Patents

Literature

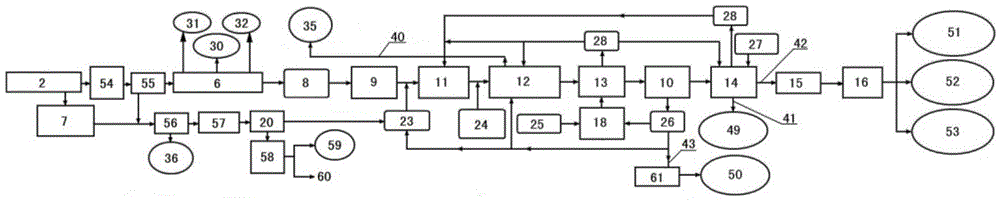

117results about How to "Flip full" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

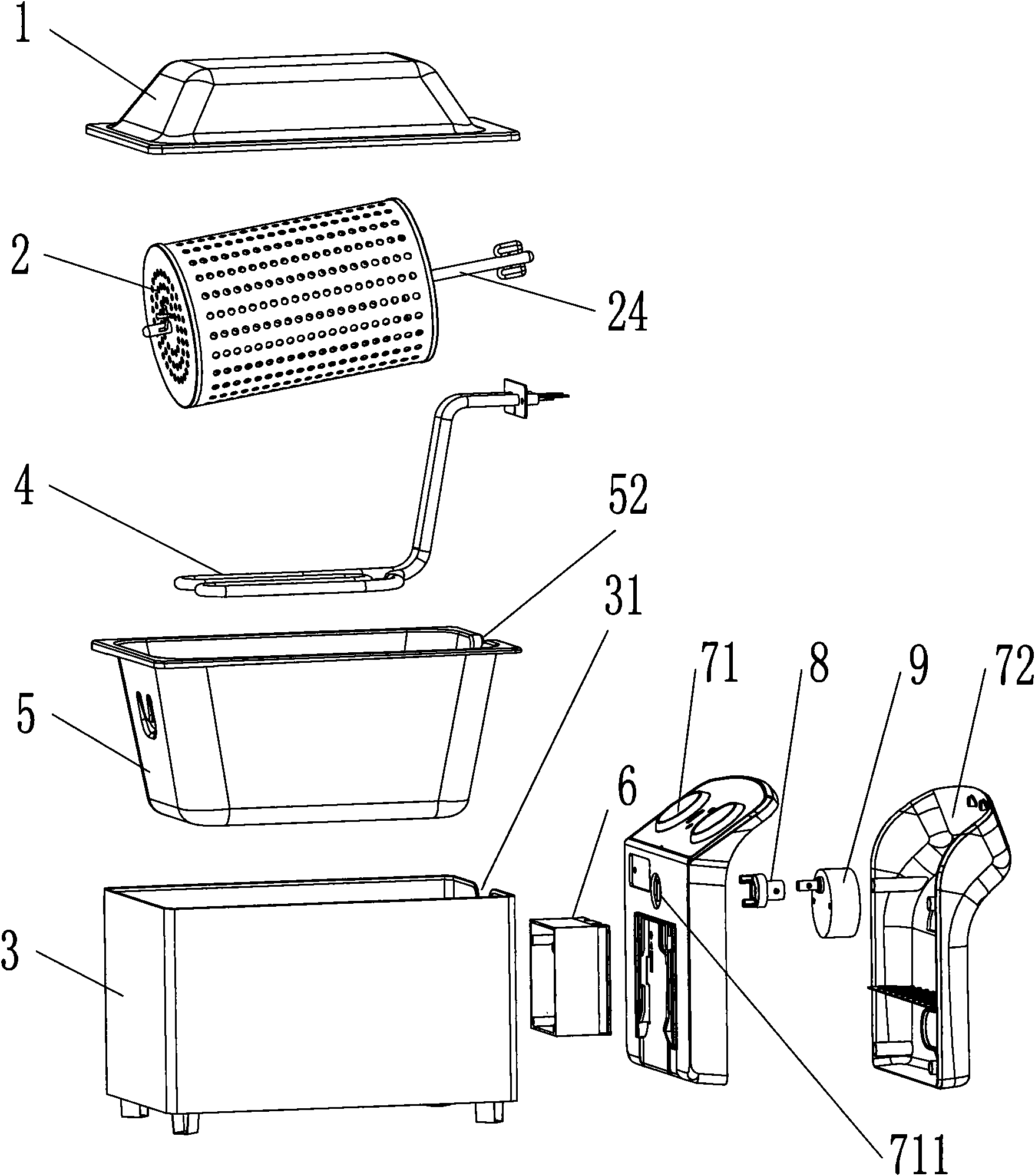

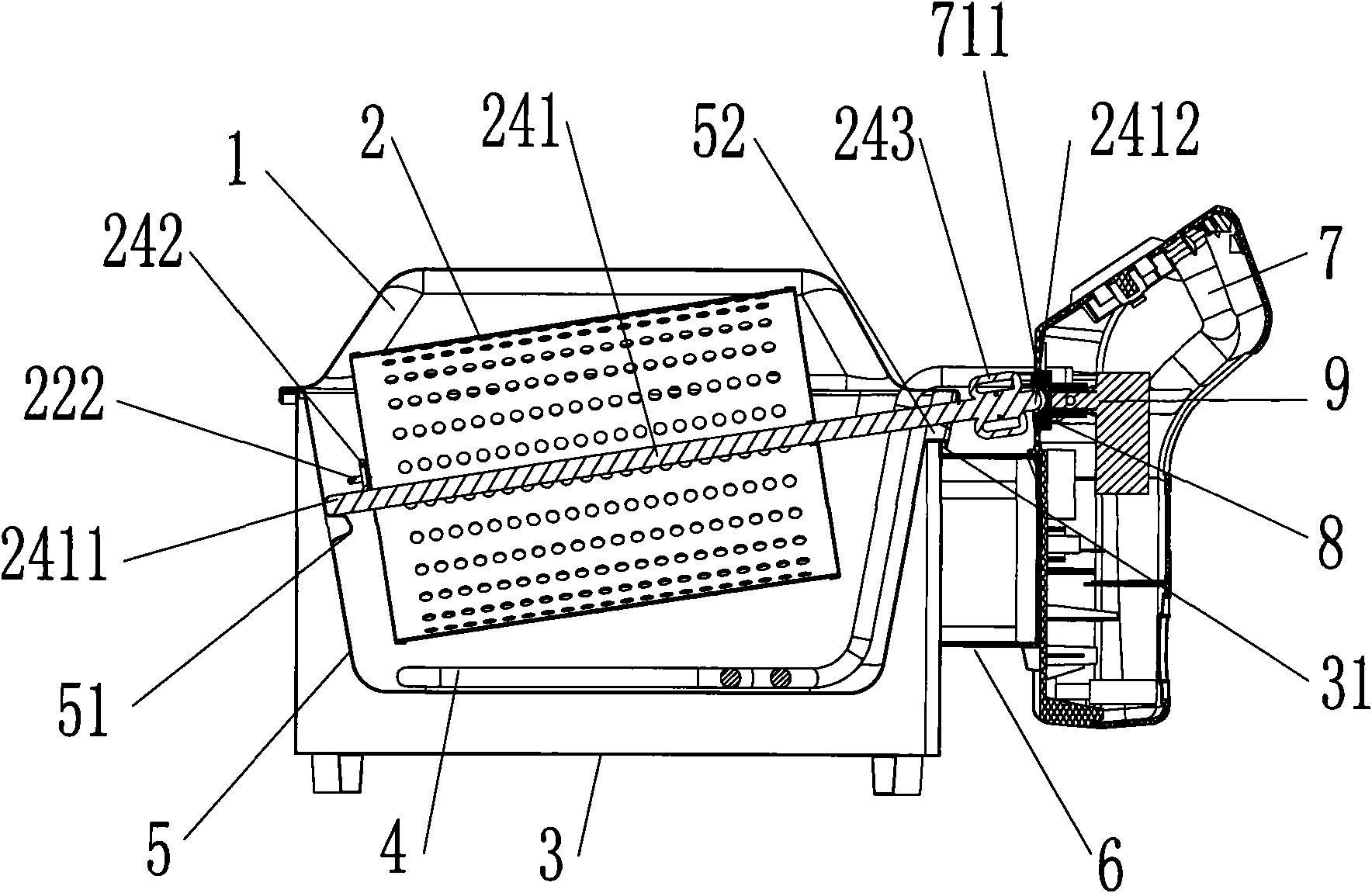

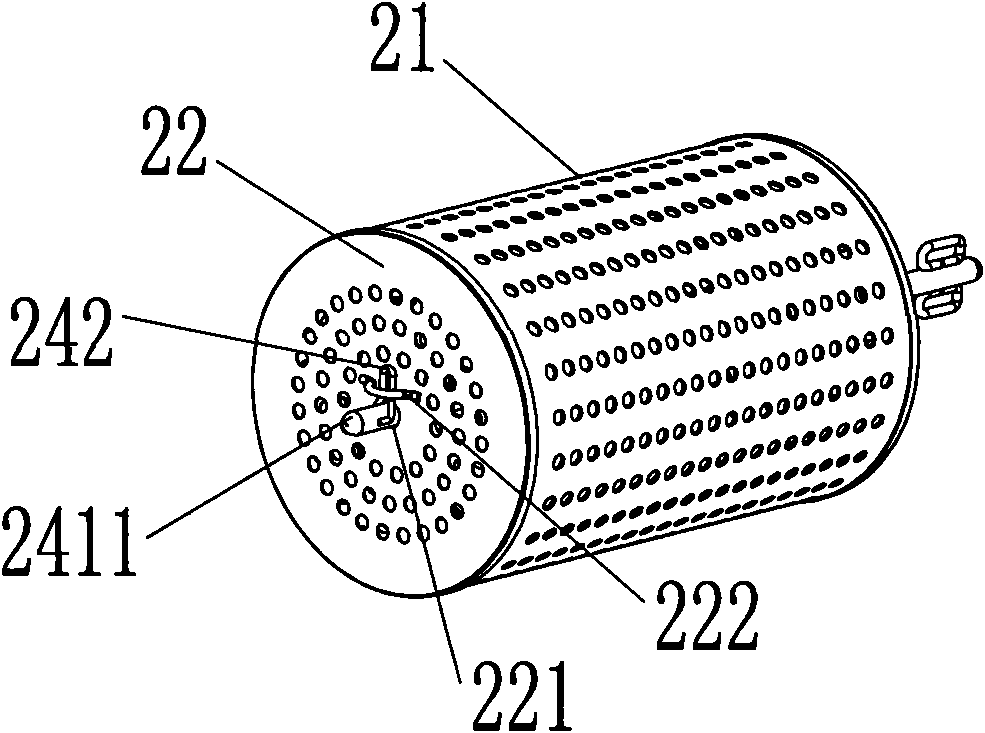

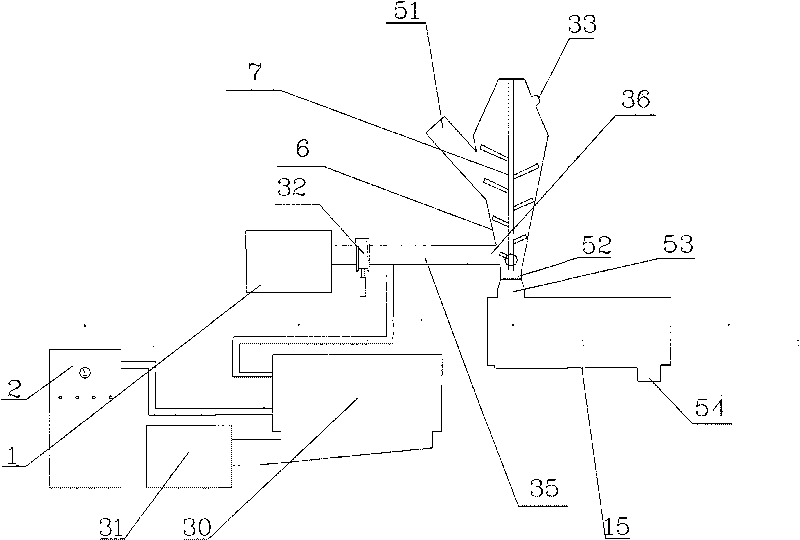

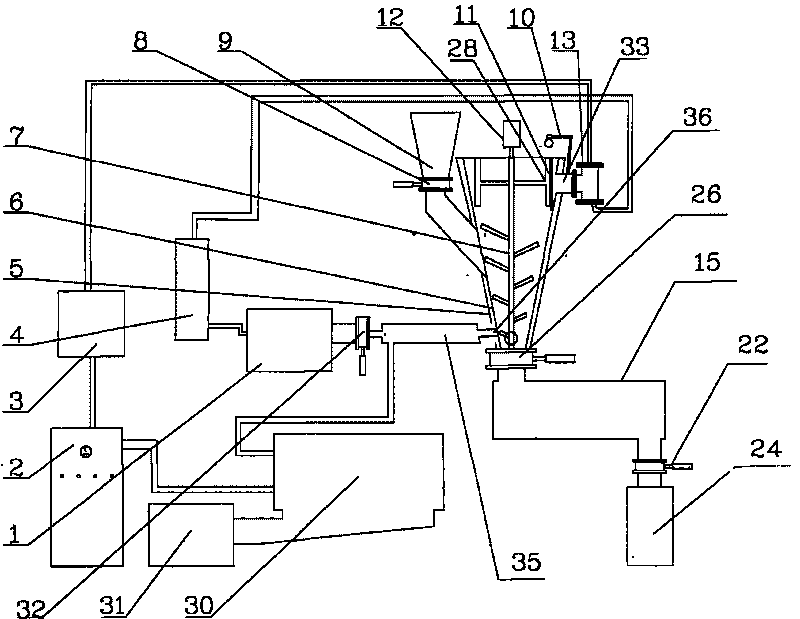

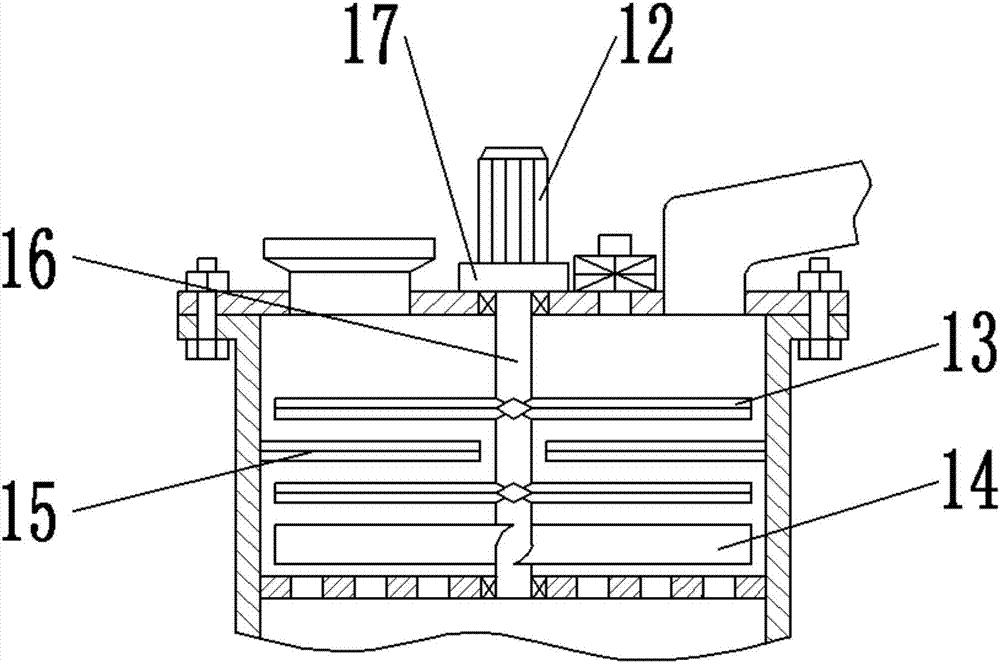

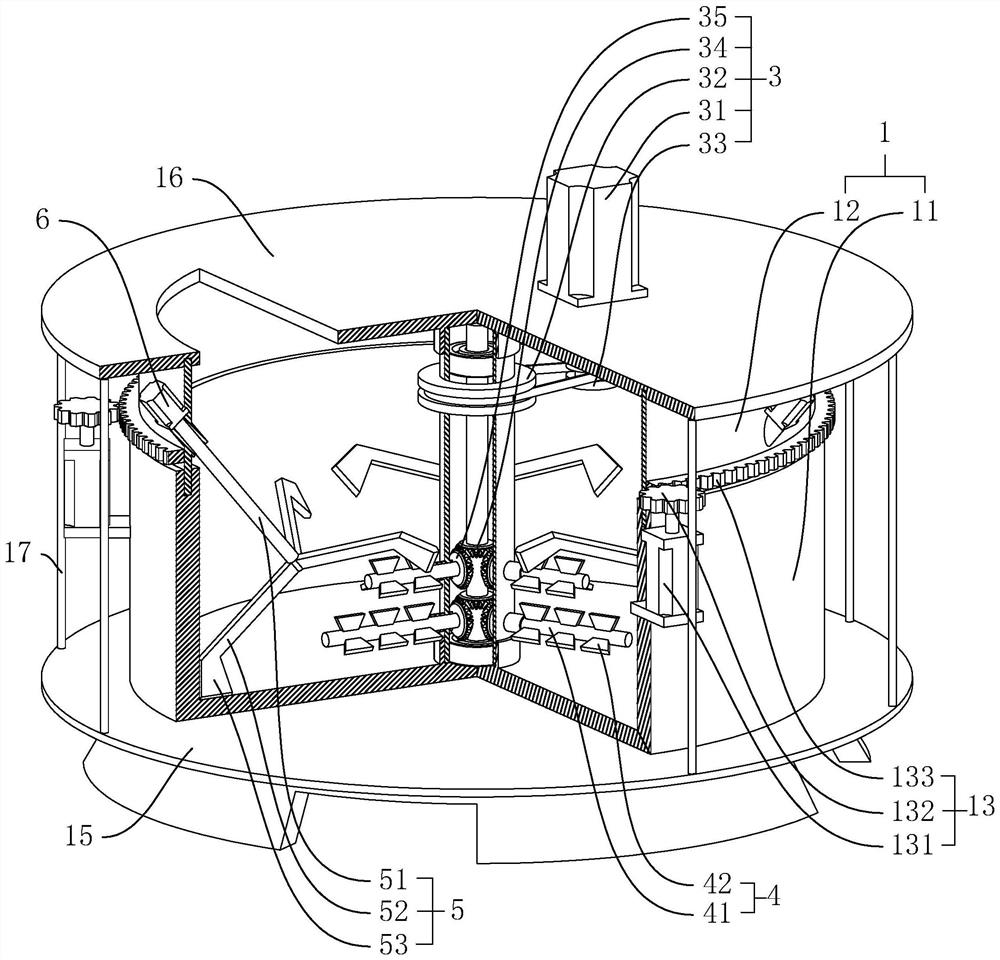

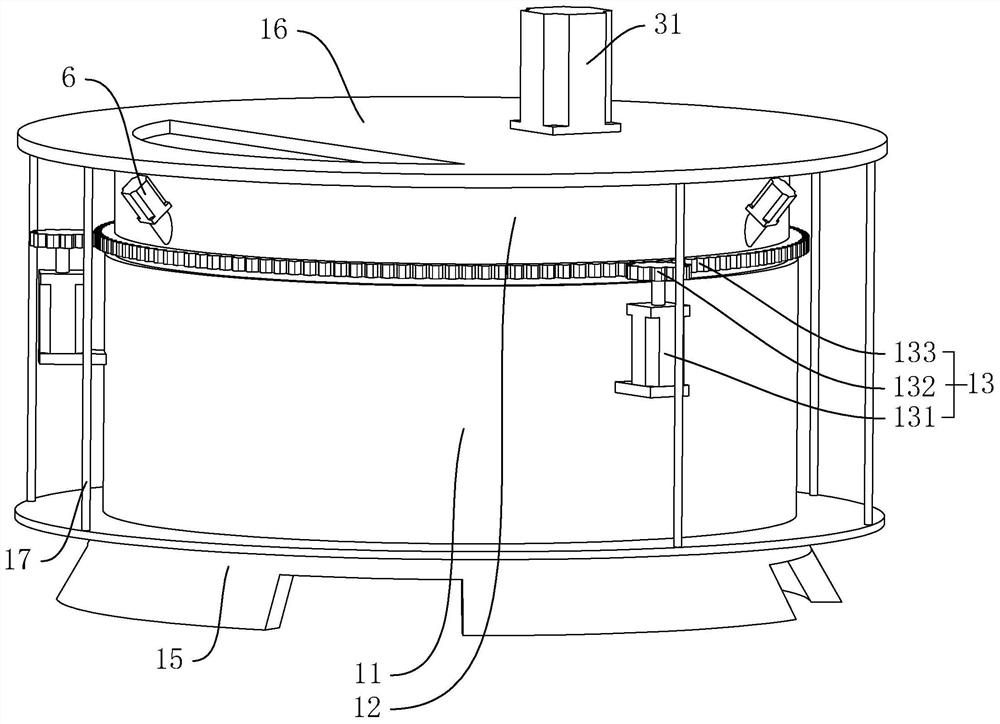

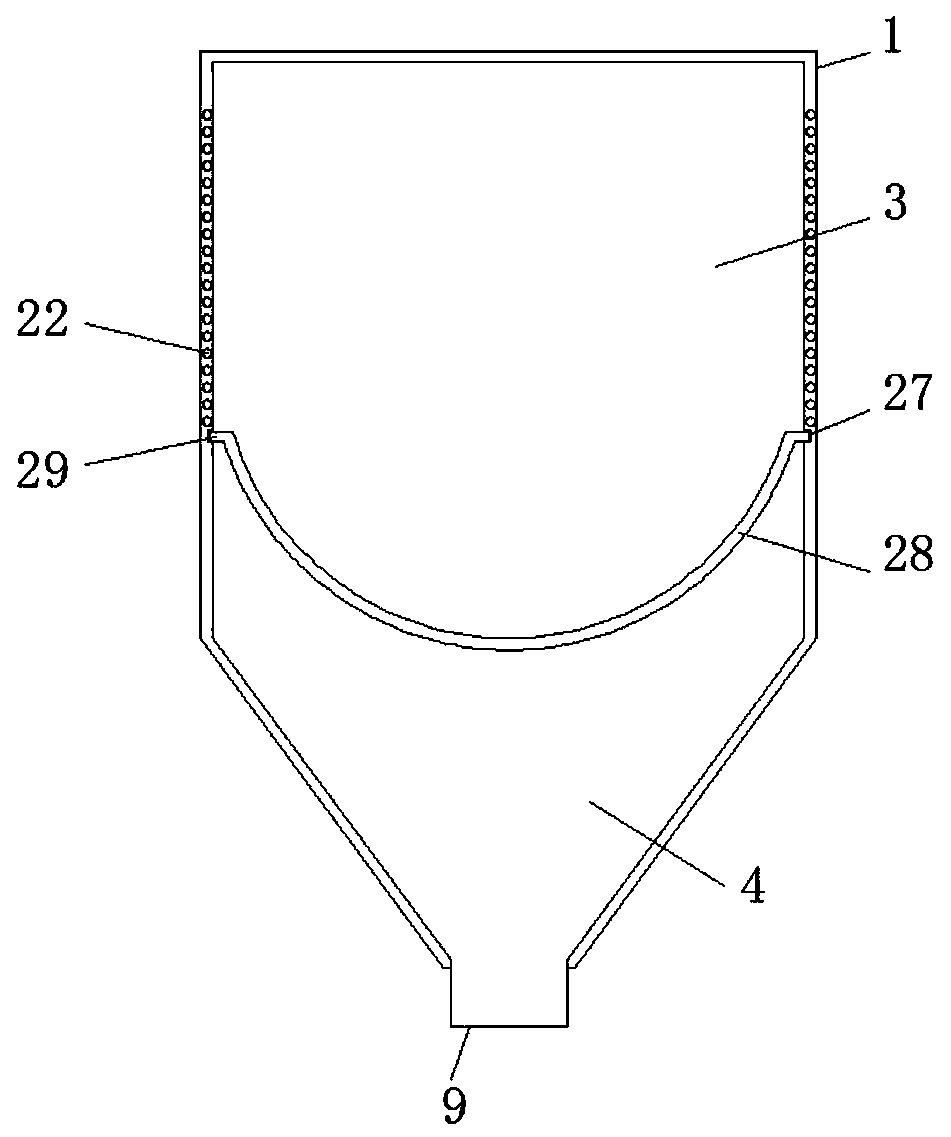

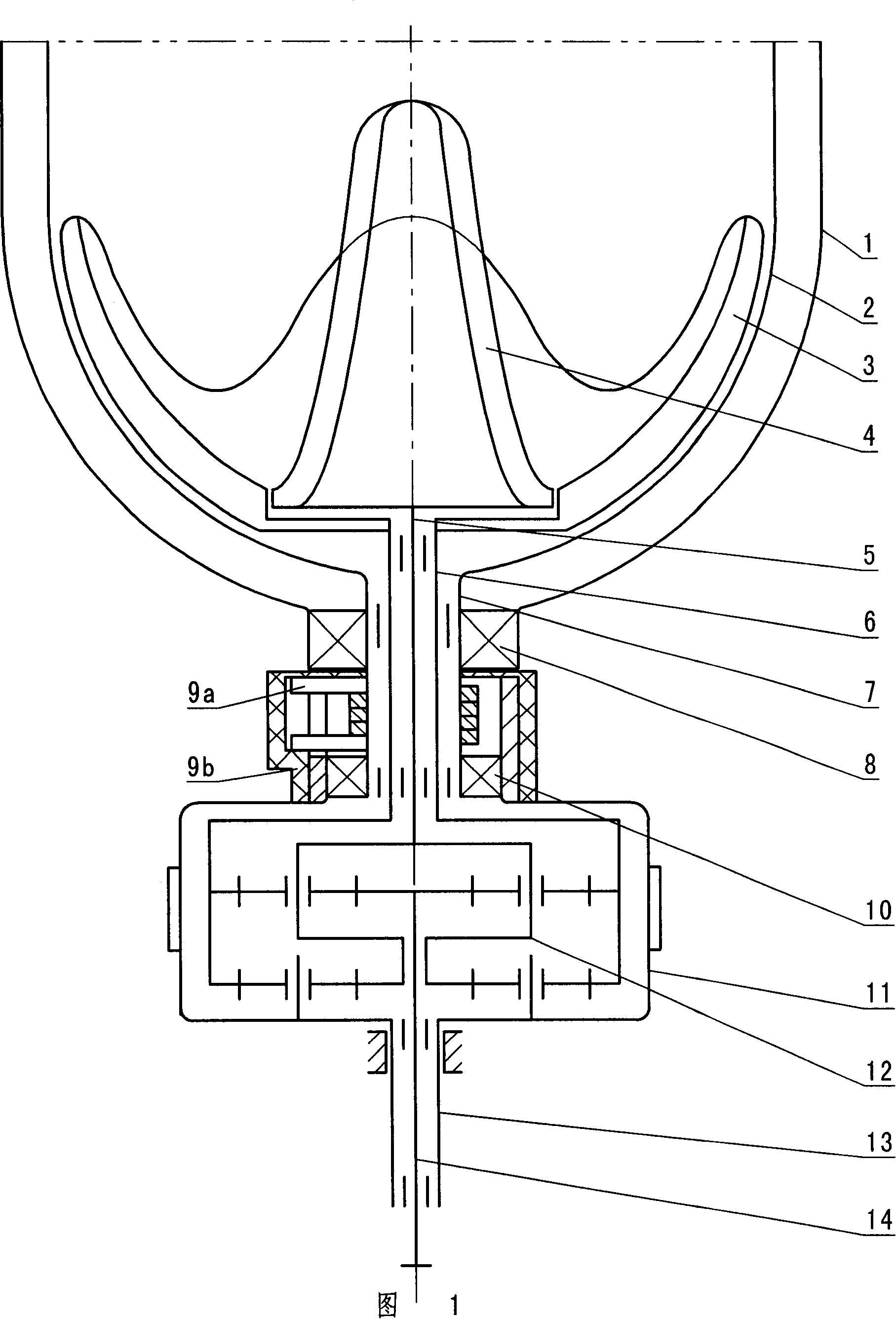

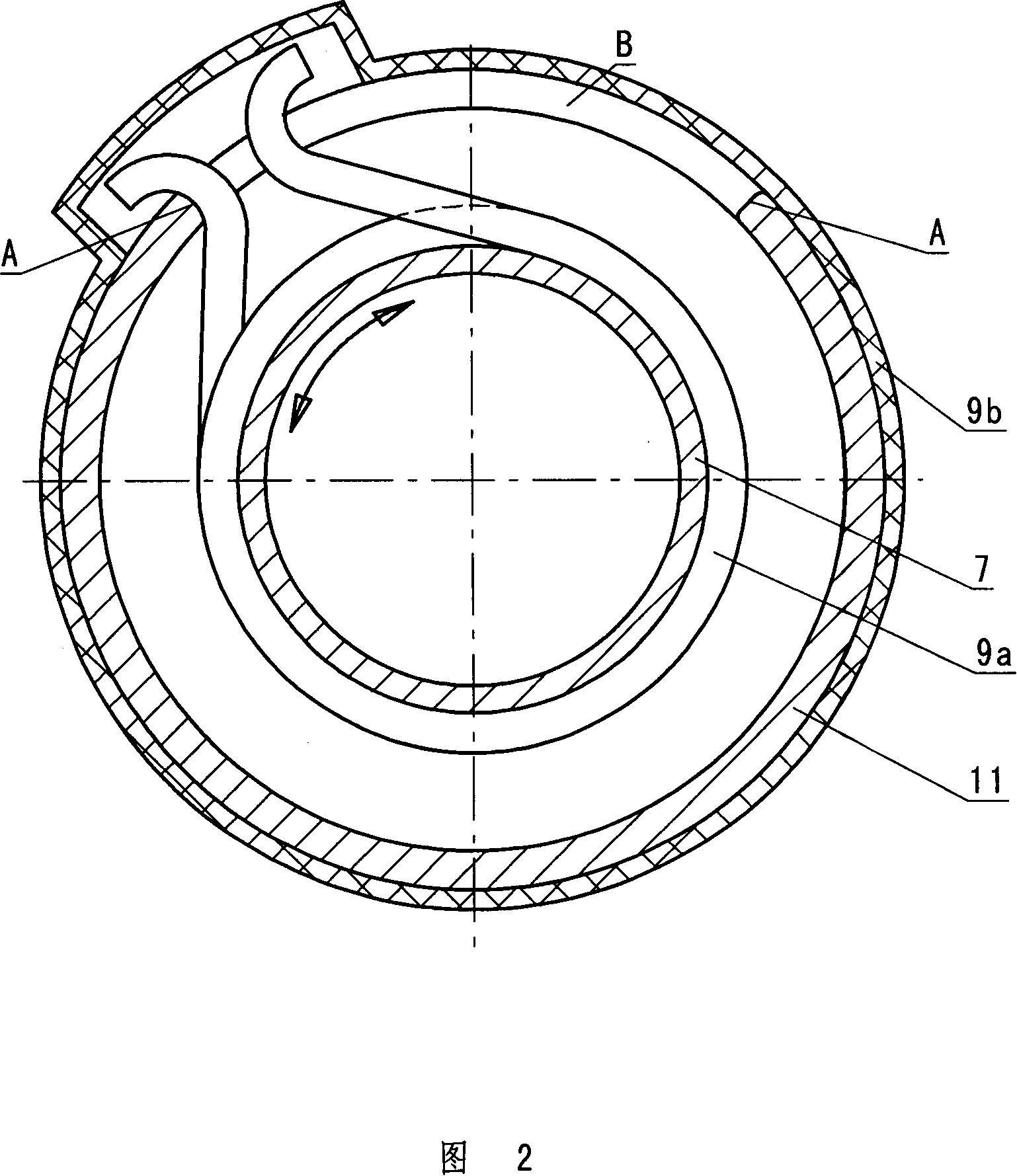

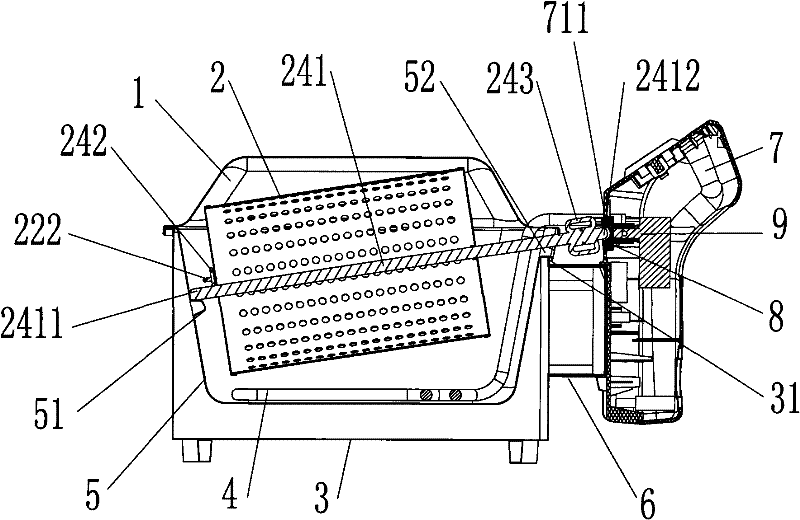

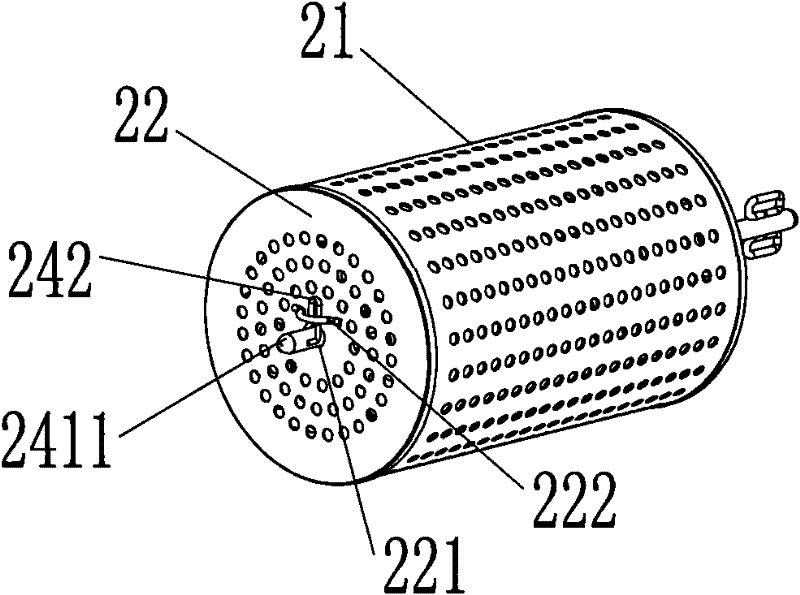

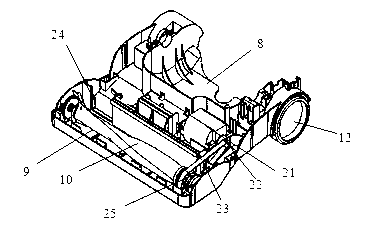

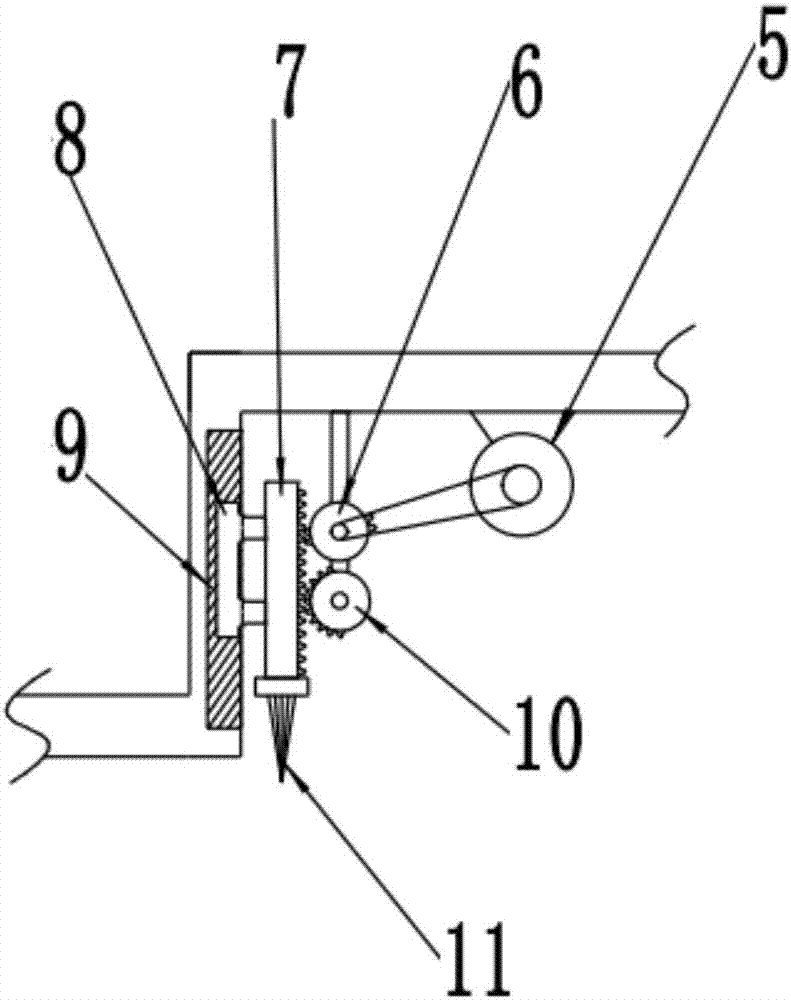

Deep fryer with rotatable frying cage

The invention discloses a deep fryer with a rotatable frying cage, which comprises an upper cover, the frying cage, a shell, an inner pot, a heater and a control box, wherein the frying cage is detachably suspended in the inner pot; the inner pot is placed in the shell; and the heater is placed at the inner bottom or the outer bottom of the inner pot. The deep fryer is characterized in that one lateral surface of the inner pot is provided with a step protruded to the center of the inner pot; a shaft assembly, a coupler and a motor which are connected together in turn are fixed on the lateral surface on the shell opposite to the step; and the shaft assembly passes through the frying cage, one end of the shaft assembly is placed on the lateral surface of the inner pot, and the other end of the shaft assembly is connected with the coupler. The frying cage can rotate in 360 degrees to fully turn food so as to save oil and improve the food frying effect; and a groove for connecting the frying cage and the motor does not need to be formed on the inner pot so as to avoid the problems of oil splash and cleaning difficulty.

Owner:MIDEA GRP CO LTD

Steam sterilizing method

