Patents

Literature

69results about "Textile treatment untwisting devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

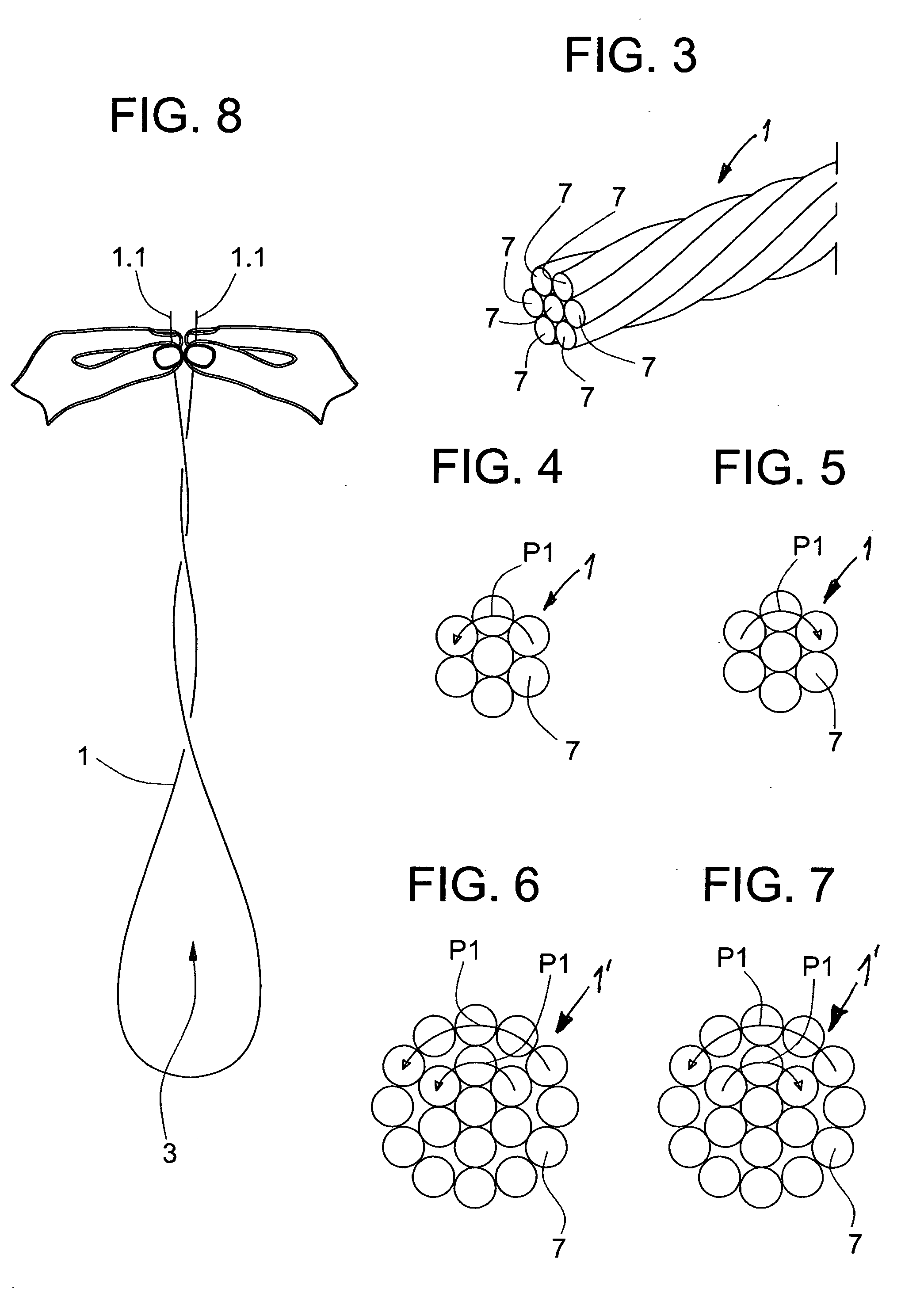

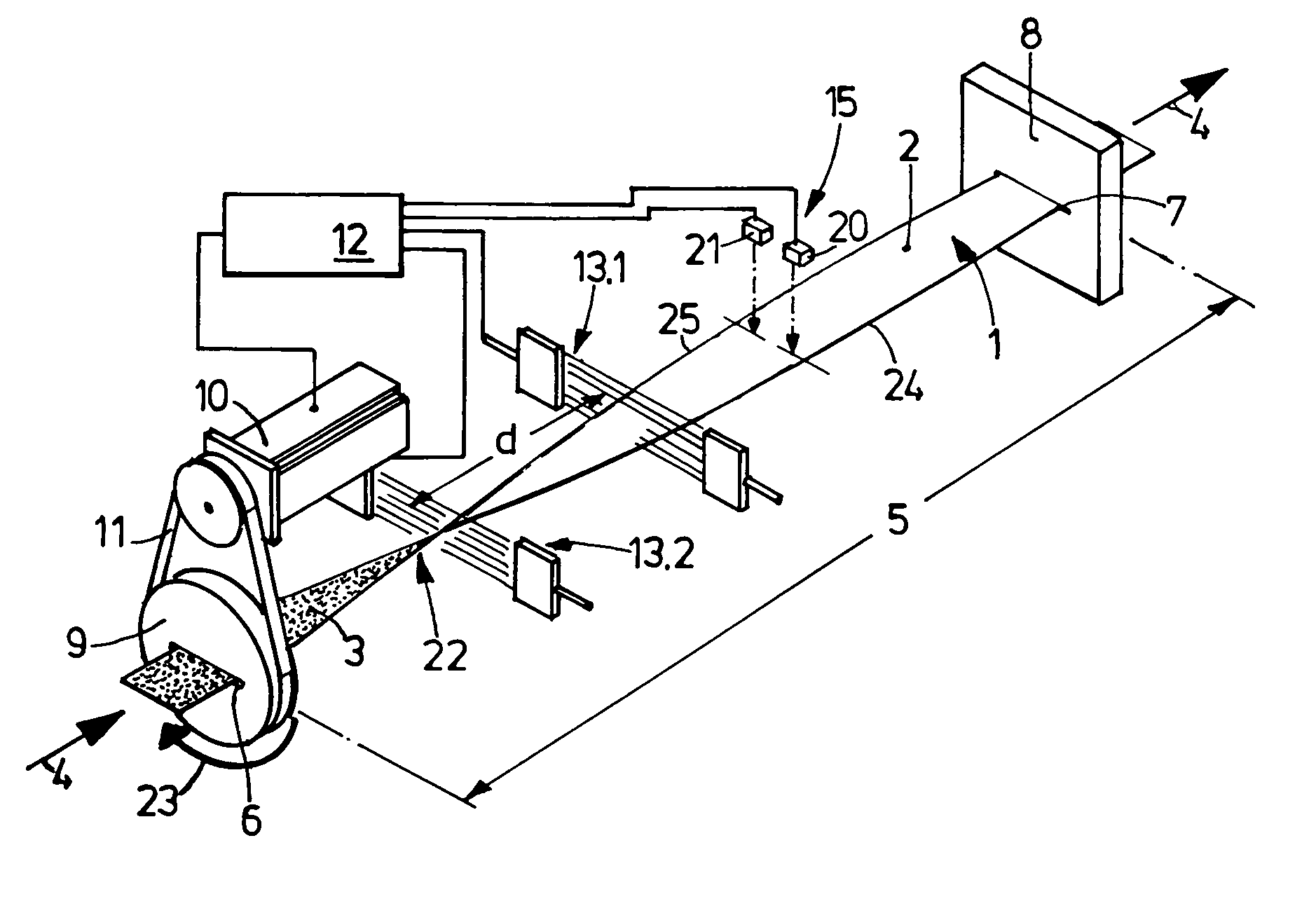

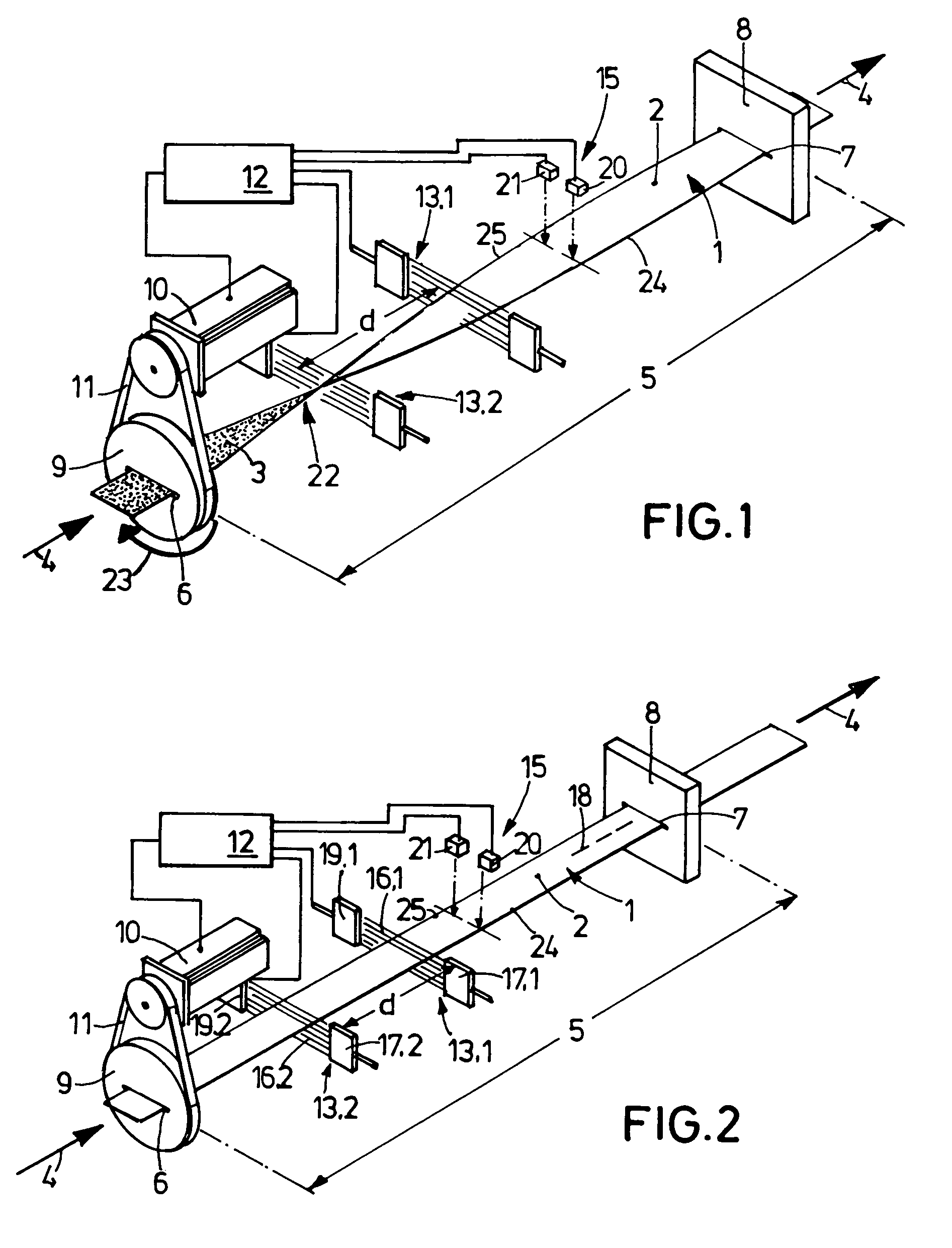

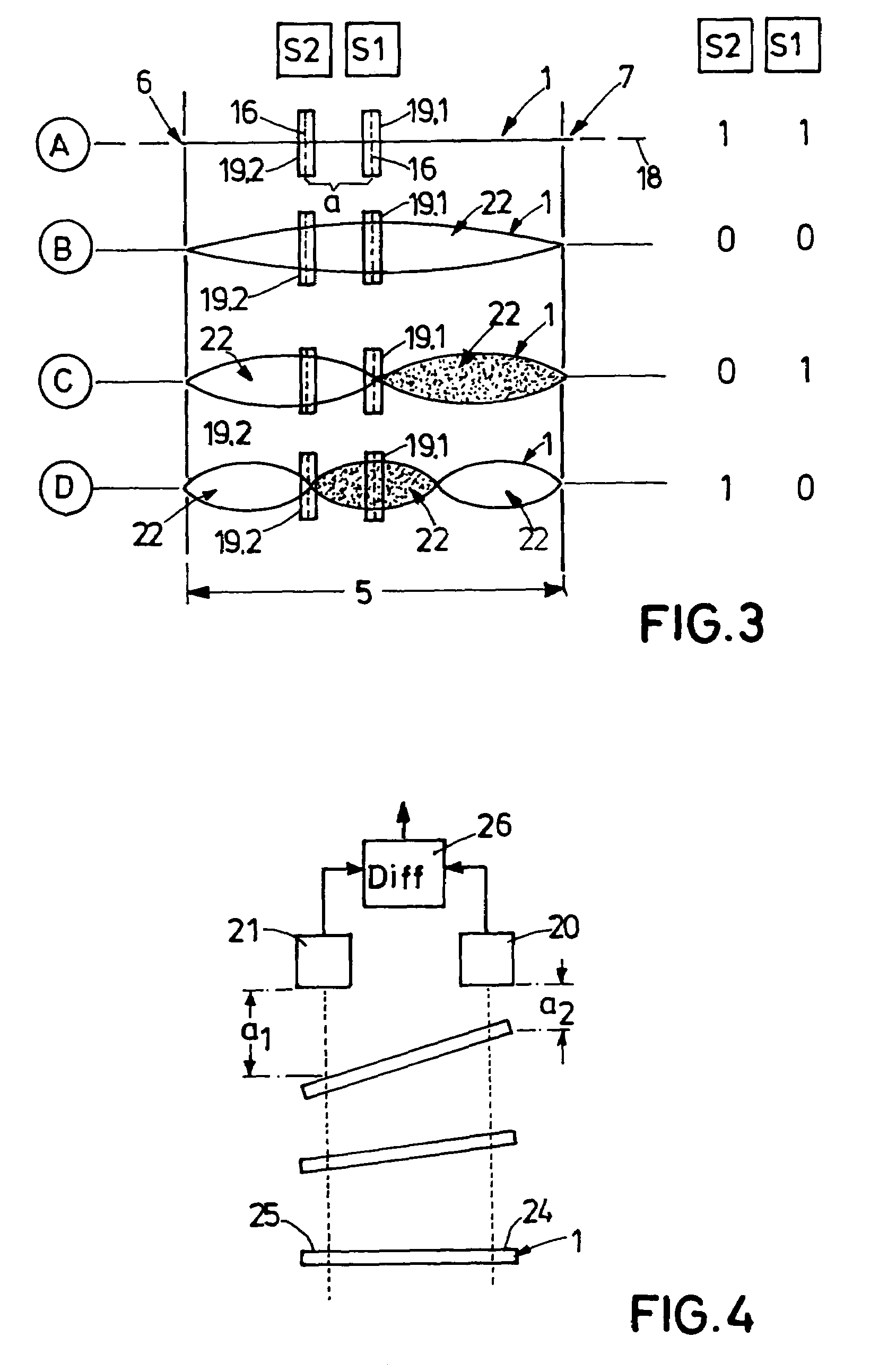

Method and device for processing a wire

ActiveUS7647759B2Quality improvementShorten production timeLine/current collector detailsTextile treatment untwisting devicesEngineeringFront and back ends

