Patents

Literature

112results about How to "Improve the rice yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel technique for processing top grade rice

InactiveCN1962066ARaise the gradeIncrease the number of varietiesGrain treatmentsNovel techniqueEngineering

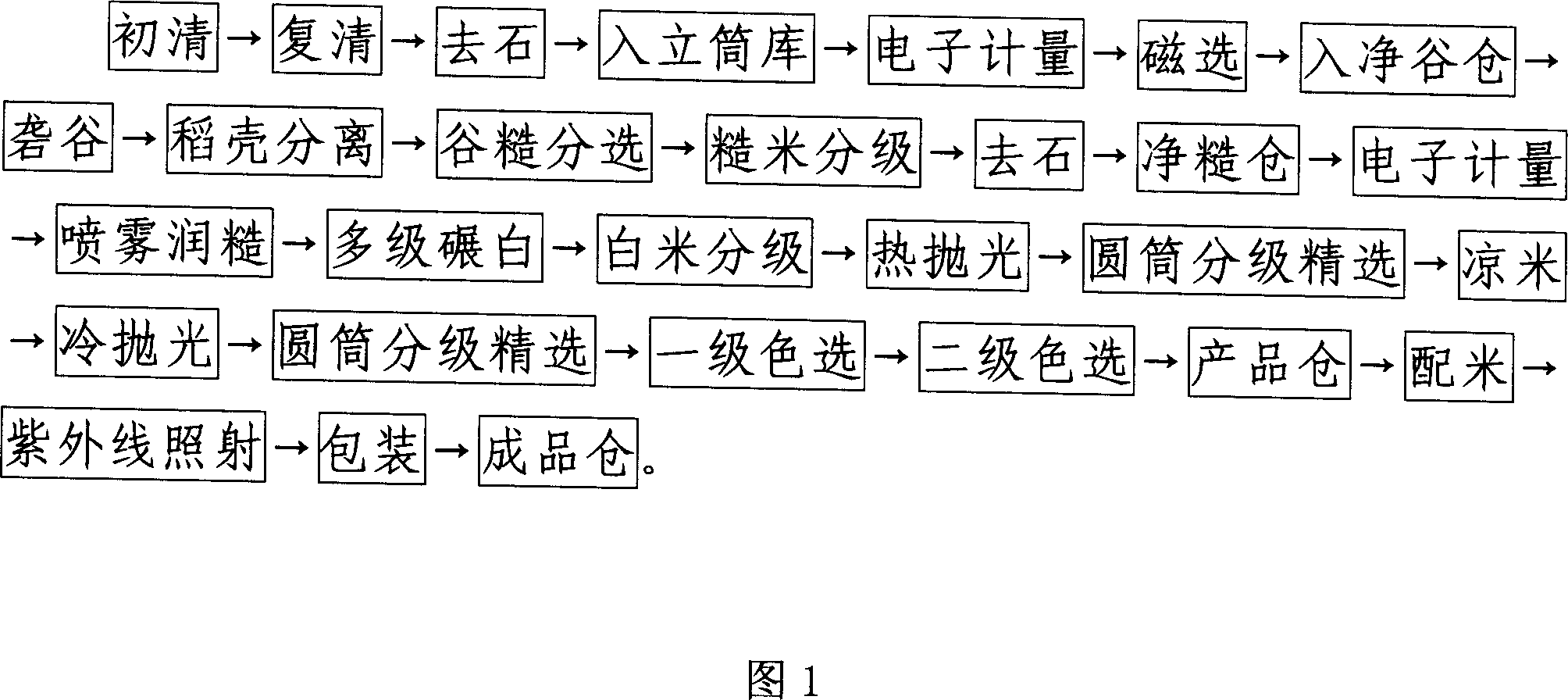

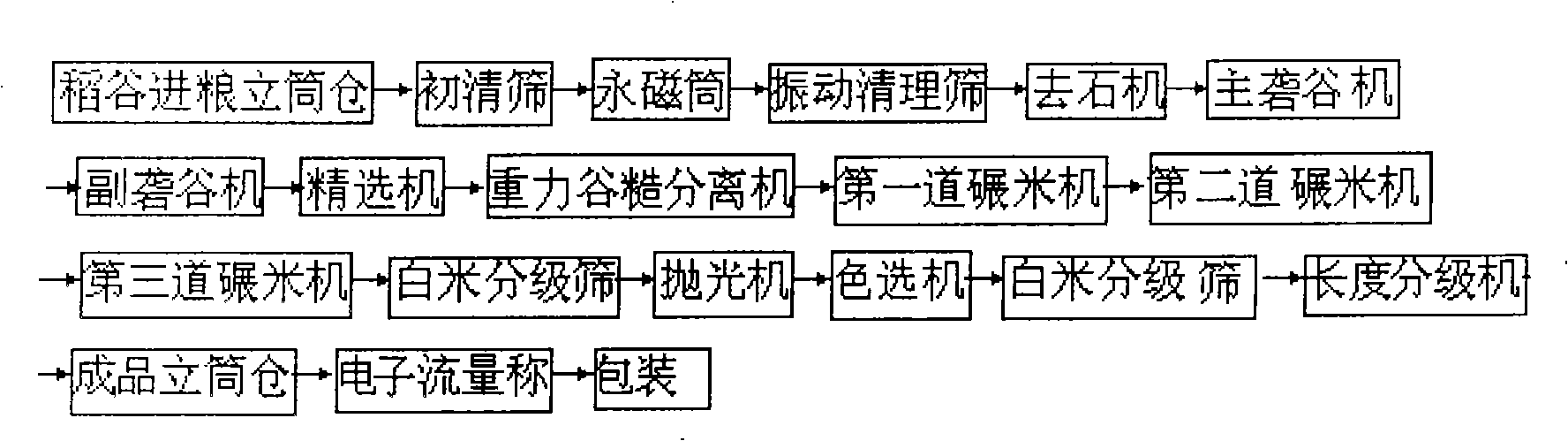

The invention relates to a method for processing high-quality rice, wherein it comprises cleaning, cleaning again, removing stone, putting into cylinder chamber, metering, magnetic selecting, feeding into rice chamber, hulling, separating the frame, selecting, classifying the unpolished rice, removing stone, cleaning the unpolished rice chamber, metering, atomizing and wetting, rolling white, classifying the rice, furnishing, selecting, cooling, furnishing cold, selecting in cylinder, selecting color, selecting color again, feeding into chamber, mixing, radiating with ultraviolet light, packing, feeding into product chamber. The invention can prolong the storage period.

Owner:湖南省天龙米业有限公司

Cold polishing technique of rice finish machining

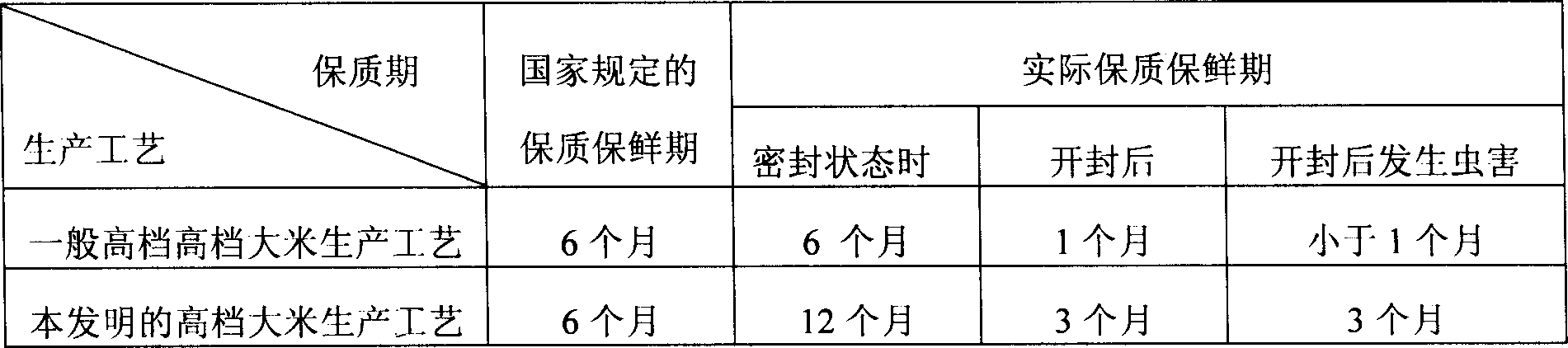

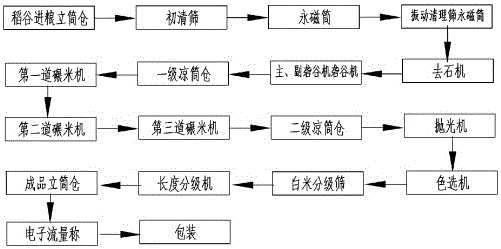

A rice fine processing and cold polishing technique includes a vertical paddy entering silo-a primary screen-a permanent magnet drum-a vibration cleaning screen-a stone removing machine-a main scouring machine-a secondary scouring machine-a fine mesh screen-a gravity paddy slug separator-a first paddy pounder-a second paddy pounder-a third paddy pounder-a rice grading screen-an abrasive finishing machine-a color selector-a rice grading screen-a length grading machine-a vertical silo for finished product-an electric flow scale-a package. The present invention is characterized in that a vertical rice cooling silo used for cooling the temperature of the rice is arranged before the abrasive finishing machine. The present invention changes the defect of the traditional thermal polishing technique. The present invention adopts the mode of combining natural cooling and mechanical cooling, thus greatly improving the cooling effect, increasing the rice yield by 4 percent, greatly reducing the rate of cracked rice and subliming the rice quality not only from the appearance, but also from the inner quality.

Owner:WUHAN GUIZI RICE IND

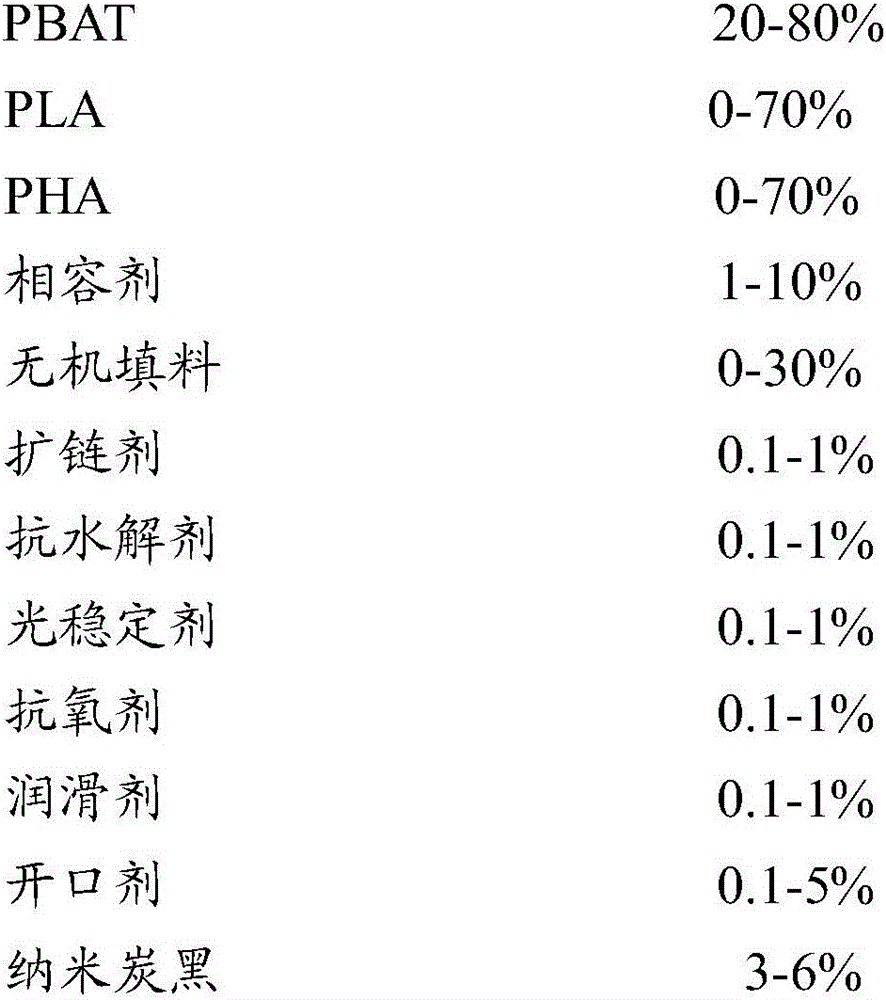

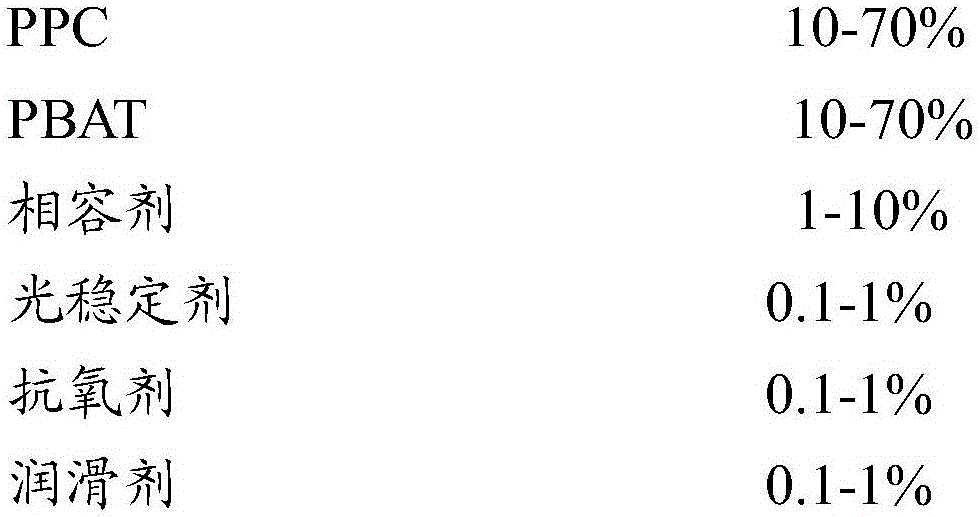

Full-biodegradation mulch film for rice planting and production method thereof

ActiveCN106633704AShortened growth periodImprove the rice yieldLayered productsClimate change adaptationAdditive ingredientPesticide residue

The invention provides a full-biodegradation mulch film for rice planting and a preparation method thereof. The full-biodegradation mulch film for rice planting comprises an inner layer, a middle layer and an outer layer, and comprises ingredients such as PBAT, PLA, PHA and PPC; the inner layer, the middle layer and the outer layer of the full-biodegradation mulch film are prepared by a three-layer co-extrusion technology. The full-biodegradation mulch film for rice planting and the preparation method at least have the following advantages that the rice growth period is shortened; the rice yield is increased; the rice quality is improved; the manual weeding cost is reduced; the pesticide consumption is reduced; the pesticide residue is reduced; the use cost of a user is reduced through thickness reduction; meanwhile, the problems that the existing full-biodegradation mulch film has poor hydrolysis resistant performance, and is not suitable for rice planting conditions are solved by adding the functional auxiliary agents through the three-layer co-extrusion process. The degradation performance controllability is high; the growth requirements of the crops can be met. The price is about 5 percent lower than that of abroad similar products.

