Cooling polishing improvement process for fine processing of rice

A rice and process technology, applied in application, grain processing, grain milling, etc., can solve problems such as low efficiency, long processing process chain, and insignificant cooling effect, and achieve simple production process, good effect, and reduced transfer cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

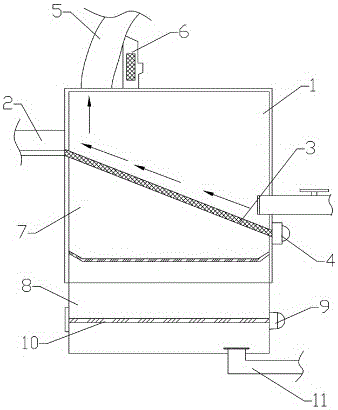

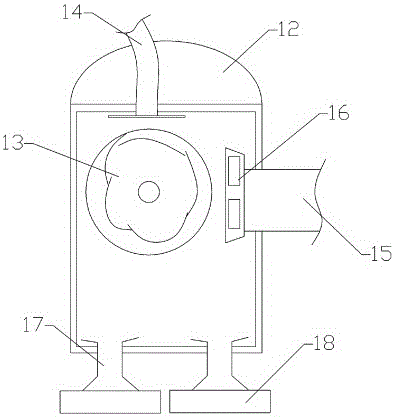

[0016] The reference signs in the drawings of the description include: warehouse body 1, feed inlet 2, vibrating sieve plate 3, vibration motor 4, exhaust pipe 5, exhaust fan 6, storage box 7, separation box 8, servo motor 9 , separation plate 10, discharge pipeline 11, cylindrical body 12, material distribution screw cylinder 13, rice inlet 14, cool air pipeline 15, nozzle 16, discharge box 17, classification box 18.

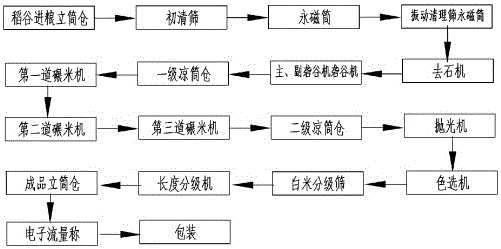

[0017] The embodiment is basically as attached figure 1 Shown: the improved cold polishing process of rice finishing in the present invention, including rice grain feeding vertical silo→primary cleaning sieve→permanent magnetic cylinder→vibrating cleaning sieve→stone remover→main husker→secondary husker→second One rice milling machine→the second rice milling machine→the third rice milling machine→polishing machine→color sorter→white rice grading sieve→len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com