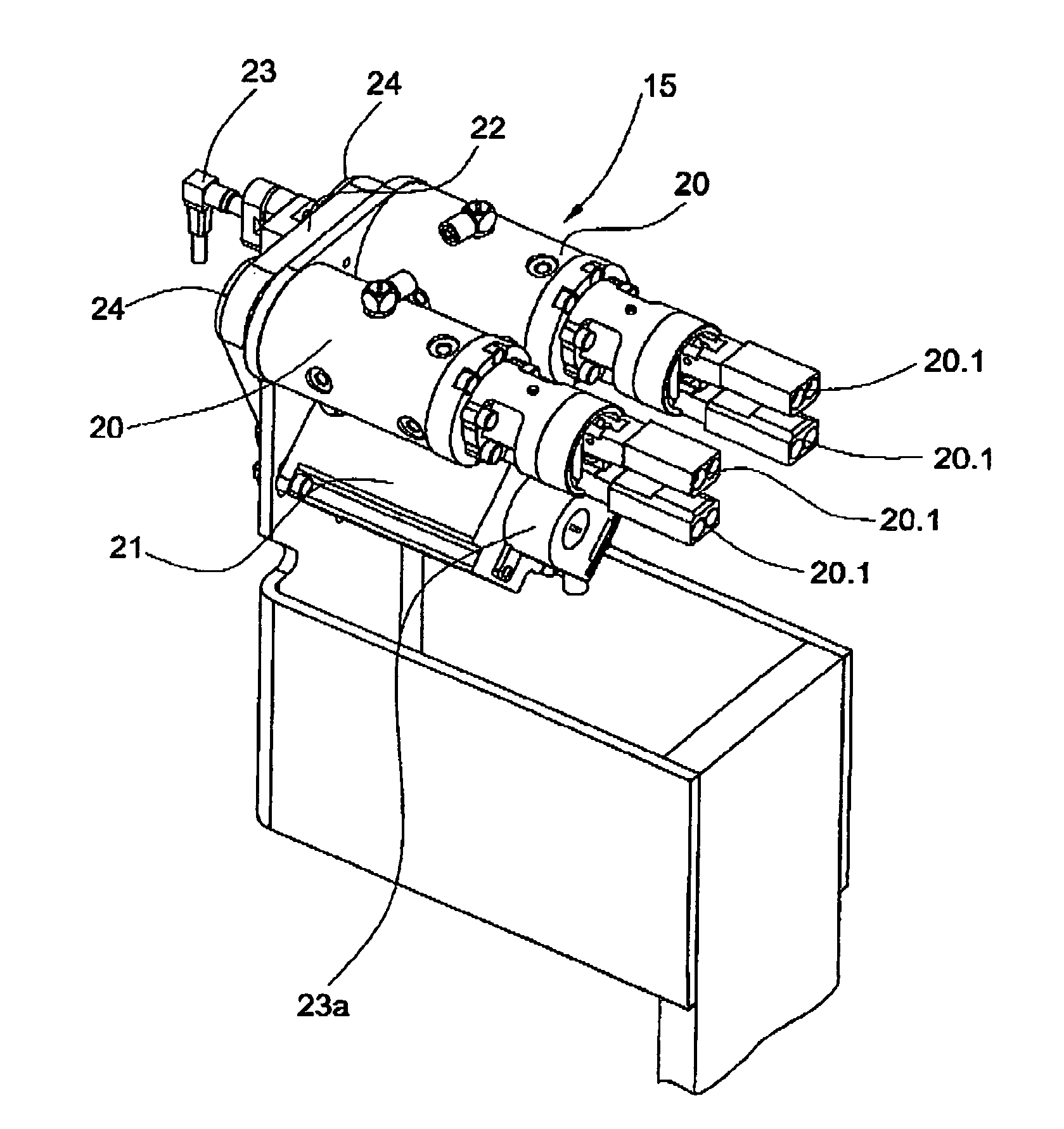

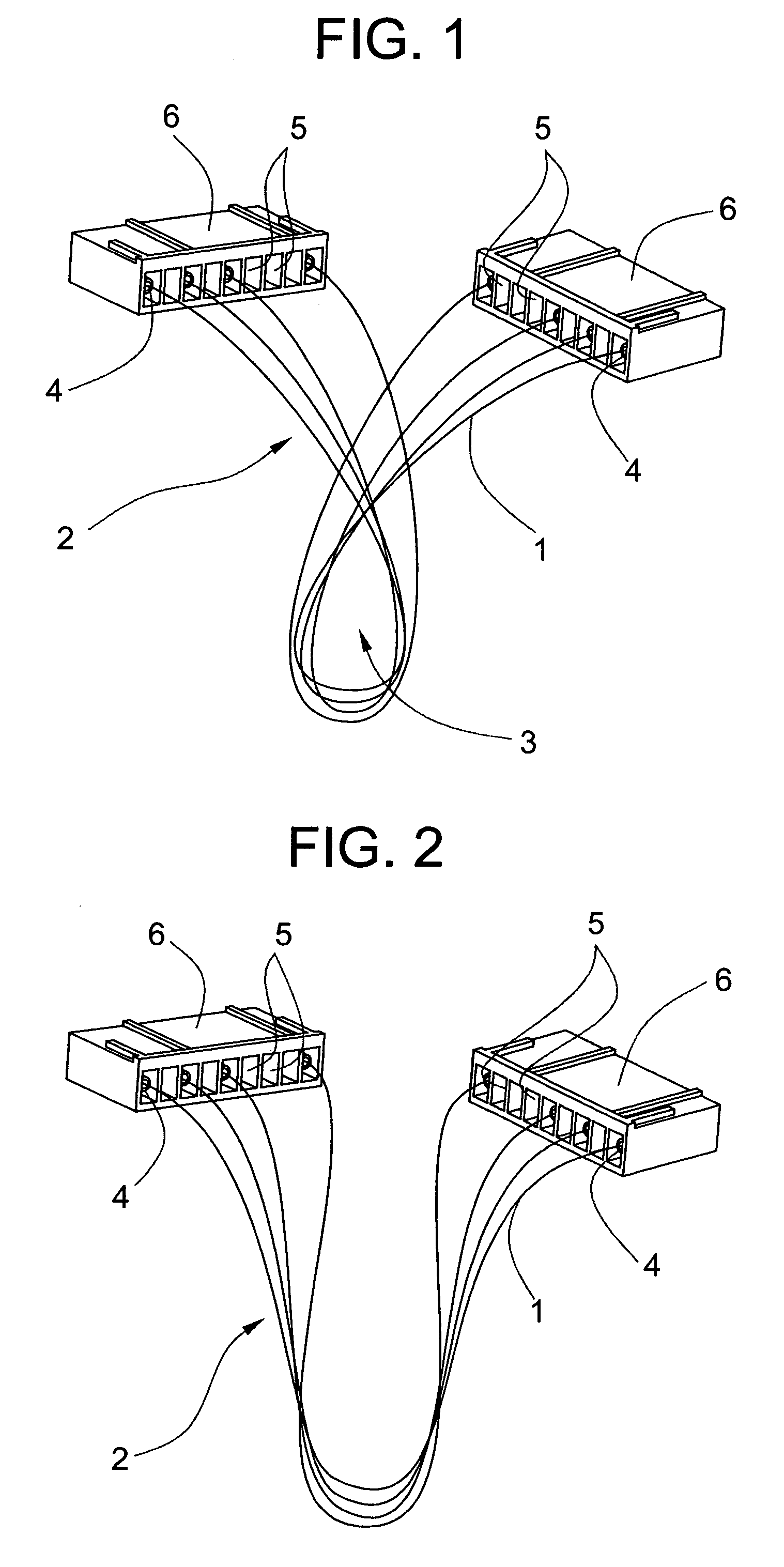

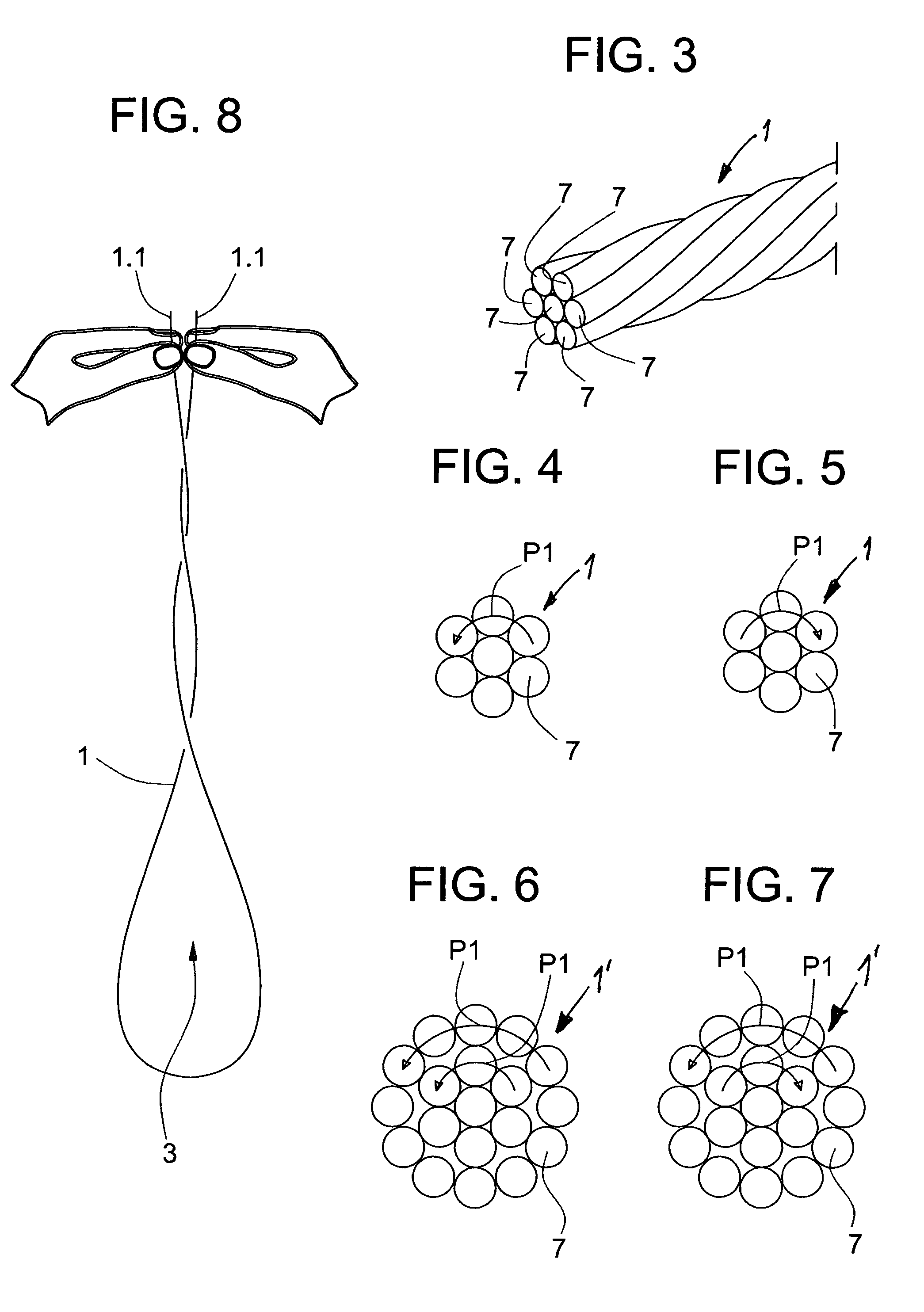

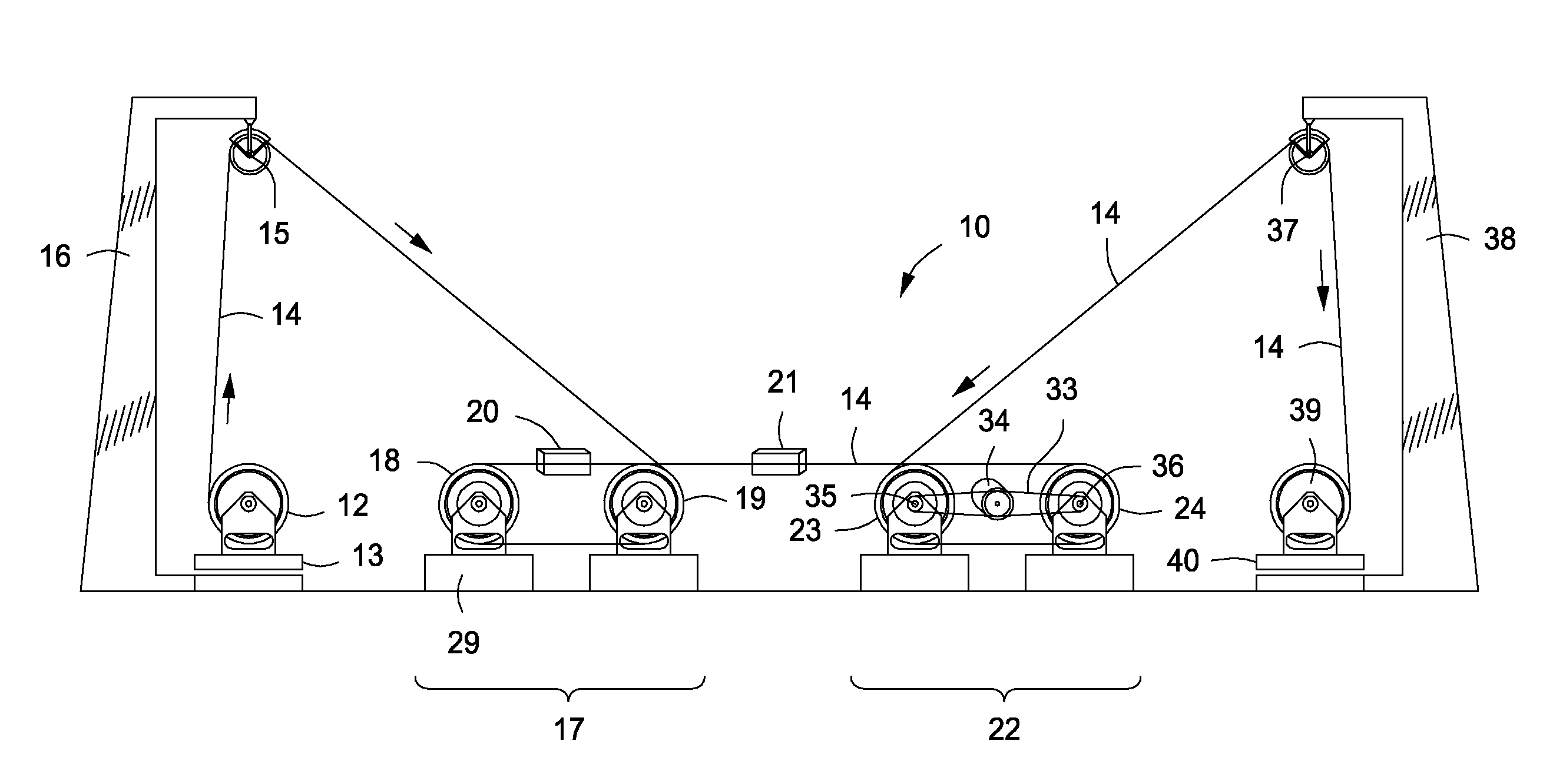

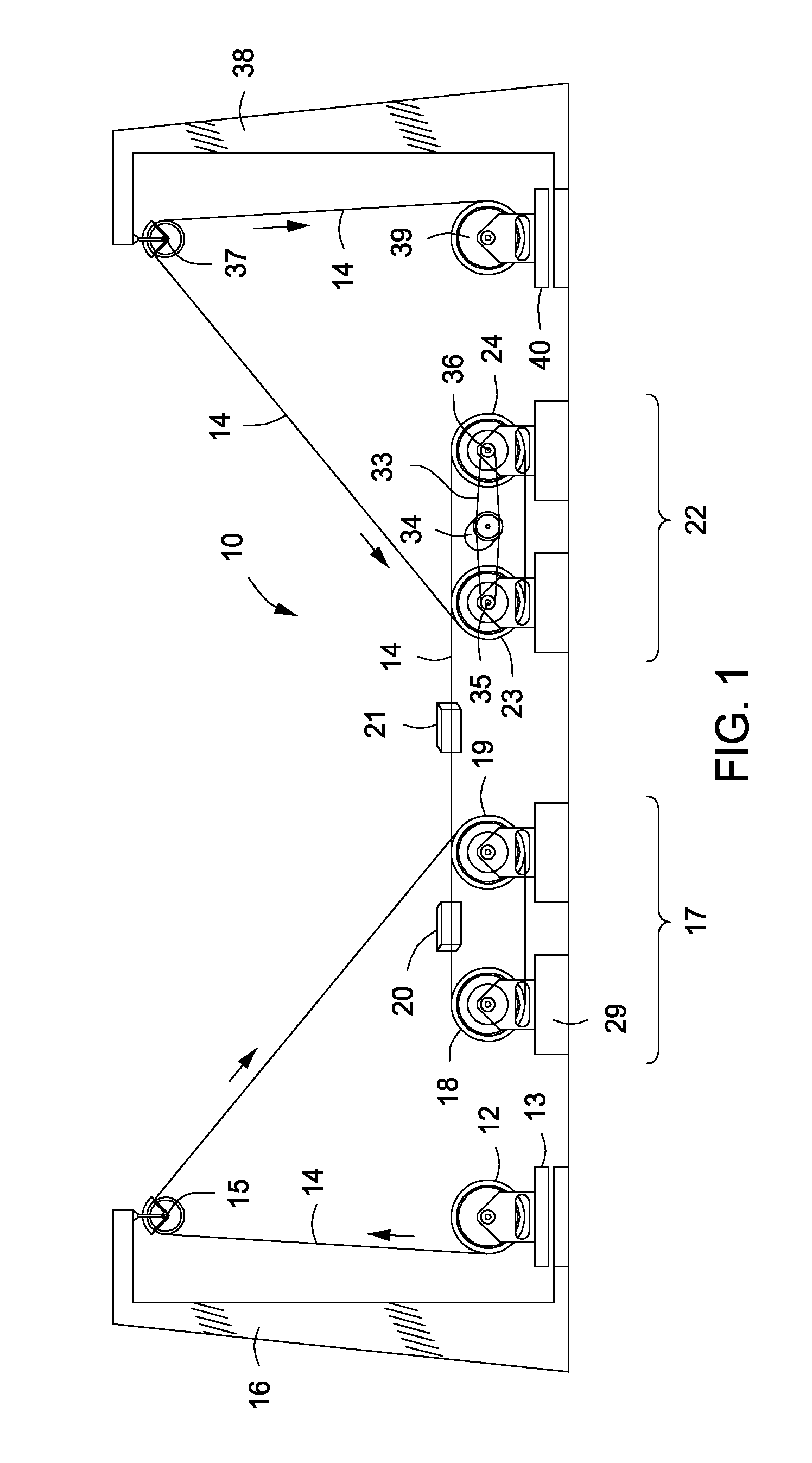

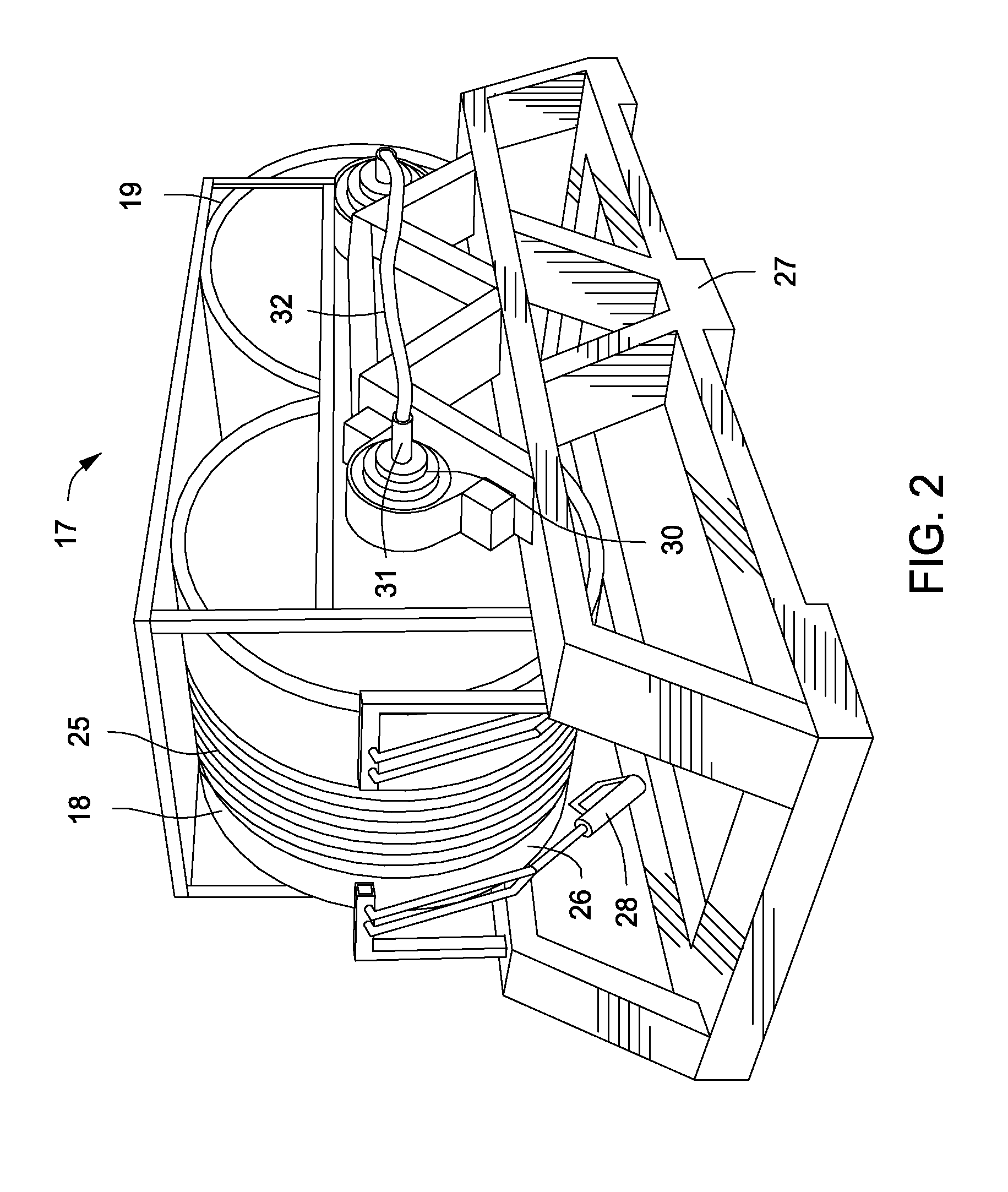

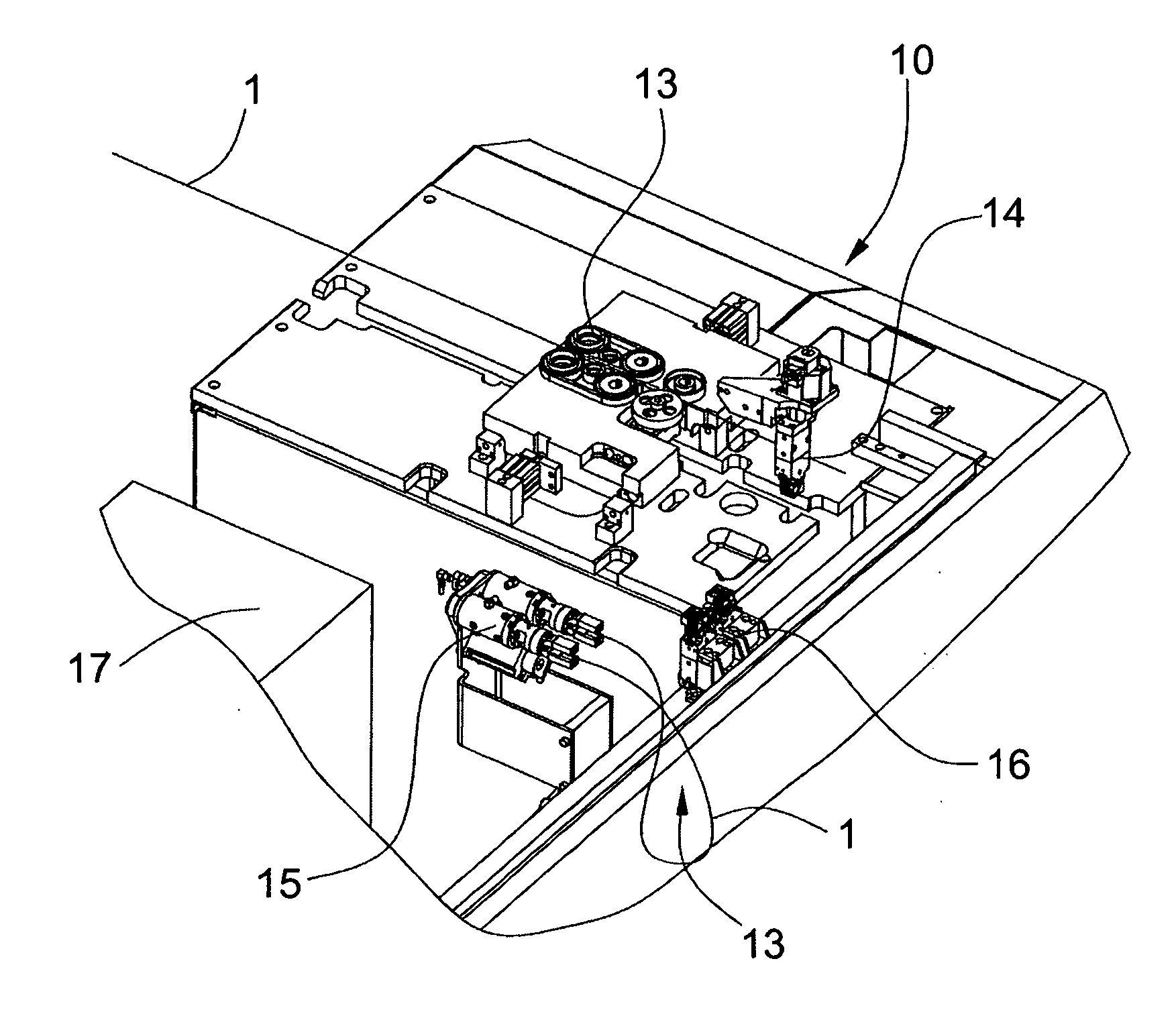

In a wire-processing device, the wire executes turns through being pulled out of a drum. The leading wire-end is held by a gripper of a loop-former. A wire that has been cut to length is held at its leading and trailing ends by an untwisting unit, the wire having before the untwisting operation a doubled-backed loop. A transfer unit takes the leading and trailing ends from the loop-former and passes the wire to the untwisting unit. After the untwisting operation, the transfer unit feeds the wire-ends to the processing units that process the wire-ends. A bundling unit takes the processed wires from the transfer unit, the bundling unit forming a wire bundle with the wires. With the untwisted wires, the wire bundle has neither doubled-back loops nor knots.

Owner:KOMAX HOLDING

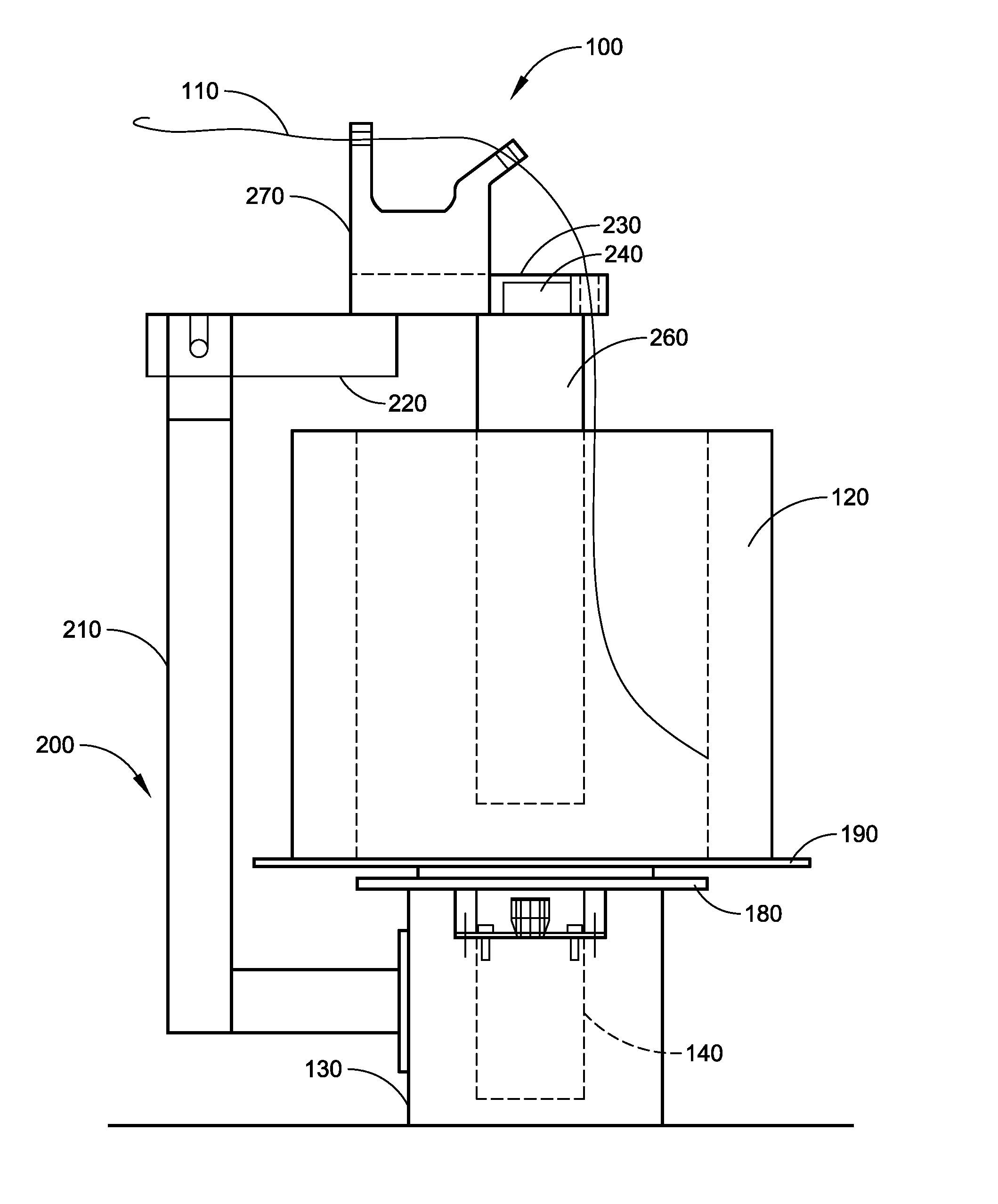

Method and apparatus for treating logging cable

InactiveUS20150371741A1High activityPrevent slippingTextile treatment untwisting devicesLinings repairElectrical conductorWell logging

A method and apparatus for removing permanent stretch characteristics of electromechanical cable by application of predetermined tension and heat to the cable while continuously moving the cable linearly from a supply drum, through spaced capstans and to a take-up drum. A cable heater is positioned at a braking capstan to soften the polymer insulation of the electrical conductor or conductors and permit tension responsive conductor movement relative to the polymer insulation, thus dissipating the permanent stretch and rendering the cable suitable for accurate well logging and for conducting other downhole well services. The outer cable armor is loosened to start the seasoning process and is tightened as it is taken up at completion of the process.