ActiveCN101732740AProtect from moistureGuaranteed qualityFood preservationHeatEngineeringSuperheated steam

The invention discloses a steam sterilizing method, which comprises a sterilizing treatment procedure and a sterilizing treatment post cooling procedure. Before the sterilizing procedure, the interior of a sterilizing chamber is preheated by adopting the hot air provided by a first hot air draught fan; and meanwhile, a second hot air draught fan connected with a hot air inlet of the sterilizing chamber through a storage steam heat exchanger is opened to preheat the storage steam heat exchanger. After the preheating treatment for the sterilizing chamber and the storage steam heat exchanger reaches a set temperature, the material is continuously preheated by the first hot air draught fan; and after the preheating treatment is finished, the material to be sterilized is sterilized by high-temperature steam or over-heated steam. The sterilizing method is simple and efficient, and avoids the problem that the high-temperature steam caused by the sterilizing method without the preheating treatment is condensed in the sterilizing chamber to damp the material so as to influence the quality.

Owner:LANZHOU NONGZHIPIN ECOLOGICAL TECH CO LTD

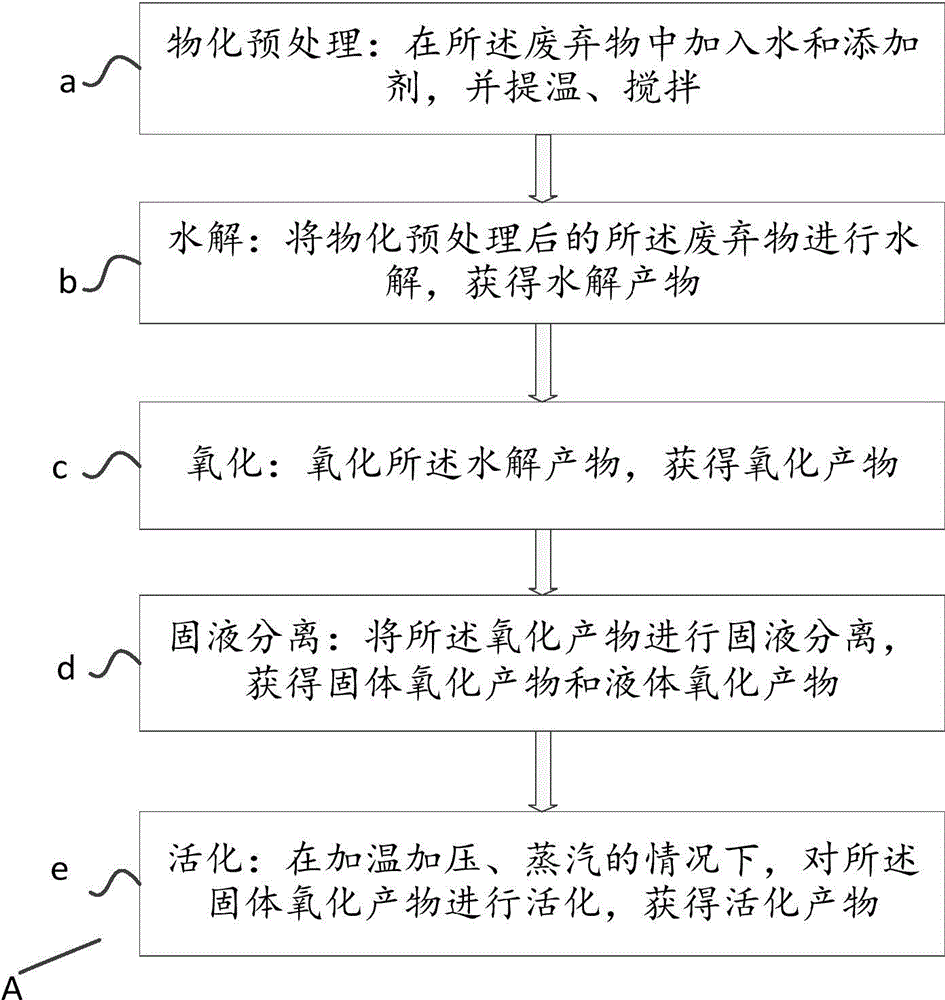

Method and device for treating organic solid waste

ActiveCN104148358AComplete oxidationAvoid lostSolid waste disposalClimate change adaptationCompound (substance)Biological activation

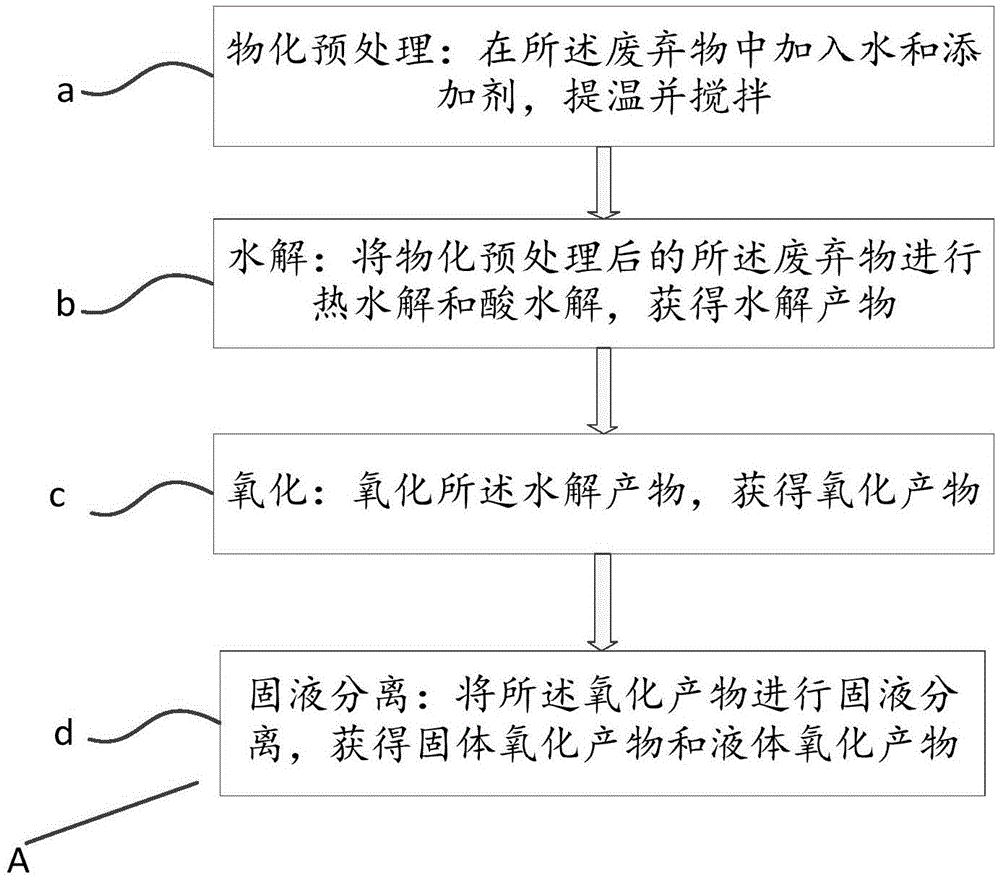

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely hydrolyzing the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; (d) carrying out solid-liquid separation, namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product; and (e) carrying out activation, namely activating the solid oxidization product in the case of heating, pressurizing, steaming and additive adding, thereby obtaining an activated product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

