Compact type high-efficiency combined rice milling machine

A rice milling machine, a compact technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of difficult maintenance and operation, high residual rate of paddy, large floor space, etc., and achieve low processing cost and rice yield. High, short processing flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

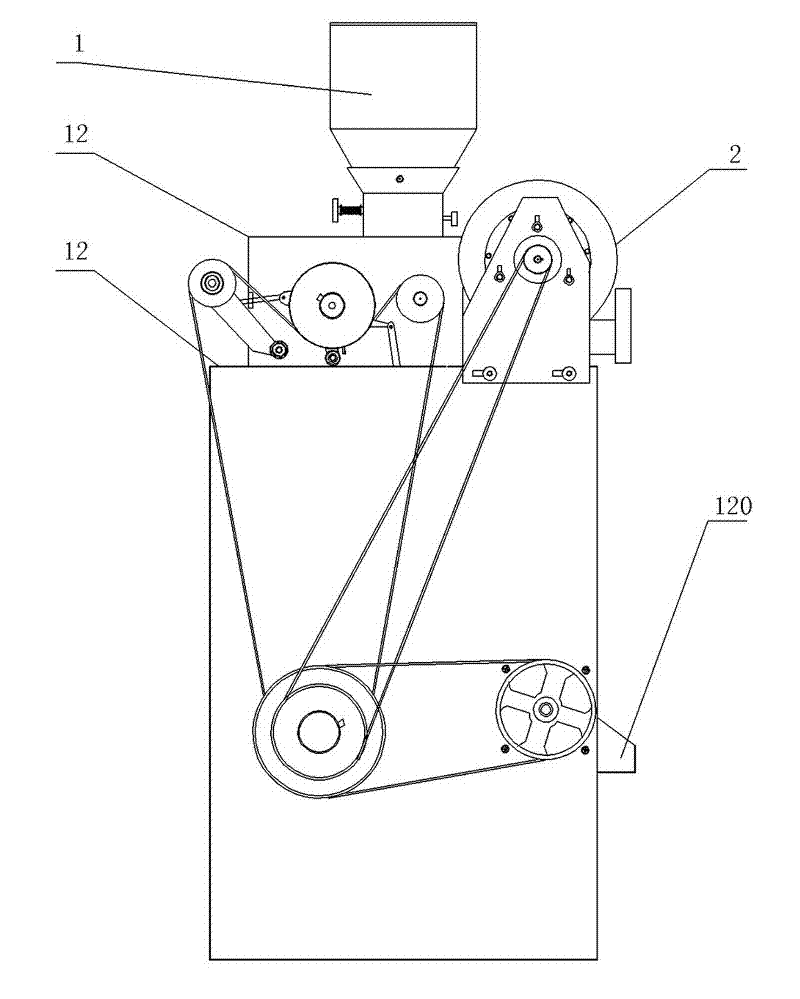

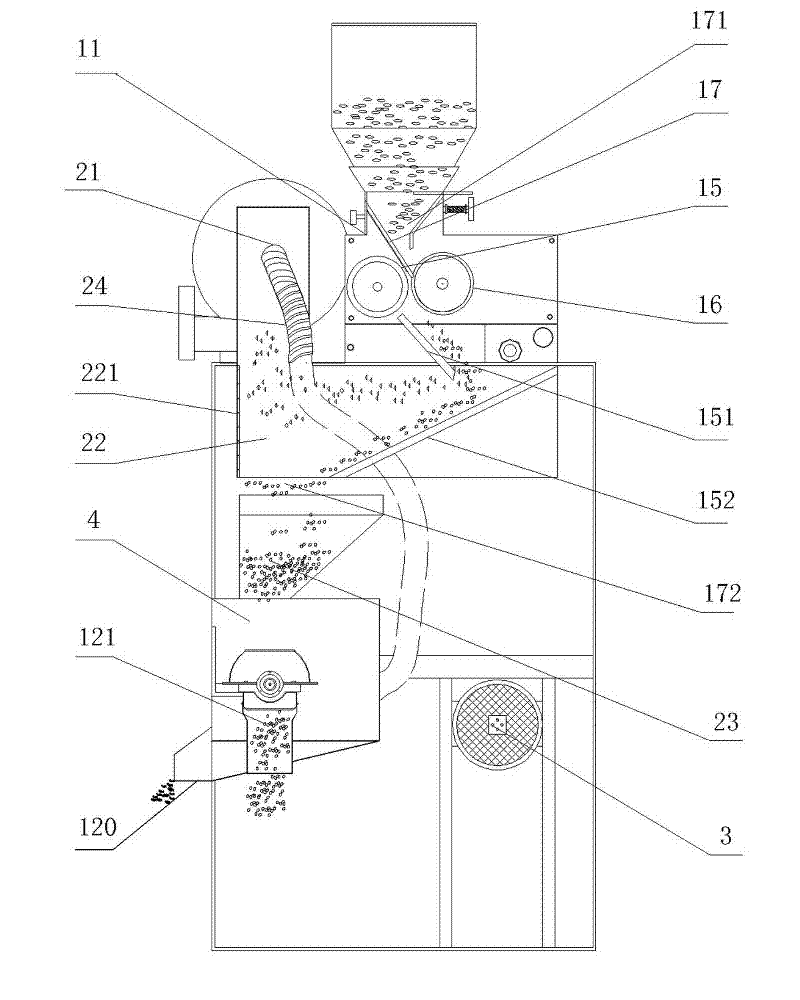

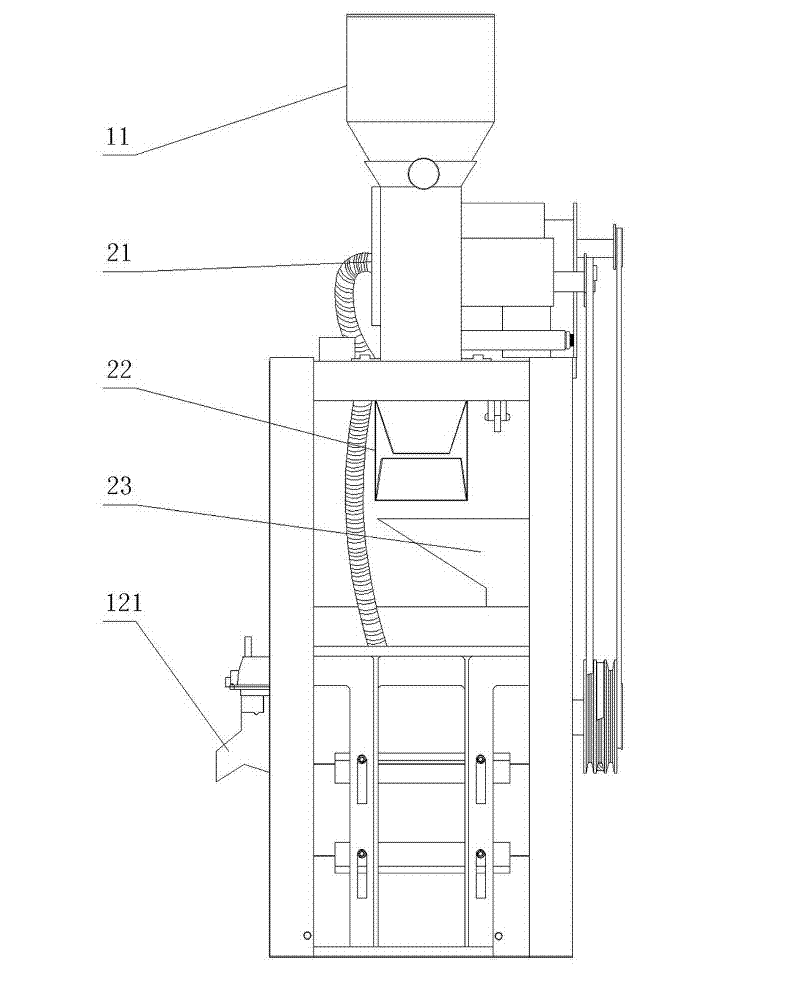

[0016] Depend on figure 1 combine figure 2 , 3 It can be seen that the compact high-efficiency combined rice milling machine includes a body 12 and a motor 3. The top of the body 12 is provided with a hulling head 11 and a fan 2. The top of the hulling head is provided with a feed hopper 1, and a feed hopper is provided below the outlet of the feed hopper 1. There is a trough deflector 17, one end of the deflector 17 is fixed at the outlet 171 of the feed hopper 1, and the other end extends between the fast rubber roller 15 and the slow rubber roller 16, and the groove edges on both sides of the deflector 17 are inserted to the gap between the end face of the rubber roller and the hull vertical plate of the huller head 11; The rice bran outlet is connected, and the rice bran separator 22 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com