Owner:白山市喜丰塑业有限公司

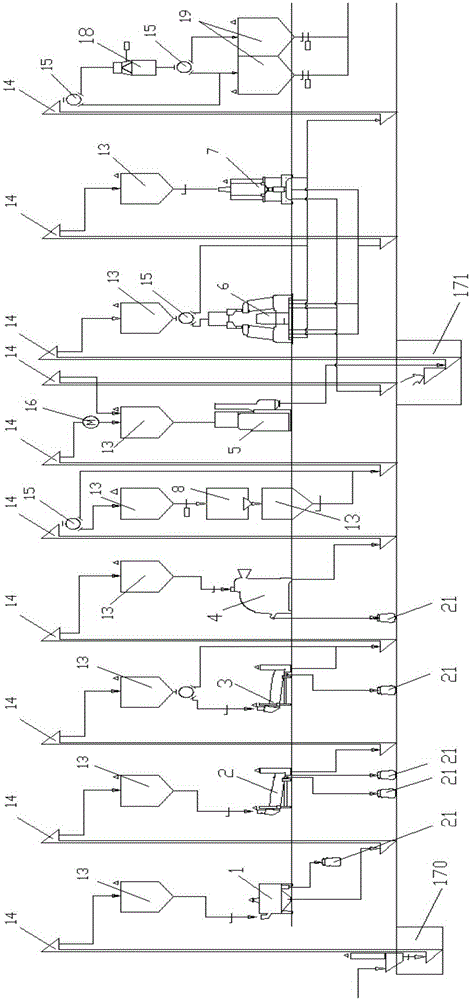

Long-shaped rice processing method and system

The invention discloses a long-shaped rice processing method and system. The processing method comprises the steps of cleaning, stone removal, husking and rice husk separation, roughness improvement, multistage rice milling, multistage polishing, multistage color sorting and the like; in addition, the steps including buffering through a buffering bin and magnetic separation are conducted before the main steps. By means of the long-shaped rice processing method and system, the appearance, color and taste of rice obtained through processing are all improved greatly, the product quality is improved, the broken rice rate is reduced, and the milled rice rate is increased.

Owner:湖北天斌机械有限公司

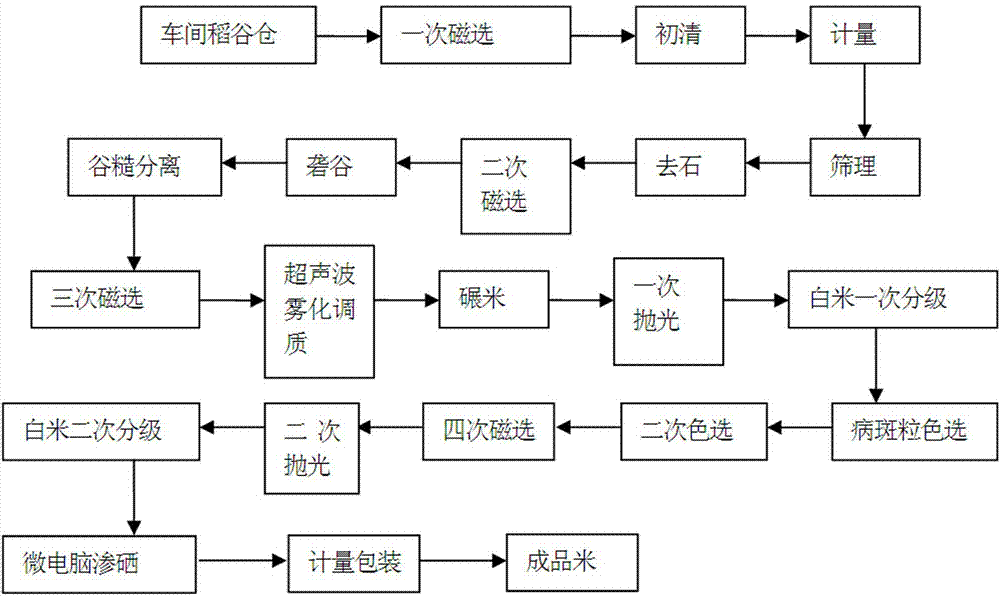

High-quality rice fine processing process

ActiveCN104772178AImprove Sorting Efficiency and PurityImprove the quality of finished riceSortingGrain millingSecondary colorChemistry

The invention provides a high-quality rice fine processing process, which comprises the processing flow processes of primary magnetic separation, primary cleaning, metering, sieving, stone removing, secondary magnetic separation, husking, husked rice separation, tertiary magnetic separation, ultrasonic atomization tempering, rice milling, primary polishing, polished rice primary grading, spotted rice color separation, secondary color separation, fourth magnetic separation, secondary polishing, polished rice secondary grading and metering and packaging. According to the ultrasonic atomization tempering, an ultrasonic atomization humidification mode is used for humidifying the rice, the tempering time is 10 to 20 minutes, the tempering temperature is controlled to be between 30 DEG C and 40 DEG C, the unit humidification quantity is 0.5 to 5 percent, the actual seeping quantity is 2 to 3 percent, and the moisture content of the polished rice finally obtained through processing is not greater than 14 percent; tempering agents adopt ultrasonic atomization water; during the spotted rice color section, a photoelectric color separation device is used for automatically picking out different-color rice, the full-process temperature reduction is carried out in the whole processing flow process, and the temperature rice in the processing process is controlled not to exceed 5 DEG C. The high-quality rice fine processing process has the advantages that the high-quality rice can be subjected to integrated utilization and deep processing, and the final product quality is improved.

Owner:YUNNAN HONGHE WOLONG RICE IND CO LTD

Rice fine processing technology

InactiveCN106391168AImprove drying efficiencyThe processing procedure is simpleGrain huskingGrain polishingBroken riceWhite rice

The invention discloses a rice fine processing technology which comprises the following steps of unhusked rice screening, stone removal, magnetic separation, soaking in a dietary alkali solution, washing, drying and moisture removal, rice husking, husked rice separation, thickness classification, rice milling, soaking in a soaking solution, drying and moisture removal, white rice classification, rice cooling, polishing, color sorting, secondary white rice classification, sterilization and packaging. According to the method, processing technological procedures are simple, the milled rice rate is high, the production cost of rice processing enterprises can be reduced, and the rice produced through the method is clean, good in degree of finish and low in broken rice rate.

Owner:金健粮食(益阳)有限公司

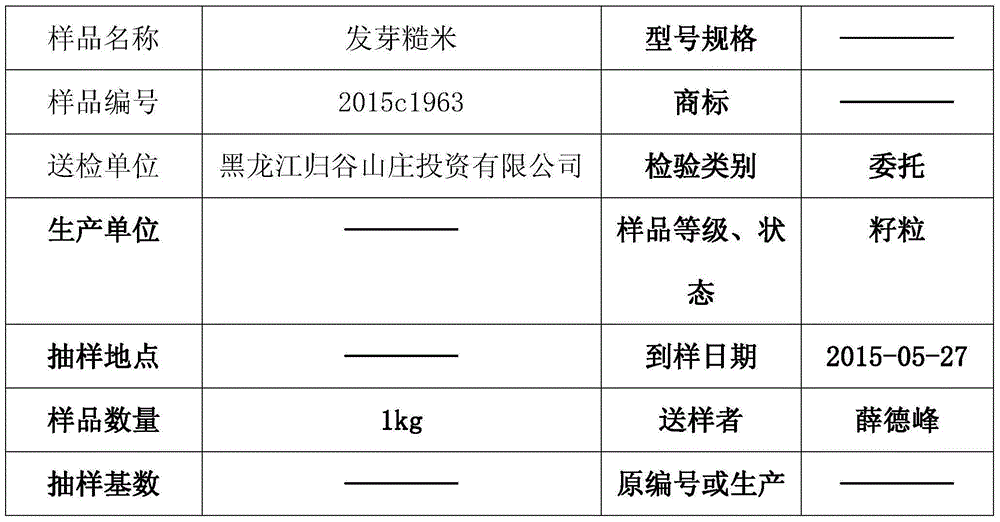

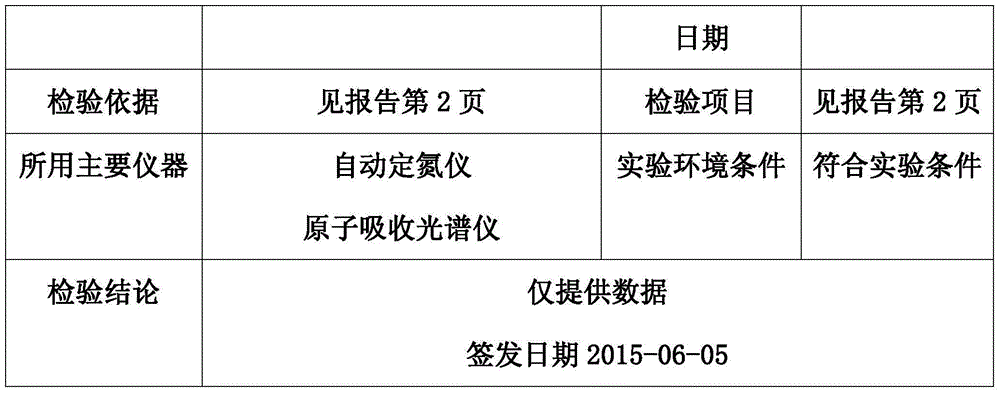

Production method for processing total-nutrient germinated brown rice and germinated milled rice

ActiveCN105080636AAffect germination rateAffect qualityGrain millingContinuous/uninterruptedWhite rice

The invention provides a production method for processing total-nutrient germinated brown rice and germinated milled rice. The production method includes the steps that new unhusked rice with the water content being below 15% is selected as raw materials and then put into an open container after being sieved and subjected to impurity removal; water is added to immerse the unhusked rice by above 10 cm; ozone with the concentration of 0.5-1.5 mg / L is introduced continuously into the water from the bottom of the container; the water is controlled to be at the constant temperature of 32+ / -1 DEG C for 36-48 hours for seed soaking and pregermination, and the water is not changed halfway; after the germinated rice with the germination length being 0.5-1 mm is obtained, the ozone supply is stopped, steam at the temperature of 80 DEG C is introduced for 4 min, and then rapid inactivation treatment is carried out; and the unhusked rice is then rapidly dried at the temperature of 50-52 DEG C until the water content is below 17%. After the unhusked rice is hulled according to a common method, the germinated brown rice is obtained. Then separation, rice milling, color sorting, polishing and grading are carried out, so that the germinated milled rice is obtained. The production method for processing the total-nutrient germinated brown rice and germinated milled rice is uniform in germination, is high in germination speed and keeps the nutrient in the unhusked rice as much as possible.

