Patents

Literature

36results about How to "Precise fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

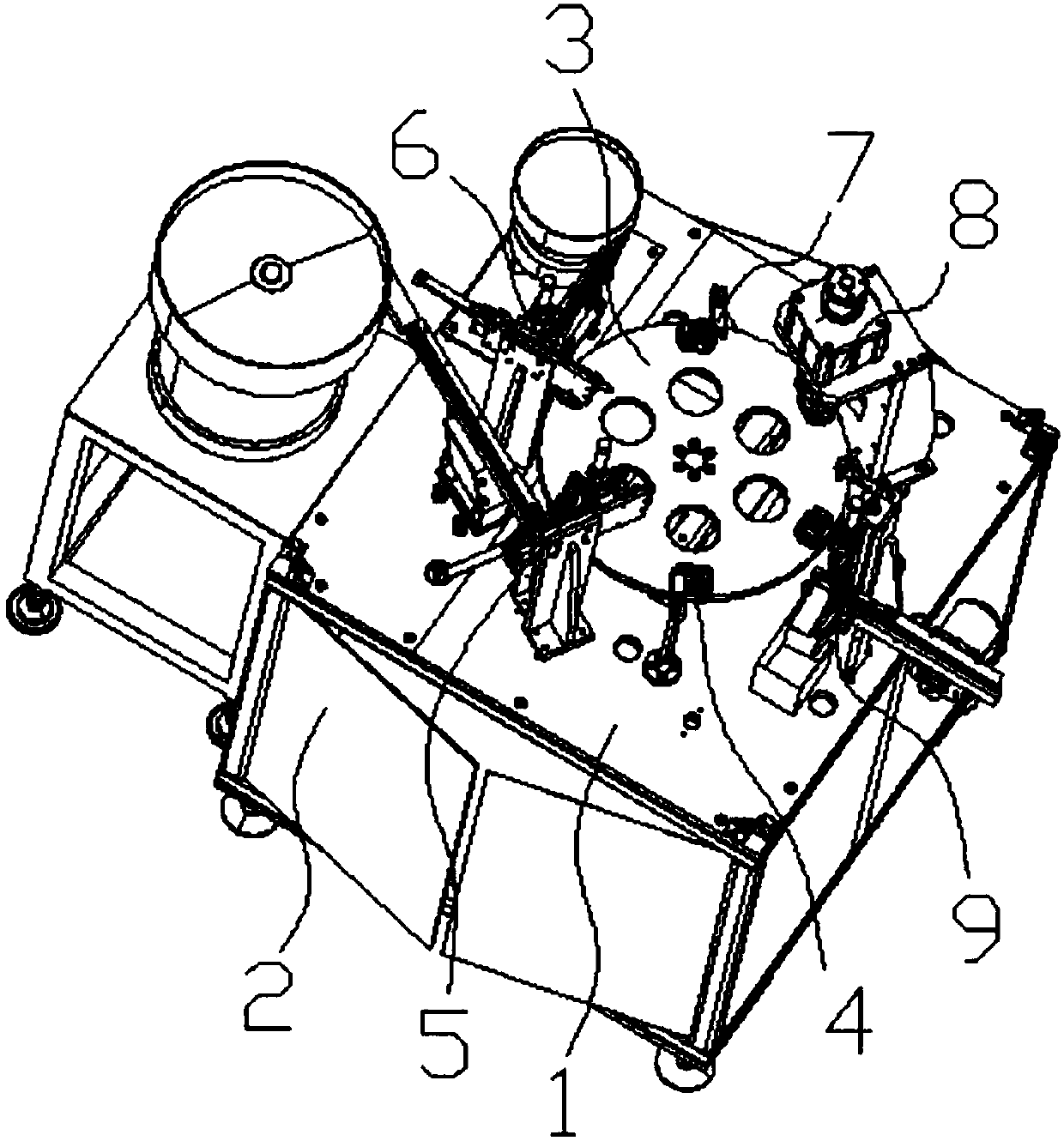

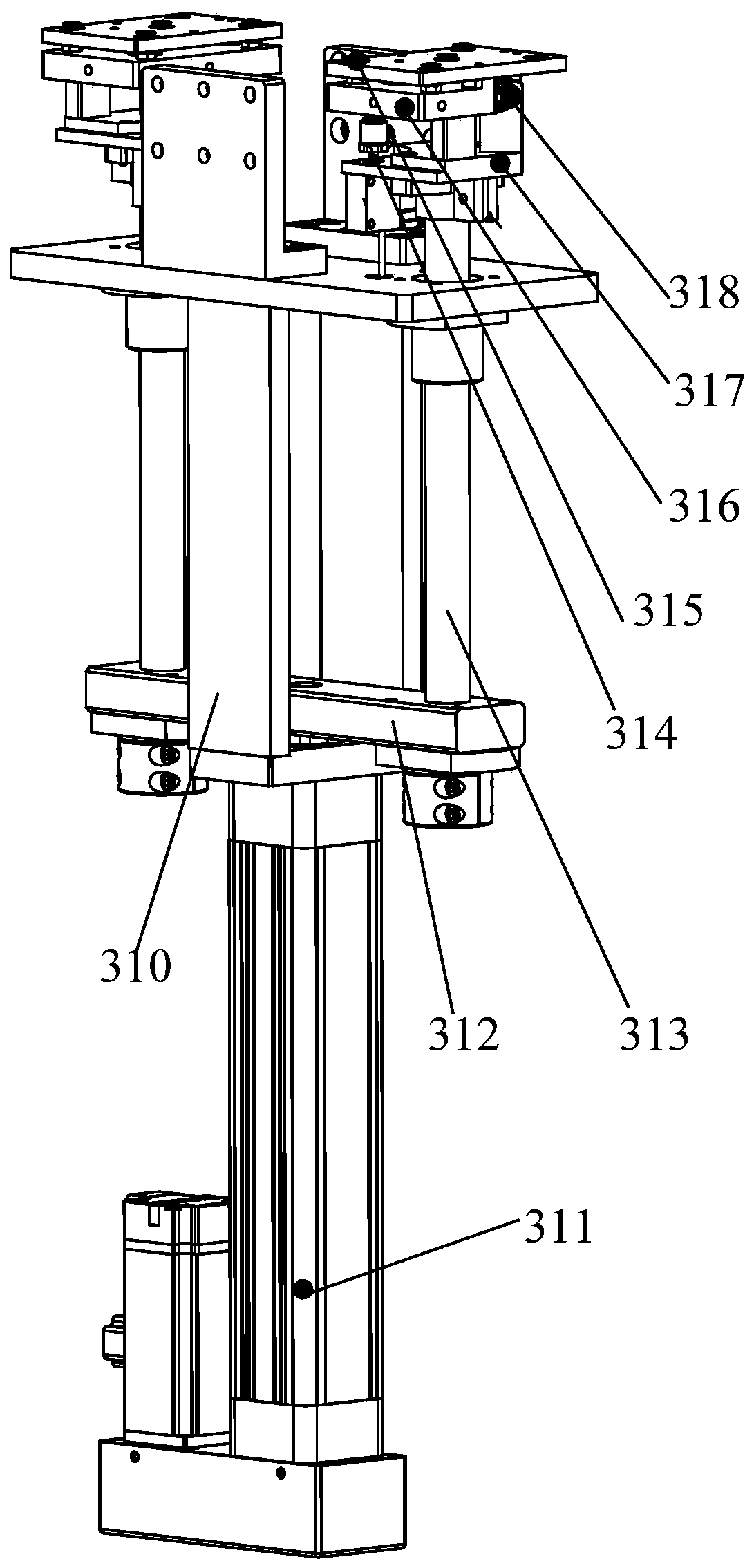

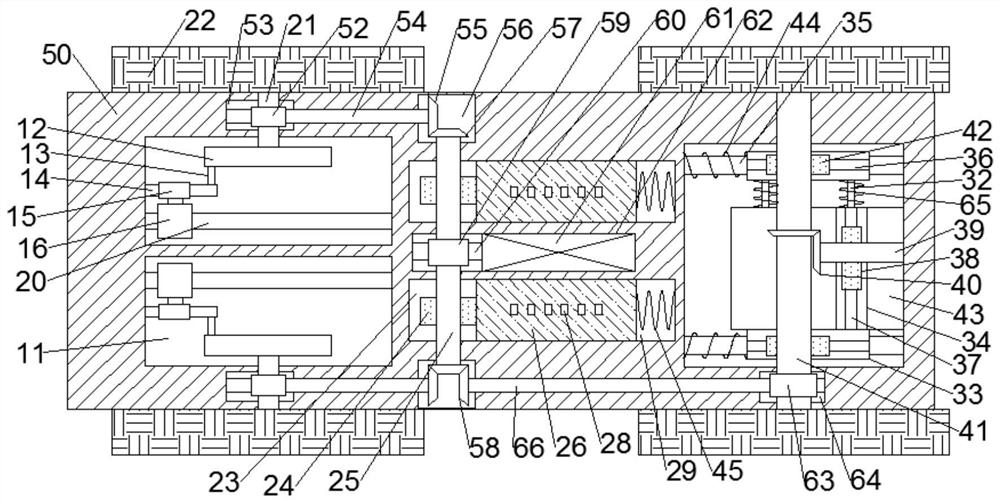

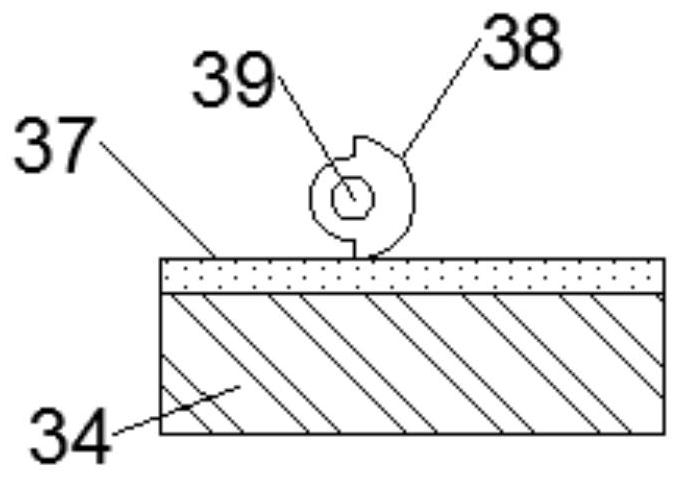

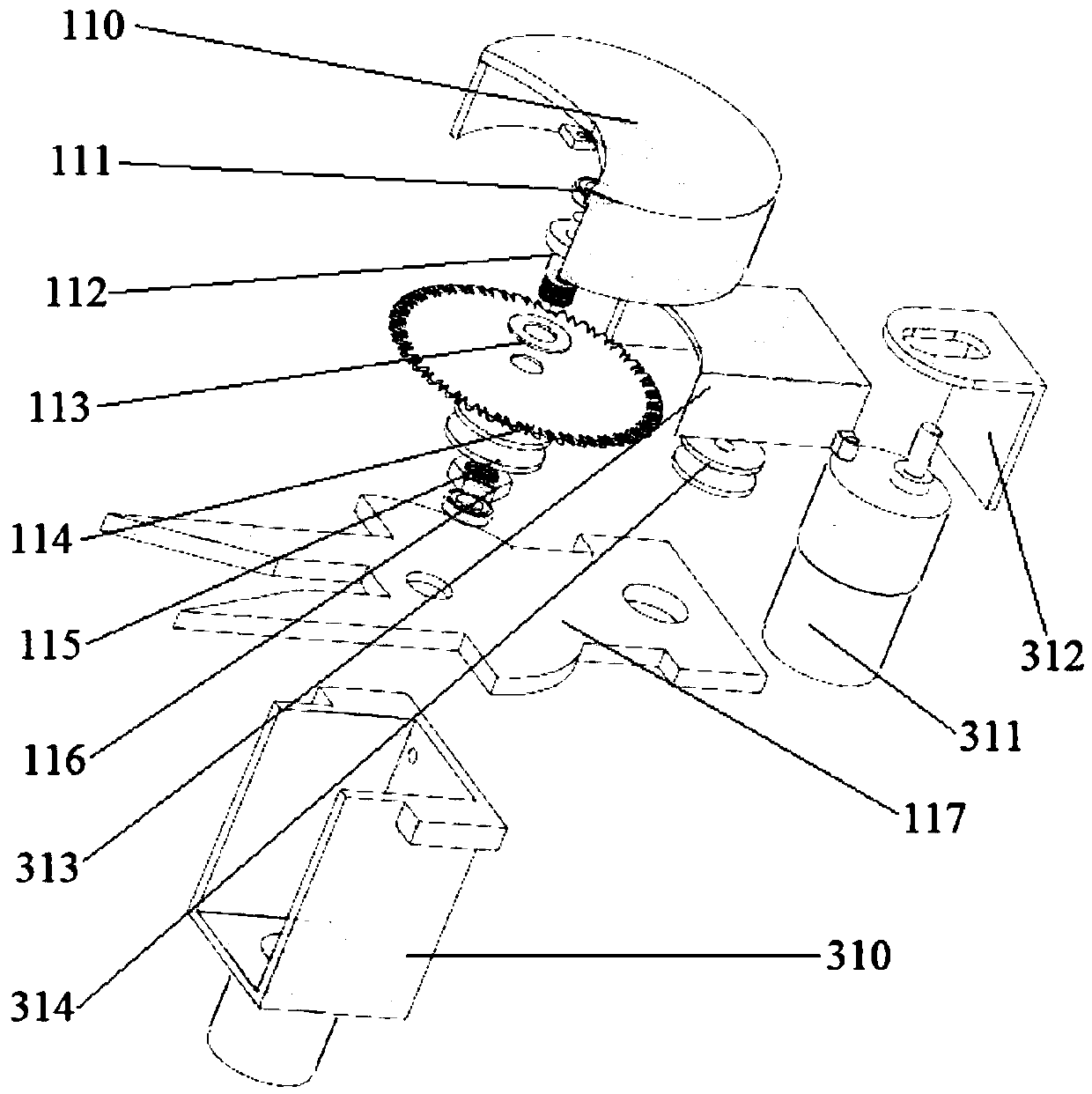

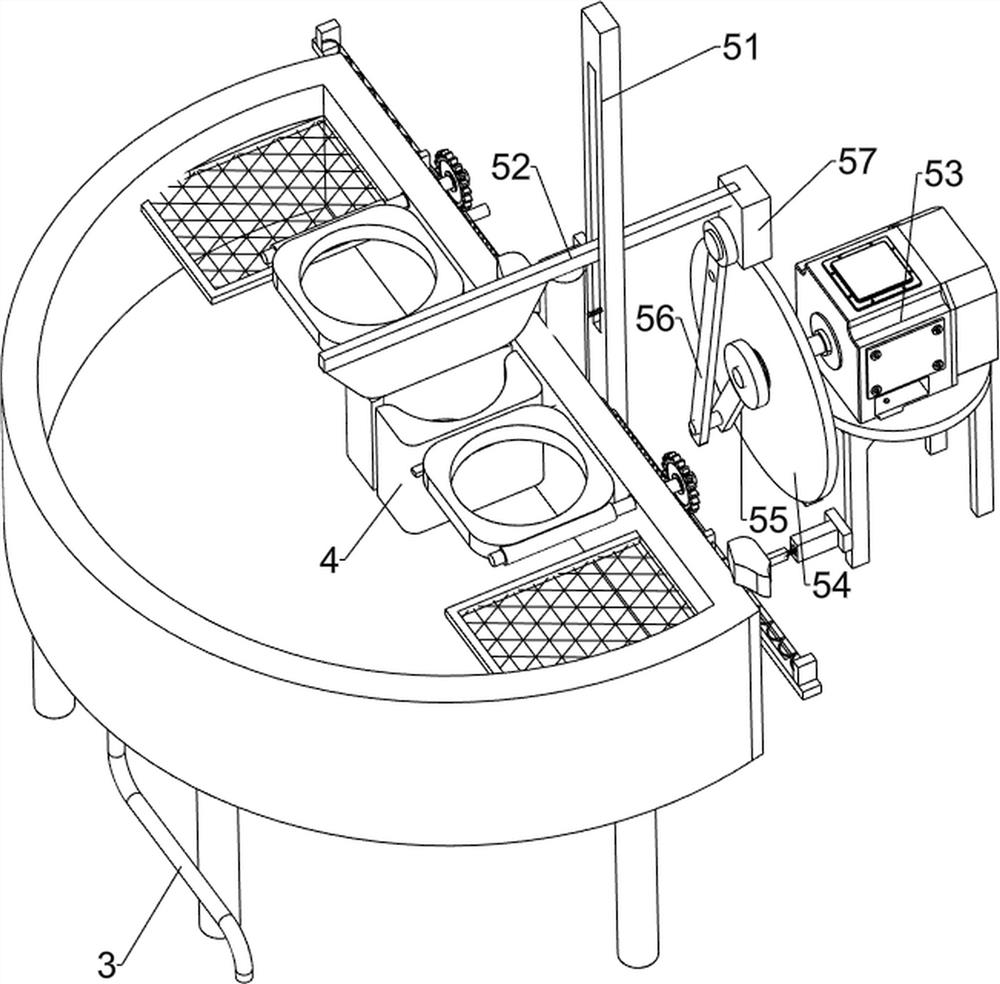

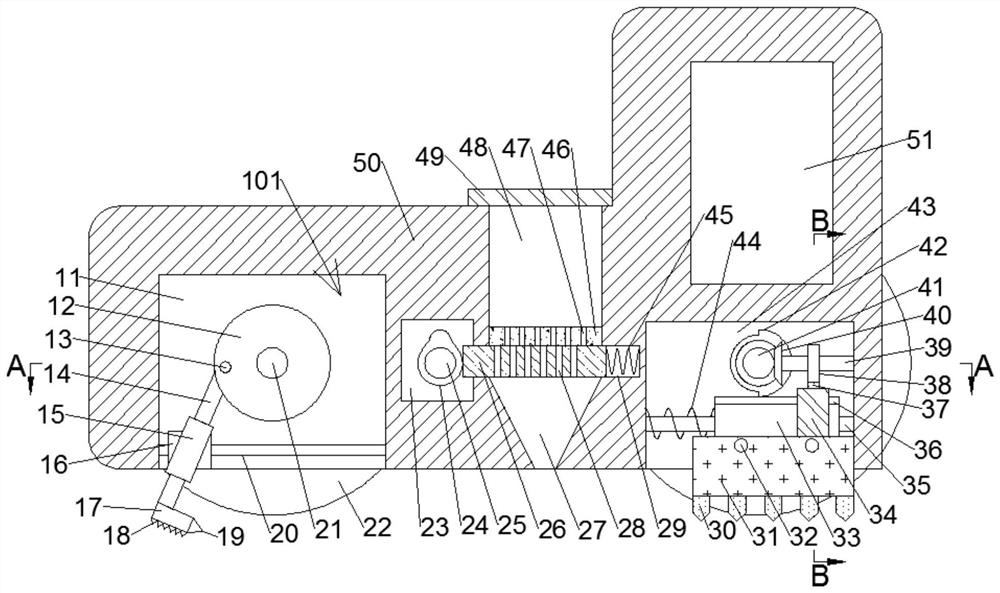

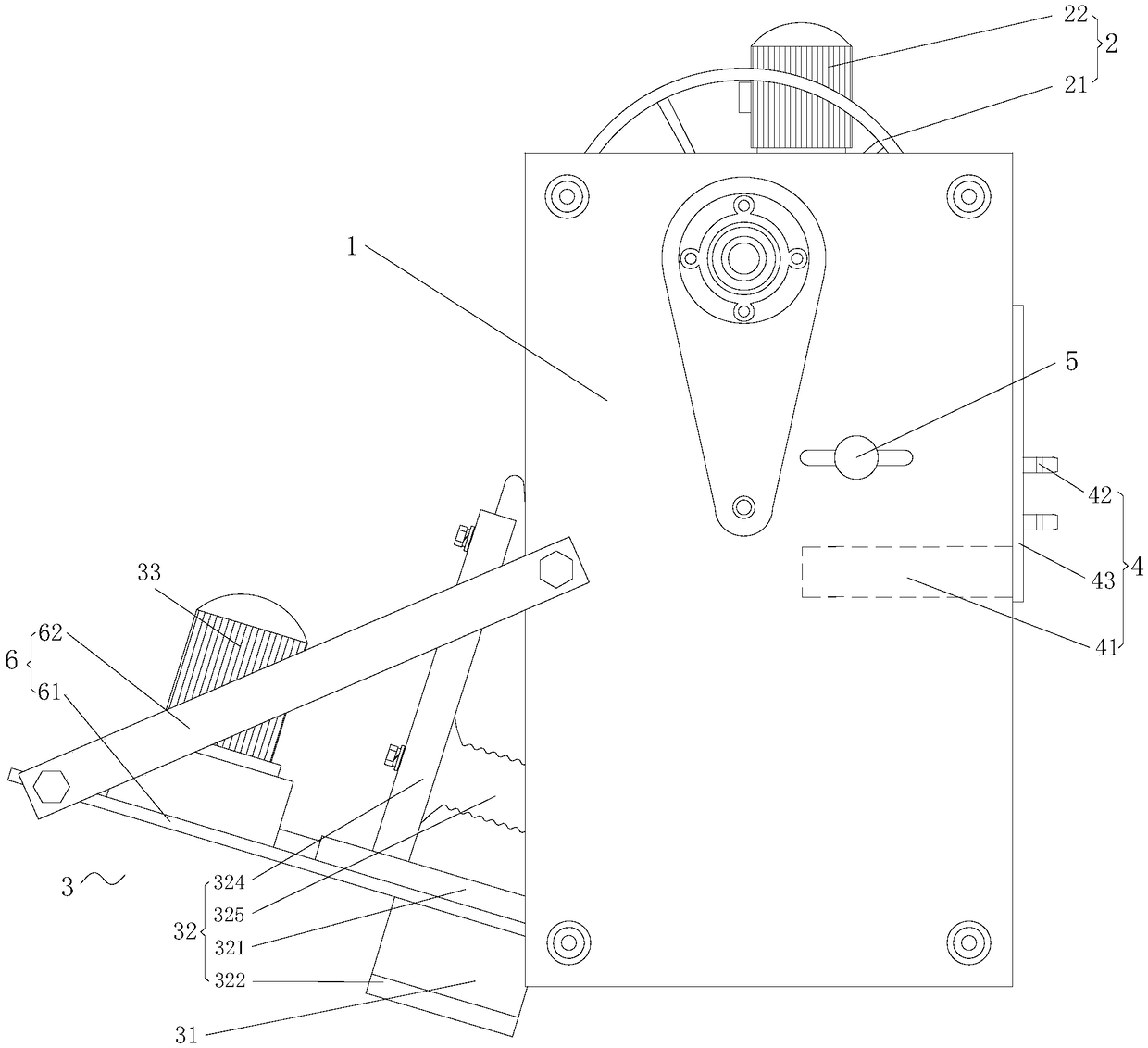

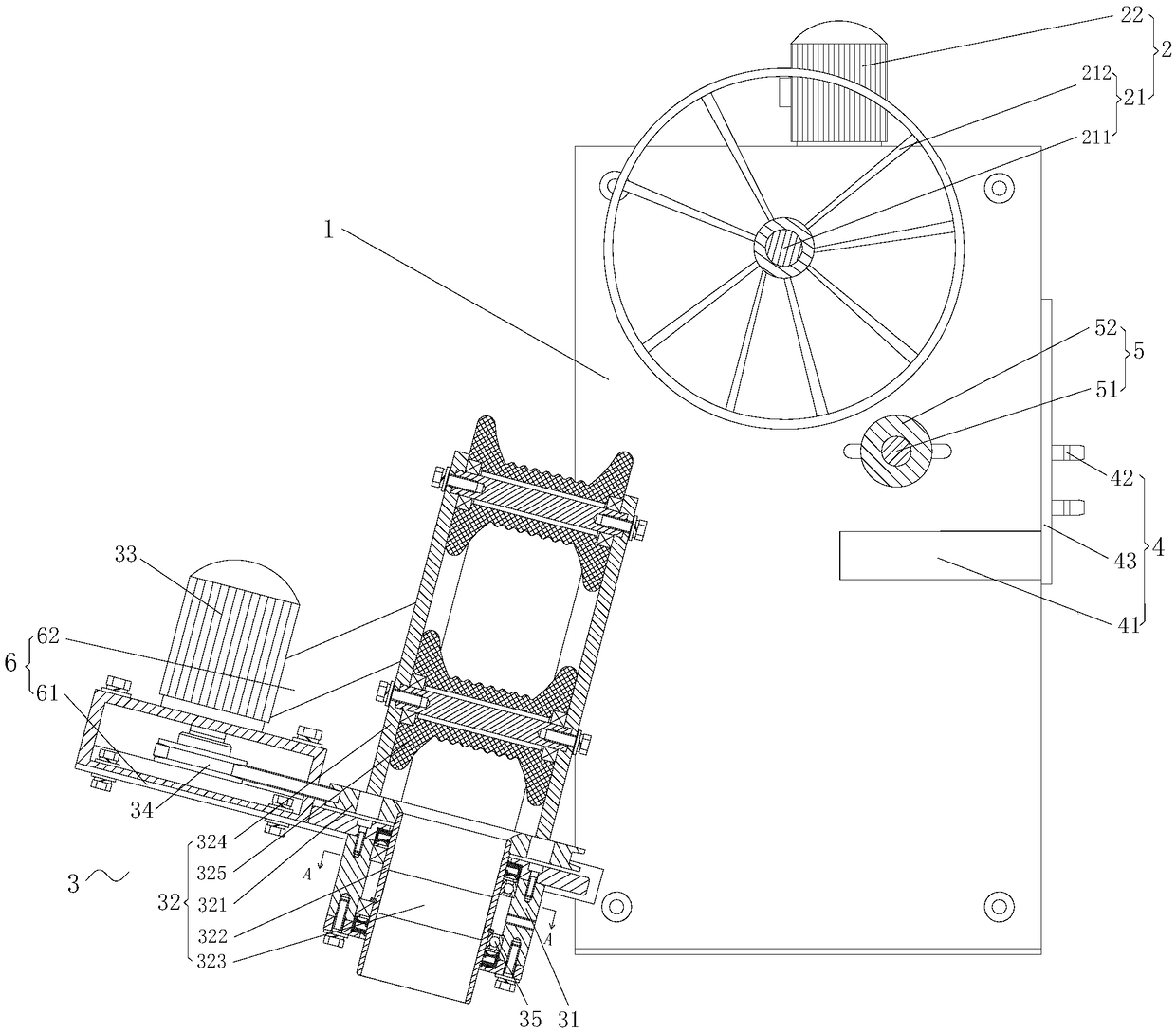

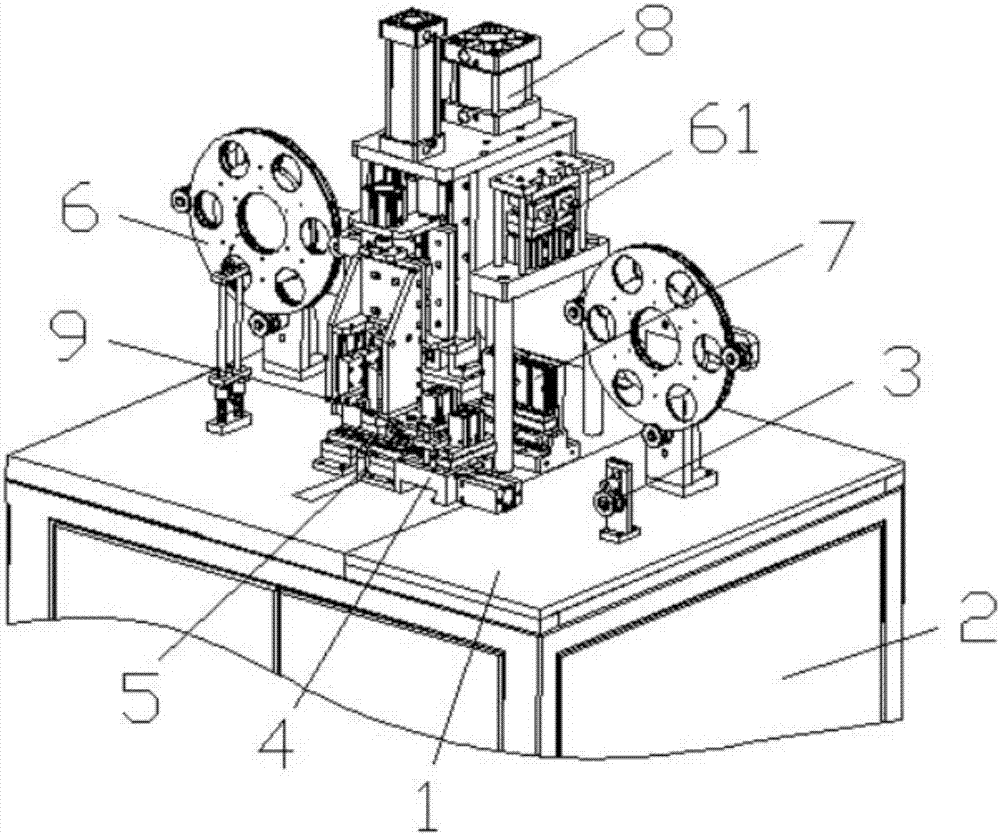

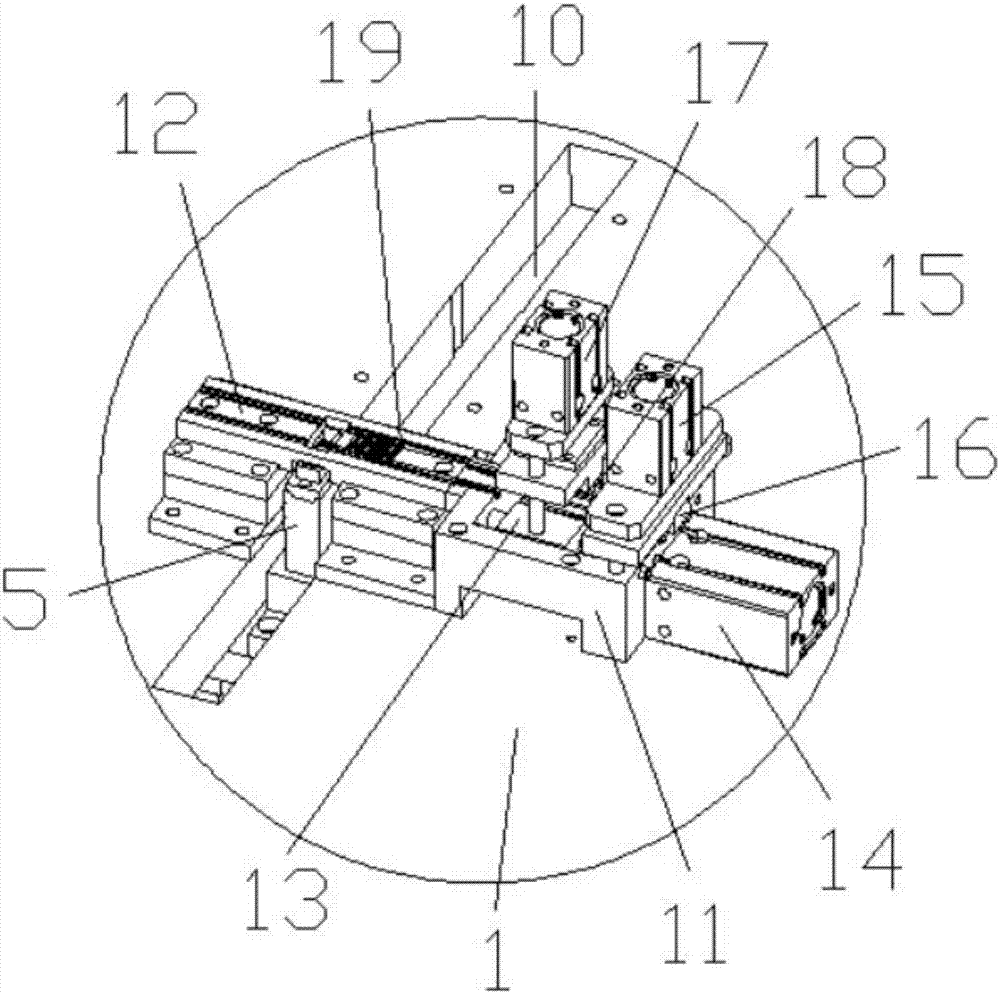

Continuous automatic assembly machine of lug plate elastic piece

ActiveCN107553107AGuaranteed accuracyAvoid elastic deformationMetal working apparatusDistribution controlButt joint