Owner:LEGGETT HENRY H

Method and device for processing a wire

ActiveUS20060179908A1Avoid disadvantagesQuality improvementLine/current collector detailsTextile treatment untwisting devicesEngineeringMechanical engineering

In a wire-processing device, the wire executes turns through being pulled out of a drum. The leading wire-end is held by a gripper of a loop-former. A wire that has been cut to length is held at its leading and trailing ends by an untwisting unit, the wire having before the untwisting operation a doubled-backed loop. A transfer unit takes the leading and trailing ends from the loop-former and passes the wire to the untwisting unit. After the untwisting operation, the transfer unit takes the leading and trailing ends of the wire from the untwisting unit and feeds the wire-ends to the processing units that process the wire-ends. A bundling unit is provided after the processing units unit and takes the processed wires from the transfer unit, the bundling unit forming a wire bundle with the wires. With the untwisted wires, the wire bundle has neither doubled-back loops nor knots.

Owner:KOMAX HOLDING

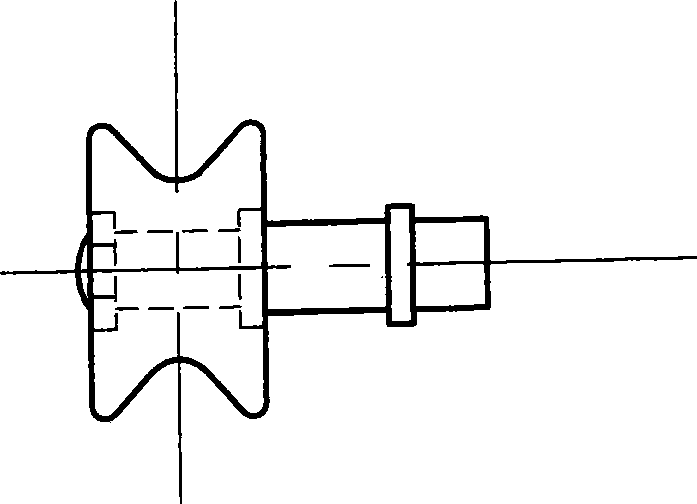

Drawing detwister in back area for spinning frame

InactiveCN101418483ACause damageTo achieve the purpose of untwistingTextile treatment untwisting devicesDrafting machinesYarnEngineering

The invention discloses a back zone draft untwisting device for a spinning machine. The device is provided with a bracket which is arranged on transverse flat iron corresponding to a yarn guiding trumpet, and is at least provided with a roller. The roller is moveably sleeved on a roller shaft; the roller shaft is fixed on the bracket; the circumferential surface of the roller is provided with a trumpet type groove for coarse roving to pass through; and the circumferential rotating trend of the groove and the trend of the coarse yarn have certain included angle. The strands of the coarse roving can reduce certain twist number when passing through the roller so as to reduce drafting force. The untwisting device is arranged on the transverse flat iron corresponding to the yarn guiding trumpet, moves along with the strands of the coarse roving in the transverse direction, obviously reduces the back zone drafting force, is favorable for increasing back zone drafting times, and is favorable for improving the front zone draft efficiency and total draft times, so the untwisting device has certain practical use for improving the spinning quality and reducing production cost.

Owner:施景琪

Web twister removal process

InactiveUS7065948B2Easy to distinguishAutomatic control devicesPrecision positioning equipmentEngineeringMechanical engineering

An apparatus for detecting and eliminating a twister in a running web of flexible material. The apparatus includes a catch section for twisters, a rotor, a scanner arrangement for detection of a twister that has entered a catch section and a control unit , which, upon detection of a twister by the scanner, triggers the drive of the rotor for untwisting the twister.

Owner:THE PROCTER & GAMBLE COMPANY

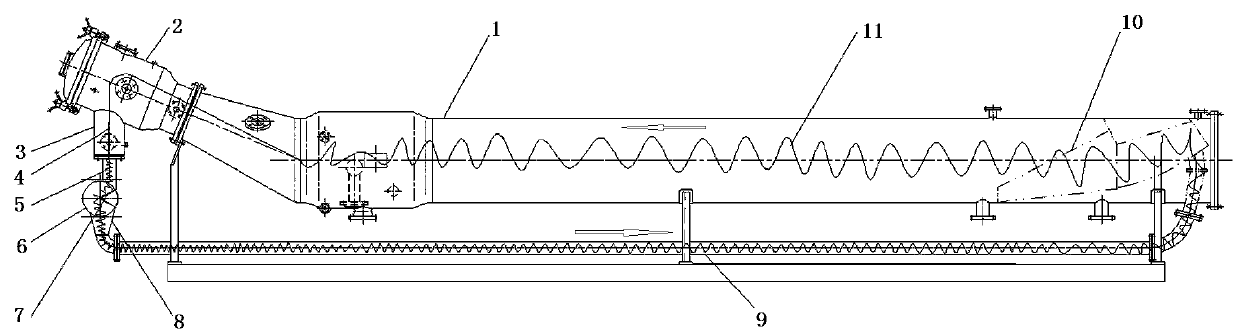

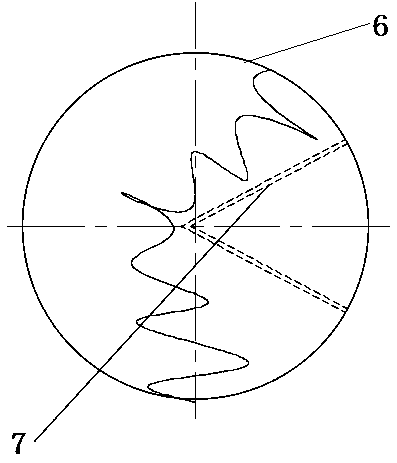

Spinning and dyeing spiral dehydration device

InactiveCN107099959AQuick breakOut of completeTextile treatment untwisting devicesLiquid/gas/vapor removal by squeezing rollersWastewaterEngineering

The invention discloses a spinning and dyeing spiral dehydration device. The spinning and dyeing spiral dehydration device comprises a spiral dehydrator, a horizontal pre-scutcher and a tractor from front to back. A dyed textile is subjected to horizontal traction by applying a tractor, in the traction process, the textile passes through a rotating dehydration cylinder on a dehydrator, a forward spiral section, a smooth buffer section and a reverse spiral section are arranged on the dehydration cylinder separately, rotating extrusion is performed on the textile through a forward spiral thread on the forward spiral section, wastewater inside the textile is rapidly and thoroughly separated, turnover release is performed on the textile through a reserve spiral thread on the reverse spiral section, pre-scutching is performed on the textile through the horizontal pre-scutcher, the next scotching work of the textile is promoted, thorough dehydration is achieved, and the dehydration speed is increased.

Owner:钱琛

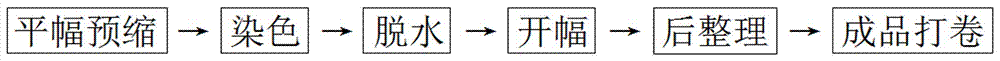

Brand new PBT fabric processing process

InactiveCN107974780AEfficient removalAvoid risk of gatheringTextile treatment untwisting devicesHeating/cooling textile fabricsElectricityEngineering

The invention discloses a brand new PBT fabric processing process. The brand new PBT fabric processing process includes: performing open-width preshrinking; dyeing; dewatering; scutching; finishing; rolling finished products. The brand new PBT fabric processing process has the advantages that the PBT fabric processing process flow is simplified greatly, and smoothness in processing is achieved; overall processing steps are reduced, processing time is shortened, and accordingly production efficiency can be increased; the use amount of water, electricity and gas is reduced, and sewage dischargequantity is lowered; in the dyeing step, fabric color yield is increased, the use amount of dye for acquiring the same color can be reduced as compared with a conventional processing process, and dyecost is further saved; the finishing step allows the fabric to further acquire elasticity, the stretching resilience of the fabric is increased, and garment wearing comfortableness is further increased.