Owner:刘毅 +2

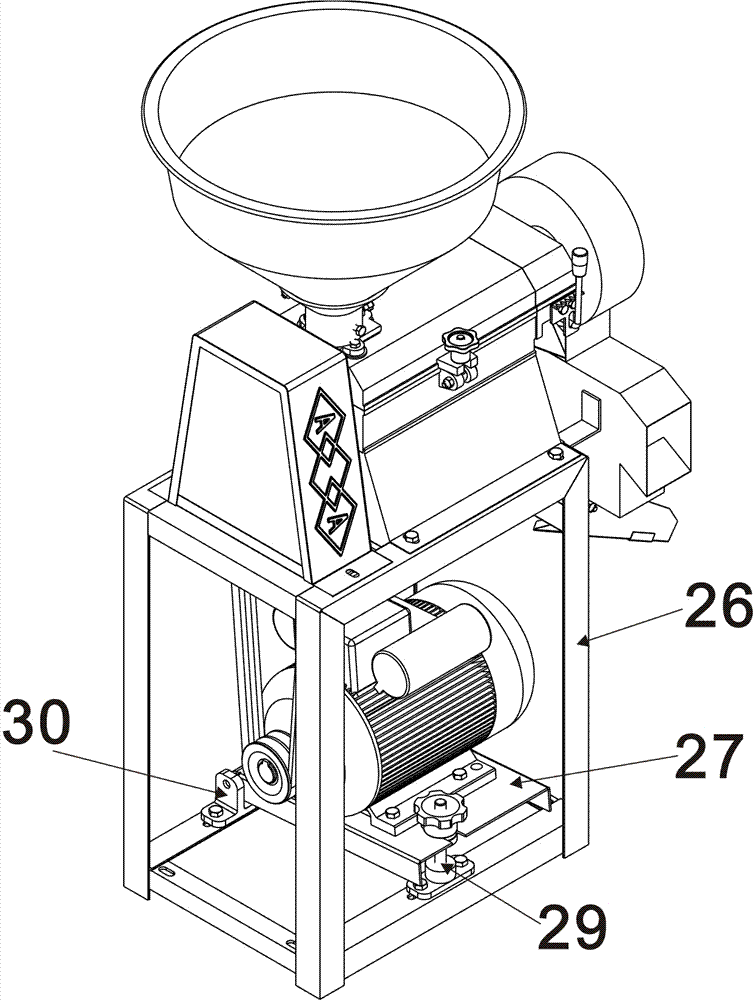

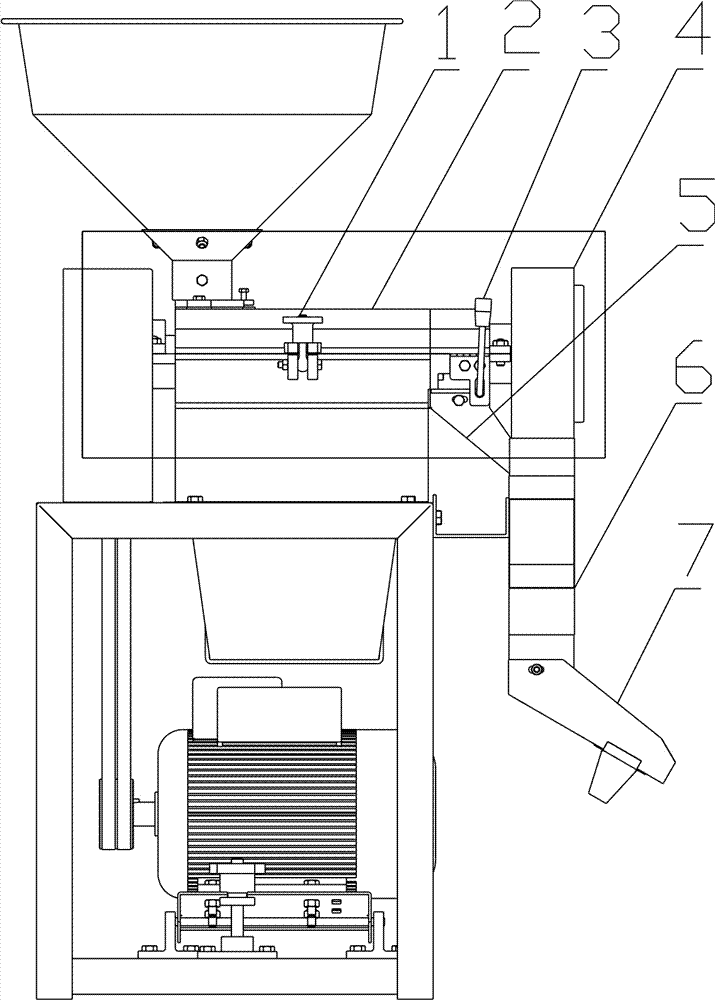

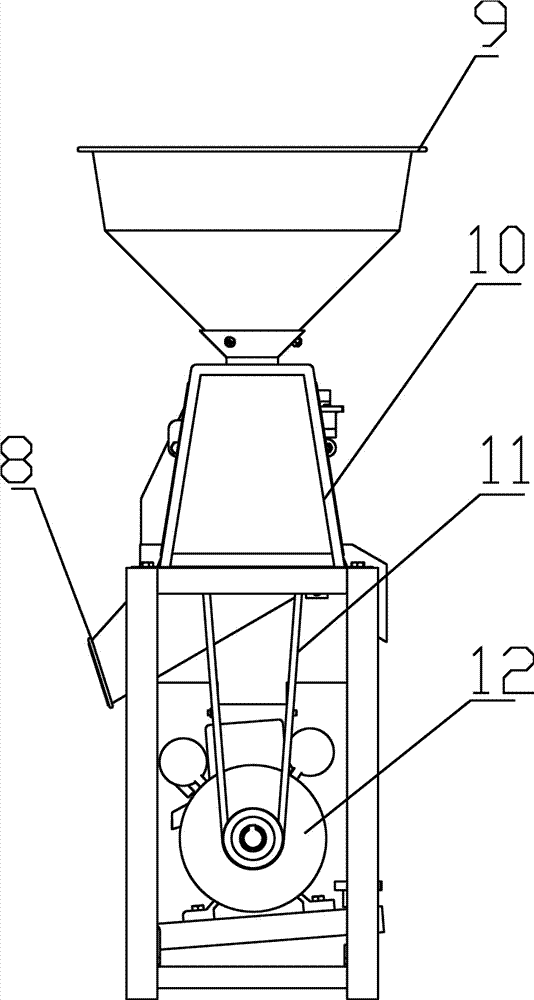

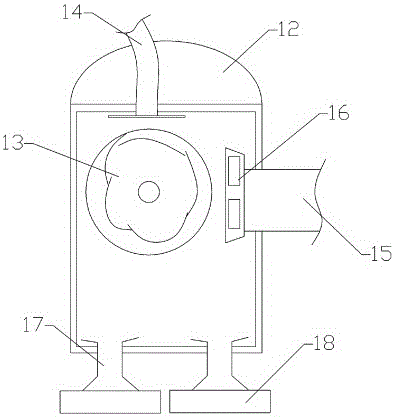

Rice polisher

The invention discloses a rice polisher which is characterized in that a shell can be locked or unlocked by a plum blossom hand wheel, a hopper seat is arranged on the shell, a feeding hopper and the hopper seat are fixed, a rice roller is arranged inside the shell, one end of the rice roller and a belt wheel are fixed, the belt wheel is connected with a motor through a belt, a safety protection cover is arranged at the belt wheel, a screw pushing end corresponding to the rice roller corresponds to the lower portion of the hopper seat, a body portion of the rice roller is made of high abrasion resistant arc-shaped rice milling ribs and positioned in an equilateral polygonal rice sieve to form a rice milling chamber, the right side of the rice roller penetrates a rear bearing block, the right end of the rice roller is arranged inside a fan shell and is fixedly provided with a wind wheel, a rice baffle and a spring are arranged on the right side of the rice roller and adjusted by a shifting fork, and the shifting fork is connected with an accuracy adjusting handle. The rice polisher is simple in structure, convenient to operate, safe and fine in rice milling quality and more importantly solves the problems of more broken rice and low milled rice rate of an existing rice milling device, and energy is saved.

Owner:四川省旭东机械制造有限公司

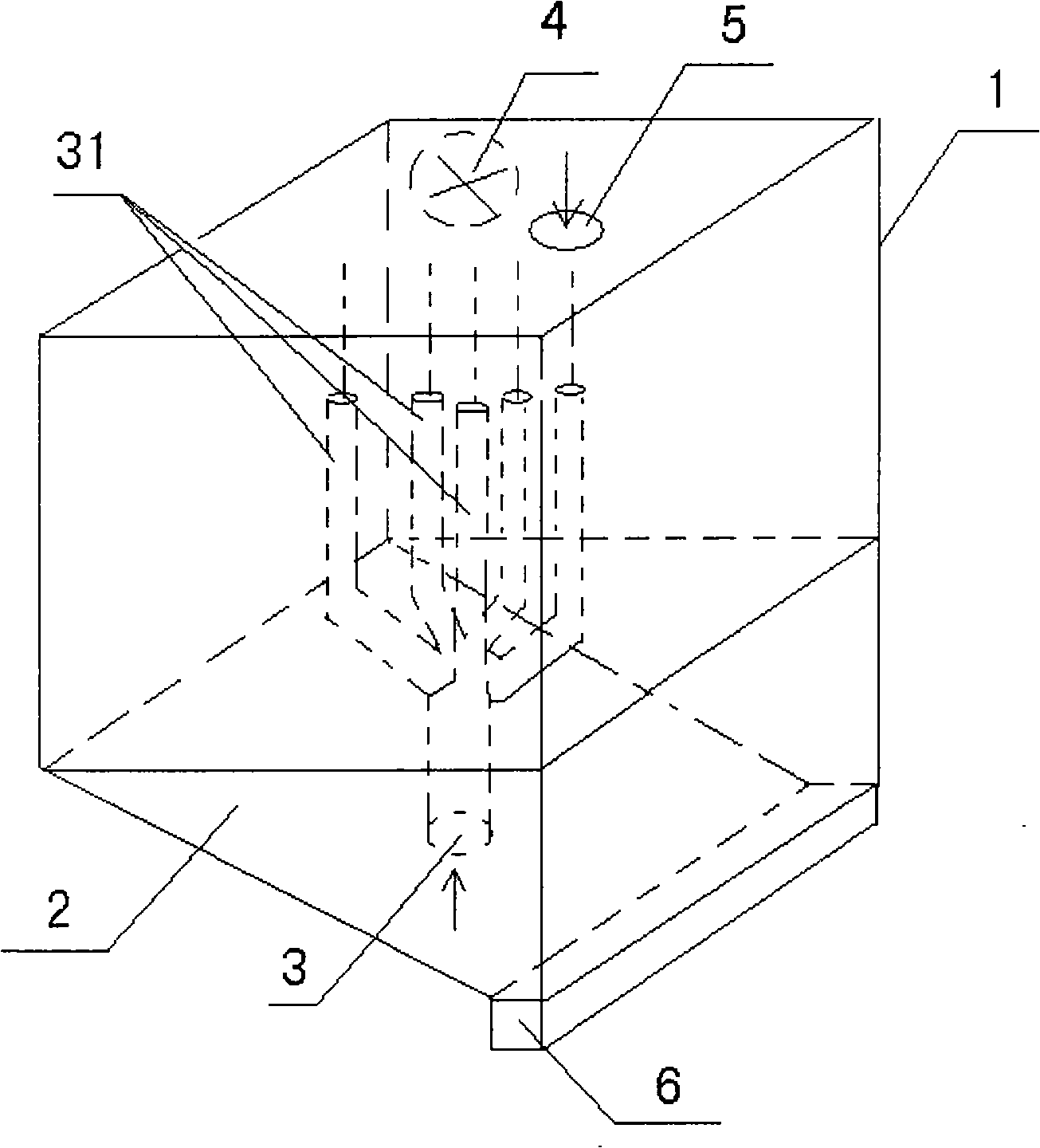

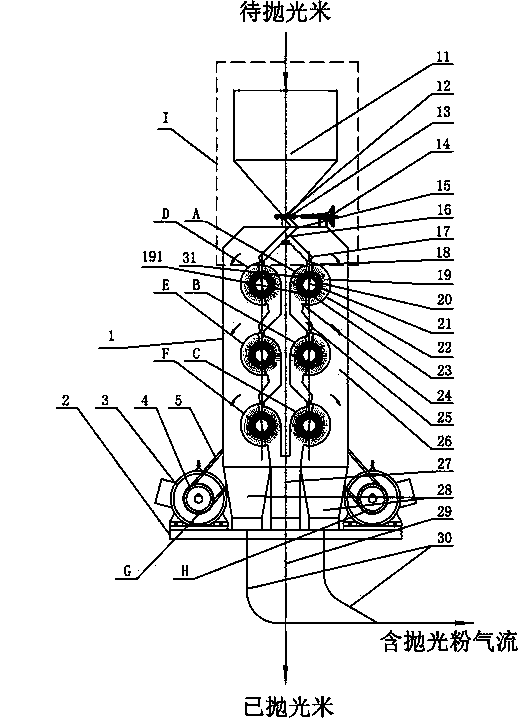

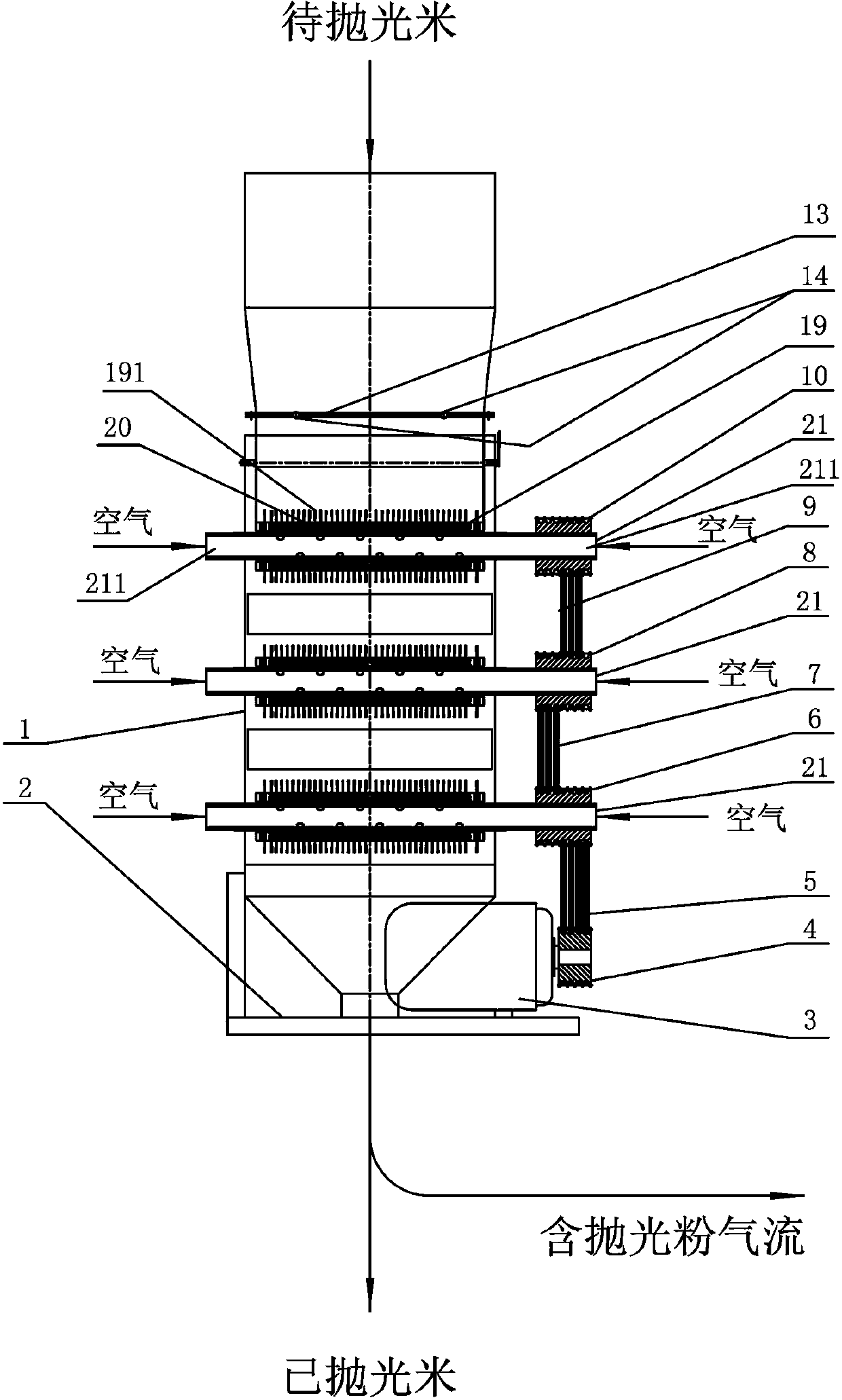

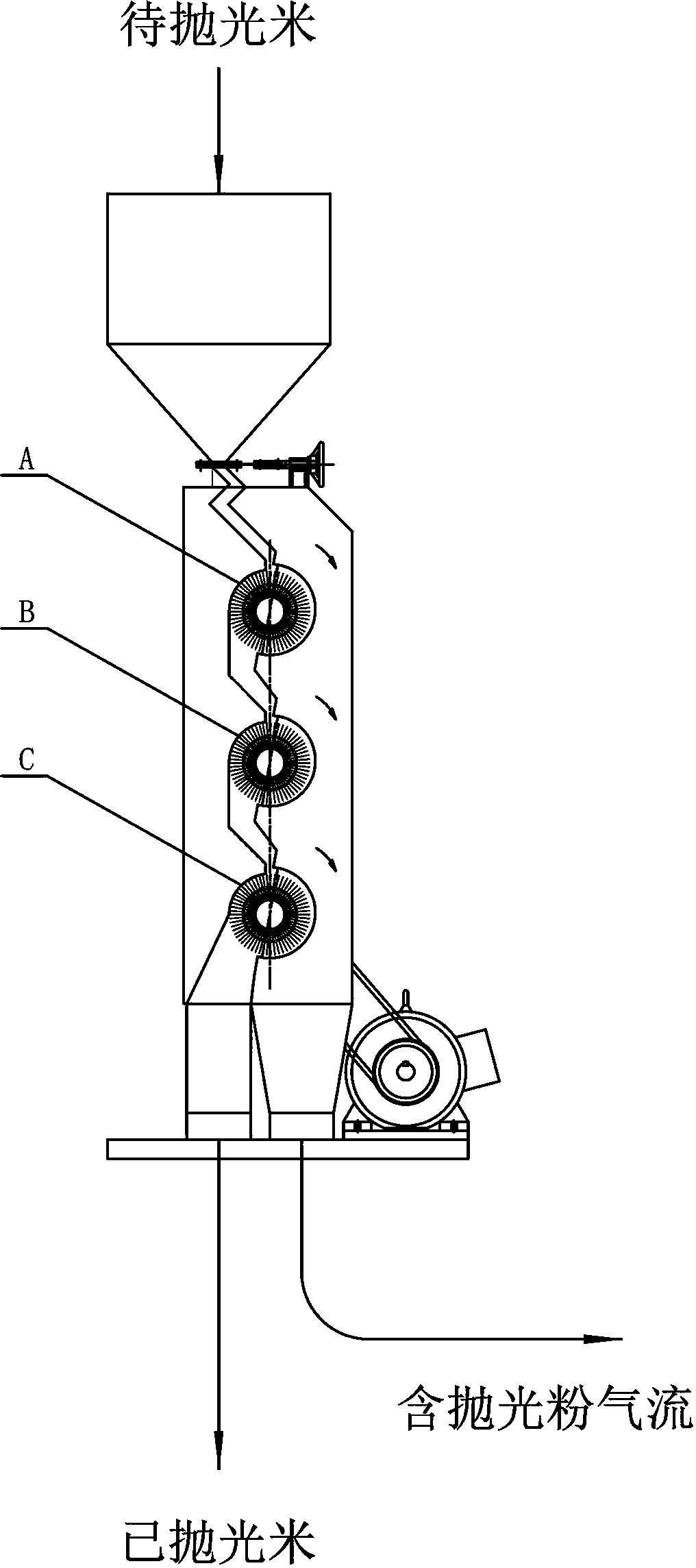

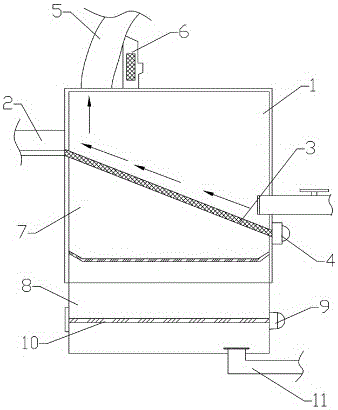

Flexible polishing device for granulated grains

ActiveCN104209156AAchieve moderate processingImprove the rice yieldGrain huskingGrain polishingFriction effectEngineering

The invention provides a flexible polishing device for granulated grains. The flexible polishing device comprises a shell, a feeding device, at least one flexible polishing unit, a bran discharging device and a rice outlet, wherein the flexible polishing unit comprises a radial gravity self-flowing flexible polishing chamber; the feeding device, the flexible polishing chamber and the rice outlet are sequentially arrayed from top to bottom along the gravity direction. According to the flexible polishing device for the granulated grains, the shear effect of the granulated grains in the polishing chamber is avoided, the flexible friction effect is improved, the damage to rice in the polishing process is greatly reduced while rice bran is cleaned and the rice is polished, the rice yield is improved and the energy consumption is reduced.

