealing mechanisms, the steel wire ropes drive the door opening mechanism, the binding mechanism, the sealing mechanisms and the cutting mechanism to move according to sequences when the pedals are stepped, two sections of a garbage bag are bound, sealed and cut, the lower garbage bag slides out from a garbage can door, the upper garbage bag is sealed and then serves as bottom of next garbage bag packaging, and the mechanisms reset through corresponding spring mechanisms when the pedals are loosened, so that a simple, efficient and continuous garbage packaging function is achieved.

Owner:CHANGAN UNIV

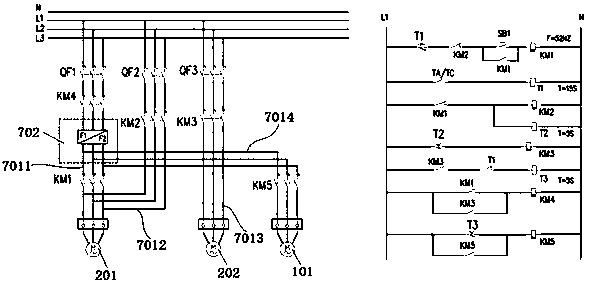

Dual main machine crushing production line and method based on frequency conversion control technology

The invention discloses a dual main machine crushing production line and method based on the frequency conversion control technology. The dual main machine crushing production line comprises a shapingmachine and a sand making machine. A discharging opening of the shaping machine and a discharging opening of the sand making machine are connected with a feeding opening of a vibration screening mechanism through an operating belt. The vibration screening mechanism comprises a vibration screen and a material divider. The shaping machine, the sand making machine and the material divider are connected with a PLC control system. By means of the frequency conversion control technology of the PLC control system, the shaping machine and the sand making machine achieve frequency conversion starting,the rotating speed and frequency of the sand making machine are adjusted and controlled, the division proportion of the material divider can be adjusted and controlled, impacting to a power grid during motor starting is effectively avoided, the stability is good, and the safety coefficient is high; and the production proportion of various discharged materials is flexibly controlled, the materialsare reasonably divided, the control precision is high, and high efficiency and energy saving are achieved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

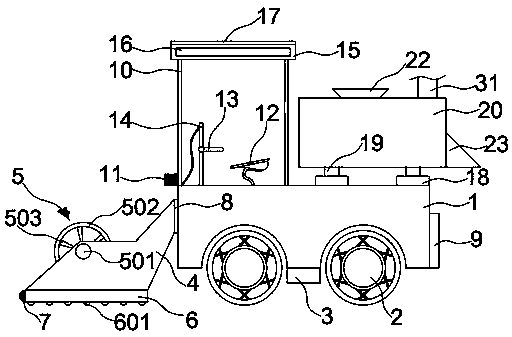

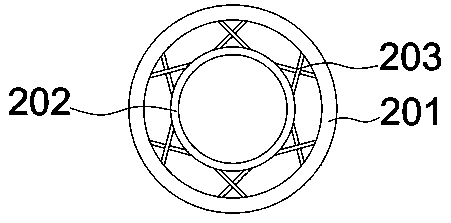

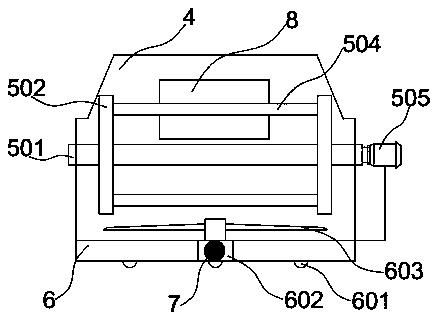

Multifunctional collecting device for sesame

InactiveCN108811717AExtended service lifeEfficient cooperationHarvestersSesamum orientaleVehicle frame

The invention provides a multifunctional collecting device for sesame. The device comprises a threshing bin; a vehicle frame is arranged on the threshing bin, a cleaning bin is arranged on the side part of the vehicle frame, the rear part of the cleaning bin is provided with a material outlet, and a material conveying pipe is connected between the cleaning bin and the threshing bin; the interior of the vehicle frame is provided with an operation and control rod operated by a driver and a safety seat, a harvesting frame is arranged in the front of the threshing bin, and a material inlet is arranged between the threshing bin and the harvesting frame; and roll wheels are arranged at the bottom of the threshing bin, each roll wheel comprises an axle and an outer ring, and cross-arranged hingecut pieces are arranged between the axle and the outer ring. According to the device provided by the invention, the sesame harvested by the harvesting frame enters the threshing bin from the materialinlet, the sesame and sesame straw can be separated in the threshing bin, the threshed sesame enters the cleaning bin through the material conveying pipe, and the sesame is discharged and collected from a material outlet after being cleaned and dusted; the hinge cut pieces are arranged between each axle and one corresponding outer ring, so that the roll wheels can be prevented from being stuck, service life of the roll wheels can be increased, cut weeds such as the sesame straw are used as a fertilizer to be fed back to land, and energy sources are saved.