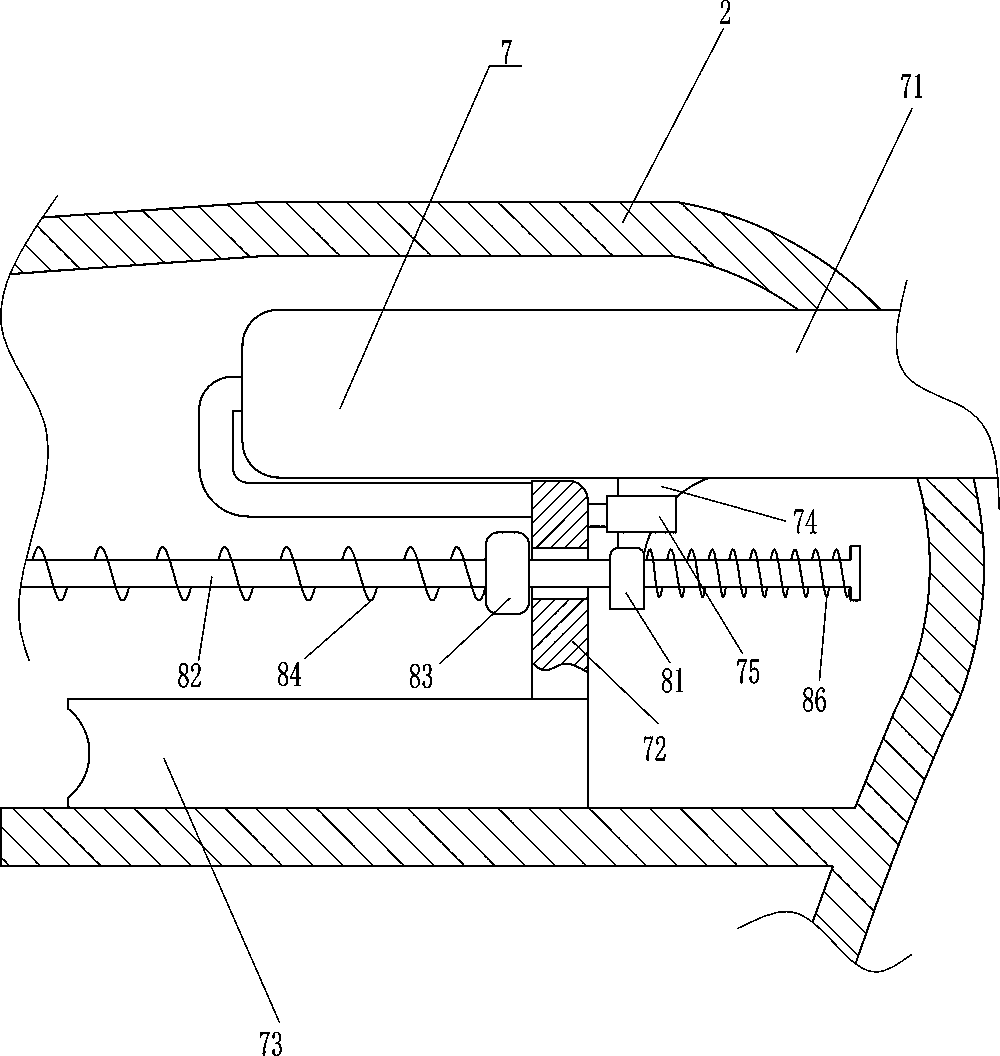

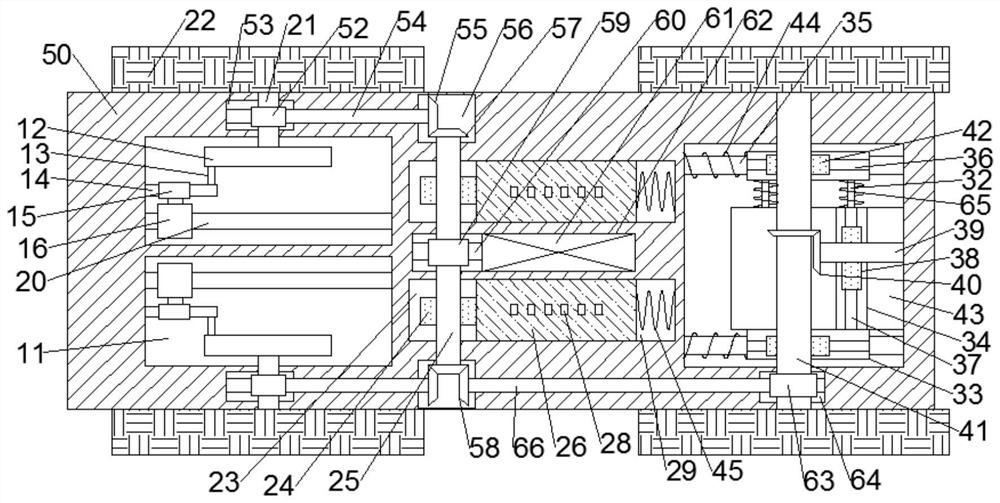

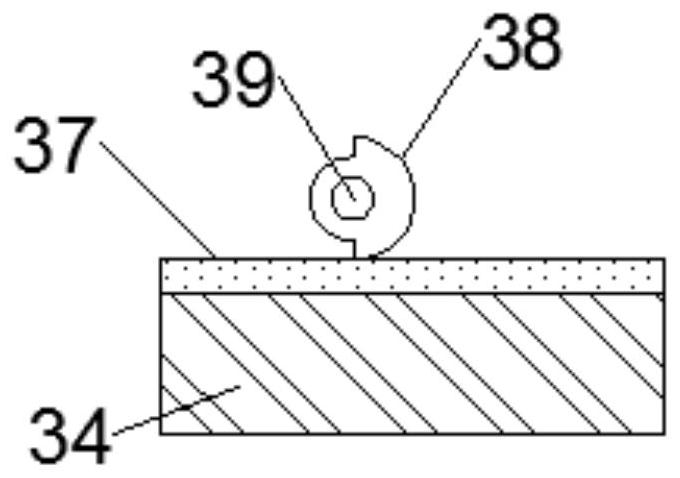

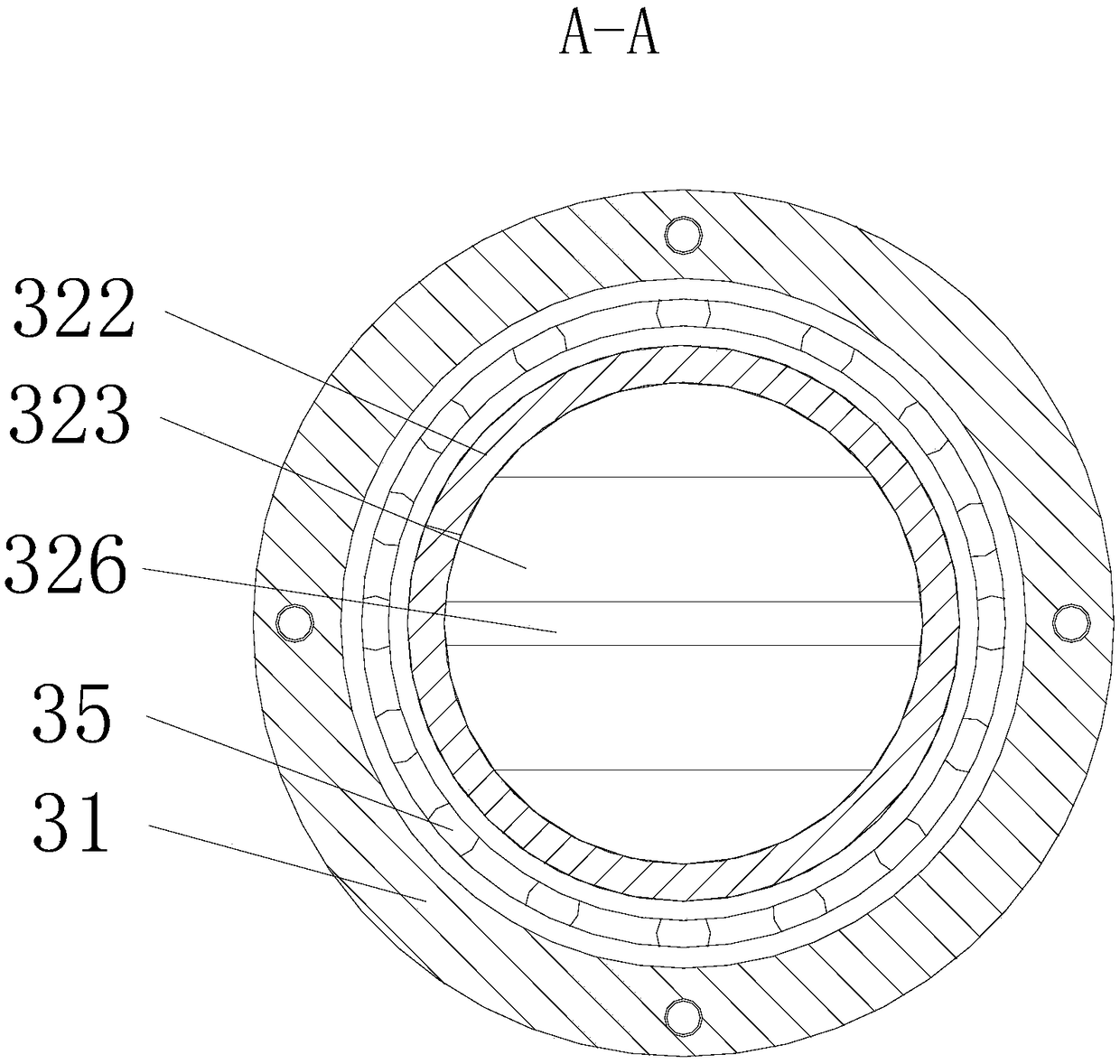

The invention relates to a continuous automatic assembly machine of a lug plate elastic piece. The continuous automatic assembly machine comprises a rack, a power distribution control box, a rotary disc and carriers. A lug plate feeding mechanism, an elastic piece feeding mechanism, a press-fitting mechanism and a discharging mechanism are arranged on the rack. Each carrier comprises a carried material mounting seat embedded into the rotary disc. A carried material seat lifting block penetrating the rotary disc is arranged in each carried material mounting seat. A vertical carried material seat composite spring is arranged between each carried material seat lifting block and the lower portion of the corresponding carried material mounting seat. A carried material seat cooperating with a product is arranged above each carried material seat lifting block. A press-fitting device comprises a press-down device cooperating with the products on the carriers and a carried material seat jackingdevice which is located below the press-down device and cooperates with the carried material seat lifting blocks. According to the continuous automatic assembly machine, the carried material seat lifting blocks and the press-down device can be in butt joint precisely, meanwhile, pressing assembly of a lock piece and a lug plate can be achieved, it can be ensured that the press-down portion is a flat plate between two elastic piece mounting columns, the press-fitting precision is ensured, elastic deformation of the elastic pieces is avoided, and meanwhile continuous automatic machining is achieved.