Owner:周颖

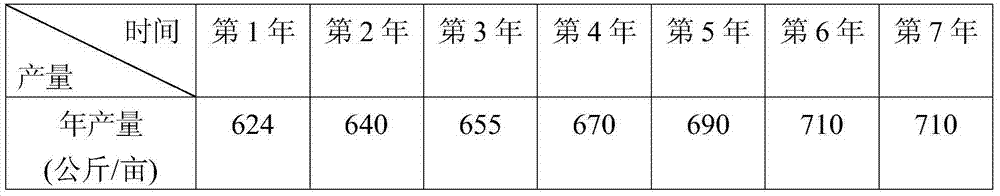

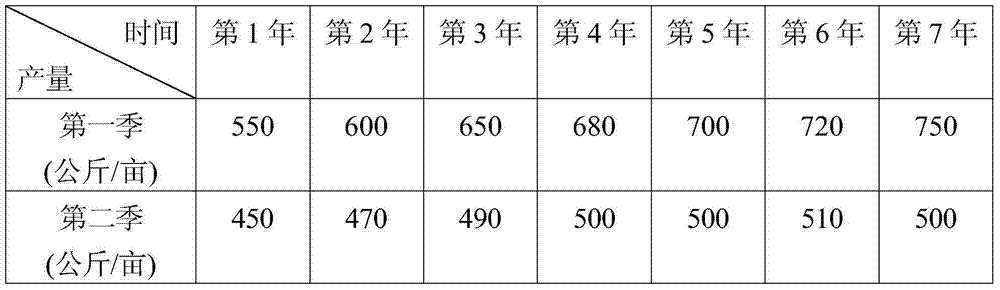

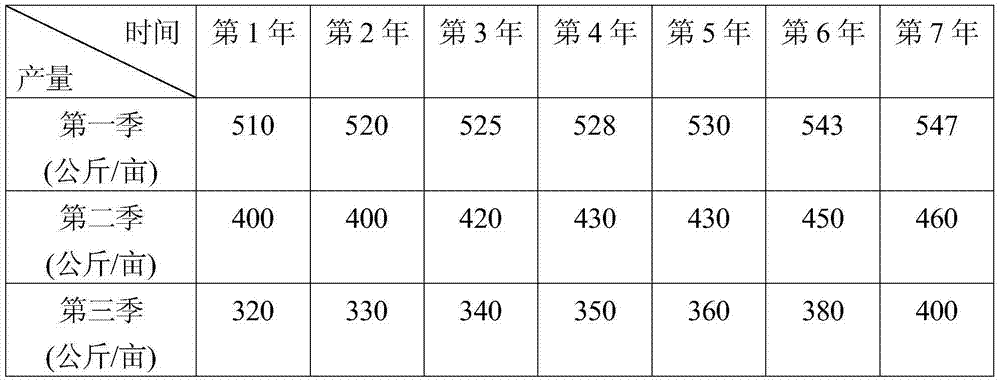

Breeding of New Varieties of High Yield and Drought Resistant Millet and Its Supporting Cultivation Techniques

Breeding and matching cultivation techniques of a new high-yield and drought-resistant millet variety (Laojinhuang No. 1) with both grain and grass abundance. Its characteristics are: under the natural conditions of nine droughts and windy conditions in ten years, select the mutant grain varieties with short plants, thick necks, wind resistance, drought resistance, and double abundance of grain and grass; the lineage is stable, and the declining lines and mixed lines are eliminated. Seeding, cultivation, high-yield comparative experiments, disease resistance surveys, stable varieties, and selection of the best among the best; after six years and six generations, a new high-yield and drought-resistant millet variety with strong adaptability to the natural climate and soil of the region has been cultivated and tested. (Old Golden No. 1) and supporting cultivation techniques. Using the present invention can reduce millet production cost, increase yield, and increase economic benefits; the yield of millet per hectare can be as high as 6000-6500kg, which is about 3 times that of common millet; The dream of producing more than 1,000 jin of millet per mu is of great significance to the adjustment of the planting industrial structure, the development of grain production, and the improvement of farmers' income in this region.