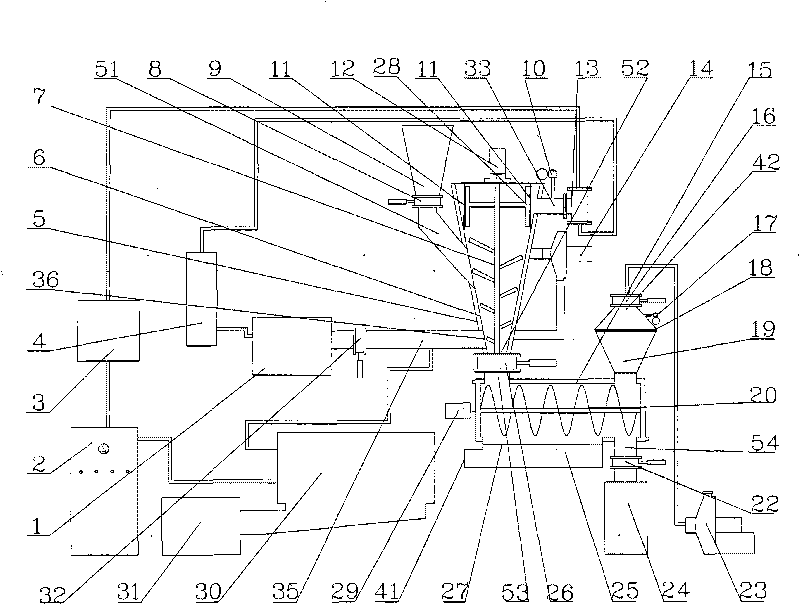

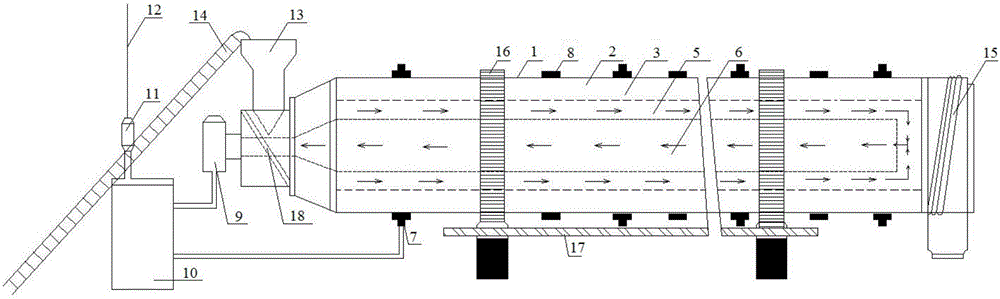

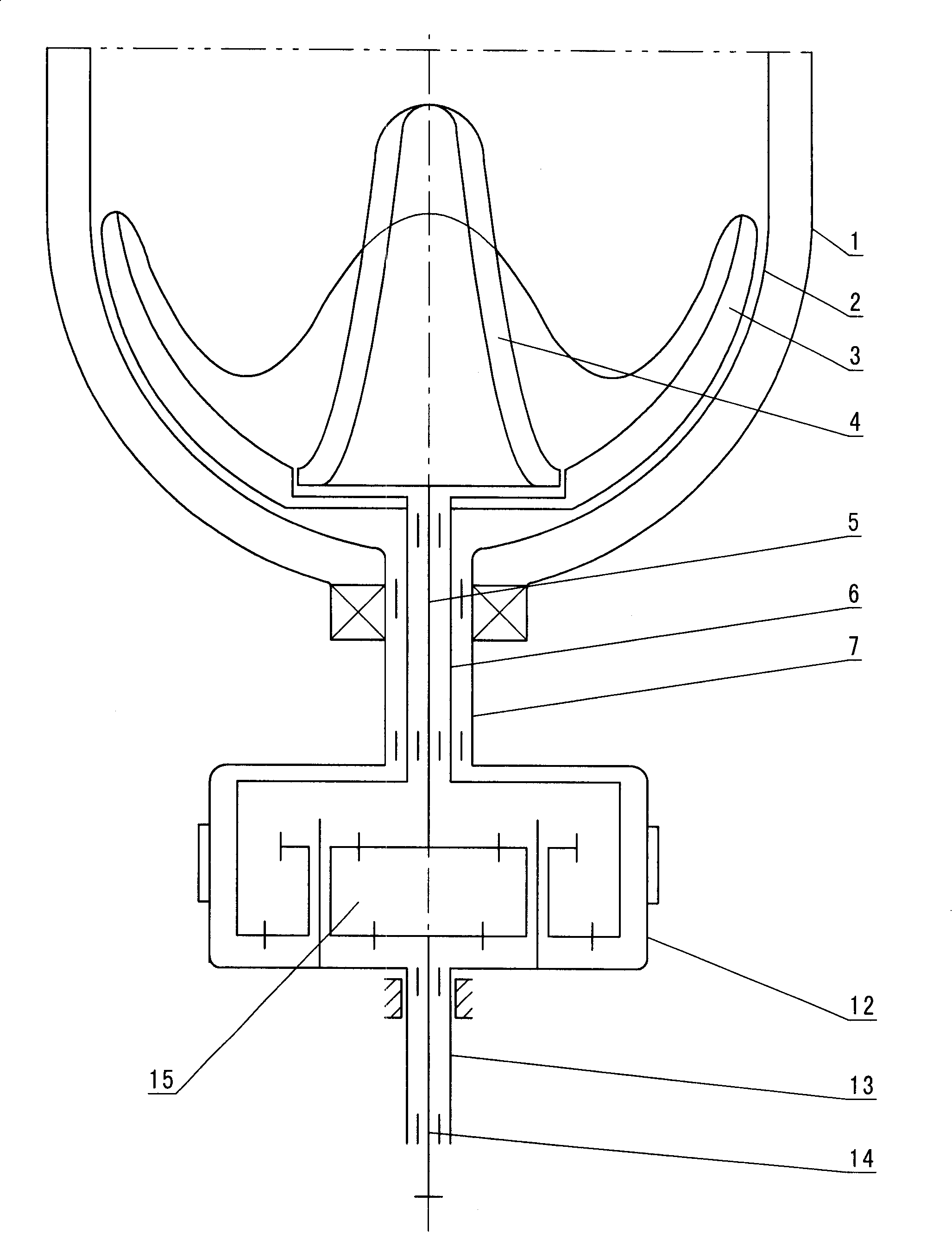

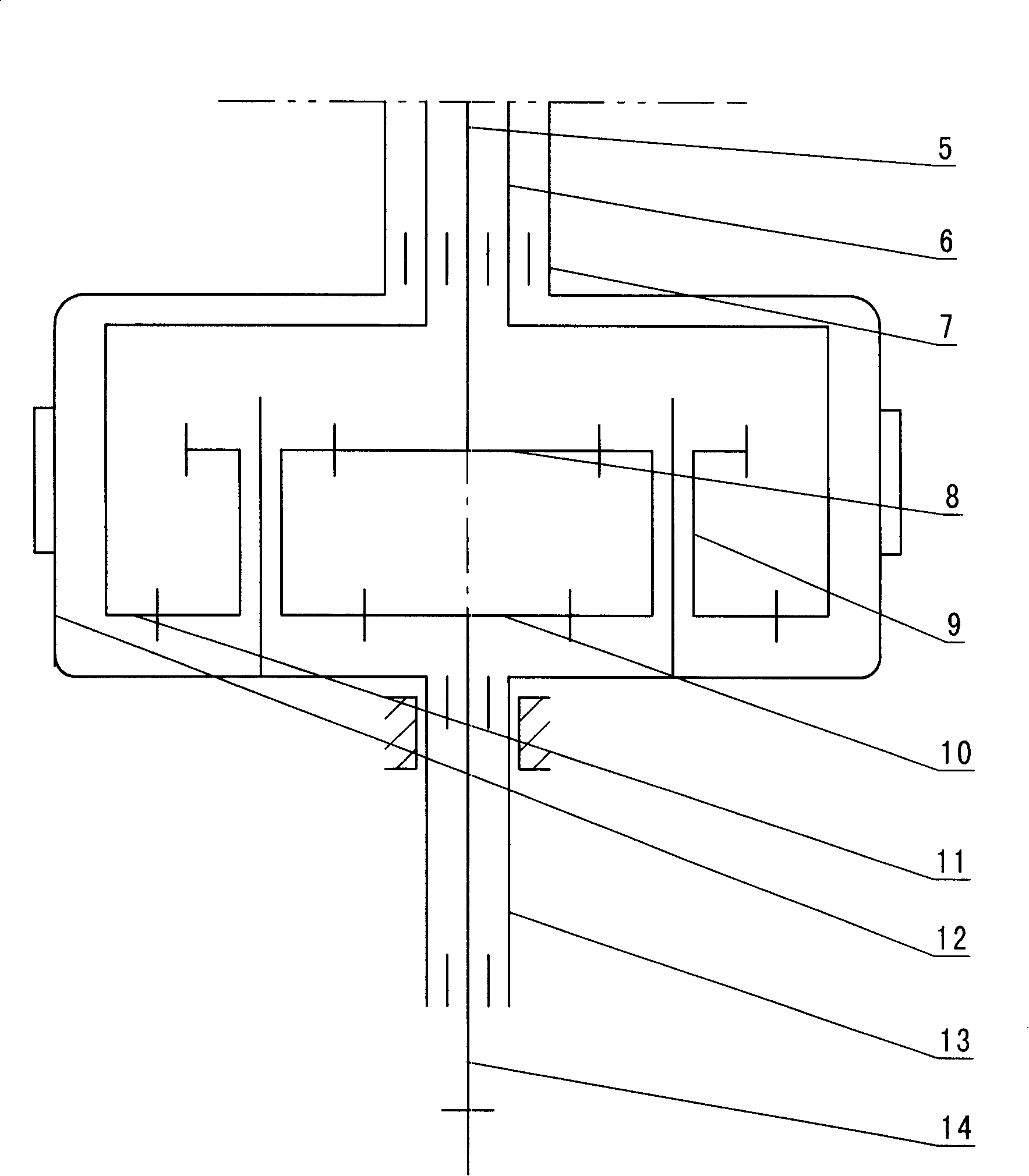

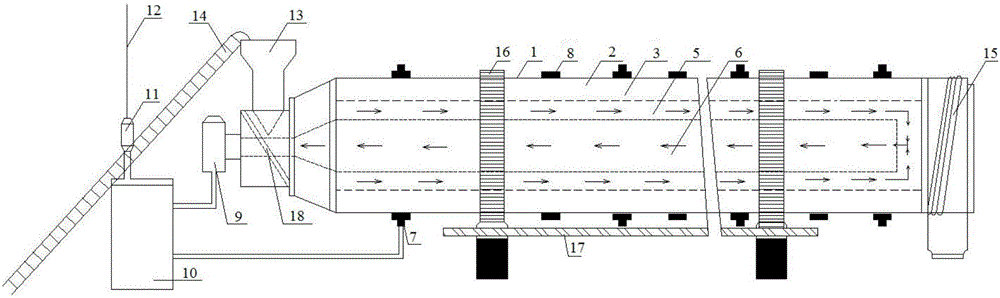

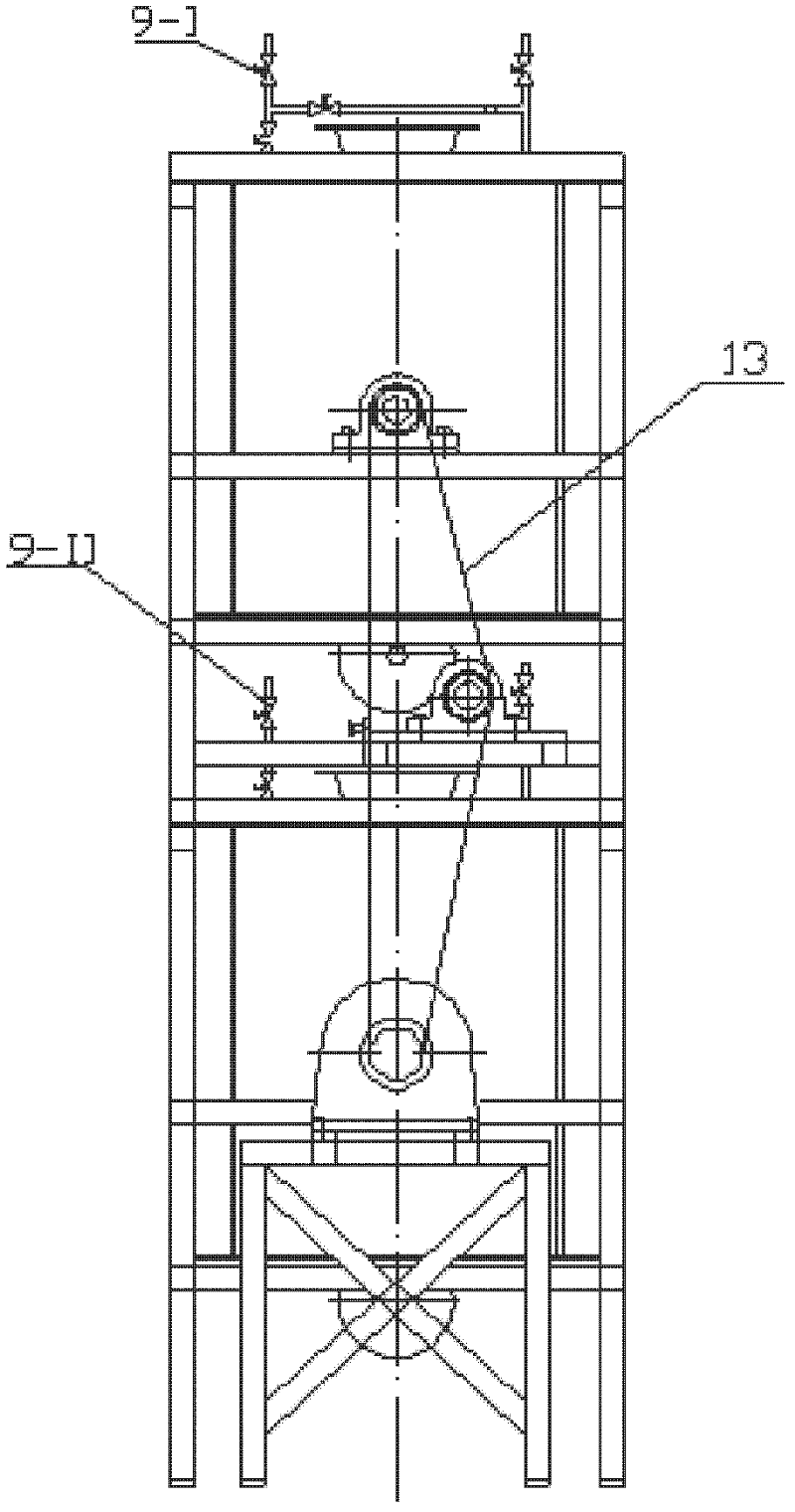

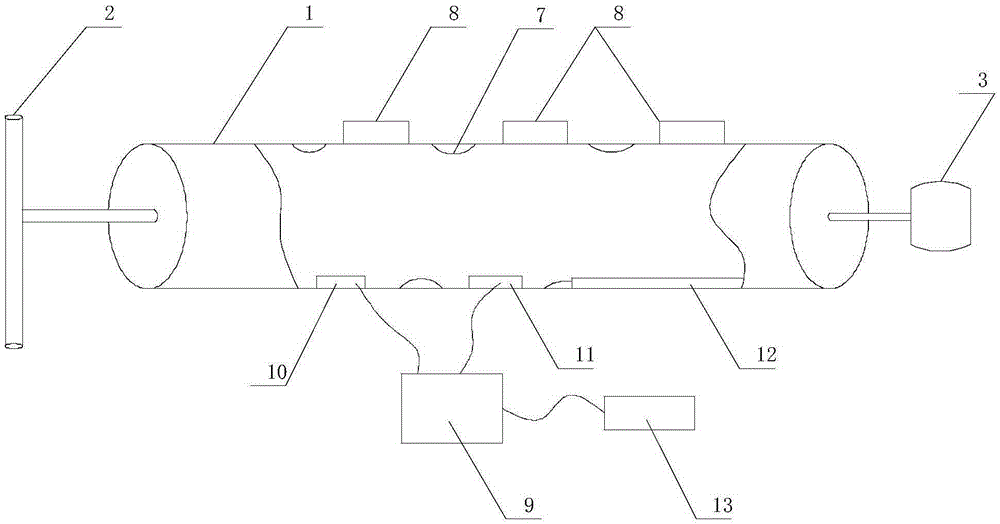

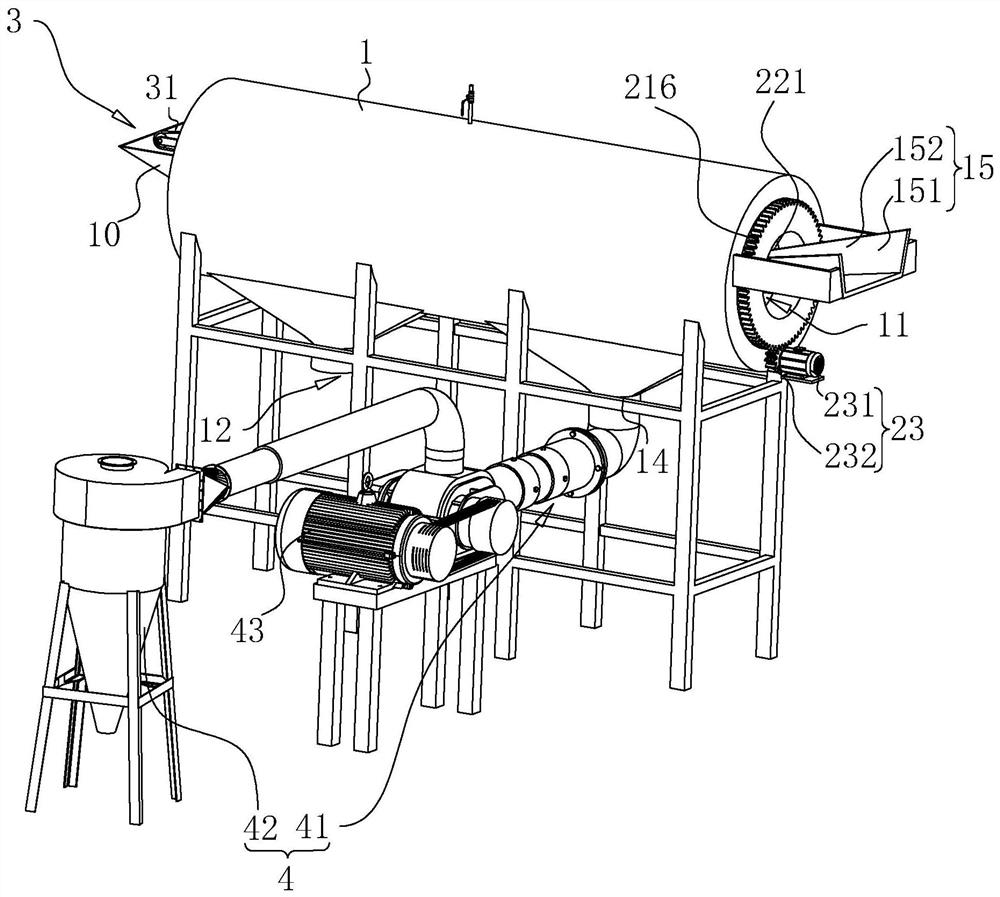

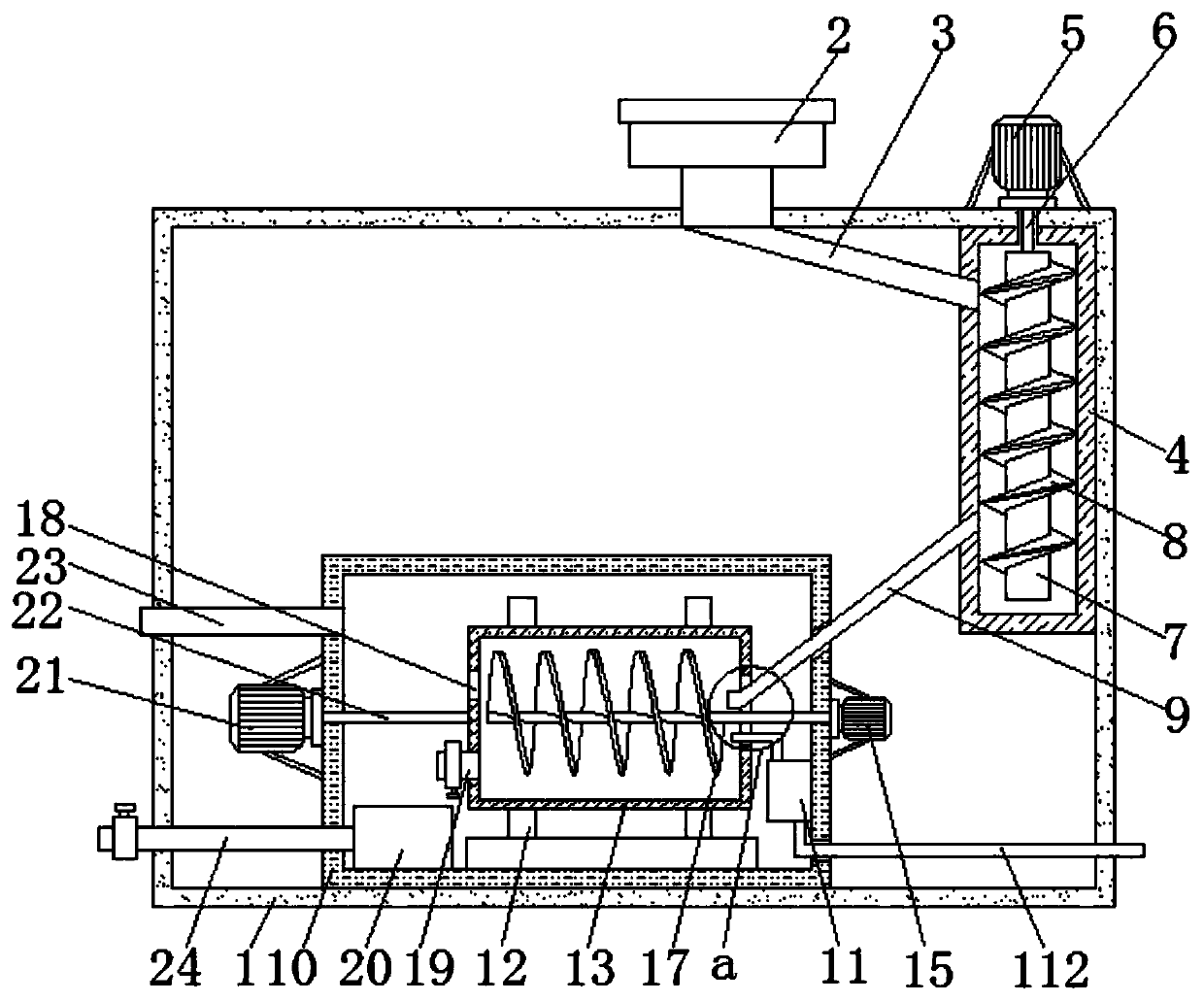

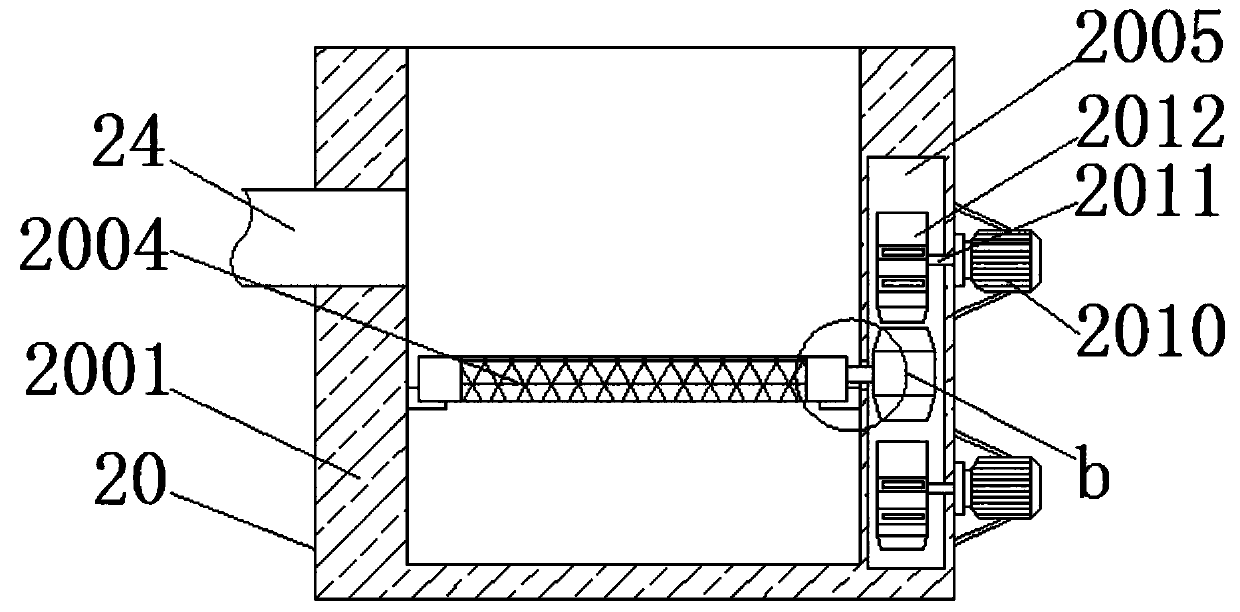

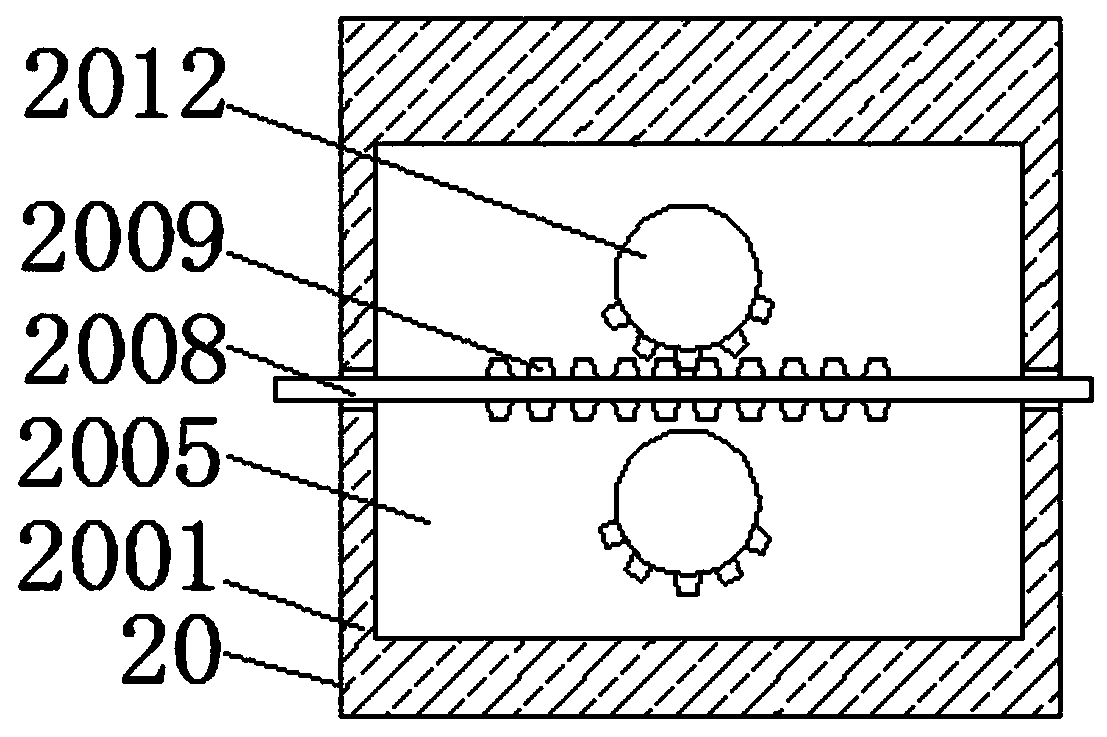

Active carbon activation furnace and active carbon production method

The invention discloses an active carbon activation furnace and an active carbon production method and relates to the field of active carbon production equipment and active carbon production technologies. The safety of an active carbon production process can be improved to a certain extent; the activation furnace works stably for a long term; and the quality and the productive capacity of produced active carbon are greatly improved. The active carbon activation furnace comprises a furnace body, a material entry device and a discharge mechanism, wherein the furnace body is internally provided with a burning passage communicated with the interior of the furnace body; air is admitted to the burning passage; the interior of the furnace body is in a negative pressure state; and air pressure in the burning passage is lower than that in the furnace body. The active carbon production method comprises the following steps: A: arranging the burning passage and material passages, B: admitting steam into the material passages, C: leading liberated gas in the material passages into the burning passage, D: heating materials in the material passages, and E: admitting flue gas generated by burning into a steam generator for heat exchange. The active carbon activation furnace and the active carbon production method are mainly used for active carbon production.

Owner:张西进

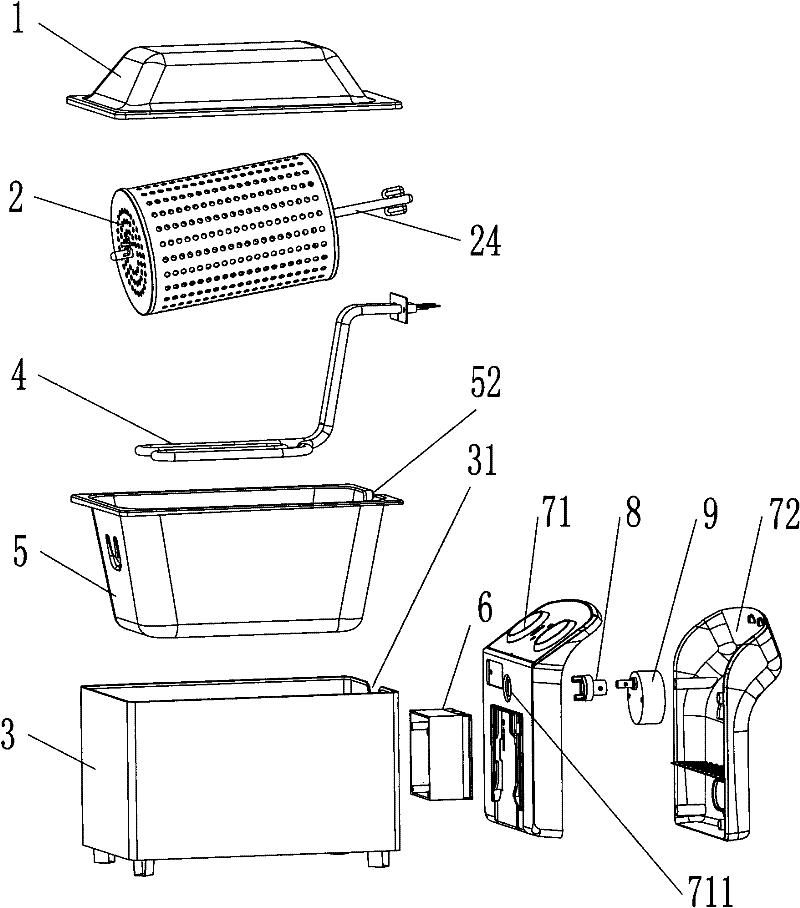

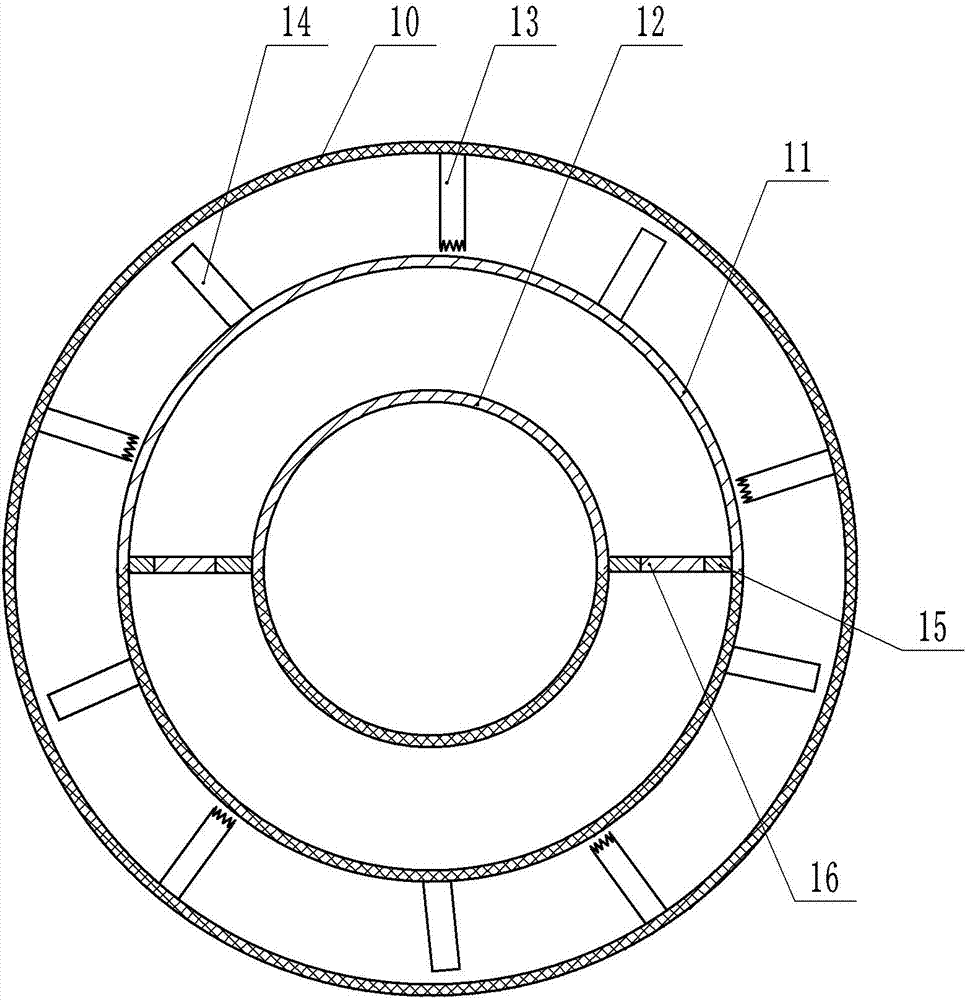

Clothes dryer and clothes drying method

ActiveCN104727109ADry evenlyImprove drying effectTextiles and paperLaundry driersProcess engineeringDrying drum

The invention discloses a clothes dryer and a clothes drying method. The clothes dryer comprises a clothes drying drum which is provided with an air inlet and an air outlet. A lifting structure is arranged on the inner wall of the clothes drying drum and comprises at least two lifting structure bodies which are arranged on the inner wall of the clothes drying drum in an inclined mode. The lifting structure bodies each inclines relative to the length direction of the clothes drying drum. The inclination directions of every two adjacent lifting structure bodies are opposite. By means of the clothes dryer and the clothes drying method, the problems of winding and rolling in the rolling and drying process of large clothes can be solved, and the large clothes can be dried in a loose mode and evenly dried, and drying is thorough.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Method and device for treating organic solid waste

ActiveCN104148357AAvoid unfit problemsImprove efficiencySolid waste disposalAcid hydrolysisCompound (substance)

The invention discloses a method and device for treating organic solid waste. The method comprises the steps: (a) carrying out physico-chemical pretreatment, namely adding water and additives into the waste, and heating and stirring; (b) carrying out hydrolysis, namely carrying out thermal hydrolysis and acid hydrolysis on the waste which is subjected to physico-chemical pretreatment, so as to obtain a hydrolyzate; (c) carrying out oxidization, namely oxidizing the hydrolyzate, so as to obtain an oxidization product; and (d) carrying out solid-liquid separation namely carrying out solid-liquid separation on the oxidization product, so as to obtain a solid oxidization product and a liquid oxidization product.

