Sliding-type concrete product distributing device

A technology for concrete products and material distributing devices, which is applied in the field of engineering construction equipment and construction, and can solve problems such as time-consuming and labor-intensive, large amount of cement, and increased safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The patent of this case will be further described below in conjunction with the accompanying drawings. Obviously, this specific embodiment is only a further description of the present invention, and should not be construed as limiting the technical solution of the patent of this case. On the basis of the structure or principle provided by the present invention Various modifications can be extended, and these modified technical solutions are all within the protection scope of the present invention.

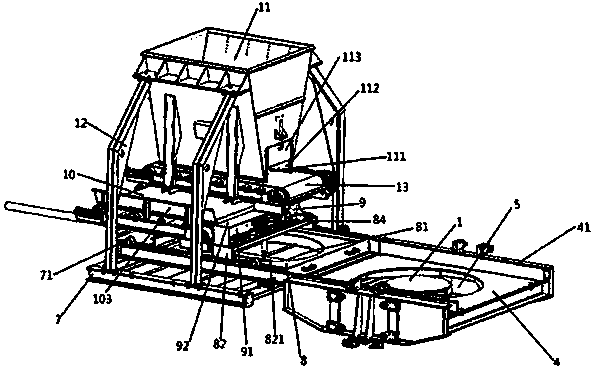

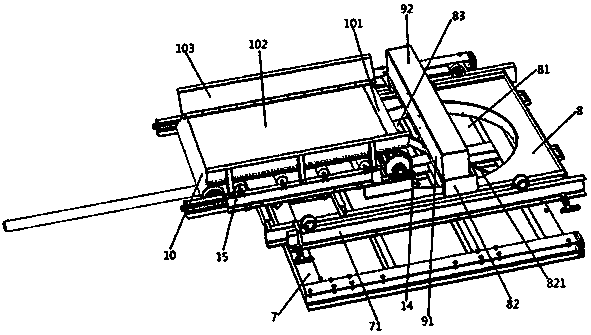

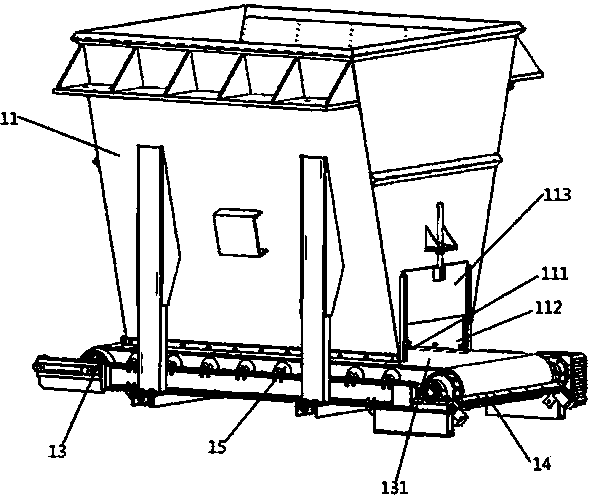

[0034] Such as Figure 1-4 As shown, a sliding concrete product distribution device includes:

[0035] Mandrel 1;

[0036] An outer mold 2 with an inner cavity, the core mold 1 is located inside the inner cavity of the outer mold 2, and there is a forming cavity 3 between the core mold 1 and the outer mold 2, and the forming cavity 3 is used to hold cement pipes for preparing raw materials ;

[0037] The outer mold fixing platform 4, the top of the outer mold 2 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com