Production method for partitioned unit glued lattice structural bodies of graphic fireworks

A technology of a lattice structure and a manufacturing method, which is applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of a large number of manpower and material resources, high cost, and large volume, and achieve the effects of convenient production, reduced difficulty and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

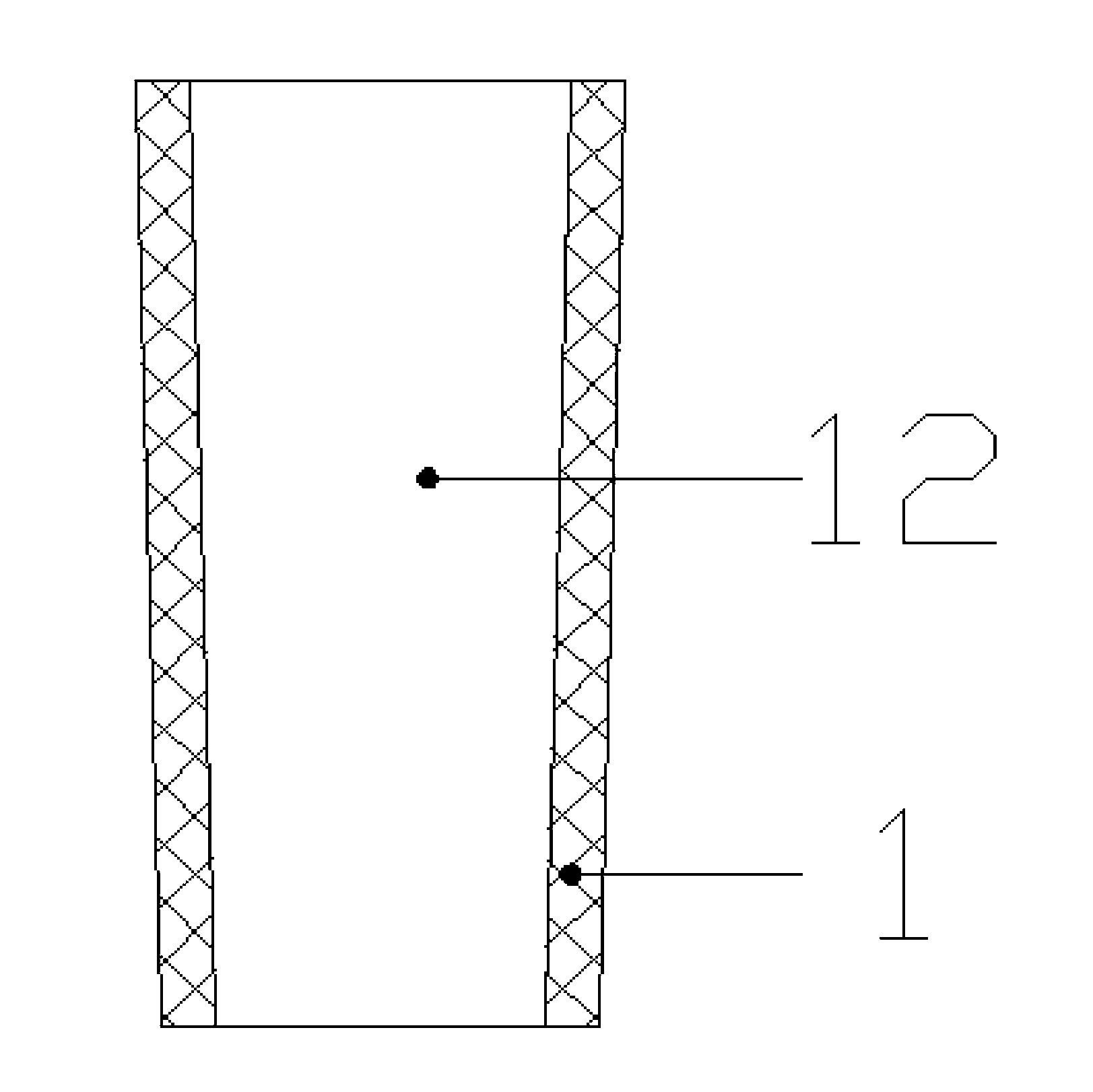