Owner:HAINING DEJUN KNITTING & DYEING GROUP

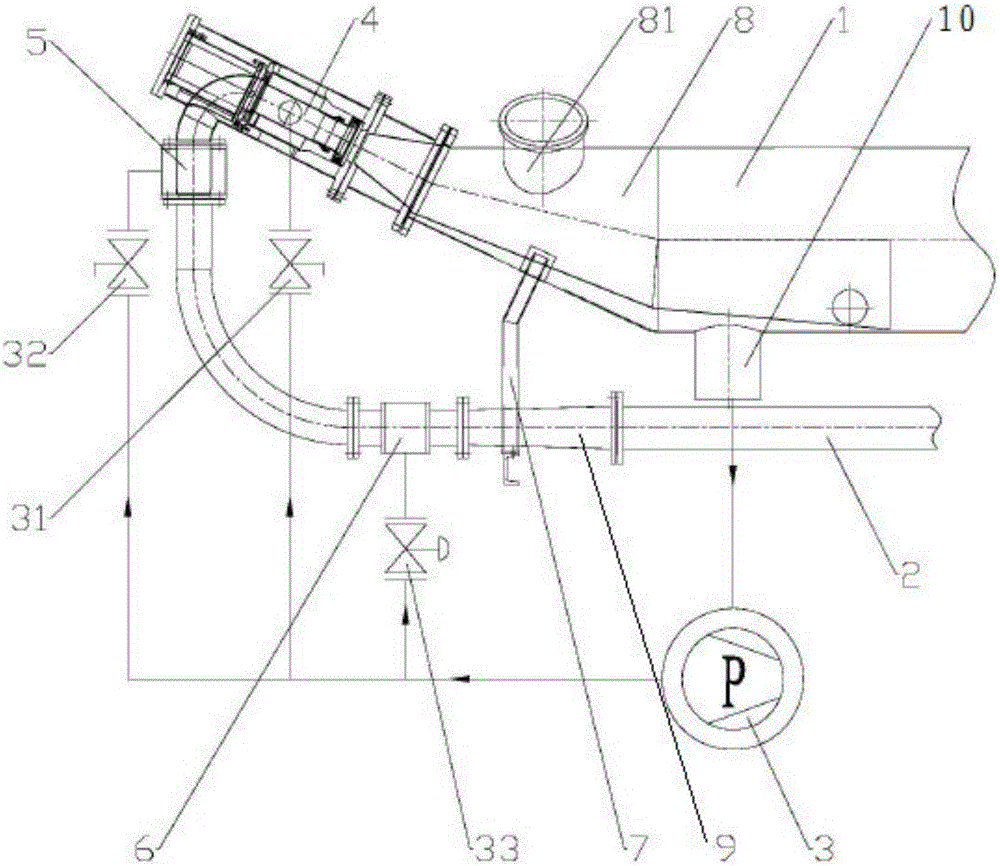

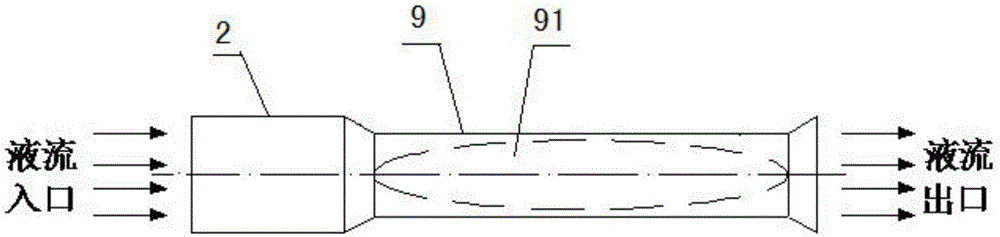

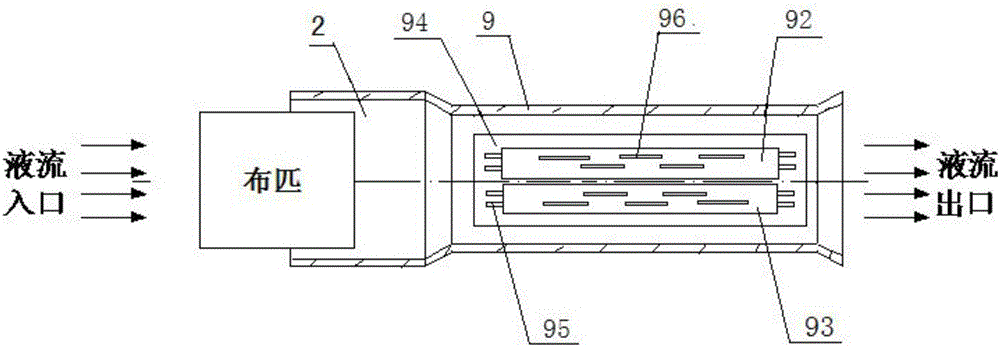

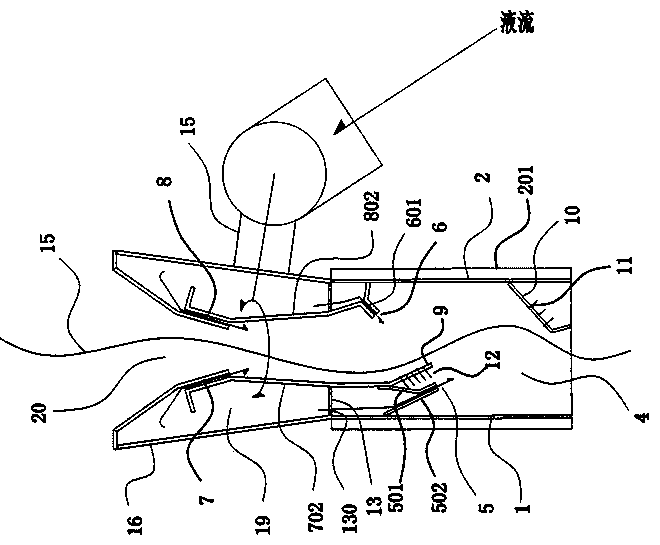

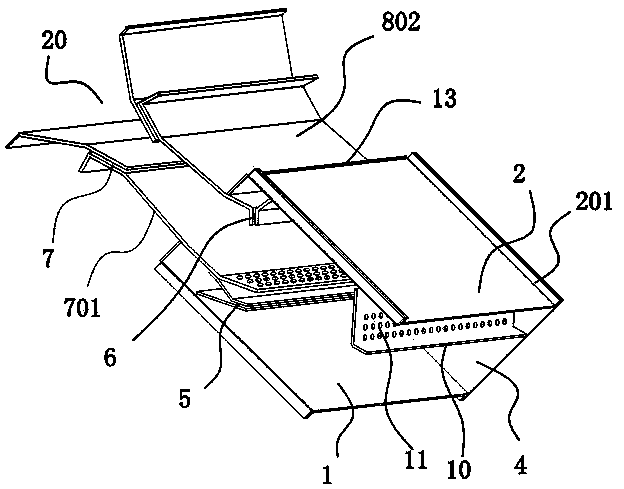

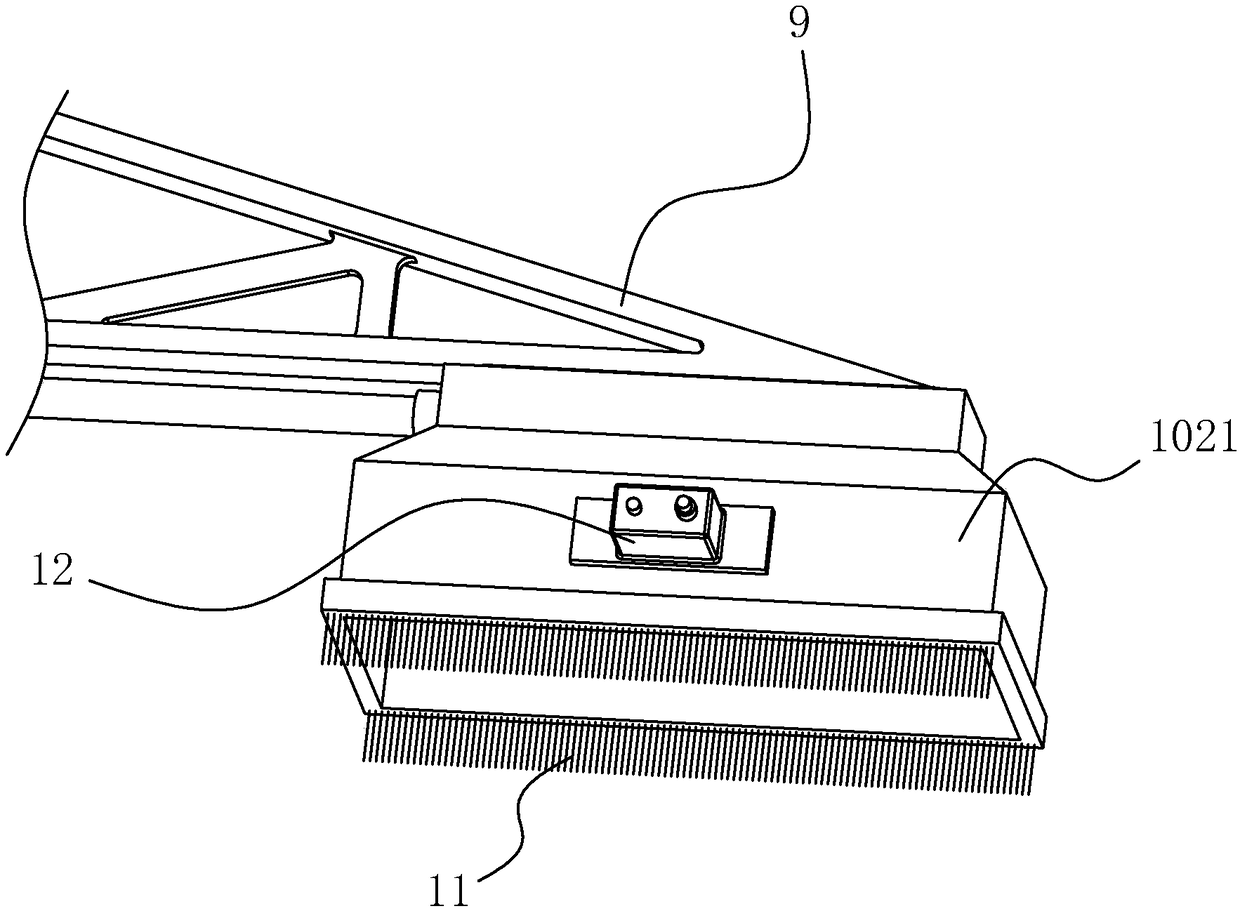

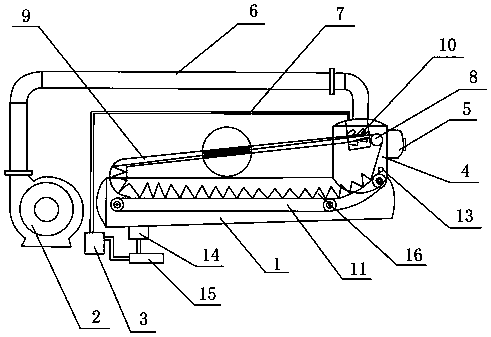

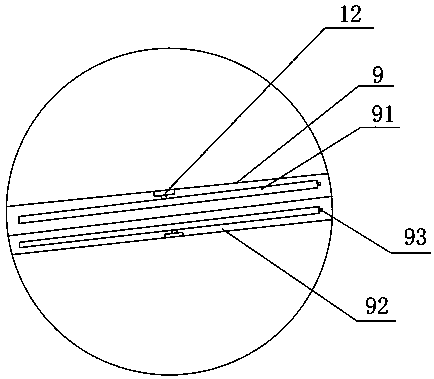

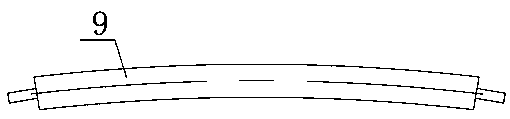

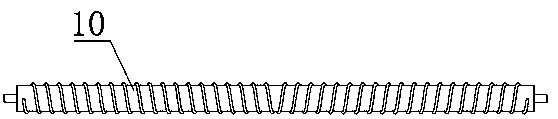

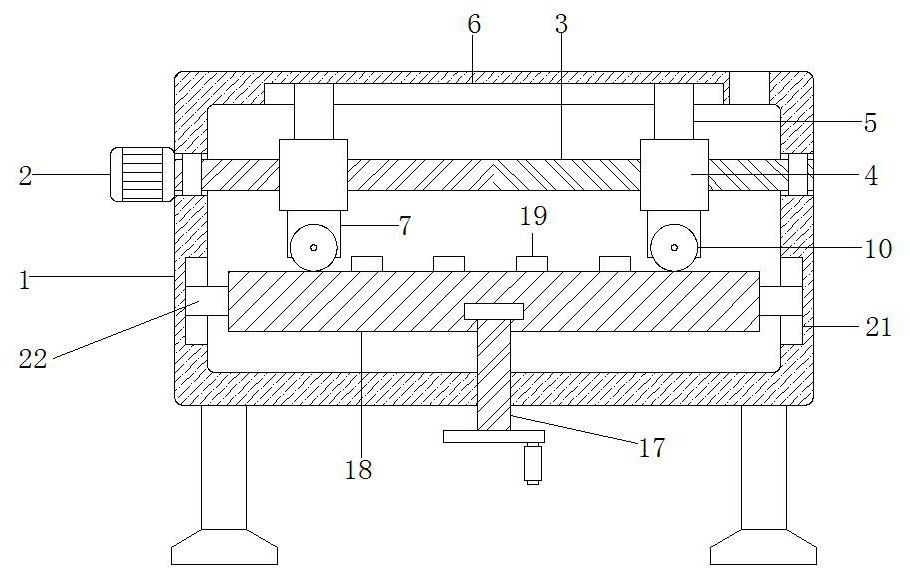

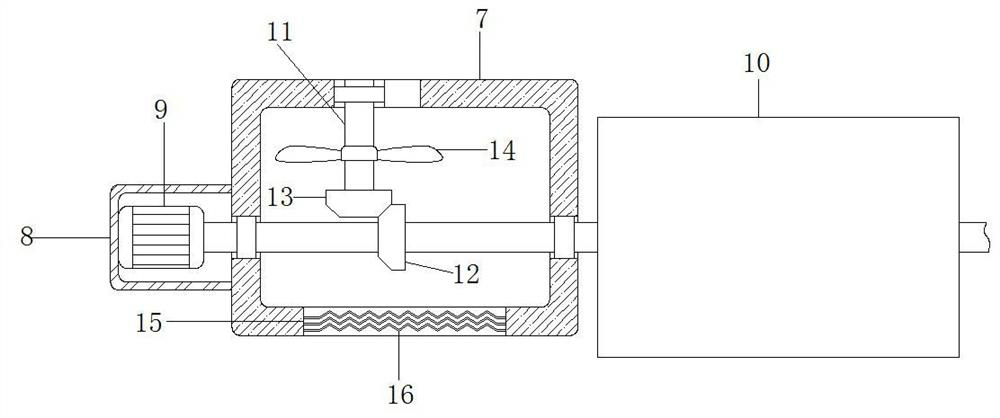

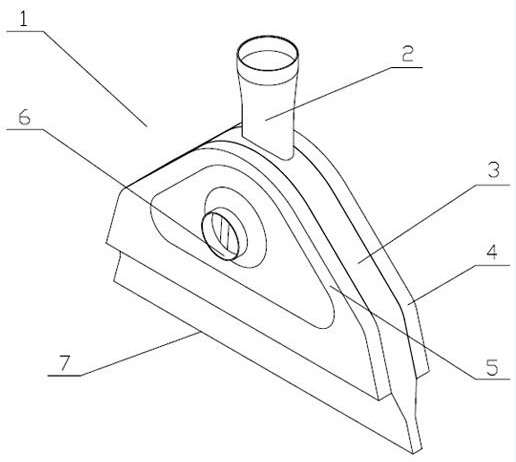

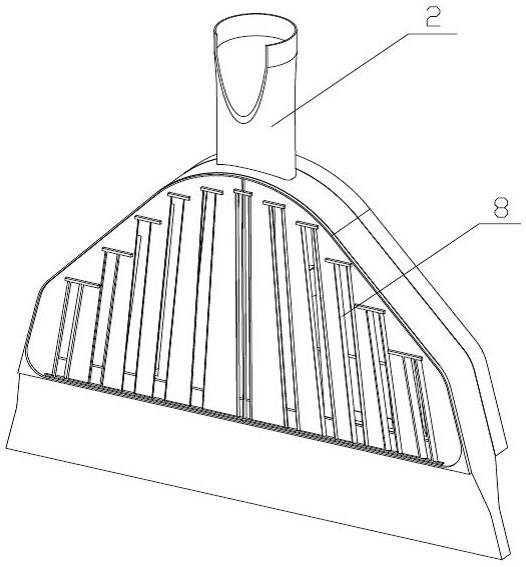

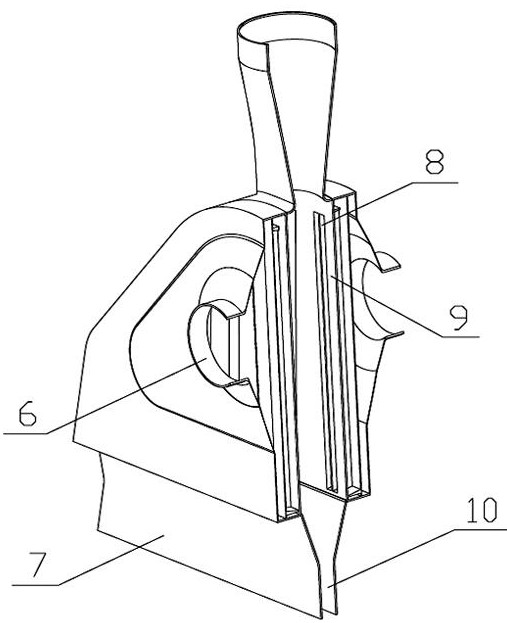

Cloth dyeing machine of cloth lifting wheel-free cloth conveying system

ActiveCN104988688AAvoid tensionGood technical effectLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor treatment of propelled fabricsDyeingNozzle

The invention relates to a cloth dyeing machine and discloses a cloth dyeing machine of a cloth lifting wheel-free cloth conveying system. The cloth dyeing machine comprises a main cylinder body (1), a cloth guide pipe (2) and a pump (3), wherein the main cylinder body (1) is connected with the pump (3); a main nozzle (4), a cloth-feeding nozzle (5) and a backpushing nozzle (6) are mounted on the cloth guide pipe (2); the cloth guide pipe (2) is connected with the main cylinder body (1) via the main nozzle (4); the cloth guide pipe (2) is orderly provided with the cloth-feeding nozzle (5) and the backpushing nozzle (6) along a flow liquid direction; and a cloth discharging end of the cloth guide pipe (2) is provided with an anti-rotating pipe (9) preventing the cloth rotating. Tension during the cloth conveying can be effectively avoided by the use of the main nozzle, the cloth-feeding nozzle and the backpushing nozzle; and with the anti-rotating pipe in the anti-rotating device, the cloth can be expanded and flattened in the cloth guide pipe, so even dyeing can be achieved.