Owner:侯国权

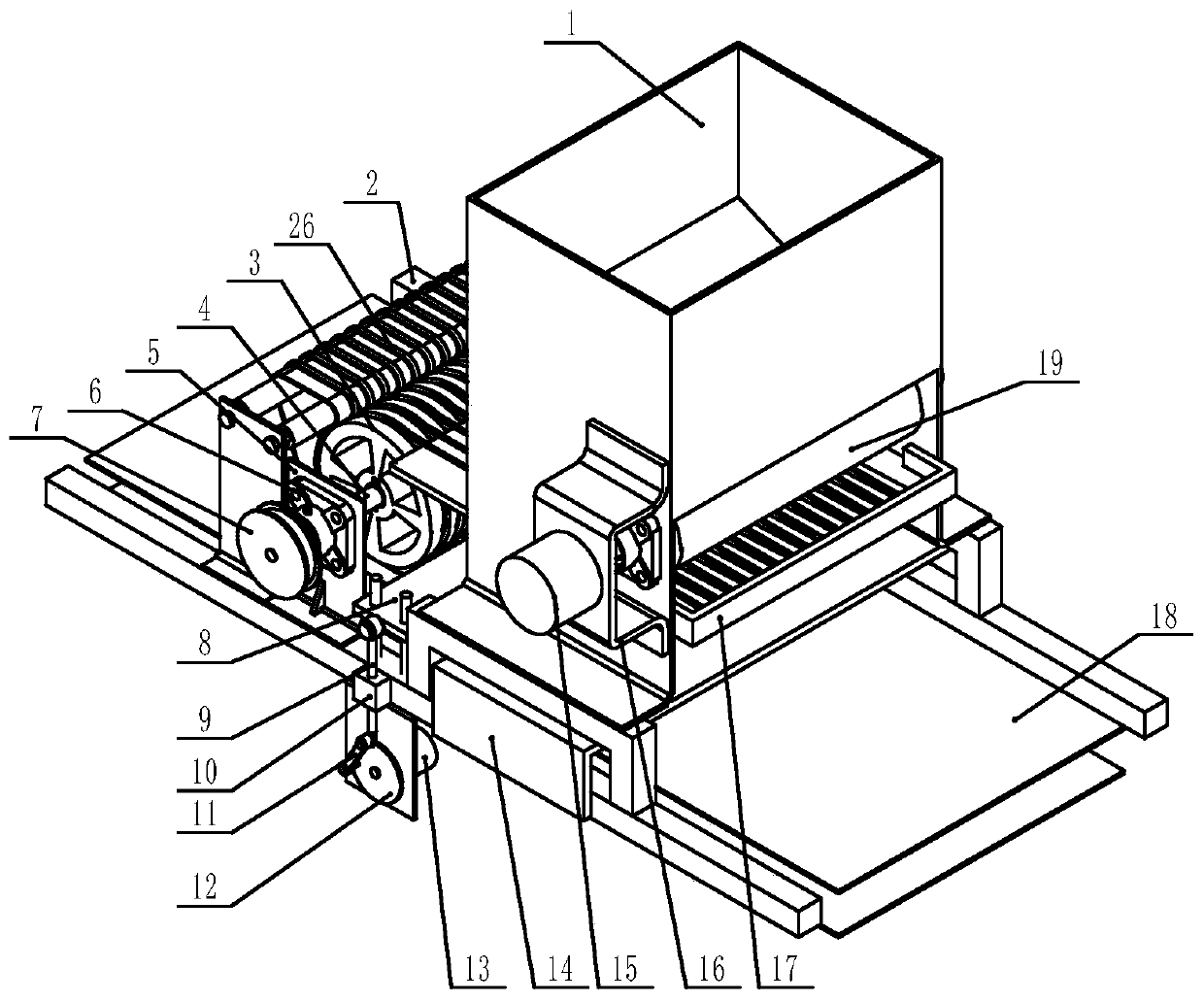

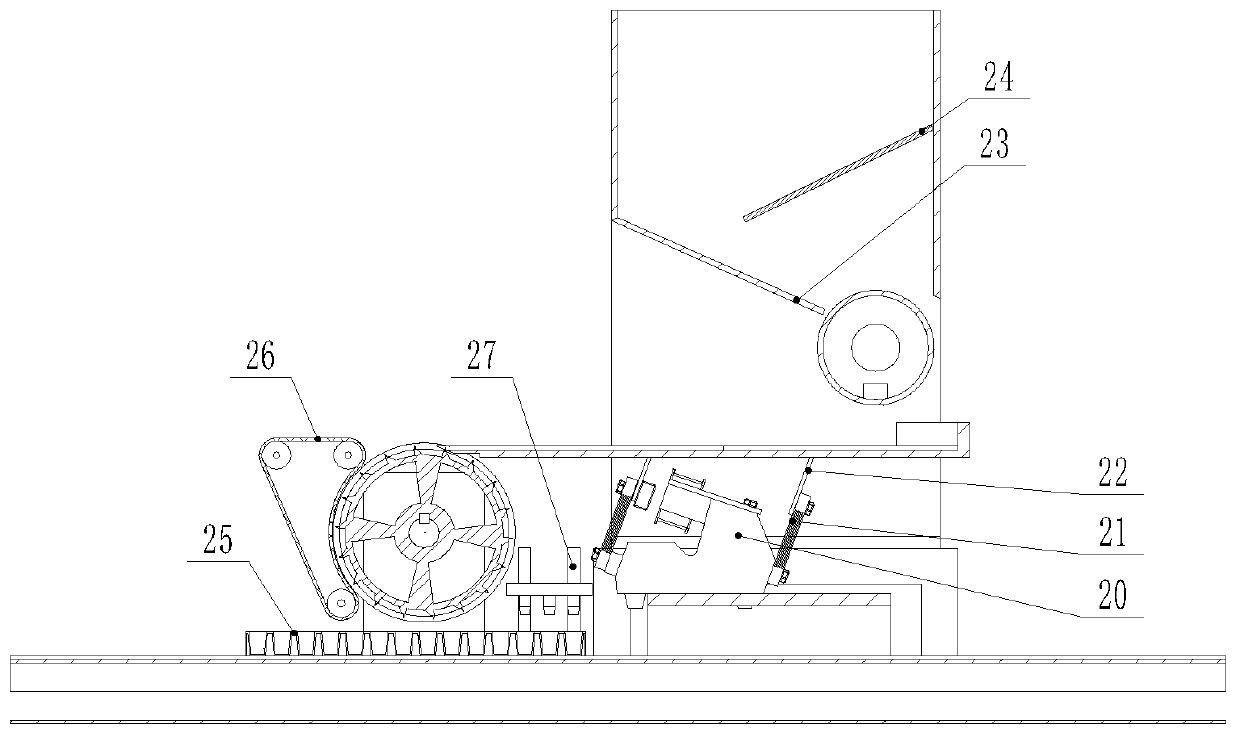

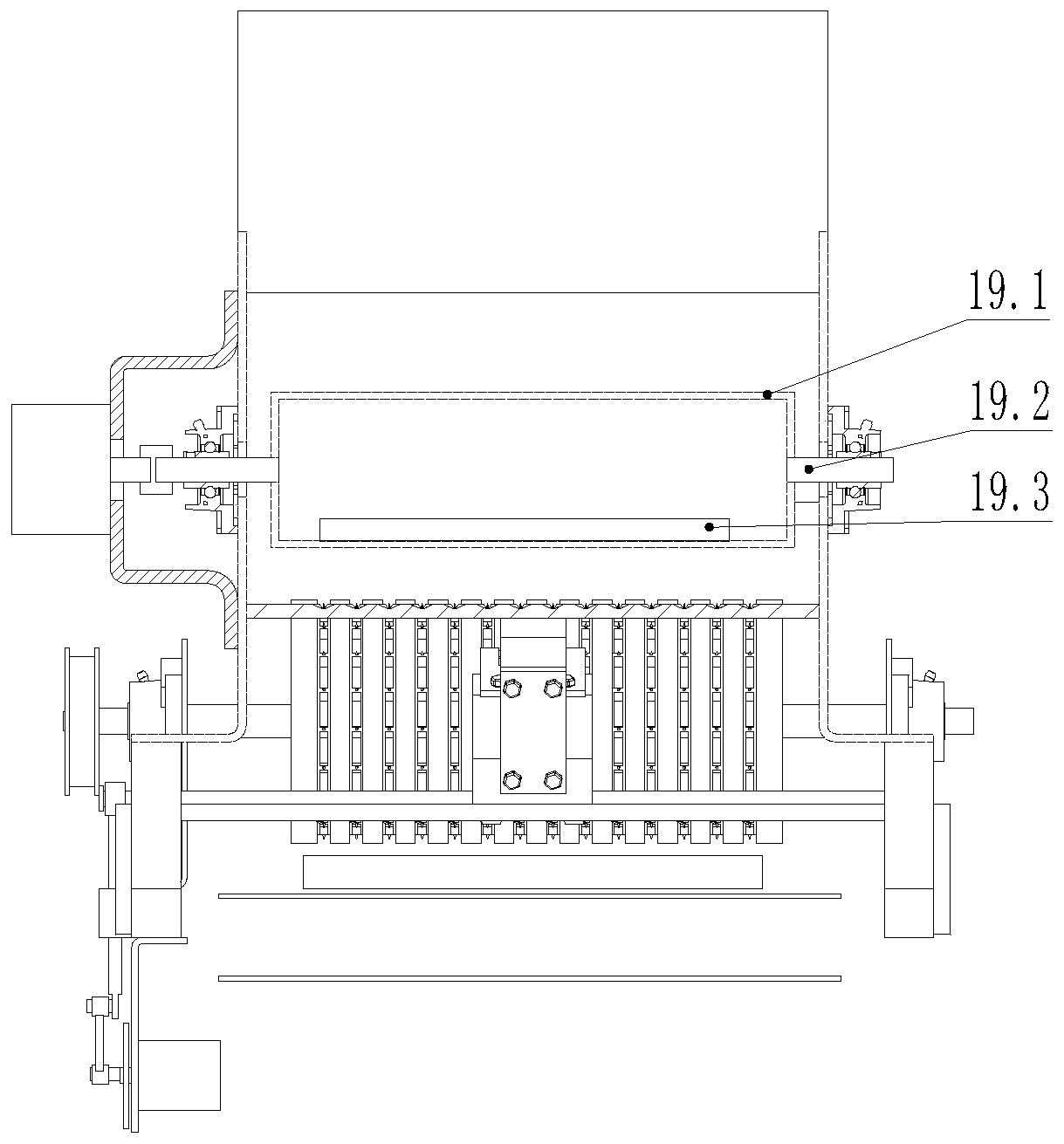

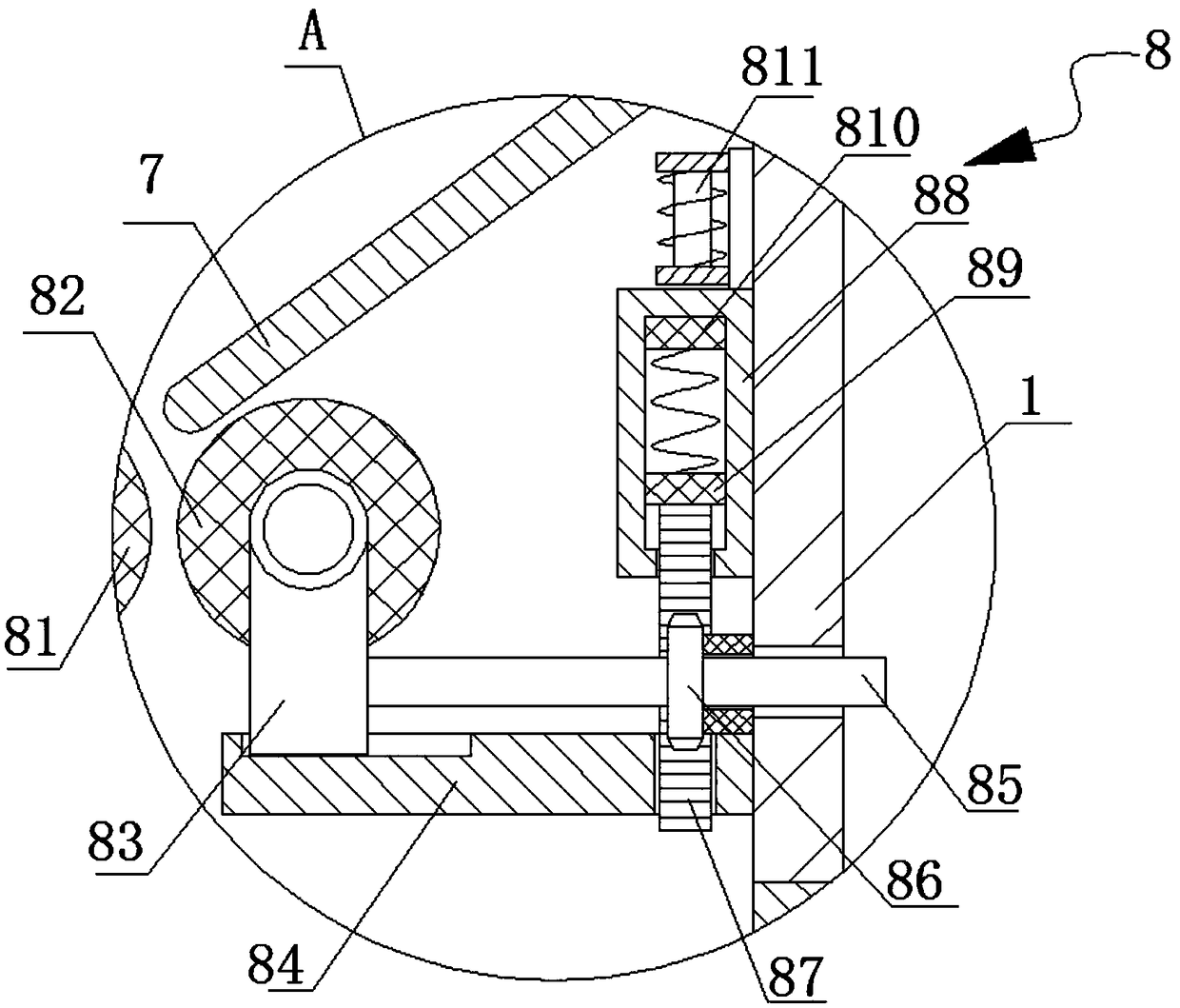

Rice single-kernel directional precision seeding device

InactiveCN110149850AAchieve precision seedingHigh single grain rateSingle grain seedersAgricultural engineeringSingle level

The invention relates to the technical field of agricultural machinery, in particular to a rice single-kernel directional precision seeding device, and overcomes the defect that the prior art experiences low single-kernel rate and high damage rate during seeding. The rice single-kernel directional precision seeding device comprises a seed box, a frame, a shift-needle rice seed feeding wheel, a reciprocating hole compression plate, a V-groove vibrating conveying plate, an eccentric vibrating feeding roller, a vibrator, a vibration damping plate and a synchronous seed-protecting belt. A mountingplate is connected to the top of the frame through screws; rice seeds are supplied nondestructively according to the principle of vibrational fluidization; the V-groove vibrating conveying plate allows seeds to be arranged and conveyed orderly in single layer; the shift-needle rice seed feeding wheel is used with the V-groove vibrating conveying plate; a seed supply direction matches with a seedfeeding direction, shift needles provide assistance to the V-groove vibrating conveying plate, the single seeds arranged orderly above are charged into holes, and therefore, high single kernel rate, high operating efficiency, low empty hole rate and good operating reliability are achieved, and precision seeding is also achieved.

Owner:苏州事泽科技有限公司

Straw biological matrix seedling-raising disk and preparation method thereof

The invention provides a straw biological matrix seedling-raising disk and a preparation method thereof. The straw biological matrix seedling-raising disk includes a seedling-raising disk and a bottom film arranged thereunder. A matrix is filled between the seedling-raising disk and the bottom film. The seedling-raising disk includes waste paper pulp, bamboo pulp, straw powder, bio-gum, a composite micro-fertilizer and water. The matrix includes plant straw, a straw fermentation agent, an additive, a seedling strengthening agent and water. The bottom film is a bast fiber mulching film. The seedling-raising disk is simple and scientific in preparation method and is free of addition of any other chemical raw materials or fertilizers, so that the seedling-raising disk keeps the characters of the raw materials and has a certain effect. The technical scheme replaces soil and a plastic seedling-raising disk by the straw biological matrix, which reduces the damage of white pollution. By means of the straw biomass for culturing seedlings of paddy rice for replacing the technology of seedling cultivation in nutrient soil in production over the years, the seedling-raising disk solves the problem that cultivated land is damaged and soil is difficult to obtain by farmers during a paddy rice seedling-raising process. The seedling-raising disk fully utilizes straw regenerated resources, thereby reducing environment-pollution due to straw incineration and achieving energy saving and emission reduction.

Owner:HUBEI NIXIMI TECH CO LTD

Technology for reserving nutrient source of germ-remaining rice

ActiveCN108579853ARetain nutrientsReduce broken rice rateGrain huskingGrain polishingAdditive ingredientAleuron

The invention relates to a technology for reserving a nutrient source of germ-remaining rice. The problem that the large number of natural nutrition ingredients of the rice are prone to running away by adopting a traditional technology is mainly solved. The technology is characterized by comprising the following steps that (1), impurities of the rice are cleared away firstly; (2), glumes are further taken off from the rice, the impurities and immature green grains are cleared; (3), the rice treated through the step (2) is lifted to a first-time slight-milling bran-stripping layer, a second-time slight-milling bran-stripping layer, a third-time slight-milling bran-stripping layer, a fourth-time slight-milling germ-remaining layer and an aleuron layer of an intelligent germ-remaining and rice-milling machine; and (4), through treatment, the germ-remaining rice is uniform in size and length, complete in condition and unified in grade. According to the technology for reserving the nutrientsource of the germ-remaining rice, the natural nutrition ingredients of germs and the aleuron layer of the nutrient source can be reserved, and the milled rice rate is high.

Owner:黑龙江省稻无疆农业科技有限责任公司

Cultivating method and seedling planting method of cross-year regrowing rice seeds

ActiveCN103782857AIncrease productionWon't dieClimate change adaptationPlant genotype modificationOryza rufipogonCold resistance

The invention provides a cultivating method of cross-year regrowing rice seeds. According to the cultivating method, wild rice containing cold-resisting and root-flourishing genes is adopted as a male parent, DS89-1 glutinous rice is adopted as a female parent, 3-5 times of recrossing is carried out, and then the cross-year regrowing rice seeds can be obtained. The invention further provides a seedling planting method of the cross-year regrowing rice seeds. Rice which is grown from the cross-year regrowing rice seeds obtained through the cultivating method and is planted according to the seedling planting method has the advantages of being high in yield and milled rice rate, good in rice quality, capable of regrowing in the next year and strong in cold resistance, drought resistance, lodging resistance and Magnaporthe oryzae resistance.

Owner:胡代书

Automatic purification husking device for rice processing

InactiveCN108855305AImprove the rice yieldEffective tearing and peelingGrain huskingGrain polishingEngineeringUltimate tensile strength

The invention provides an automatic purification husking device for rice processing. The automatic purification husking device comprises a device shell and a feeding hopper. The feeding hopper is connected to the upper end of the device shell in an inserted and penetrating mode, and the lower end of the feeding hopper reaches an inner cavity of the device shell and is connected to the upper end ofa cleaning device in a penetrating mode. The upper end of the cleaning device is fixedly connected to the inner top wall of the device shell, and a motor is welded to the upper end of the outer sidewall of one side of the device shell through a first bracket. The automatic purification husking device overcomes the deficiencies of the prior art, has reasonable design and a compact structure, effectively purifies dried-up seed and grass seed in rice, improves the milled rice rate of the rice and can timely and effectively transport the processed brown rice; and the labor intensity of rice processing personnel is reduced, and the quality of the brown rice is improved.

Owner:怀宁县谷丰米业有限公司

Production method of germinated rice

InactiveCN102599435ASimple production processEasy to implementFood preparationOzone generatorPesticide residue

The invention relates to the technical field of food processing, one of grain deep processing, in particular to a production method of germinated rice. The production method has the following advantages: more particularly, germination of unhusked rice is directly accelerated to prepare germinated unhusked rice and then the germinated unhusked rice is processed into the finished product, namely germinated rice; in the implementation process, the unhusked rice is soaked and sterilized in ozone water solution prepared by an ozone generator and a gas-liquid mixing pump, so that the pesticides on the surface of the unhusked rice can be effectively oxidized, the pesticide residues can be reduced and the quality of the germinated rice product can be guaranteed; after being soaked in cold water and warm water alternately, the unhusked rice is put in the environment with temperature being 30-33 DEG C and relative humidity being 85-90% to undergo germination acceleration to prepare the germinated unhusked rice; the germinated unhusked rice is processed into the germinated rice after being dried in the low temperature state; the comprehensive nutritive indexes of the germinated rice product produced by the method greatly exceed the comprehensive nutritive indexes of the common rice; the germinated rice product has magical effect on improving sub-health of modern people; and the product has low production cost, good effects and good prospect.

Owner:何寒

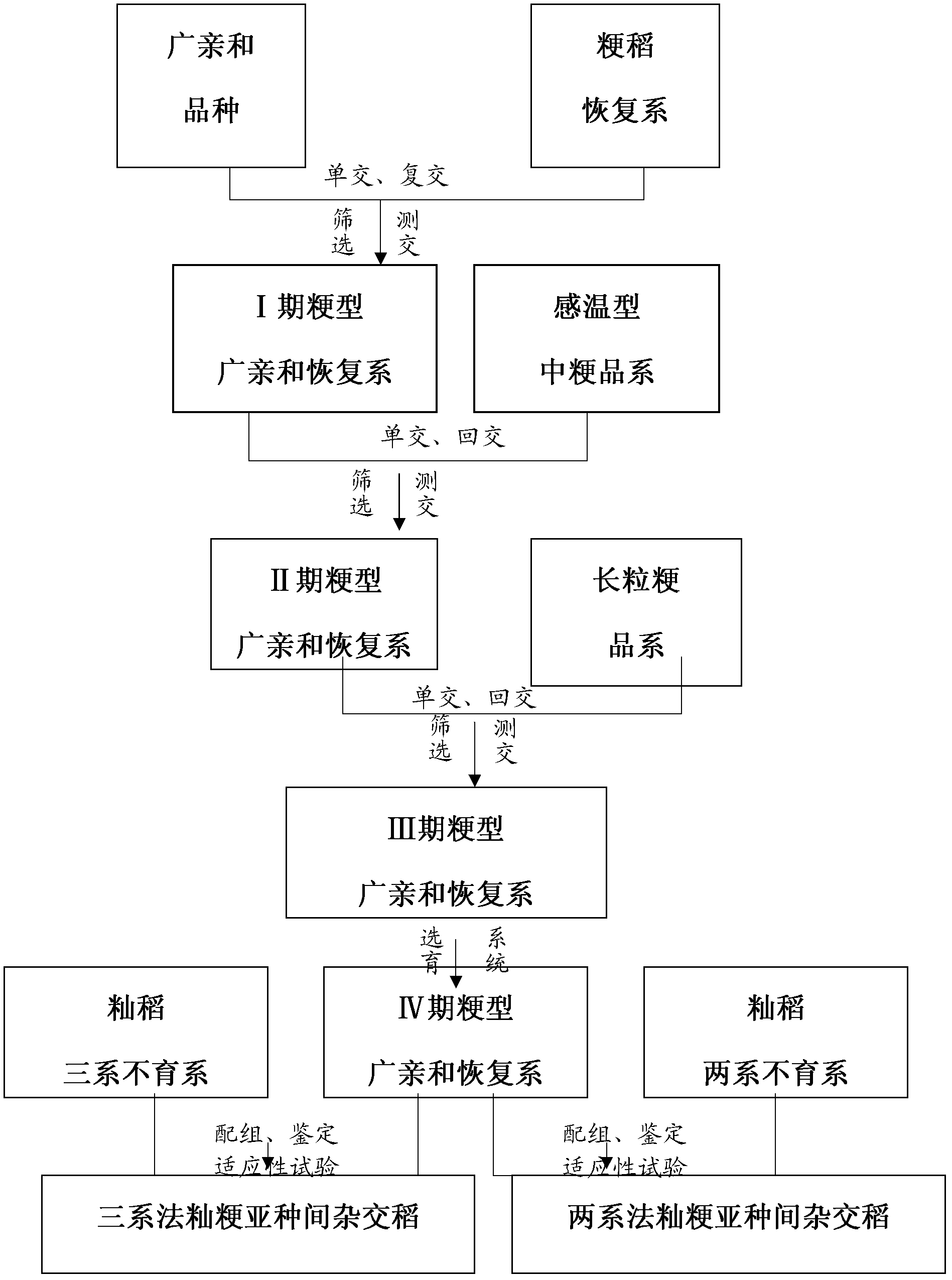

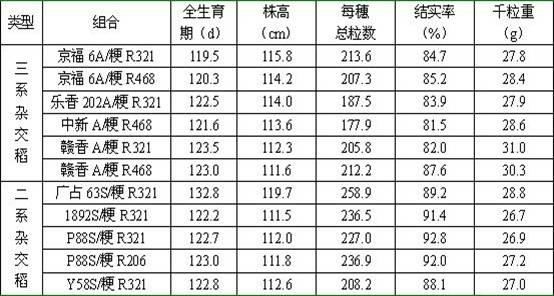

Method for breeding indica sterile line-japonica restorer line intersubspecific hybrid rice and application of method

ActiveCN102577933AImprove the rice yieldEffective technical meansPlant genotype modificationOryzaAgricultural science

The invention discloses a method for breeding indica sterile line-japonica restorer line intersubspecific hybrid rice. A hybridization polymerization and testcross screening alternate progressive breeding method is utilized according to a breeding target; a japonica type widely compatible restorer line in which a wide compatibility gene, a male sterile cytoplasmic restorer gene and multiple kinds of functional genes are polymerized is bred by integrating various breeding technologies; when an indica-japonica intersubspecific hybrid rice combination is prepared by using the japonica type widely compatible restorer line, an indica three-line sterile line and an indica two-line sterile line, the problems that first generation of indica-japonica hybrid is low in yield, high in plant, long in growth period and low in grain plumpness can be effectively solved; an effective breeding way and an effective breeding method are provided for breeding indica-japonica hybrid rice which directly utilizes powerful intersubspecific hybrid advantages; and the method is applied in the field of the research on the utilization of intersubspecific hybrid advantages of rice three-line and two-line methods.

