Method for preparing composition of carbon nano tube and graphene by using sheet material

A carbon nanotube and lamellar material technology, applied in the field of new materials and their preparation, can solve the problems of poor quality of carbon nanotubes and affect performance expression, and achieve the effect of facilitating engineering scale-up and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

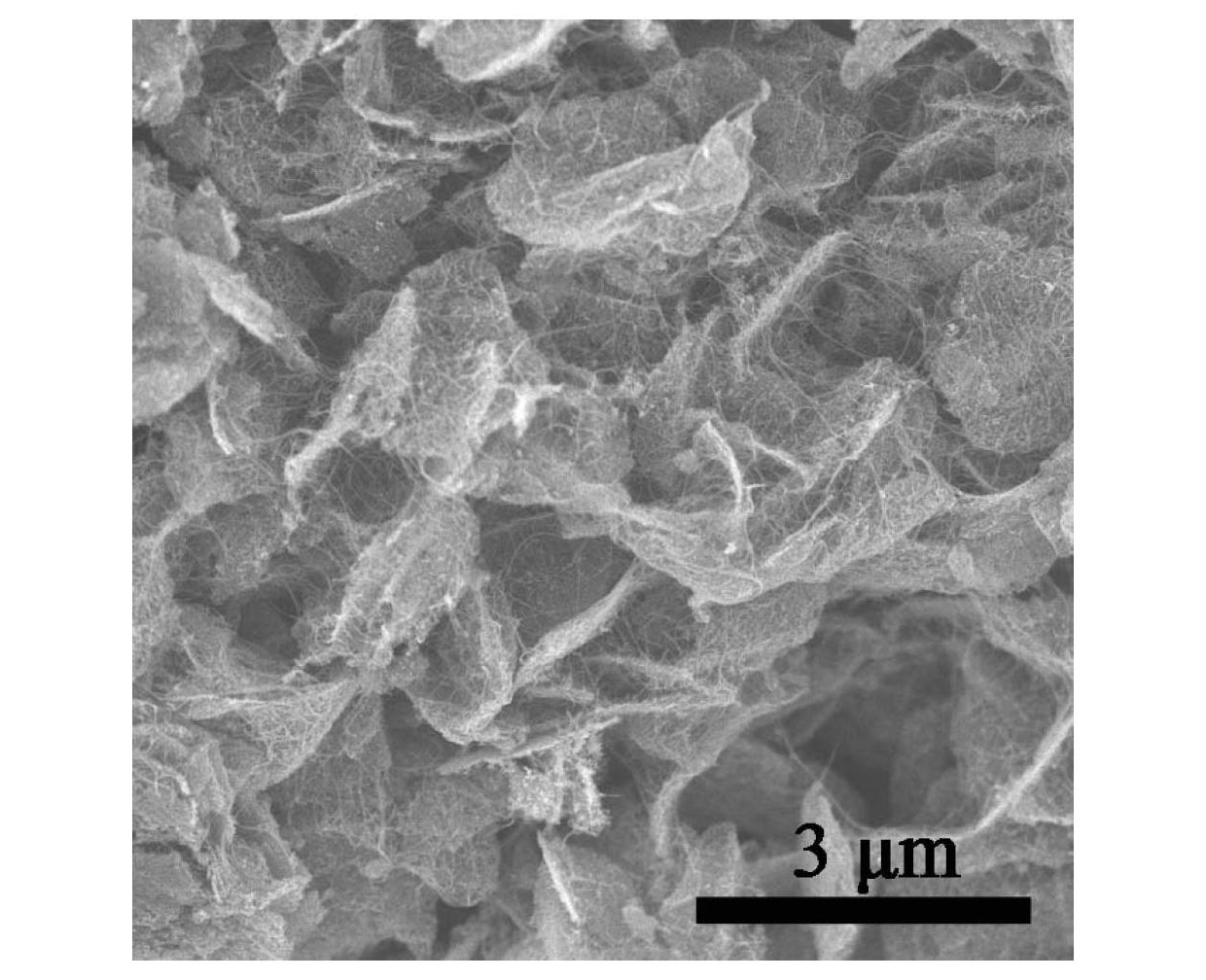

[0026] Example 1: Using FeMgAl LDH as a catalyst to prepare a carbon nanotube and graphene composite through a fixed bed.

[0027] FeMgAl LDHs with a Fe content of 10% was used as a catalyst, and 50 mg was uniformly spread in a porcelain boat, and then placed in a tubular fixed-bed reactor. Argon was used as the carrier gas with a flow rate of 600 sccm. Under this atmosphere, the temperature of the reactor was raised from room temperature to 950°C; after that, the reaction temperature was maintained at 950°C, and a mixture of carbon source methane, hydrogen and argon was introduced, wherein the partial pressure of carbon source methane was 80%, A chemical vapor deposition process is performed to simultaneously deposit carbon nanotubes and graphene. After 20min, turn off the carbon source methane and H 2 , the solid phase product was removed after cooling to room temperature under an argon atmosphere. The solid phase product is first treated with 3mol / L NaOH aqueous solution...