Owner:CHONGQING TECH & BUSINESS UNIV

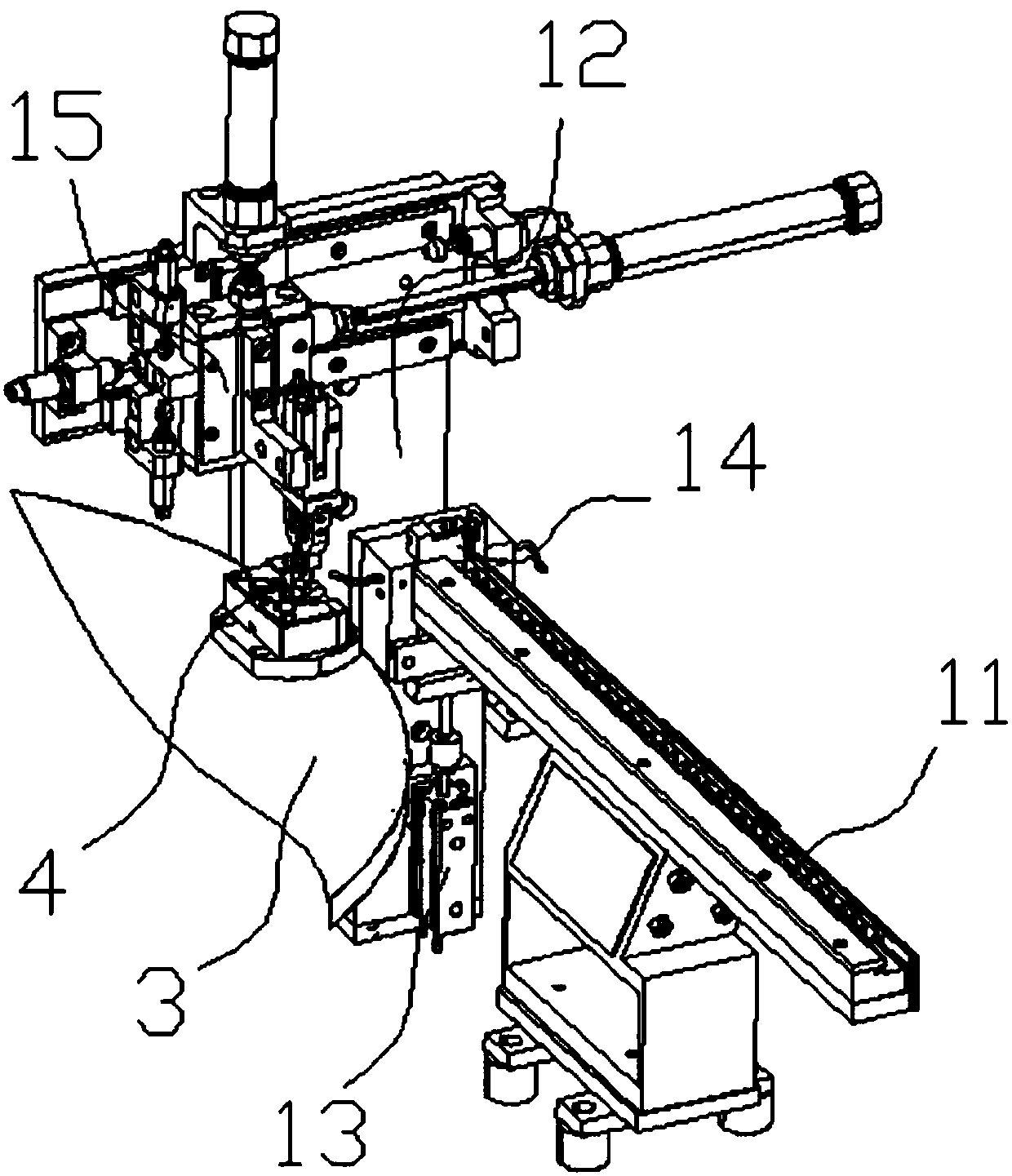

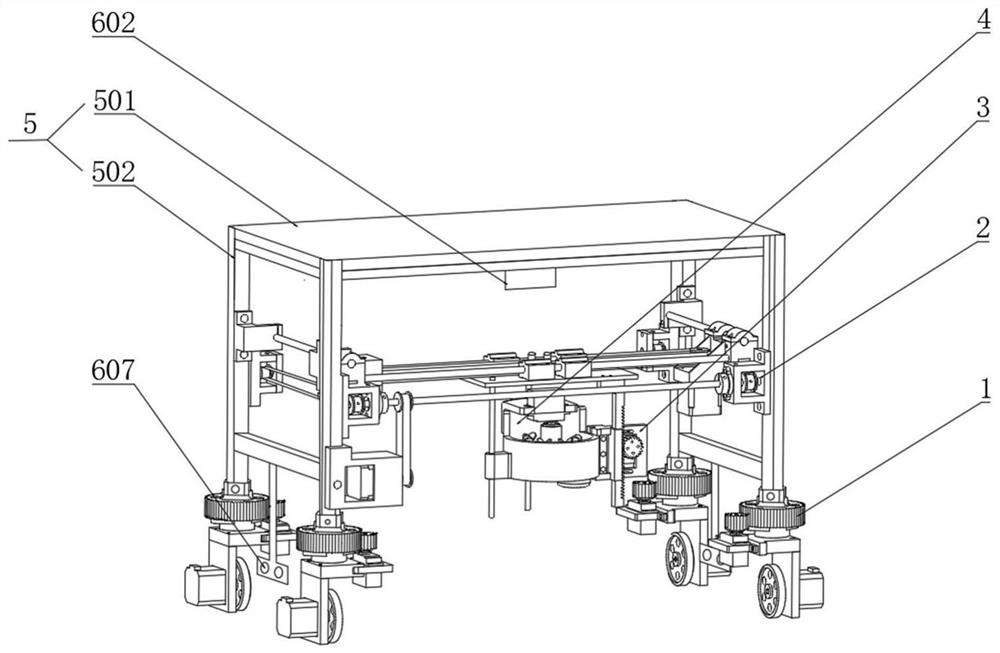

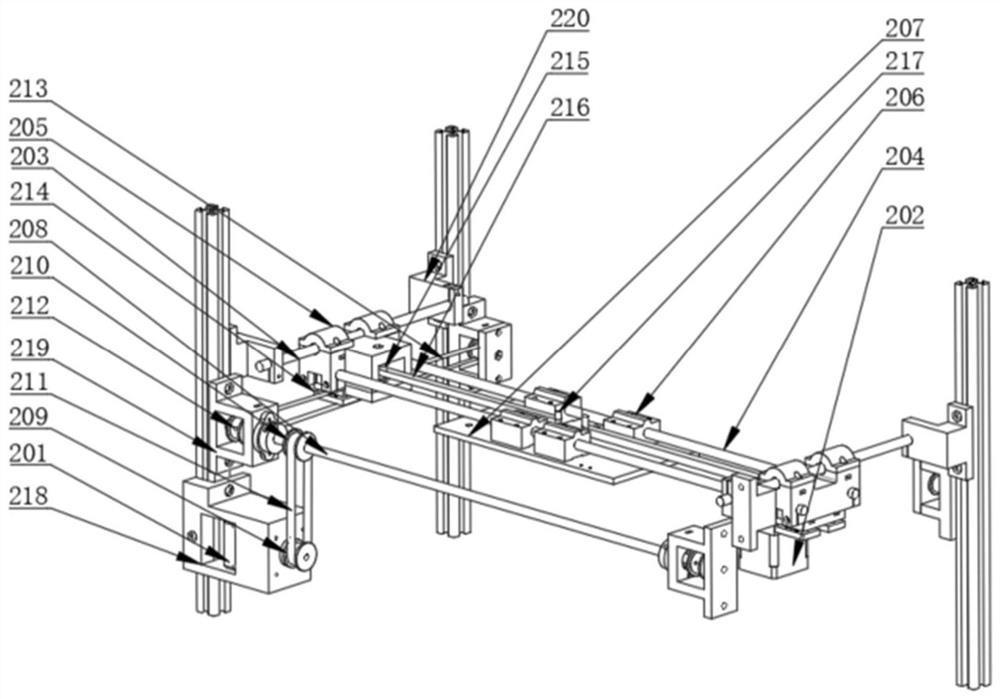

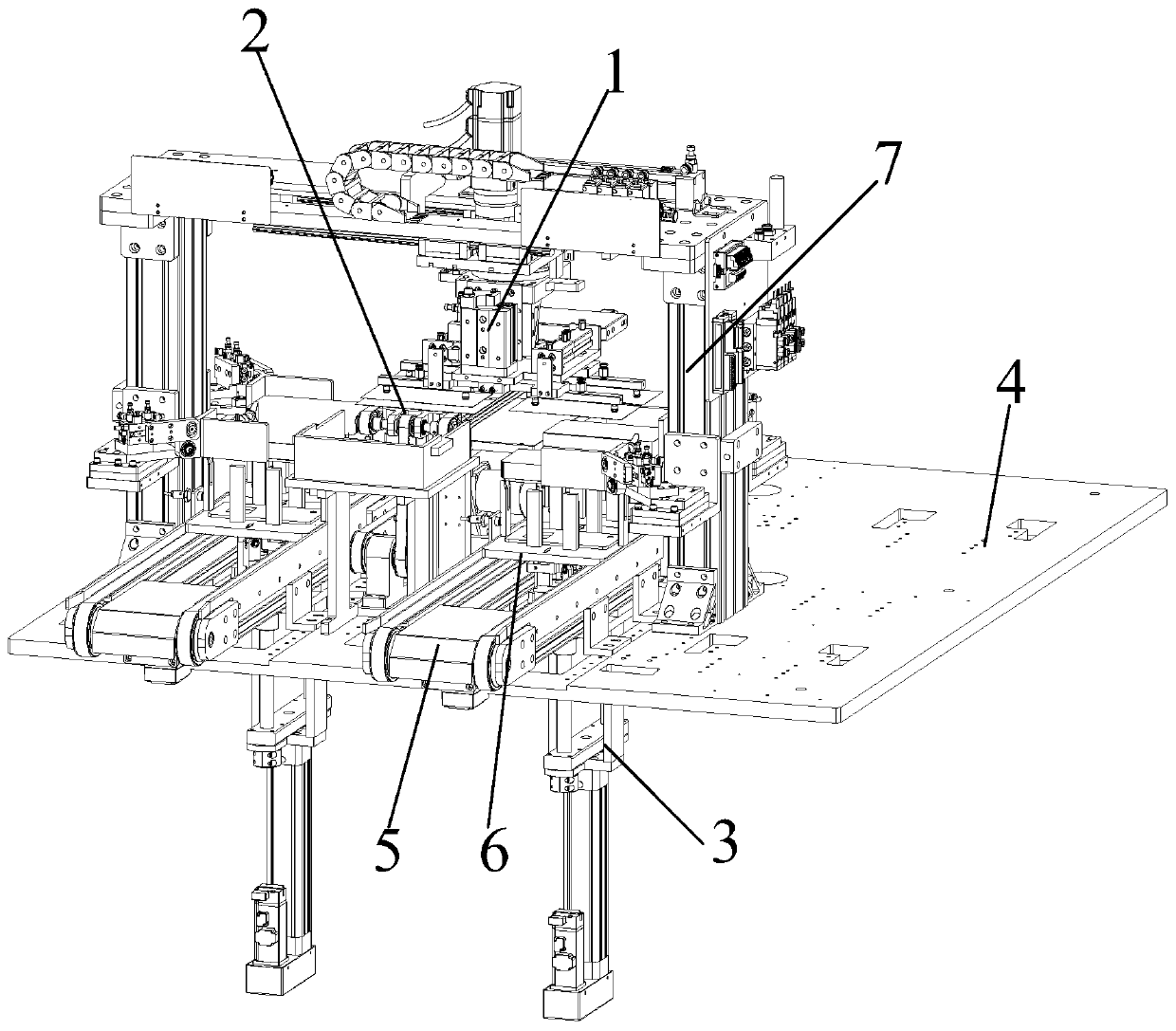

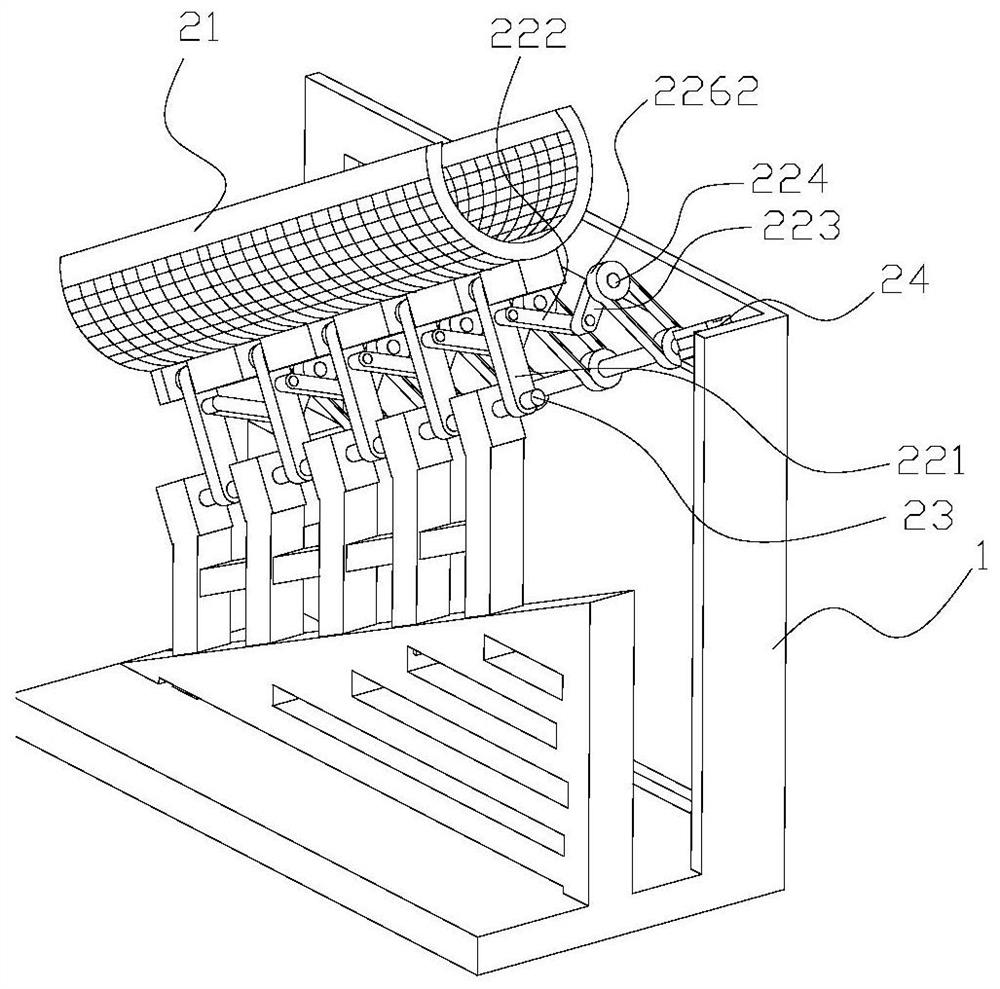

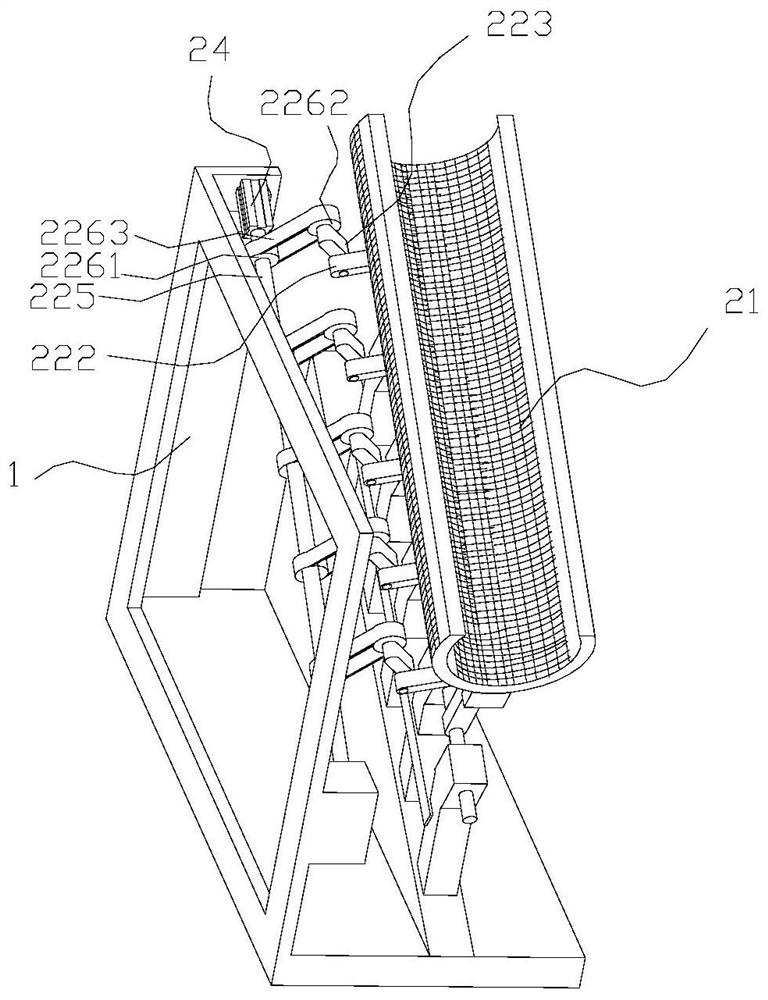

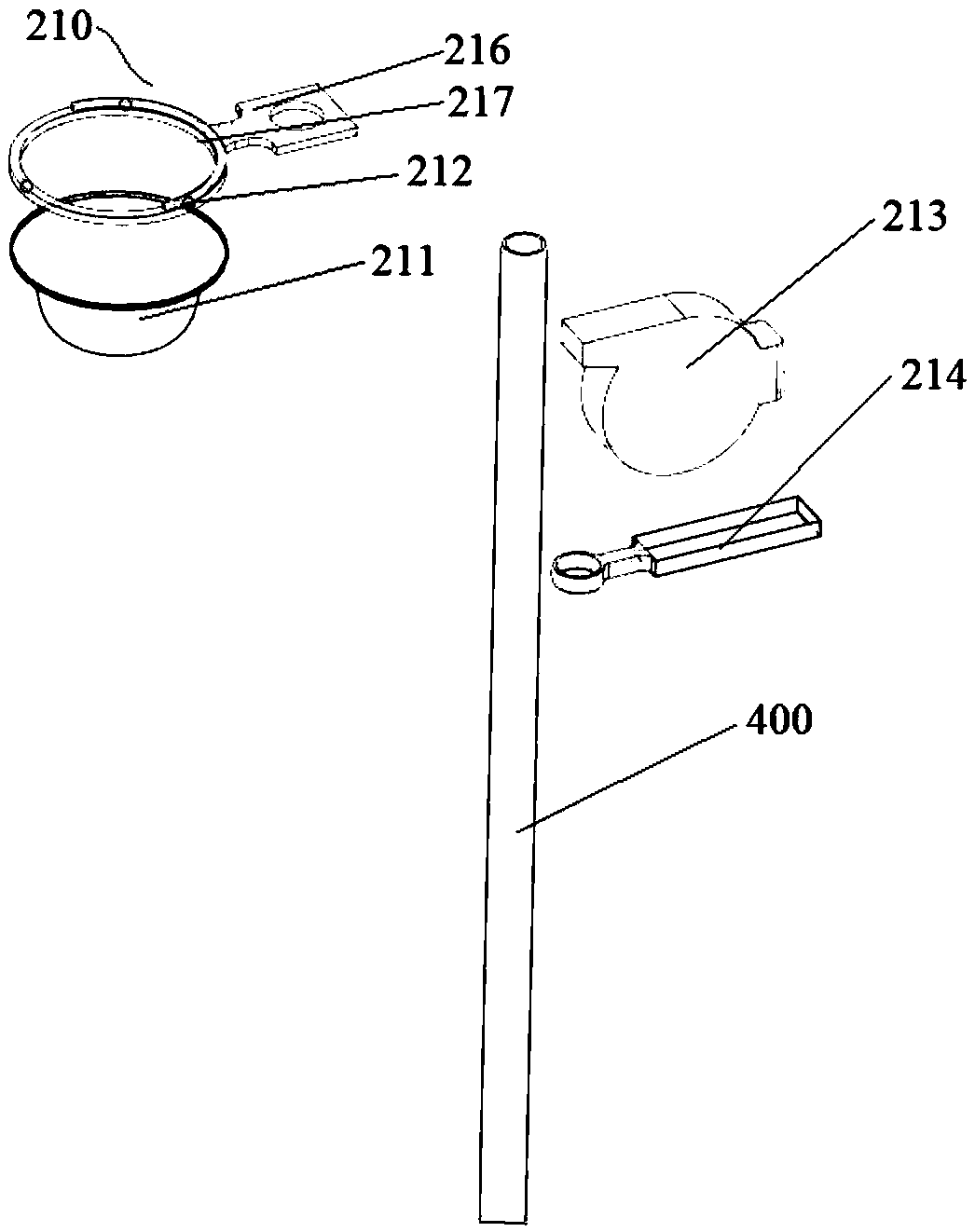

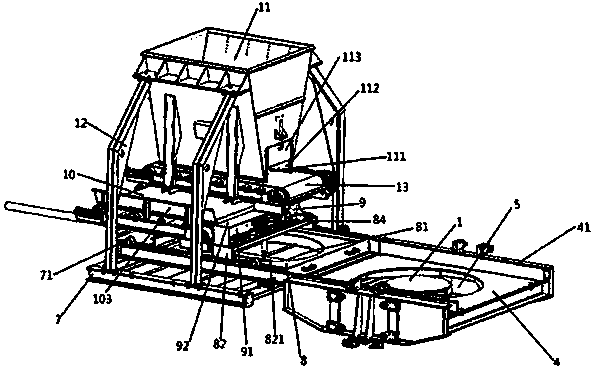

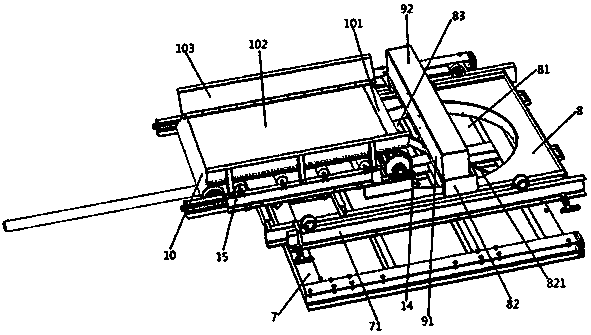

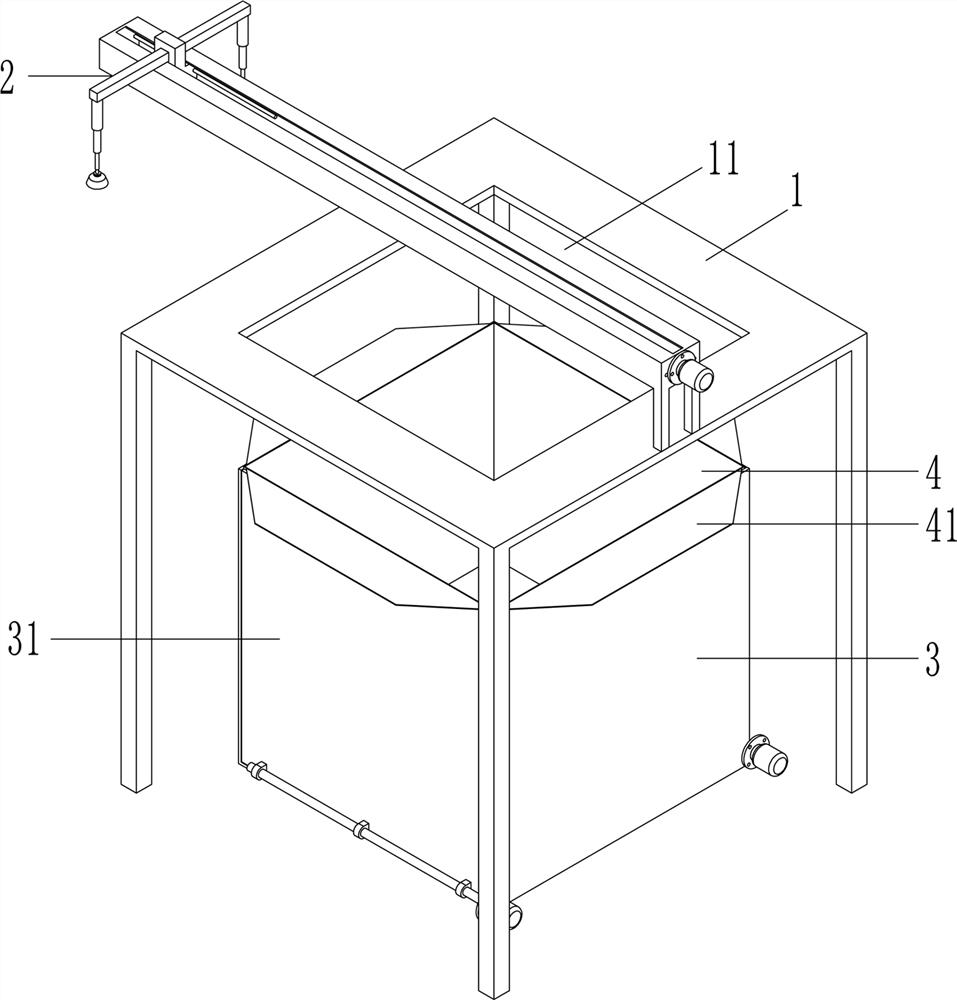

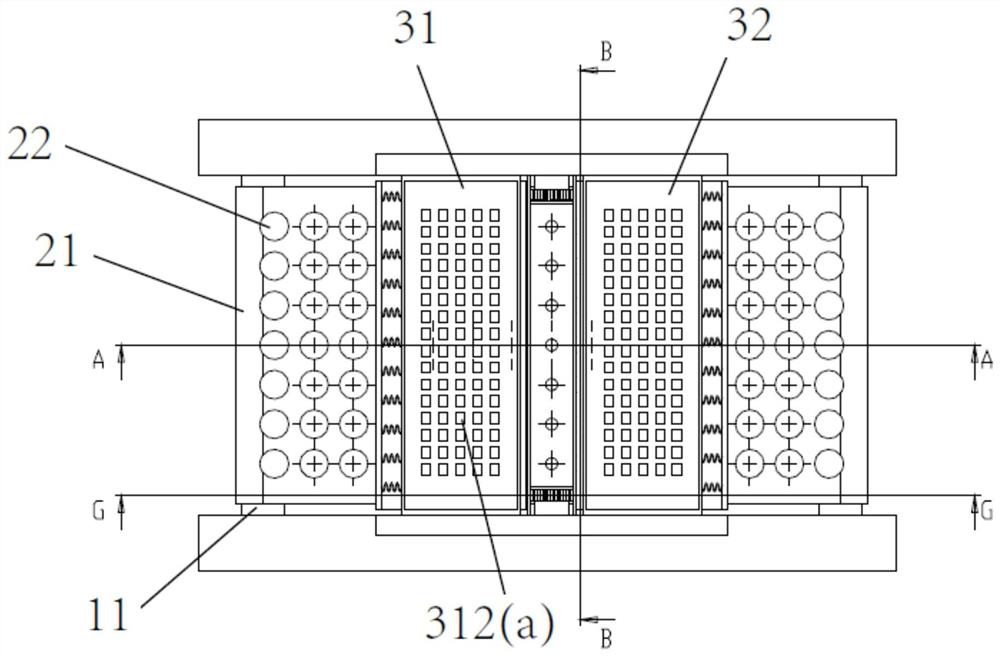

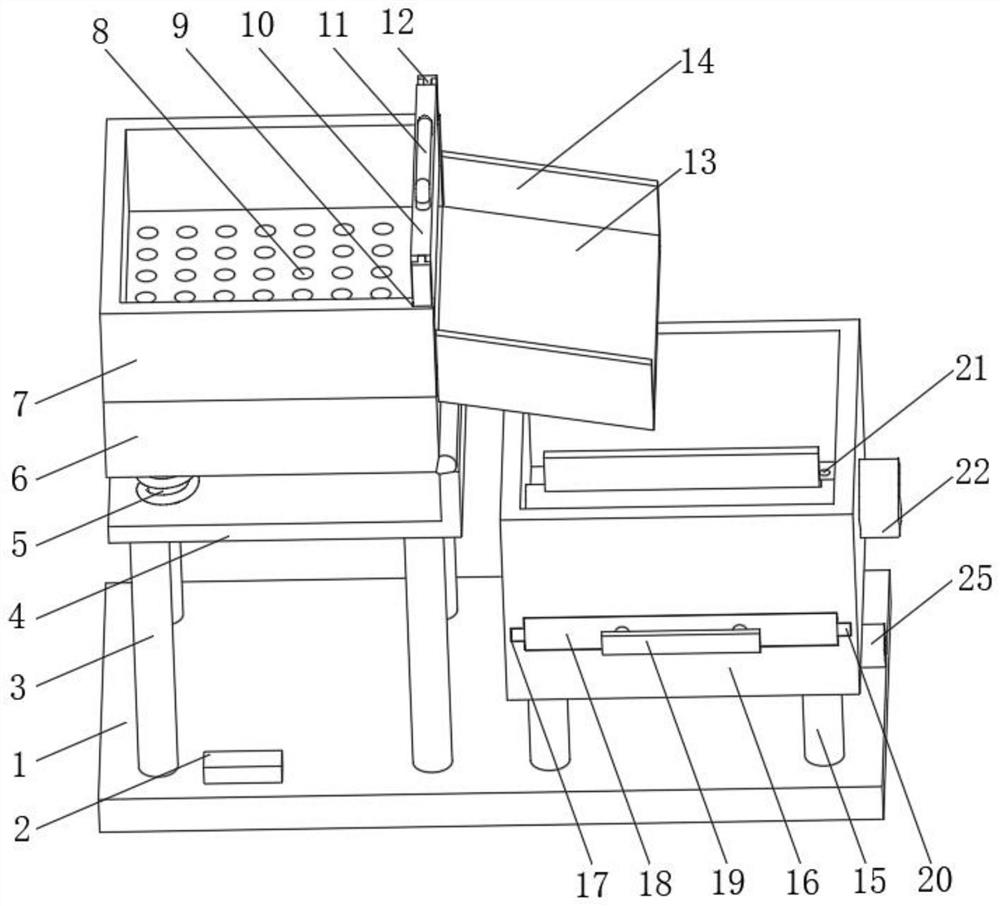

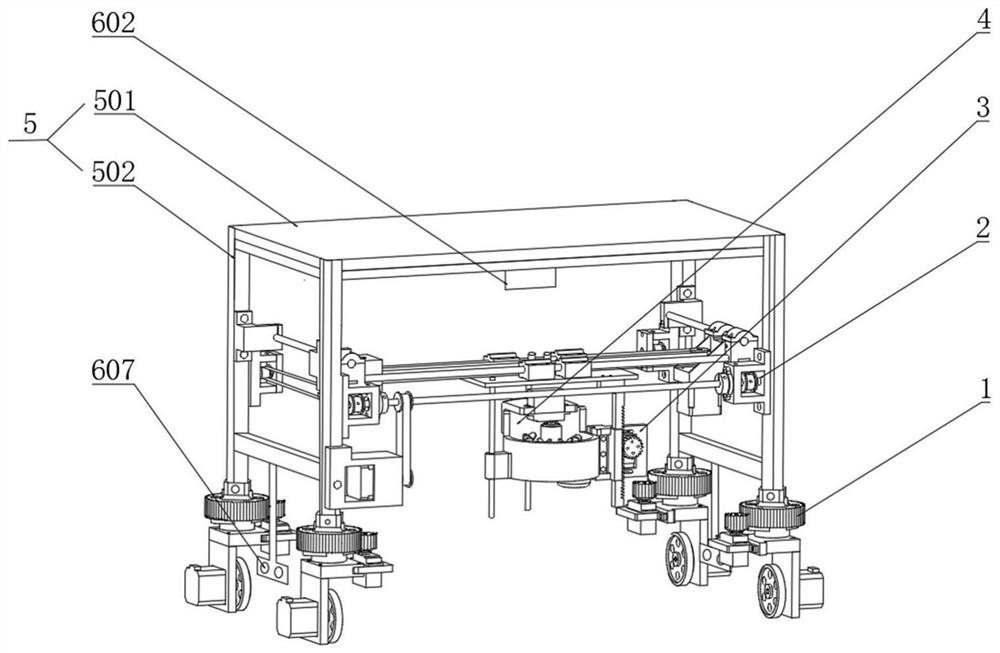

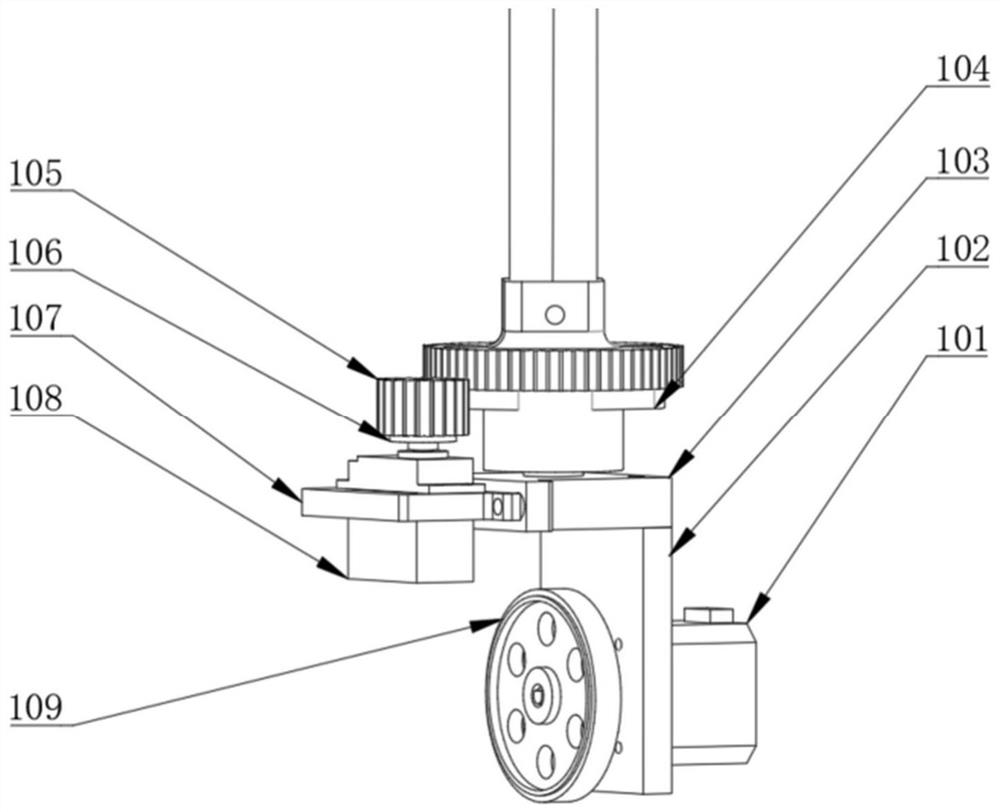

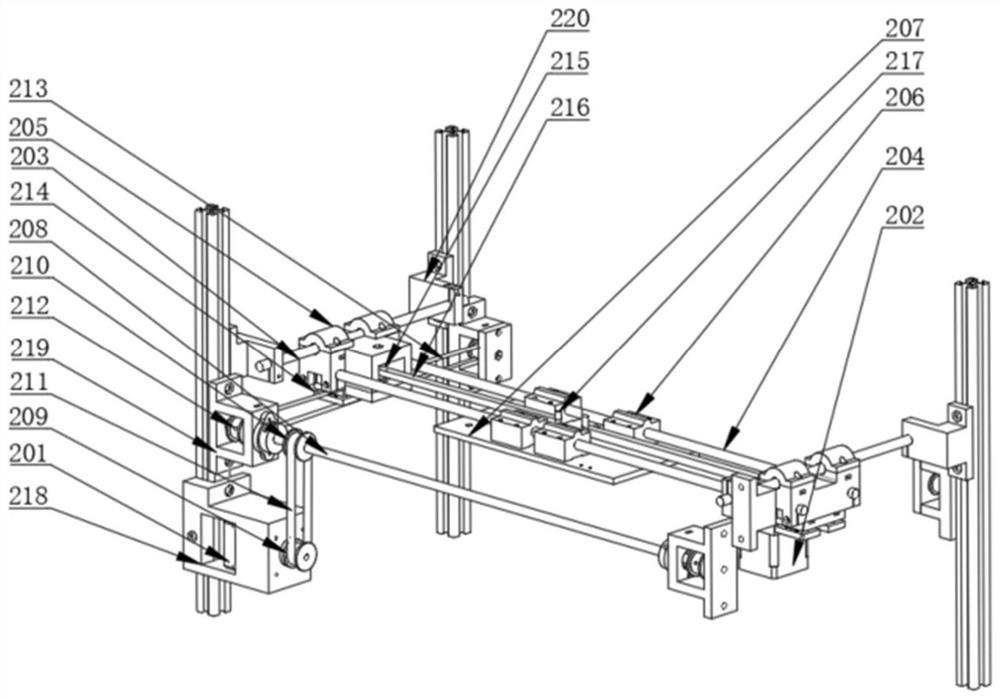

Seedling supplementing device and method

ActiveCN113228900AIngenious structural designPrecise positioningTransplantingImaging processingMachine vision

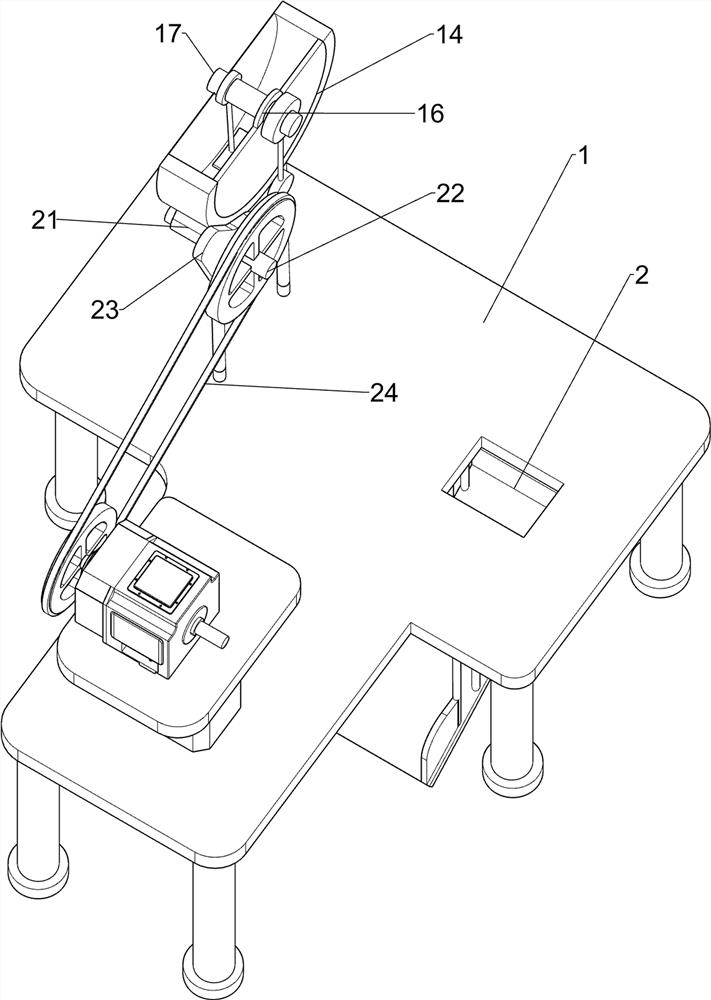

The invention belongs to the field of agricultural equipment, and relates to a seedling supplementing device and method. The seedling supplementing device comprises a walking mechanism, a positioning mechanism, a seedling feeding height adjusting mechanism, a seedling storing and feeding mechanism, a frame and a control mechanism. The seedling feeding height adjusting mechanism and the seedling storing and feeding mechanism are controllably arranged below a frame platform through the positioning mechanism, and the positioning mechanism can drive the seedling feeding height adjusting mechanism and the seedling storing and feeding mechanism to move in the transverse direction and the longitudinal direction. According to the seedling supplementing device, through a walking mechanism, pivot steering can be achieved through four-wheel steering joint matching, and walking and steering in a complex environment can be achieved through independent control of four wheels. The positioning mechanism realizes accurate positioning of seedling filling through calibration and matching of image coordinates and the position of a seedling guide pipe. A camera captures the ground environment in real time, and machine vision and image processing based on Raspberry Pi are rapid and accurate. Due to the ingenious structural design of the seedling storing and feeding mechanism and the seedling feeding height adjusting mechanism, a certain quantity of seedlings can be stored, and the seedlings can accurately fall into holes.

Owner:CHINA AGRI UNIV

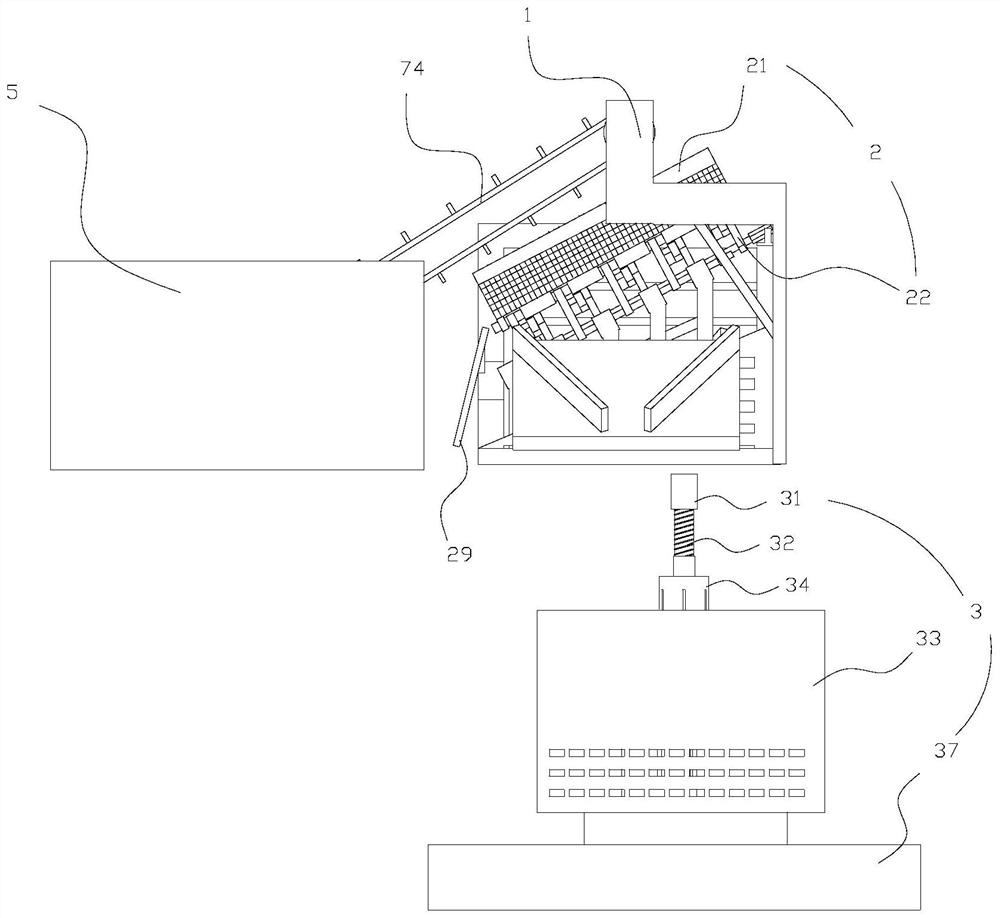

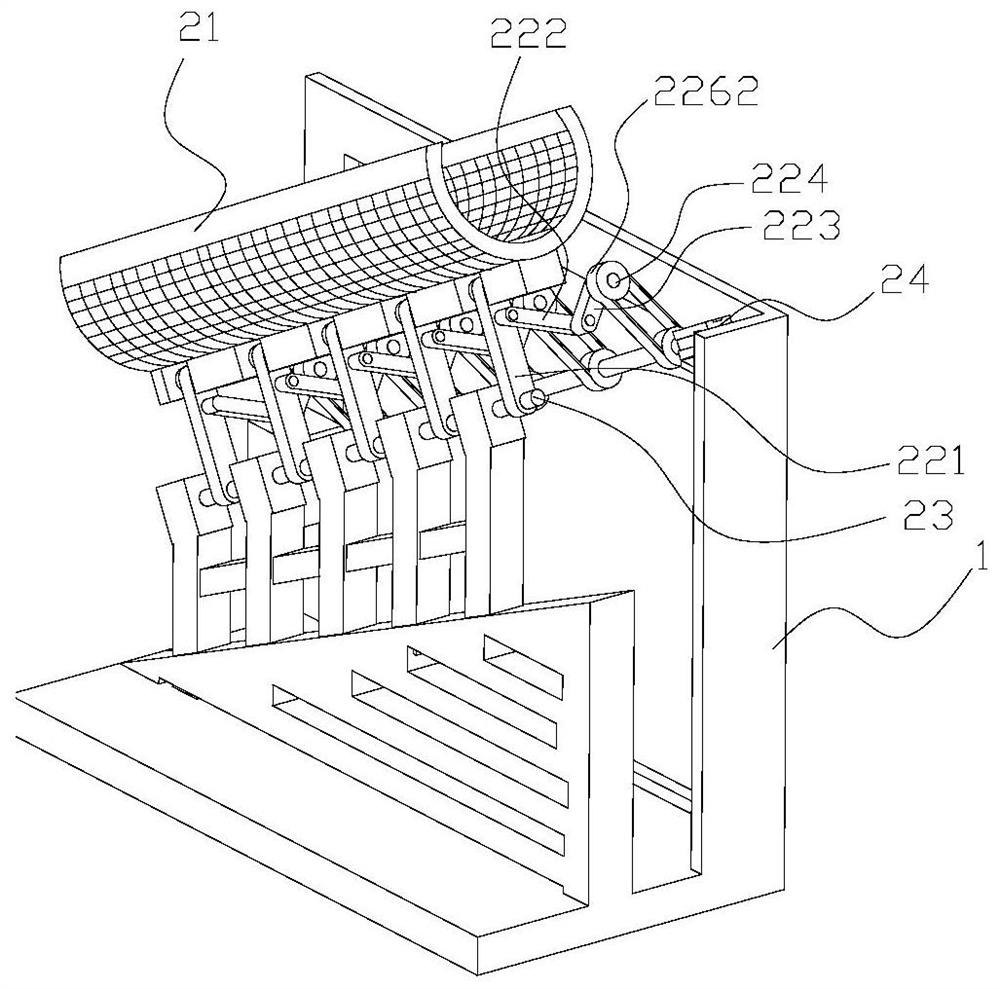

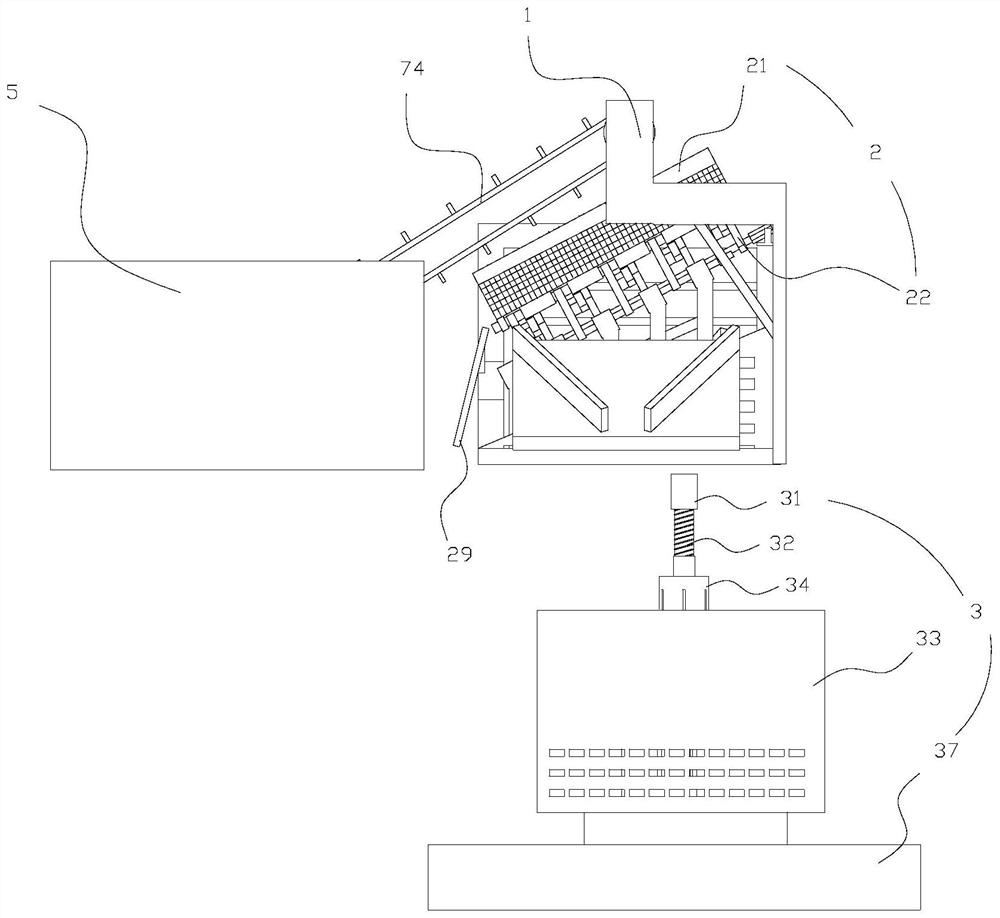

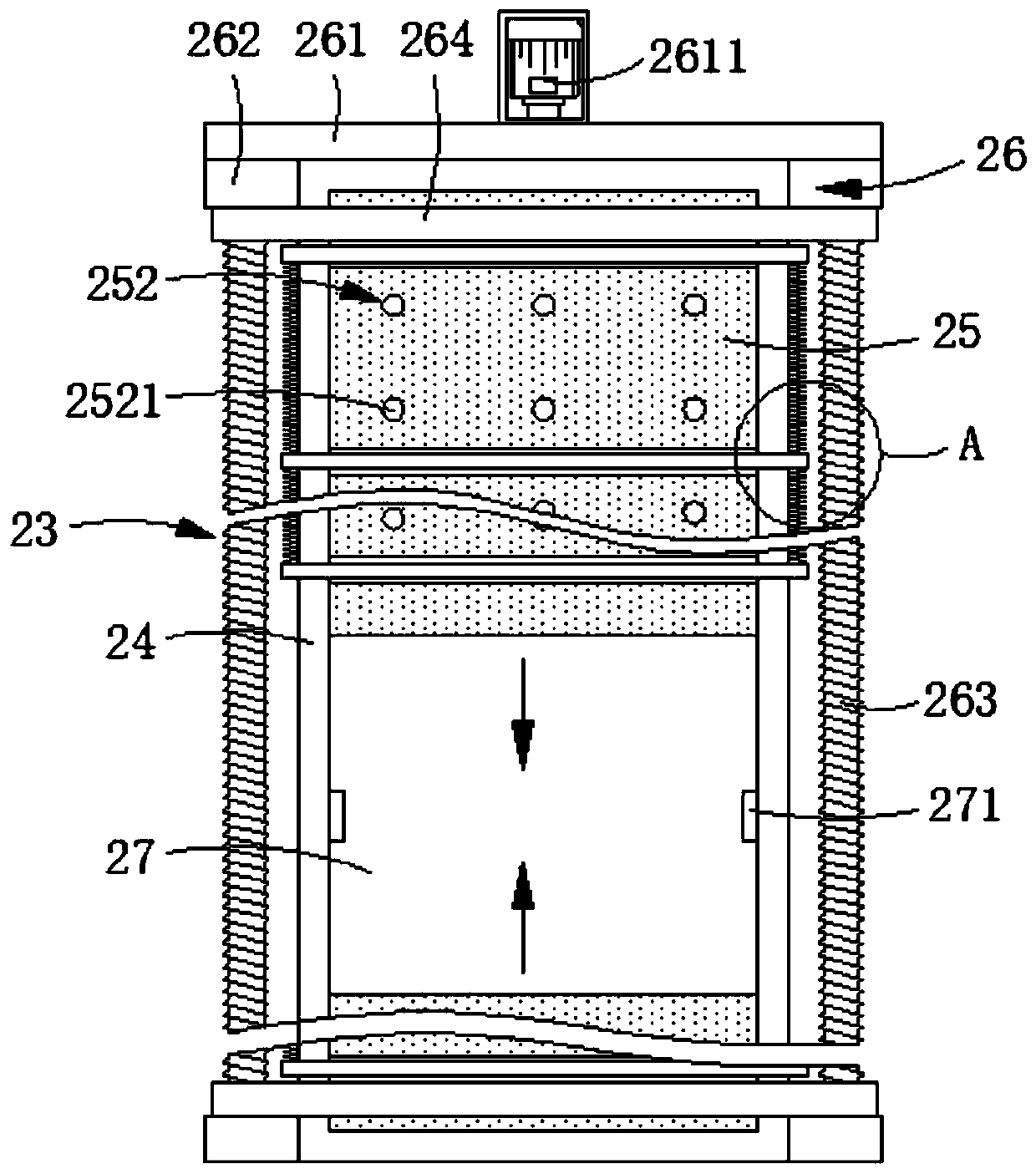

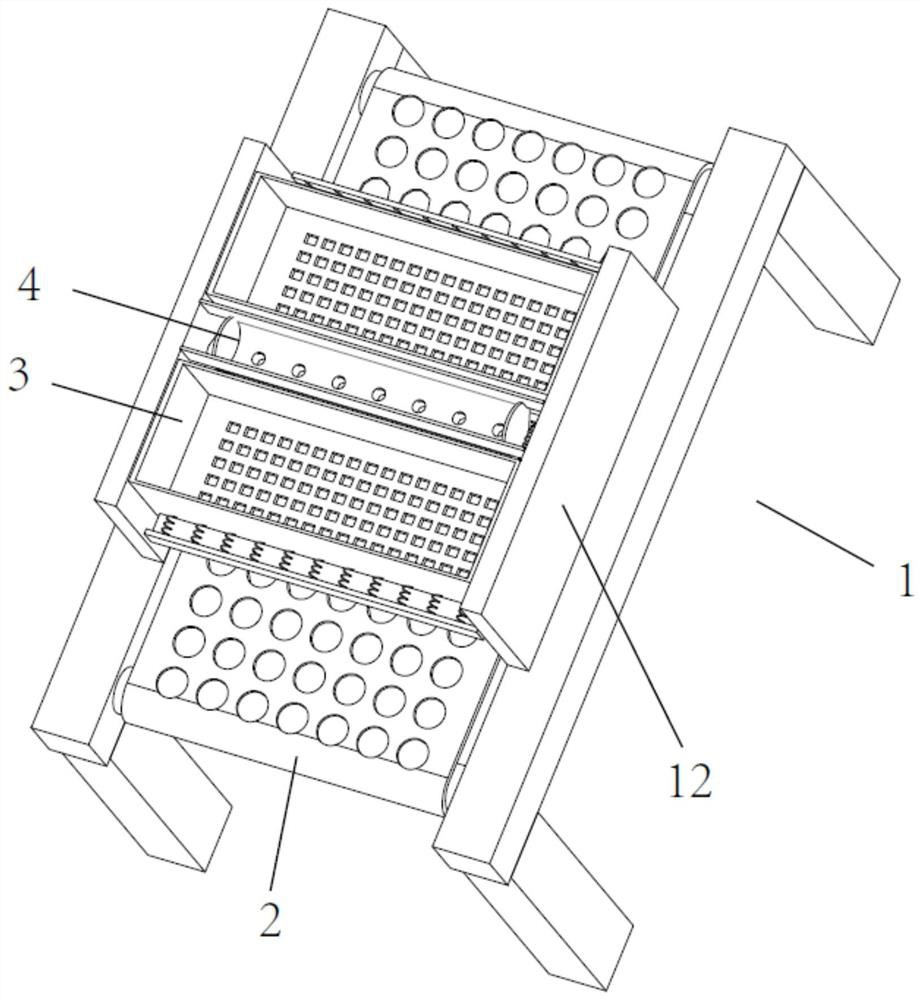

Multi-stage screening mechanism and concrete gravel screening device

The invention discloses a multi-stage screening mechanism for screening in a spatial position sequence. A primary screening device and a secondary screening device are sequentially arranged from top to bottom, a first driving motor is used for driving a swing mechanism to swing, and then an arc screen is driven to swing; materials screened by the arc screen can fall into the secondary screening device; an output shaft of a second driving motor is connected with the top of a connecting rod, and the bottom of the connecting rod extends downwards; a sleeve is arranged on the periphery of the connecting rod, and a gap exists between the sleeve and the connecting rod; a downward moving pressing piece can drive a movable block to slide downwards so that the other end of a second connecting rod can extend out of a through groove; a secondary screen is connected to the sleeve; the secondary screen comprises a bottom screen and a side screen, and the bottom screen and the side screen define a screen structure with an opening in the top and the periphery and the bottom connected; and the secondary screen can rotate relative to a chassis. The invention further discloses a concrete gravel screening device. The multi-stage screening mechanism and the concrete gravel screening device have the advantage of being high in screening efficiency.