Owner:安庆常润米业股份有限公司

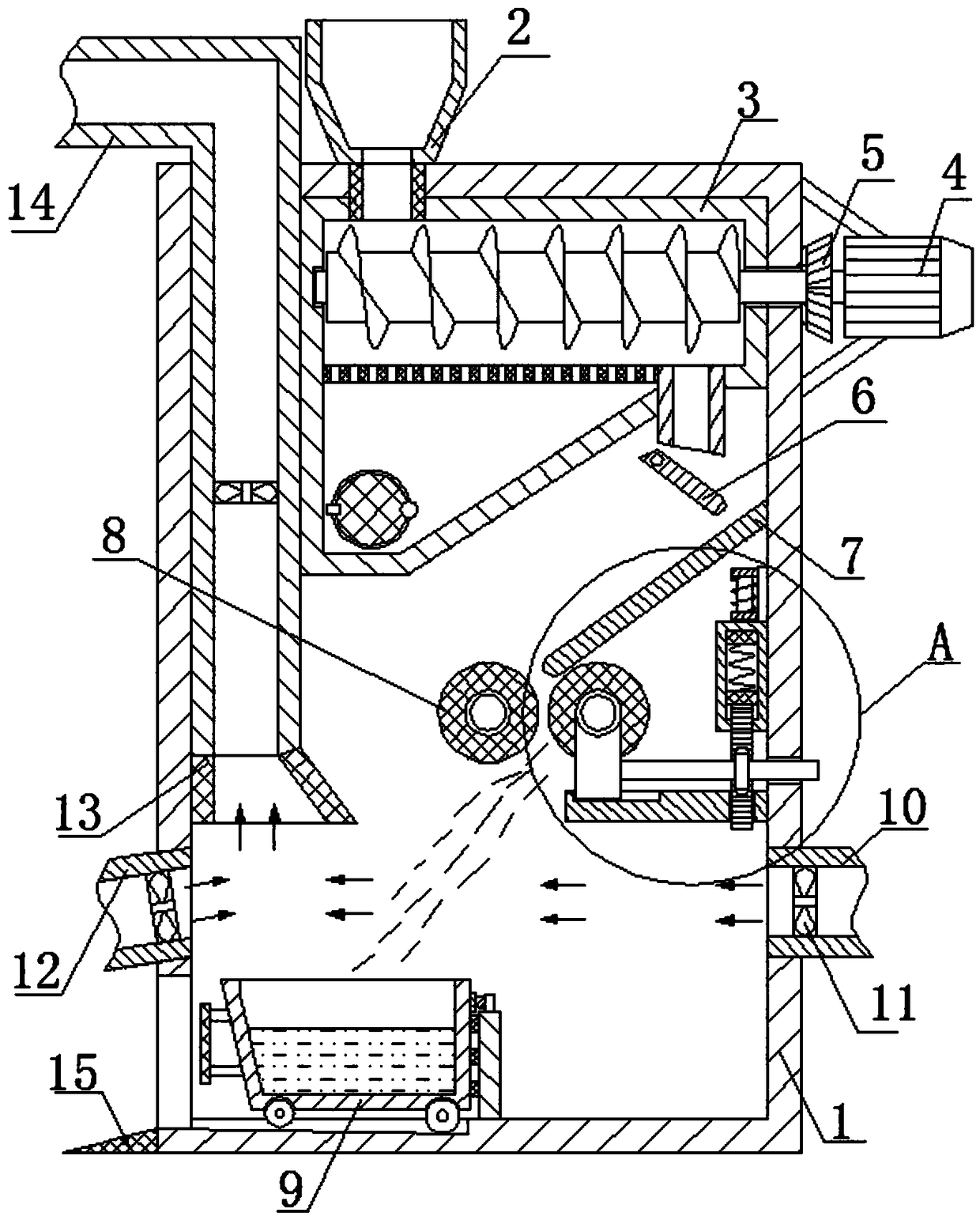

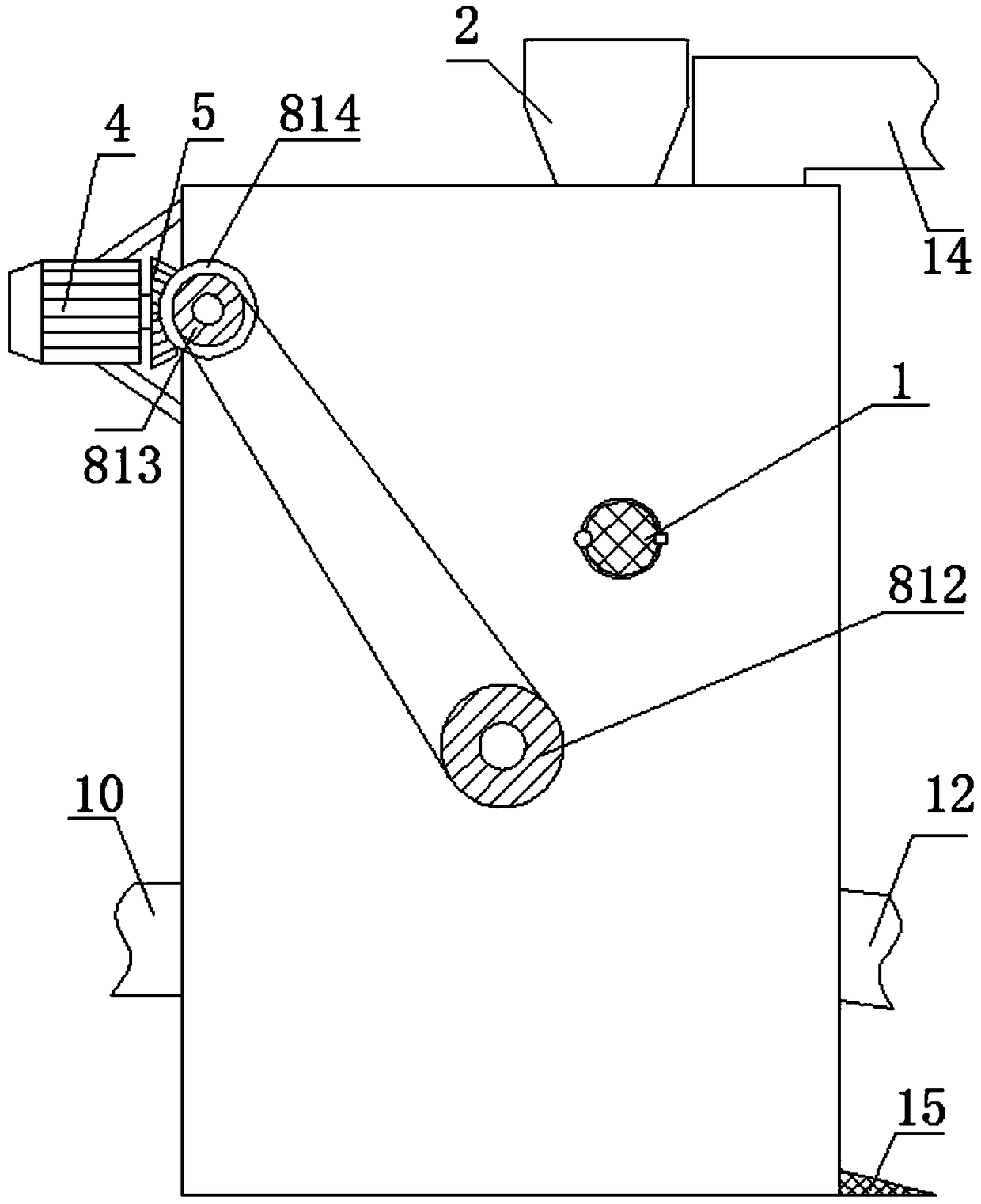

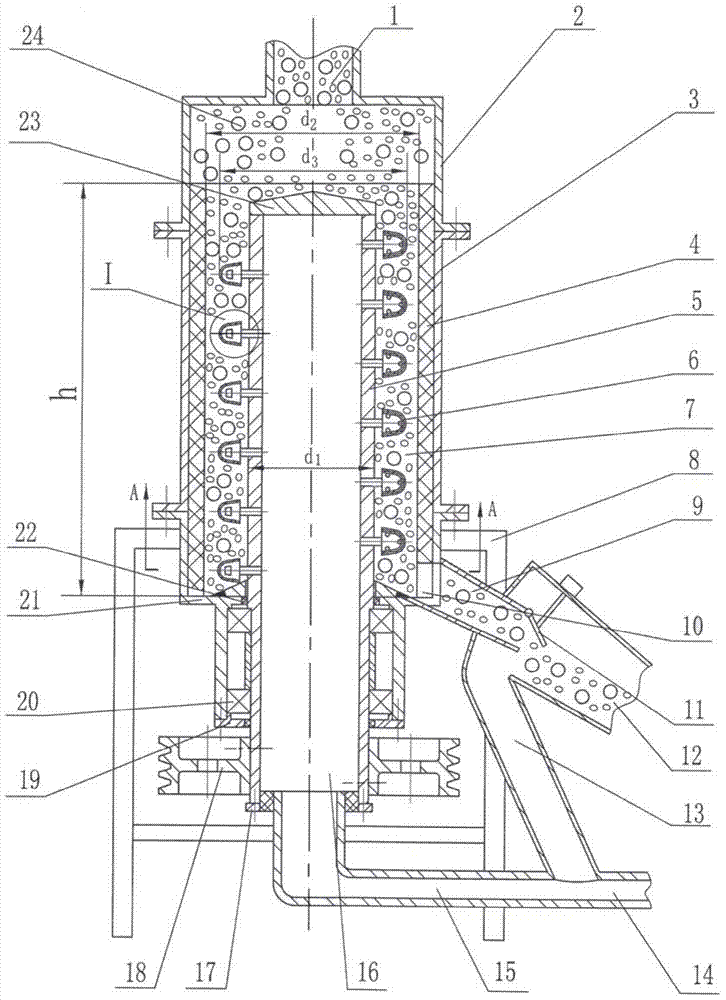

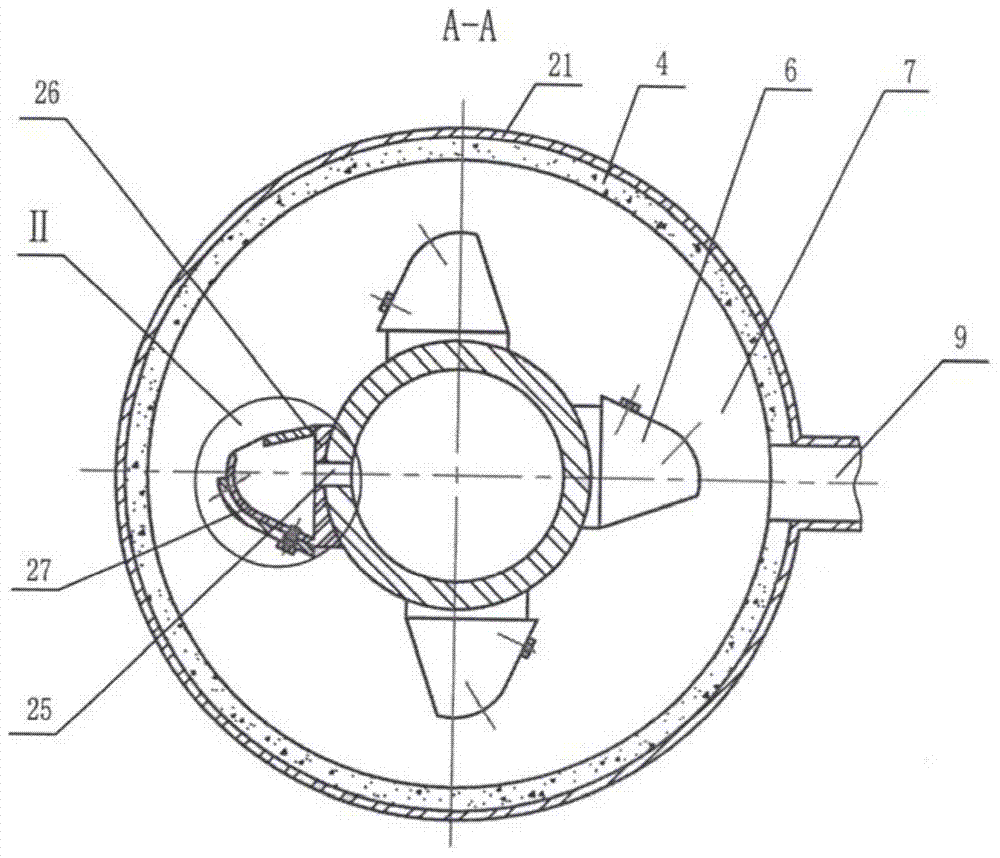

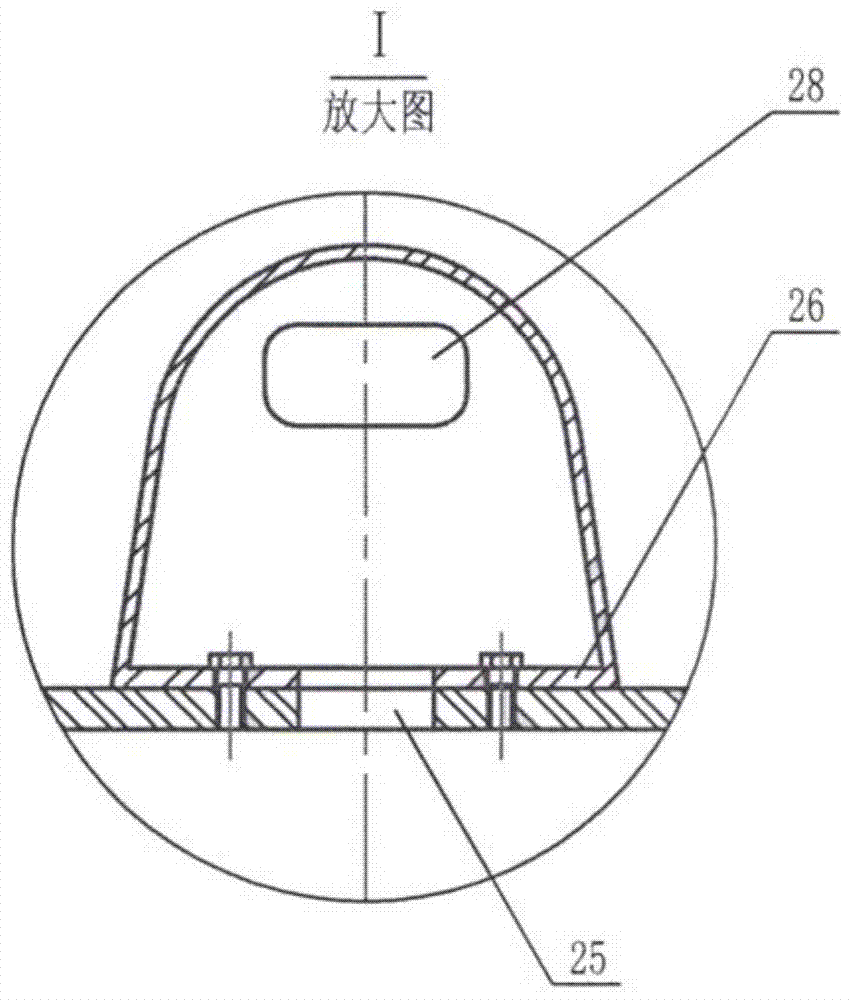

Flexible rice mill with abrasive balls and grain milling method

ActiveCN104492522AIncrease the direct grinding areaGood for grinding and sheddingGrain huskingGrain polishingBroken riceEngineering