Owner:浦江县顺光科技有限公司

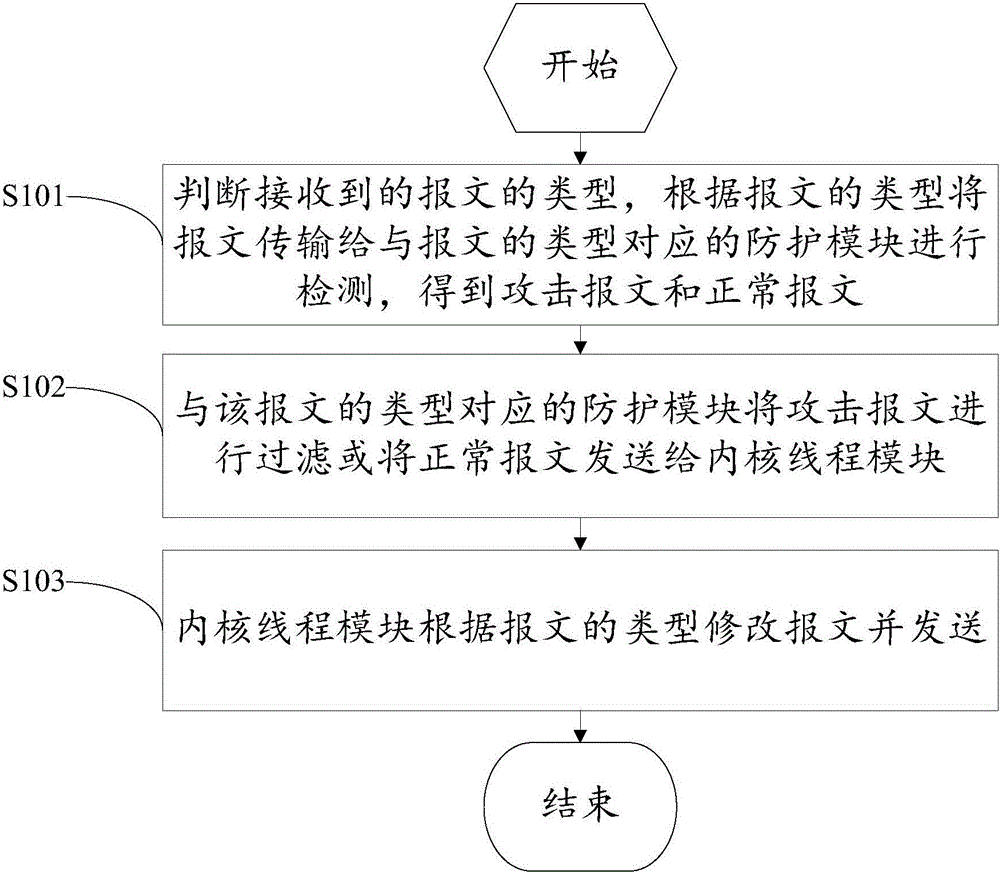

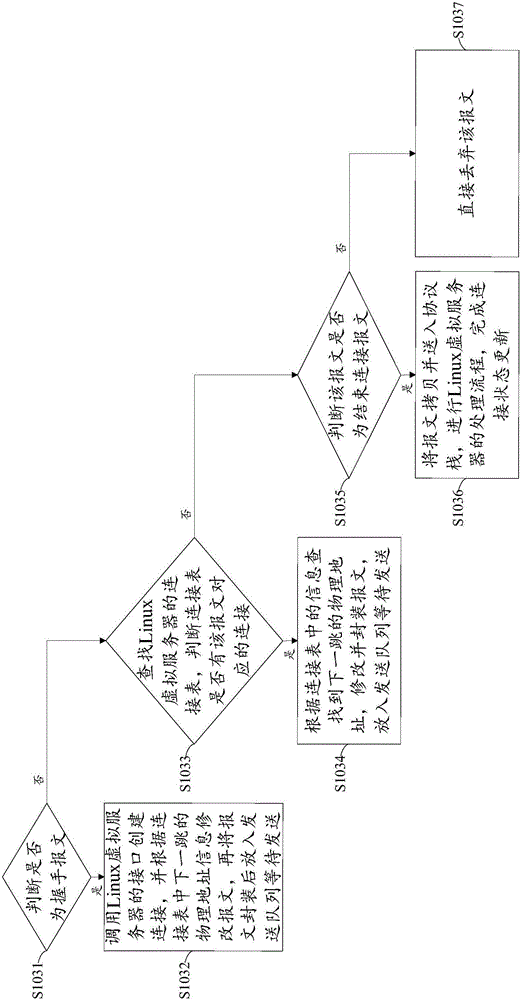

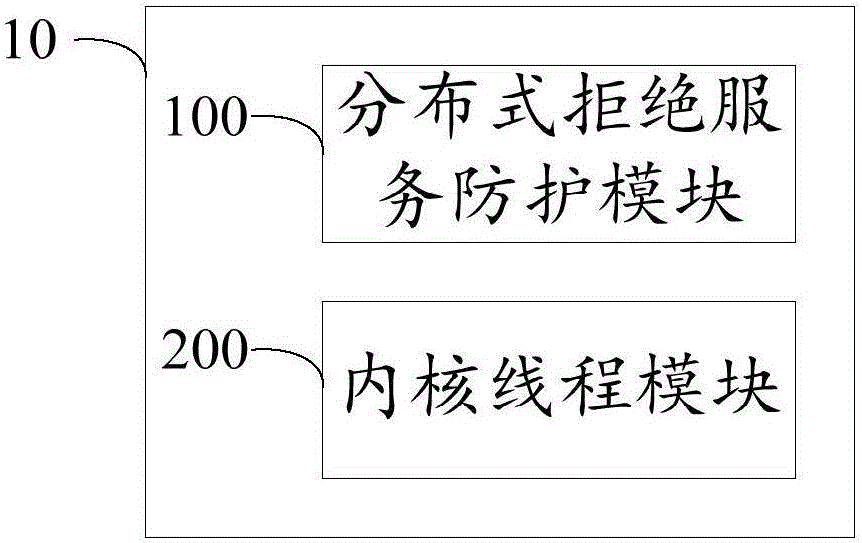

Method and system for integrating protection and load balancing of distributed denial of service