Owner:郑州市金禄市政工程有限公司

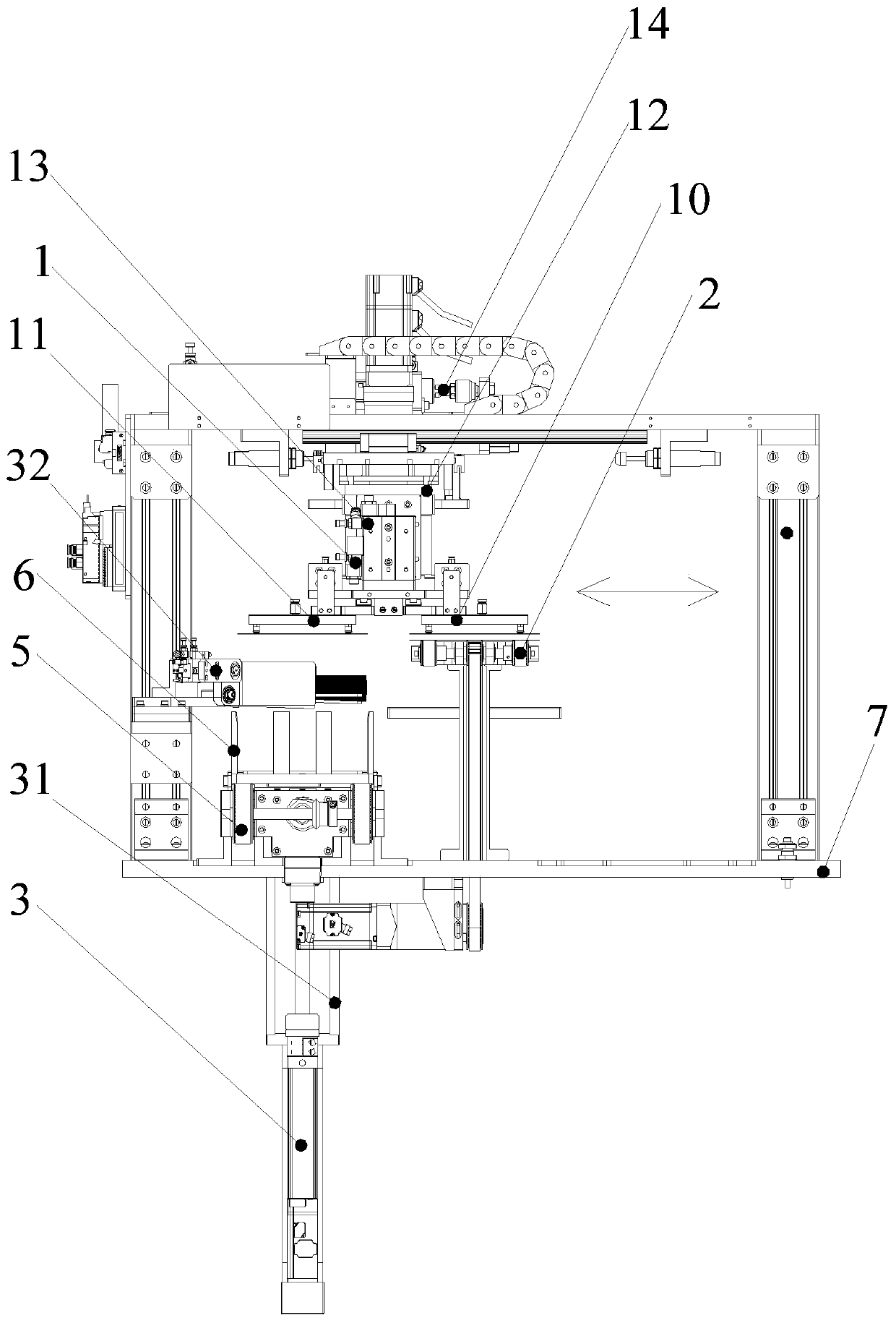

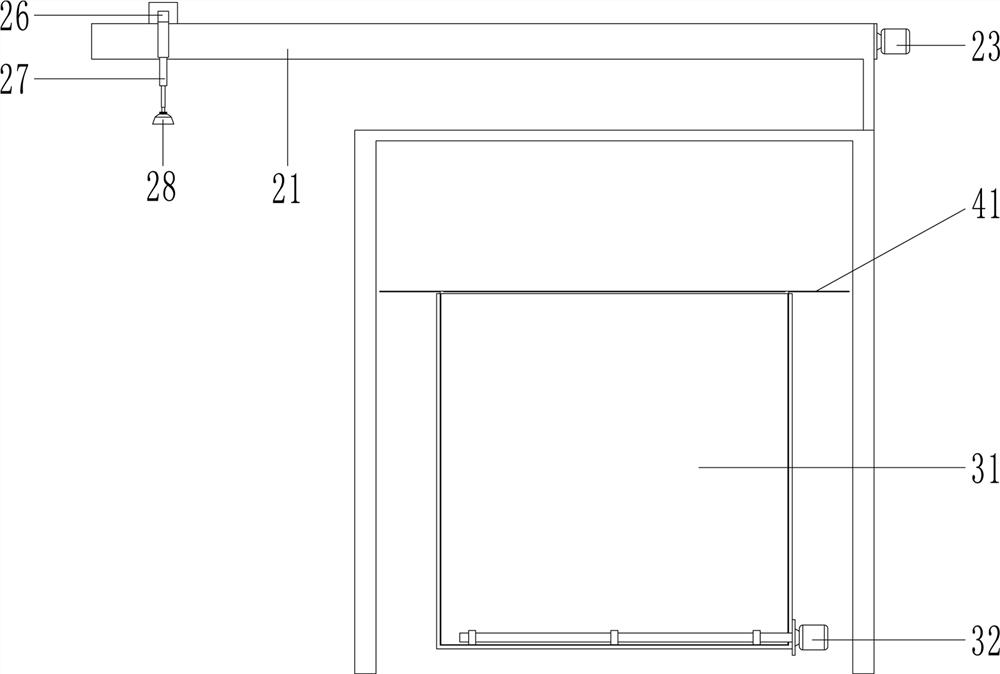

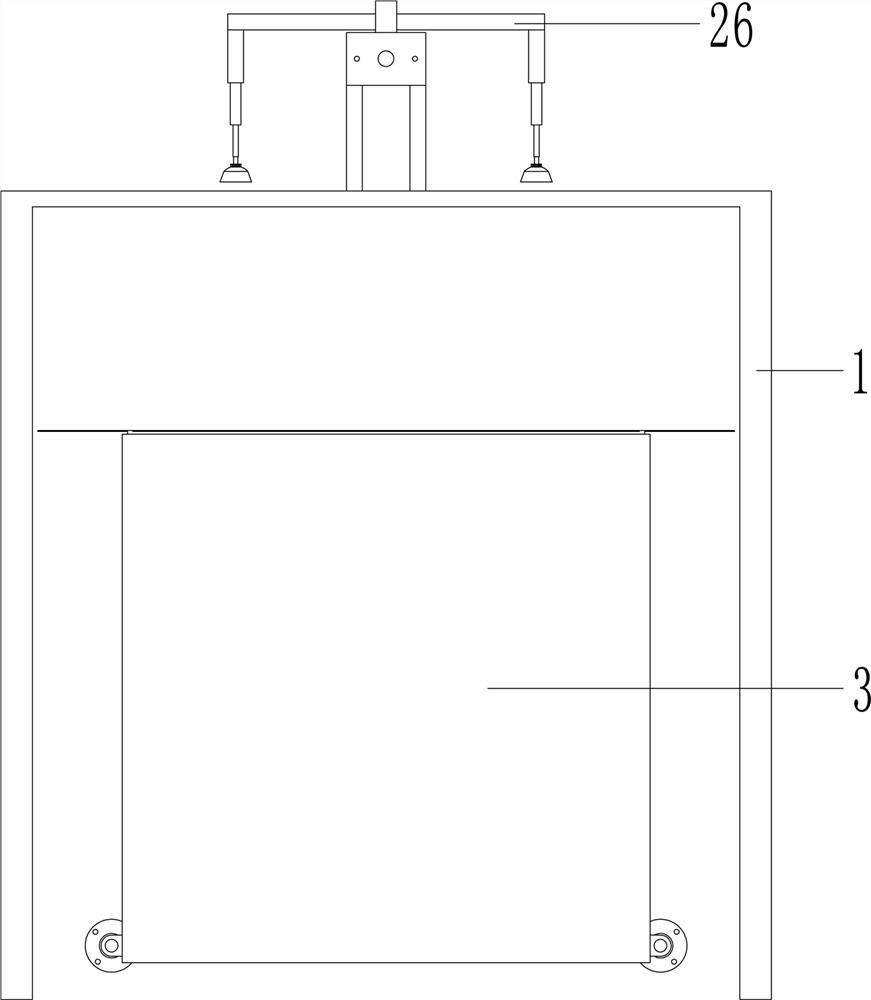

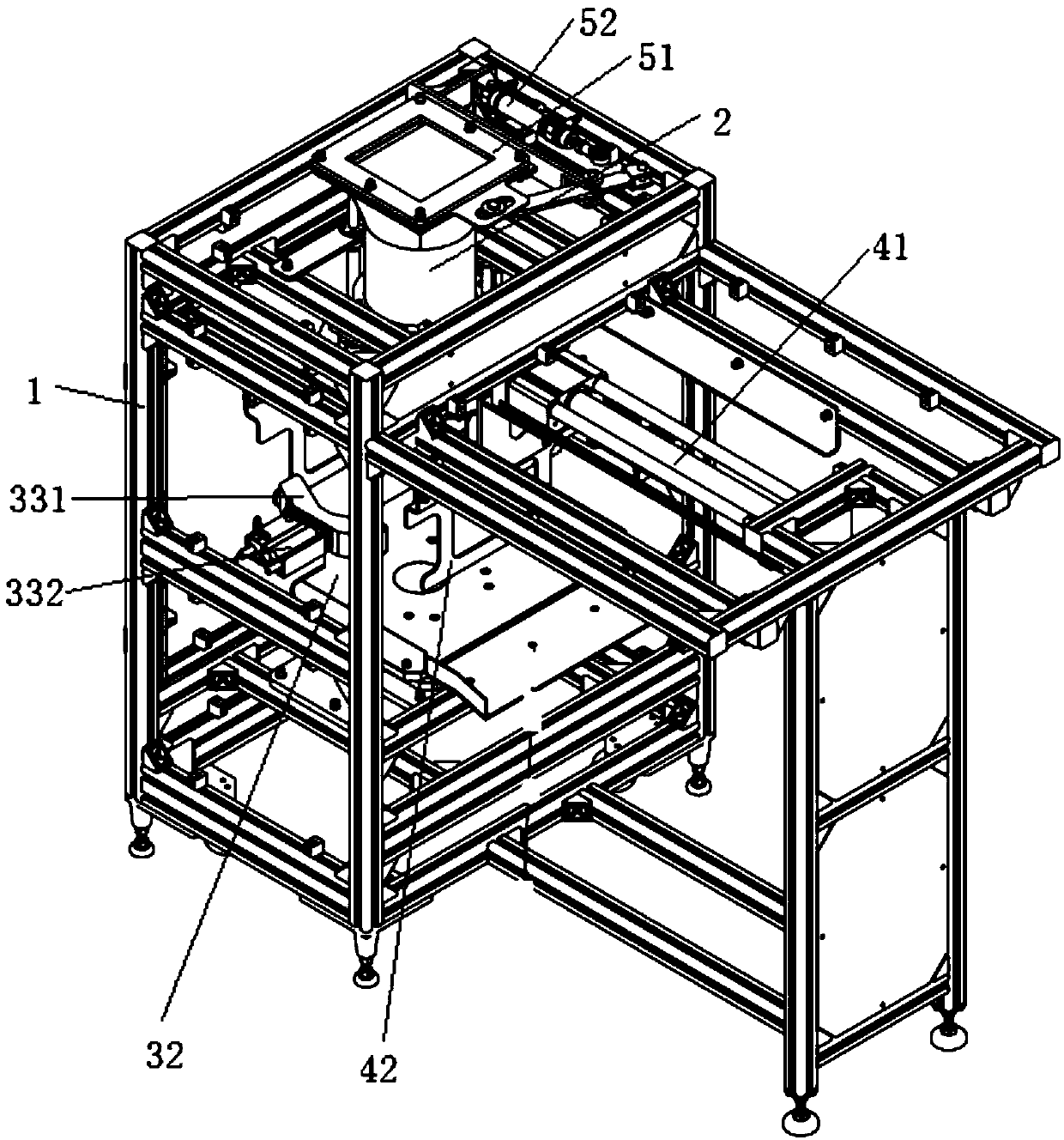

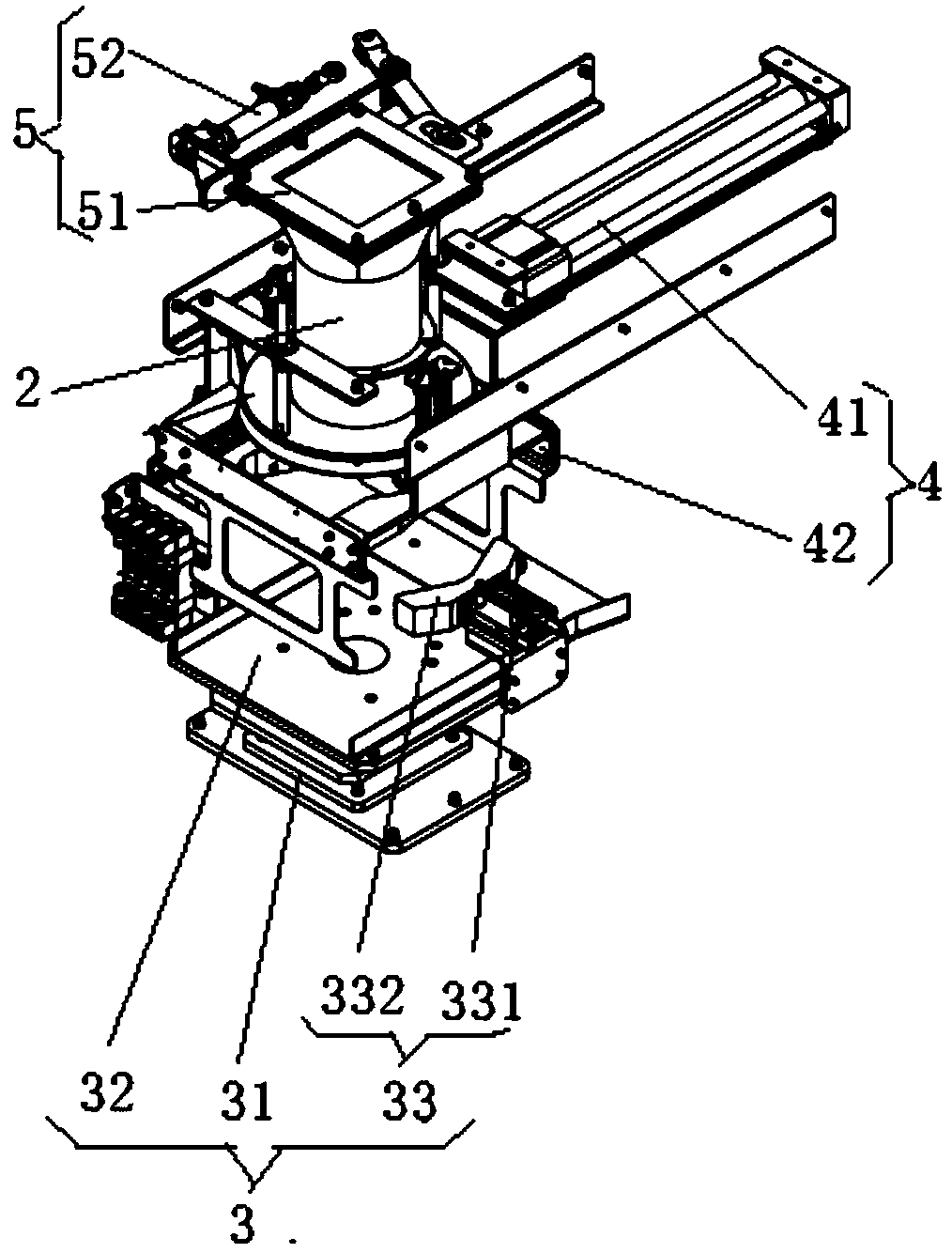

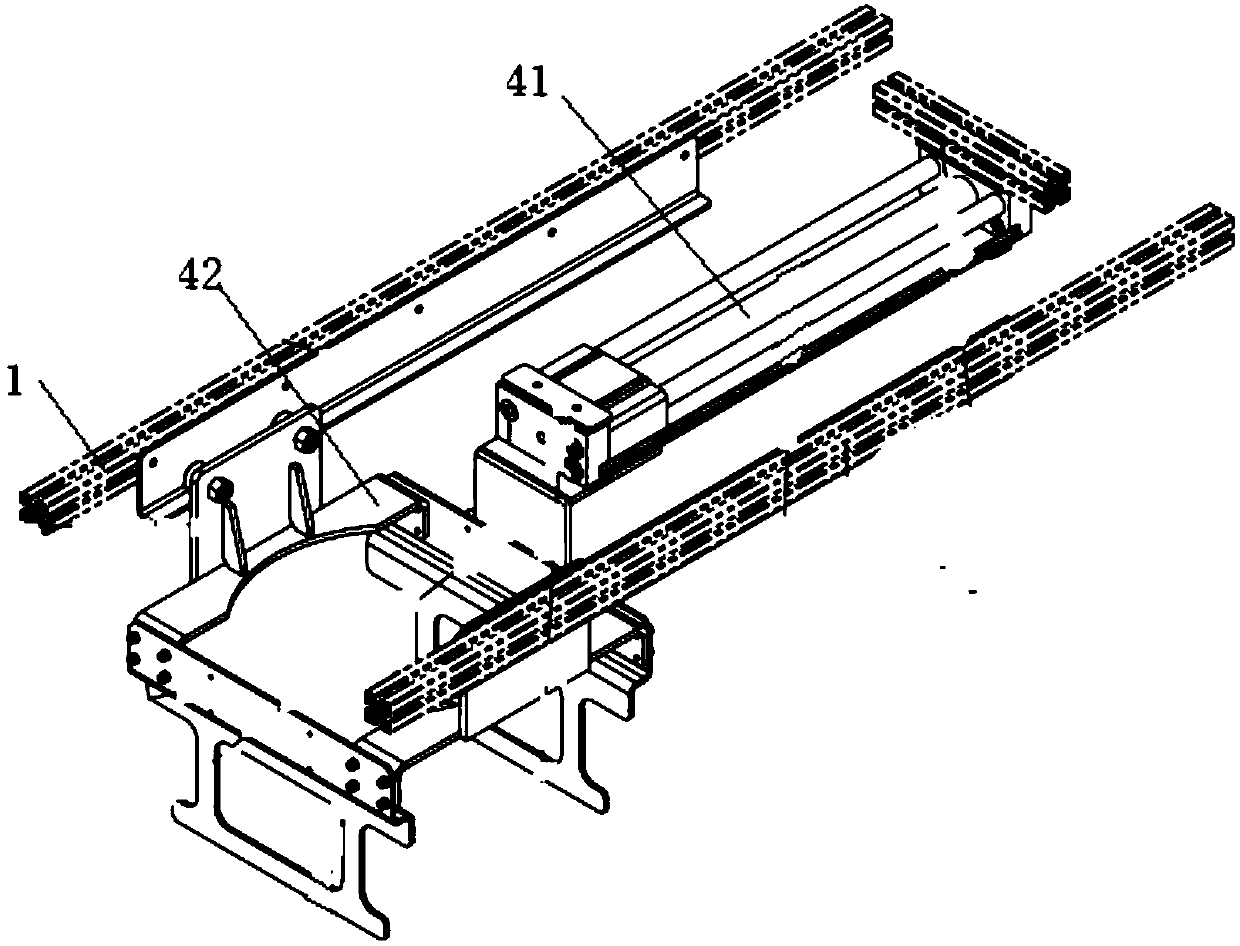

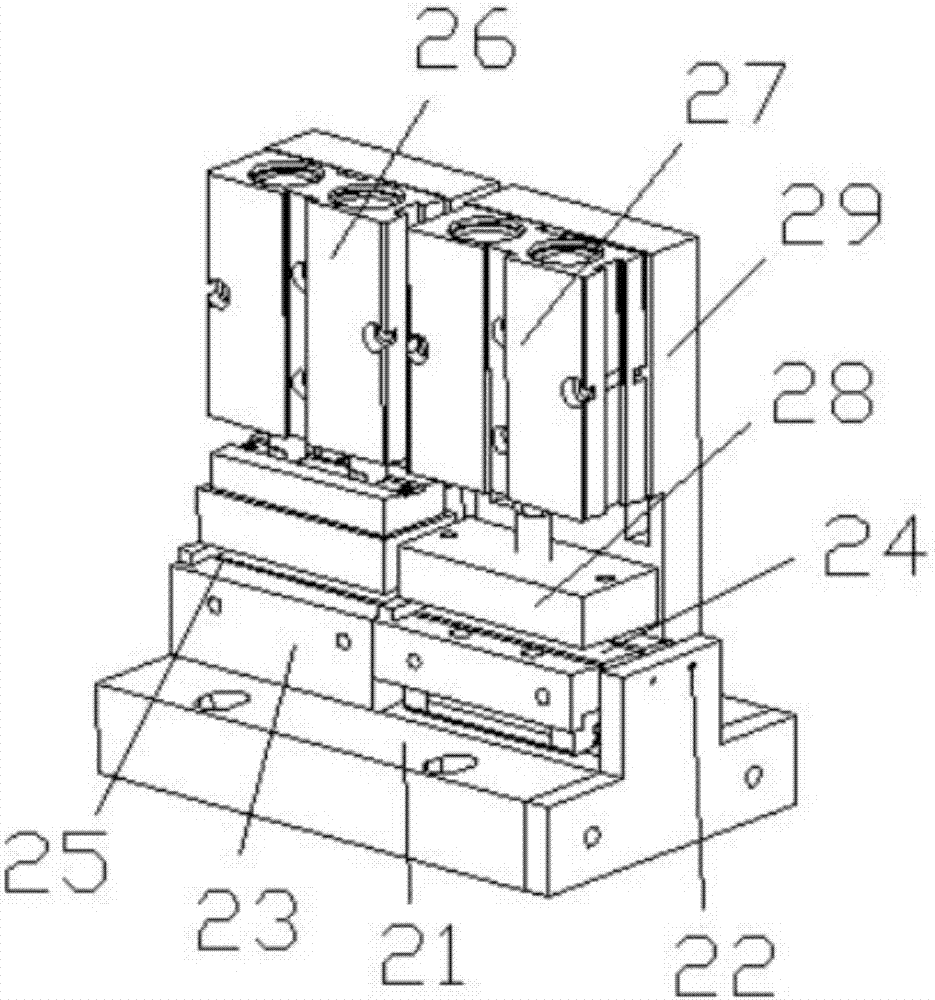

Precise unloading device of laser scribing machine

PendingCN111302064ASolve common problemsAvoid damageCharge manipulationConveyor partsLaser scribingMachine

The invention relates to a precise unloading device of a laser scribing machine. The precise unloading device comprises a working table, a product conveying line used for conveying products, an unloading box used for loading the products, an unloading box conveying line used for conveying the unloading box, an unloading carrying mechanism used for conveying the products on the product conveying line to a precise unloading mechanism and the precise unloading mechanism used for receiving the products from the unloading carrying mechanism and tidily stacking in the unloading box. The unloading carrying mechanism is mounted on a bracket, the bracket is fixed to the working table, and the product conveying line and the unloading box conveying line are located below a motion trajectory of the unloading carrying mechanism. Battery pieces automatically and precisely fall into a loading box of a series welder, the laser scribing machine can directly adopt the loading box of the series welder during unloading, and the problem of common use of the loading box of the series welder and the unloading box of the laser scribing machine is solved; and artificial participation is obviously reduced,and the possibility of the battery pieces being damaged in the carrying process is avoided.