The invention discloses a flexible rice mill with abrasive balls and a grain milling method. The flexible rice mill is technically characterized in that a frame unit 8 comprises a housing composed of a cylinder base 21, an outer cylinder 3 and a cover 2; a carborundum inner cylinder 4 is disposed inside the outer cylinder 3 inside the upper portion of the cylinder base 22; a hollow shaft 5 mounted through a bearing set 20, a top sealing set 22, a bottom sealing set 17 and a bearing cap 19 is disposed inside the housing; a thrower disc 23 is disposed at the top end of the hollow shaft 5; a plurality of paddles are symmetrically and evenly distributed on the outer surface of the hollow shaft. The grain milling method includes proportional compounding of grain and the abrasive balls, feeding of mixture, flexible milling by the abrasive balls, lifting of the mixture, secondary milling by the abrasive balls, grading of grain and abrasive ball mixture, finishing of finished products, recycling of the abrasive balls and the like. The flexible rice mill and the grain milling method have the advantages that the flexible rice mill is simple in structure, milling contact area is great, interior milling pressure is low, speed is low, rate of broken rice is low, and rice yield is high.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Bioenzyme-enriched organic green fertilizer

InactiveCN103351249AImprove the rice yieldIncrease commodity rateFertilizer mixturesGround temperatureBiotechnology

The invention discloses a bioenzyme-enriched organic green fertilizer which comprises the following components in parts by weight: 25-35 parts of potato straw, 25-35 parts of wild oat straw, 25-35 parts of broad bean straw, 25-35 parts of wheat straw, 1-2 parts of kuh-seng, 1-2 parts of pine needle, 1-2 parts of Isatis indigotica Fort, 0.5-1.5 parts of chitosan, 1-6 parts of calcium nitrate, 2-6 parts of magnesium sulfate, 2-6 parts of sodium chloride, 1-4 parts of ammonium dihydrogen phosphate, 1-3 parts of sodium acid pyrophosphate, 0.1-0.3 part of azotobacter powder, 0.1-0.3 part of phosphobacteria powder, 0.1-0.3 part of arbuscular mycorrhizal fungi powder, 15-35 parts of soybean straw and 10-25 parts of potato straw. After being applied into soil, the fertilizer can efficiently increase the yield, improve the soil, restore the land capability, enhance the fertilizer efficiency, decompose the heavy metals in the soil, enhance the ground temperature and water temperature, and promote prematurity.

Owner:QINGDAO ZHAXI BIOLOGICAL TECH

Method for creating corn autotetraploid

InactiveCN108522271ASimple methodHigh doubling efficiencyPlant genotype modificationExisting TreatmentDiploid cells

The invention relates to a method for creating corn autotetraploid. The method comprises the following steps: treating corn filaments by adopting a conventional chromosome doubling agent and a conventional treatment method; doubling somatic chromosomes in induced organs without the need of pollination, so as to directly obtain autotetraploid seeds; then carrying out microscope examination on chromosome ploidy and screening the autotetraploid; carrying out fruitfulness breeding when the fructification percentage is relatively low; preparing autotetraploid hybrid seeds by utilizing an autotetraploid selfing line after the fructification percentage reaches the requirements. The method provided by the invention has the beneficial effects that the method is simple and feasible; seed germination, germ low-temperature treatment and seedling transplanting processes of an existing treatment method are omitted; the doubling efficiency is improved, and the problem that a chromosome ploidy chimerarepels tetraploid cells due to competitive advantages of diploid cells in a somatic cytotropism development process is avoided, so that the doubling efficiency is improved; the yield and quality areimproved and the purity is easy to ensure.

Owner:SHENYANG JINSEGU SPECIAL CORN +1

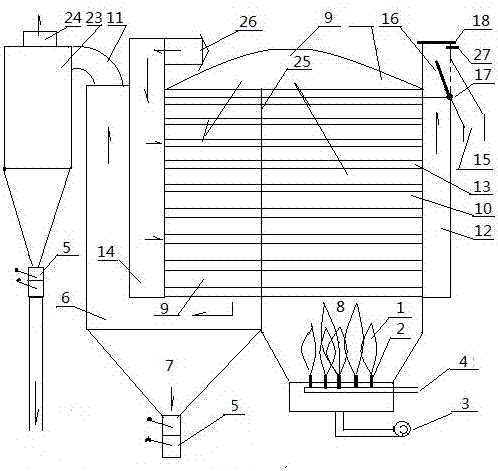

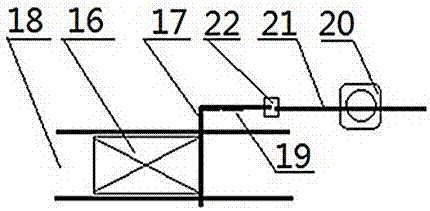

Fuel gas hot blast stove

InactiveCN107957137AImprove product qualityEvenly dehydratedDrying gas arrangementsAir heatersCombustion chamberAir filter

The invention discloses a fuel gas hot blast stove. The hot blast stove comprises the fuel gas flame, nozzles, an air return pipe, a lower ash bucket, a hot blast stove combustion chamber, an air return chamber, a main air chamber, an air outlet pipe, a hot air flue air outlet chamber, a hot air exchange pipe, a hot air flue air inlet chamber, a cold air pipe, an adjustable air door, an air door shaft, a hot air exhaust port, an air door shaft connecting lever, an electric screw motor, an electric screw, a dust remover, a dust remover exhaust pipe, a middle partition plate, an air filter and atemperature sensor; and the hot blast stove is characterized in that the hot blast stove is internally provided with an air blower, a heat exchanger is provided with the lower ash bucket, and an ashdischarging valve is used for automatically locking the air and discharging the ash; the hot air subjected to the heat exchange passes through the dust remover and is discharged to a chimney through an induced draft fan; a hot air exchange pipe is arranged between a secondary hot air flue main air chamber and the air return chamber and is made of stainless steel materials; the air exchanges heat through the hot air exchange pipe and then reaches a secondary hot air exhaust port; the electric screw is controlled by an thermo-sensitive adjusting device to enable the adjustable air door to undergo the thermo-sensitive adjustment, and constant-temperature air discharging is achieved. The exchange furnace is simple in design and high in exchange rate, is a very ideal constant-temperature dryingair source for grains and can be widely popularized.

Owner:杨朴

Refining method for processing of rice

The invention relates to the technical field of rice processing, and discloses a refining method for processing of rice. The refining method comprises the following steps of removing impurities from unhulled rice, screening the unhulled rice without impurities, removing husks of the screened unhulled rice, separating husked rice, performing careful selection, performing rice milling and polishing,performing color sorting and classifying, performing sterilization and performing packing. The weight of the unhulled rice is weighed, early stage experiment can be performed, and the results show that the weight of the unhulled rice is the same as that of water. An appropriate amount of water is added to an atomization plant, and is uniformly sprayed for wetting the unhulled rice, so that the brown rice moisture in the unhulled rice is maintained to 13.5%15.0%. The brown rice is atomized, sprayed with water and moisturized for some time, so that the friction coefficient of the surface of thebrown rice is increased, grinding, cutting, applying and separating of the cortex of the brown rice are facilitated, the milling pressure can be reduced, the brown rice in the rice milling process can be reduced, and the milled rice rate is increased. The refining method for processing of rice can solve the problem that the moisture of the brown rice in the unhulled rice is low to cause more broken rice during processing.

Owner:湖南溢香园粮油有限公司

Gamma-quantum original energy recovery compound

InactiveCN105669300AStrong chelating functionAvoid absorptionNitrogenous fertilisersOrganic fertilisersGlycineMicrobial agent

The invention discloses a gamma-quantum original energy recovery compound including gamma-poly-glutamic acid, a quantum synergistic factor, an active organic matter, amino acid, humic acid and a trace element; the gamma-poly-glutamic acid is a fermentation culture substance; the quantum synergistic factor is a microbial agent; the amino acid includes a mixture of glycine, glutamic acid, alanine and aspartic acid; the trace element includes a soluble compound of iron, copper, boron, zinc and manganese; the amount of the gamma-poly-glutamic acid is 5%-50%; the amount of the quantum synergistic factor is 3%-12%; the amount of the active organic matter is 20%-50%; the amount of the amino acid is 5%-15%; the amount of humic acid is 2%-18%; the amount of the trace element is 2%-25%; the amount of an accessory auxiliary agent is 1%-3%. The gamma-quantum original energy recovery compound has the multiple properties of quick acting, slow release, fertilizer saving, production increasing, and green environmental protection; and with the long-term use, the gamma-quantum original energy recovery compound can improve a soil environment, increases the utilization rate of a fertilizer, and can obviously improve the quality of crops.

Owner:江苏博尔丰源农业科技有限公司

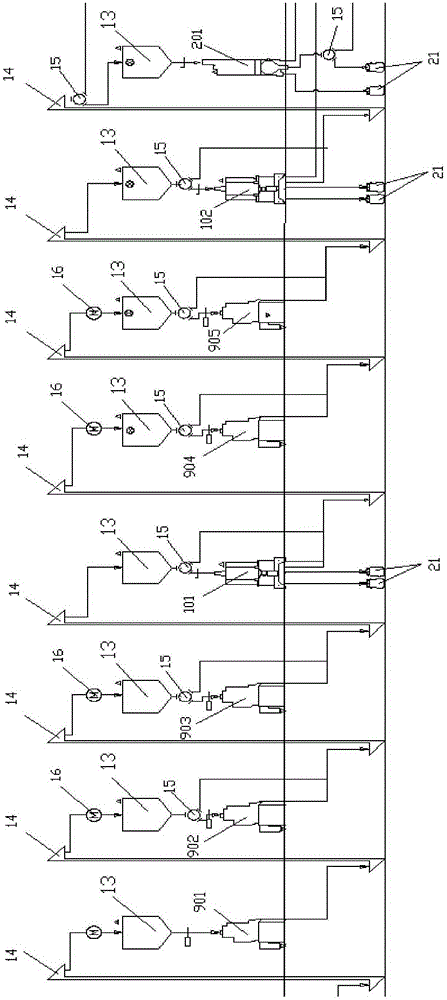

Cooling polishing improvement process for fine processing of rice

ActiveCN105879955AImprove processing efficiencyImprove cooling effectGrain millingWhite riceEngineering

The invention discloses a cooling polishing improvement process for fine processing of rice. The cooling polishing improvement process comprises the steps that unhusked rice enters a grain vertical silo, a precleaner, a permanent magnet cylinder, a vibrating cleaner, a stoning machine, a main rice husker, an auxiliary rice husker, a first rice mill, a second rice mill, a third rice mill, a polisher, a color sorter, a white rice grader, a length grader, a finished product vertical silo, an electronic flow balance and packages in sequence. A primary cooling silo integrating the functions of selection, husked rice separation and rice temperature reduction is arranged between the first rice mill and the auxiliary rice husker. A secondary cooling silo integrating the functions of screening and rice temperature reduction is arranged between the polisher and the third rice mill. The cooling polishing improvement process for fine processing of rice aims at solving the problems that through an existing cooling polishing process for fine processing of rice, the processing procedure chain is long, efficiency is low, and the temperature reduction effect is not obvious.

Owner:GUIZHOU FENGGANG COUNTY SHENNONG RICE IND

Rice processing technological process

InactiveCN109622113AImprove the rice yieldExtended shelf lifeGrain treatmentsWater sprayProcess design

The invention discloses a rice processing technological process. The process comprises the steps of rice screening, husking, whitening, polishing, cleaning, drying, color sorting, magnetic separationand packaging. Before whitening, unpolished rise obtained after husking is subjected to water spraying wetting, and then whitening is performed; whitening is performed in a repeated slight grinding and fine grinding mode; during packaging, pepper is added so that insects and moths are prevented. The rice processing technological process has the advantages of being reasonable in process design, high in production efficiency and rice output rate, long in storage life, good in rice quality and the like.

Owner:湖南新世米业有限公司

Organic substrate for raising rice seedlings

InactiveCN107926610AHigh organic contentReduce utilizationCalcareous fertilisersMagnesium fertilisersEarly maturationPeat

The invention discloses an organic substrate for raising rice seedlings. The substrate is prepared from powders of livestock and poultry manure subjected to harmless treatment, waste powders after plant straw and fruit processing, humic acid, metalaxyl, fludioxonil, azoxystrobin, trace elements, complexing agents, enhancers, drought-resistant agents, nitrogenous fertilizers, phosphate fertilizers,potash fertilizers, long-acting organic PH regulating agents, fillers and additives. The organic substrate, by adopting the leftovers after crop straw and fruit processing, the powders of livestock and poultry manure subjected to harmless treatment and microbial strains as the main raw materials, does not need peat and plough layer soil, thereby reducing the utilization of non-renewable resourcesand the damage to farmland soil. The organic substrate for raising the rice seedlings has good packing, reduces the incidence of blight, bakanae disease and cotton rot, promotes fast green return, more tillering and early maturation of rice, and can increase the yield and the rice output rate.