ActiveCN106790310AEfficient cooperationReduce the amount of copyTransmissionDenial-of-service attackDistributed computing

The invention discloses a method and a system for integrating protection and load balancing of distributed denial of service. The method comprises the following steps: judging the type of a received message, and transmitting the message to a protection module corresponding to the type of the message according to the type of the message to perform detection to acquire an attach message and a normal message; filtering the attack message or transmitting the normal message to a kernel thread module by the protection module corresponding to the type of the message; and modifying the message according to the type of the message by the kernel thread module and transmitting the message. According to the method and the system, the protection function and the load balancing function of the distributed denial of service are integrated on the same equipment, the cost problem caused by single protection equipment is solved, and protection equipment and load balancing equipment can cooperate with each other efficiently; and the copy quantity of the message is reduced during load balancing, and influence on equipment performance is avoided.

Owner:CHINANETCENT TECH

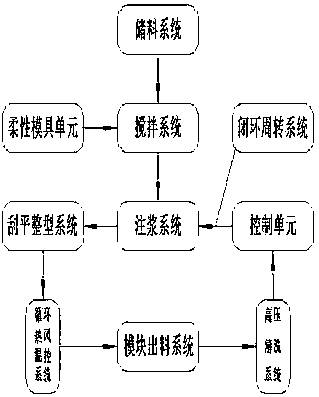

Automatic production technology of fabricated building blocks

PendingCN109693307AOperational CoordinationEfficient cooperationCeramic shaping plantsFeeding arrangmentsClosed loopHigh pressure

The invention mainly relates to an automatic production technology of fabricated building blocks. The automatic production technology is mainly used for the production and manufacture of fabricated building blocks for non-load bearing walls in the construction industry. The automatic production technology includes the automatic production and processing of gypsum building blocks, concrete buildingblocks and environment-friendly material building blocks. The automatic production technology is mainly composed of a material storage system, a mixing system, a grouting system, a closed loop turnover system, a scraping and leveling system, a circulating hot air temperature control system, a high pressure cleaning system, a flexible mold unit, a molded block discharging system and a control unit. The applied fabricated building block production technology adopts a full-automatic production and transportation system and adopts a movable flexible mold unit or a plurality of mold groups, and material grouting is carried out at an grouting station of a grouting system through the movement of the movable flexible mold unit or the mold groups so as to reduce manpower operation; and an accuratemechanical control system is adopted, a sensing control device is utilized to ensure linkage operation of parts so as to realize full operation and implementation until finished product discharging is completed, the problems that a large great of manual labor and turnover cycles are solved, and resource waste is less.

Owner:王海峰

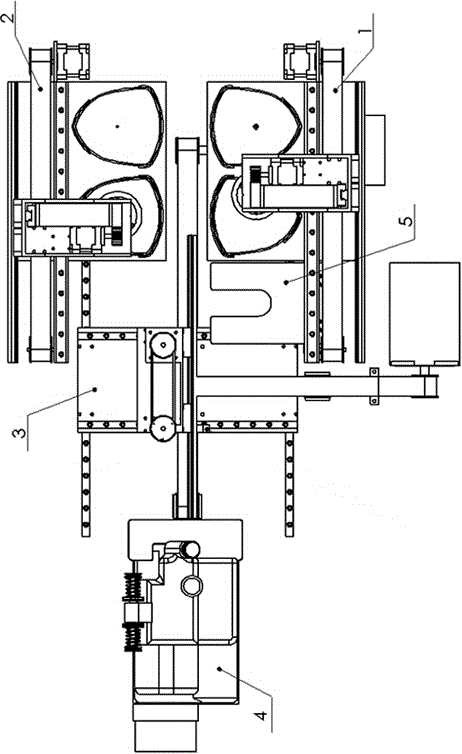

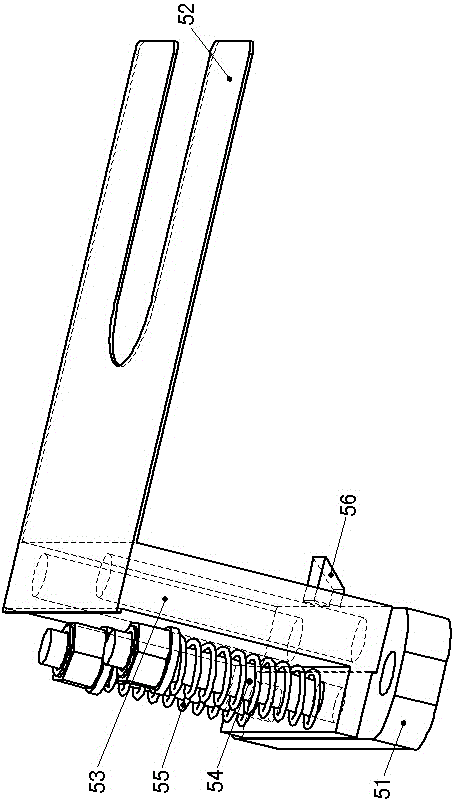

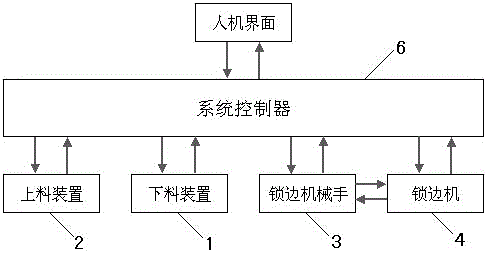

Automatic armband stitch locking production device and stitch locking processing method thereof