Owner:江阴德龙能源设备有限公司

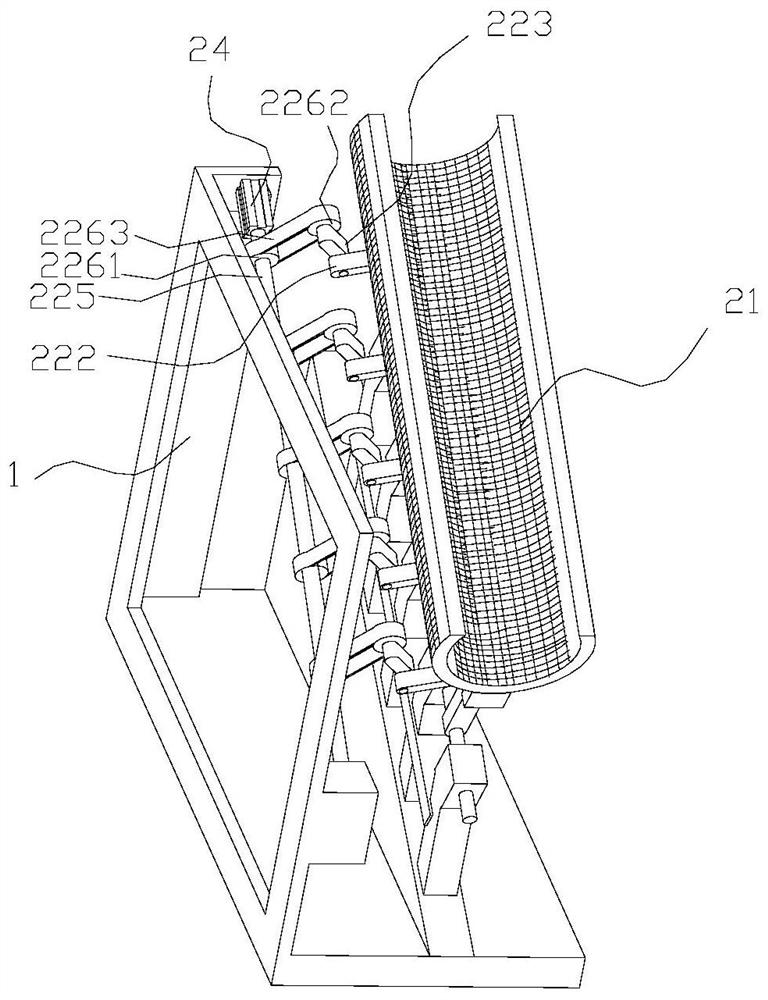

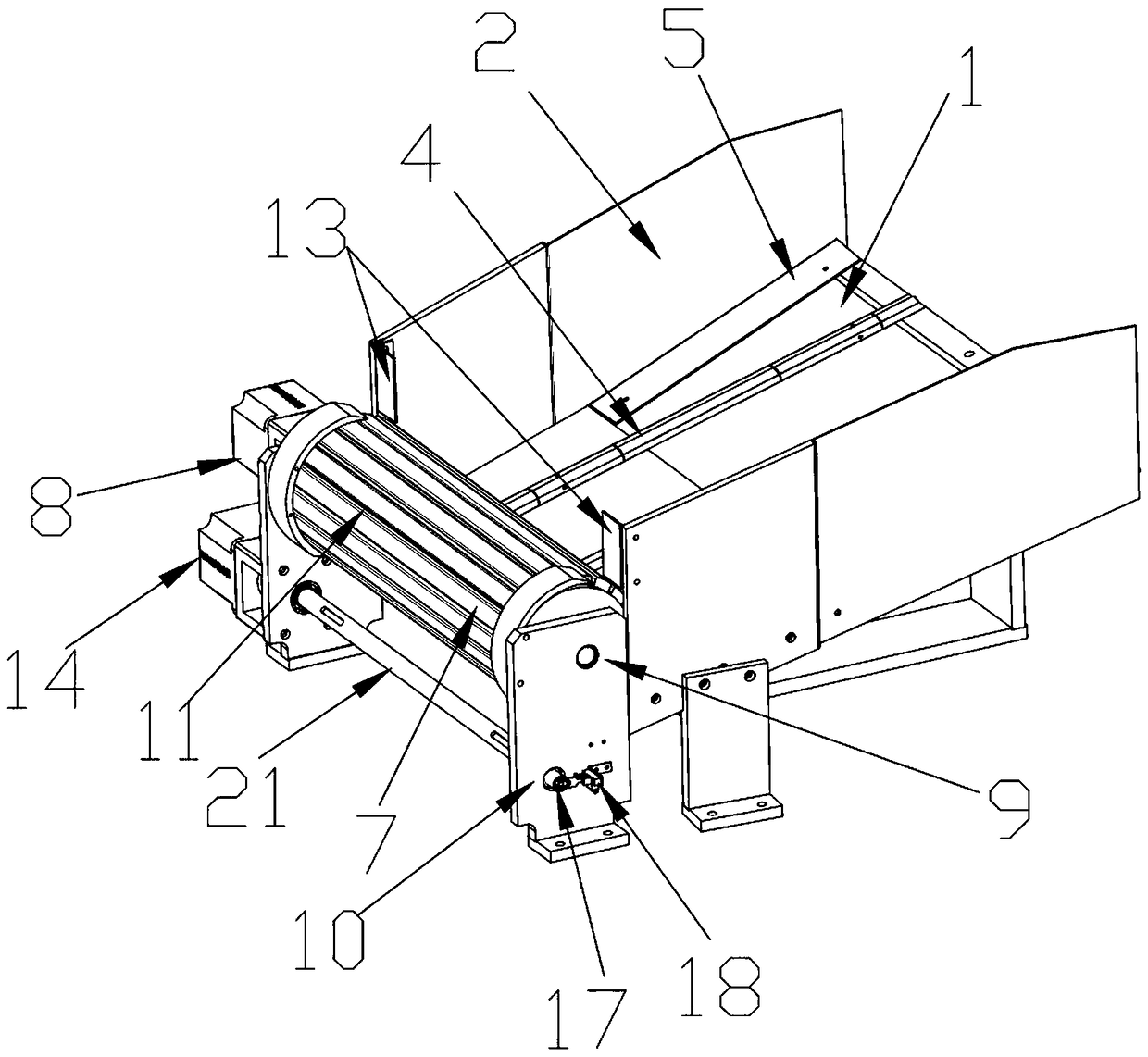

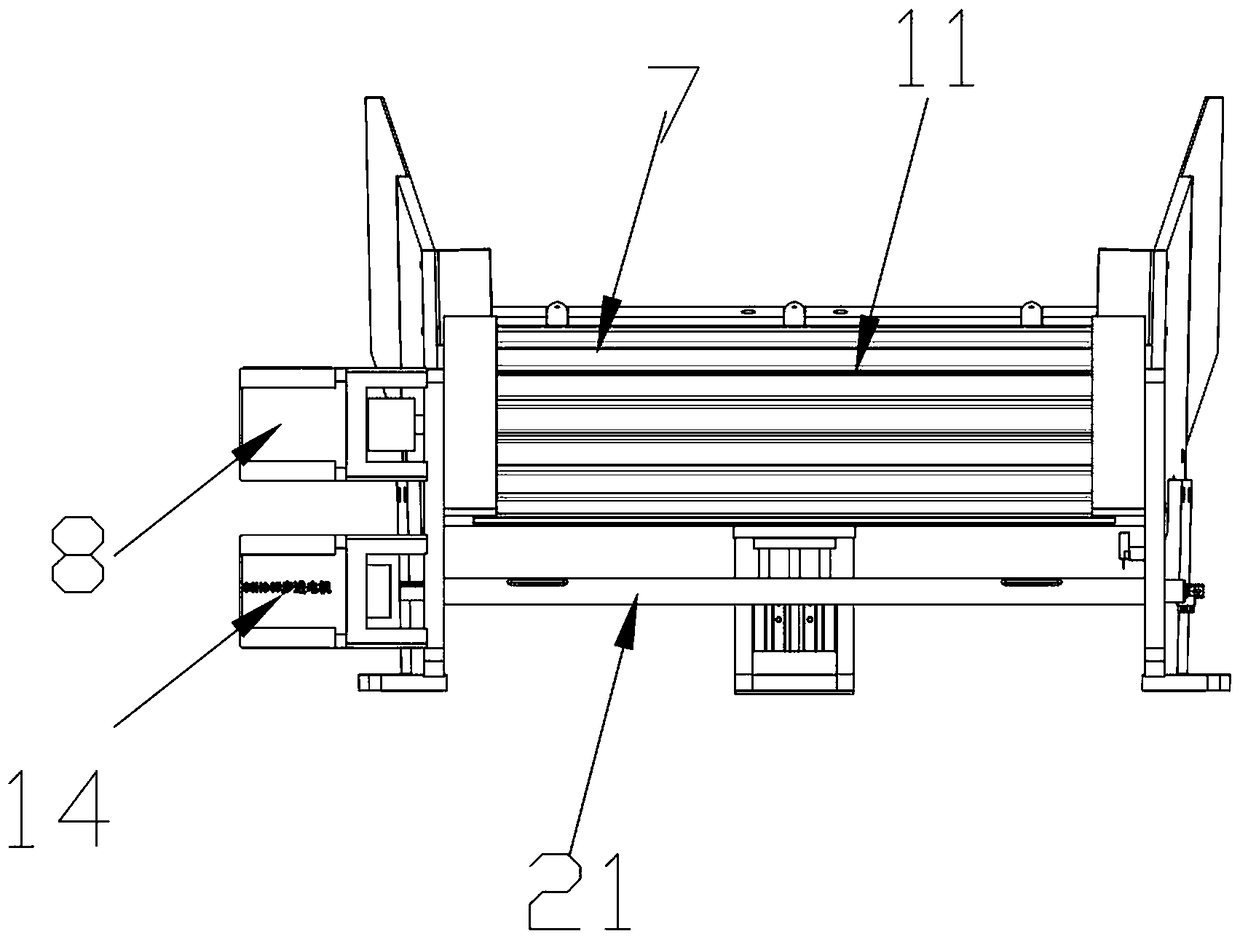

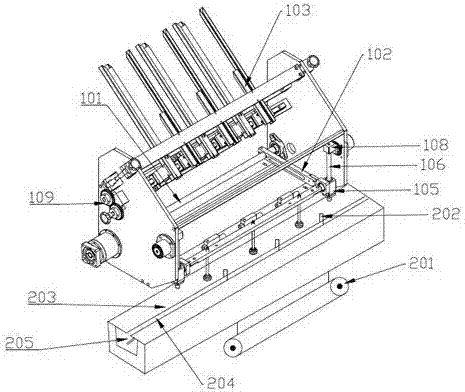

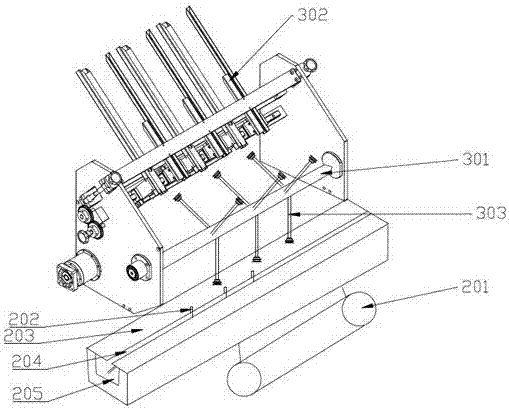

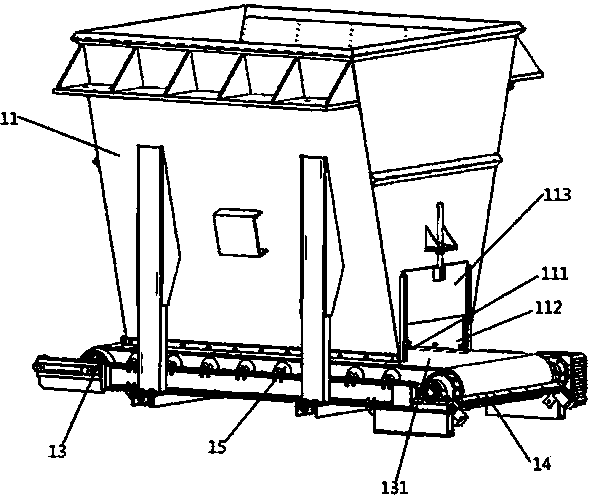

Full-automatic material distribution device for conveying long-strip-shaped rubber hose

The invention relates to a full-automatic material distribution device for conveying a long-strip-shaped rubber hose and belongs to the field of automatic equipment. The full-automatic material distribution device comprises a rubber hose material distribution mechanism and a rubber hose conveying mechanism, wherein the rubber hose material distribution mechanism comprises a discharging hopper anda material distribution assembly which are downwards and obliquely arranged; the material distribution assembly is composed of a mounting seat, a round roller and a material distribution stepping motor for driving the round roller to rotate; the rubber hose conveying mechanism is composed of two conveyor belts which are structurally symmetrical and a conveying stepping motor; the rubber hose material distribution mechanism can realize automatic discharging and regular automatic material distribution; meanwhile, a rubber hose is automatically conveyed to the rubber hose conveying mechanism; a whole discharging, material distribution and feeding process has a high automation degree and each rubber hose can orderly and accurately fall onto a jig; the rubber hose can be driven by the conveyingstepping motor and is conveyed backwards, and continuous discharging, material distribution and feeding can be realized, so that the conveying efficiency can be improved and the full-automatic material distribution device is especially applicable to an automatic assembling line which needs to work continuously.

Owner:上海新上橡汽车胶管有限公司

Intelligent agricultural seeder

ActiveCN112042301AUniform soil surfaceConducive to growthSpadesPloughsAgricultural engineeringAgricultural science

The invention discloses an intelligent agricultural seeder. The intelligent agricultural seeder comprises a machine body, wherein four advancing wheels distributed in an array mode are rotationally arranged on the front side face and the rear side face of the machine body, two control cavities which are symmetrical front and back and provided with downward openings are formed inside each advancingwheel, a sliding cavity with a downward opening is formed inside each advancing wheel, the sliding cavities are located on the right sides of the control cavities, and a seeding mechanism capable ofcarrying out turn-digging, seeding and earthing on soil at the lower side of the machine body is arranged inside the machine body. According to the intelligent agricultural seeder, the operation of the machine body and the effects of turn-digging, seeding and earthing on the soil at the lower side can be achieved by only adopting one power source, and in the advancing process of the machine body,through the back-and-forth movement of a soil turning shovel in a seeding mechanism, the intermittent turn-digging effect can be achieved, the soil can be turned up at the position with the fixed interval, the soil can further be loosened, through left-right reciprocating movement of a moving block in the seeding mechanism, seeds can accurately fall into soil holes, and through left-right reciprocating movement and front-back reciprocating movement of an earthing block, a rake can cover the soil better, so that the surface of the soil is more uniform, and growing of the seeds is facilitated.

Owner:ANHUI LONGCOM INTERNET OF THINGS

Tray opening and conveying process

The invention discloses a tray opening and conveying process which comprises a tray opening step and a tray conveying step. In the tray opening step, the bottom of the inner side of a tray with a downward opening is attracted and turned to enable the opening to face up by a tray opening structure, and the tray is disposed on a tray conveying station where a material pushing block is located. In the tray conveying step, the material pushing block pushes the tray located on the tray conveying station to move. According to the tray opening and conveying process, after being taken down, the tray with the upward opening is disposed on the tray conveying station where the material pushing block is located, the tray can be directly loaded with materials after being sent out through the tray conveying station, and there is no need to conduct tray arrangement on the tray.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

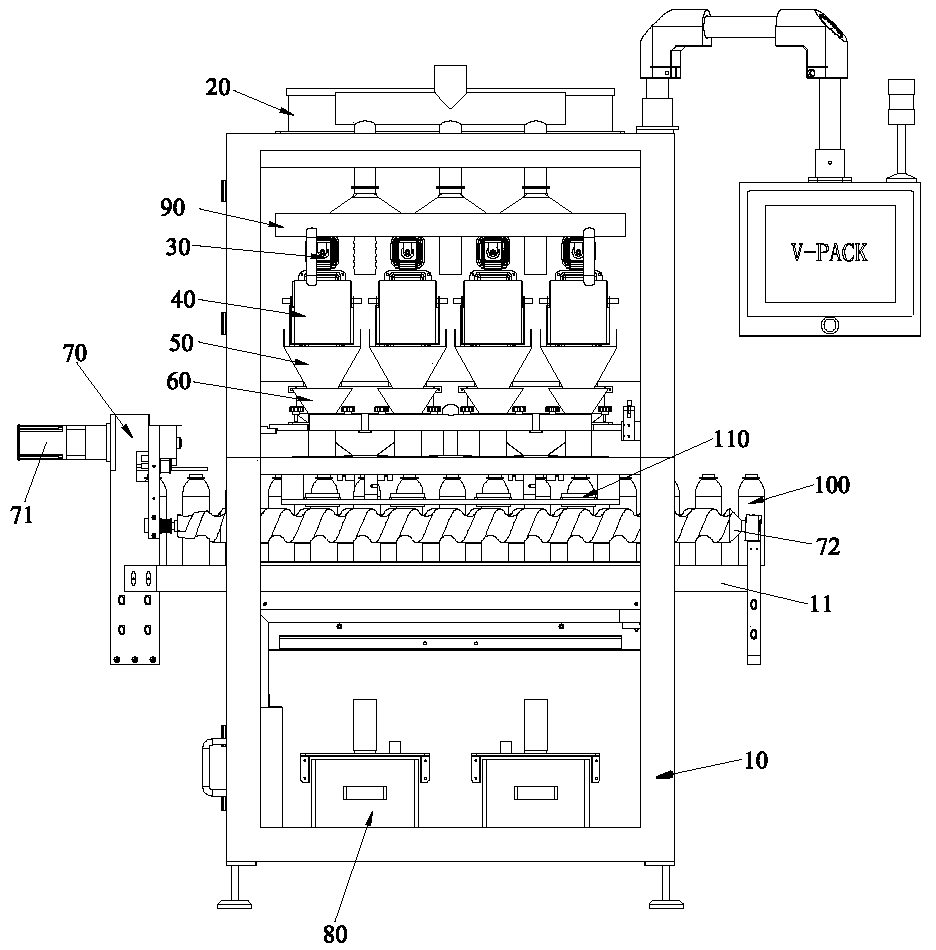

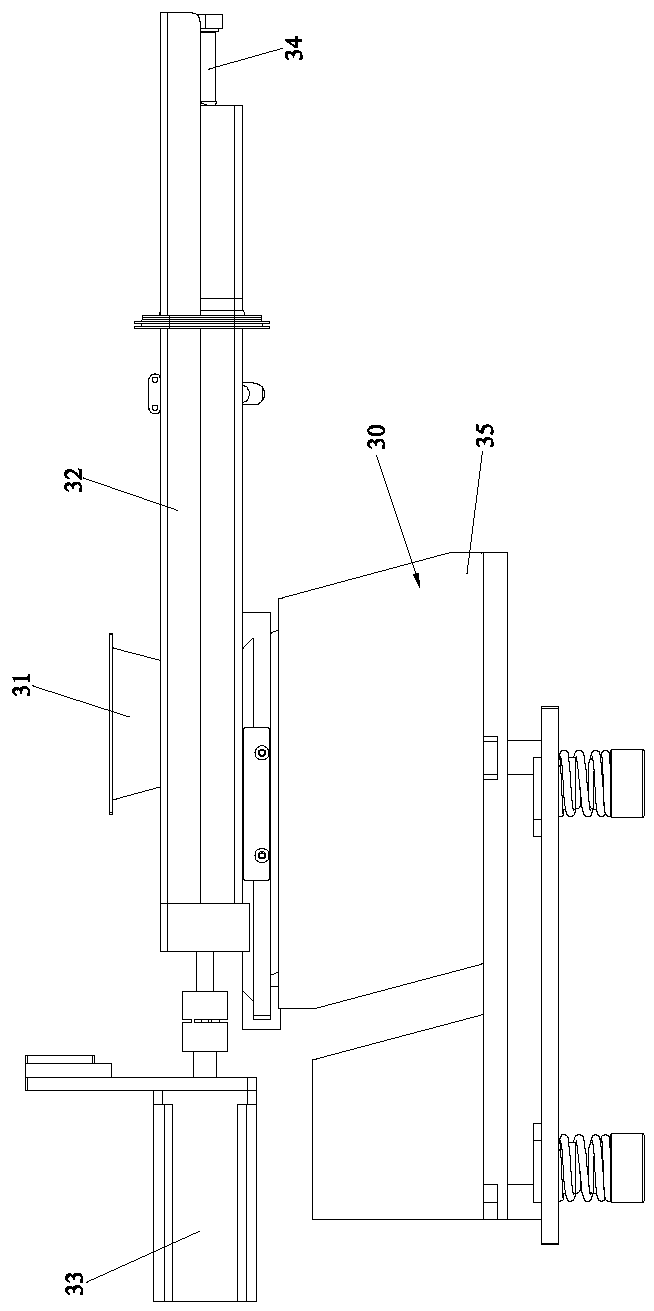

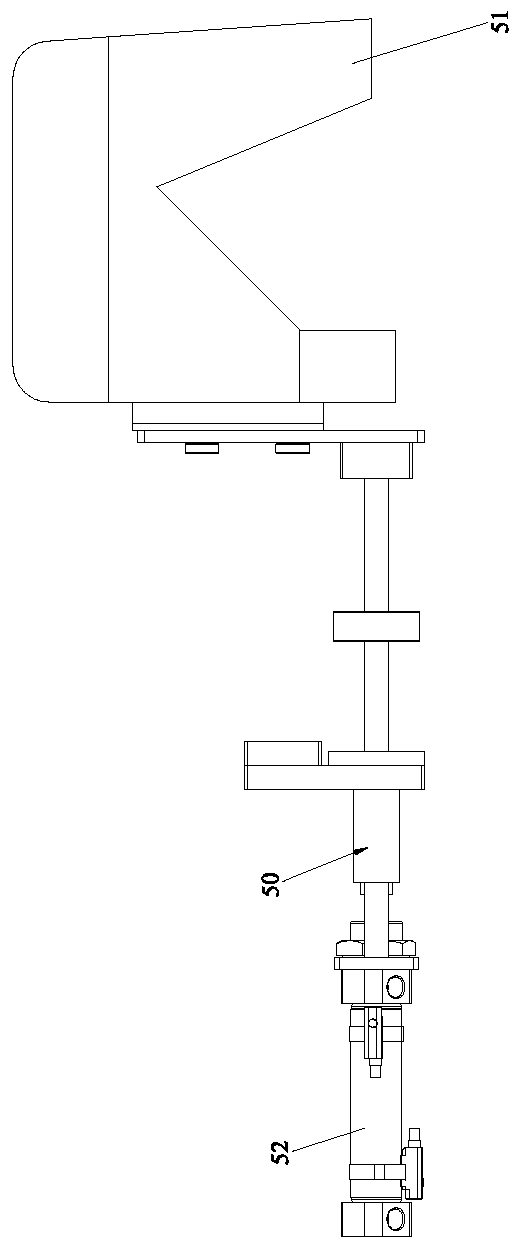

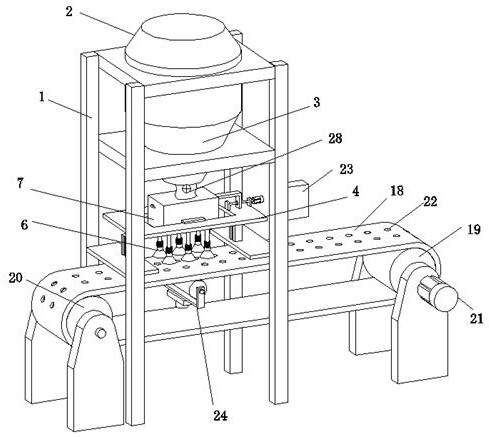

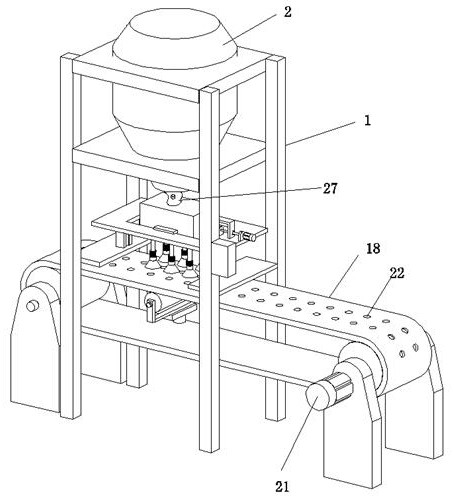

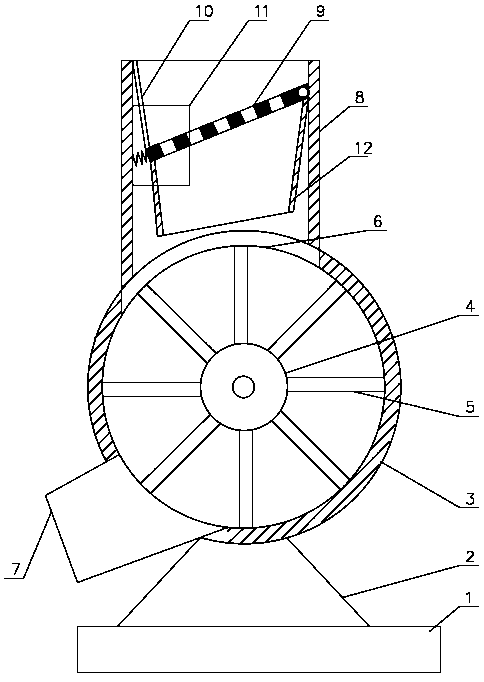

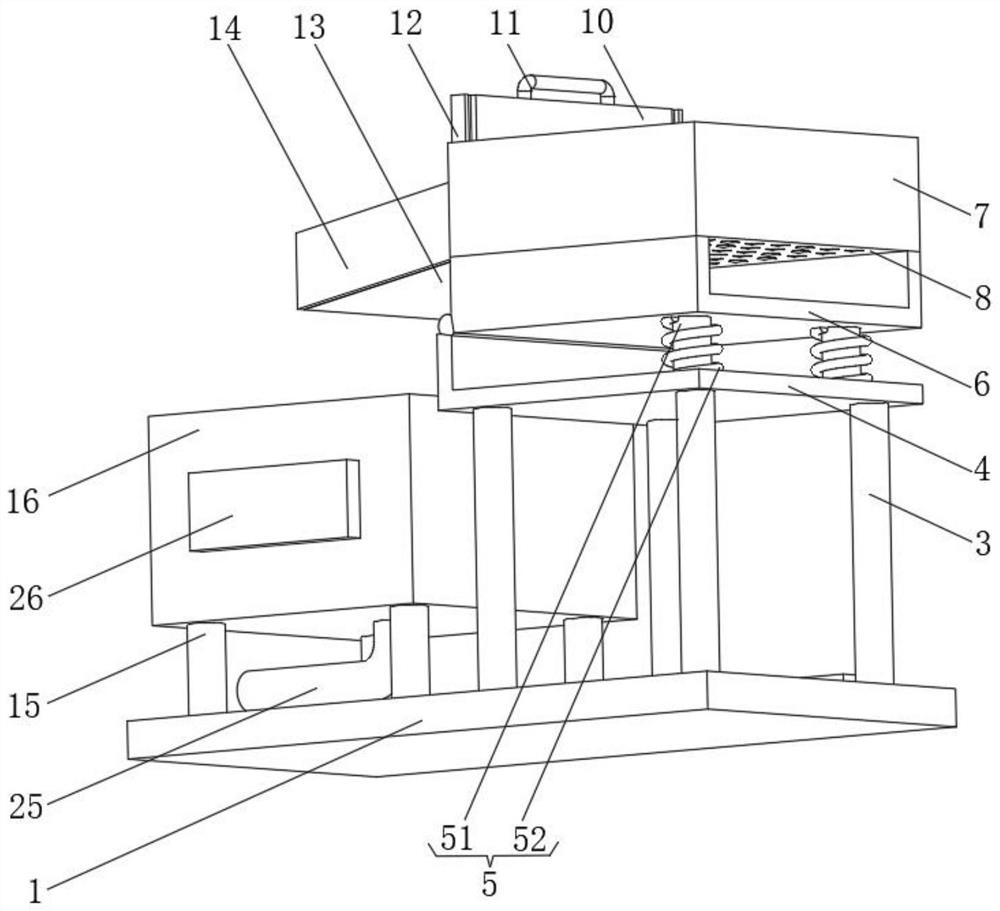

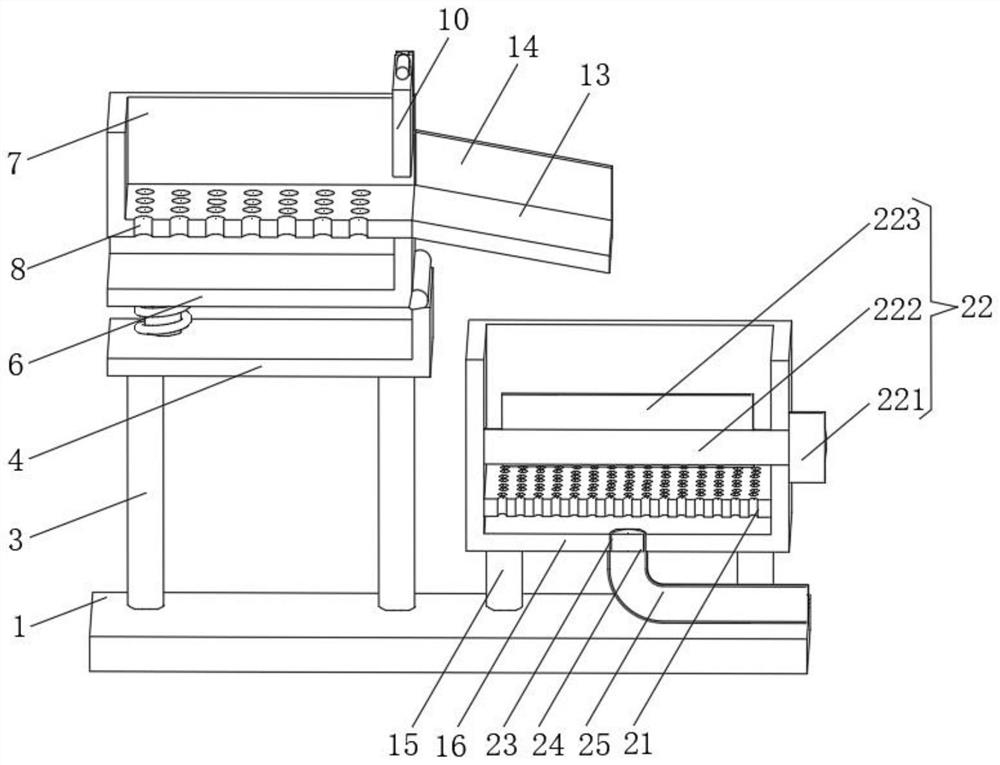

Automatic bottling machine for Chinese medicinal granules

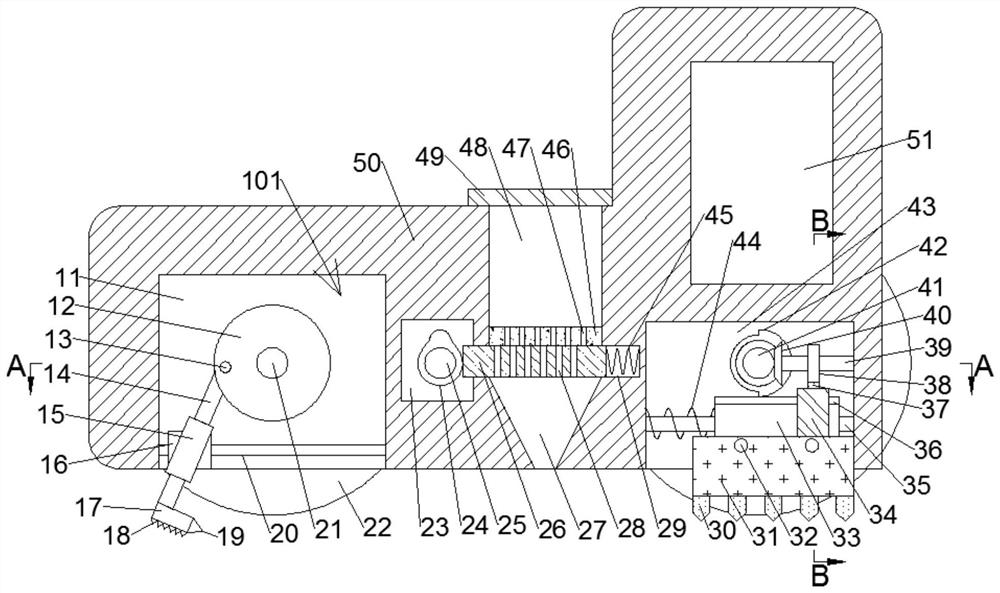

ActiveCN107933986APrecise fallPrecise deliverySolid materialPackaging automatic controlEngineeringBottle

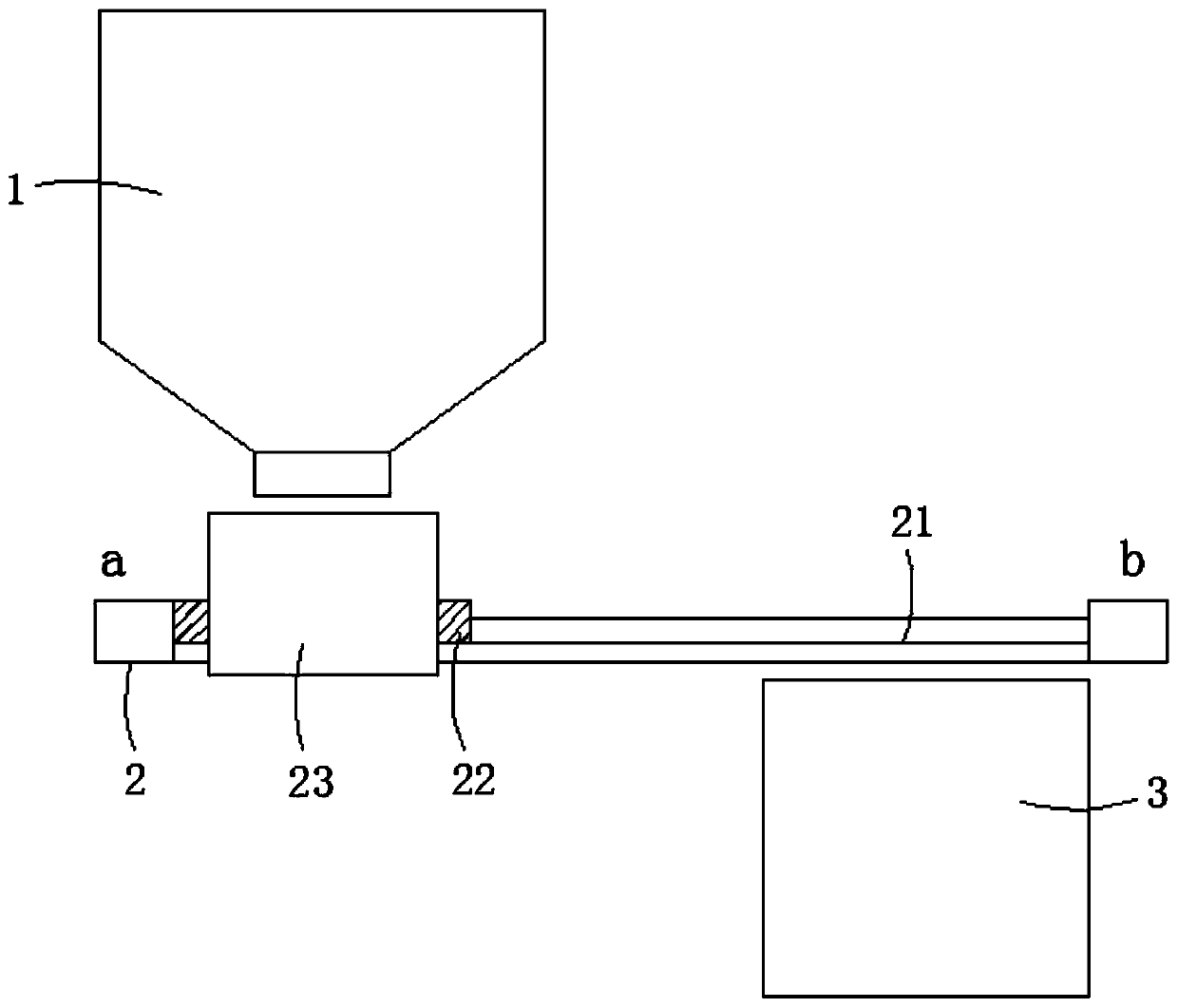

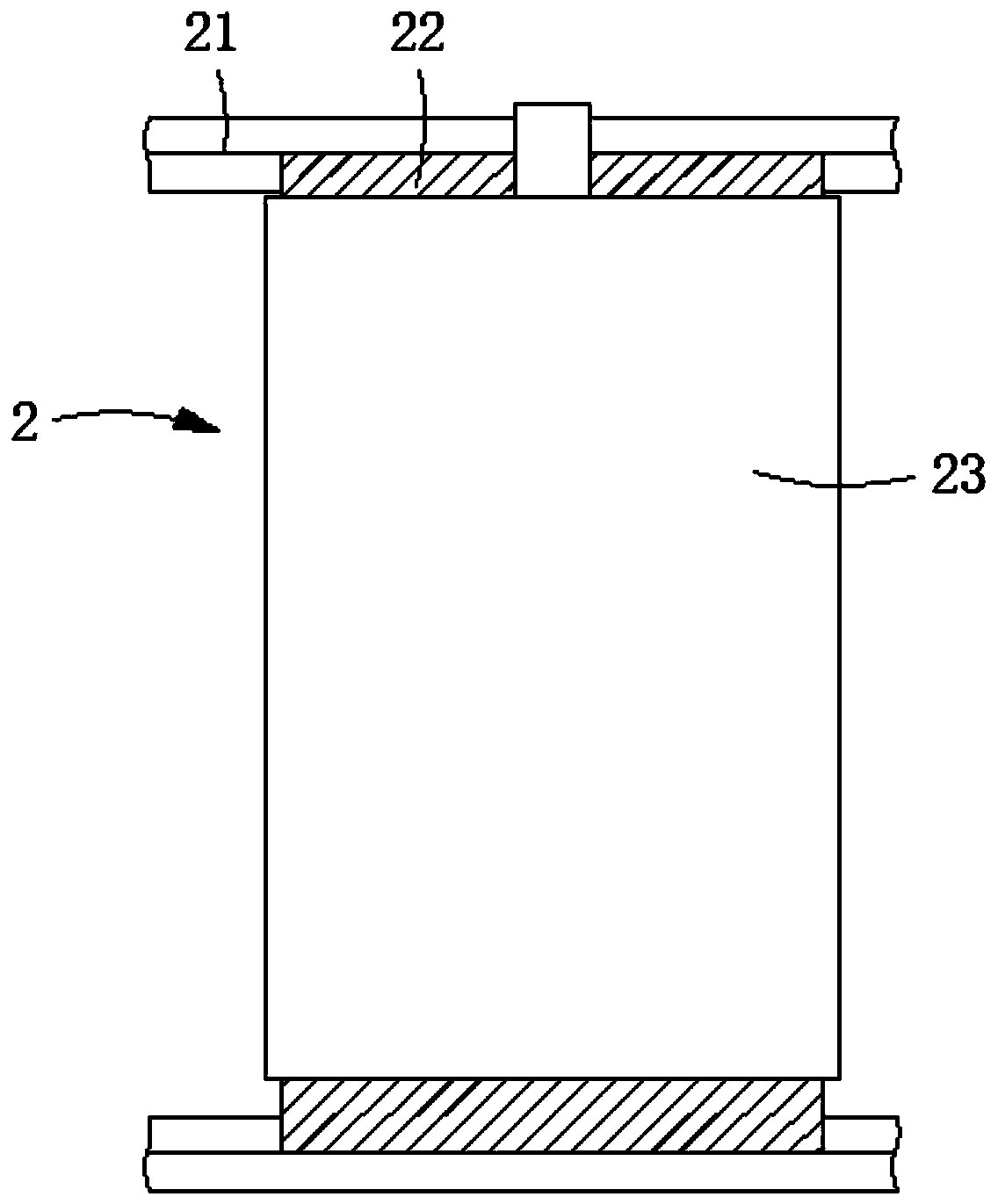

The invention discloses an automatic bottling machine for Chinese medicinal granules. The automatic bottling machine comprises a machine frame, a storage bin, a discharging device, a weighing device,a removing device, a bottling device, a bottle conveying device and a recovery tank; the discharging device communicates with a discharging outlet of the storage bin; the weighing device communicateswith a discharging outlet of the discharging device; the removing device is arranged on the side of the position below the weighing device; the bottling device communicates with a discharging outlet of the weighing device; the bottle conveying device is arranged under the bottling device; and the recovery tank is arranged under the removing device. The functions of storing, discharging, weighing,bottling and bottle conveying are integrated together, high automation is achieved, and the production efficiency is improved; precise discharging of the materials is achieved through the dischargingdevice, so that the material weight requirement meets the standard; materials unqualified in weight are removed through the removing device, and the removed materials are recycled; and bottles are precisely conveyed through the bottle conveying device, and thus, the materials can fall into the bottles accurately.