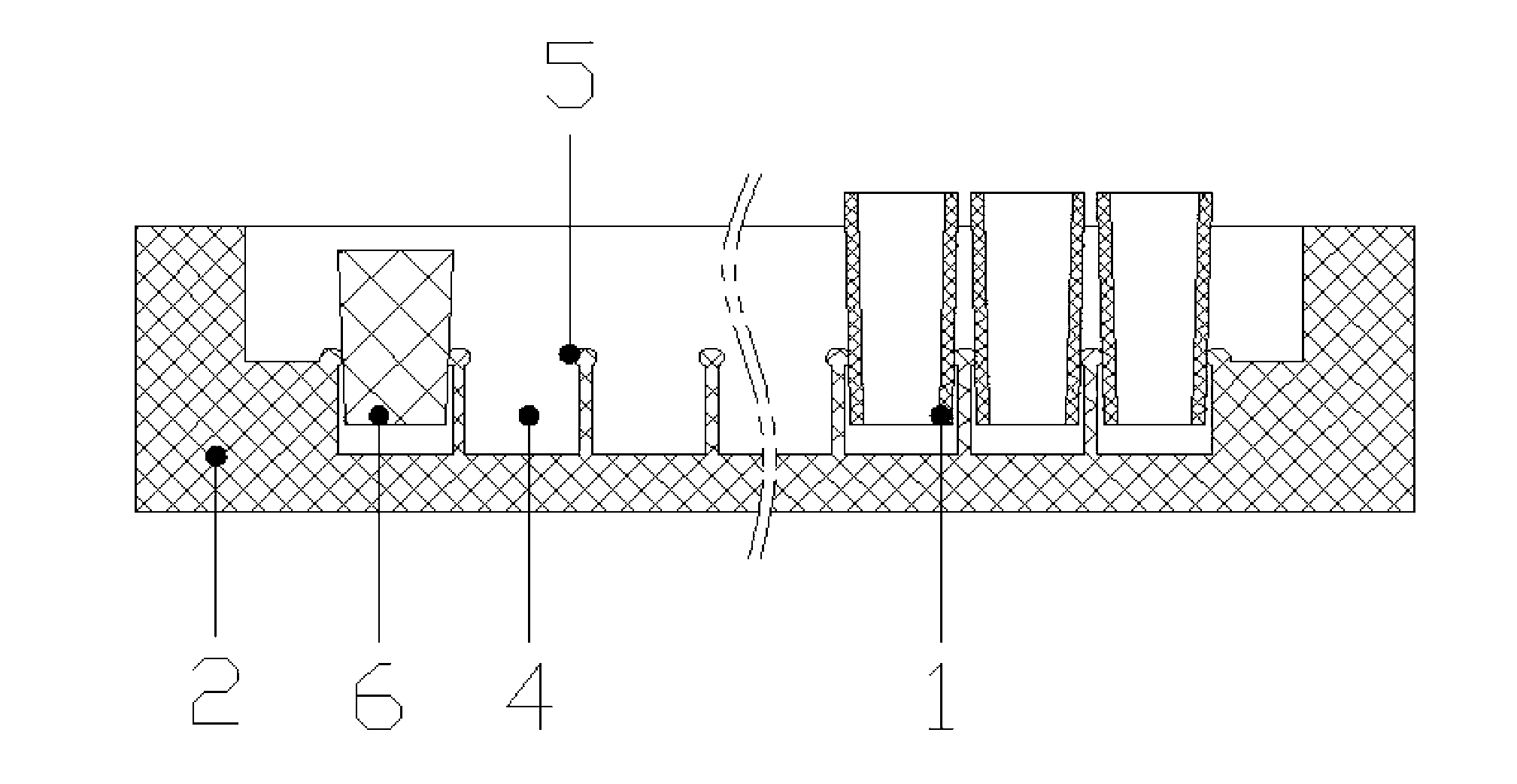

[0034] refer to Image 6 As shown, a split unit glued graphic fireworks dot matrix structure includes a dot matrix structure completion body 11, and the dot matrix structure completion body 11 includes a split unit 1 and glue 3, and the split unit 1 is fixed by glue 3, and the split units 1 are closely arranged in a dot matrix, and the split units 1 are equipped with pyrotechnic propellant and pyrotechnic display charge 12.