Owner:黑龙江省苗必壮农业科技有限公司

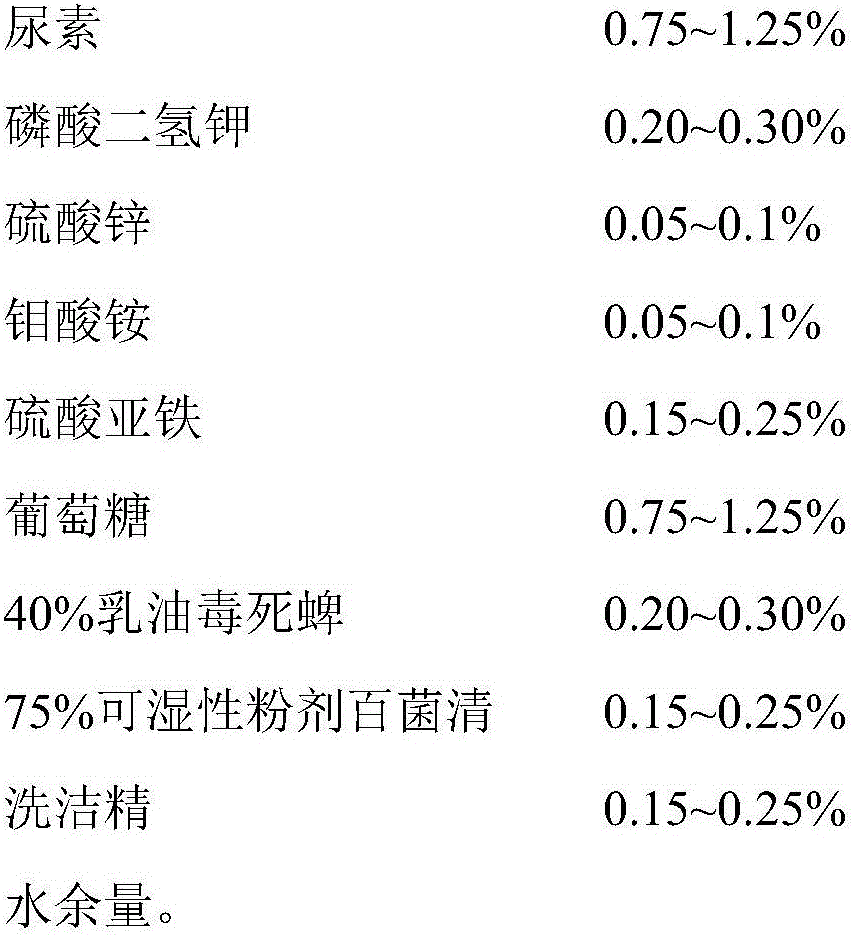

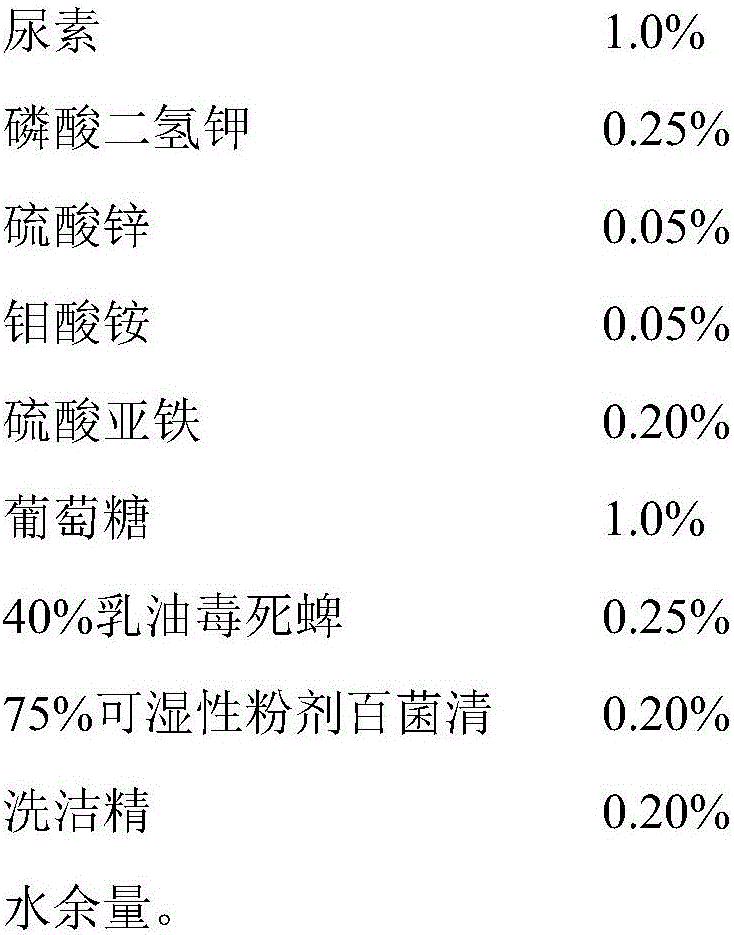

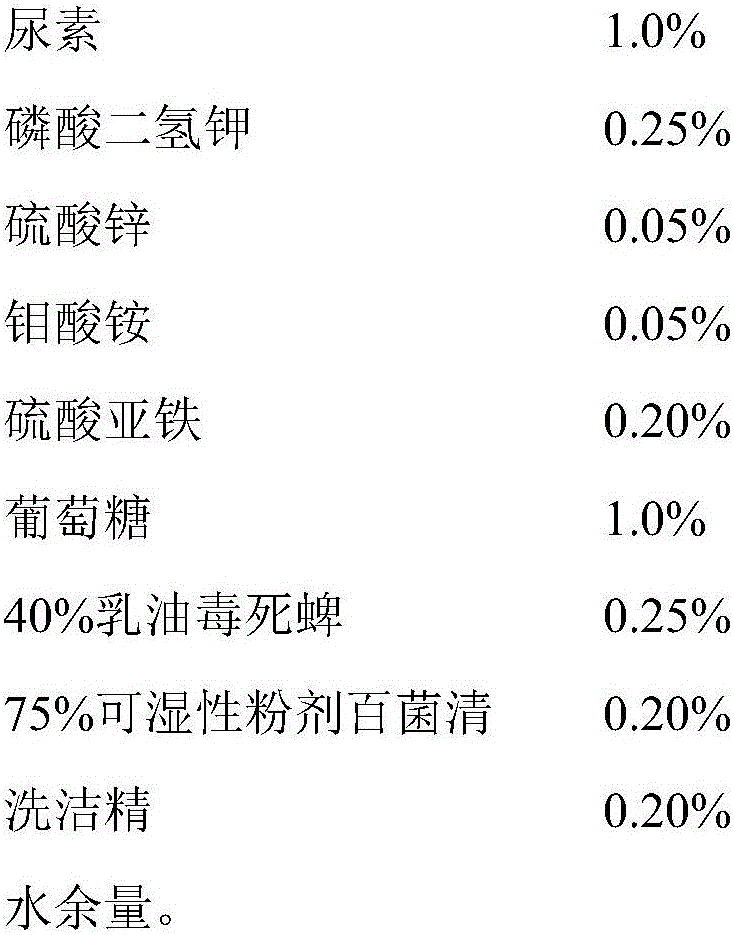

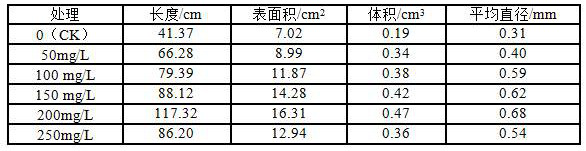

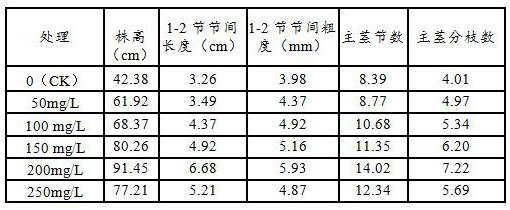

Multifunctional peanut leaf fertilizer and application method thereof

InactiveCN106748350APromote growth and developmentPromote photosynthesisSuperphosphatesAlkali orthophosphate fertiliserChlorpyrifosLow fertility

The invention relates to a multifunctional peanut leaf fertilizer which comprises the following components in percentages by weight: 0.95-1.55% of macroelements, 0.25-0.45% of trace elements, 0.75-1.25% of organic monosaccharide, 0.35-0.55% of a pesticide, 0.15-0.25% of a wetting agent and the balance of water. The macroelements are a salt containing any one or more of nitrogen, phosphorus and potassium; the trace elements are a salt containing any one or more of iron, copper, zinc, cobalt, manganese, chromium, selenium, iodine, nickel, fluorine, molybdenum, vanadium, tin, silicon, strontium, boron, rubidium and arsenic; the organic monosaccharide is any one or more of glucose, fructose and galactose; the pesticide is one or two of chlorpyrifos and chlorothalonil; the wetting agent is a detergent. By separately applying the multifunctional peanut leaf fertilizer provided by the invention to field blocks with low fertility and high fertility, growth and development of peanuts are obviously promoted; the ability of photosynthesis of the peanuts is obviously enhanced, the output and milled rice rate are increased, and the quality indexes, for example, proteins and fat, of the peanuts are obviously improved.

Owner:SHANDONG PEANUT RES INST

Cultivation method for improving fullness of thin-shell tartary buckwheat

PendingCN112753502AImprove fullnessImprove qualityCereal cultivationHorticulture methodsBiotechnologyIndole acetic acid

The invention discloses a cultivation method for improving fullness of thin-shell tartary buckwheat. The cultivation method comprises the steps of soil preparation, base fertilizer application, seed selection, seed soaking, sowing, field management, harvesting and the like, the whole plant is sprayed with indoleacetic acid in the seedling stage and the flowering stage of the thin-shell tartary buckwheat to promote the rapid growth of the root system and the overground part of the thin-shell tartary buckwheat, meanwhile the fullness of the thin-shell tartary buckwheat can be increased, furthermore, the quality of thin-shell tartary buckwheat is improved, the rice yield is increased, and the tartary buckwheat industry development is promoted.

Owner:GUIZHOU NORMAL UNIVERSITY

Low-temperature treatment method for rice

InactiveCN109126935AQuality improvementRetain nutrientsSeed preservation by freezing/coolingSeed preservation by dryingBiotechnologyNutrients substances

The invention discloses a low-temperature treatment method for rice. The low-temperature treatment method comprises the steps of low-temperature drying of unprocessed grain, low-temperature storage ofthe unprocessed grain, low-temperature processing, low-temperature storage of finished rice and low-temperature storage of a client side. By systematically controlling the temperature and humidity ofrice, the low-temperature treatment method greatly reduces the possibility of mildewing, improves the quality of rice, furthest preserves the delicate flavor and nutrient substances of rice, and improves the economic value of rice.

Owner:NINGXIA HAOWANG RICE IND GRP

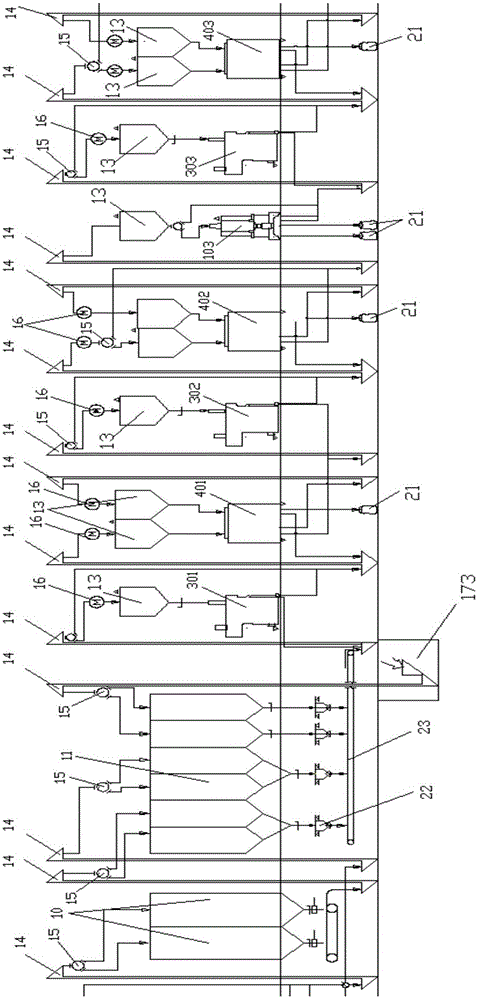

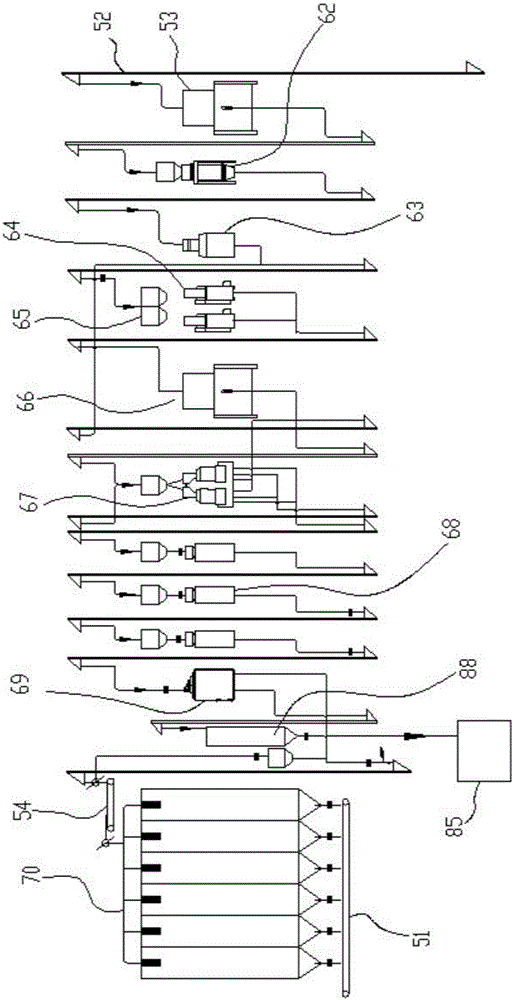

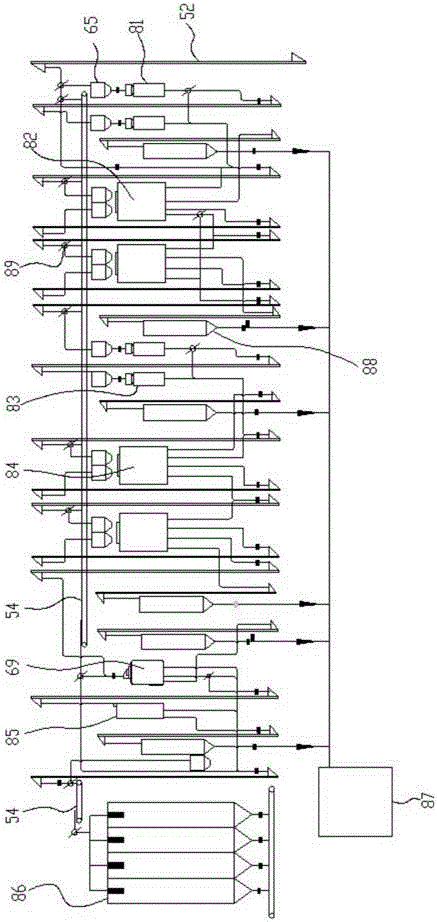

Full-automatic efficient complete-set rice milling device system

InactiveCN105903507AImprove processing efficiencyRealize fully automatic managementGrain huskingGrain polishingAutomatic controlEngineering

The invention discloses a full-automatic efficient complete-set rice milling device system. The full-automatic efficient complete-set rice milling device system comprises an unprocessed grain processing device system, a common grain processing device system and a polished rice processing device system which are sequentially connected in series through an elevator. The common grain processing device system comprises a vibration screen, a flow scale, a stoning machine, a rice huller, a grain tidying screen, a grain coarse screen, a rice machine, a white rice screen and a rice cooling bin, all of which are sequentially connected in series through an elevator. The polished rice processing device system comprises a primary polisher, a primary color selector, a secondary polisher, a secondary color separator, a white rice screen, a classificator and a finished product bin, all of which are sequentially connected in series through an elevator. Each polisher is internally provided with an ultrasonic humidifier and a ventilation brush barrel. An air guiding shaft is arranged in each polishing roller, an air guiding strip is arranged between each air guiding shaft and a corresponding rotating shaft, a hair brush is arranged in each ventilation brush barrel, and a screen drum is connected with each rotating shaft through a planetary wheel mechanism. The full-automatic efficient complete-set rice milling device system is high in machining efficiency, capable of achieving full-automatic control, convenient to control and flexible in operation, the quality of processed polished rice is high, and manpower and material resources are greatly saved.

Owner:CHANGSHA RONGXIN GRAIN & OIL MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com