Owner:GUANGZHOU V PACK IND CO LTD

Multi-stage screening mechanism, concrete sand and gravel screening device

ActiveCN112246622BAvoid technical problems of poor swing stabilityGuaranteed stabilitySievingScreeningElectric machineryDrive motor

Owner:郑州市金禄市政工程有限公司

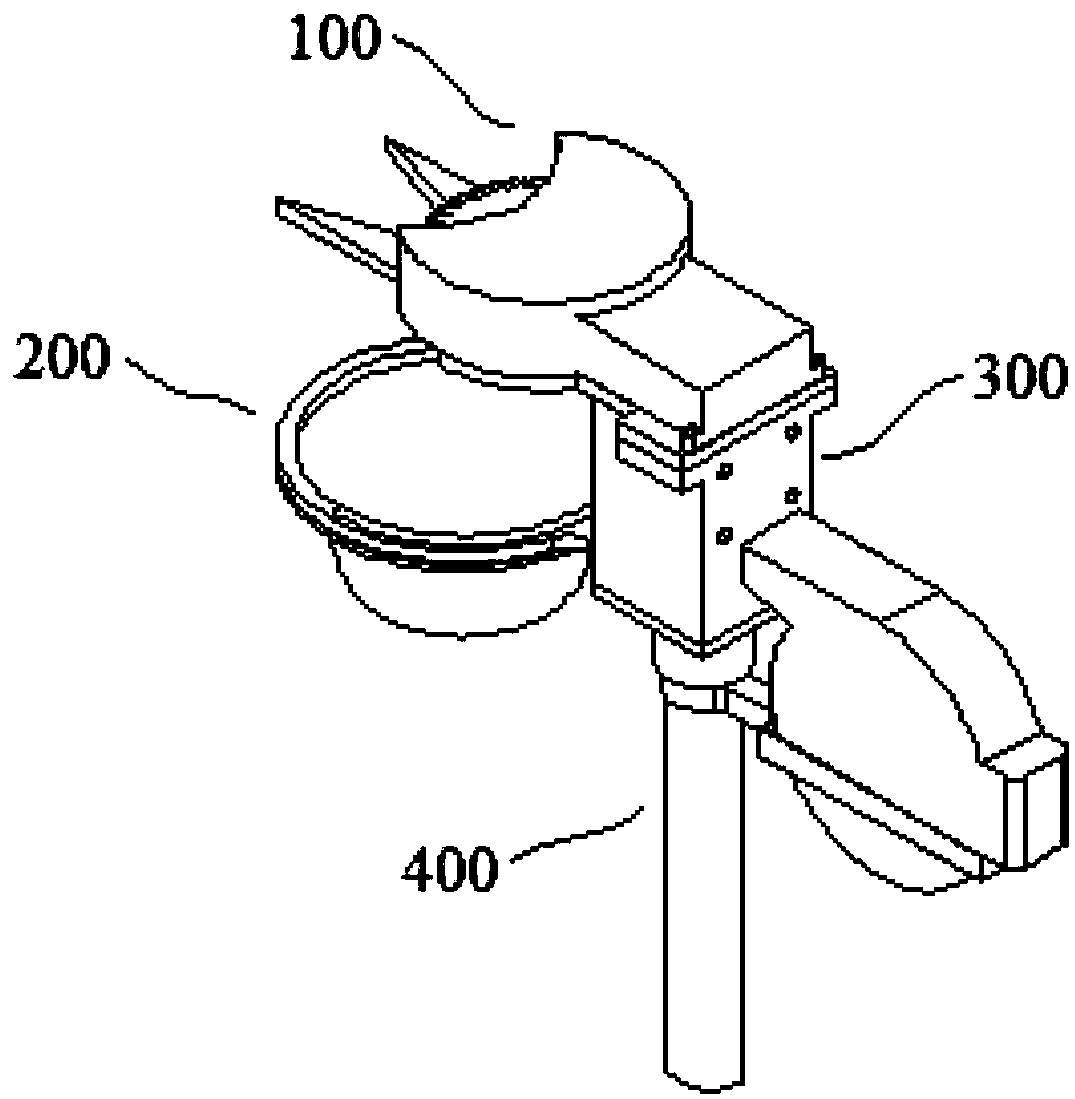

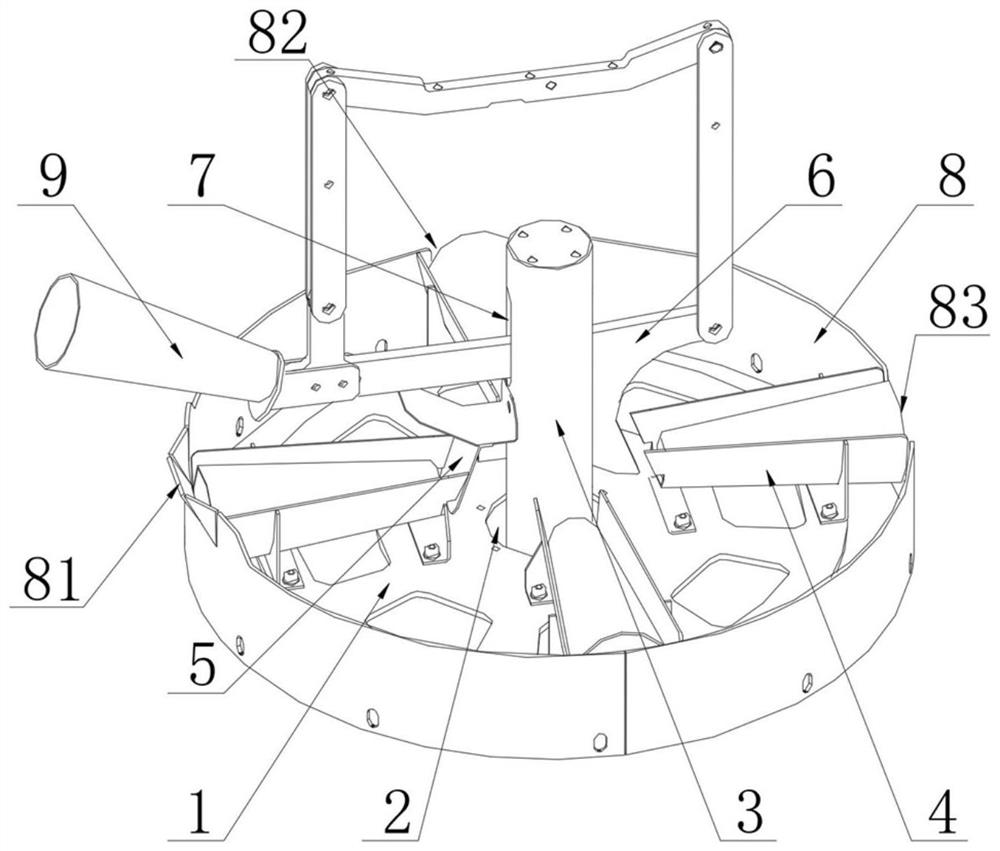

Fruit picking and collecting device

The invention discloses a fruit picking and collecting device, and belongs to the field of picking of fruits and vegetables. The device comprises a cutting unit, a driving unit, a supporting rod and acollecting unit, wherein the cutting unit comprises a blade and a guiding fork rack; the blade is intersected with a guiding groove of the guiding fork rack; the driving unit comprises a motor and isused for driving the blade to rotate; a connecting seat is arranged at the top end of the supporting rod; the cutting unit and the driving unit are mounted on the connecting seat; the collecting unitcomprises a net frame, a receiving net and a reel; the net frame and the reel are mounted on the supporting rod; at least three groups of wire holes which are distributed at intervals are formed in aring of the net frame; and elastic ropes penetrate through the wire holes in the net frame and are connected with the receiving net. The invention aims to overcome the shortcoming that the quality and efficiency of an existing fruit picking device finished product cannot be ensured, and provides the fruit picking and collecting device. By the collecting unit in the device, picked fruits can be effectively prevented from being damaged, the picking efficiency can be improved, and a using process is convenient and safe.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

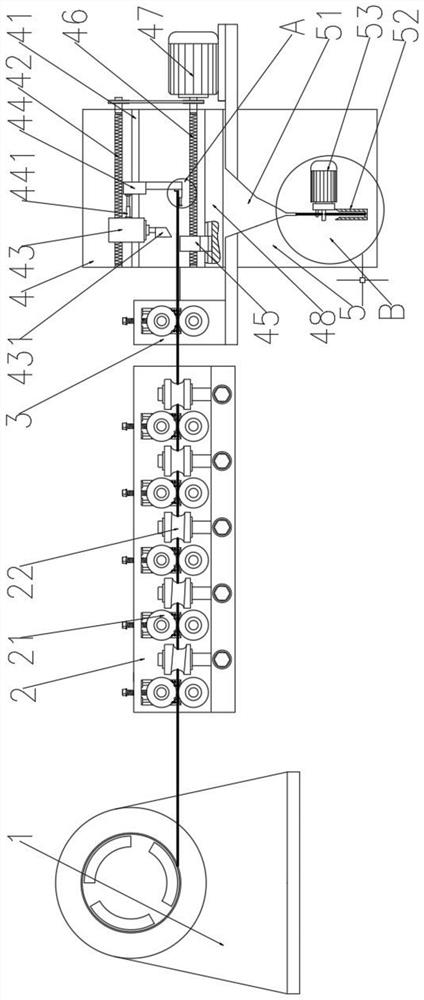

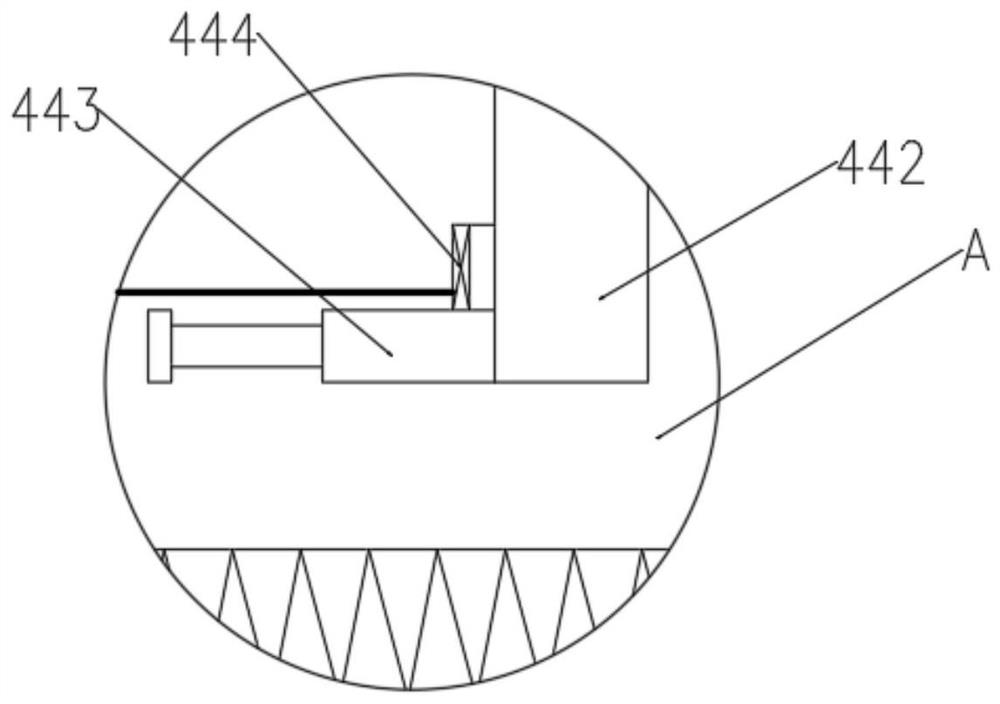

Precise special-shaped stud rapid forming device and working method

ActiveCN112355174AHigh degree of automationReduce residual stressIncreasing energy efficiencyScrew-threads articlesScrew threadAbnormal shaped

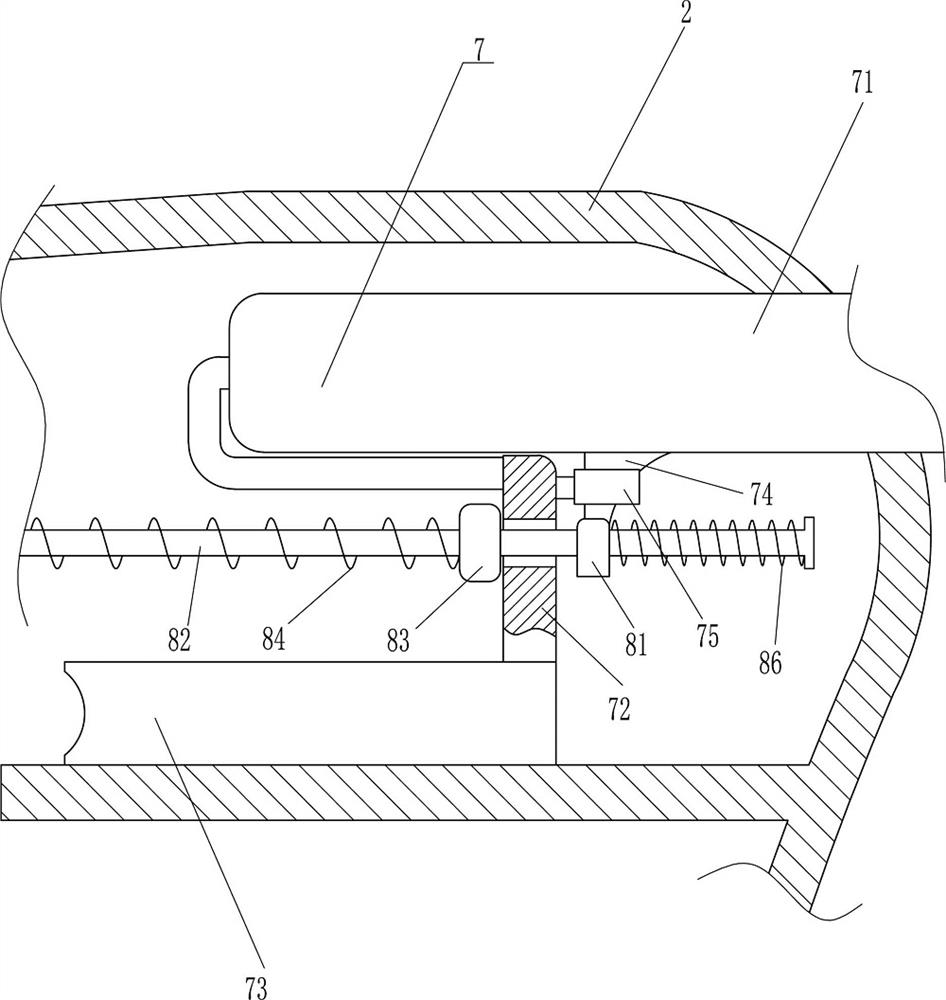

The invention discloses a precise special-shaped stud rapid forming device. The device comprises an uncoiler, a straightener, a feeding device, a cutting-off device and a bending device, a plurality of sets of straightening wheels are arranged on the straightener, wheel grooves are formed in the straightening wheels, and the angles between the sections of the wheel grooves and the axes of the straightening wheels are decreased progressively; the cutting-off device comprises a sliding rail, a first lead screw, a cutting-off air cylinder, a length control device, a lower cutting die and a secondlead screw, wherein the sliding rail is arranged under the first lead screw; the sliding rail and the first lead screw both penetrate through the cutting-off air cylinder, and the cutting-off air cylinder is in threaded connection with the first lead screw; the upper end of the length control device is arranged on the sliding rail in a sleeving mode, the length control device is connected with the cutting-off air cylinder through a supporting rod, and the length of the supporting rod can be adjusted; the lower cutting die is arranged below the cutting-off air cylinder; and the second lead screw penetrates through the lower cutting die, and the lower cutting die is in threaded connection with the second lead screw.

Owner:太仓太标汽车部件有限公司

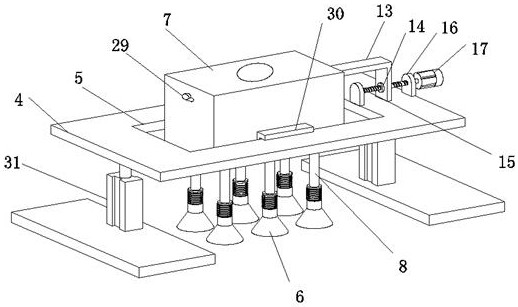

Automatic filling device for hard capsule medicine

The invention relates to the technical field of hard capsule filling, in particular to an automatic hard capsule medicine filling device which comprises a rack and a storage bin, the storage bin is fixedly mounted at the top of the rack, the bottom end of the storage bin communicates with a discharging hopper, a bracket is mounted in the rack in an up-down moving mode, and a mounting groove is formed in the surface of the bracket. A discharging bin is slidably mounted in the mounting groove, the bottom of the discharging bin communicates with a plurality of medicine powder conveying pipes distributed in an array mode, medicine meters are arranged at the joints of the medicine powder conveying pipes and the discharging bin, and medicine injection gun heads are arranged at the bottom ends ofthe medicine powder conveying pipes; a connecting frame is fixed to the right side wall of the discharging bin, a threaded sleeve is installed on the connecting frame, a threaded rod is in threaded connection with the interior of the threaded sleeve, and the threaded rod is rotationally installed in the pair of bearing pedestals; the device can prevent external wind or airflow from blowing medicines to cause scattering of the medicines, can improve the quality filling precision of the medicines, and can prevent smell of medicine powder from diffusing.

Owner:ANHUI LIANYI PHARMA

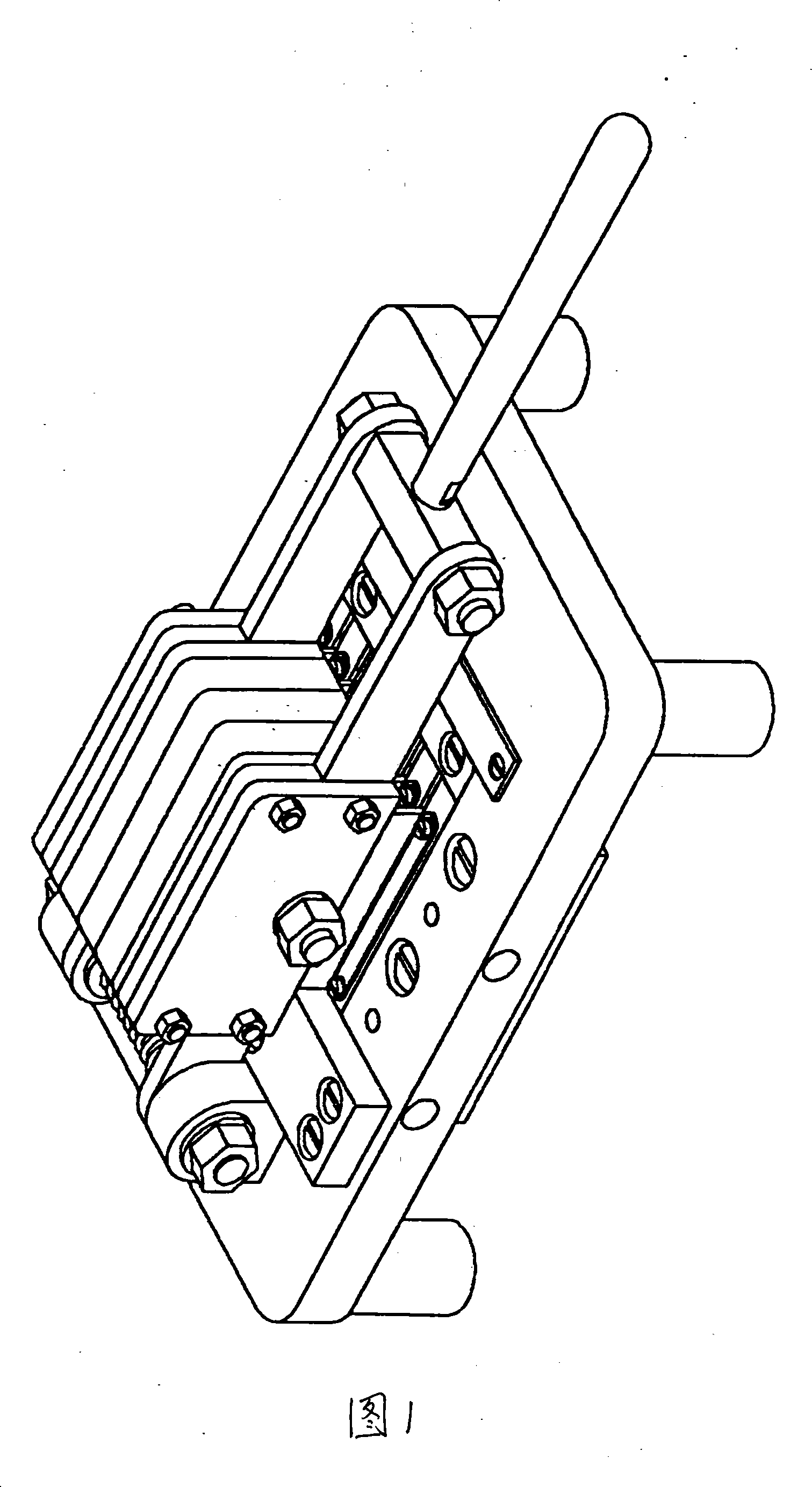

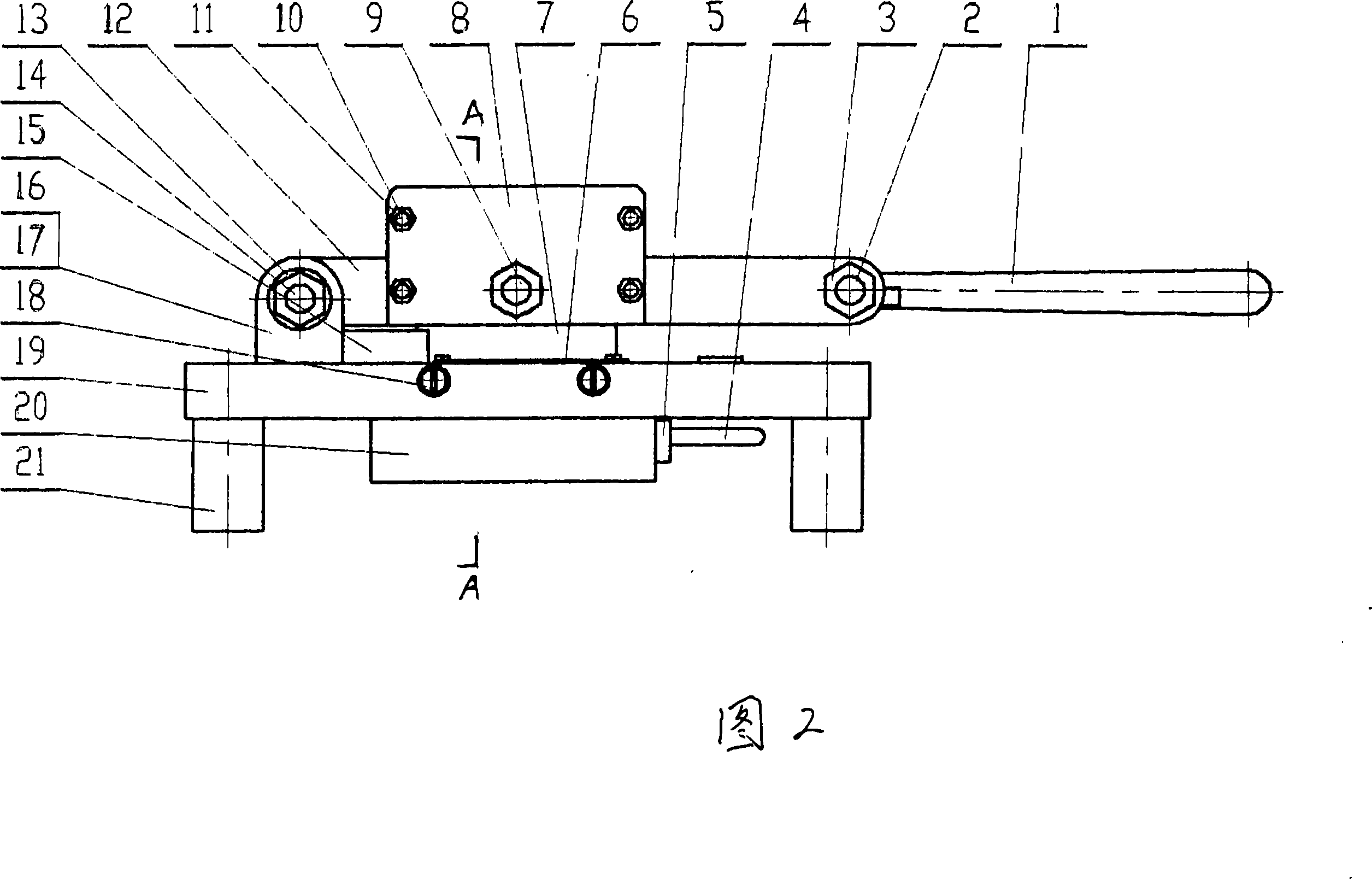

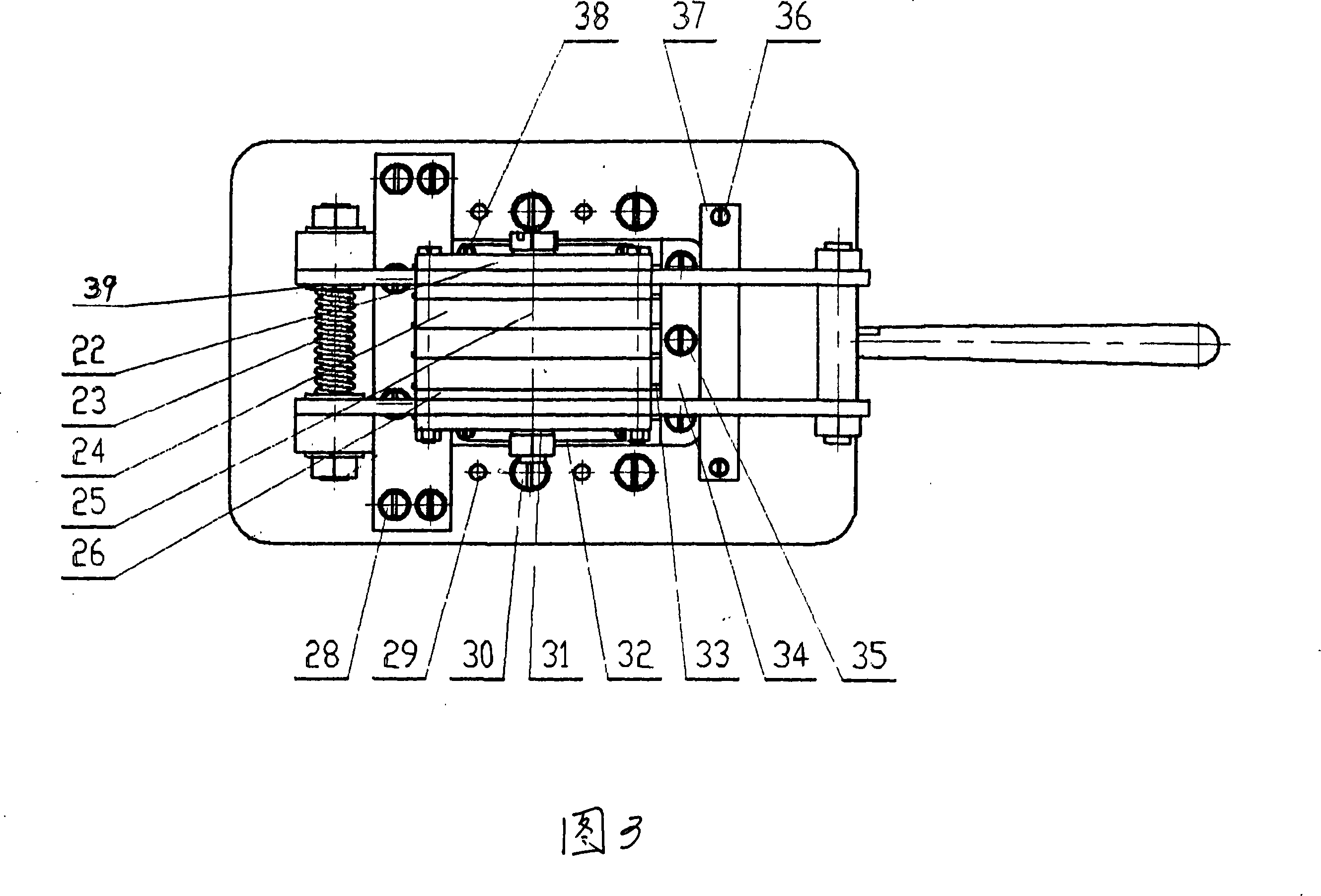

Floccus sectionalized sample cutting instrument

InactiveCN101225597AMeet the sampling requirementsTest growthInspecting textilesWithdrawing sample devicesAnimal hairKnife holder

The invention relates to a device for cutting animal hair under certain requirement to do research or be used in other special situation, which comprises an immovable knife holder, and a movable knife holder fixed on the immovable knife holder by a hinge; wherein, the movable knife holder comprises a U-shaped device with a handle, a movable knife clamping device fixed on the U-shaped device by a bolt, and at least two movable knives. The U-shaped device is provided with a hole matching the hinge. The immovable knife holder is provided with a plurality of immovable knives that are matching with the movable knives and have the same number of holes of the movable knives.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