Owner:ZHEJIANG HAILIANG SOLID WASTE TREATMENT TECH

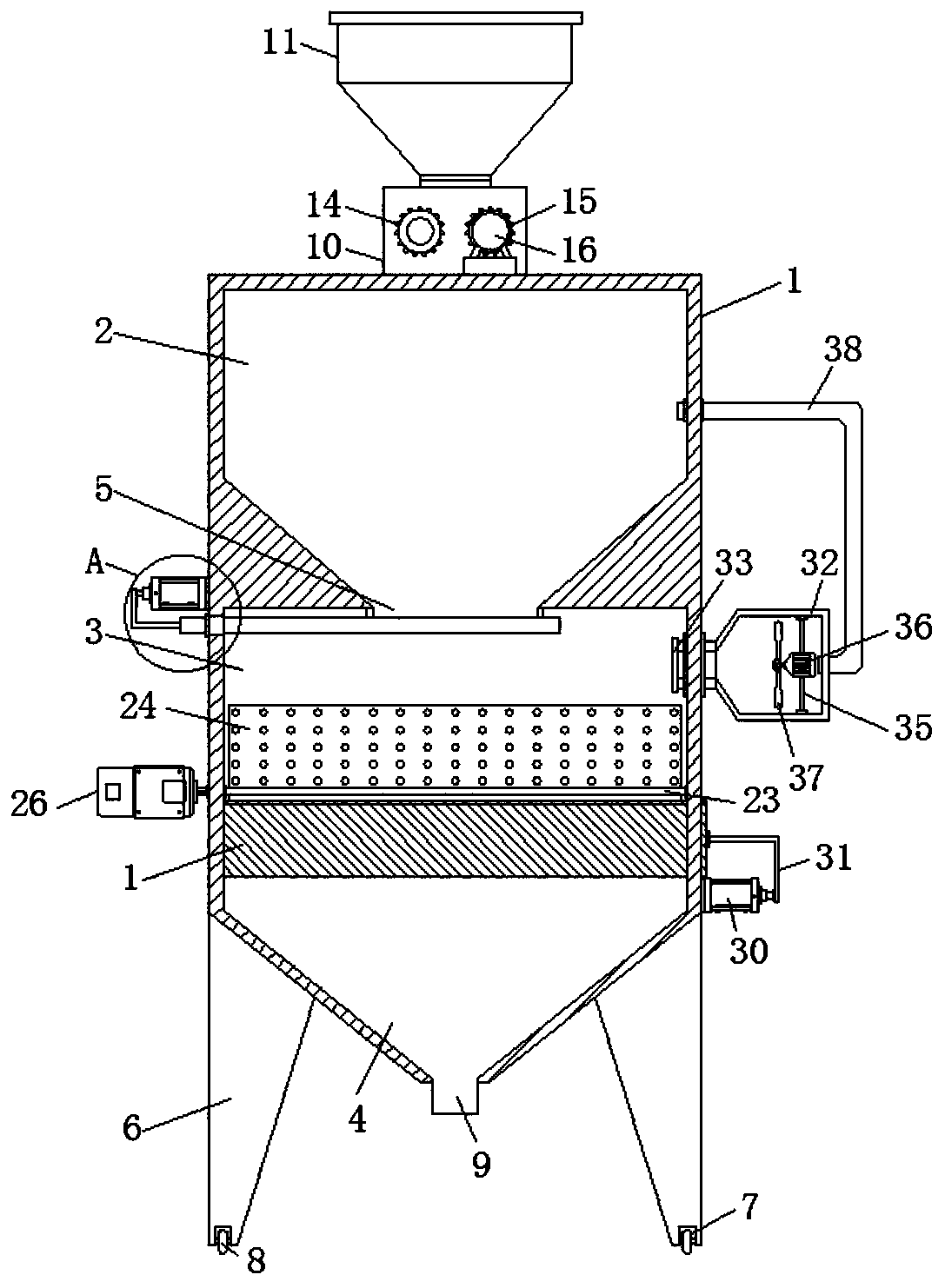

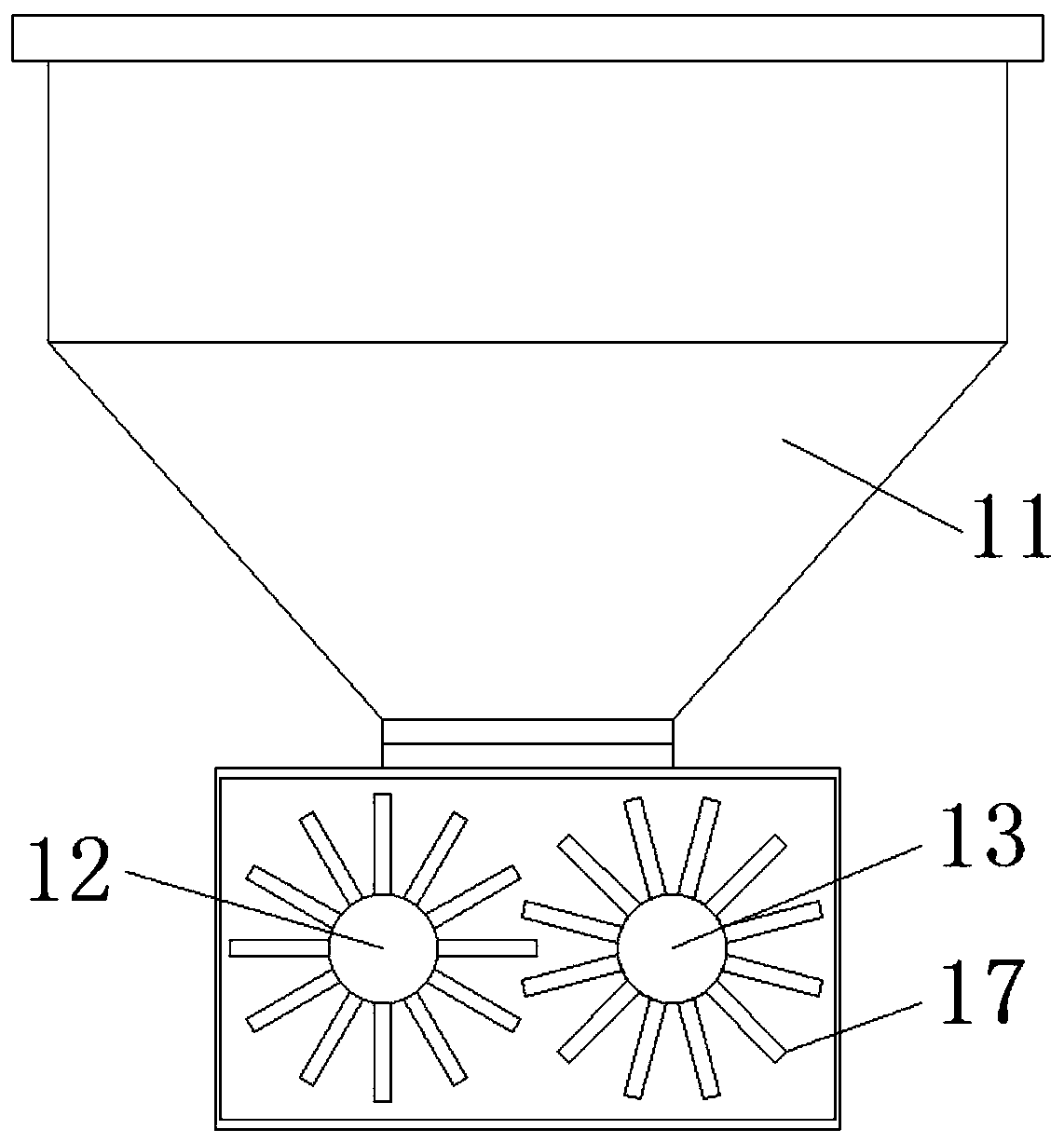

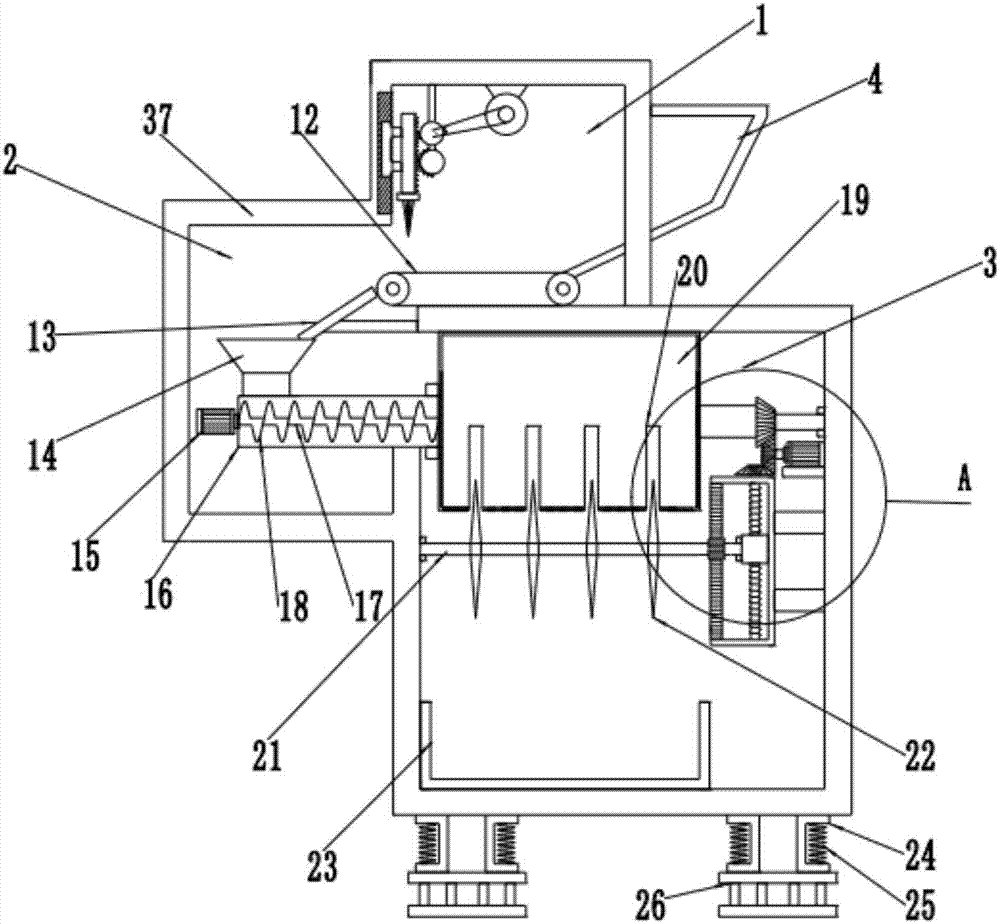

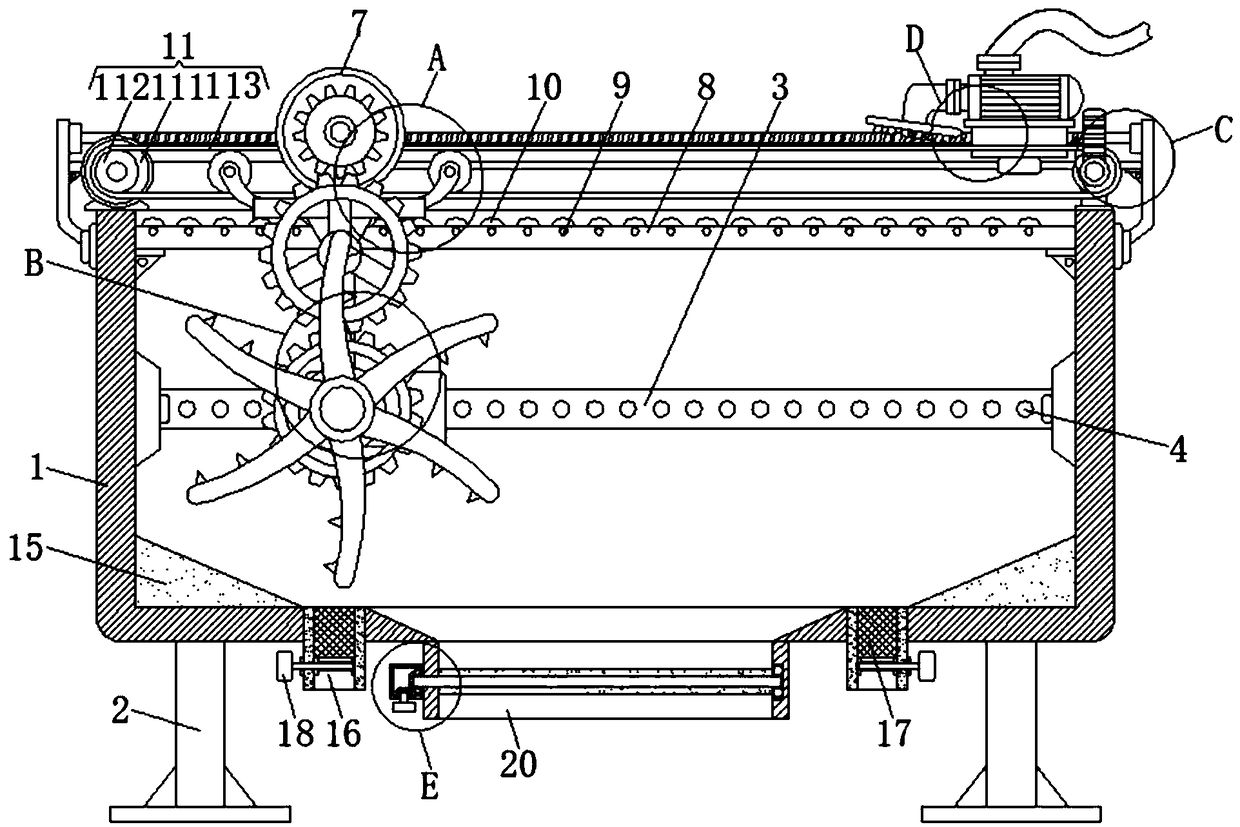

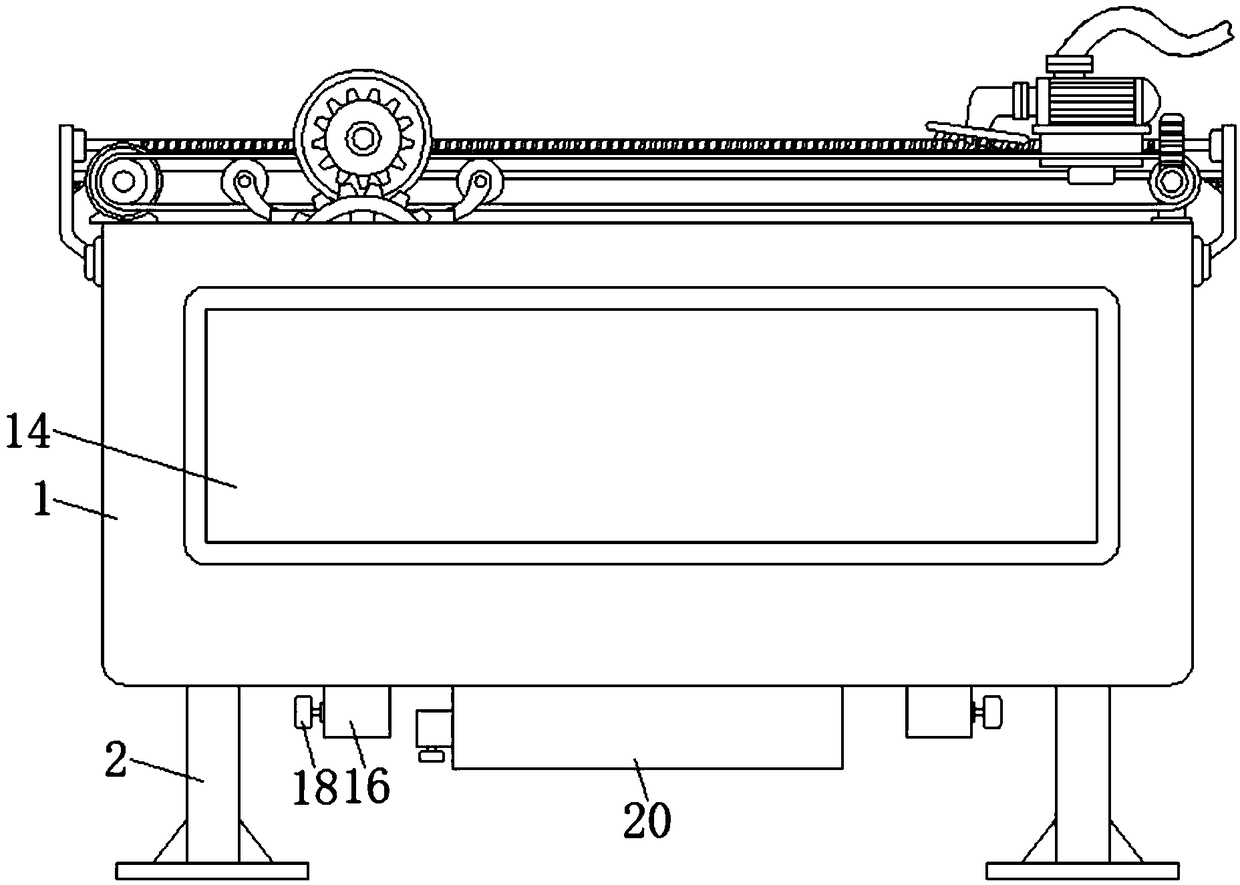

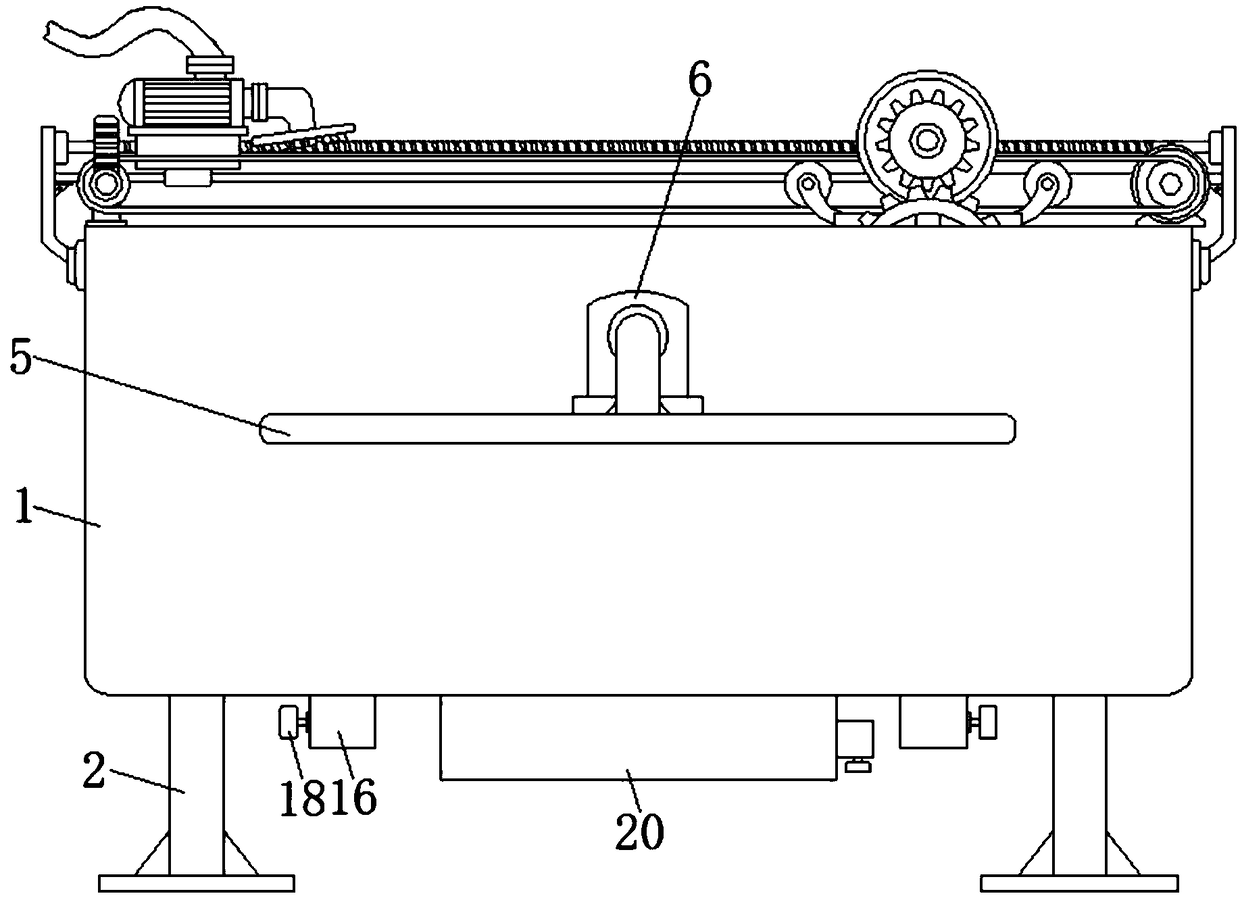

Brewer's grain vertical circulating drying device with material crushing function

InactiveCN107328201AExpand the drop areaEasy accessDrying gas arrangementsDrying machines with non-progressive movementsGastric tube feedingEngineering

The invention provides a beer grains vertical circulation drying equipment with crushing function, which includes a tank body; a cover plate is arranged at the top opening of the tank body; a feed pipe is welded and fixed on the left side of the cover plate surface, and the cover plate A dehumidification device is installed on the right side of the surface; a discharge pipe is welded and fixed on the bottom side wall of the tank body; a material distribution plate is welded and fixed in the middle of the tank body; a crushing and material distribution device is installed inside the tank body above the material distribution plate, and the tank body below the material distribution plate There is a stirring and drying device inside; a lifting device is provided on the outer wall of the tank; the invention breaks up the agglomerated beer grains through the crushing and distributing device, and evenly distributes the crushed beer grains to expand the whereabouts of the beer grains The area of the brewer's grains is stirred and turned by the stirring and drying device, and the hot air blown by the hot air blower is evenly distributed to facilitate full contact with the brewer's grains; the circulation of the brewer's grains is realized by the lifting device, which is beneficial to the beer's grains Provides thorough and even drying.