ActiveCN104404715AQuality improvementContinuous work with high efficiency and qualityWork-feeding meansEngineeringManipulator

The invention discloses an automatic armband stitch locking production device. The automatic armband stitch locking production device comprises a stitch locking mechanical arm, wherein a stitch locking machine is arranged at one end of a running guide rail of the stitch locking mechanical arm, a loading device and an unloading device are arranged at the other end of the running guide rail of the stitch locking mechanical arm, the loading device and the unloading device are respectively located on two sides of the running guide rail of the stitch locking mechanical arm, a stripping device is arranged on one side of the unloading device, and the stitch locking mechanical arm, the stitch locking machine, the loading device and the unloading device are controlled through a system controller. The automatic armband stitch locking production device automatically completes the whole process including loading, stitch locking and unloading from beginning to end without stopping, and can continuously perform high efficiency and high quality work as long as a thread on the stitch locking machine is not broken.

Owner:JIANGSU WANGONG TECH GRP CO LTD

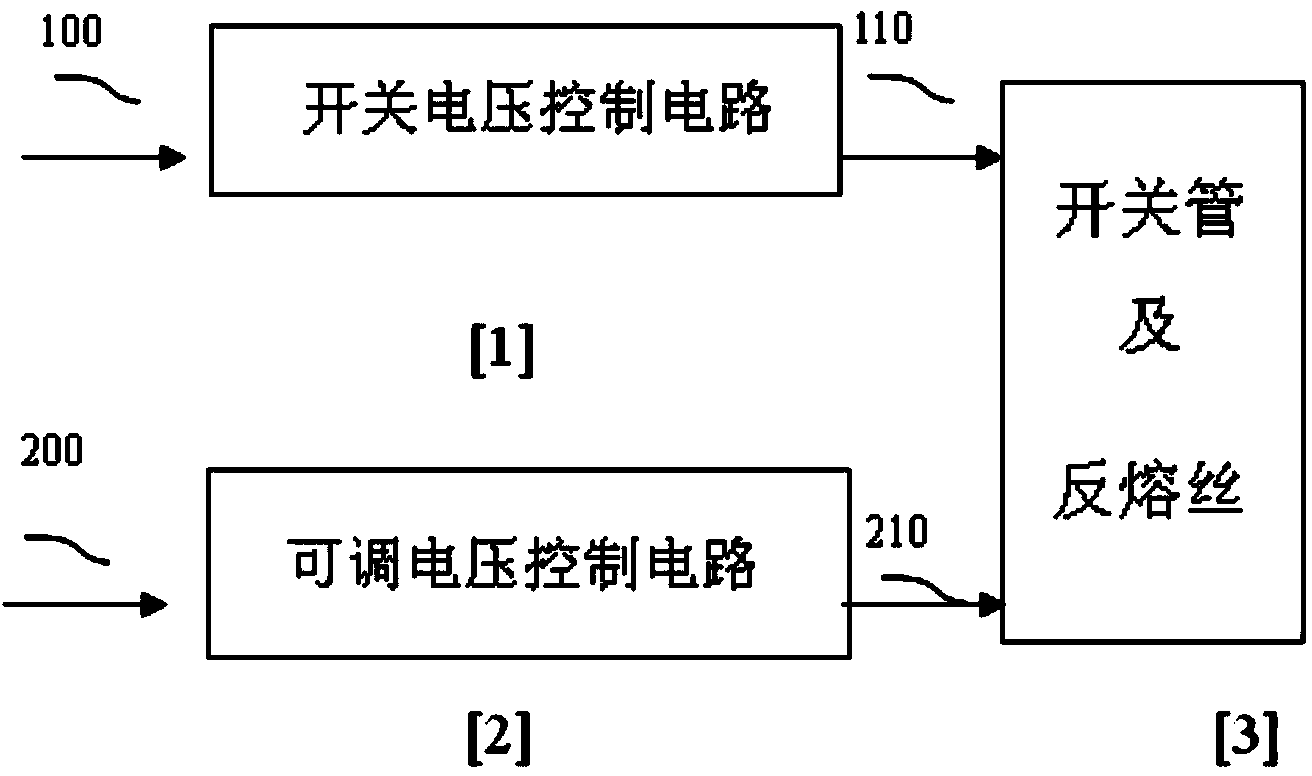

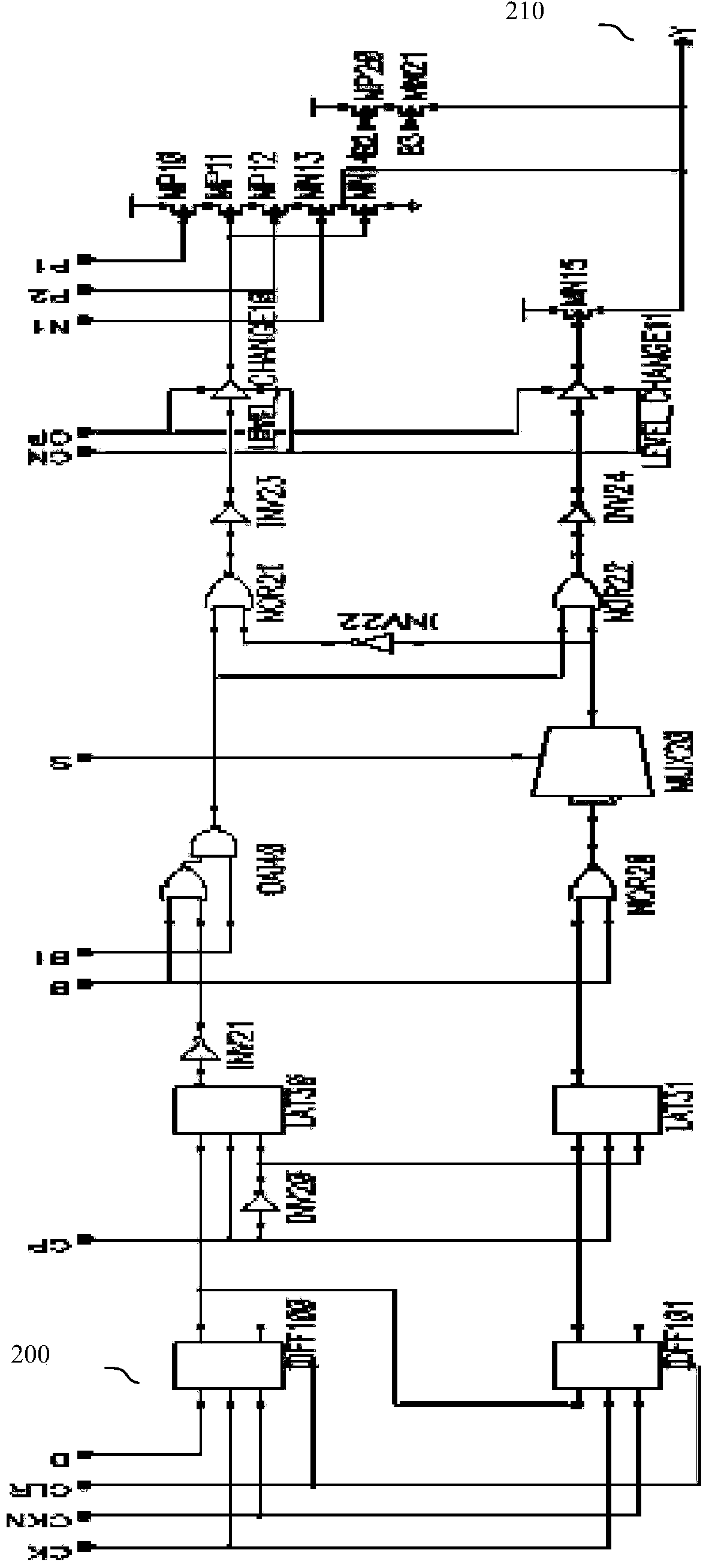

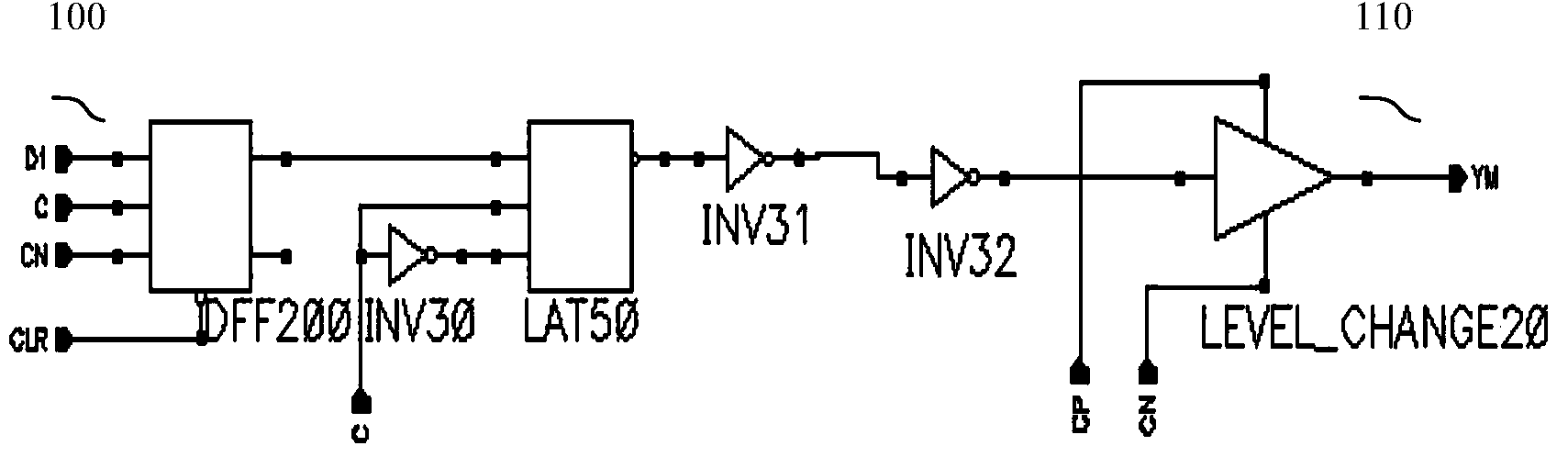

Programmed burning device for anti-fuse

ActiveCN104409100ASimple circuit structureFlexible controlRead-only memoriesElectronic switchingElectricityEngineering