Embodiment 2

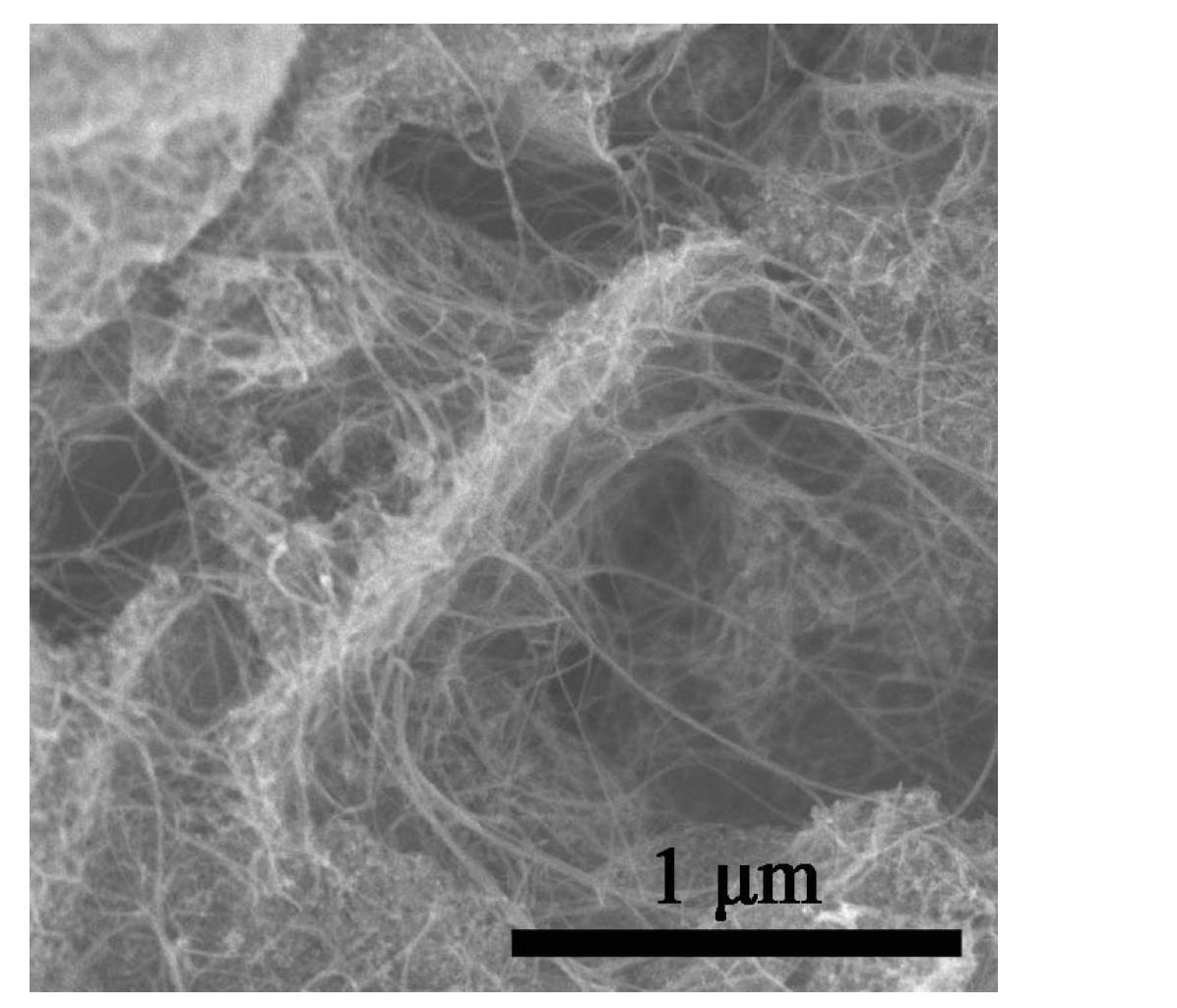

[0028] Example 2: Using FeMgAl LDH as a catalyst to prepare a carbon nanotube and graphene composite through a fixed bed.

[0029] FeMgAl LDHs with a Fe content of 50% was used as a catalyst, and 50 mg was evenly spread in a porcelain boat, and then placed in a tubular fixed-bed reactor. Argon was used as the carrier gas with a flow rate of 600 sccm. Under this atmosphere, the temperature of the reactor was raised from room temperature to 1200 ° C; after that, the reaction temperature was maintained at 1200 ° C, and a mixture of carbon source methane and argon was introduced, wherein the partial pressure of carbon source methane was 80%, and the chemical reaction was carried out. Graphene is deposited by a vapor deposition process. After 10 minutes, the carbon source methane was turned off, and the reactor was cooled to 750°C under an argon atmosphere, and then a mixture of carbon source ethylene, hydrogen and argon was introduced, wherein the partial pressure of carbon sourc...