Owner:合肥多智科技开发有限公司

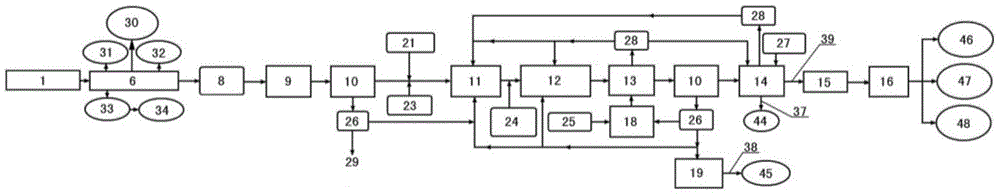

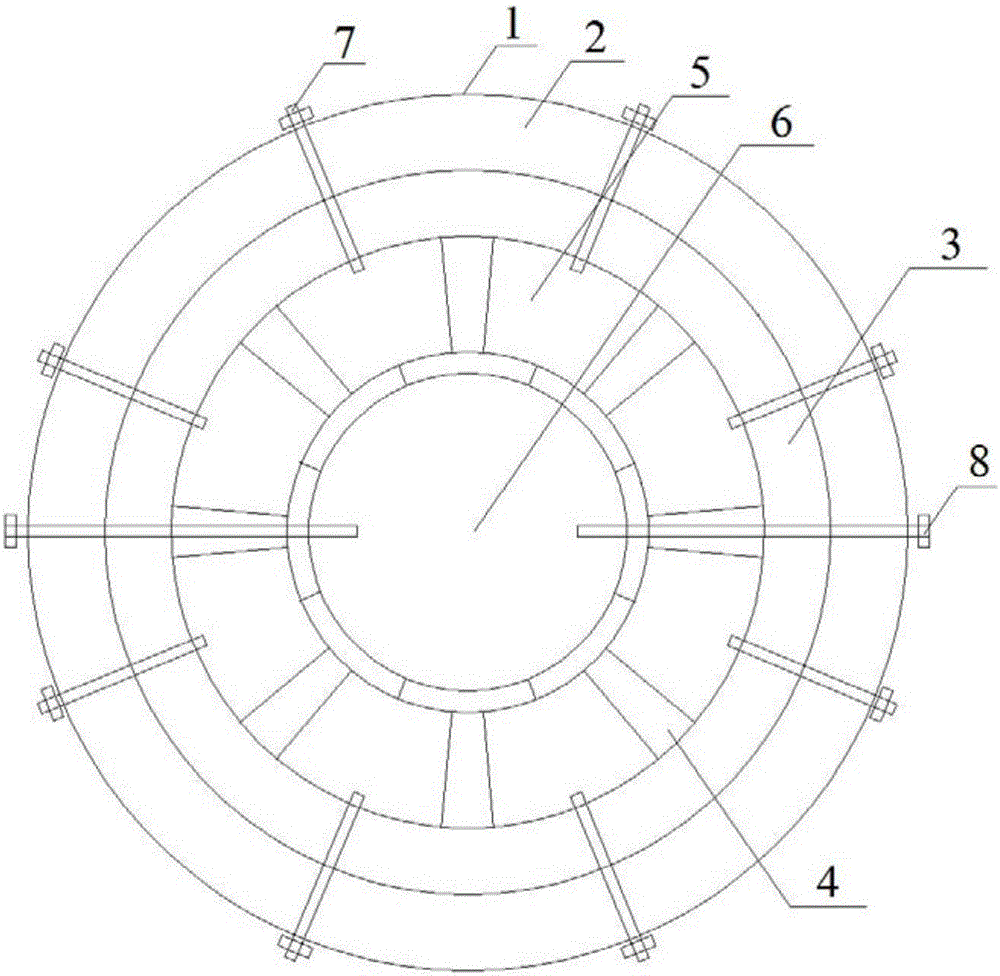

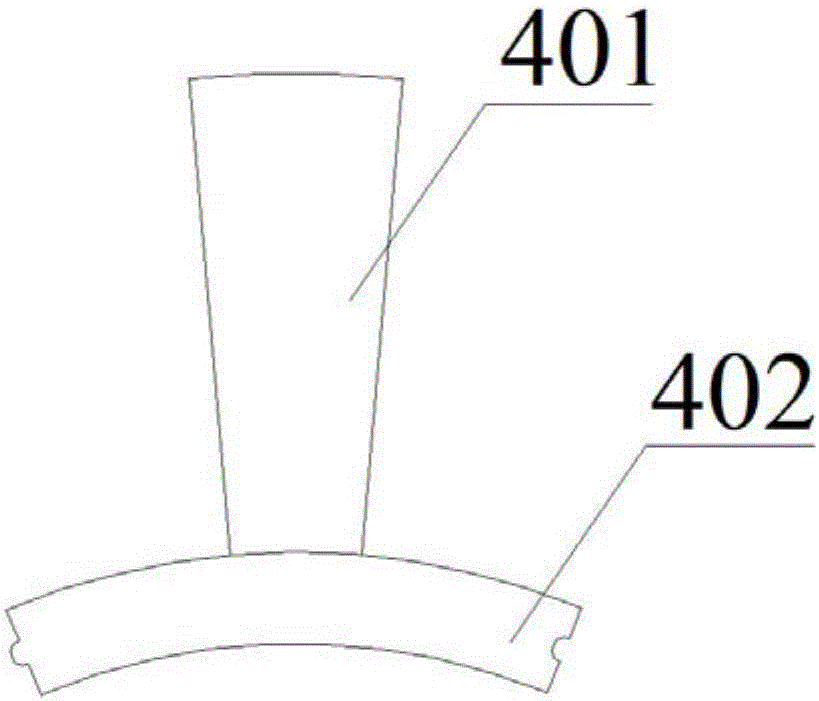

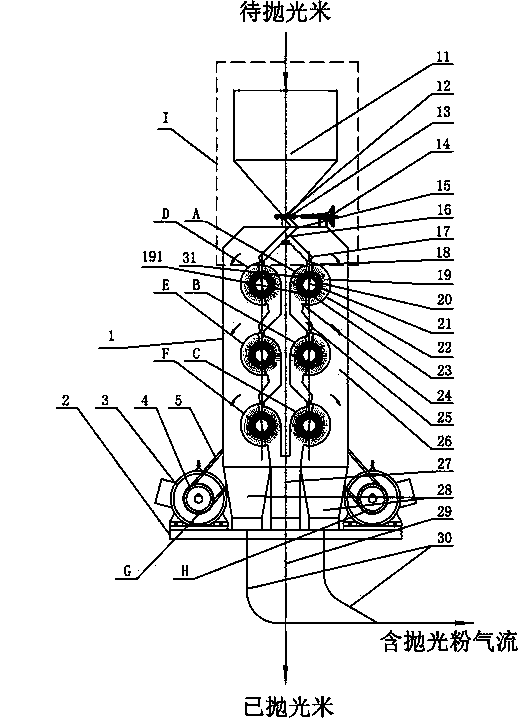

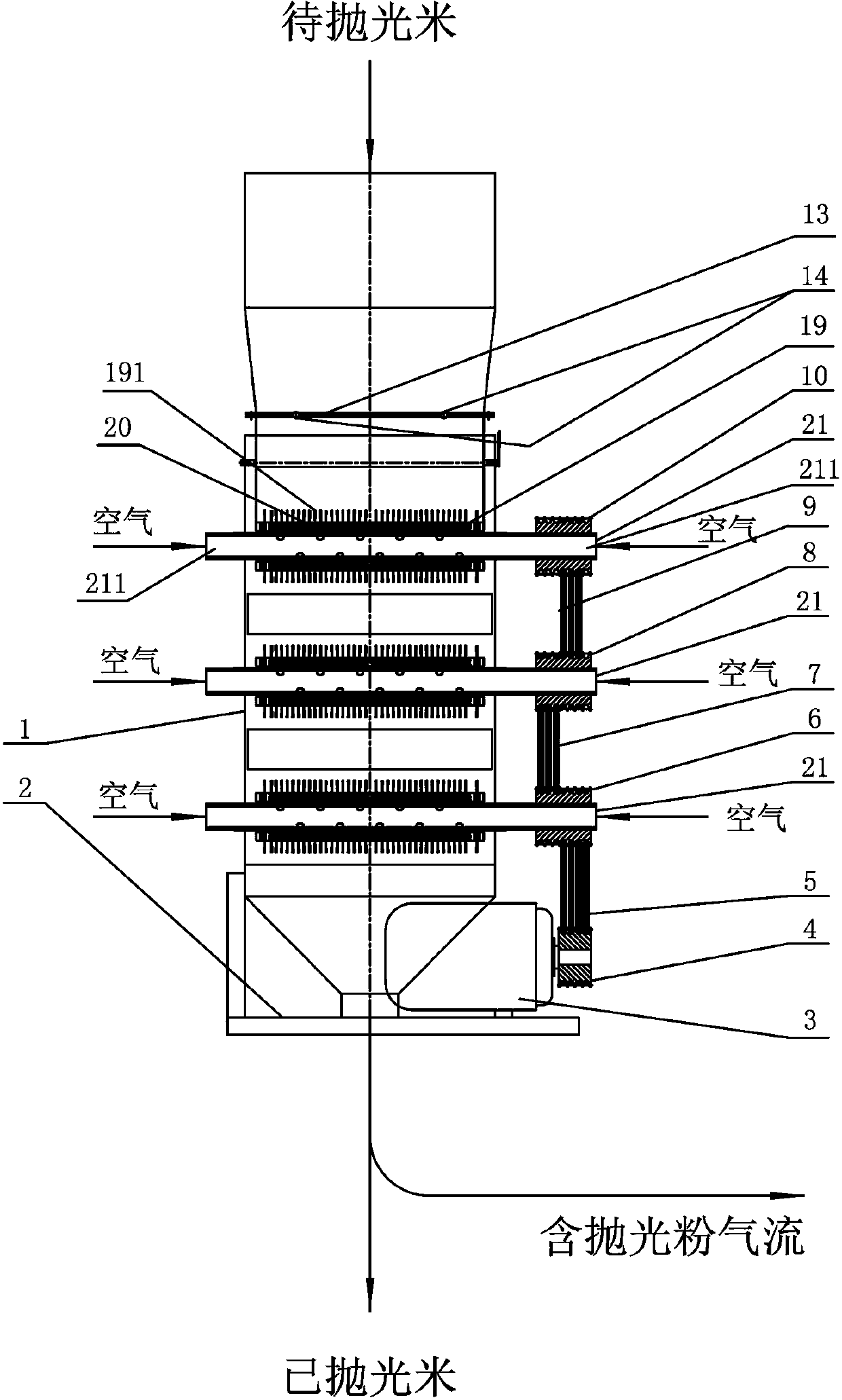

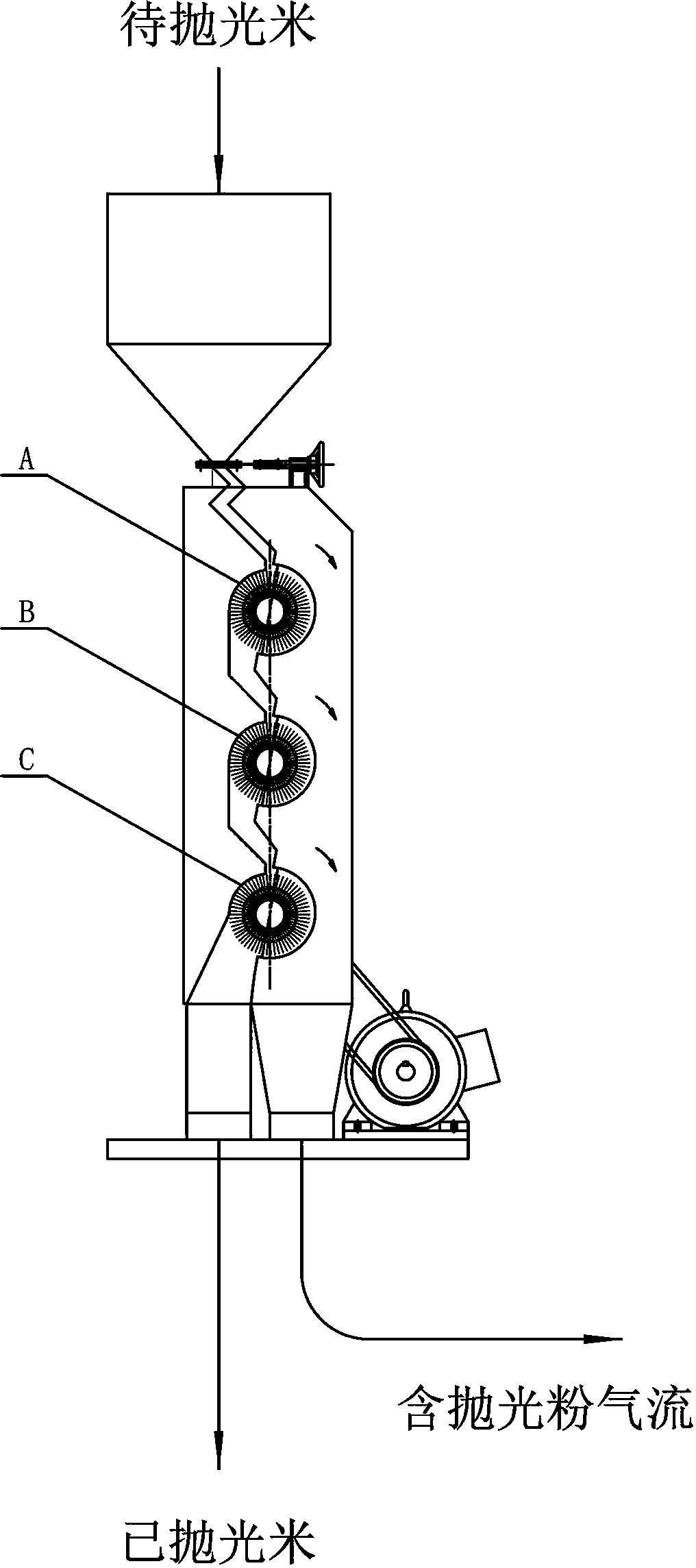

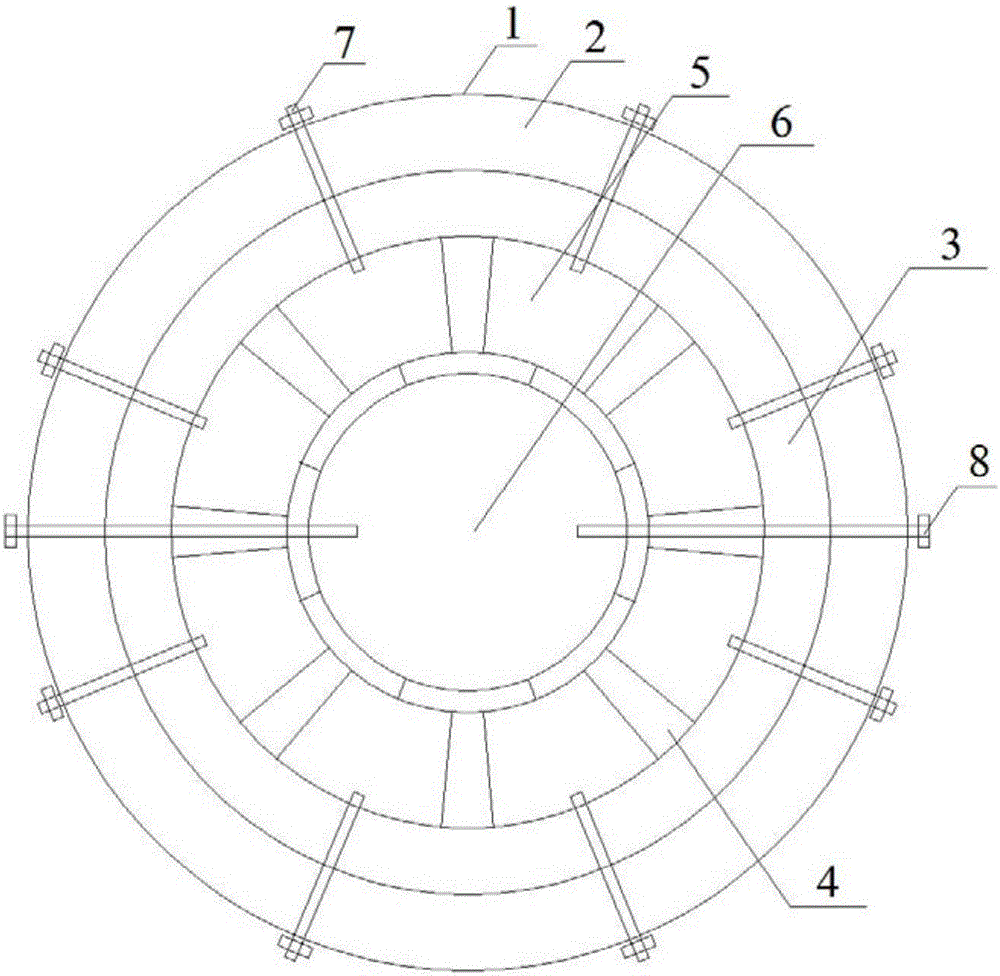

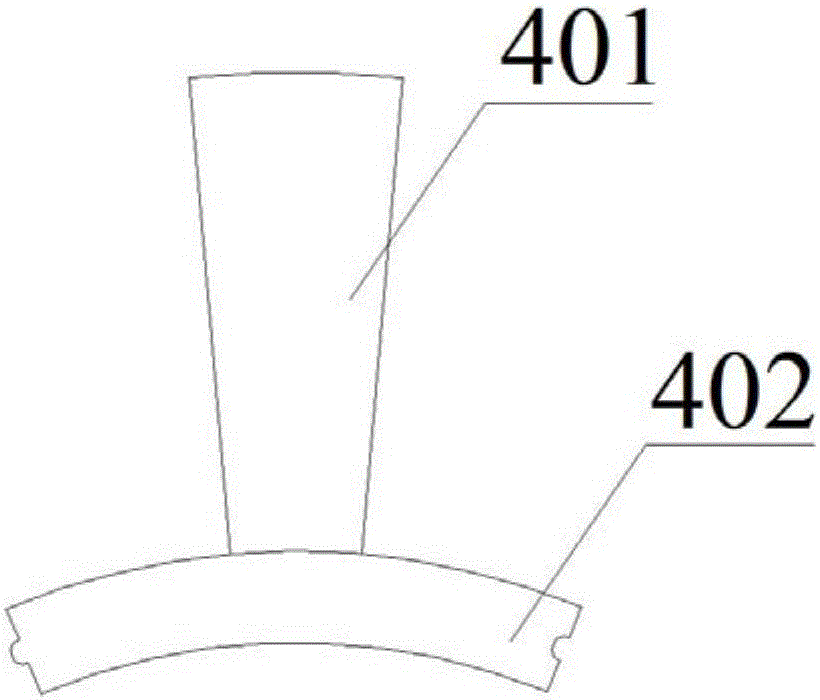

Flexible polishing device for granulated grains

ActiveCN104209156AAchieve moderate processingImprove the rice yieldGrain huskingGrain polishingFriction effectEngineering

The invention provides a flexible polishing device for granulated grains. The flexible polishing device comprises a shell, a feeding device, at least one flexible polishing unit, a bran discharging device and a rice outlet, wherein the flexible polishing unit comprises a radial gravity self-flowing flexible polishing chamber; the feeding device, the flexible polishing chamber and the rice outlet are sequentially arrayed from top to bottom along the gravity direction. According to the flexible polishing device for the granulated grains, the shear effect of the granulated grains in the polishing chamber is avoided, the flexible friction effect is improved, the damage to rice in the polishing process is greatly reduced while rice bran is cleaned and the rice is polished, the rice yield is improved and the energy consumption is reduced.

Owner:周颖

Recycled concrete mixer capable of improving mixing uniformity

InactiveCN111745820AWell mixedImprove work efficiencyCement mixing apparatusBLENDER/MIXERStructural engineering

Owner:苏州一统混凝土有限公司

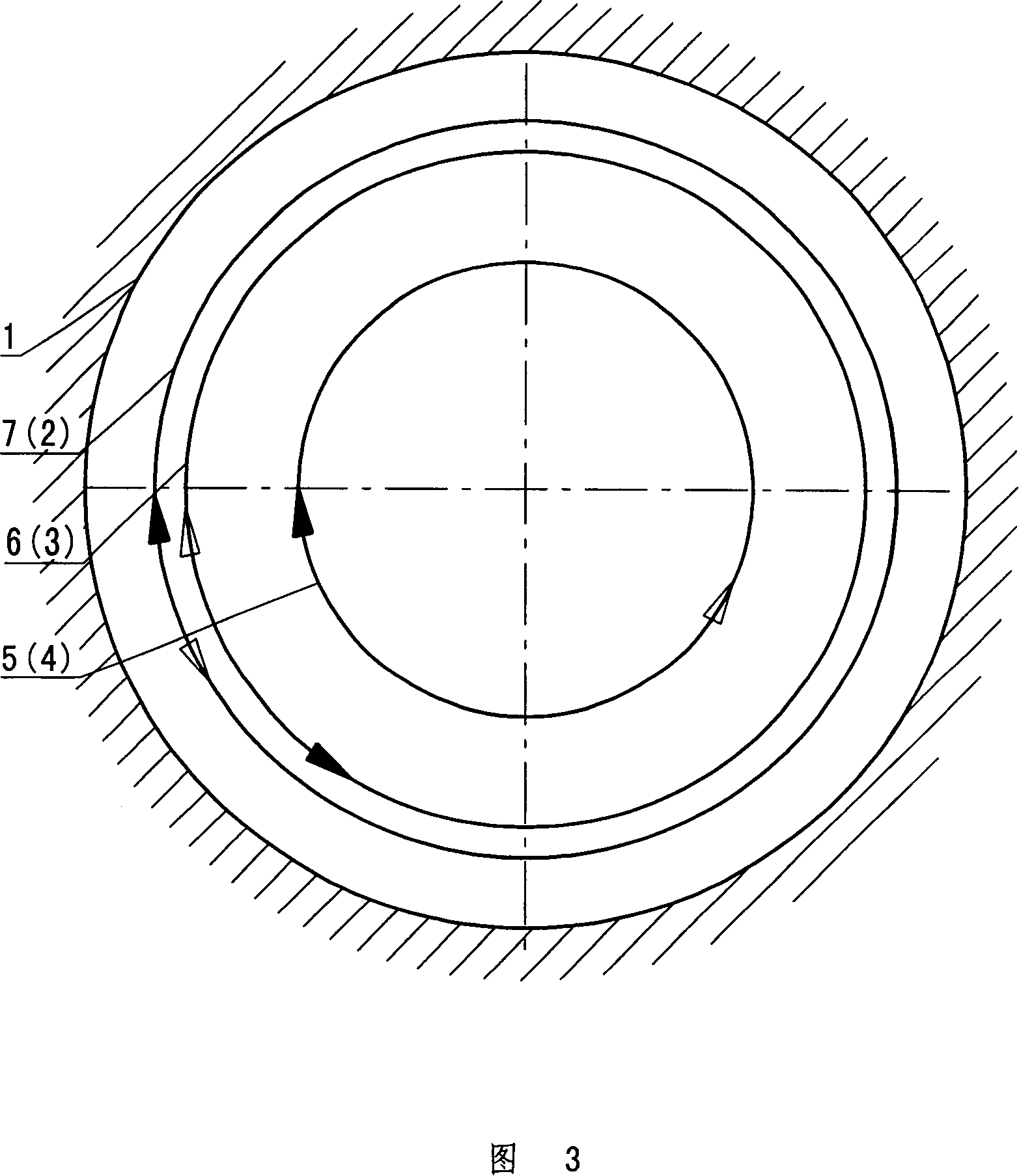

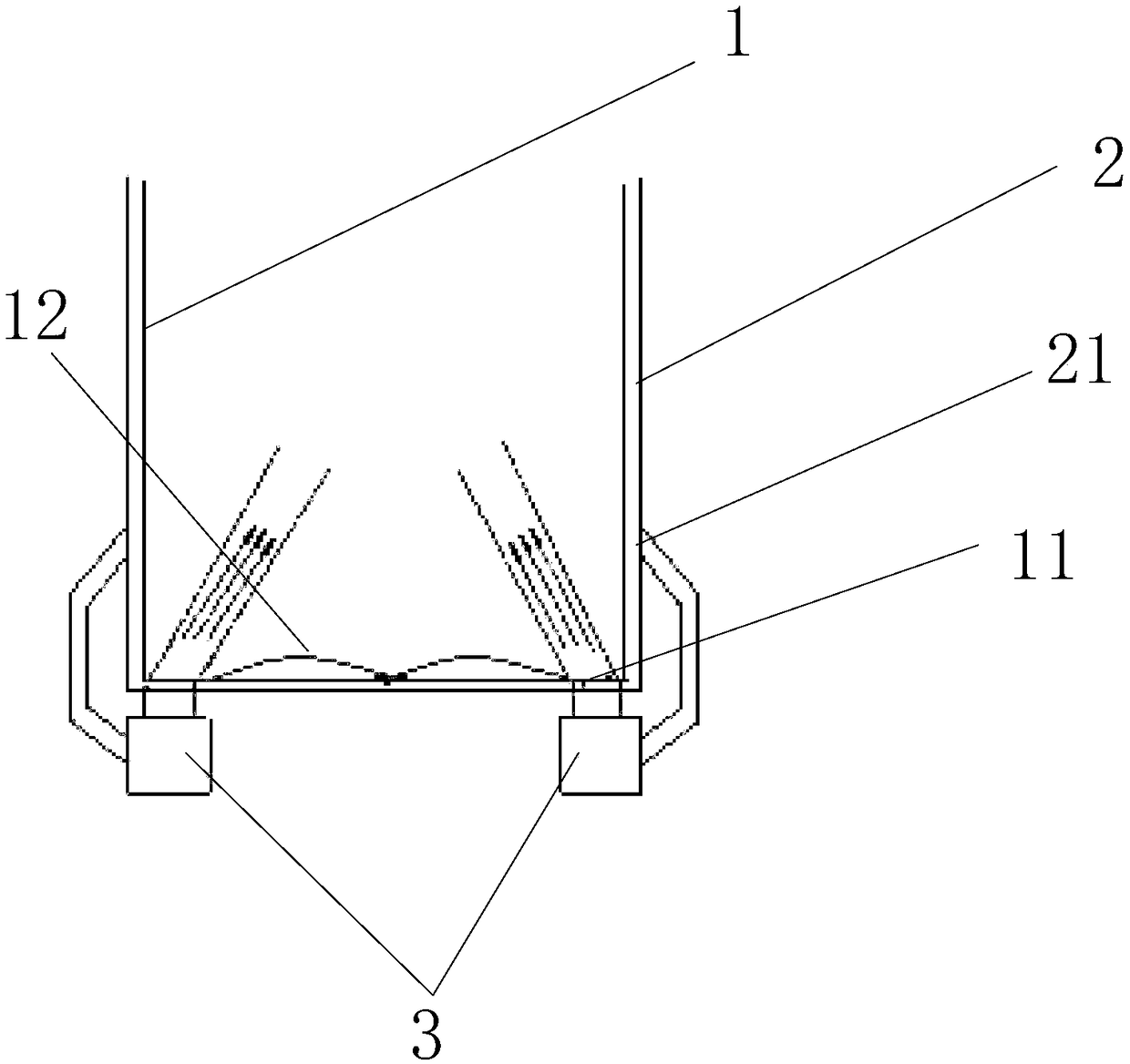

Washing machine deceleration clutch, washing machine and washing mode thereof

ActiveCN101210373AOptimize internal structureReduce manufacturing costOther washing machinesToothed gearingsClutchEngineering

A decelerating clutch of a washer and the washer and a washing mode thereof relates to the technical field of washers. An output shaft of the decelerating clutch includes a small wave wheel shaft, a large wave wheel shaft and a dewatering shaft. By adopting optimized inner structure design, the invention can simultaneously drive the larger and the small wave wheels to rotate actively, and a brake wheel is directly connected with the dewatering shaft and an input shaft sleeve, thus reducing the production cost. A washer manufactured by using the decelerating clutch comprises a small wave wheel and a large wave wheel, wherein the small wave wheel is fixedly arranged on the small wave wheel shaft and positioned at the middle portion of the large wave wheel; the large wave wheel is fixedly arranged on the large wave wheel shaft; and an inner barrel is fixedly arranged on the dewatering shaft. The washer manufactured by using the decelerating clutch is operated in such a mode that the small wave wheel, the large wave wheel and the inner barrel make reciprocating rotation in mutually reverse directions at different speeds and different rotation angles by a ratio in two directions to produce complex and crossing shock water flow to scrub and clean the clothes, thus completely rotating the clothes, achieving strong scrubbing force, improving the cleaning rate and preventing twisting of the clothes.

Owner:NINGGUO JULONG IND

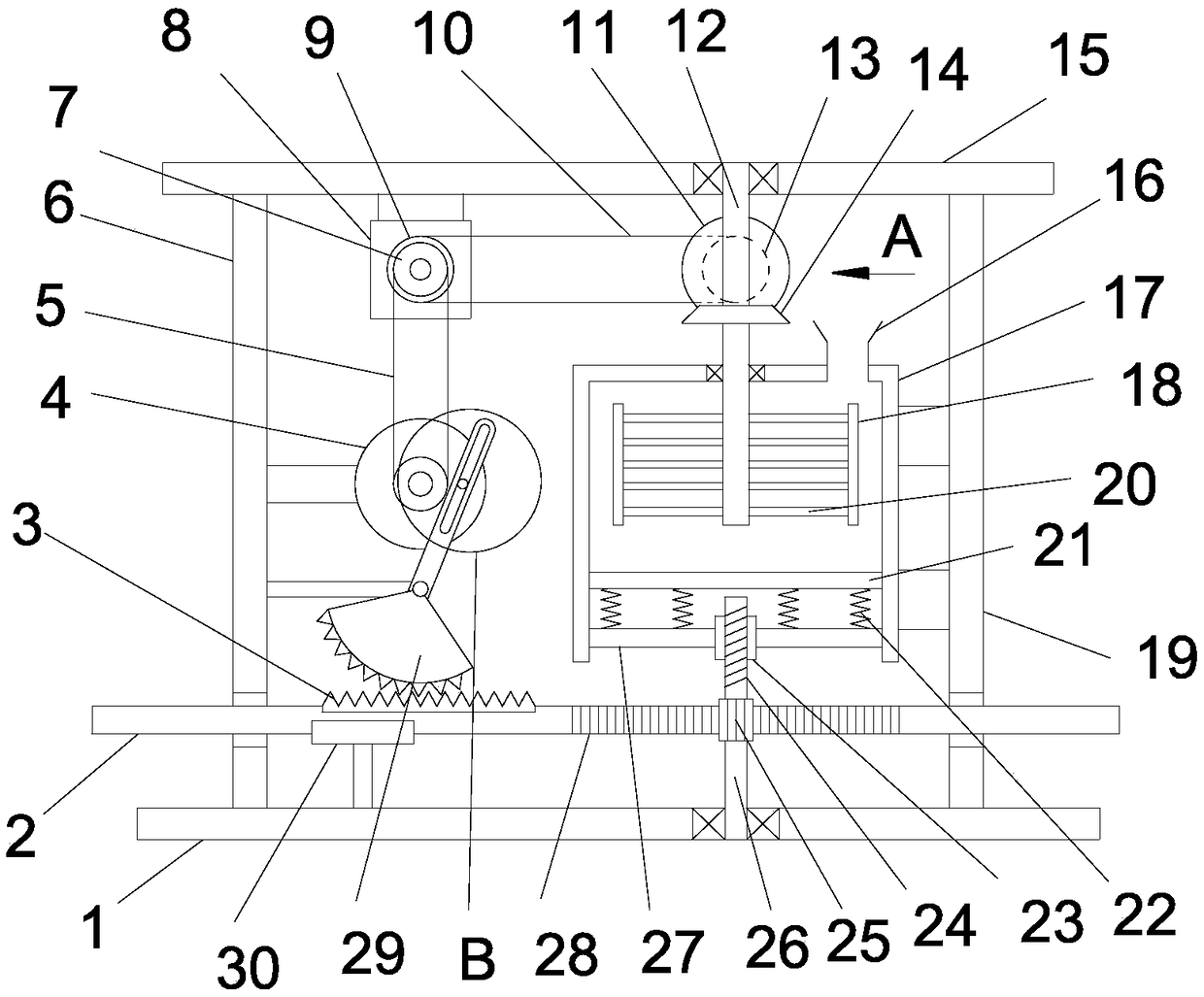

Efficient barrel type grinding and screening device for traditional Chinese medicine pharmacy

The invention discloses an efficient barrel type grinding and screening device for a traditional Chinese medicine pharmacy. The efficient barrel type grinding and screening device comprises a bottom plate, supports, a conveying mechanism, a grinding mechanism and a screening mechanism. The supports are fixedly mounted at the upper end of the bottom plate. Supporting plates are fixedly mounted on the inner sides of the two vertical supports. The conveying mechanism is arranged at the upper ends of the supporting plates and comprises a second rotary shaft, a conveying cavity, a feeding hopper, aspiral blade, a cutting knife, a stirring rod, an air blower and a heating device. The grinding mechanism is arranged under the supporting plates. The screening mechanism is arranged below the grinding mechanism and comprises a bevel gear A, a bevel gear B, a crankshaft, a connecting rod, a screening plate, a first collection groove and a second collection groove. The efficient barrel type grinding and screening device is novel in design and stable in structure, the crushing process and the drying prices are additionally conducted before grinding, the subsequent grinding efficiency is improved, the grinding effect is good, traditional Chinese medicines which do not meet the standards can be screened out after grinding, the machining procedures are reduced, and the practicability is high.