The invention discloses a programmed burning device for an anti-fuse. The programmed burning device disclosed by the invention comprises a switching tube, a switching voltage control circuit and an adjustable voltage control circuit, wherein the switching tube is electrically connected with the anti-fuse; the switching voltage control circuit is connected with the switching tube and is used for providing switching voltage for the switching tube; and the adjustable voltage control circuit is connected with the switching tube and is used for providing different control voltages for the switching tube. The circuit disclosed by the invention is simple in structure, flexible to control and high in circuit speed, insufficient burning or excessive burning of the anti-fuse is avoided, the programming quality of the anti-fuse is improved, and the programming reliability of the anti-fuse is enhanced.

Owner:NO 47 INST OF CHINA ELECTRONICS TECH GRP

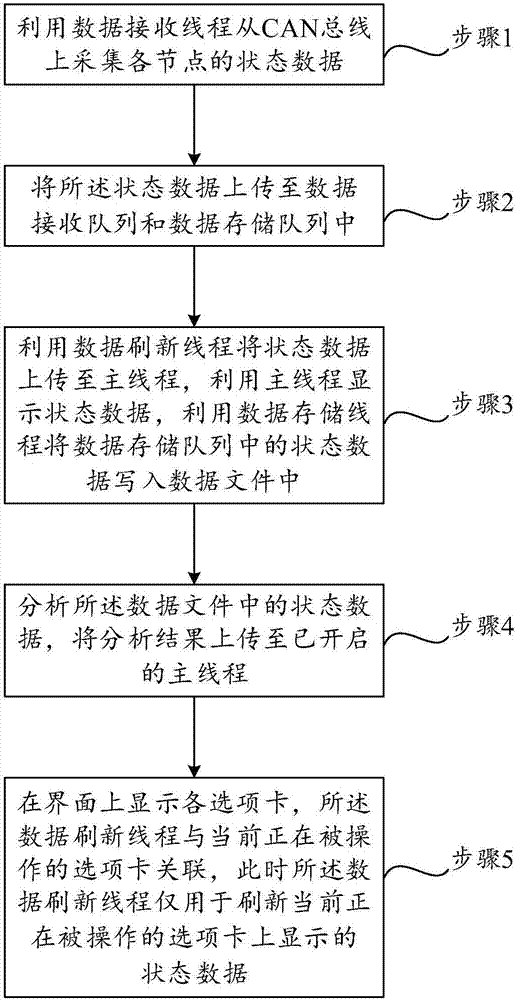

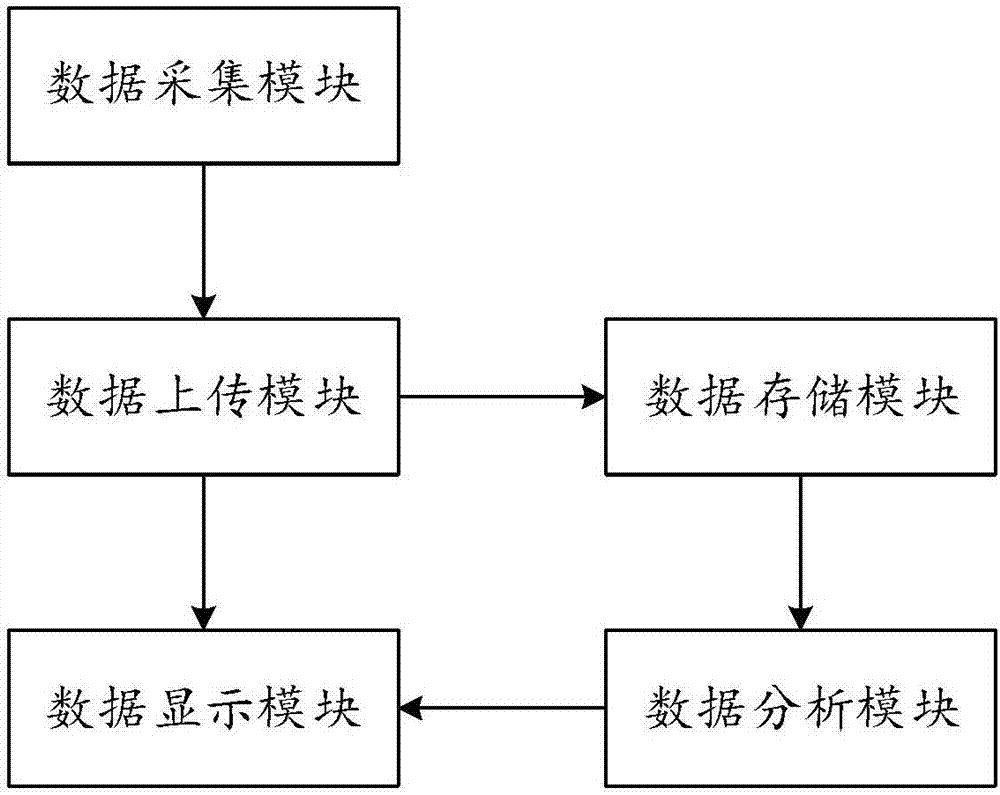

Monitoring method of emission vehicle states and device

ActiveCN106970580AReduce consumptionRealize monitoringProgramme controlComputer controlData displayData acquisition