Embodiment 3

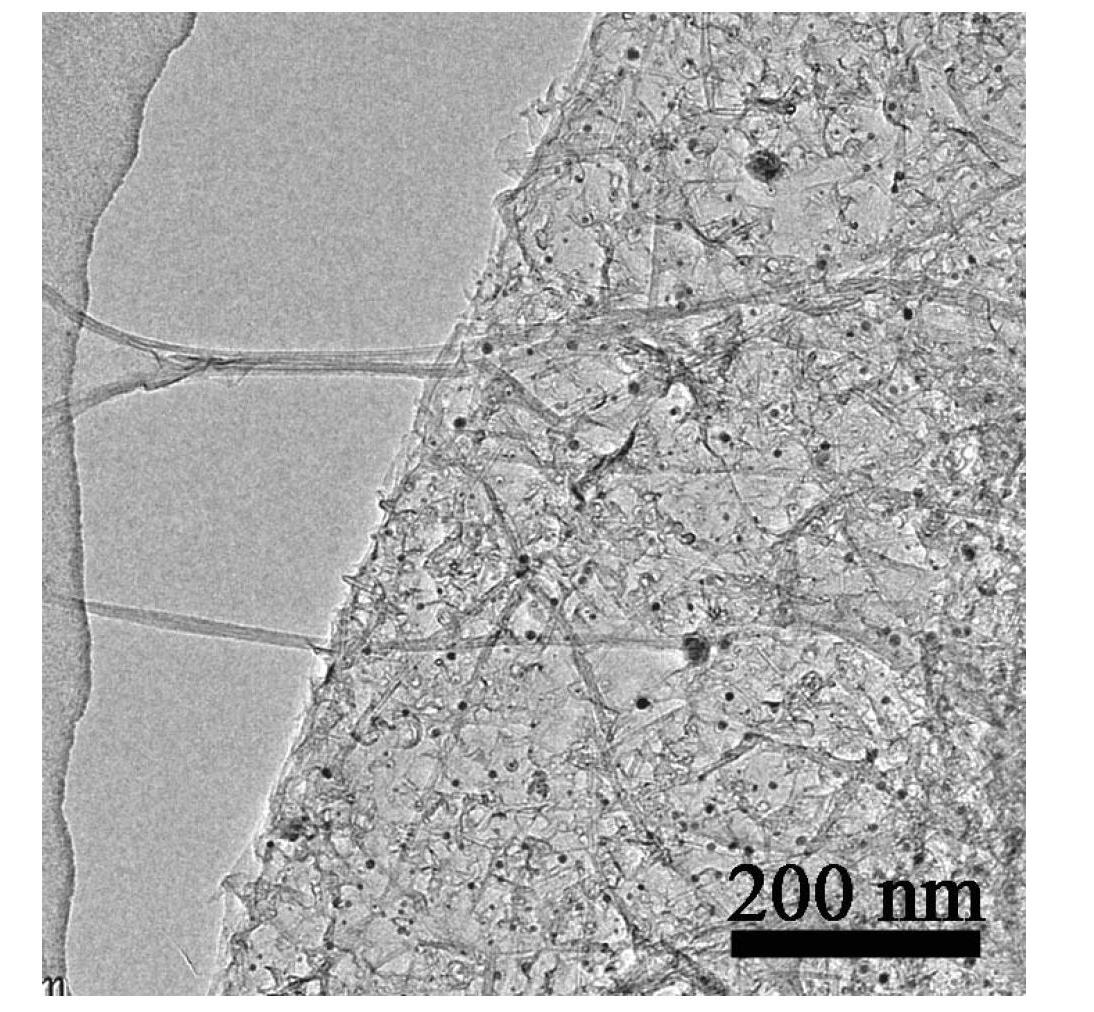

[0030] Example 3: Using FeMoMgAl LDH as a catalyst to prepare a carbon nanotube and graphene composite through a fixed bed.

[0031] FeMoMgAl LDHs with a Fe content of 20% and a Mo content of 0.2% were used as catalysts, and 50 mg of FeMoMgAl LDHs was evenly spread in a porcelain boat, and then placed in a tubular fixed-bed reactor. Nitrogen was used as the carrier gas with a flow rate of 600 sccm. In this atmosphere, the temperature of the reactor was raised from room temperature to 750°C, and then a mixture of carbon source propylene, hydrogen and nitrogen was introduced, wherein the partial pressure of carbon source propylene was 10%, and the chemical vapor deposition process was carried out to deposit carbon nanometers. Tube. After 30min, turn off the carbon source propylene and H 2 After that, the temperature of the reactor was raised to 1000°C, and then a mixed gas of carbon source methane and argon was introduced, wherein the partial pressure of carbon source methane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com