Owner:甘肃省和顺元中药饮片有限公司

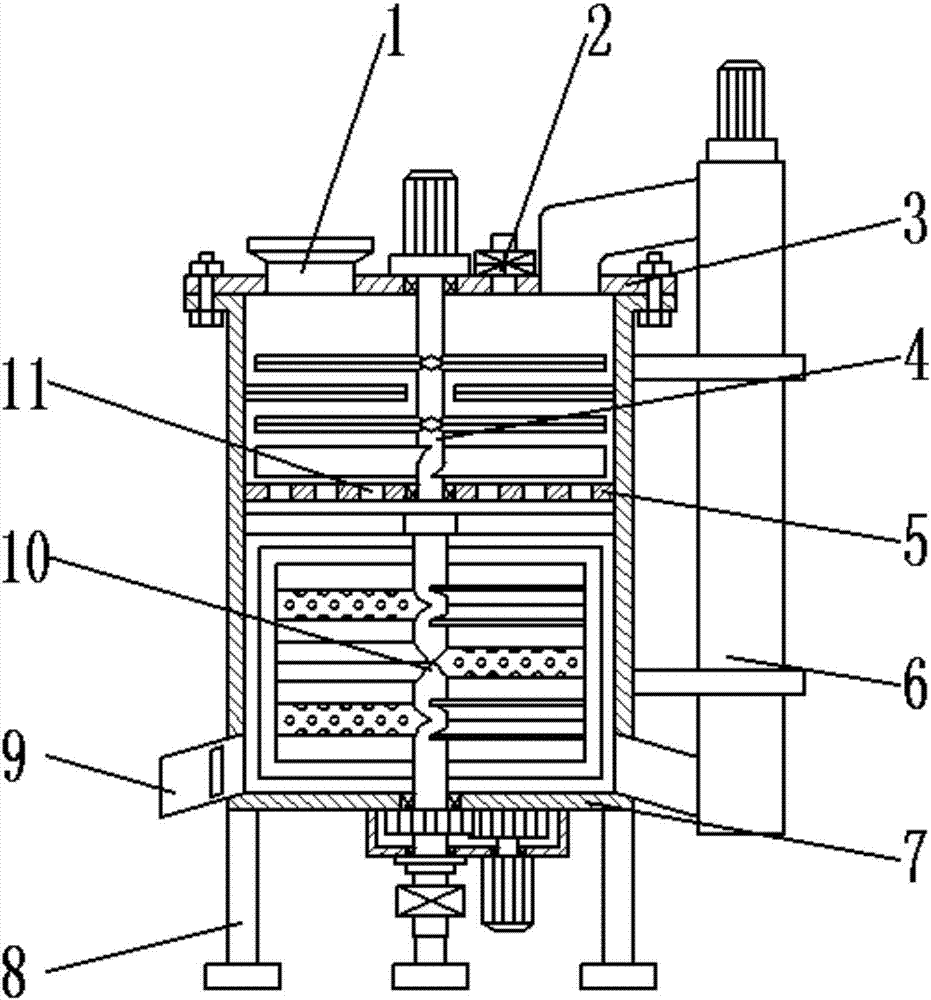

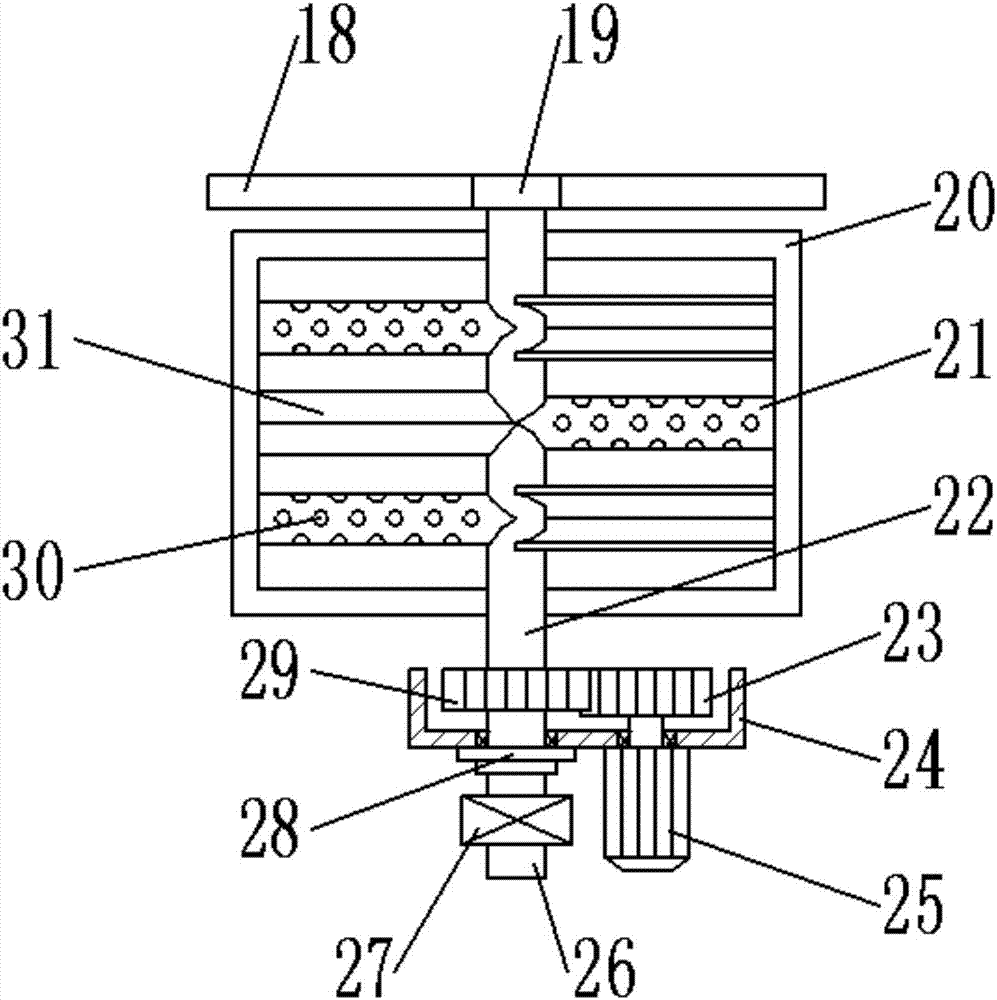

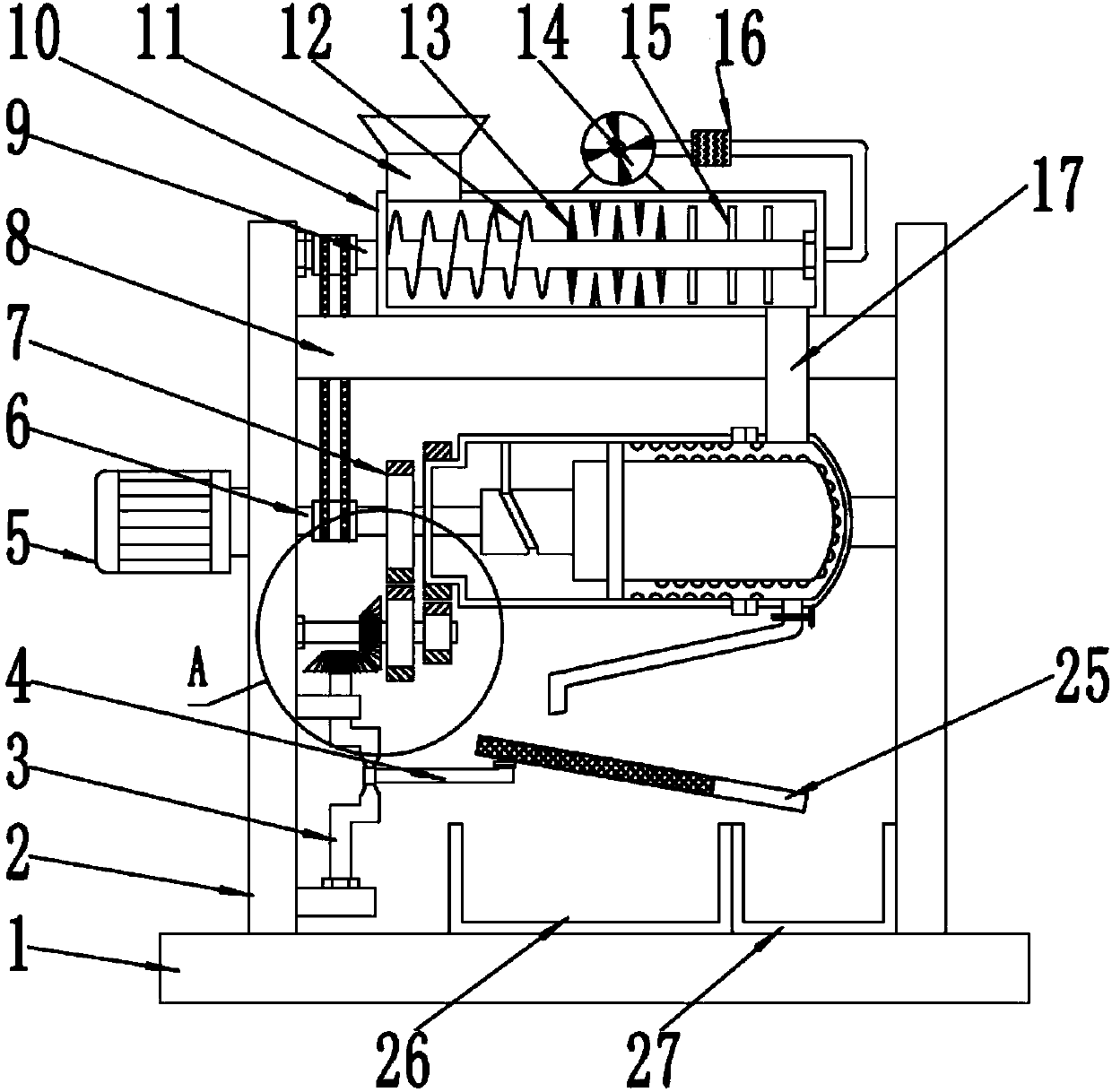

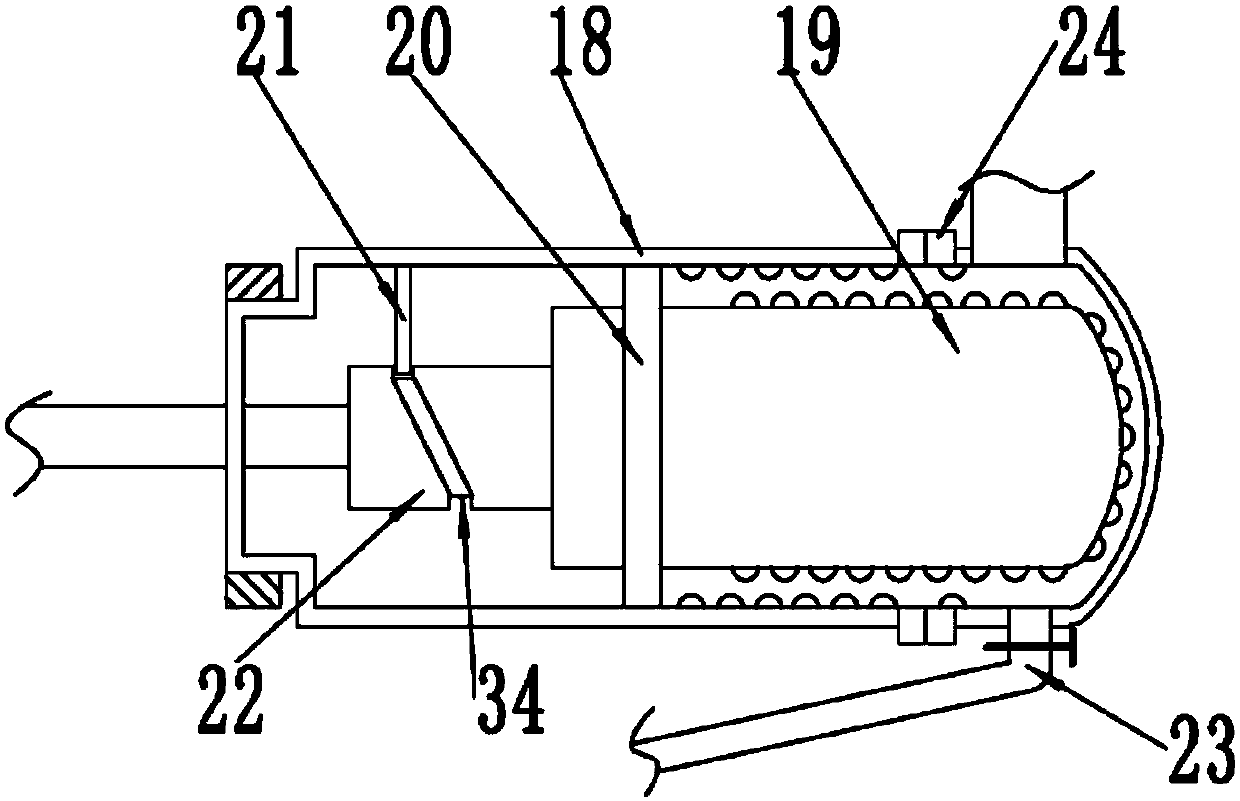

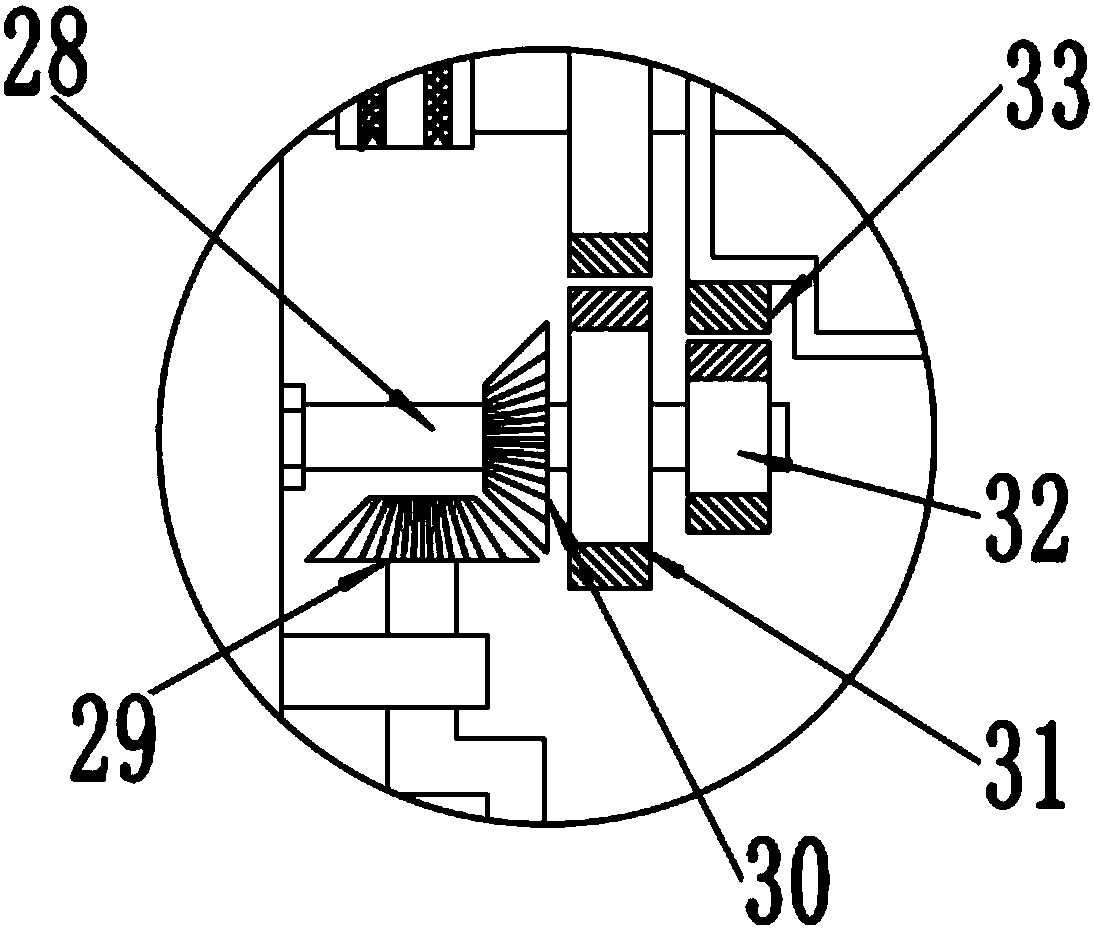

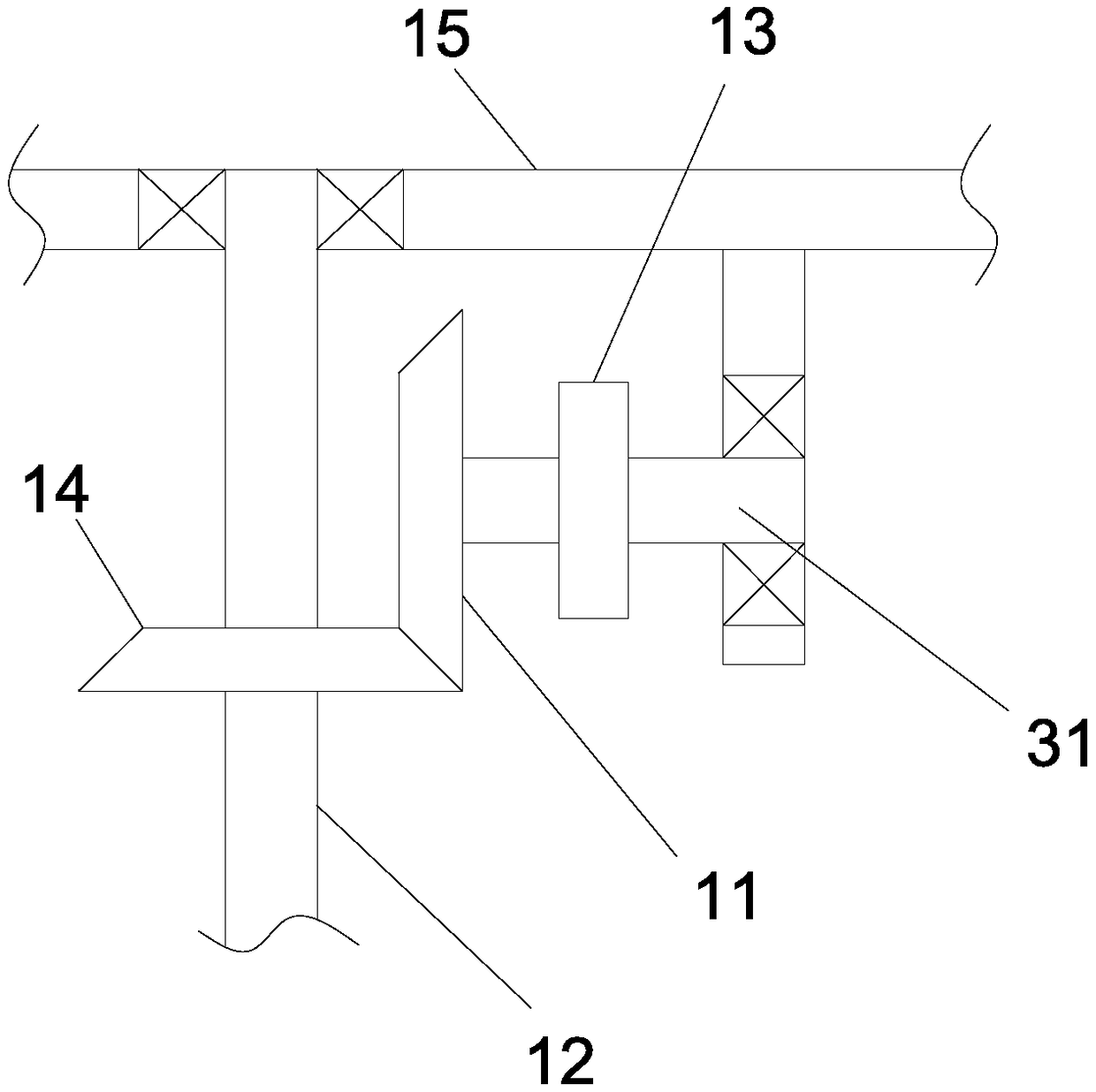

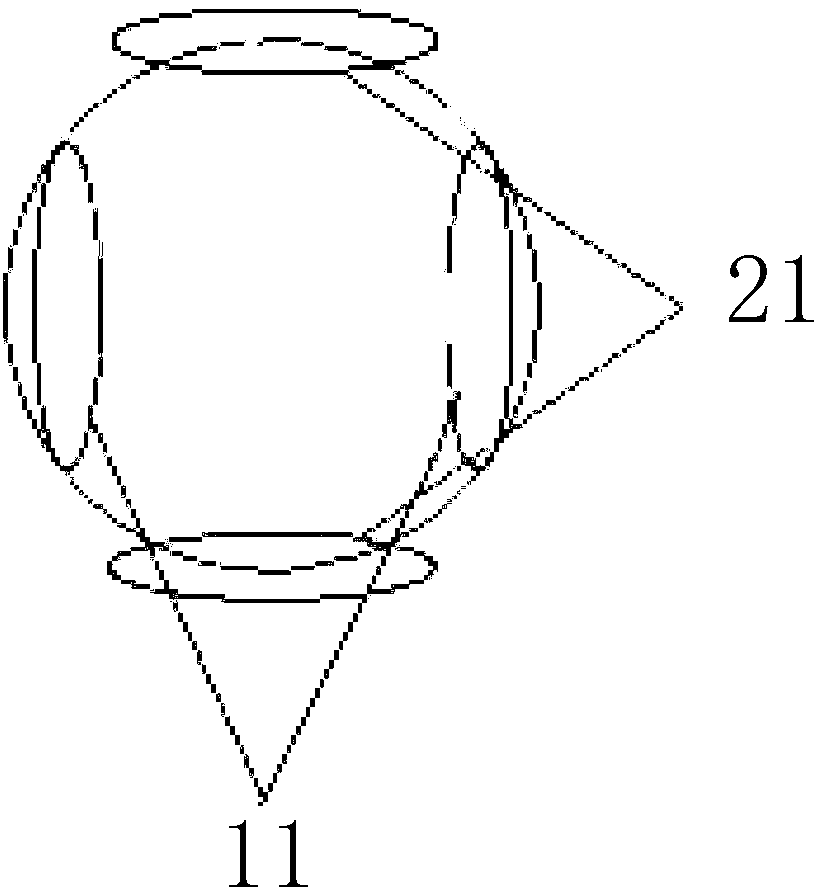

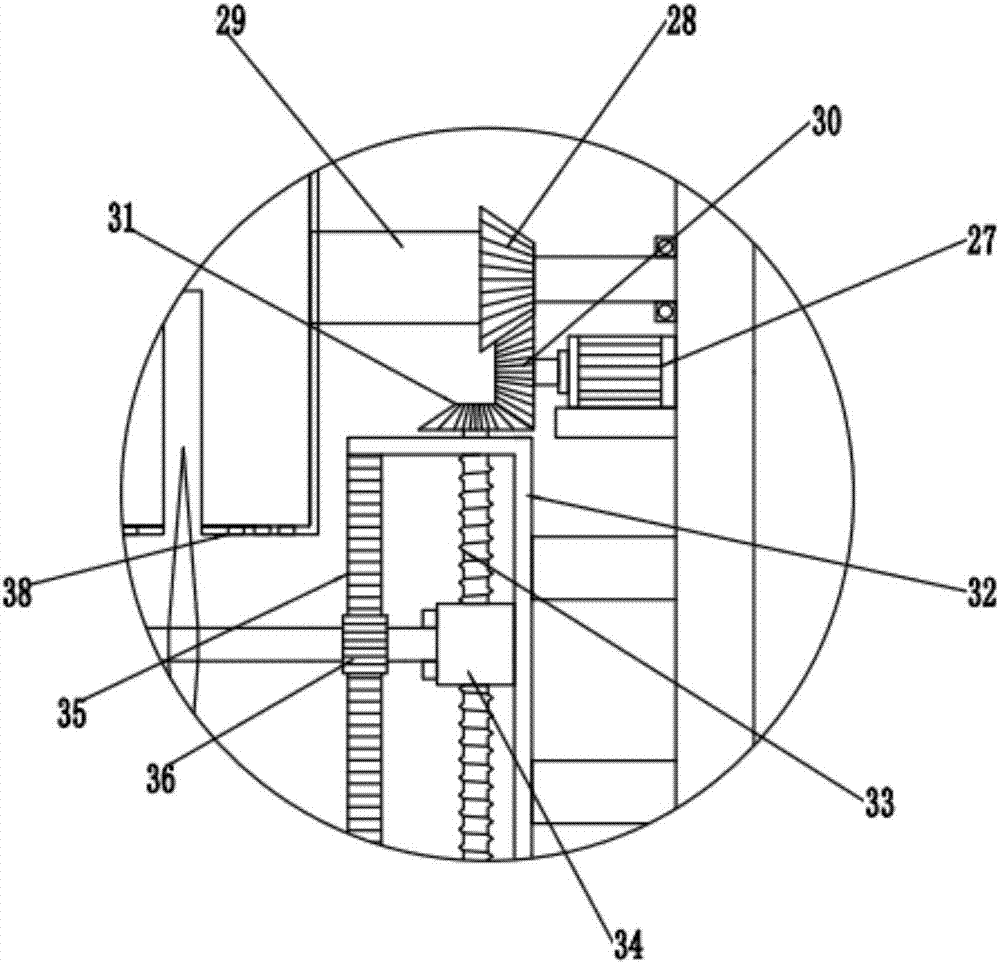

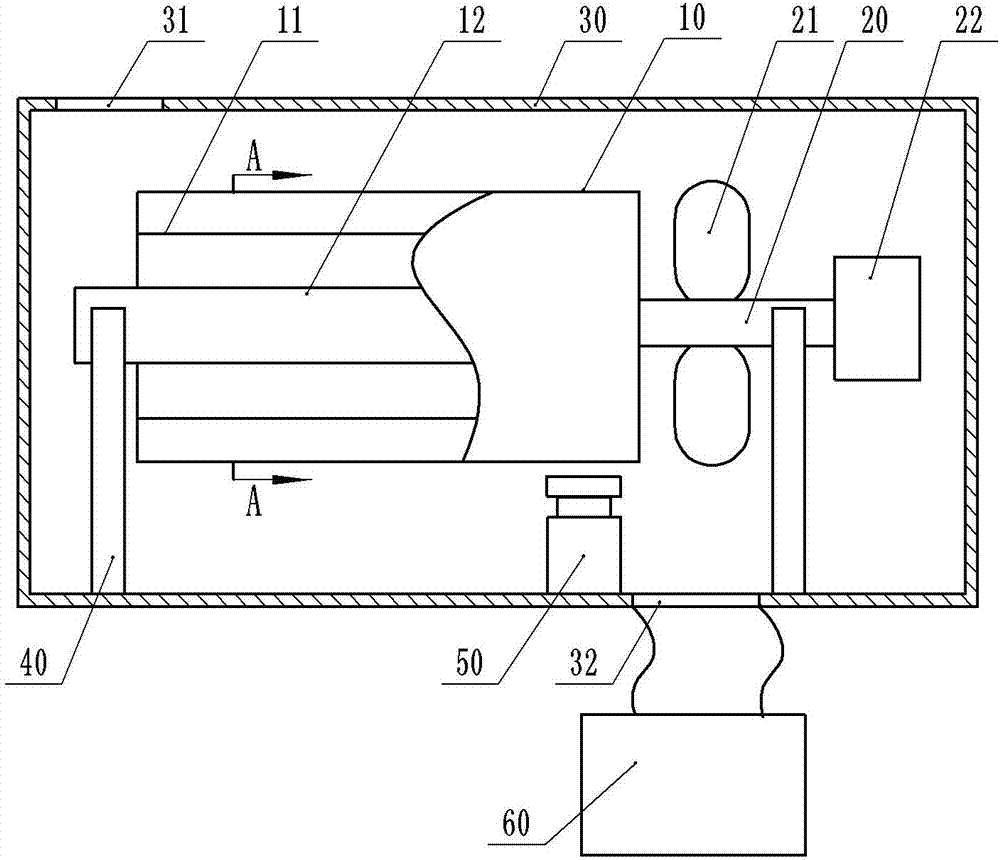

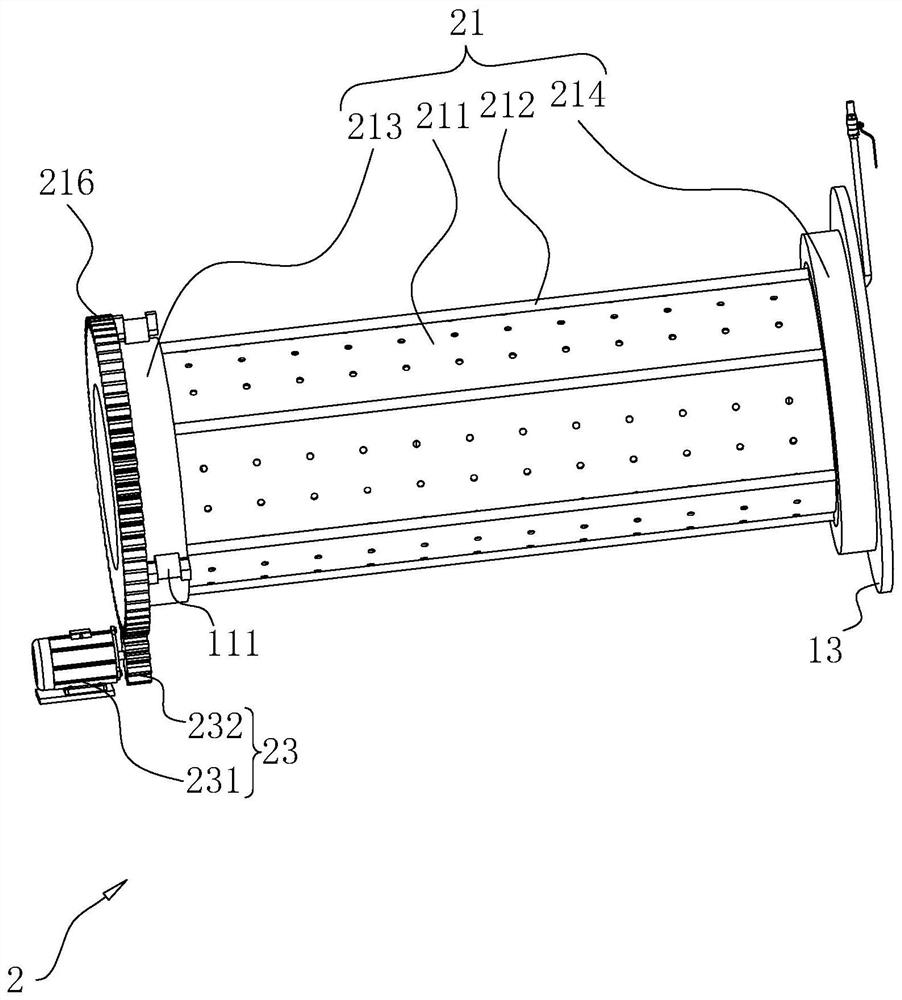

Furnace body of activated carbon activation furnace

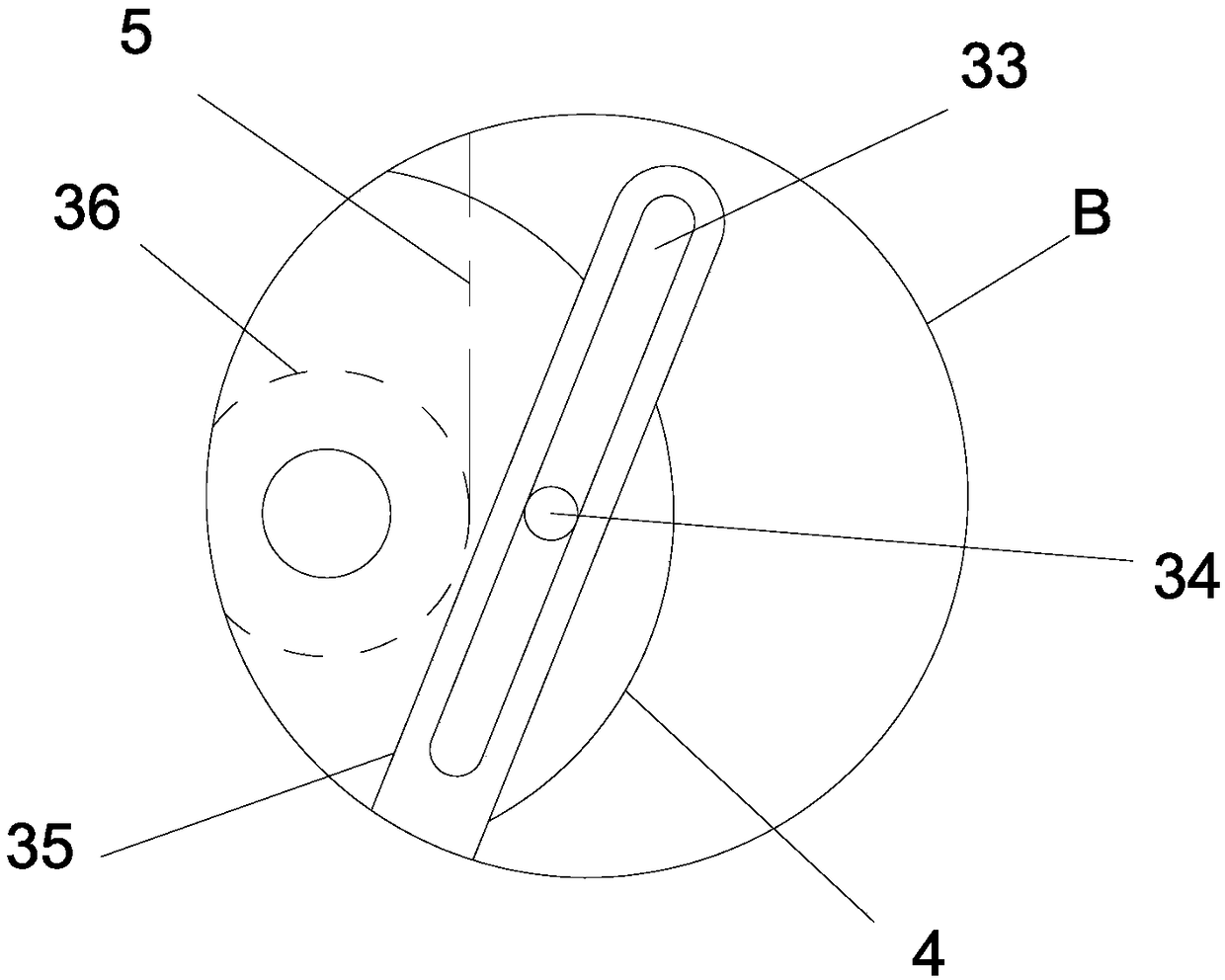

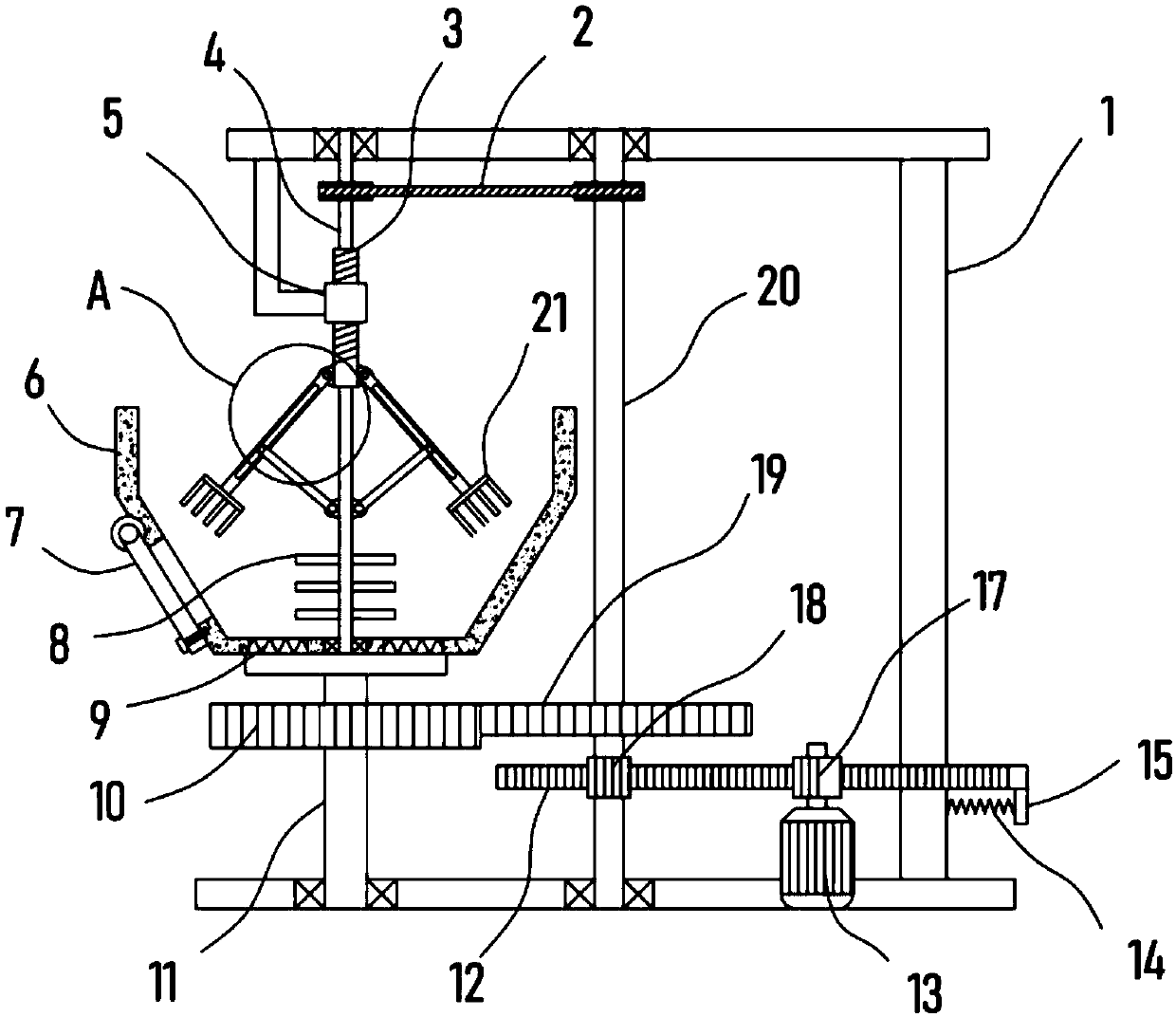

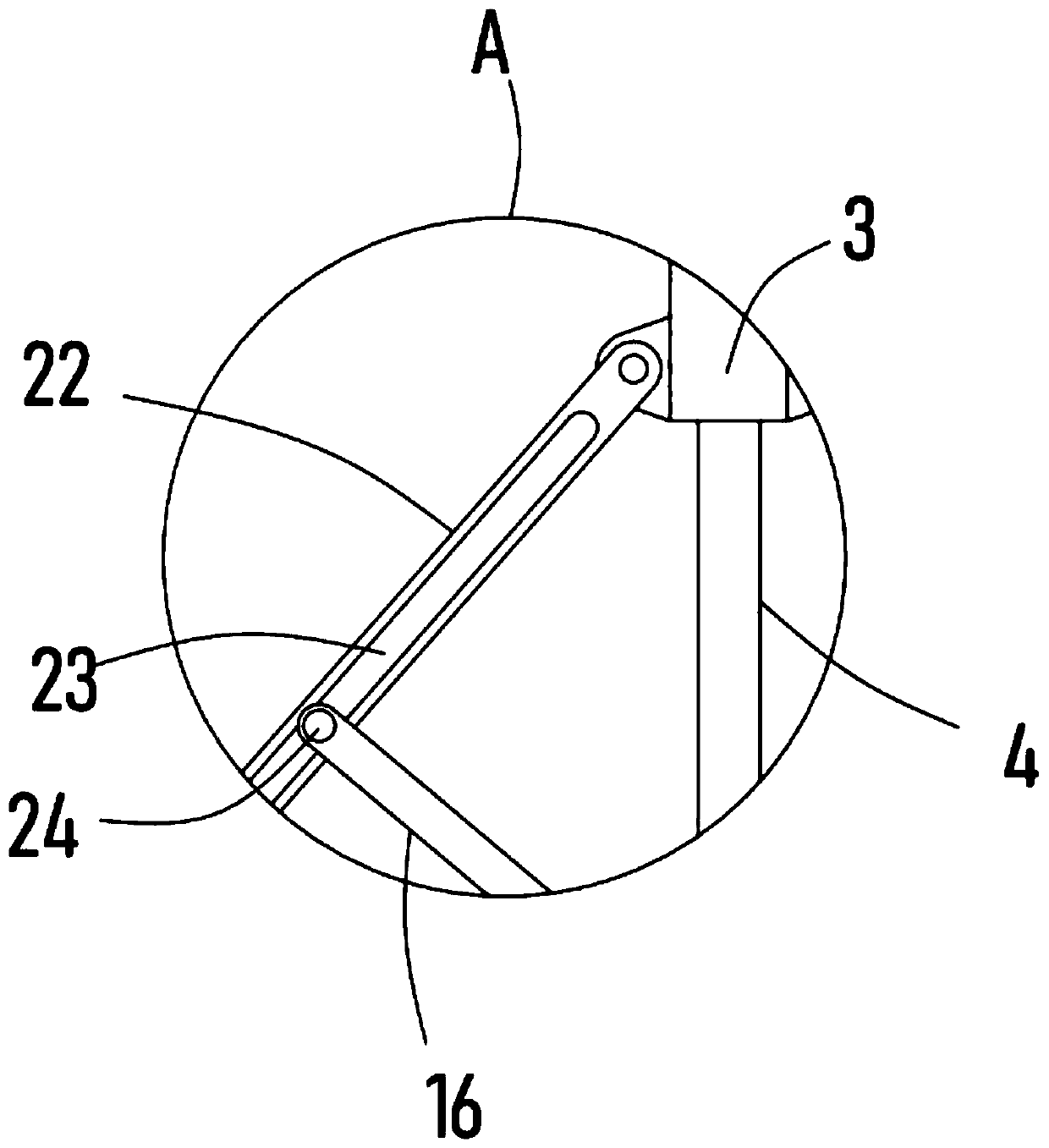

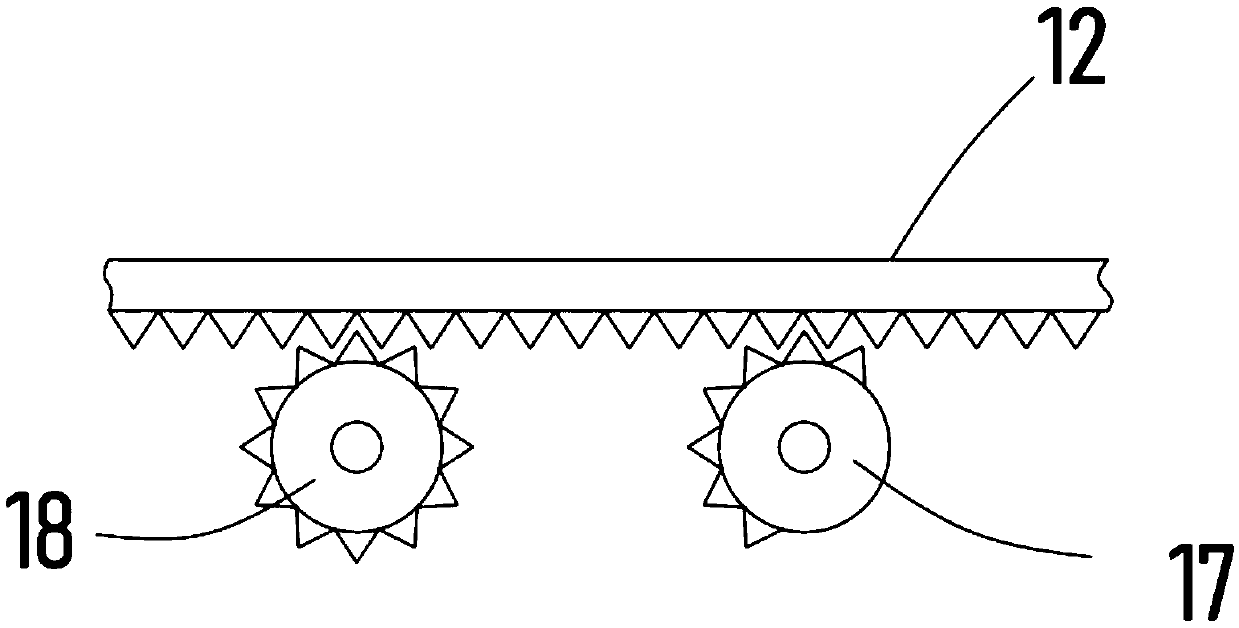

ActiveCN106276889AIncrease the number of flipsFlip fullRotary drum furnacesActivated carbonCombustion chamber

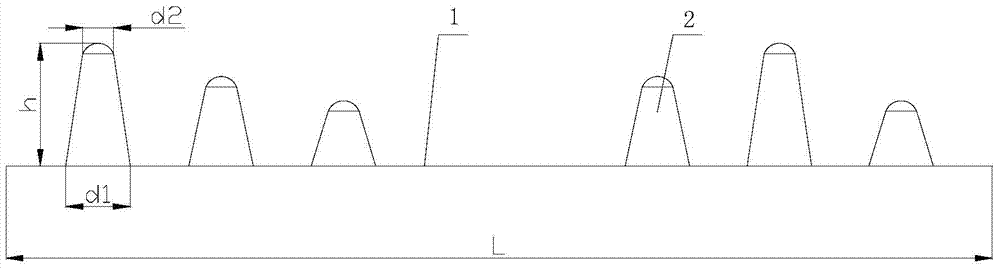

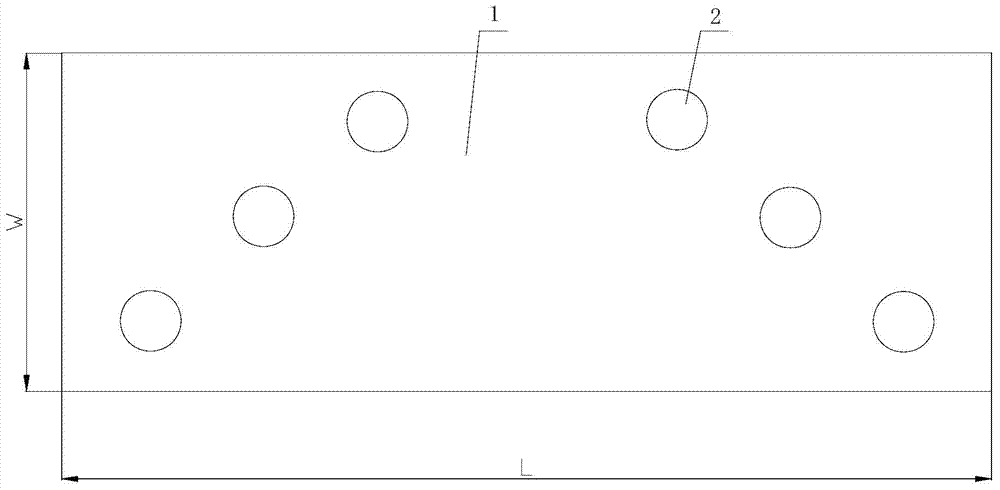

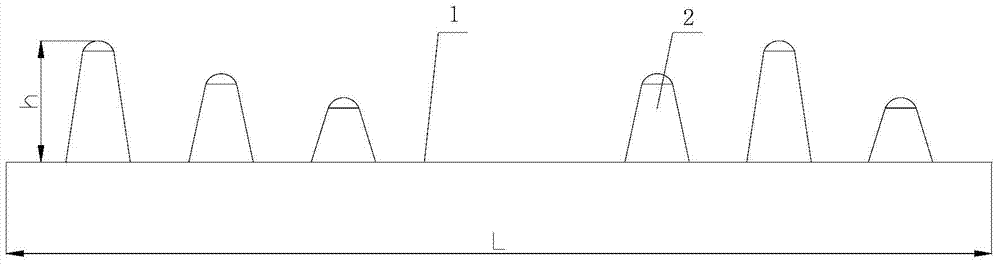

The invention discloses a furnace body of an activated carbon activation furnace, and relates to the field of activated carbon production devices. The furnace body can improve the safety of the activated carbon production process to a certain degree, can stably run for a long time, and can greatly improve the quality and yield of produced activated carbon. The furnace body is internally provided with a combustion channel communicated with the interior of the furnace body. Air is introduced in the combustion chamber. The interior of the furnace body is divided into at least two material channels. The material channels are arranged in the length direction of the furnace body. Vapor is introduced in each material channel. The furnace body comprises an outer cylinder. At least two branch warehouse supporting pieces are arranged in the circumferential direction of the inner wall of the outer cylinder and form the combustion chamber. One material channel is formed among two adjacent branch warehouse supporting pieces, the inner wall of the outer cylinder and the outer wall of the combustion chamber. The furnace body is mainly used for producing activated carbon.

Owner:张西进

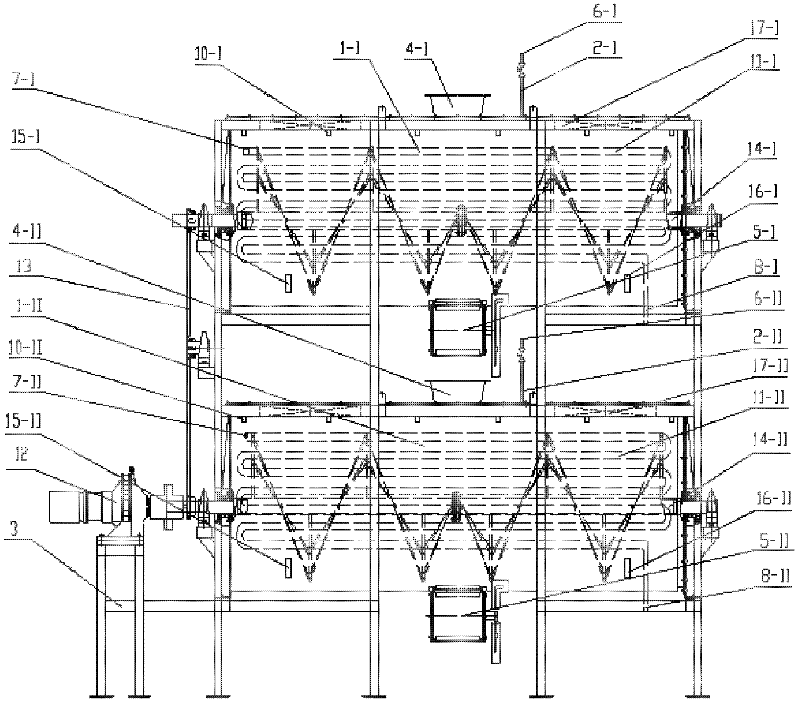

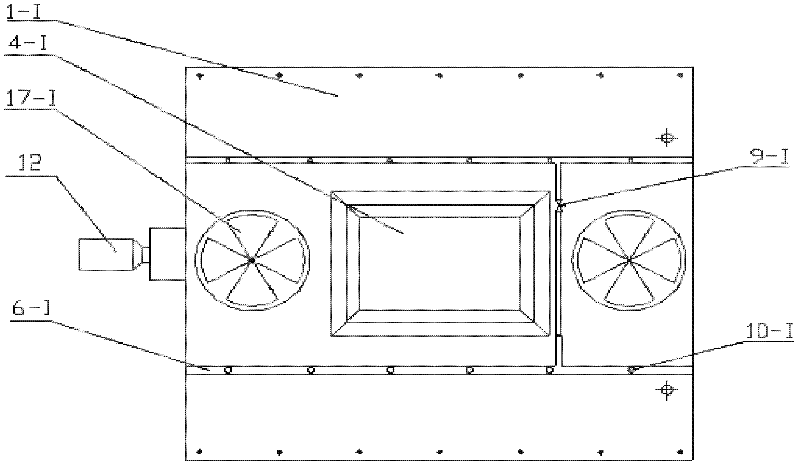

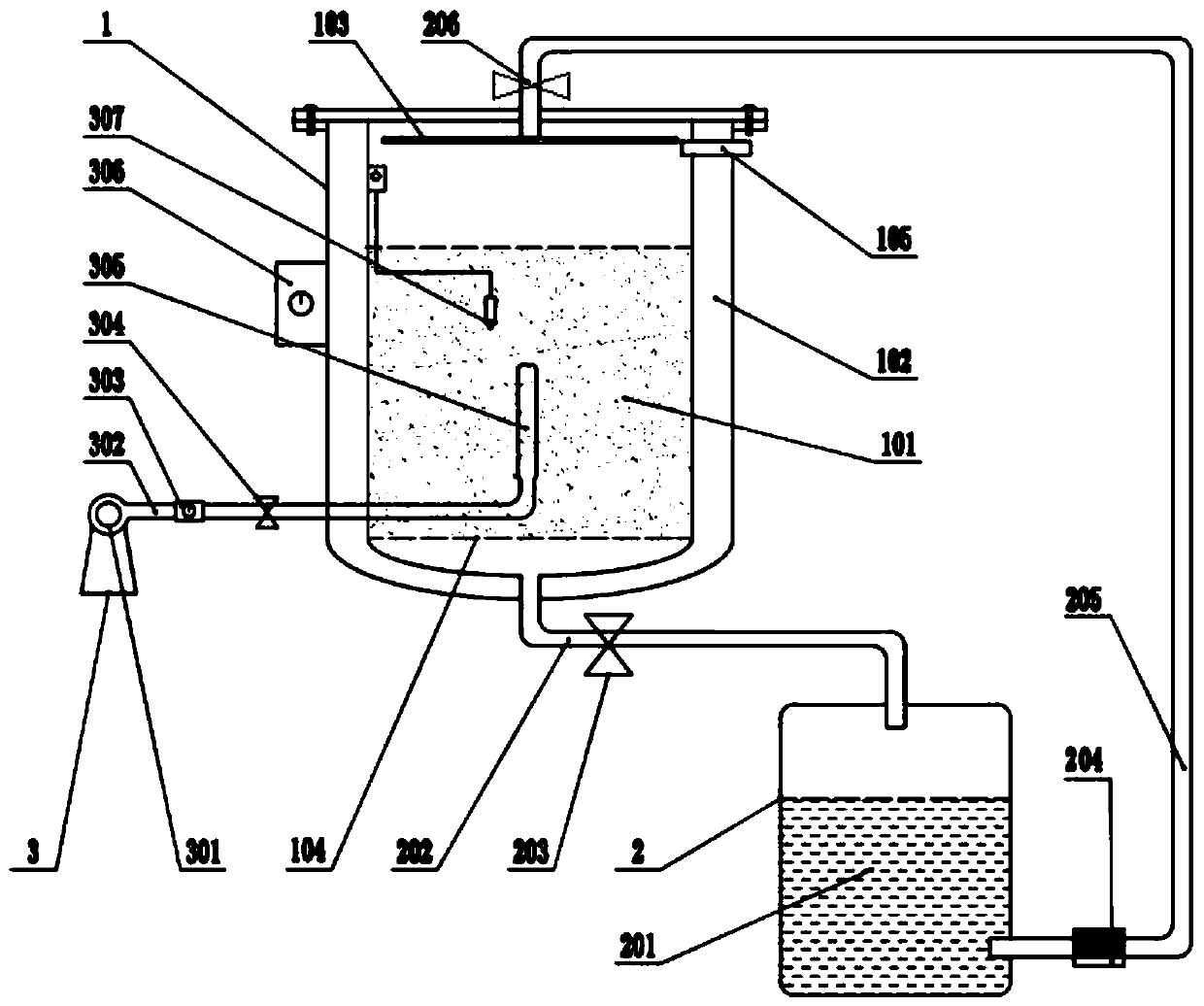

A kind of biomass fermentation reaction device and its application

ActiveCN102286361AReduce energy consumptionLow costBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlOxygen

The invention relates to a biomass fermentation reaction device, which consists of a fermentation reactor, a liquid adding pipeline, a heating device, a stirring device, a temperature measuring device, a moisture measuring device and a support frame, wherein the fermentation reactor comprises an upper layer fermentation reactor and a lower layer fermentation reactor, and the fermentation reactor is in a rectangular box type structure and is fixed on the support frame in an overlapped type. The reaction device is used for carrying out the biomass fermentation reaction by adopting a method of adding bacterium liquid and adopting a two-step fermentation method. The reaction device has the characteristics that the energy consumption is low, the cost is low, the operation is easy, and safety and reliability are realized. The sufficient turning of materials can be realized under the regular reciprocating stirring of the stirring device, and the aerobic goal is reached. Through the precise thermocouple temperature control and the combination with the solar technology, the energy consumption is greatly saved. Through the design of the double-layer reactor, the material processing capability is improved, simultaneously, the materials are respectively positioned in the upper layer reactor and the lower layer reactor according to the characteristics of different stages of the reaction, the respective treatment of reactants is realized, and the fermentation efficiency is improved.