Owner:HANGZHOU DONGLIN DYEING & FINISHING MACHINERY

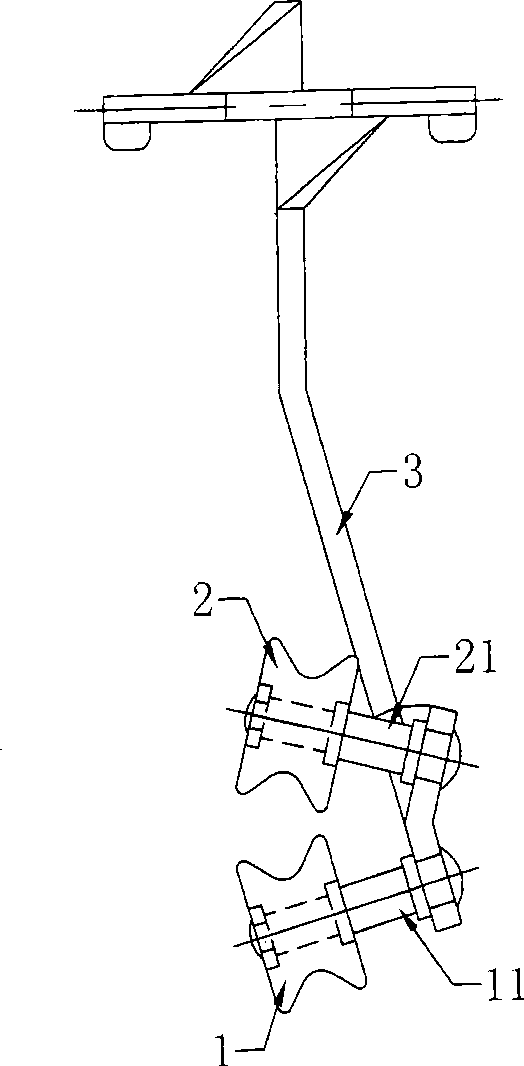

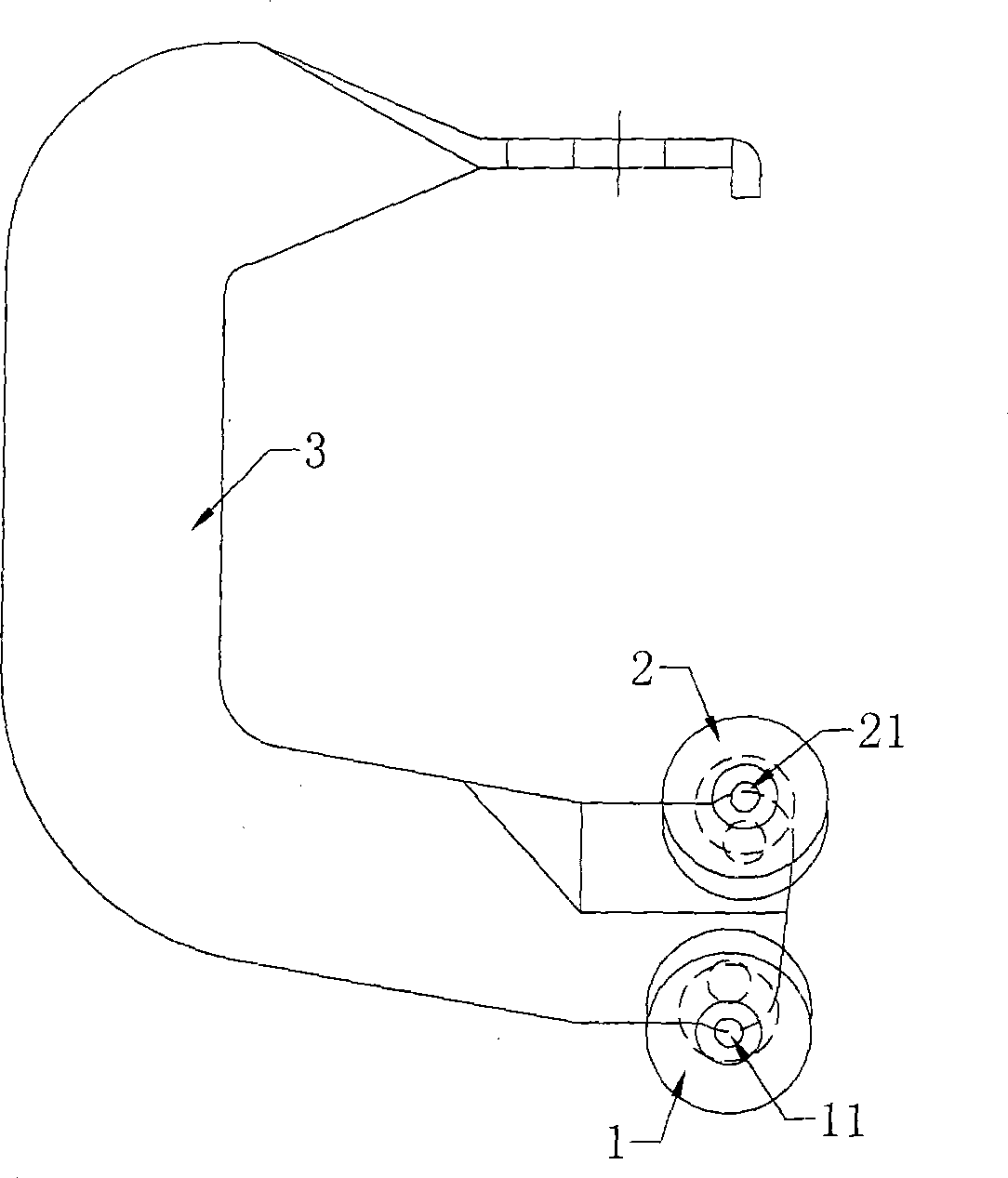

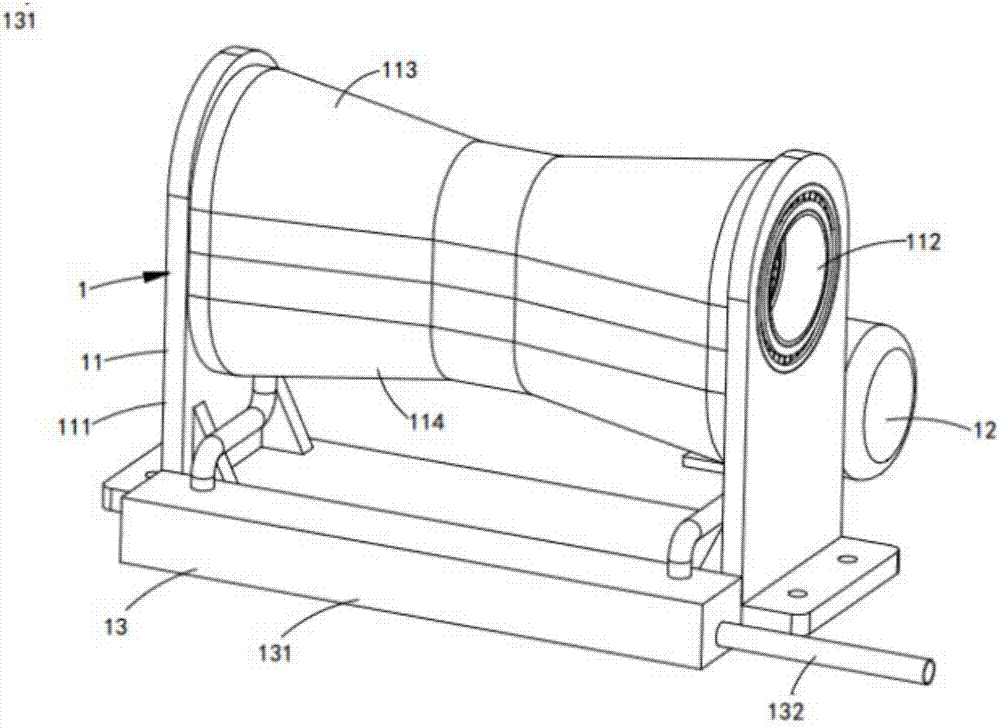

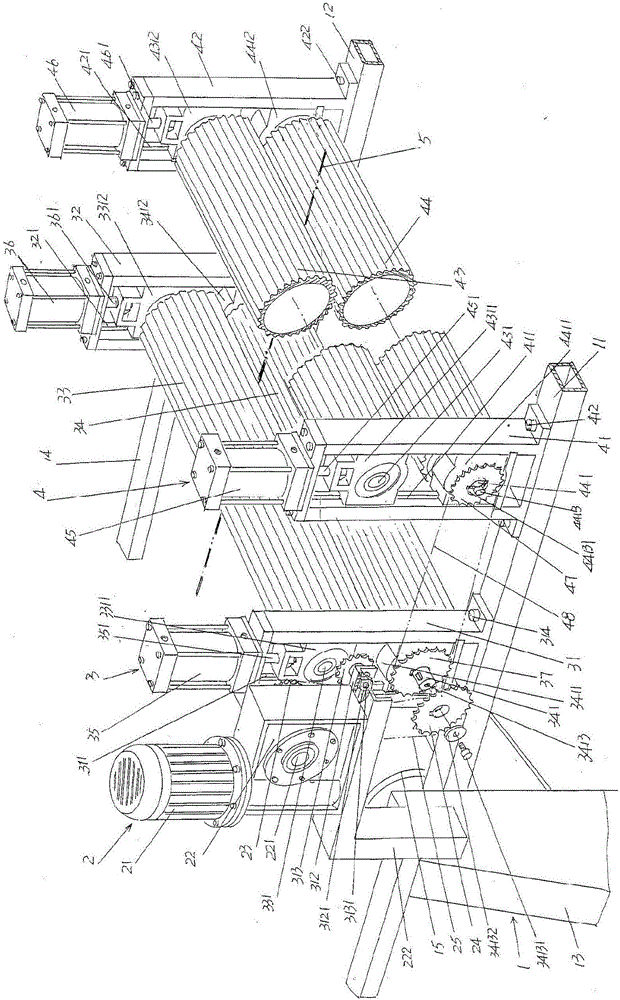

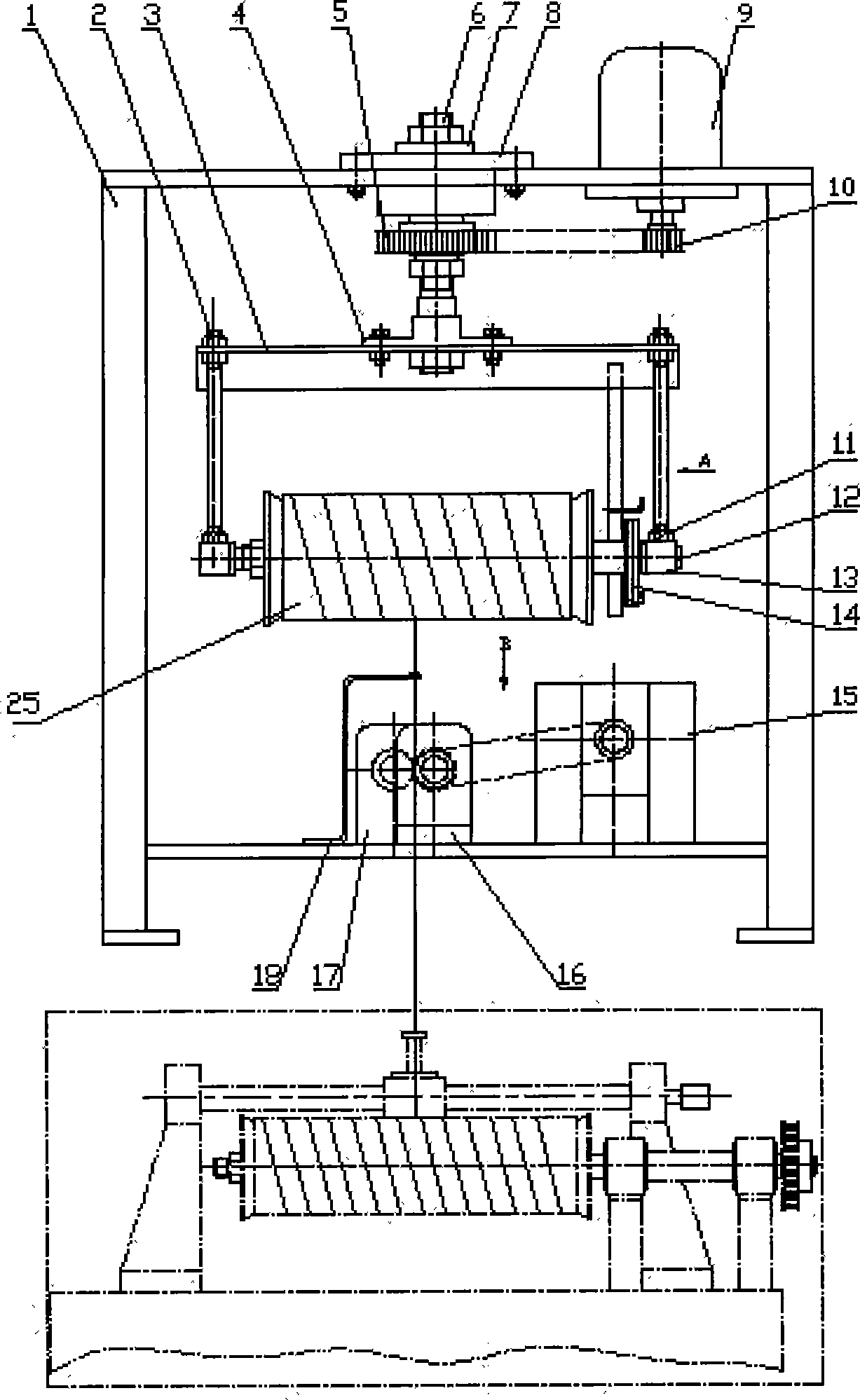

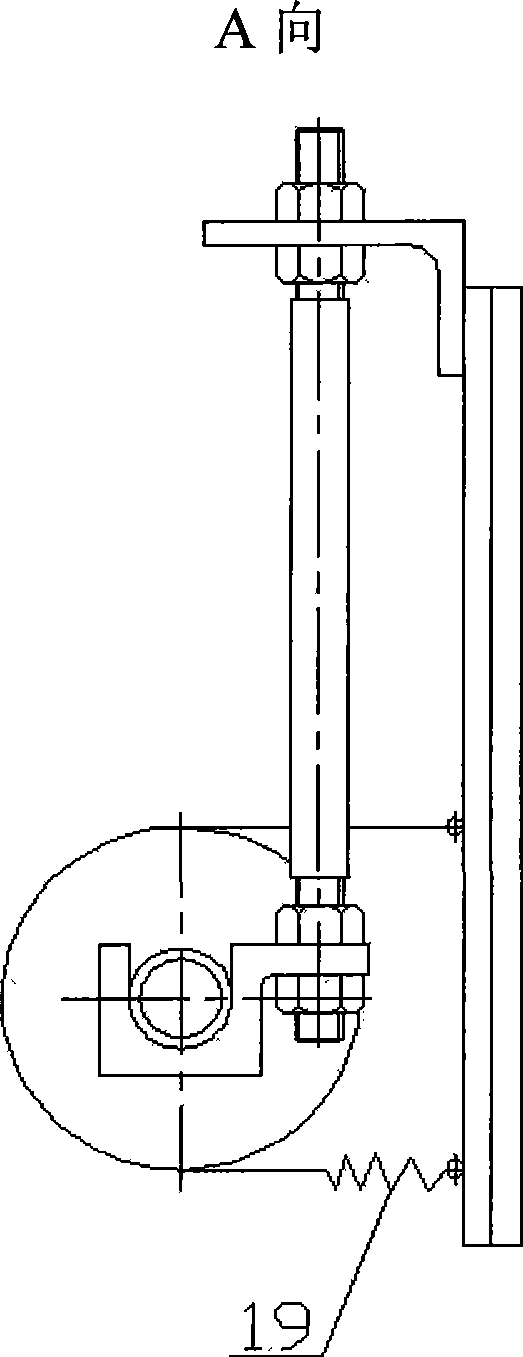

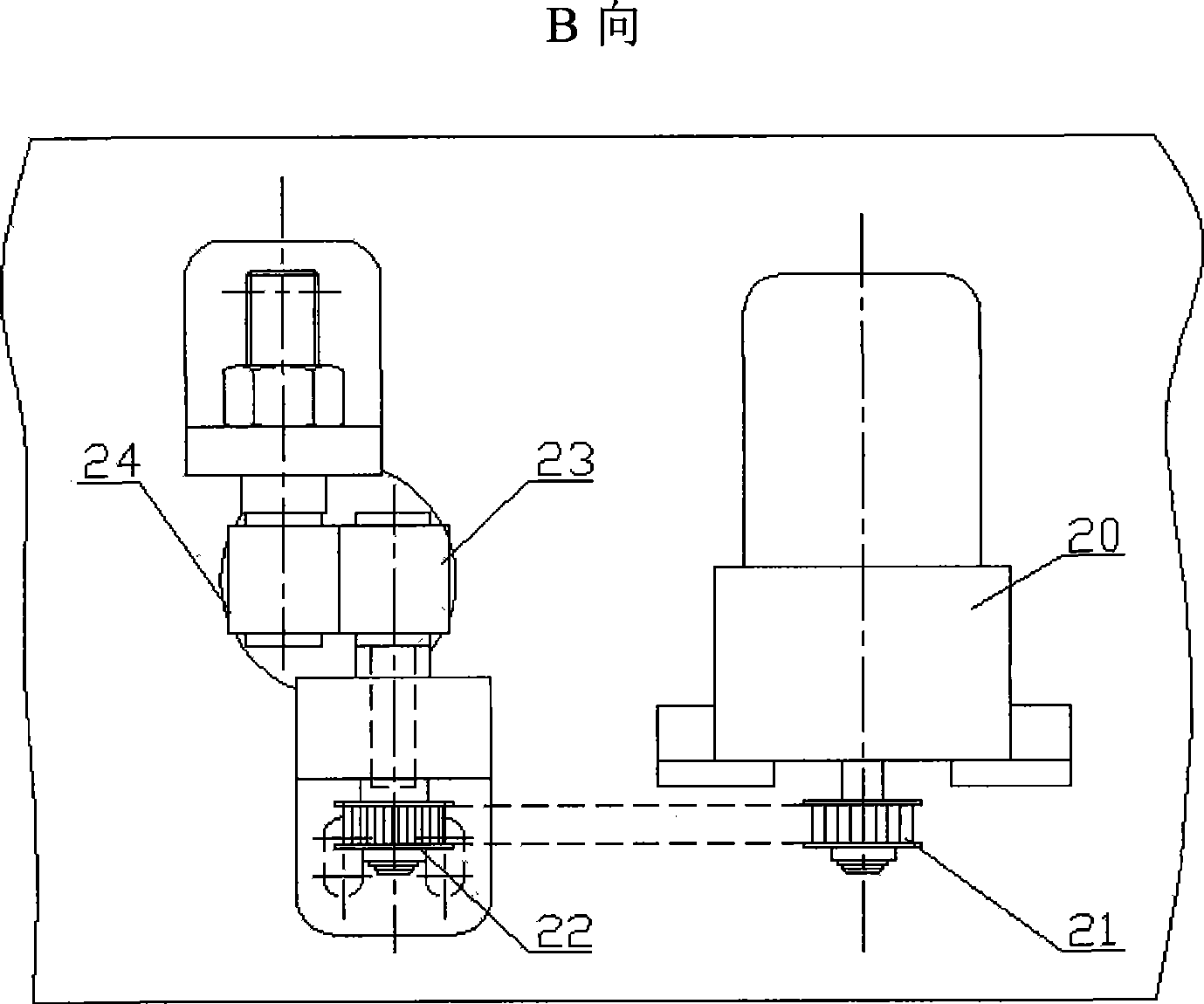

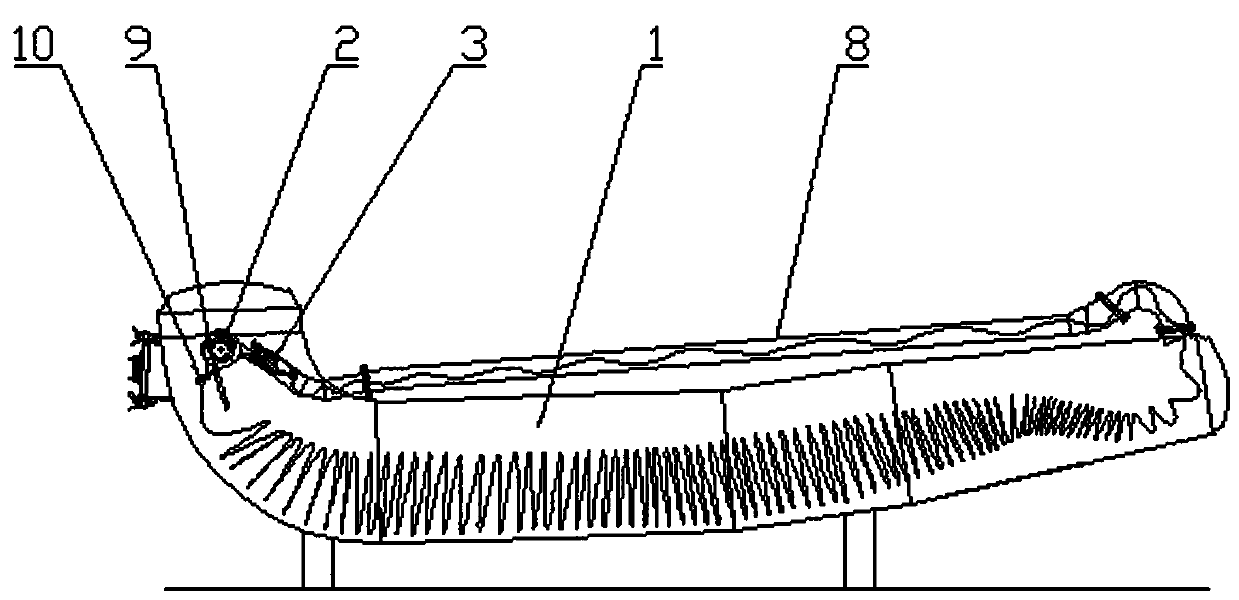

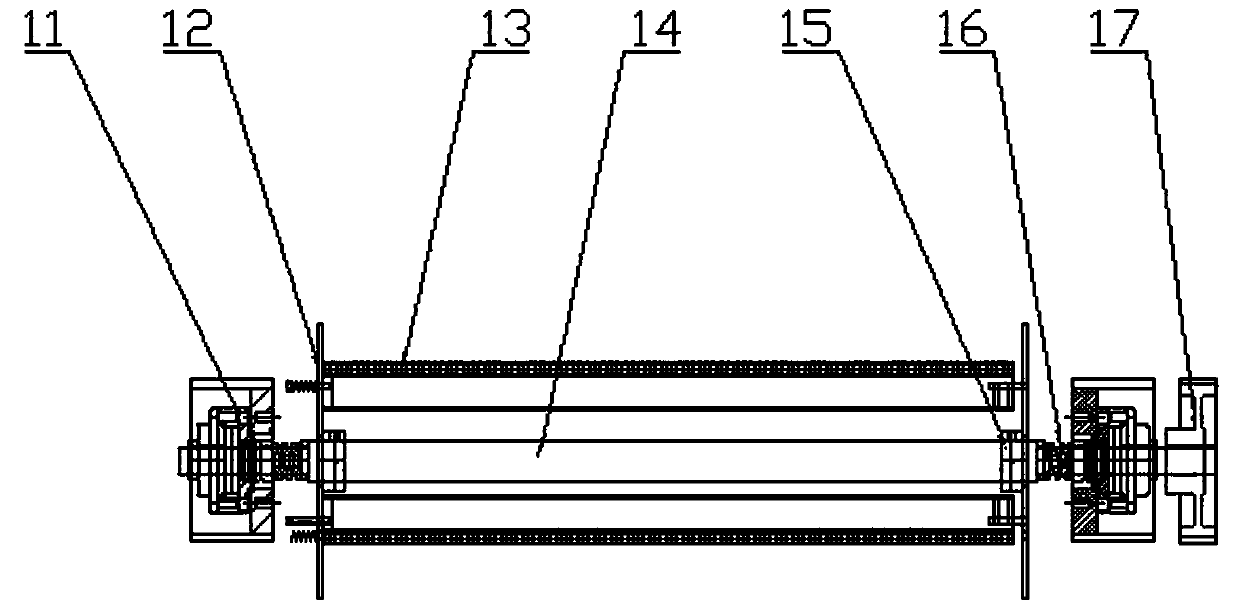

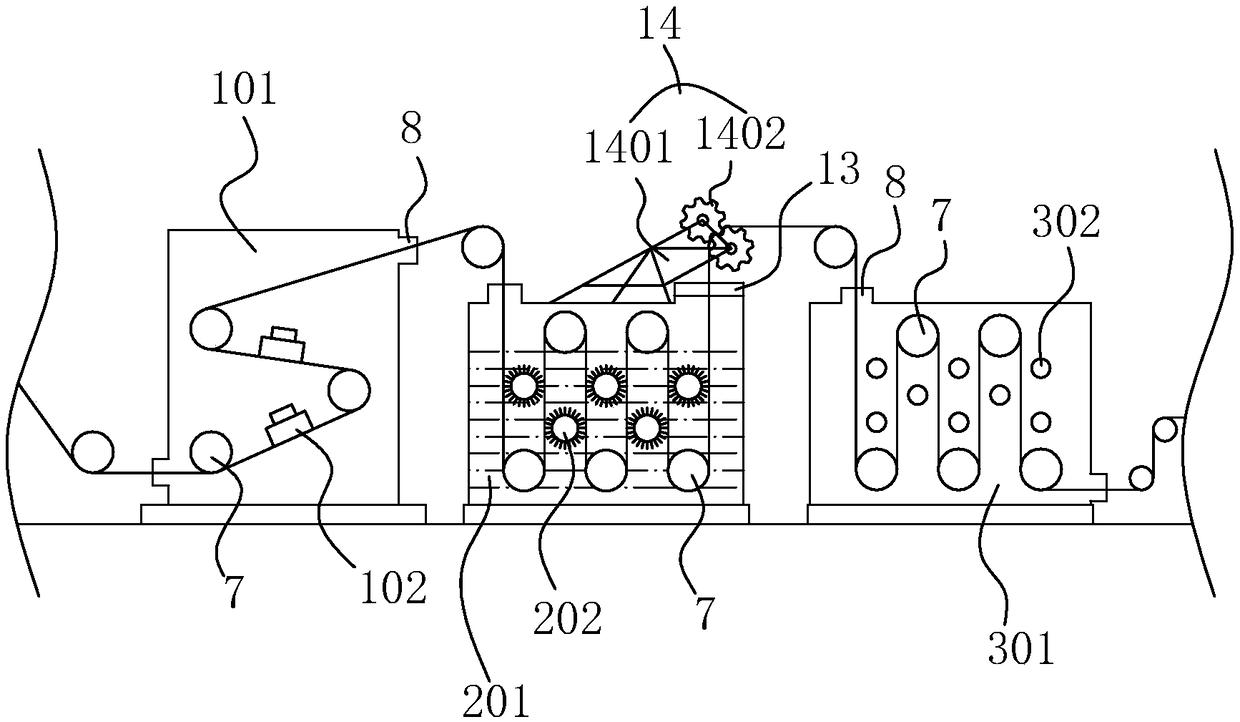

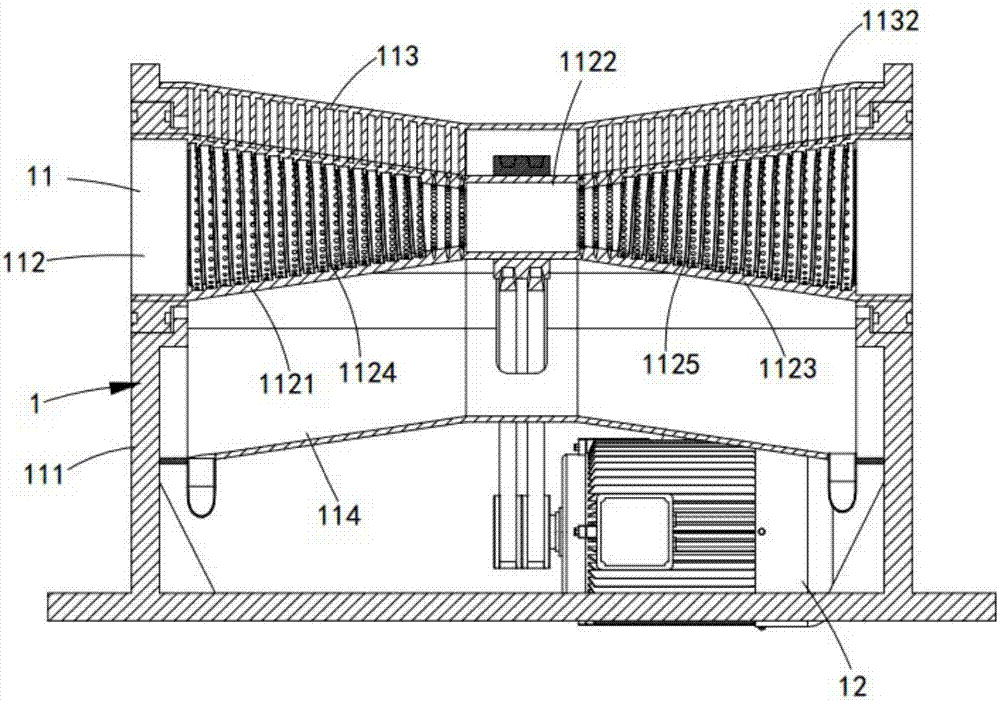

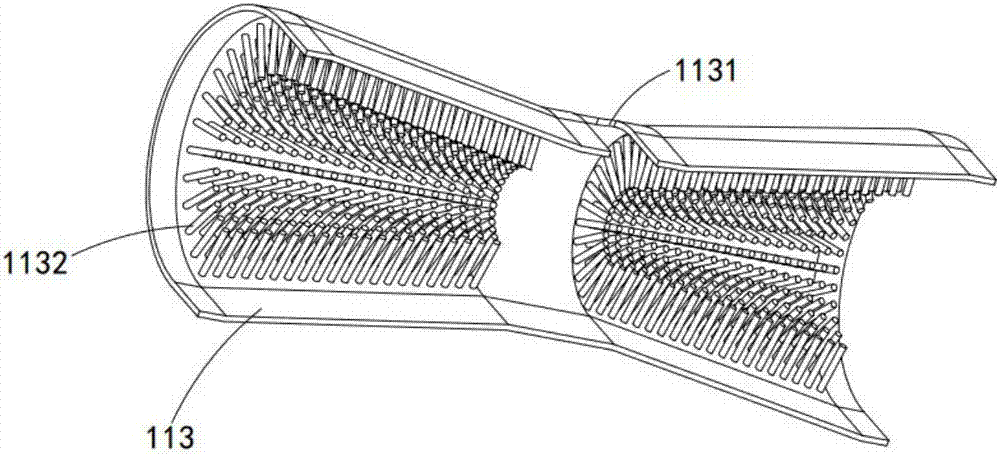

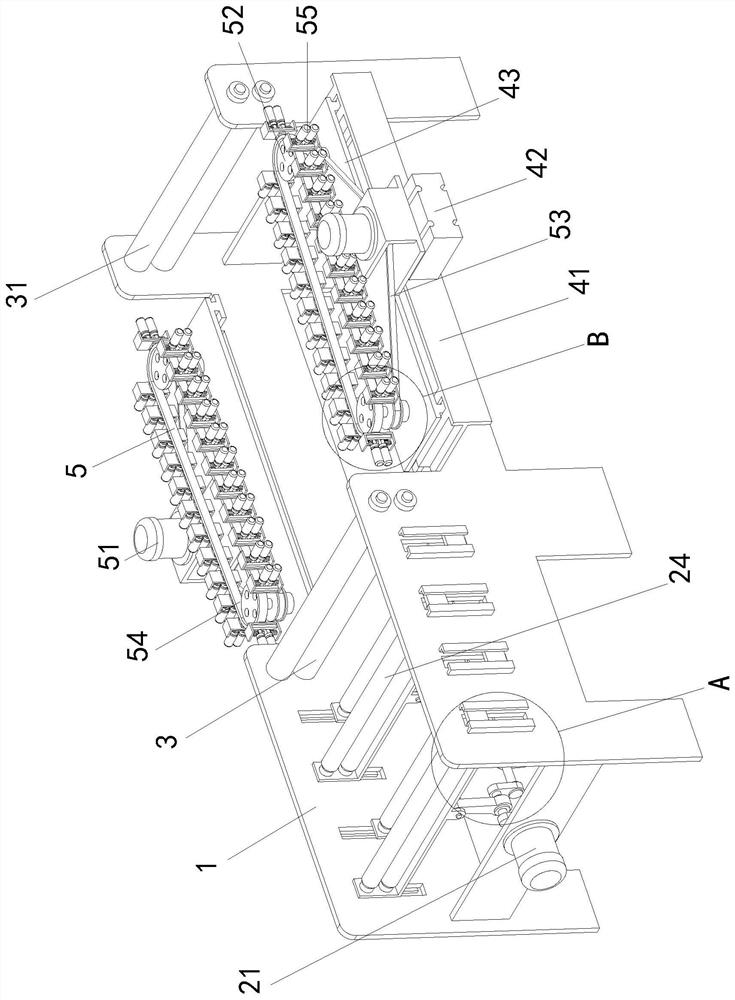

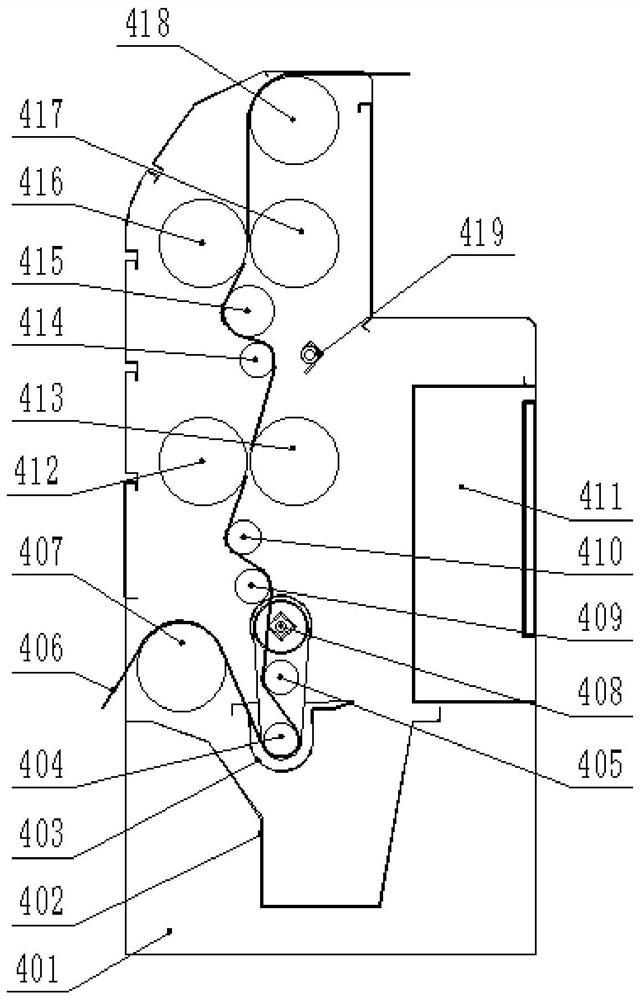

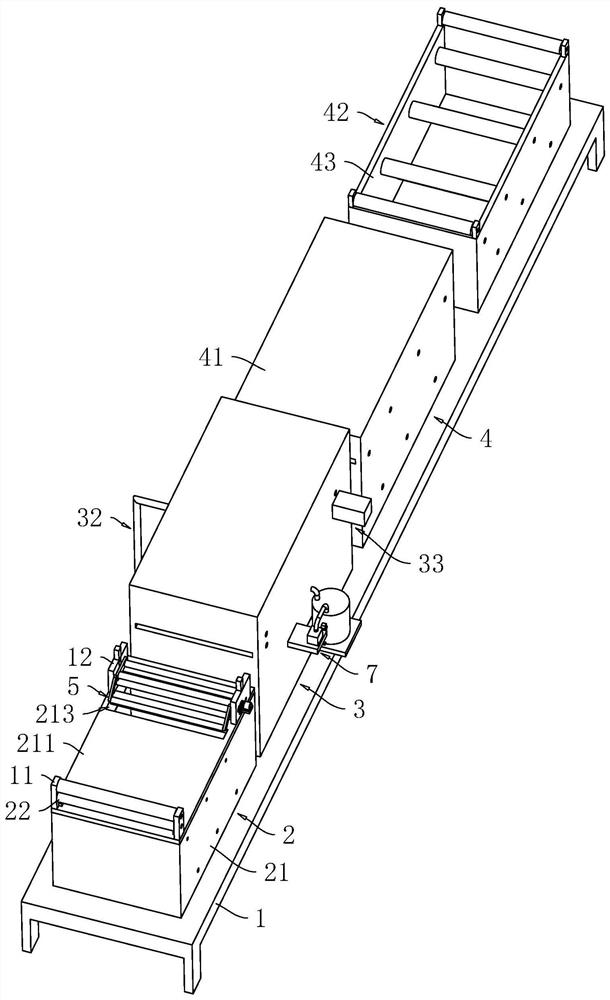

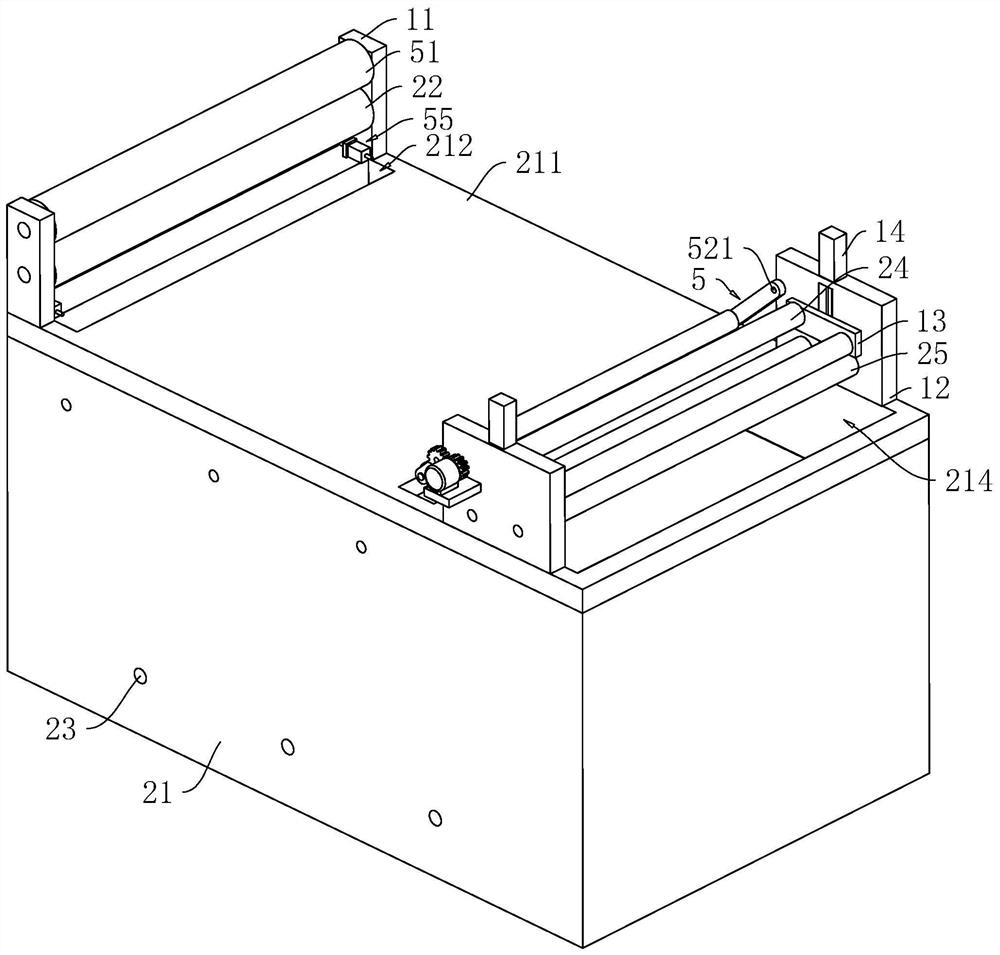

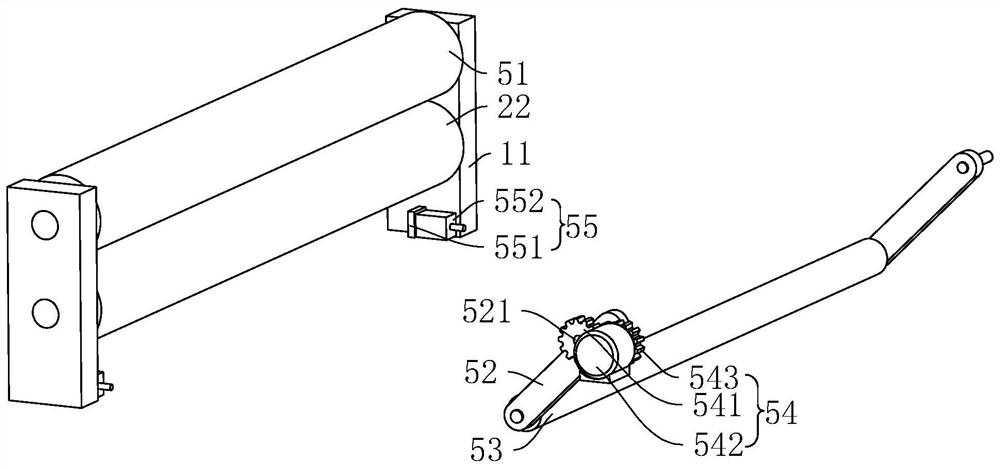

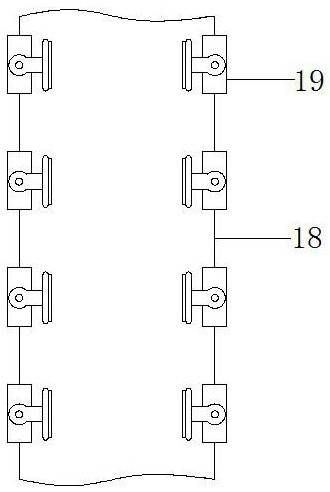

Wool top drafting and opening device matched with wool top processing tank

ActiveCN105803717AEnsure full wetting treatment effectMeet the rhythm requirementsTextile treatment untwisting devicesTextile treatment carriersBack supportPetroleum engineering

The invention discloses a wool top drafting and opening device matched with a wool top processing tank, and belongs to the technical field of wool top processing facilities. The wool top drafting and opening device comprises a rack, a power transmission mechanism, a left wool top drafting and opening mechanism and a right wool top drafting and opening mechanism; the rack is composed of a front supporting beam, a back supporting beam and supporting beam fixing legs; the power transmission mechanism is fixed to the portion, corresponding to the left end of the front supporting beam, of one supporting beam fixing leg in the state of rising to the position over the left end of the front supporting beam; the left wool top drafting and opening mechanism is arranged between the front supporting beam and the back supporting beam and connected with the power transmission mechanism; the right wool top drafting and opening mechanism is arranged between the front supporting beam and the back supporting beam in the state of corresponding to the right side of the left wool top drafting and opening mechanism and connected with the left wool top drafting and opening mechanism, and a wool top support protecting guide roller is arranged between the positions corresponding to the left end of the front supporting beam and the left end of the back supporting beam. According to the wool top drafting and opening device, wool tops before entering the processing tank can be opened, and the comprehensive wetting processing effect of processing liquid on the wool tops is guaranteed; resources are saved, and the configuration cost is reduced; the whole structure is simple and convenient to manufacture and operate; the progress requirements of a wool top processing technology can be met.

Owner:CHANGSHU XINGUANG WOOL TOP SPECIALIST PROCESSOR

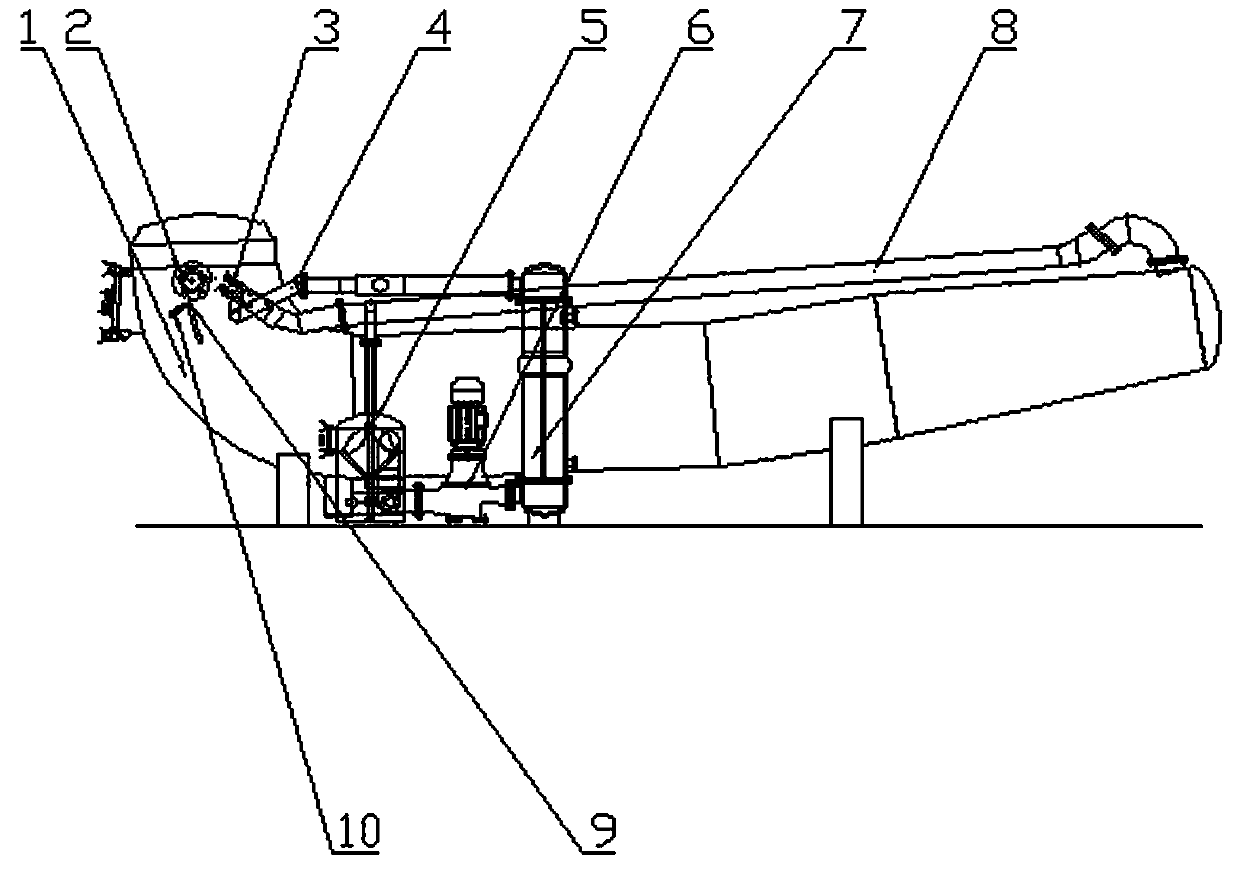

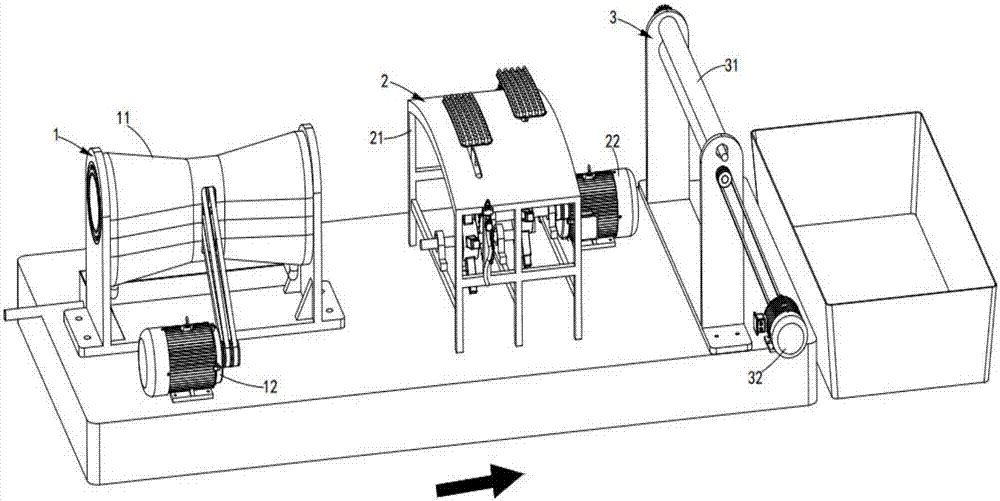

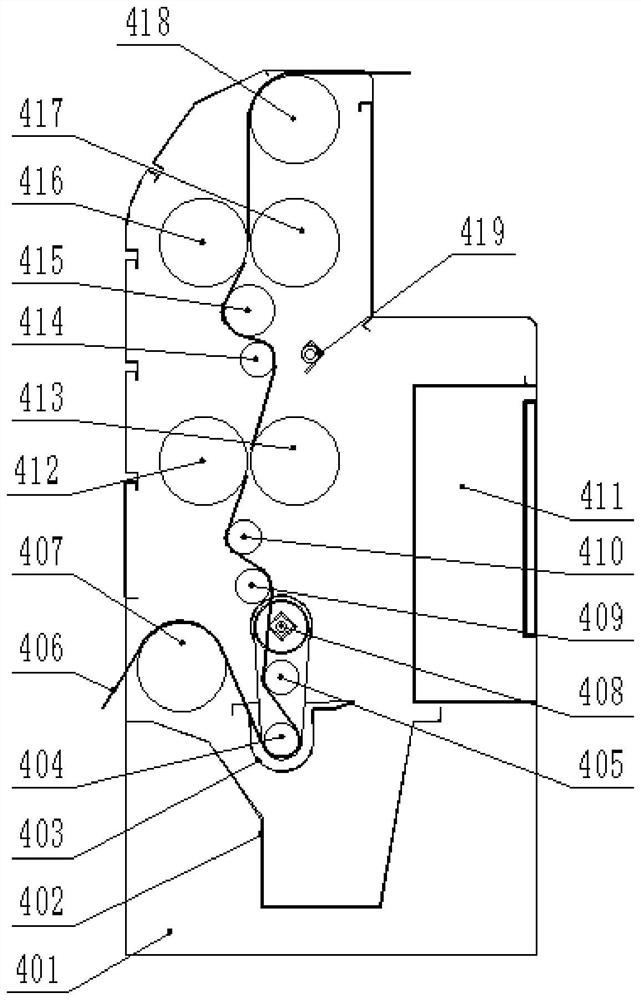

Filament untwisting apparatus

InactiveCN101476224ASolve the problem of natural twist (≤20 twist/m) of filaments that are difficult to untieSimple structureTextile treatment untwisting devicesLow noiseEngineering

The invention relates to a filament twist returning device comprising machine device and control means. The machine device comprises a frame and a filament twist returning rotating mechanism, a filament unwinding rotating mechanism and a filament traction and length determining mechanism installed on the frame; the control means comprises: a touch-screen, a PLC controlled frequency converter and a motor. The twist returning device of the invention can perform the twist returning of filament, mainly solves the problems of difficulty for returning the natural twist (<=20 twists / meter) of filament in large-scale weaving machine, and achieves the advantages of stable running, accurate control, low noise and convenient operation.

Owner:TIANJIN POLYTECHNIC UNIV

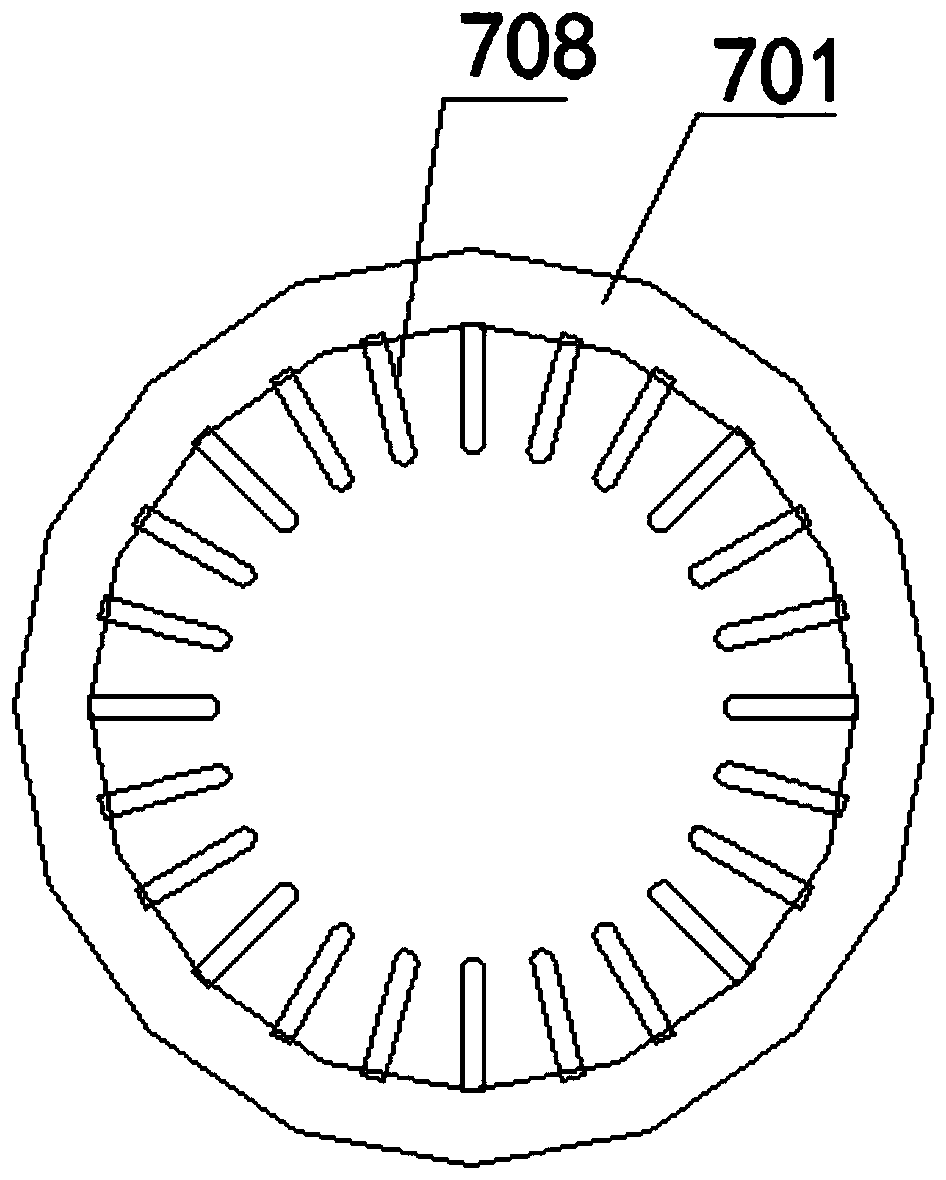

Dyeing device with long and flat nozzle and automatic filter system and unwinding control method of dyeing device

ActiveCN110258042AGood dyeing processShort dyeing processTextile treatment untwisting devicesTextile treatment machine arrangementsFilter systemEngineering