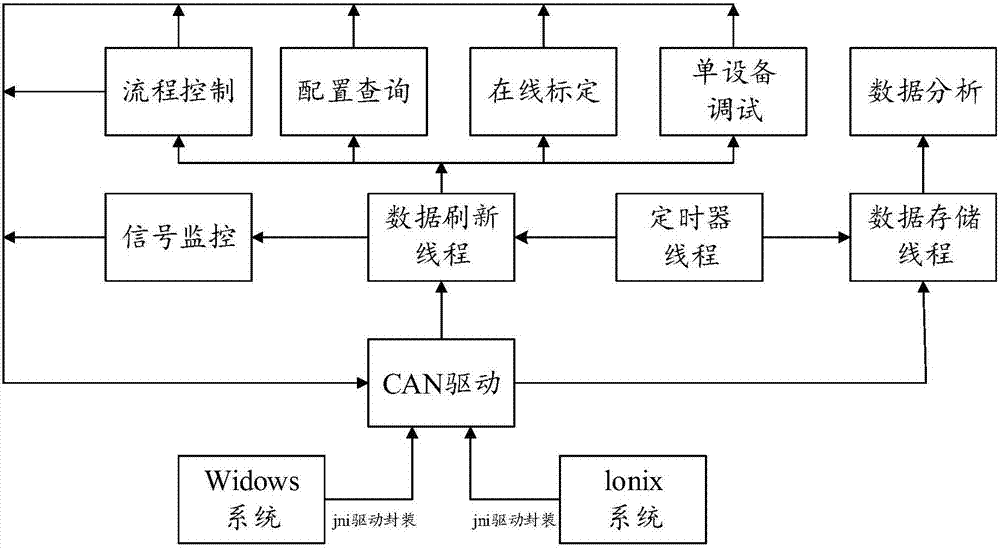

The invention discloses a monitoring method of emission vehicle states and a device. The monitoring method comprises following steps of step 1, starting a data receiving thread, and acquiring state data of each node from a CAN bus by use of the data receiving thread; step 2, uploading the state data into a data receiving queue; and step 3, starting a data refresh thread, uploading state data in the data receiving queue to an already started main thread by use of the data refresh thread and displaying the state data on an interface by use of the main thread. A monitoring device comprises a data acquisition module, a data uploading module, a data display module, a data storage module and a data analysis module. According to the invention, a cross-platform comprehensive state monitoring method based on JAVA multi-threads is provided, so various and complex state monitoring requirements of emission vehicles are met, a function of multi-state monitoring is achieved and an expected effect is achieved.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Request processing method and device based on service grid

PendingCN111767157AEfficient cooperationImprove experienceInterprogram communicationComputer networkEngineering