[0035] A method for manufacturing a split-unit adhesive-type graphic and text fireworks dot matrix structure, comprising the following steps:

[0036] Step 1) Preset the outline shape of the graphic fireworks after they are set off;

[0037] Step 2) Make the height-limiting collar 7 according to the outline shape;

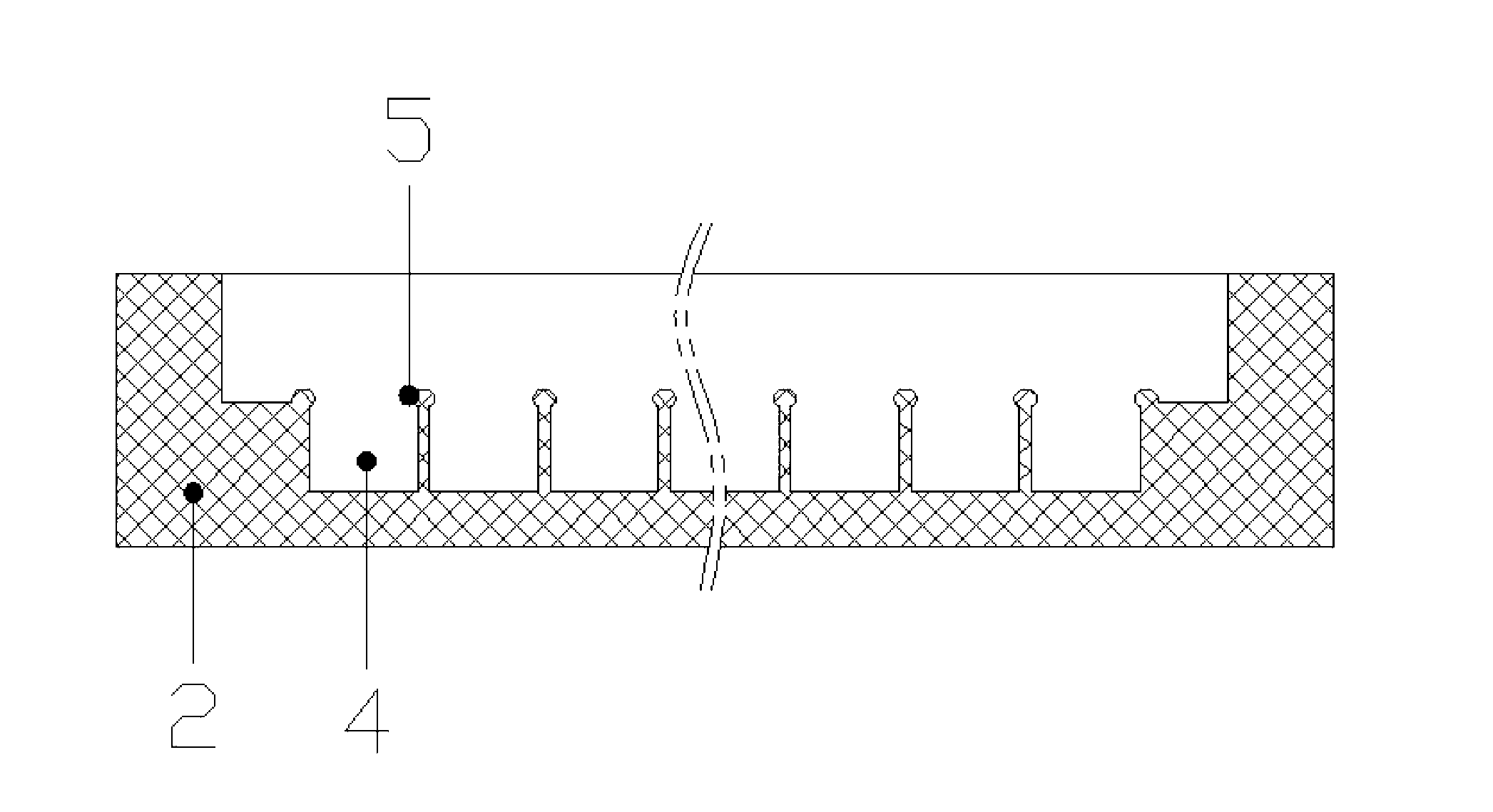

[0038] Step 3) Place the dot matrix molding fixture 2, refer to figure 2 As shown, put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com