The invention relates to a dyeing device with a long and flat nozzle and an automatic filter system and an unwinding control method of the dyeing device and belongs to the technical field of printing and dyeing equipment. The dyeing device comprises a dyeing vessel and is characterized in that a cloth guide wheel turning and side changing component fixed to the inner wall of the dyeing vessel is arranged in the dyeing vessel, the lateral side of the cloth guide wheel turning and side changing component is provided with an overflow cloth guide pipe in pipeline communication with the dyeing vessel, a patting type jet printing and dyeing component in integrated pipeline communication with the overflow cloth guide pipe is arranged between the overflow cloth guide pipe and the cloth guide wheel turning and side changing component, the lateral side of the dyeing vessel is provided with a dye liquor filter in pipeline communication with the dyeing vessel, and a dye liquor feeding pipe in pipeline communication with the patting type jet printing and dyeing component is arranged between the dye liquor filter and the patting type jet printing and dyeing component. The dyeing device is compact in structure, complete in function, good in dyeing color uniformity, short in dyeing process, capable of solving the problem of dyeing process termination caused by cloth winding due to unsmooth cloth wheel operation and capable of increasing product quality stability.

Owner:HANGZHOU BAISHISHENG ENVIRONMENTAL PROTECTION TECH

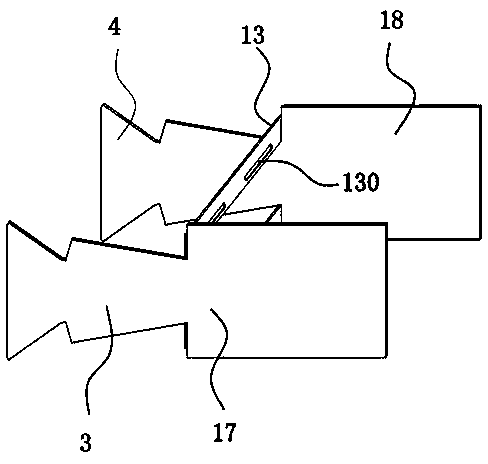

Dyeing nozzle and dyeing machine

InactiveCN111394899AHelps with multiple impactsGood for multiple impactsTextile treatment untwisting devicesSpray nozzlesPolymer sciencePolymer chemistry

The invention provides a dyeing nozzle and a dyeing machine, and relates to cloth dyeing equipment. The dyeing nozzle and the dyeing machine solves the problem that in the prior art, cloth is wound and knotted. The dyeing nozzle comprise a cloth channel, a dye liquor outlet and a dye liquor inlet, wherein the section of the cloth channel is a flat channel adapting to the width of the cloth, a lower dye liquor outlet and an upper dye liquor outlet facing the upper surface and the lower surface of the cloth are formed in the inner wall of the cloth channel, a dyeing opening is obliquely formed relative to the cloth channel, the lower dye liquor outlet and the upper dye liquor outlet communicate with the same isobaric cavity, after a liquor in the isobaric cavity reaches certain pressure, thedye liquor faces the surface of the cloth from the lower dye liquor outlet and the upper dye liquor outlet, and the isobaric cavity communicates with the dye liquor inlet. According to the dyeing nozzle, the slit-shaped dye liquor outlets located in the two sides of the cloth are adopted to spray the two sides of the cloth at the same time, winding and knotting of the cloth are avoided, and it isguaranteed that the two dye liquor outlets have enough pressure by using the isobaric cavity.

Owner:杭州宏事晟机械科技有限公司

Mercerizing equipment

ActiveCN109487519AImprove cleanlinessQuality assuranceMechanical cleaningPressure cleaningPulp and paper industryImpurity

The invention relates to the field of cloth treatment equipment, in particular to mercerizing equipment. The mercerizing equipment comprises a dust removal device, a washing device and a drying device. When cloth enters a dust removal box of the dust removal device, dust collectors in the dust removal box suck knitting wool and dust attached to the surface of the cloth away, and the effect of preliminary cleaning is achieved; then the cloth enters the washing device, dirt, difficult to remove, on the surface of the cloth is brushed away under the effects of water in a water tank and brush rollers arranged in the washing device, and therefore the cleanliness of the cloth is further improved; after the cloth is output from the washing device, the cloth enters the drying device, and the surface of the cloth is blow-dried through air sprayed out of air spraying pipes; thus, the cloth is cleaned before a mercerizing procedure, impurities are prevented from being mixed in the cloth, and theeffect during mercerizing is improved.

Owner:浙江乐丰纺织机械有限公司

Apparatus and method for minimizing waste and improving quality and production in web processing operations by automatic narrow web twist defect correction

InactiveUS20130063587A1Reduce wasteIncrease productionTextile treatment untwisting devicesColor television detailsProcess engineeringVisual perception

Apparatus and methods are provided to minimize waste and improve quality and production in web processing operations. The apparatus and methods provide defect detection in deposition of acquisition material, which on current machines frequently flips and is difficult to detect when it has flipped causing manufacturers to scrap thousands of products. Using the present invention, defects are able to be detected by discerning a difference in the appearance from side to side with a vision camera, and an acquisition inverter can flip the material to a correct orientation.