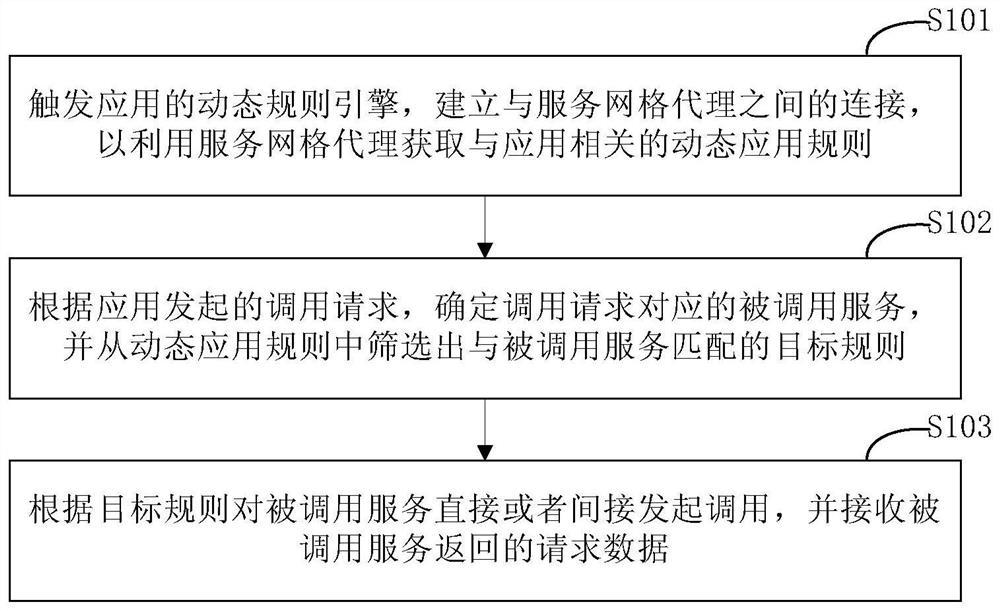

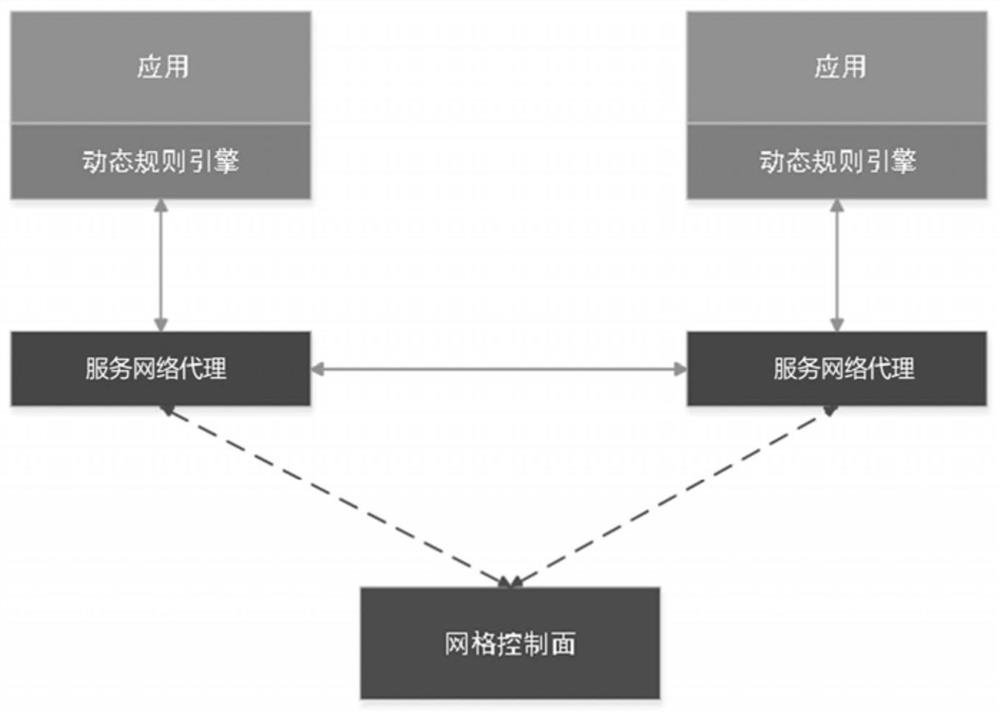

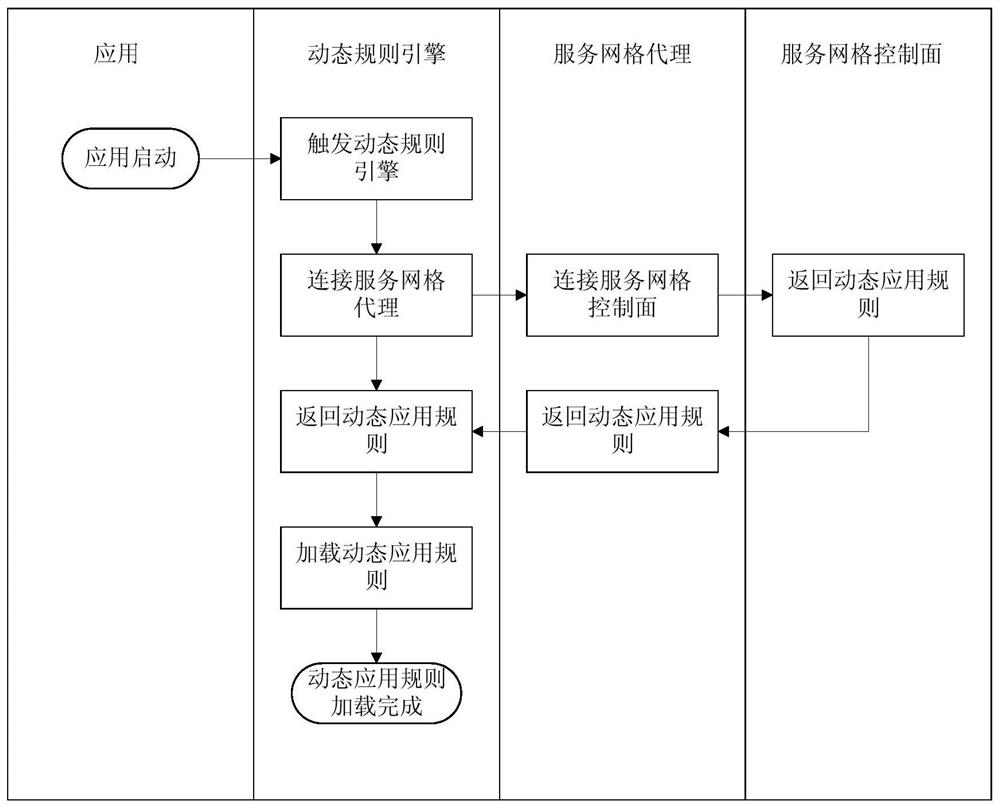

The invention discloses a request processing method and device based on a service grid, and relates to the technical field of computers. One specific embodiment of the request processing method comprises the following steps: triggering a dynamic rule engine of an application, and establishing connection with a service grid agent so as to obtain a dynamic application rule related to the applicationby utilizing the service grid agent; determining a called service corresponding to the calling request according to the calling request initiated by the application, and screening out a target rule matched with the called service from the dynamic application rules; and directly or indirectly initiating calling of the called service according to the target rule, and receiving request data returnedby the called service. According to the embodiment, the dynamic application rule is obtained from the service grid agent by means of the dynamic rule engine, and the calling is initiated according tothe target rule in the dynamic application rule, so that the efficient cooperation between the application and the service grid agent can be realized through the dynamic rule engine, and the requestprocessing efficiency is improved.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com