Flexible polishing device for granulated grains

一种柔性抛光、粮食的技术,应用在粮食加工领域,能够解决挤压力小、限制糙米销售量、碎米率高等问题,达到增大柔性摩擦效应、避免剪切效应、提高出米率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

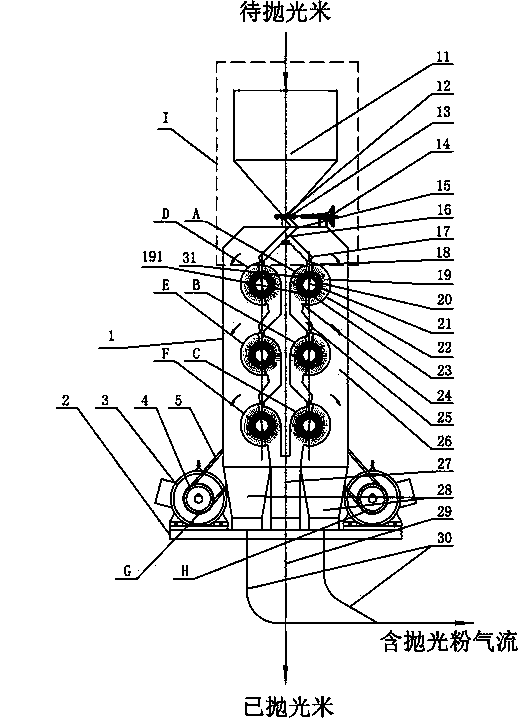

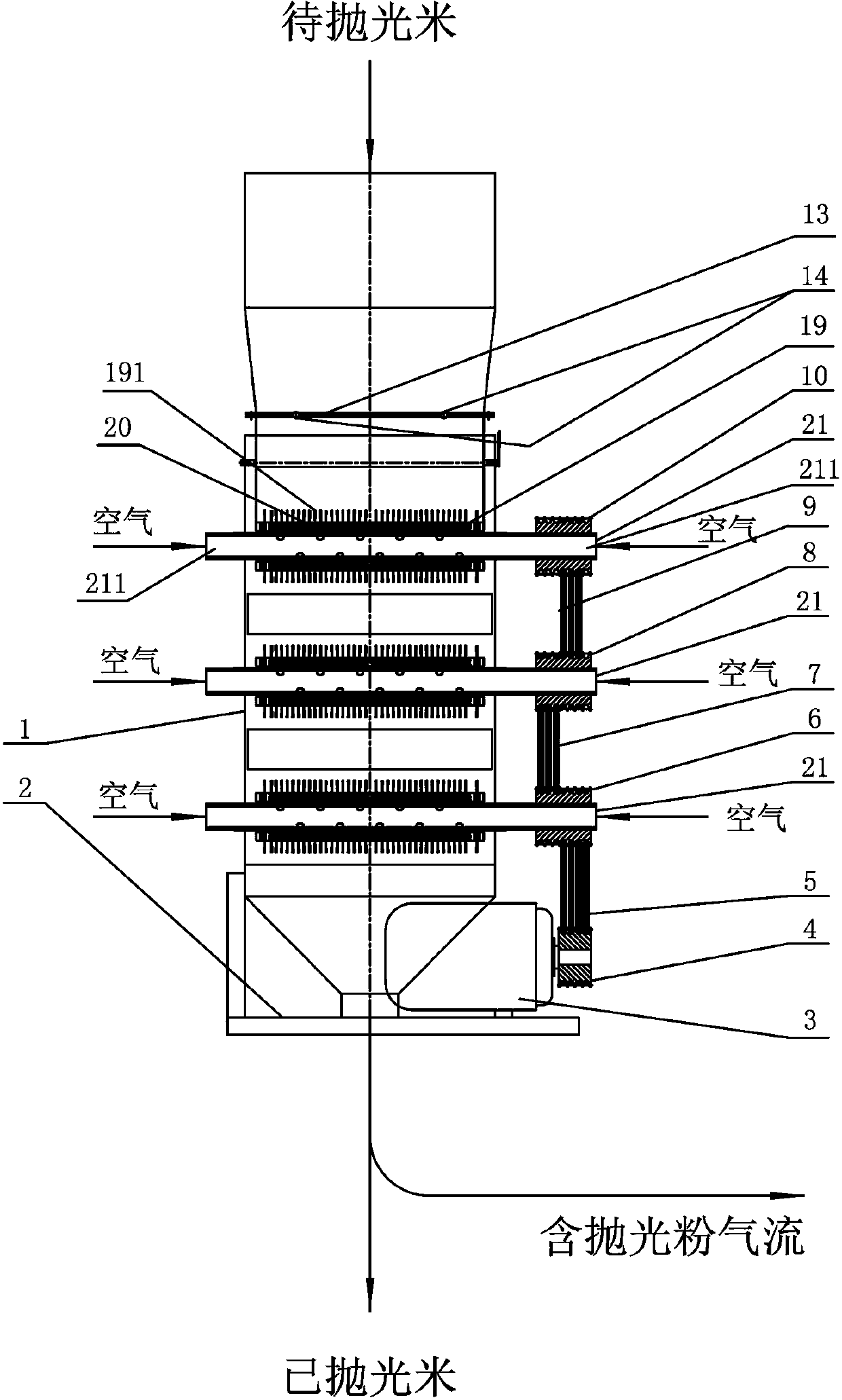

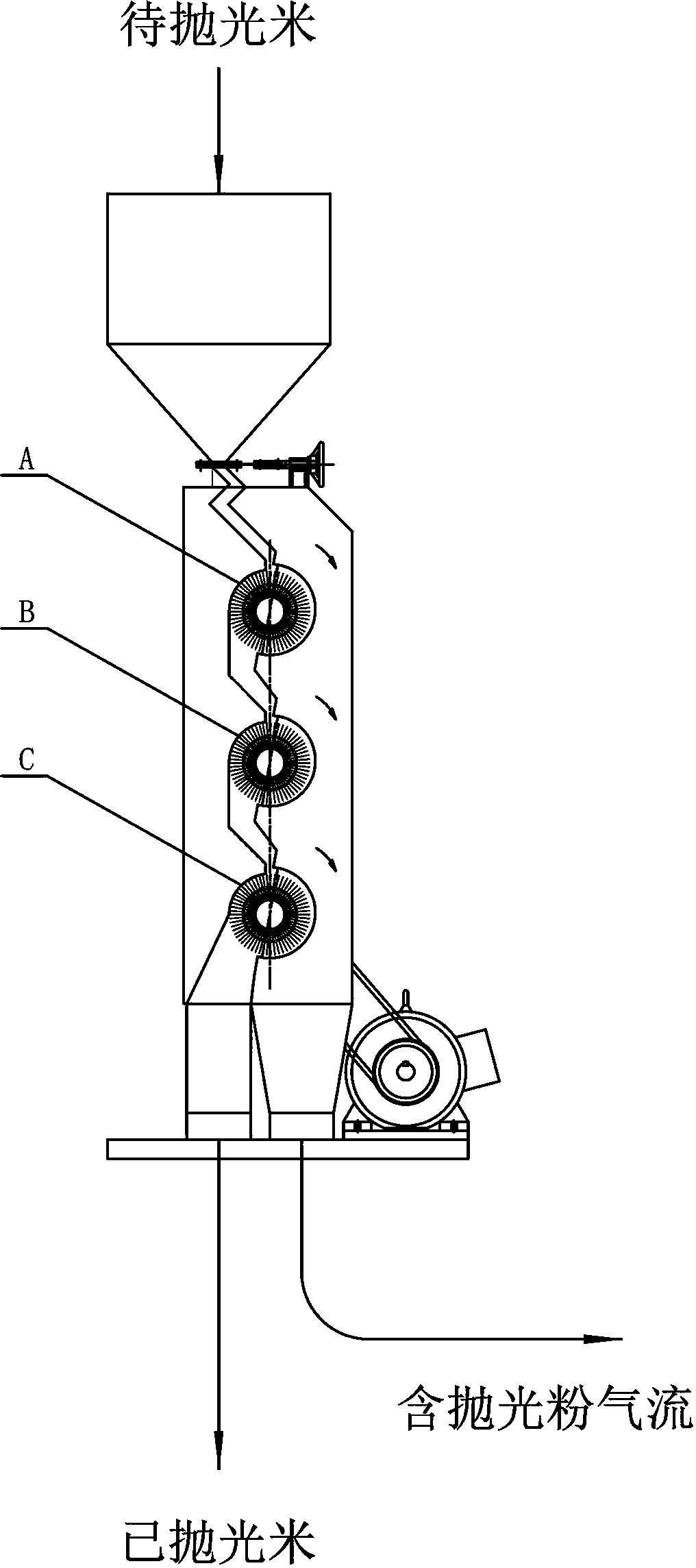

[0034] Please refer to figure 1 and figure 2 The particle grain flexible polishing device 100 provided by an embodiment of the present invention includes a casing 1, a feeding device 1, a transmission device, at least one flexible polishing unit, a bran removal device, and a rice outlet 27, and the flexible polishing unit includes a diameter To the gravity self-flowing flexible polishing chamber 31 (hereinafter referred to as the flexible polishing chamber), the feeding device 1, the flexible polishing chamber and the rice outlet 27 are arranged sequentially from top t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com