Owner:NANKAI UNIV +1

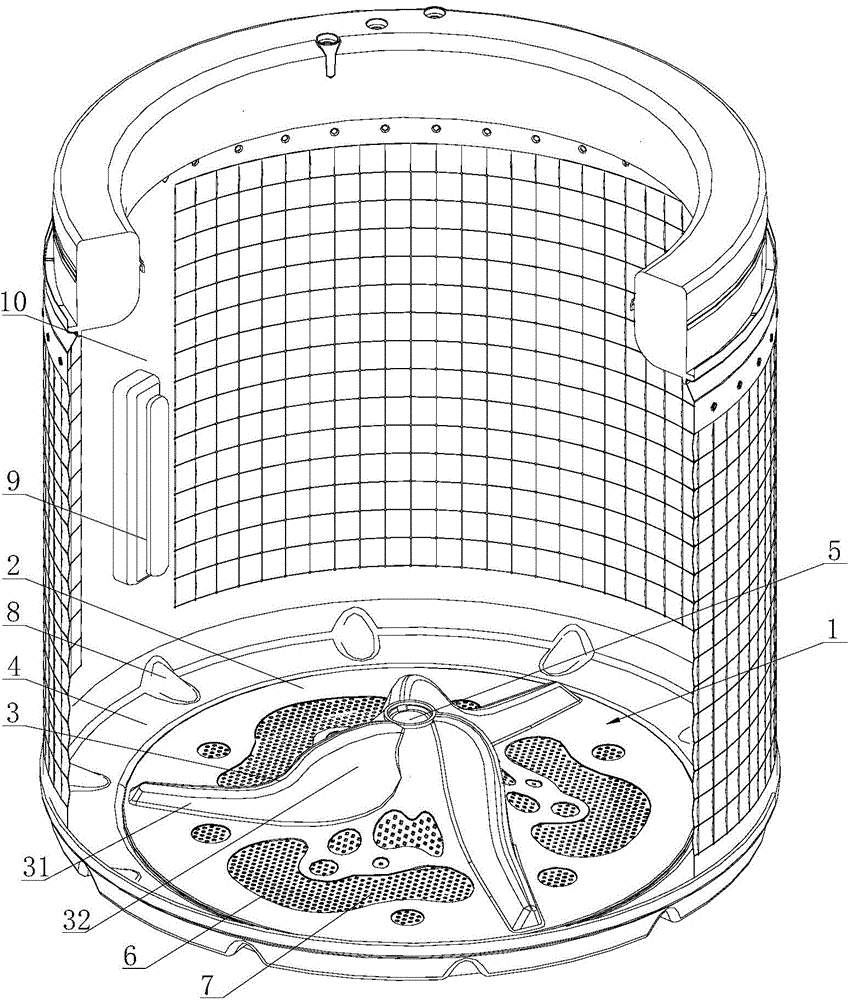

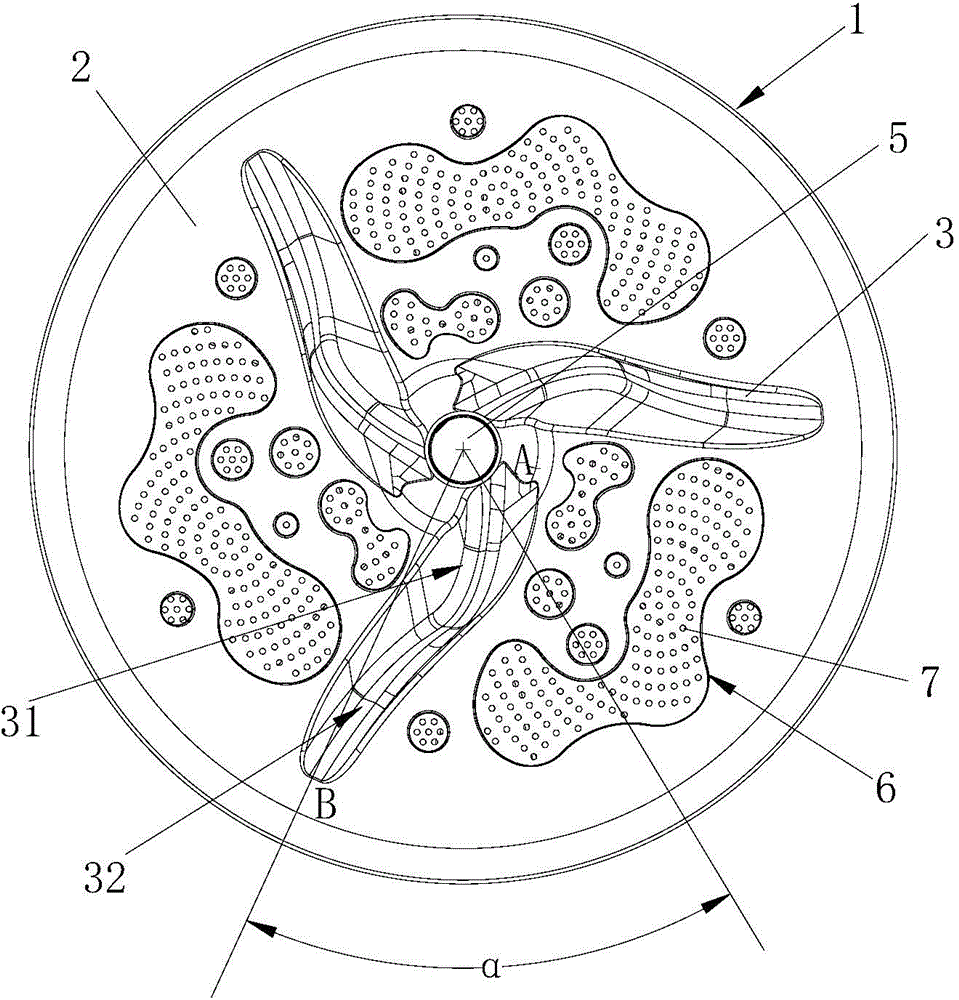

Washing machine and washing method

ActiveCN105350212ASave washing waterIncrease the number of up and down flipsOther washing machinesControl devices for washing apparatusImpellerDehydration

The invention discloses a washing machine and a washing method. The washing machine comprises a wash bucket and an impeller on the bottom of the wash bucket. The impeller comprises a rotary plate and a plurality of water-stirring blades arranged on the surface of the rotary plate, the rotary plate is a discoid structure with a ridgy center, each water-stirring blade extends from the ridgy center of the rotary plate to the edge of the rotary plate, the inner wall of the wash bucket is provided with a plurality of strip-shaped protruding ribs which are vertically arranged, a certain distance is left between the external periphery of the impeller and the bottom edge of the inner wall of the wash bucket, a bucket bottom outer ring is arranged between the external periphery of the impeller and the bottom edge of the inner wall of the wash bucket, and the joint of the bucket bottom outer ring and the inner wall of the wash bucket is provided with a plurality of projections which protrude from the bucket bottom outer ring and the inner wall of the wash bucket in the circumferential direction. With respect to the washing machine, washing water is saved, the concentration of the washing agent is increased, the up-down overturn speed is increased, the cleaning ratio is increased, the cleaning uniformity is improved, washing time is reduced, and clothes winding phenomena are reduced, after being washed, clothes are distributed uniformly in the bucket, and subsequent stable dehydration is facilitated.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Drying equipment for sodium formate

InactiveCN110736303APrecise fallPrevent fallingDrying gas arrangementsDrying machines with non-progressive movementsThermodynamicsHeat conservation

The invention discloses drying equipment for sodium formate. The drying equipment comprises a machine box, wherein a preheating chamber, a drying chamber and a material collecting chamber are sequentially distributed inside the machine box from top to bottom, a first-stage discharging opening is formed in the bottom of the preheating chamber, the preheating chamber communicates with the drying chamber through the first-stage discharging opening, supporting legs are fixedly mounted at the bottom of the machine box, and grooves are formed in the bottom parts of the supporting legs. According tothe drying equipment for the sodium formate, complete crushing is carried out by crushing teeth on the outer sides of a secondary crushing roller and a primary crushing roller, so that the caked sodium formate is prevented from falling into the inside of the preheating chamber, and the drying effect is improved; the sodium formate in the process of drying is turned over by an arranged material turning plate, so that the powdery sodium formate is fully dried, the drying speed can be accelerated, and the working efficiency is improved; and the sodium formate is conveyed to the inside of the preheating chamber by a guiding pipe, and a heat preservation cotton on the outer side of the guiding pipe can reduce the loss of heat, so that the temperature inside the preheating chamber is improved, the energy consumption is reduced while the working efficiency is improved, and the use is facilitated.