Owner:CURT G JOA

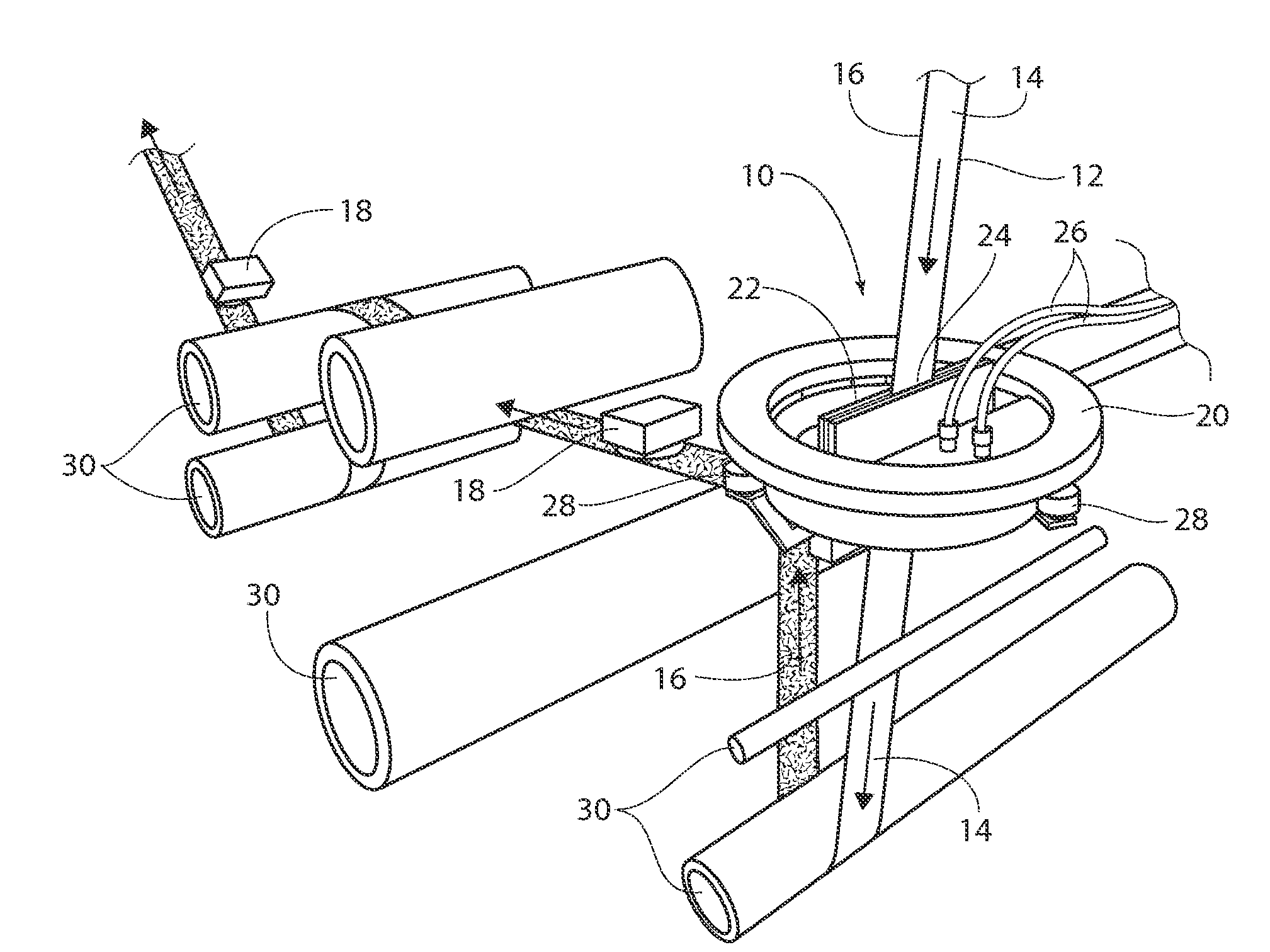

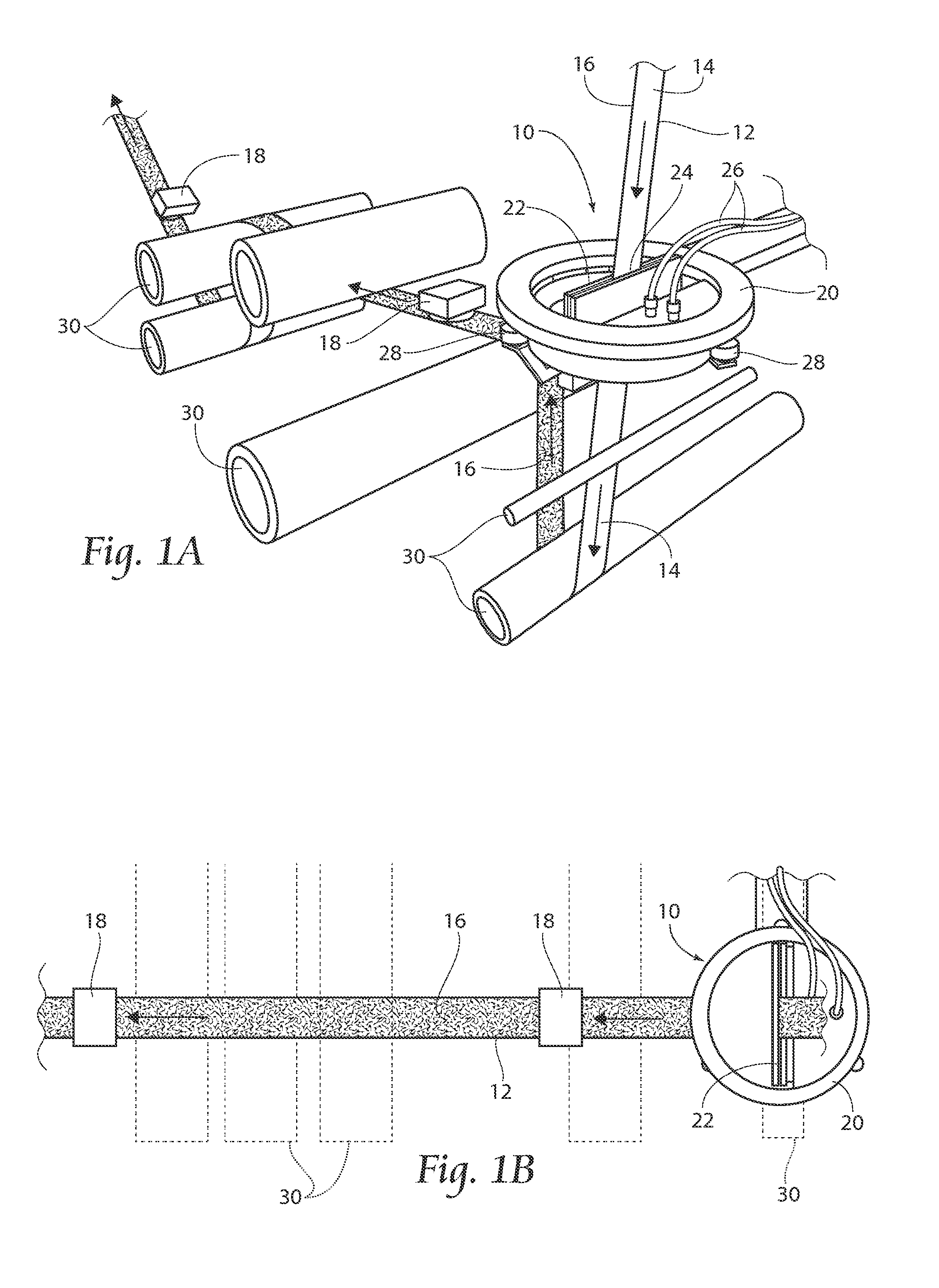

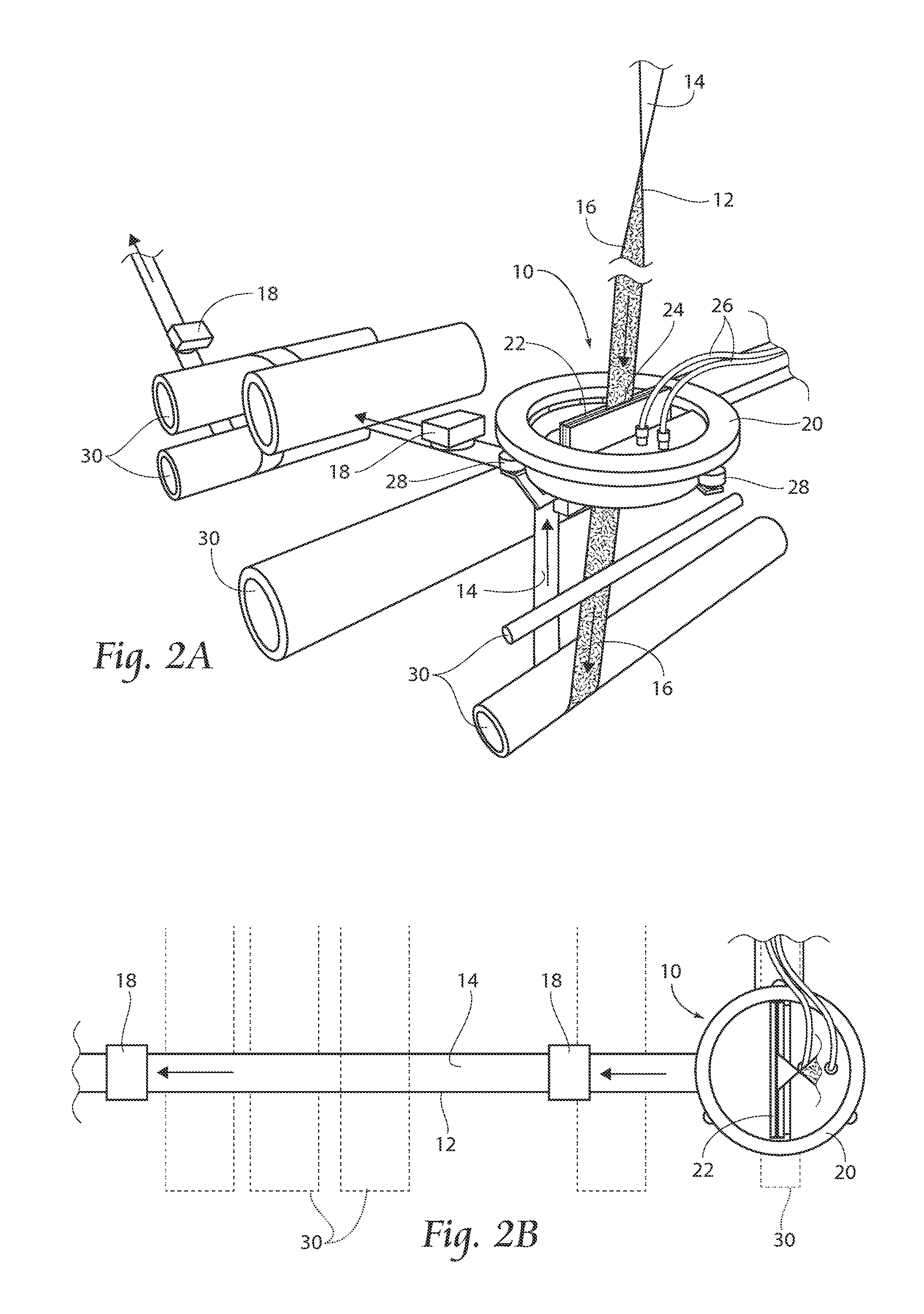

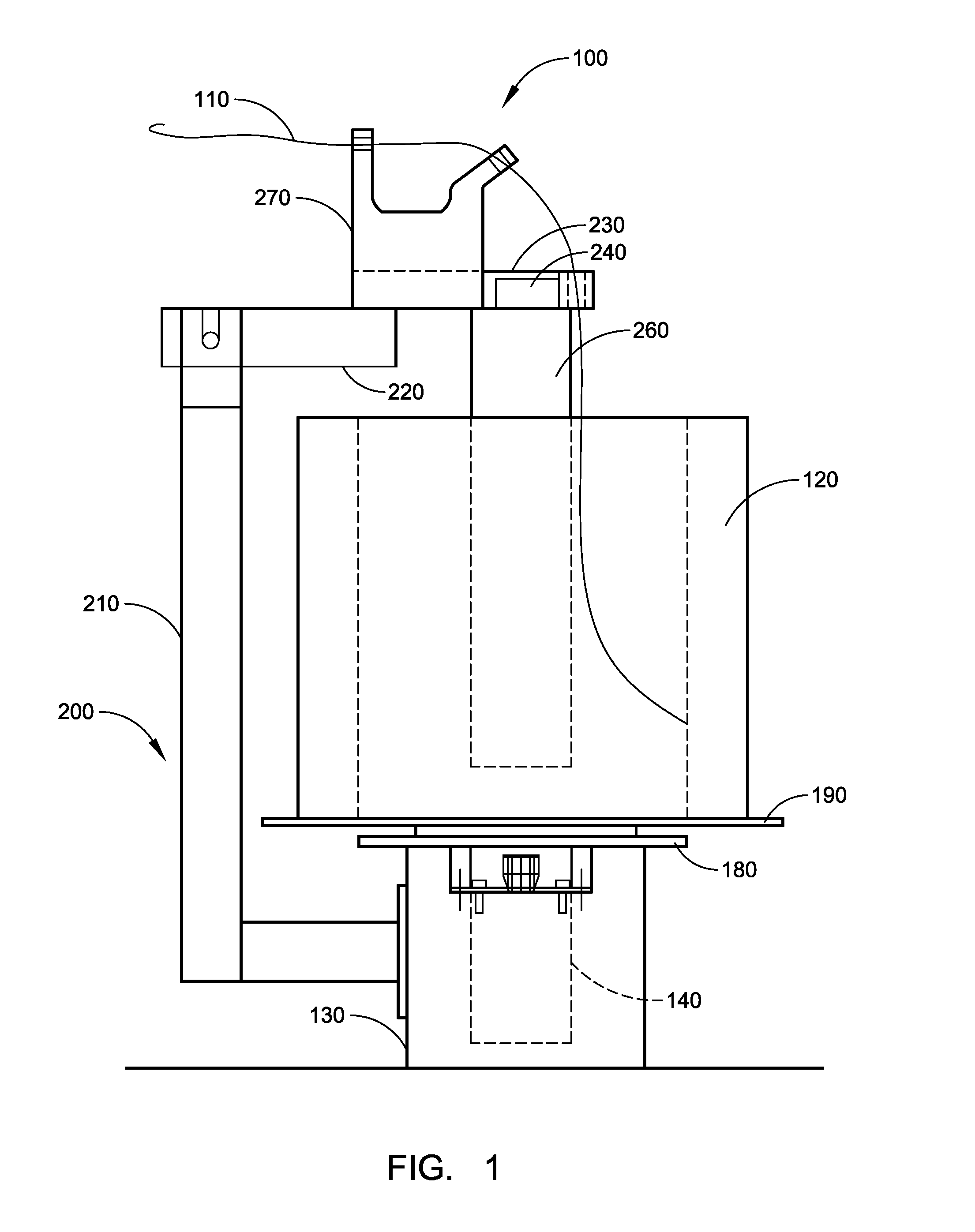

System and method for maintaining the location of a fiber doff inner-diameter-tow at the point of payout within a constant inertial reference frame

ActiveUS7690179B2Low costAvoid distortionTextile treatment untwisting devicesFilament handlingFiberPull force

A method of maintaining the location of a fiber doff inner-diameter-tow at a point of payout within a constant inertial reference frame includes providing a flat fiber tow payout system with a center-pull doff of flat fiber tow that pays out at a point of payout along an inner diameter of the center-pull doff with rotation of the center-pull doff about a vertically oriented axis of rotation, the flat fiber tow payout system including a constant inertial reference frame for payout of the flat fiber tow along the inner diameter of the center-pull doff without twisting the flat fiber tow; and accelerating and stopping rotation of the center-pull doff with the flat fiber tow payout system so as to maintain payout of the flat fiber tow along the inner diameter of the center-pull doff in the constant inertial reference frame, preventing twisting of the flat fiber tow.