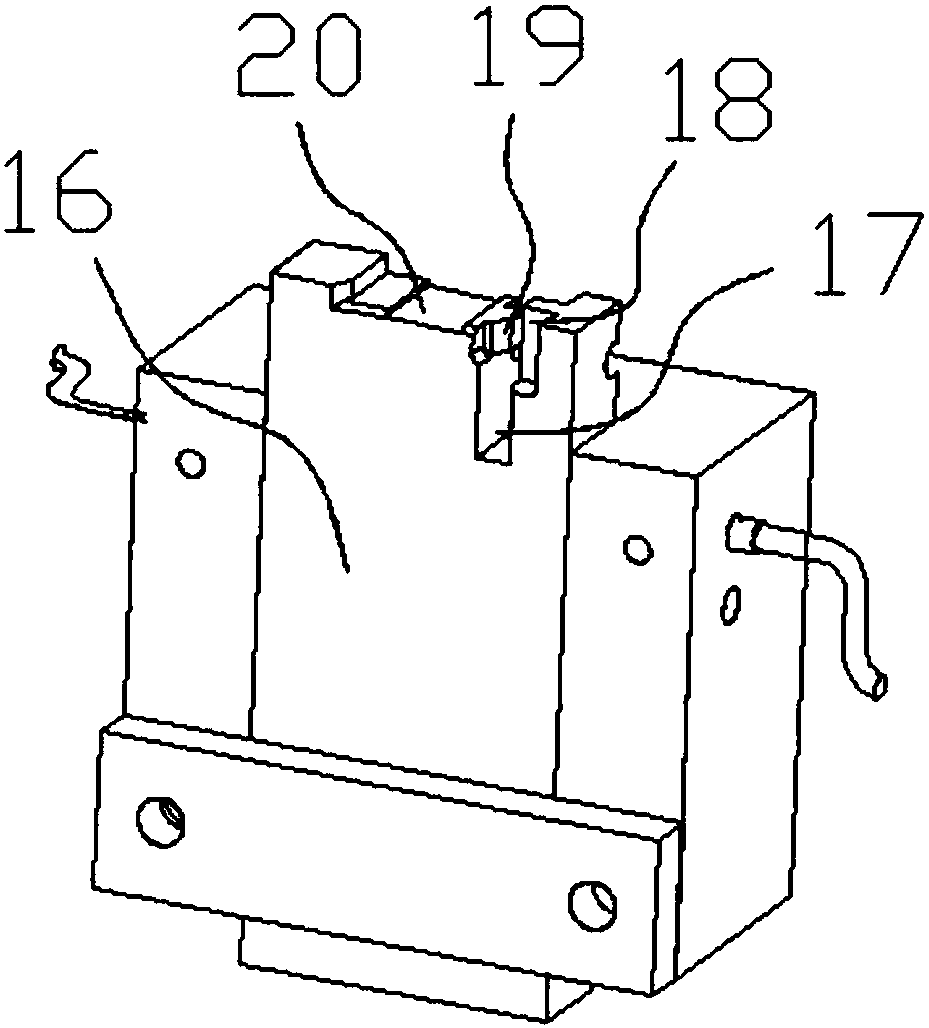

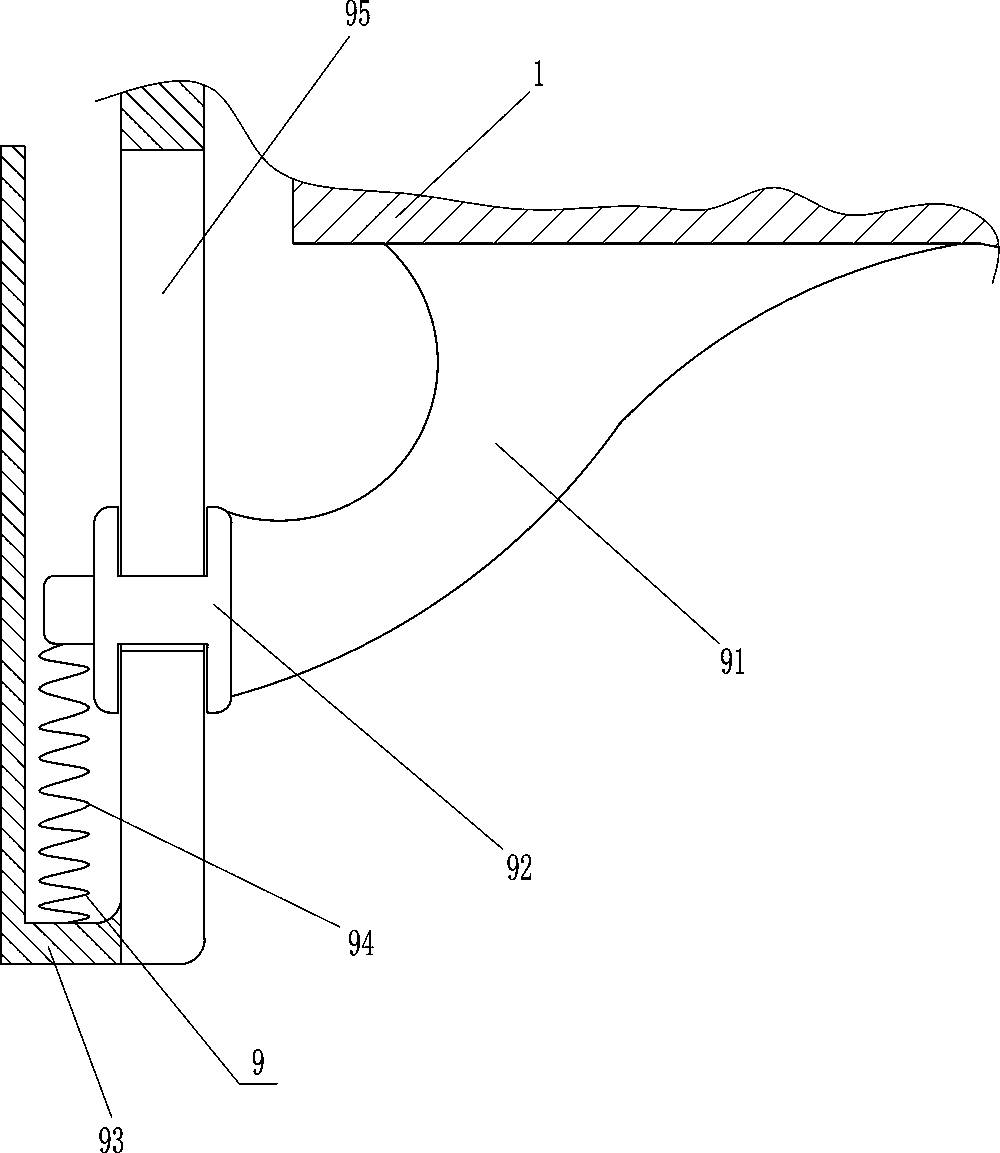

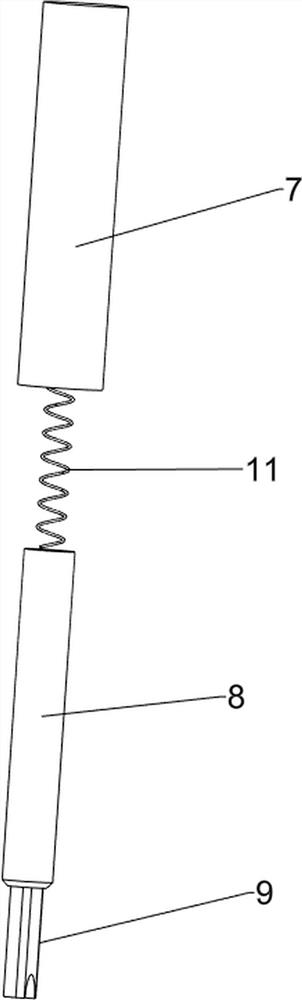

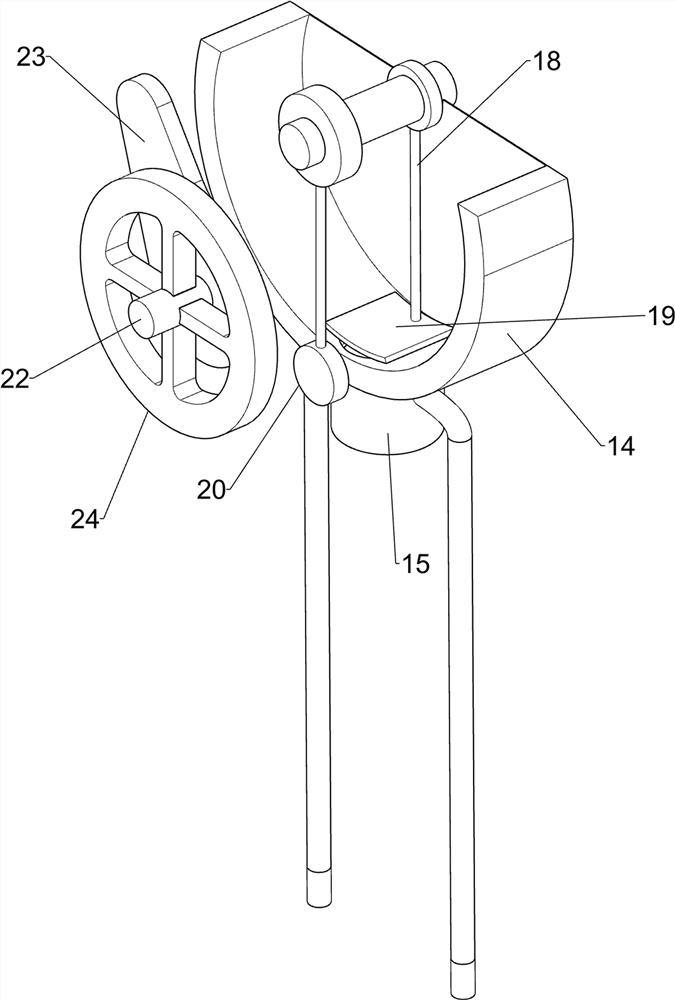

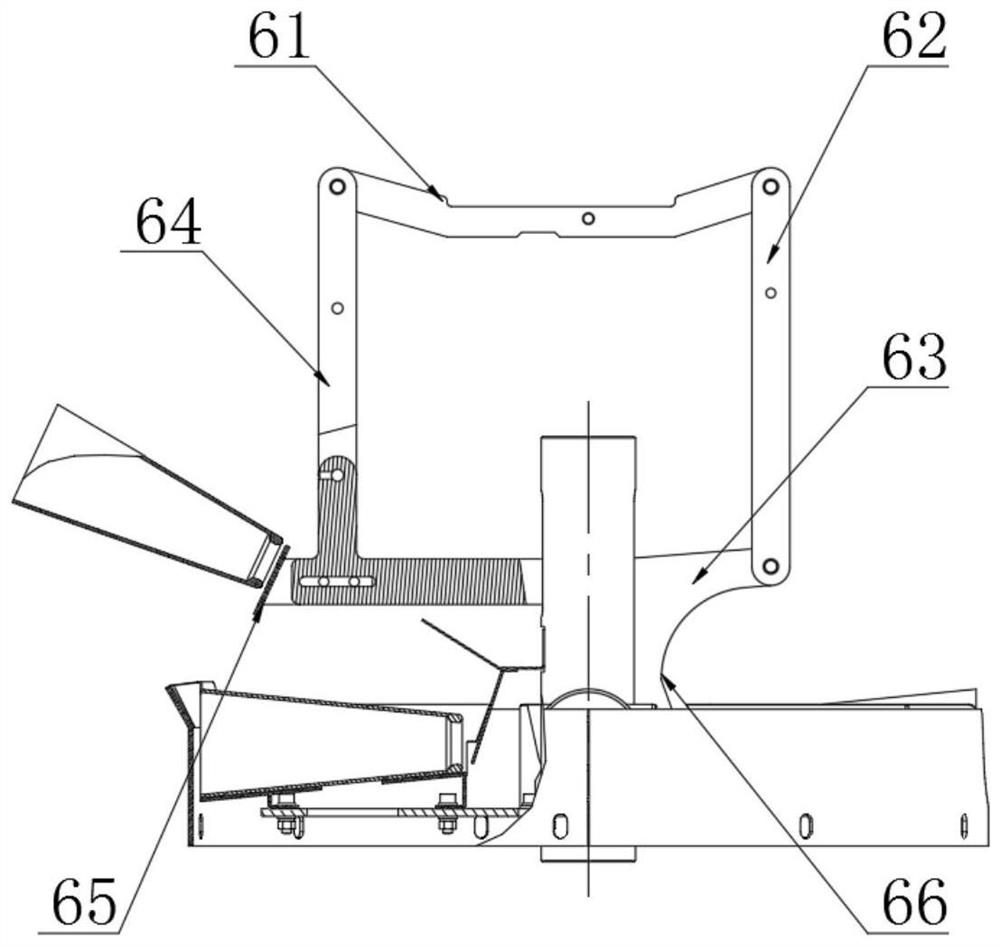

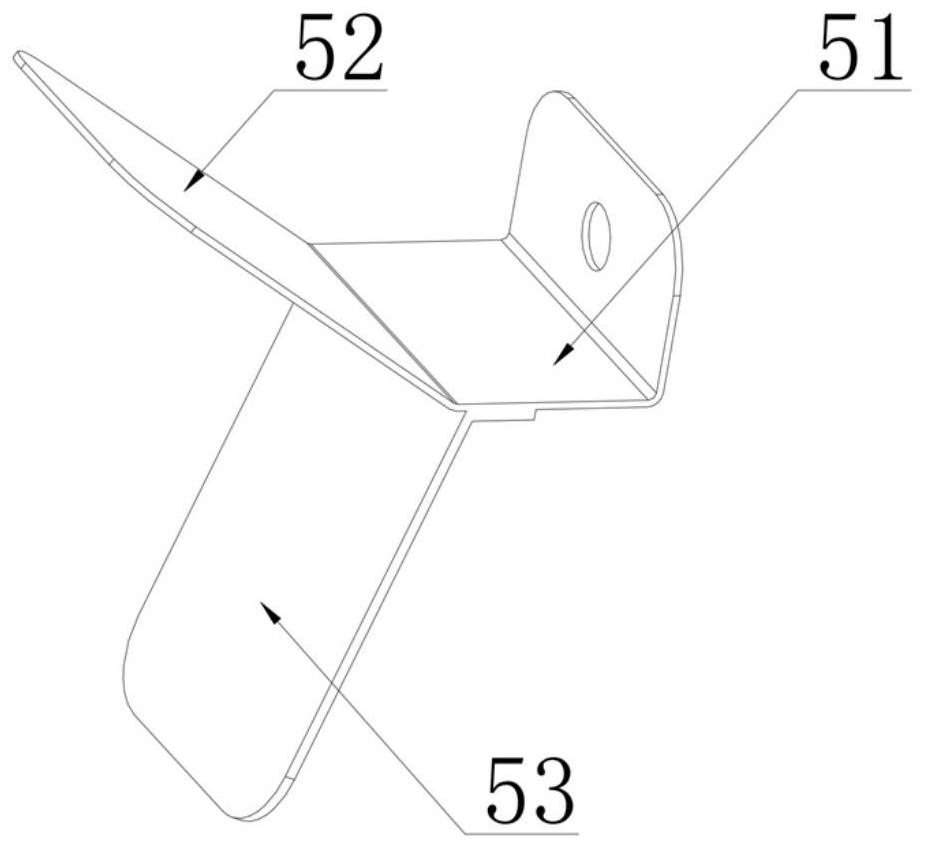

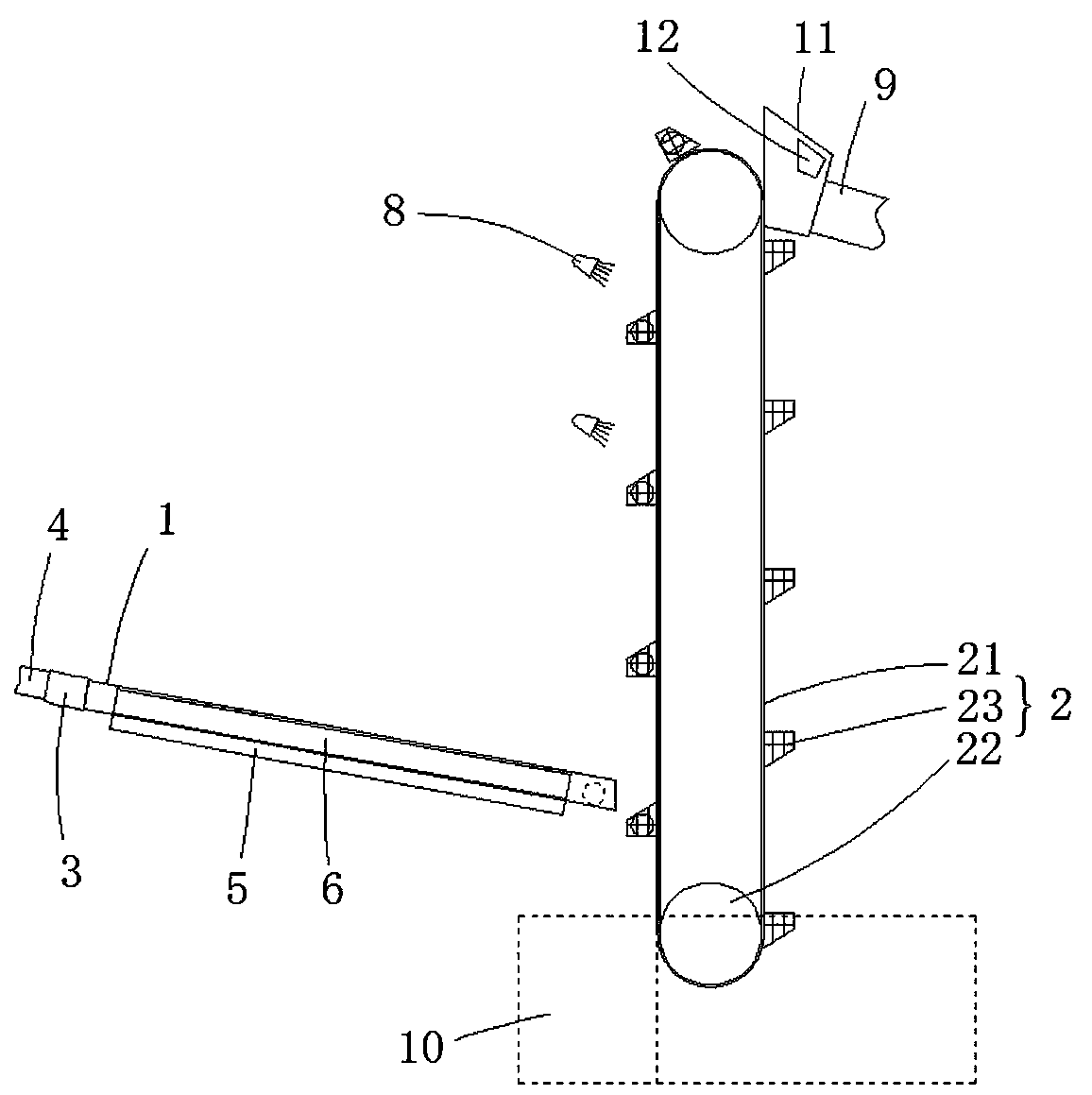

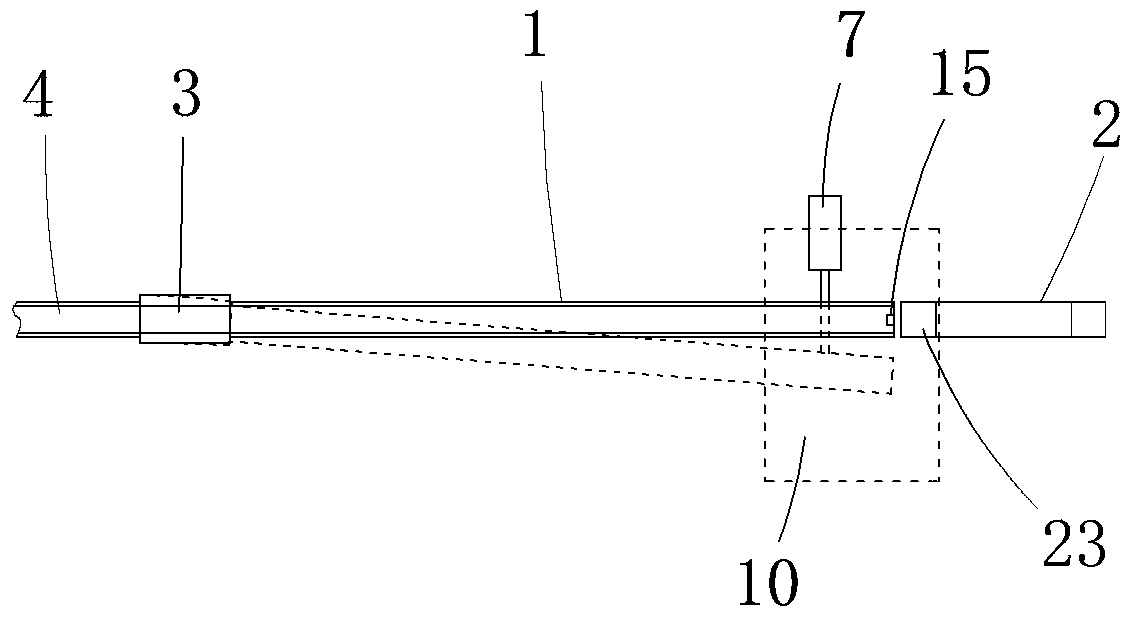

Chemical anchor bolt rubber tube inserter

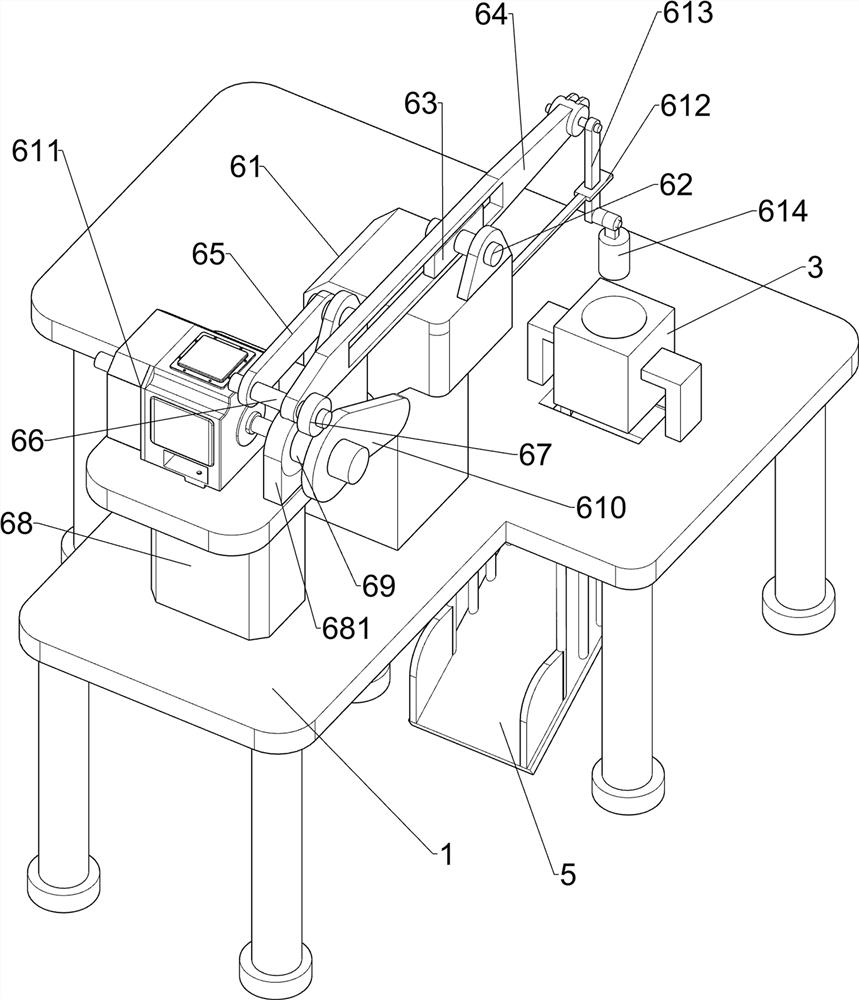

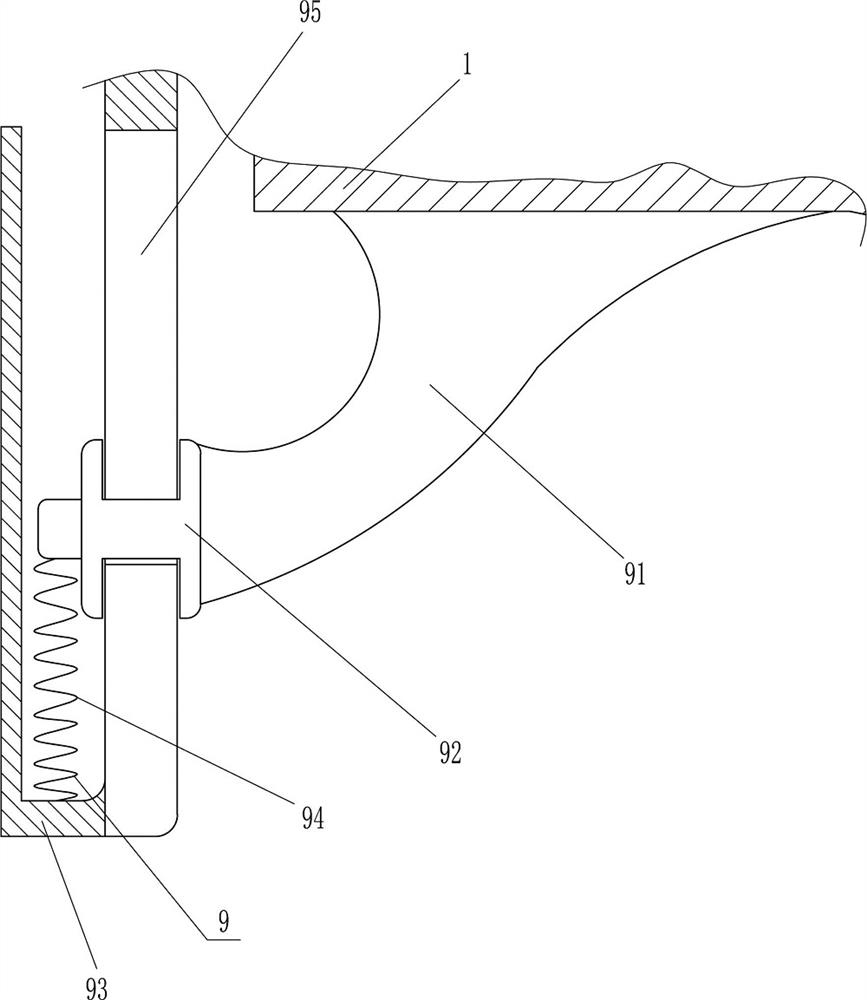

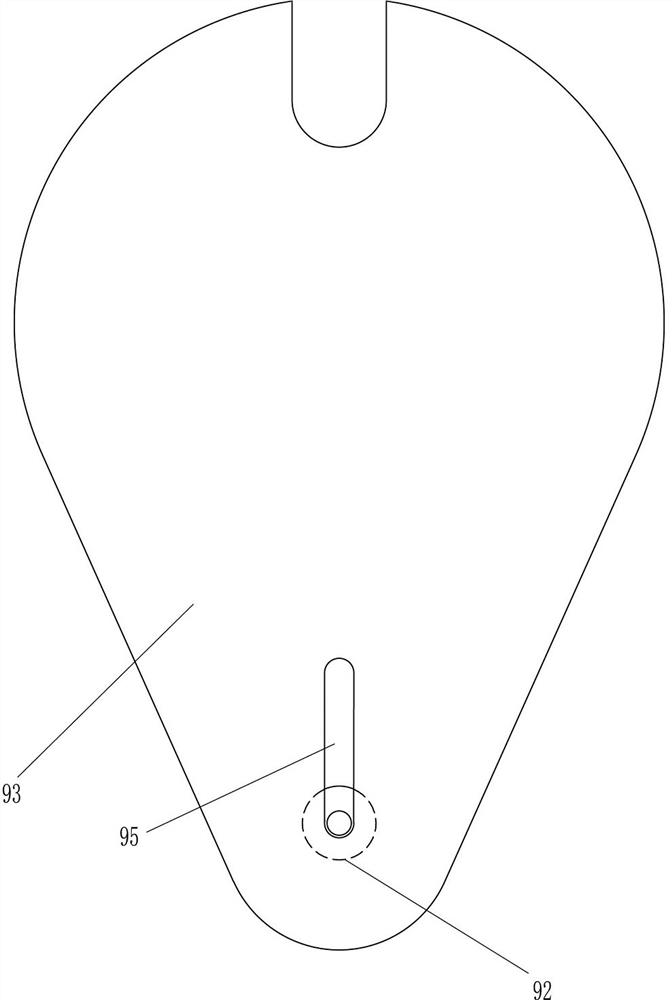

ActiveCN111206785APrecise alignmentPrecise fallBuilding material handlingPolymer scienceMechanical engineering

The invention relates to a rubber tube inserter, in particular to a chemical anchor bolt rubber tube inserter. According to the chemical anchor bolt rubber tube inserter, a chemical anchor bolt rubbertube can be automatically placed, and a chemical anchor bolt can be automatically pushed into a hole. The chemical anchor bolt rubber tube inserter comprises a handle, a mounting box and the like, wherein the mounting box is arranged at the top end of the handle. According to the chemical anchor bolt rubber tube inserter, by means of a discharging mechanism and a pushing-out mechanism, the chemical rubber tube can be automatically placed and then automatically pushed into the hole, so that the efficiency of inserting the chemical rubber tube into the hole is improved; meanwhile, in the process of automatically inserting the chemical anchor bolt rubber tube into the hole, a discharging tube can be aligned with the interior of the hole more accurately through a spherical rod in a guide mechanism, so that the inserted chemical rubber tube falls into the hole more accurately; and finally, an arranged limiting plate can block the left portion of an arc-shaped groove, and accordingly the chemical anchor bolt rubber tube placed in the arc-shaped groove can be prevented from sliding out.

Owner:山东中元绿色生物工程有限公司

Automatic batching and mixing machine of magnesia-carbon daub for wet ladle

InactiveCN110681305AHigh degree of automationIncrease productivityTransportation and packagingMixer accessoriesProcess engineeringBLENDER/MIXER

The invention belongs to the technical field of production of magnesia-carbon daub and discloses an automatic batching and mixing machine of magnesia-carbon daub for a wet ladle. The machine comprisesa discharge hopper, a feeding device and a stirring machine, wherein the feeding device is mounted between the discharge hopper and the stirring machine; the feeding device comprises guide tracks, linear motors and a feeding tank; the number of the guide tracks is two; the two guide tracks are both connected with the linear motors in a sliding manner; and the feeding tank is fixed between the twolinear motors through bolts. The machine is provided with the feeding device which comprises the guide tracks, the linear motors and the feeding tank, the linear motors of the guide tracks cooperatewith each other to effectively achieve reciprocation movement of the feeding tank, and the feeding tank is capable of effectively achieving weighing, feeding and lead out of formula raw materials of the magnesia-carbon daub, and is in mutual match with the discharge hopper and the stirring machine, so that discharge, batching, feeding and mixing of the magnesia-carbon daub in the production process can be fully automatically completed conveniently.

Owner:浙江康斯迪冶金科技有限公司

Sliding-type concrete product distributing device

PendingCN108115824ASolve the problem of disorderly scatteringInterfering with pressing and rubbingFeeding arrangmentsBatch productionSeries production

Disclosed is a sliding-type concrete product distributing device. The device comprises core molds, a cement pipe lifting platform, outer molds with inner cavities, an outer mold fixing platform, cement extruders and a device body; the cement extruders are fixedly installed above the device body through lifting devices, the outer mold fixing platform is fixedly installed on the portion, below the cement extruders, of the device body through a lifting device, and the cement pipe lifting platform is fixedly installed on the portion, below the outer mold fixing platform, of the device body througha lifting device. The sliding-type concrete product distributing device has the advantages that the core molds are in a fixed state, and the overall occupied space is greatly reduced; cement pipe materials enter the tops of the outer molds and directly flow into a forming cavity under the effect of gravity, the time of manufacturing cement pipes is shortened, the efficiency of manufacturing the cement pipes is greatly improved, and the compactness of cement materials is increased; the structure is simple, the demolding process of the manufactured cement pipes is simple, and the manufacturingefficiency is high; the numbers of core molds, outer molds and cement extruders can be increased without limitation, and the batched production of the cement pipes can be achieved.

Owner:高唐县鼎力建筑机械有限公司

Coconut rapid cutting device for beverage processing

PendingCN112586761ARealize the collectionQuick cutJuice extractionGravity filtersAgricultural engineeringStructural engineering

The invention relates to a cutting device, in particular to a coconut rapid cutting device for beverage processing. The invention provides the coconut rapid cutting device for beverage processing, which can automatically convey coconuts and directly filter the coconuts after cutting is finished. The coconut rapid cutting device for beverage processing comprises a base, filter screens, a liquid outlet pipe, placement tables, a cutting device and a rotary containing device; a processing box is arranged in the middle of the base; the inner bottom face of the processing box is an inclined face andinclines in a semi-circular radian direction; the filter screens are symmetrically arranged on the processing box close to the straight side wall; the liquid outlet pipe is arranged at the lower partof the semicircular central position of the processing box; and the placement tables are symmetrically arranged at the bottom in the processing box relative to the axis position, and the placement tables are close to the straight side wall of the processing box. Coconut can be rapidly cut through the cutting device, coconut juice is collected through overturning of the rotary containing device, and waste is avoided.