Owner:山东凯米科化工股份有限公司

High-efficiency mixing device of feed for livestock culturing

ActiveCN108713776APromote up and down shakingFlip fullFeeding-stuffUltimate tensile strengthMechanical engineering

The invention discloses a high-efficiency mixing device of feed for livestock culturing. The device comprises a base plate. A left vertical plate and a right vertical plate are vertically and fixedlymounted on the base plate. A first rack which engages with a sector gear is fixedly mounted on the upper surface of a slide bar. A second rack is horizontally and fixedly mounted on the front surfaceof the slide bar. A vibration damping spring is connected between a sliding push plate and a horizontal board. The top of a mixing barrel is provided with a material inlet pipe. A moving door is rotatably arranged on the sidewall of the mixing barrel. According to the mixing device, through rotation of a mixing shaft, a mixing rod which is fixedly connected with the mixing shaft is driven for realizing mixing of the livestock feed in the mixing barrel; alternative clockwise rotation and counterclockwise rotation of the lead screw in a threaded sleeve drives a sliding push plate to perform vertical movement, and furthermore vertical shaking of the feed on the sliding push plate is promoted; furthermore through sufficient mixing of the mixing rod, the feed at bottom of the mixing barrel is sufficiently turned, and comprehensive and thorough mixing of the feed is realized. The high-efficiency mixing device has advantages of high mixing efficiency and low labor intensity.

Owner:邳州正邦饲料有限公司

Stir-frying device for nut processing

The invention discloses a stir-frying device for nut processing, and relates to the technical field of food processing. The stir-frying device comprises a support frame, a stir-frying trough is rotationally mounted in the support frame, the bottom of the stir-frying trough is vertically provided with a rotating shaft, a heater is embedded in the bottom of the stir-frying trough, the support frameis vertically provided with a driven shaft extending downwards to the stir-frying trough in a rotatable mode, a plurality of flipping plates are evenly fixed on the surface of the driven shaft, a driving shaft is fixedly sleeved by a gear, and a driven gear meshed with the driving gear is fixedly disposed on the driven shaft in a sleeving way. According to the invention, through rotation of the flipping plates and a stirring frame, repeated rotary stir-frying of nuts in the stir-frying trough is achieved; through alternate forward and reverse rotation of the driven shaft, vertical reciprocating movement of an external threaded pipe is realized, further swing of a swinging plate is achieved, the stirring range of the nuts in the stir-frying trough is greatly improved, and stir-frying is more sufficient; and since the rotation directions of the stir-frying trough and the driven shaft, the stirring of the nuts is more sufficient and comprehensive, and thus the stir-frying efficiency of the nuts is greatly improved.

Owner:北京臻味坊食品有限公司

Full-automatic deceleration clutch and washing machine thereof

ActiveCN101113558ASave raw materialsLow costOther washing machinesWashing machine with receptaclesWater flowEngineering

A wholly automatic decelerating clutch and a washing machine thereof pertain to washing machine technical field; an output shaft of the wholly automatic decelerating clutch consists of a small whirlpool agitator shaft, a large whirlpool agitator shaft and a dewatering shaft that are sleeved concentrically; the whirlpool agitator of the washing machine adopting the wholly automatic decelerating clutch is a small whirlpool agitator and a large whirlpool agitator, wherein the small whirlpool agitator is fixedly arranged on the small whirlpool agitator shaft and in the center part of the large whirlpool agitator, and the large whirlpool agitator is fixedly arranged on the large whirlpool agitator shaft, and an inner bucket is fixedly arranged on the dewatering shaft. The washing manner of the washing machine adopting the wholly automatic decelerating clutch is that: the small whirlpool agitator, the large whirlpool agitator and the inner bucket are mutually, reversely and bidirectionally rotated to and fro at a certain ratio, different speeds and different rotating angles, to produce complicated, vertically and horizontally crossed impacting water flow, to strike and rinse clothes, and fully roll, strongly rub and sway the clothes, thus improving the cleanness rate of clothes and not twisting the clothes; when the clothes are dewatered, a torsional spring automatically integrates the decelerating clutch into a whole, and decenters and dewater the clothes in high speed, without needing a whole set of clutch parts and operating mechanisms of the normal decelerating clutch.

Owner:NINGGUO JULONG IND

Deep fryer with rotatable frying cage

The invention discloses a deep fryer with a rotatable frying cage, which comprises an upper cover, the frying cage, a shell, an inner pot, a heater and a control box, wherein the frying cage is detachably suspended in the inner pot; the inner pot is placed in the shell; and the heater is placed at the inner bottom or the outer bottom of the inner pot. The deep fryer is characterized in that one lateral surface of the inner pot is provided with a step protruded to the center of the inner pot; a shaft assembly, a coupler and a motor which are connected together in turn are fixed on the lateral surface on the shell opposite to the step; and the shaft assembly passes through the frying cage, one end of the shaft assembly is placed on the lateral surface of the inner pot, and the other end of the shaft assembly is connected with the coupler. The frying cage can rotate in 360 degrees to fully turn food so as to save oil and improve the food frying effect; and a groove for connecting the frying cage and the motor does not need to be formed on the inner pot so as to avoid the problems of oil splash and cleaning difficulty.

Owner:MIDEA GRP CO LTD

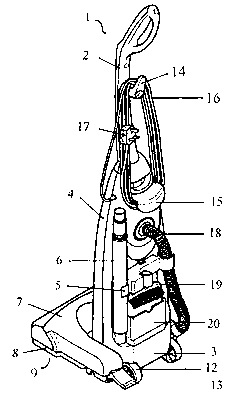

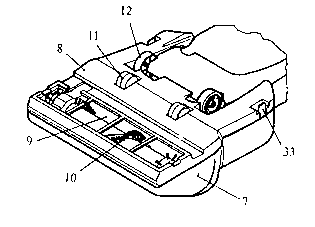

Rolling brush with axial brushing structures

The invention discloses a rolling brush with axial brushing structures. The rolling brush comprises a rolling brush body, bristles arranged on the rolling brush body in a spiral manner, a left connecting part and a right connecting part, wherein the left connecting part and the right connecting part are arranged at two ends of the rolling brush body and connected with a base plate of a suction nozzle; the axial brushing structures with the middle lines perpendicular to the axial line of the rolling brush body are arranged on the rolling brush body; and the two sides of the middle lines of the axial brushing structures are inclined for a certain angle relative to the middle line. The rolling brush with the axial brushing structures has the advantages and positive results that the brushing structures are arranged on the rolling brush body, when the rolling brush is rotated, the bristles arranged on the rolling brush body in a spiral manner can brush a carpet transversely, and bristles of the axial brushing structures can brush the carpet axially; and the rolling brush rotates very quickly, so that when being brushed transversely, carpet wool can be fully turned over and better cleaned in case of small amount of axial movement, and then the cleaning effect of a dust collector can be improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Washing machine

ActiveCN108103737AGuaranteed reliabilityFlip fullOther washing machinesTextiles and paperImpellerWater circulation

The invention belongs to the technical field of laundry treatment equipment, and particularly provides a washing machine. The washing machine aims at solving the problem that clothes cannot be washedcleanly due to the fact that a washing machine has a poor turning effect on clothes. The washing machine comprises an inner tub, an outer tub, an impeller and a turnover device. The turnover device comprises at least one water circulation component, a positioning lock and a controller, the water circulation component comprises a water pump, a circulating water inlet is formed in the side wall of the outer tub and communicated with a water inlet end of the water pump through a pipe, a circulating water outlet is formed in the bottom of the inner tub, the positioning lock can position the innerbarrel to the position where the circulating water outlet and a water outlet end of the water pump are aligned with each other, and the controller controls the coordination action of the water pump and the impeller and controls the flow and pump head of the water pump according to the water level. Through the arrangement, the washing machine can fully turn over clothes, the turning effect on clothes is enhanced, and the cleaning ability of the washing machine and user experience are improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Organic fertilizer drying machine

InactiveCN106766753AFlip fullEvenly heatedDrying solid materialsDrying machines with non-progressive movementsAgricultural engineeringOrganic fertiliser

The invention discloses an organic fertilizer drying machine mainly used for solving the problems that fertilizer particles dried by the existing organic fertilizer drying machine in the prior art are heated non-uniformly and dust is easily generated during secondary use. The organic fertilizer drying machine comprises a drum, a fixed column and a motor; one end of the drum is rotatably connected with the fixed column, and the other end of the drum is rotatably connected with a rotating shaft of the motor; the inner wall of the drum is uniformly provided with a plurality of bulges; the distance between every two adjacent bulges is larger than the particle size of each fertilizer particle; the height of each bulge is smaller than or equal to 1 / 3 of the particle size of each fertilizer particle; and the outer wall of the drum is provided with at least one vibrator. According to the technical scheme, the aims that the fertilizer particles are heated more uniformly and the dust is not easily generated during secondary use are achieved, and the organic fertilizer drying machine has very high practical and popularization values.

Owner:华蓥市禄市镇小学

Forage grass smashing device for animal husbandry

InactiveCN107535201AImprove crushing efficiencyCrushed fullyFeeding-stuffCuttersAnimal ForagingSpiral blade

The invention discloses a pasture crushing device for animal husbandry, which comprises a support, a cutting chamber, a feeding chamber, a crushing chamber, a collecting tank and a shock absorbing mechanism; the upper end of the support is provided with a cutting chamber, the cutting chamber is provided with a cutting mechanism, and It includes a first rotating motor, an irregular gear A, a bar-shaped tooth plate, a slide bar, a chute, an irregular gear B and a cutting knife; a feeding chamber is arranged on the left side of the cutting chamber, and a feeding hopper is arranged in the feeding chamber. The lower end of the hopper is provided with a feeding mechanism, and the feeding mechanism includes a second rotating motor, a feeding chamber, a first rotating shaft and a spiral blade; a crushing chamber is arranged on the right side of the feeding chamber, and a crushing bucket is arranged in the crushing chamber; the lower end of the support is symmetrical A shock absorbing mechanism is provided, and the shock absorbing mechanism includes an inverted U-shaped plate, a spring and a bottom plate. The invention cuts through the cutting mechanism and then crushes through the crushing bucket, which increases the grass crushing efficiency.

Owner:周建明

Anaerobic dry fermentation device and method of pre-aeration temperature-rising sequencing batch type

PendingCN110468045AUniform heating areaImprove reaction efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsChemistrySelf heating

The invention discloses an anaerobic dry fermentation device of pre-aeration temperature-rising sequencing batch type. The fermentation device comprises an anaerobic dry fermentation reactor and an aeration mechanism. The anaerobic dry fermentation reactor is detachably covered with a sealing cover, a material reaction zone is arranged in the anaerobic dry fermentation reactor, the material reaction zone is used for placing reaction materials, the upper end of the anaerobic dry fermentation reactor is provided with an air outlet hole, and the lower end of the anaerobic dry fermentation reactoris provided with a liquid outlet hole; the aeration mechanism comprises a fan, an air inlet pipe and an aeration pipe, one end of the air inlet pipe is communicated with the fan, the other end of theair inlet pipe is communicated with the aeration pipe through the air inlet hole of the anaerobic dry fermentation reactor, and the aeration pipe is located inside the material reaction zone; and theupper part inside the anaerobic dry fermentation reactor is provided with a spray head, liquid can be sprayed from the spray head to the material reaction zone, so as to realize self-heating of the reaction materials, ensure the temperature requirements of the materials for anaerobic fermentation, and improve the reaction efficiency and output rate.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

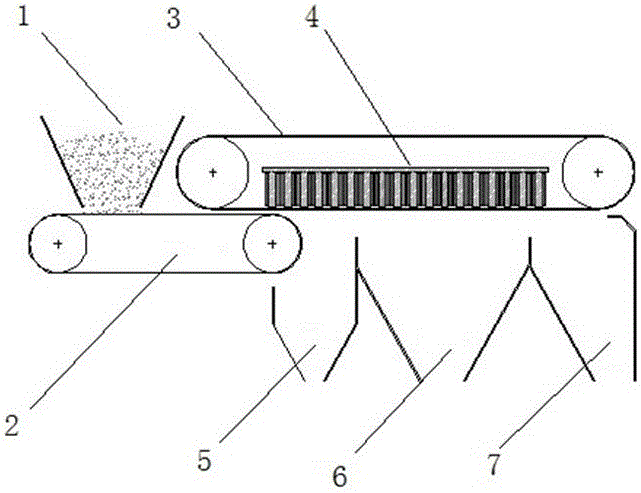

Magnetic-field-alterable belt type magnetic separator

The invention discloses a magnetic-field-alterable belt type magnetic separator. The magnetic-field-alterable belt type magnetic separator comprises a feeding conveying belt; a quantitative feeding bin is installed above the feeding conveying belt, to-be-separated materials are contained in the quantitative feeding bin and can be quantitatively conveyed onto the feeding conveying belt through the quantitative feeding bin according to requirements, and a magnetic separating conveying belt is installed on the upper portion of the tail end of the feeding conveying belt in the movement direction of the feeding conveying belt; a magnetic-field-alterable magnetic source body is installed in the magnetic separating conveying belt, a tail ore bucket, a middle ore bucket and a fine ore bucket are installed on the lower portion of the magnetic separating conveying belt in the movement direction of the magnetic separating conveying belt, and the to-be-separated materials are attracted by the magnetic-field-alterable magnetic source body and tightly attached to the magnetic separating conveying belt; and in the conveying process of the magnetic separating conveying belt, the magnetic-field direction of the magnetic-field-alterable magnetic source body changes so that the to-be-separated materials with different characters can be dropped into the tail ore bucket, the middle ore bucket and the fine ore bucket correspondingly, and through a low-frequency pulsing-type planer magnetic system, all magnetic-field spaces can be sufficiently used. The ore separating efficiency is greatly high, and manufacturing cost is reduced.

Owner:CHENGDU LEEJUN IND

Tea deblocking device

InactiveCN106954695ANot easy to damageNot easy to breakSievingPre-extraction tea treatmentEngineeringMechanical engineering

The invention belongs to the field of tea processing equipment, and specifically discloses a tea deblocking device. The tea deblocking device comprises a machine frame, a hot air generator, a sieve column and a sieve tube; a material inlet and a first air hole are formed on a surface of the sieve tube; one end of the sieve column is connected onto the machine frame, and the other end is located in the sieve tube; the sieve column is a hollow columnar structure; multiple second material inlet holes are formed on an upper surface of the sieve column, and multiple second air holes are formed on a lower surface of the sieve column; one end of the sieve tube is connected with a rotation shaft; the rotation shaft is connected onto the machine frame in a rotary way, and is arranged with rotary blades; an annular sieve net is fixed in the sieve tube, and is located outside the sieve column; multiple first material inlet holes are formed on an upper surface of the annular sieve net, and multiple third air holes are formed on an lower surface of the annular sieve net; a clapboard is arranged at a joint of the upper and lower surfaces of the annular sieve net; multiple one-way gates are arranged on the clapboard; and multiple split combs are fixed on an inner surface of the sieve tube. Being adopted for deblocking tea, the tea deblocking device is not liable to cause damage or extrusion-break on tea leaves; moreover, the tea leaves can be dried during the deblocking process.

Owner:重庆毓堡农业开发有限责任公司

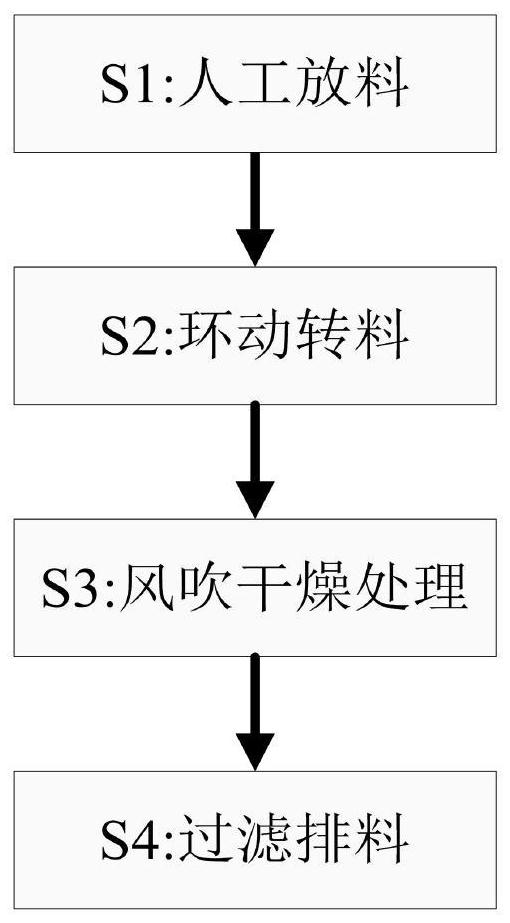

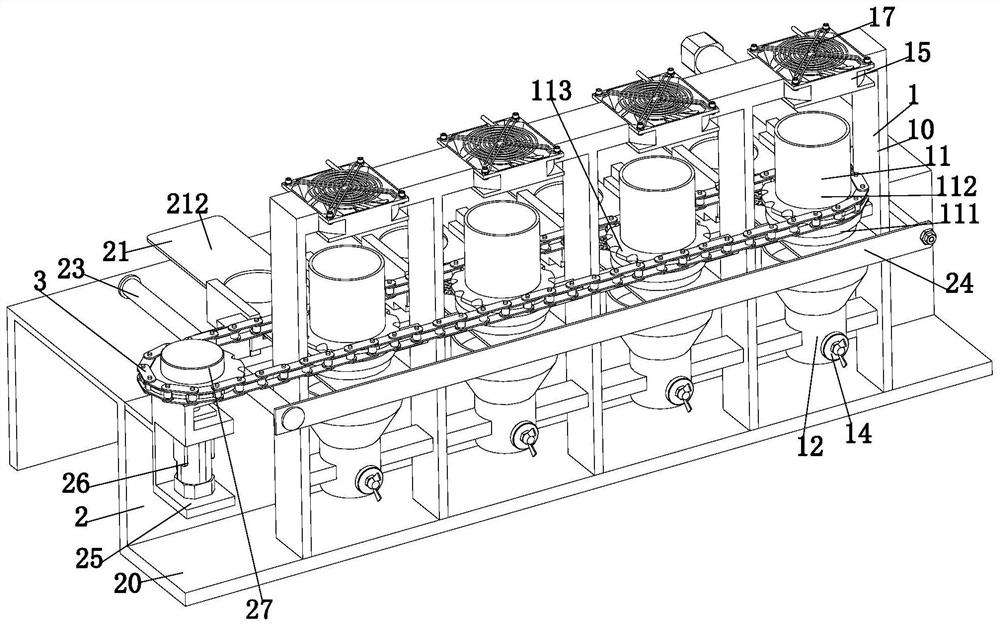

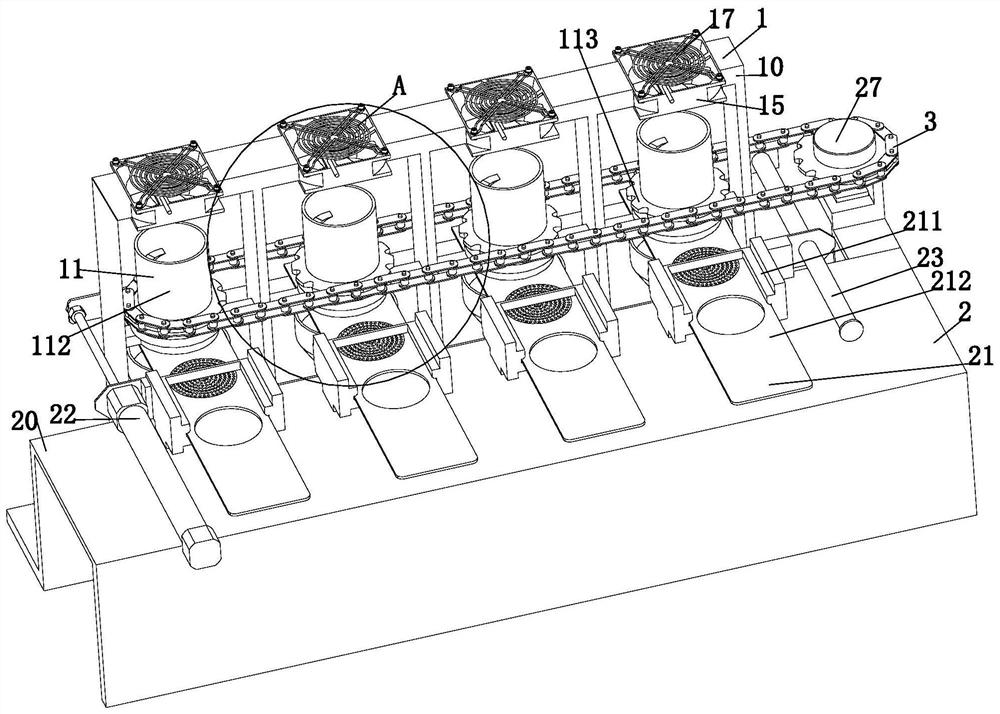

Microbial fertilizer particle production process

ActiveCN112050576AFlip fullExtension of timeSievingGas current separationAgricultural engineeringEnvironmental engineering

The invention provides a microbial fertilizer particle production process which comprises a circle drying mechanism, a replacement mechanism and a chain. The circle drying mechanism is arranged on thereplacement mechanism, the circle drying mechanism is positioned on the front part of the replacement mechanism, and the circle drying mechanism mutually is rotatably connected with the replacement mechanism in a mutual meshing mode through the chain arranged on the outer ring. The problems that fertilizer particles can only enter next coating processes after being dried, when fertilizer is driedthrough drying equipment at present, the fertilizer particles are directly turned over through a connecting rod, so that the fertilizer with damp particles is prone to being damaged, the damaged particles of the fertilizer are not screened out, and the overall quality of received materials is reduced are solved.

Owner:STANLEY FERTILIZER GUIGANG

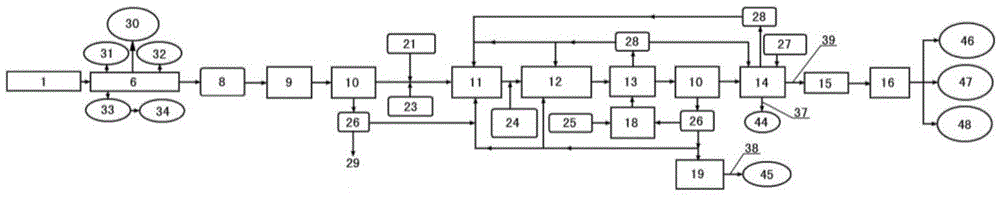

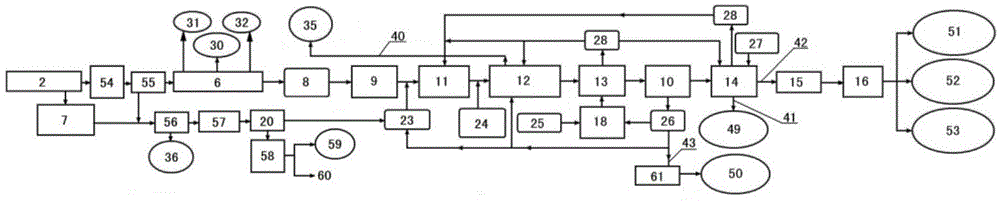

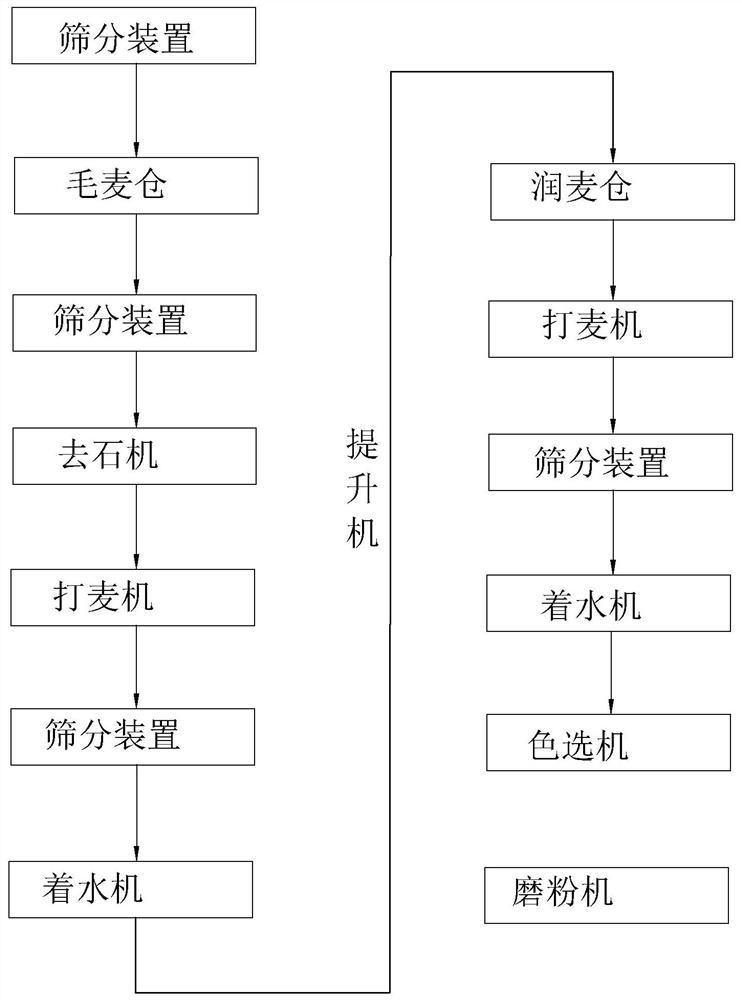

Flour production system

The invention relates to a flour production system. The system comprises a screening device, a raw wheat bin, a screening device, a first wheat processing assembly, a dampener, a wheat wetting bin, asecond wheat processing assembly, a color selector and a flour mill, the screening device comprises a box body, a screening mechanism and a magnetic separation mechanism, the box body is provided witha feeding port and a discharging port, a partition plate is arranged between the feeding port and the discharging port, the screening mechanism and the magnetic separation mechanism are located on the two sides of the partition plate, the screening mechanism comprises a screening cylinder, a spiral blade and a driving part, the screening cylinder comprises a screen, a plurality of supporting rods, a first connecting ring and a second connecting ring, the first connecting ring is rotationally connected to the box body, the second connecting ring is rotationally connected to the partition plate, an air supply hole extending along the spiral line of the spiral blade is formed in the spiral blade, the spiral blade is provided with a plurality of vent holes communicating with the air supply hole, the air supply hole communicates with an air supply piece used for supplying air, and the bottom of the box body is provided with an exhaust hole and communicates with a separation mechanism. Thew system has a relatively good wheat screening effect.

Owner:陕西省泾阳县自强面粉有限责任公司

Power reciprocating overturning type cobblestone cleaning device based on pressurized flushing

The invention discloses a power reciprocating overturning type cobblestone cleaning device based on pressurized flushing, and relates to the technical field of cobblestones. The power reciprocating overturning type cobblestone cleaning device based on pressurized flushing comprises a machine body and two supporting plates. The tops of the two supporting plates are fixedly connected to the left side and the right side of the bottom of the machine body correspondingly. The rear side of the inner wall of the machine body is fixedly connected with the back face of a guiding sliding rod. The left end and the right end of the guiding sliding rod are fixedly connected with the left side and the right side of the inner wall of the machine body correspondingly. An exhaust port is formed in the front face of the guiding sliding rod and communicates with an inner cavity of the guiding sliding rod. According to the power reciprocating overturning type cobblestone cleaning device based on pressurized flushing, an overturning mechanism is arranged in the machine body, and accordingly, cobblestone piles in the machine body can be effectively overturned; and meanwhile, through the reciprocating motion of a pressurized flushing mechanism, sufficient and careful flushing is conducted on the cobblestone piles, and the problems that due to manual cobblestone cleaning, a large amount of time and alarge amount of manpower are consumed are solved.

Owner:HANGZHOU GONG SHU TECH CO LTD

Drum-type tea leaf fixation device

The invention relates to the technical field of tea production equipment, and discloses a drum-type tea leaf fixation device. The drum-type tea leaf fixation device includes a housing; the inner top wall of the shell fixedly communicates with a feeding hopper; a feeding box is fixedly mounted on the inner top wall of the shell; a first motor is fixedly mounted at the top of the shell through a bracket; a feeding screw is fixedly mounted on the outer surface of the connecting column; a box body is fixedly installed on the inner bottom wall of the shell; a heating device is arranged on the rightside wall of the box; two symmetrical bearings are fixedly mounted on the inner bottom wall of the box body through a base; a roller is movably connected between inner rings of the two bearings; a feeding port is formed in the right side face of the roller; a second motor is fixedly installed on the right side face of the box through a support; a rotating shaft is fixedly installed at the outputend of the second motor; spiral stirring blades are fixedly installed on the outer surface of the rotating shaft; and a screening device is arranged on the inner bottom wall of the box. Tea leaves canbe fully overturned in the roller, and the surfaces of the tea leaves are fully contacted with hot air, so that the fixation effect and fixation efficiency of the tea leaves are improved.

Owner:安徽皖源食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com