Owner:高艳红

An intelligent agricultural seeder

Owner:ANHUI LONGCOM INTERNET OF THINGS

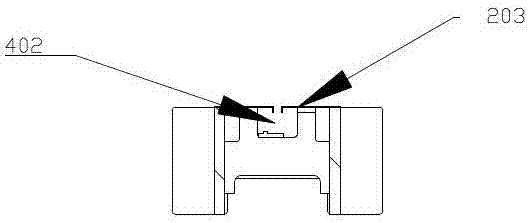

A ball valve auxiliary fit installation equipment

The invention belongs to the technical field of ball valve manufacture, and in particular relates to a ball valve auxiliary matching installation equipment. Provides a ball valve that can be automatically unloaded and is conveniently embedded to assist in the installation of equipment. A ball valve auxiliary installation equipment, comprising: a workbench, a blanking hole is opened on one side of the top of the workbench, and a placing frame is arranged on the top of the workbench directly above the blanking hole; a discharge mechanism is placed close to the knuckle position of the top of the workbench The position of the frame is equipped with a discharge mechanism, which cooperates with the placement frame; the slideway, the bottom of the worktable is located directly below the blanking hole, and a slideway is provided; the pressing mechanism, the top of the workbench is provided with a pressing mechanism, and the pressing mechanism and the placement frame Cooperate. The invention achieves the effects of automatic material cutting and convenient embedding.

Owner:HANGZHOU DONGCHEN HEATING POWER AUX

Gravity type packaging and sealing equipment and method suitable for packaging ceramic tiles

PendingCN114872978APrecise fallSpeed up the descentPackage recyclingPackagingStructural engineeringTransfer mechanism

The self-falling type packaging and sealing equipment comprises a rack, an adsorption transfer mechanism, an opening and closing box and a packaging box, flexibly-connected turned-over edges are arranged on all sides of a box opening of the hard packaging box, the packaging box is located in the opening and closing box, and the adsorption transfer mechanism arranged on the upper portion of the opening and closing box is connected with the rack; when the opening and closing box is opened and closed, the packaging box can enter and exit from the side face of the opening and closing box, after the packaging box is filled with ceramic tiles and enters the opening and closing box from the conveying belt, the opening and closing box is closed, the adsorption transfer mechanism adsorbs and transfers the sealing plate to enable the sealing plate to fall into the packaging box, the sealing plate covers the upper portions of the ceramic tiles in the packaging box, and the jacking cylinder rapidly retracts to enable the packaging box to rapidly descend. The turnup is interfered by the edges of the box opening of the opening and closing box to turn over, the sealing plate and the turnup attract each other through the magnetic strip and the iron sheet to seal the packaging box, halting is avoided, ceramic tiles are not prone to being damaged, labor intensity is low, halting links are reduced, the automation rate during packaging is increased, and packaging efficiency is improved.

Owner:XINLAILI CERAMIC DEV CO LTD

Automatic filling device for secondary coal samples

PendingCN109649705ASimple structureSimple and fast operationSolid materialEngineeringTransfer mechanism

The invention relates to an automatic filling device for secondary coal samples. The automatic filling device for the secondary coal samples comprises a frame, a filling hopper, a weighing mechanism and a barrel transferring mechanism, wherein the filling hopper, the weighing mechanism and the barrel transferring mechanism are arranged on the frame; the filling hopper is arranged on the upper portion of the frame and is used for feeding the coal samples; the weighing mechanism is located below the filling hopper and is used for storing a sample barrel and weighing the sample barrel after the sample barrel is filled with coal samples; and the barrel transferring mechanism is located on one side of the weighing mechanism and is used for transferring the weighed sample barrel filled with thecoal samples. The automatic filling device for the secondary coal samples has the beneficial effects that the structure is simple, the automation degree is high, automatic weighing and filling of thesecondary coal samples are achieved, and the production efficiency is high.

Owner:国能长源汉川发电有限公司

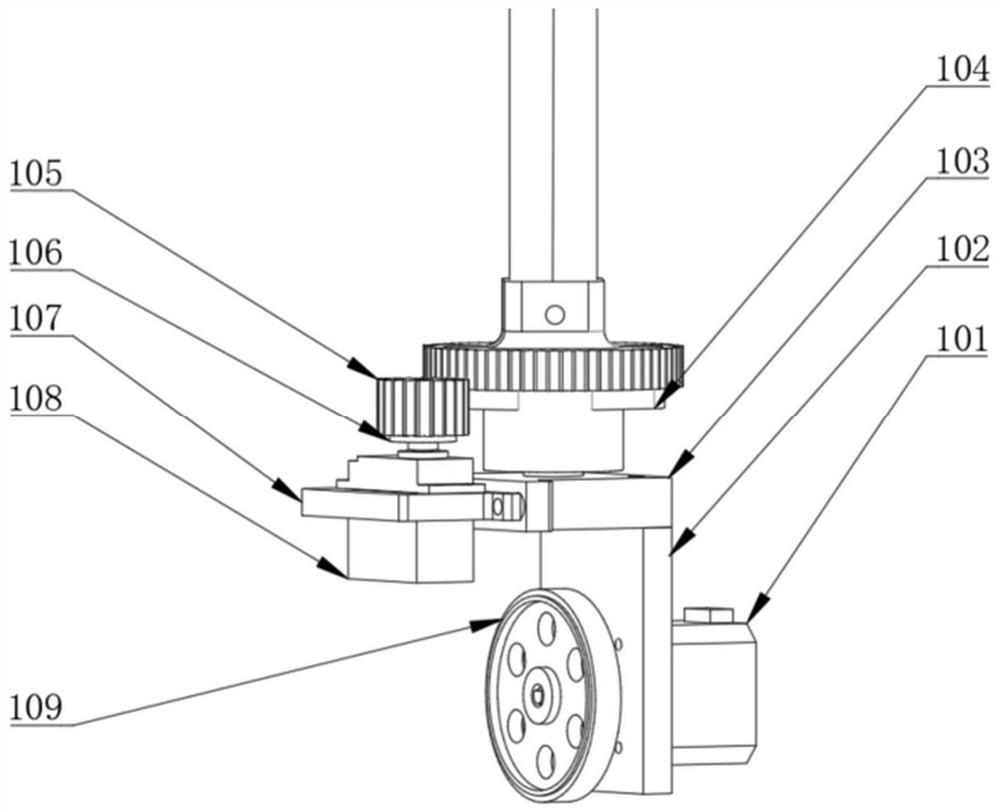

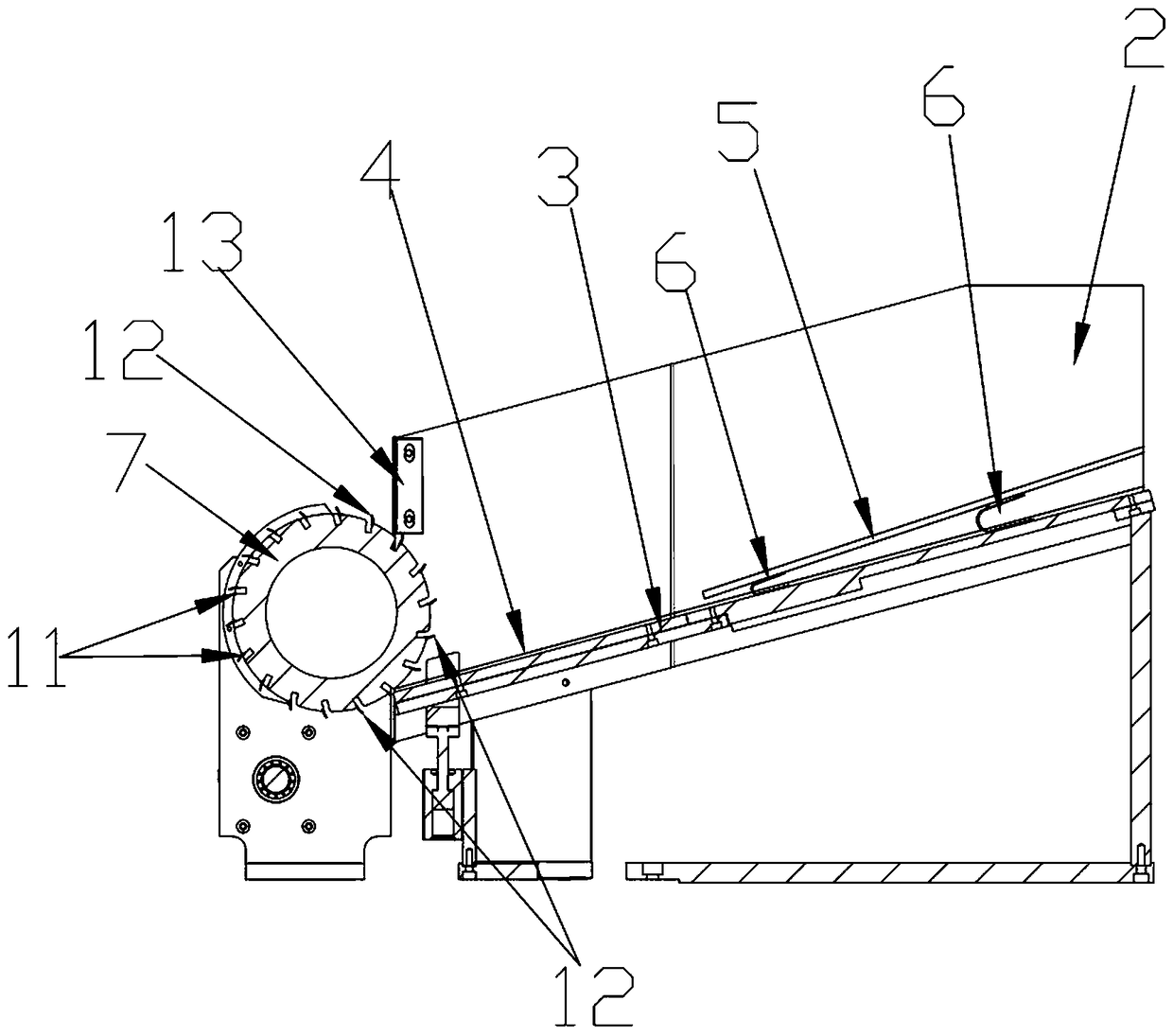

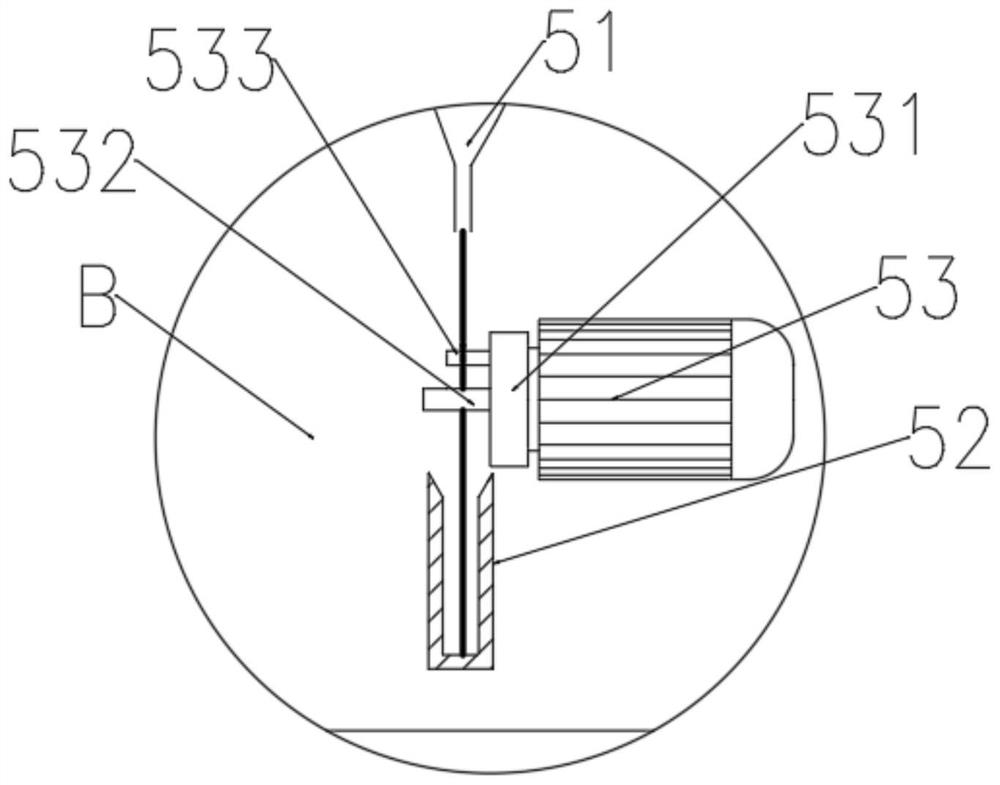

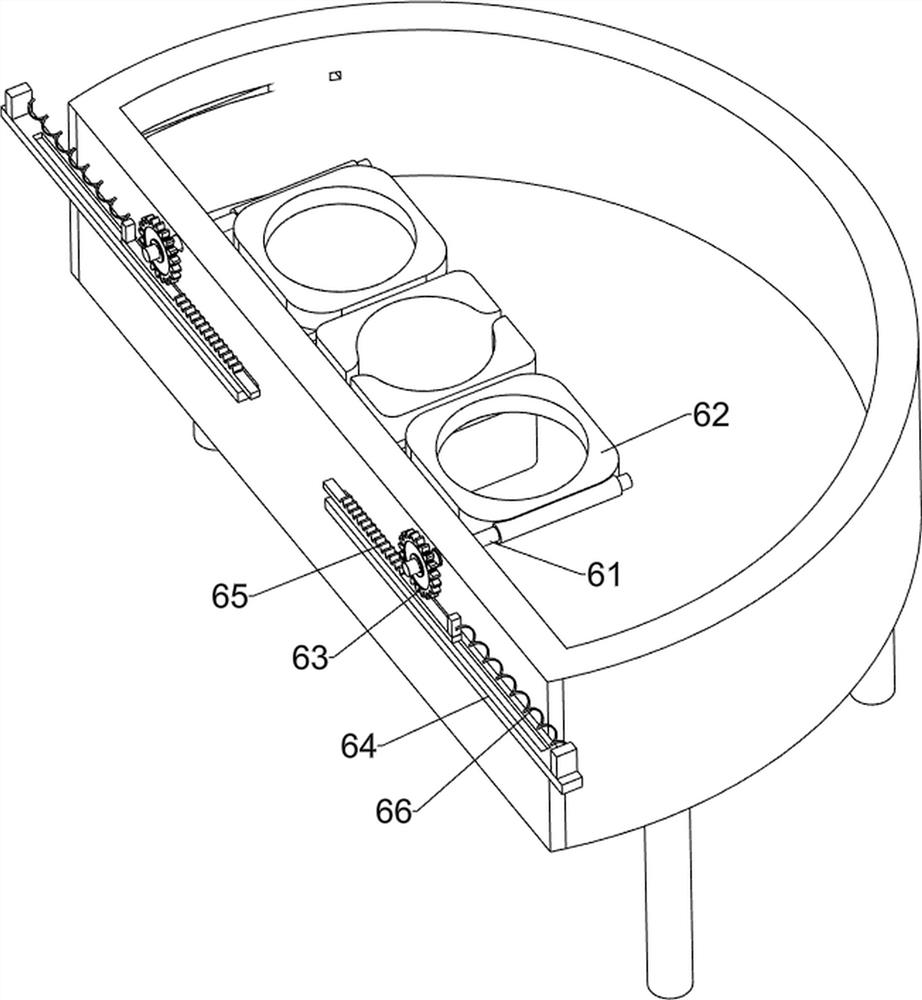

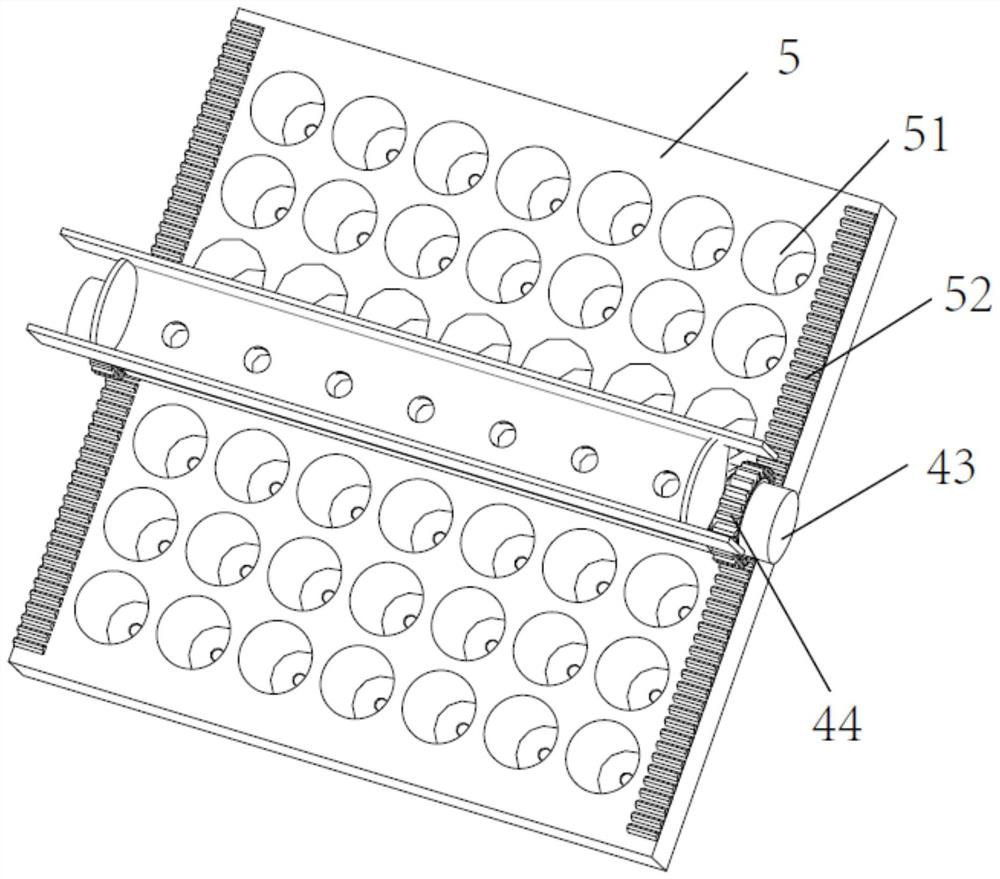

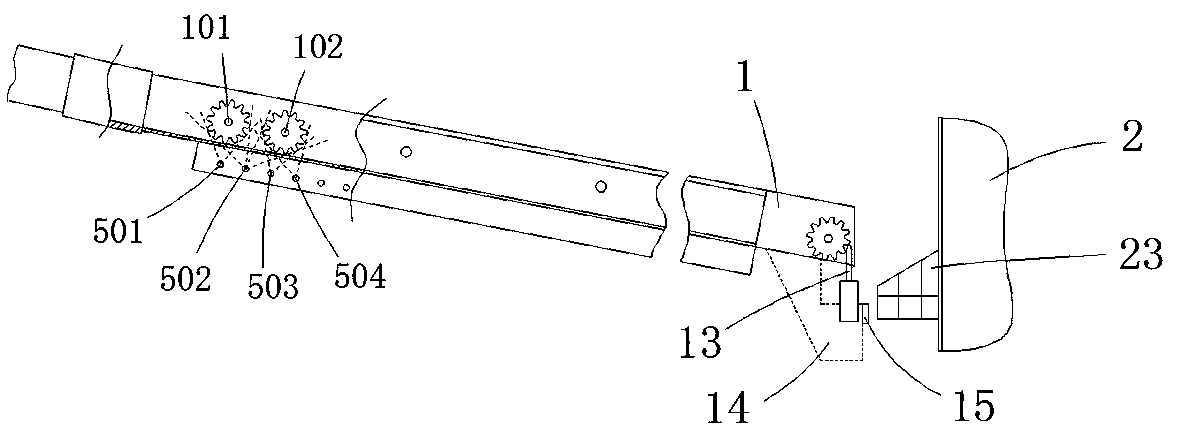

Cone tube rotary table feeding limiting mechanism

PendingCN113233112AEffective limitPrecise fallConveyor partsRotary conveyorsMechanical engineeringPhysics

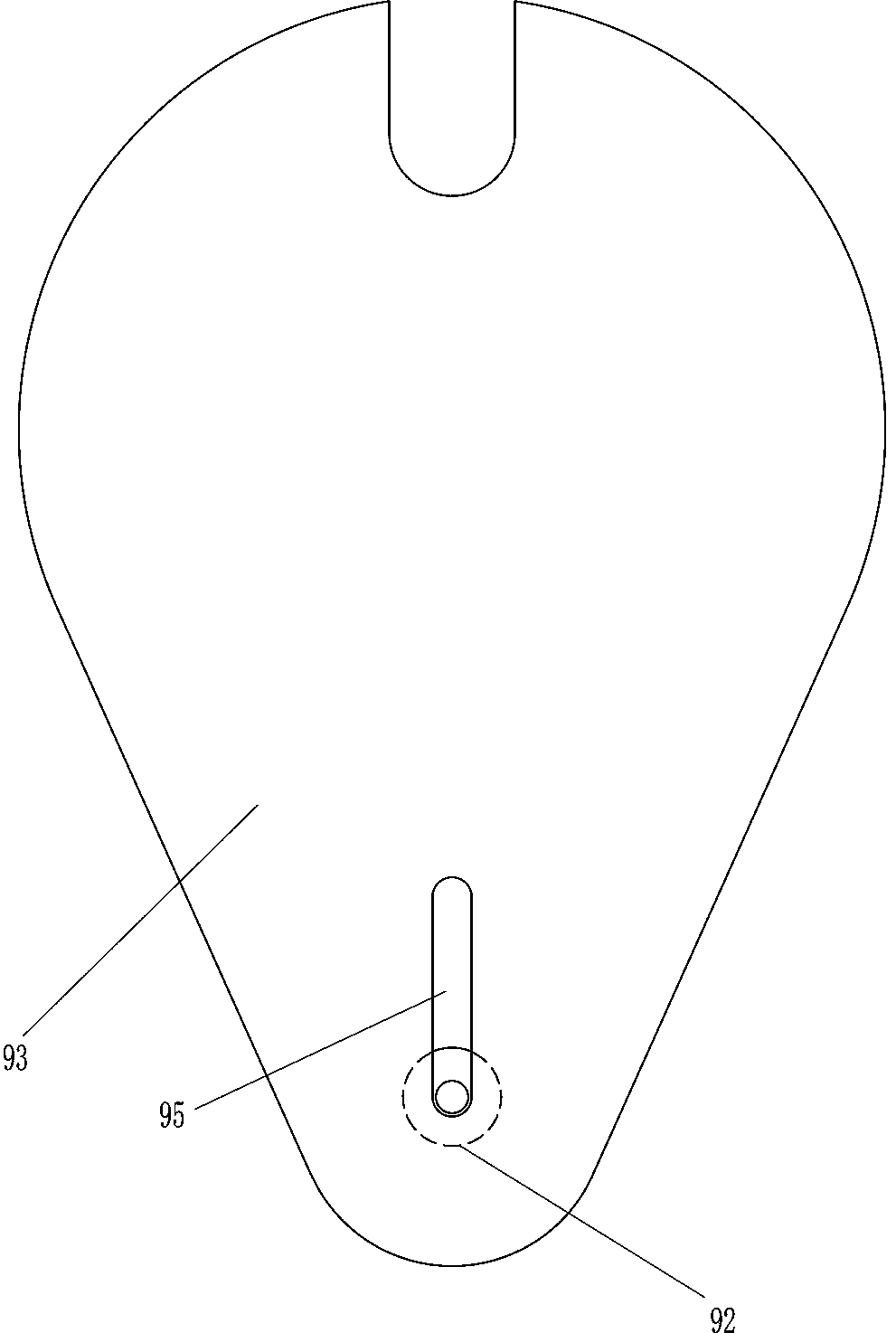

The invention relates to a cone tube rotary table feeding limiting mechanism which comprises a rotary table (1), a hole (2) is formed in the center of the rotary table (1), a center shaft (3) is vertically installed in the hole (2) in a penetrating mode, a plurality of cone tube supporting grooves (4) are evenly formed in the rotary table (1), the cone tube supporting grooves (4) are arranged in the radial direction of the rotary table (1), and limiting mechanisms (5) are arranged on the inner sides of the cone tube supporting grooves (4). The cone tube rotary table feeding limiting mechanism is simple in structure, cone tubes can be effectively limited, it is ensured that the cone tubes accurately fall into the supporting grooves, and the cone tubes are prevented from jumping out of or rushing out of the supporting grooves due to the inertia and gravity effect when sliding to the supporting grooves.

Owner:江阴市华方新技术科研有限公司

Untwisting device

PendingCN109402920AIn line with interestsImprove efficiencyTextile treatment untwisting devicesTextile treatment carriersTextile printerElectric machinery

The invention relates to the field of textile printing and dyeing equipment, in particular to an untwisting device. The device comprises a rack, a cloth carrying assembly, a cloth releasing assembly and a cloth clamping and discharging assembly; the cloth carrying assembly comprises a cloth carrying wheel and a first motor for providing power required by the cloth carrying wheel; the cloth releasing assembly is mounted at the portion, on a cloth feeding side of the cloth carrying wheel, of the rack; the cloth releasing assembly comprises a bearing sleeve, a rotating assembly, a second motor and a belt pulley transmission assembly; the rotating assembly comprises a rope releasing belt pulley, two rotating sleeve cloth releasing rollers, a nylon roller mounting piece and a nylon roller; thebearing sleeve coaxially sleeves the rotating sleeve, and rotating bearings for connecting the rotating sleeve with the bearing sleeve are arranged between the bearing sleeve and the rotating sleeve;a gap for allowing a fabric to pass through is formed between the two cloth releasing rollers; the cloth clamping and discharging assembly is mounted at the portion, on a cloth discharging side of thecloth carrying wheel, of the rack. According to the untwisting device, the twisted fabric can be efficiently untwisted into a flat fabric for output, the untwisting efficiency and quality are improved, and the manpower consumption and the time cost are greatly reduced.

Owner:福建宇邦纺织科技有限公司

A chemical anchor hose inserter

The invention relates to a rubber hose inserter, in particular to a chemical anchor bolt rubber hose inserter. The technical problem to be solved is how to provide a chemical anchor rubber hose inserter that automatically places the chemical anchor rubber hose and automatically pushes the chemical anchor into the hole. A chemical anchor bolt rubber hose inserter includes a handle, an installation box, etc.; the top of the handle is provided with an installation box. The present invention can automatically place the chemical rubber hose and automatically push the placed chemical rubber hose into the hole through the provided discharge mechanism and push-out mechanism, which improves the efficiency of inserting the chemical rubber hose into the hole, and automatically inserts the chemical anchor bolt rubber hose into the hole. During the internal process, the discharge pipe can be more accurately aligned with the hole through the ball rod in the guide mechanism, so that the inserted chemical hose can fall into the hole more accurately, and the set limit plate can block the arc groove. On the left, prevent the chemical anchor hose placed in the arc groove from slipping out.

Owner:山东中元绿色生物工程有限公司

An automatic cultivation device for seedling trays

ActiveCN113455143BEasy to operatePromote aerobic respirationDibble seedersCultivating equipmentsSeederSoil science

Owner:衢州市农业林业科学研究院

Rotary seal valve for production of liquid crystal polyester

PendingCN110436129AAvoid jammingEliminate potential safety hazardsLoading/unloadingRotary conveyorsPolyesterLiquid crystal

The invention provides a rotary seal valve for production of liquid crystal polyester. The rotary seal valve for the production of the liquid crystal polyester comprises a trolley, wherein a machine frame is installed on the trolley, a valve body is installed on the machine frame, a rotor is installed in the valve body, a material receiving groove is formed in the rotor through a group of dummy plates, a feeding port is formed in the upper portion of the valve body, a discharging port is formed in the lower portion of the valve body, a feeding channel which communicates with the interior of the valve body is formed in the feeding port, a screen plate obliquely arranged is installed in the feeding channel, one side of the screen plate is connected with the inner wall of the feeing channel through a rotation shaft, the other side of the screen plate is connected with the inner wall of the feeding channel through a pull spring, a shock excitation hammer is arranged on a part, located on one side of the pull spring, of the screen plate, and a transparent seal door is arranged on a position, corresponding to the bottom of the screen plate, in the feeding channel where the screen plate is installed. Jamming of the rotary seal valve for the production of the liquid crystal polyester can be effectively prevented in the work process, and therefore smooth proceeding of the production isguaranteed, and potential safety hazard of workers is eliminated.

Owner:NANJING QINGYAN POLYMER NEW MATERIAL CO LTD

Gear appearance detection channel and working method thereof

A gear appearance detection channel comprises an obliquely-arranged detection channel. The detection channel is connected with a feeding opening through a flexible part, is provided with a transposition drive device and can shift under the action of the transposition drive device. A gear face detection device is arranged at the bottom of the detection channel, and end face detection devices are arranged on the two side walls of the detection channel correspondingly. The gear face detection device comprises a set of camera shooting units arranged in the axial direction of the detection channel.A telescopic stop rod structure and a sensor are arranged at the end of the detection channel. The telescopic stop rod structure comprises a telescopic rod and an oil cylinder. Integrated action of appearance detection and sorting of the gear face and the end face is achieved, gear face appearance detection of all gear shapes is achieved, the gear face and the end face are detected at the same time, unqualified parts can be demounted in a manner of enabling the detection channel to shift in the falling process, qualified parts are conveyed one by one, the work efficiency is high, and controllability is good.

Owner:苏州聿知新机械科技有限公司

Automatic punching welding machine of hardware fasteners

InactiveCN107470917AImprove welding efficiencyImprove welding precisionOther manufacturing equipments/toolsPunchingDistribution control

The invention relates to an automatic punching welding machine of hardware fasteners. The automatic punching welding machine comprises a rack and a power distribution control cabinet, wherein a carrier feeding groove is formed in the rack; a welding carrier is arranged in the carrier feeding groove; the lower part of the welding carrier is arranged on a carrier feeding device; four square matching grooves which communicate with each other are formed in the upper part of the welding carrier; the lower part of the welding carrier is energized; a silver needle conveying device matched with the welding carrier and a punching device are separately arranged on the front and back sides on the rack; the side surface of the punching device is matched with an iron wire conveying device; and a welding device matched with the welding carrier is arranged above the position, matched with the silver needle conveying device, of the welding carrier. According to the automatic punching welding machine, front-back feeding of the welding carrier is matched with a silver needle conveying stripping device and the iron wire punching device, iron wires and silver needles are accurately placed and four regular to-be-welded points are formed through the square matching grooves which are formed in the upper part of the welding carrier and communicate with each other, and accurate automatic welding can be achieved through cooperation with the welding device.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

Dedusting and cleaning device for sunflower seed oil production

InactiveCN112090731AImprove dust removal efficiencyReduce labor intensitySievingScreeningAgricultural engineeringSunflowerseed oil

The invention discloses a dedusting and cleaning device for sunflower seed oil production. The dedusting and cleaning device comprises a bottom plate and a vibration unit; four supporting columns areevenly arranged on the left side of the upper surface of the bottom plate, and the upper surfaces of the supporting columns are fixedly connected with base plates; and the base plates are L-shaped plates, and the right ends of the upper surfaces of the base plates are rotatably connected with collecting tanks through rotating shafts. According to the dedusting and cleaning device for the sunflowerseed oil production provided by the invention, raw material tanks can vibrate frequently through the base plates and the vibration unit, impurities and dust in the raw material tanks can be filteredinto the collecting tanks through filtering holes, the labor intensity of soaking work can be reduced while the dedusting efficiency of sunflower seeds is improved, the dedusted sunflower seeds can besoaked through a soaking barrel, and the sunflower seeds accumulated in the soaking barrel can be stirred through a stirring unit, therefore, the sunflower seeds are prevented from accumulating in the soaking barrel for a long time, and the soaking efficiency of the sunflower seeds can be improved.

Owner:李小霞

Device and method for supplementing seedlings

ActiveCN113228900BIngenious structural designPrecise positioningTransplantingAgricultural scienceImaging processing

The invention belongs to the field of agricultural equipment and relates to a device and method for replenishing seedlings. The seedling replenishing device includes a walking mechanism, a positioning mechanism, a seedling throwing height adjustment mechanism, a seedling storage and seedling throwing mechanism, a vehicle frame and a control mechanism; the seedling throwing height adjustment mechanism and the seedling storage and seedling throwing mechanism are controllably arranged under the frame platform through the positioning mechanism , the positioning mechanism can drive the seedling throwing height adjustment mechanism and the seedling storage and seedling throwing mechanism to move horizontally and vertically. The walking mechanism of the present invention can realize in-situ steering by using four-wheel steering joint matching, and the four wheels can be independently controlled to realize walking and steering in complex environments; the positioning mechanism realizes seedling replenishment through calibration and matching of image coordinates and seedling guide tube positions Precise positioning; the camera captures the ground environment in real time, and the machine vision and image processing based on the Raspberry Pi are fast and accurate; the ingenious structural design of the seedling storage mechanism and the height adjustment mechanism of the seedlings can not only store a certain amount of seedlings, but also accurately fall into the hole.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com