Owner:EBERT COMPOSITES

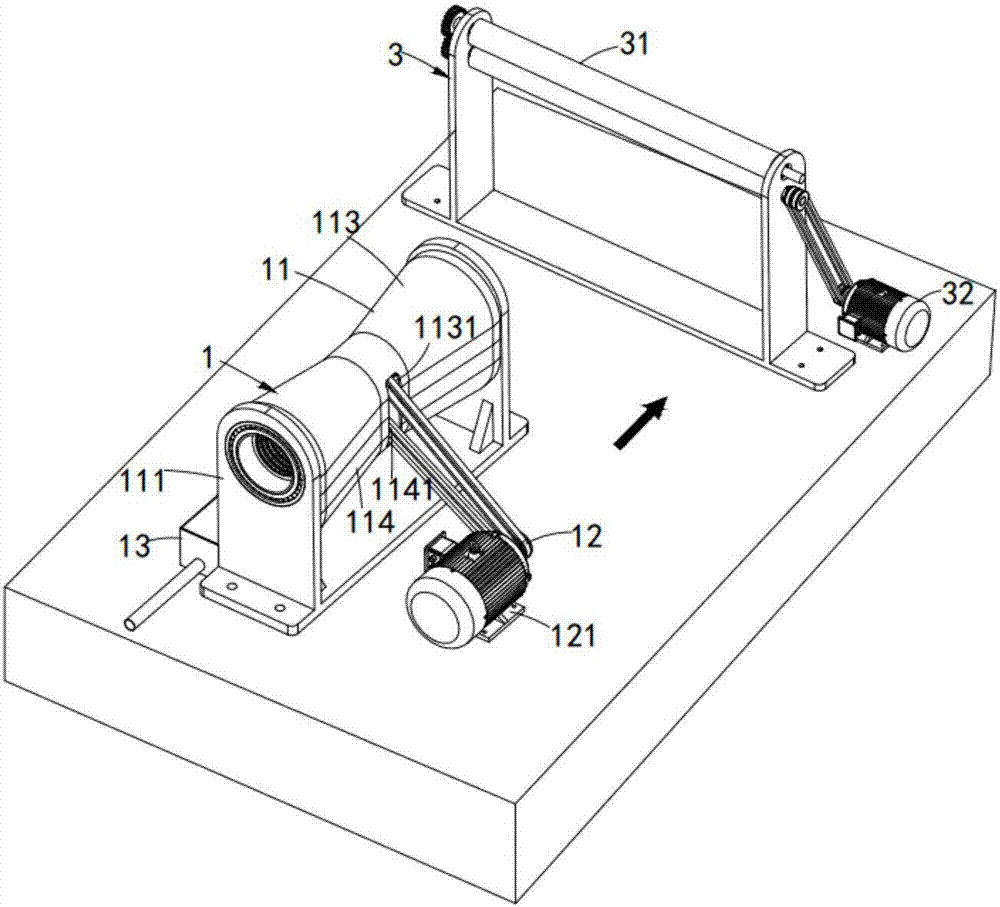

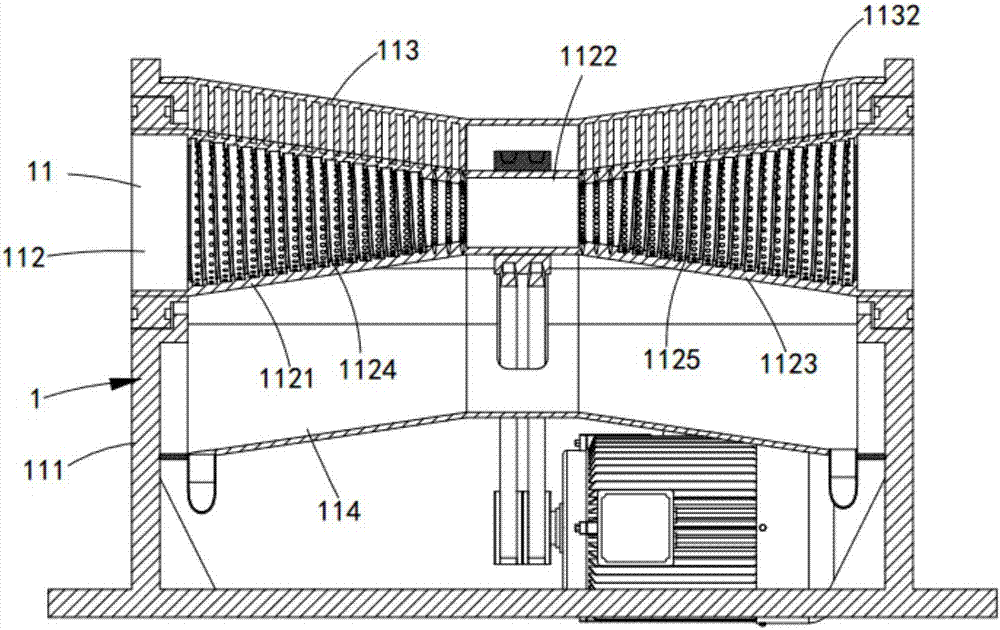

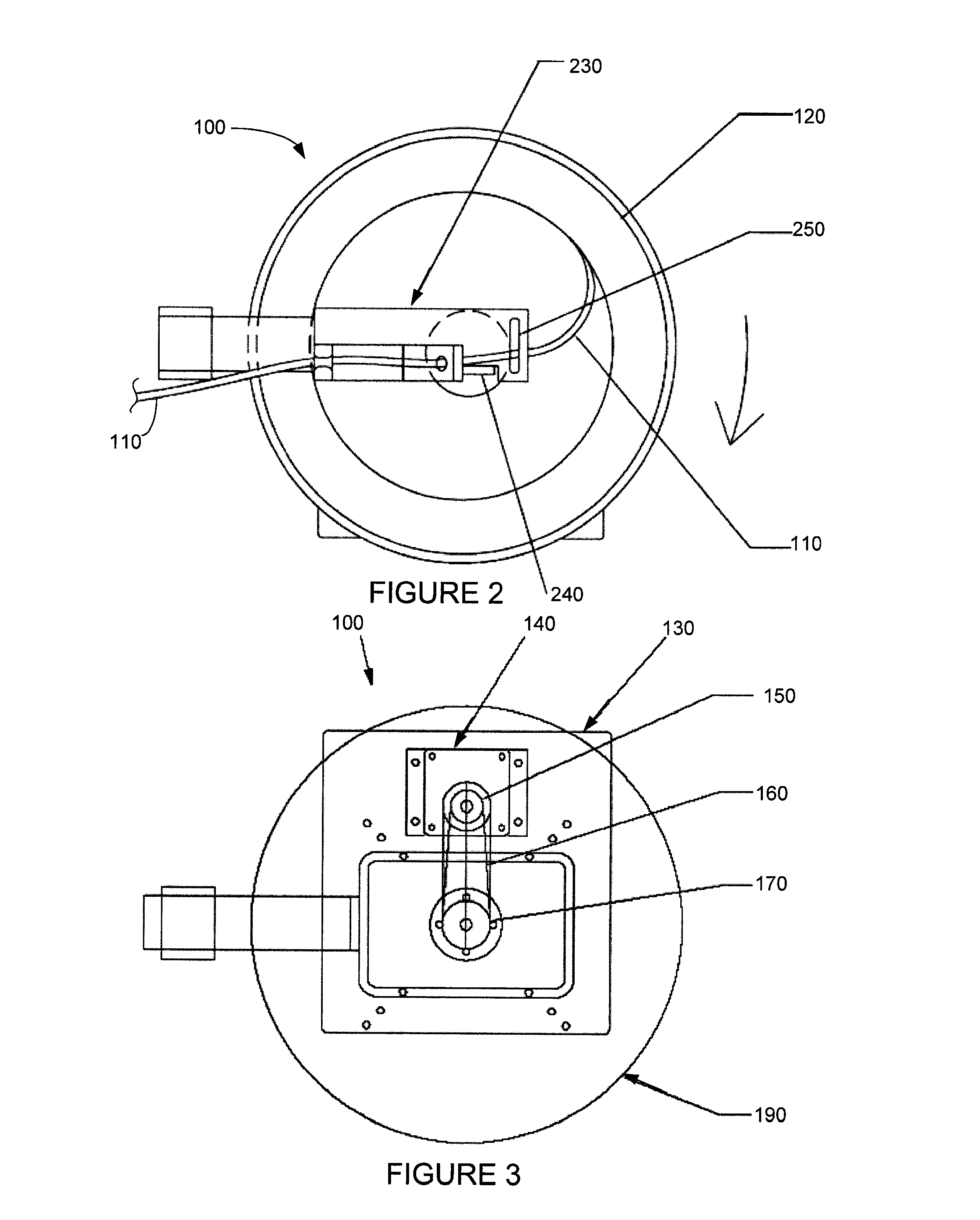

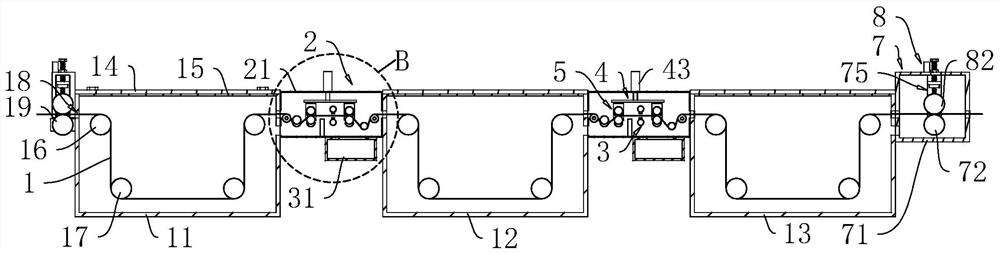

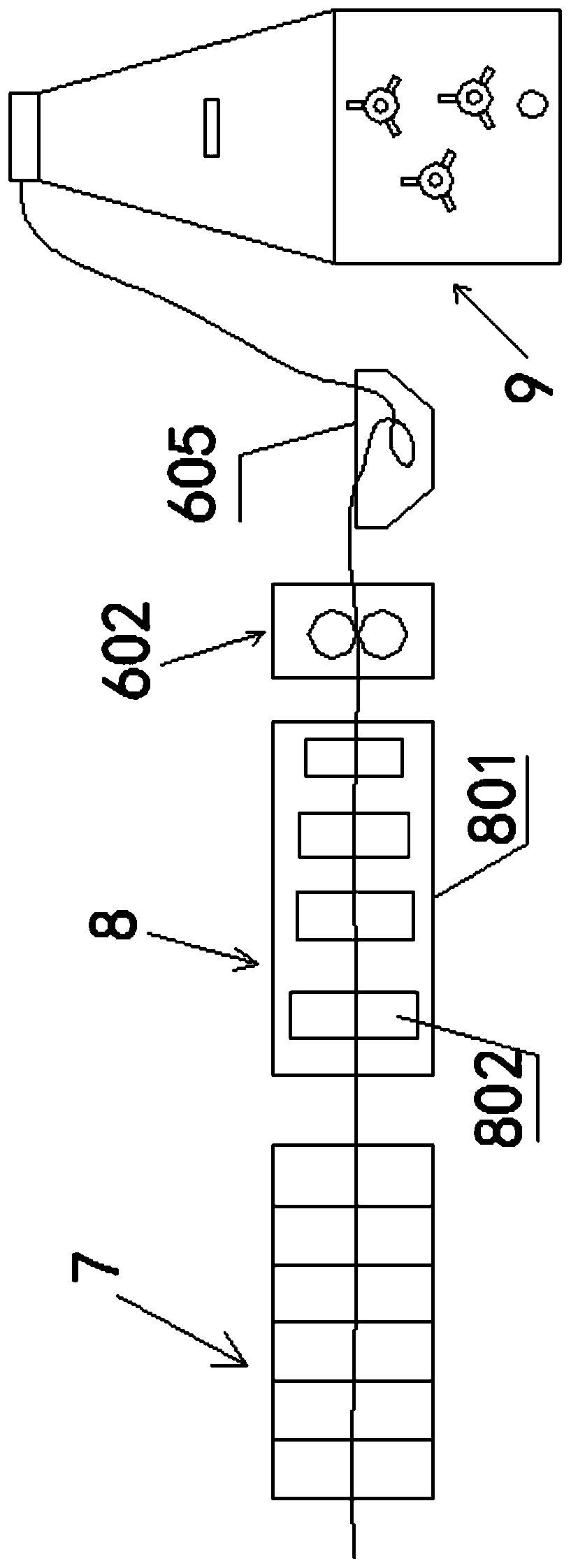

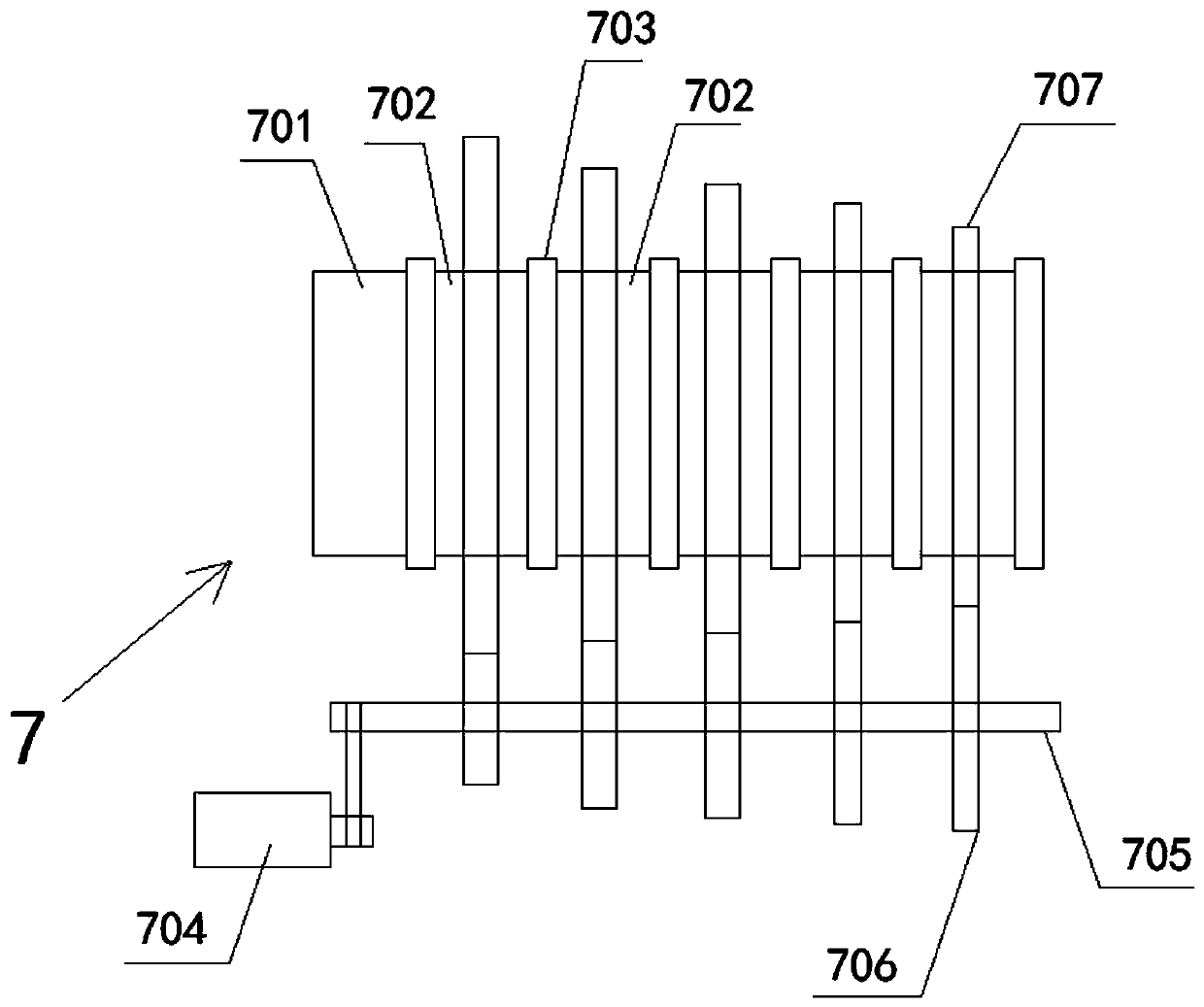

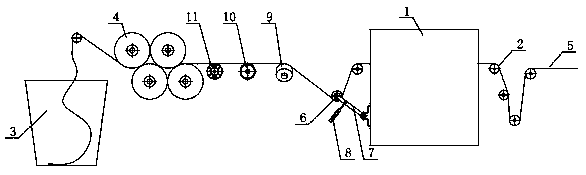

Dewatering, untwisting and opening equipment for textile printing and dyeing

InactiveCN106868759AEliminate twistingQuick breakTextile treatment untwisting devicesTextile treatment machine arrangementsTextile printerWastewater

The invention discloses a textile printing and dyeing dehydration and untwisting opening equipment. By changing the dehydration mode of textiles, the textiles are horizontally drawn by a tractor. The spiral untwisting and dewatering cylinder is equipped with a spiral dehydration section, a smooth buffer section and a spiral untwisting section respectively, and the textiles are rotated and extruded by using the positive spiral threads on the spiral dehydration section, so that the waste water in the textiles is quickly and completely separated , while the anti-rotation thread of the spiral untwisting section is used to reverse and untwist the textiles to eliminate the torsion of the textiles. Wrinkles generated in the dehydration process; solve the technical problem that no additional untwisting device is needed, and perfectly solve the technical problem of wrinkles in the textile during the rotary extrusion dehydration process.

Owner:潘杰

Dyeing machine

InactiveCN107904825AAvoid Knots and FoldsNovel structureLiquid/gas/vapor treatment of propelled fabricsTextile treatment untwisting devicesSpray nozzleEngineering

The invention discloses a dyeing machine. The dyeing machine comprises a dye vat, a blower and a dyeing liquid cylinder; an extension part is arranged at one end of the dye vat vertically and upwards,a sealing door is arranged on the side face of the extension part, an air pipe is arranged on the blower, a dyeing liquid pipe is arranged on the dyeing liquid cylinder, a cloth guide roller is arranged on one side of the extension part, a cloth guide pipe is arranged on the side, corresponding to the cloth guide roller, of the extension part, the other end of the cloth guide pipe is communicatedwith the dye vat, a spray nozzle is arranged between the cloth guide roller and the cloth guide pipe and communicated with the air pipe and the dyeing liquid pipe separately, the dye vat is internally provided with a conveyor belt, and the cloth guide pipe is internally provided with a cloth leveling device. The dyeing machine is novel in structure and reasonable in design; by means of the clothleveling device, leveling can be conducted on any fabrics, the phenomenon that the fabrics are knotted and folded in the dyeing machine can be effectively avoided, the dyeing uniformity is guaranteed,the times of repeated dyeing are reduced, and then the dyeing efficiency is improved.

Owner:浙江宏涛印染机械有限公司

Automatic carding system for dyed textile fabric

InactiveCN112553818AImprove flexibilityElimination of disordered nodulesTextile treatment untwisting devicesStretchingCardingTransmission belt

The invention relates to an automatic carding system for a dyed textile fabric. The automatic carding system comprises a rack and further comprises a shaking and stretching mechanism, a fabric conveying roller set, a carry platform mechanism and a fabric tentering mechanism; the shaking and stretching mechanism comprises a driving motor, a crankshaft, a connecting rod and a shaking roller set assembly; and the fabric tentering mechanism comprises a traction conveying motor, two transmission shafts, a transmission belt, a conveying chain and a traction tentering assembly. According to the automatic carding system provided by the invention, fabrics with different widths and different elastic characteristics can be shaken and stretched after being dyed, thus the flexibility of the shaped fabrics is improved, and the stretched fabrics are subjected to tentering shaping so that the dyed fabrics can be automatically and continuously carded and processed.

Owner:郭召勋

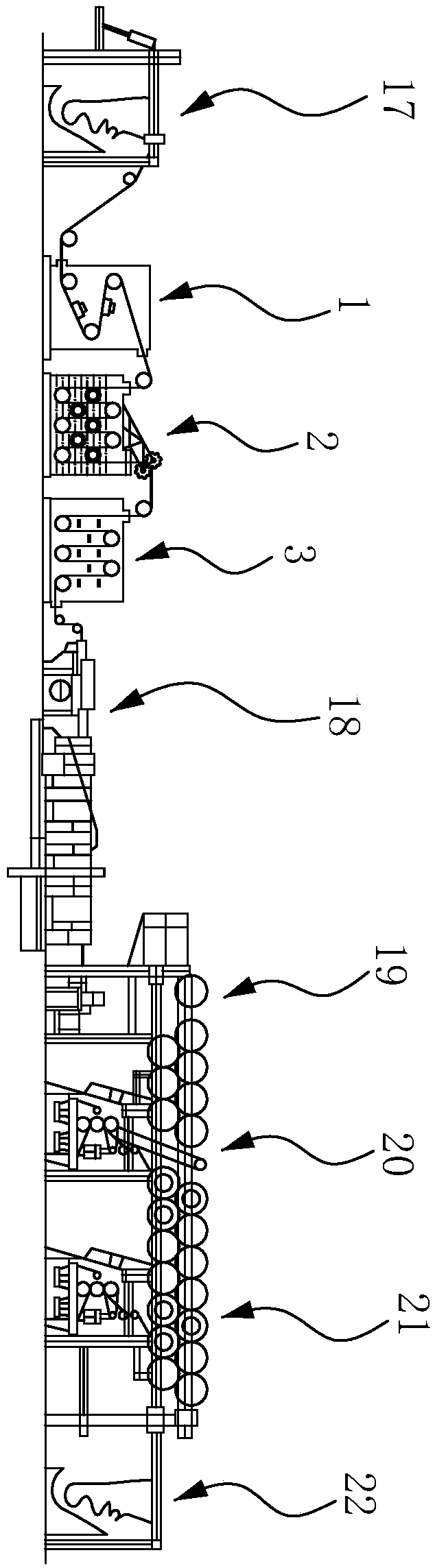

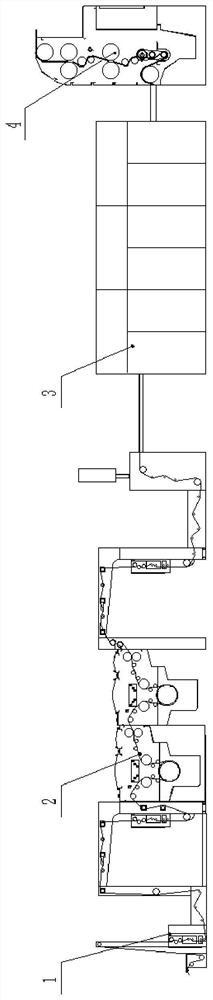

Chromatic aberration-free textile dyeing and finishing integrated production system

InactiveCN112779707ARealize integrationGood synchronous performanceTextile treatment untwisting devicesHeating/cooling textile fabricsProcess engineeringManufacturing engineering

The invention discloses a chromatic aberration-free textile dyeing and finishing integrated production system, and belongs to the technical field of textile fabric production. The chromatic aberration-free textile dyeing and finishing integrated production system comprises a scutching unit, an oil removing and washing unit, a preheating setting unit, a uniform light rolling system, a post-dyeing washing unit and a heat setting unit; the scutching unit is connected with the oil removing and washing unit; the oil removing and washing unit is connected with the preheating setting unit; the preheating setting unit is connected with the uniform light rolling system; the uniform light rolling system is connected with the post-dyeing washing unit; and the post-dyeing washing unit is connected with the heat setting unit. According to the chromatic aberration-free textile dyeing and finishing integrated production system, the integration and centralized control of the scutching unit, the oil removing and washing unit, the preheating setting unit, the uniform light rolling system, the post-dyeing washing unit and the heat setting unit are achieved, a dyeing and finishing integrated machine is good in joint synchronization performance, the occupied area is reduced, the energy is saved, and the expected uniform liquid carrying rate of fabric padding and dyeing is achieved, so that the aim of no chromatic aberration is achieved.

Owner:广东亚生新能源科技有限公司

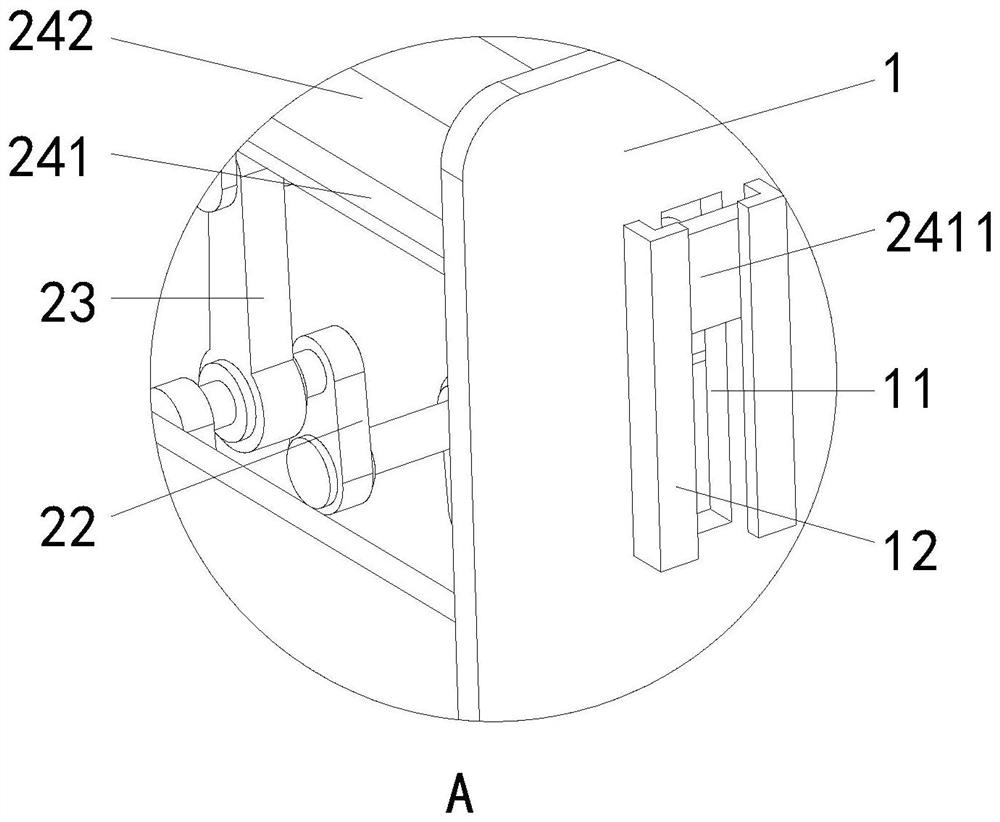

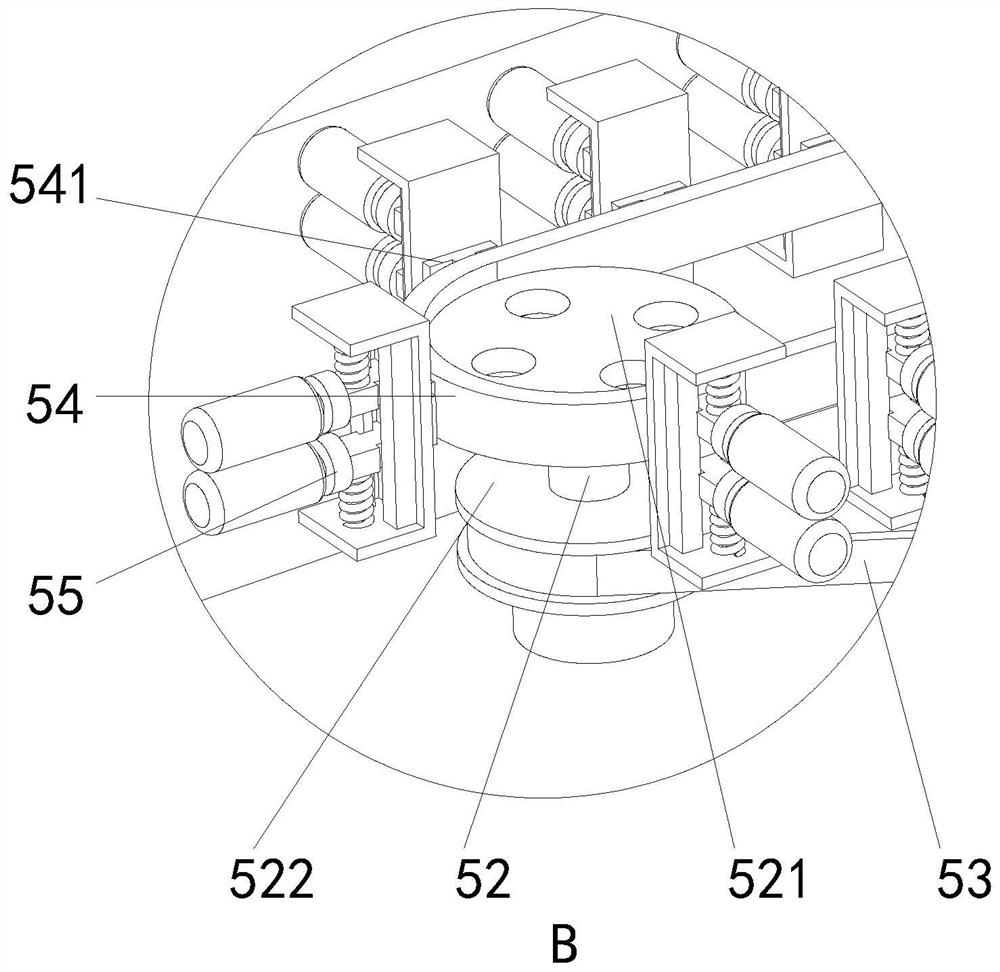

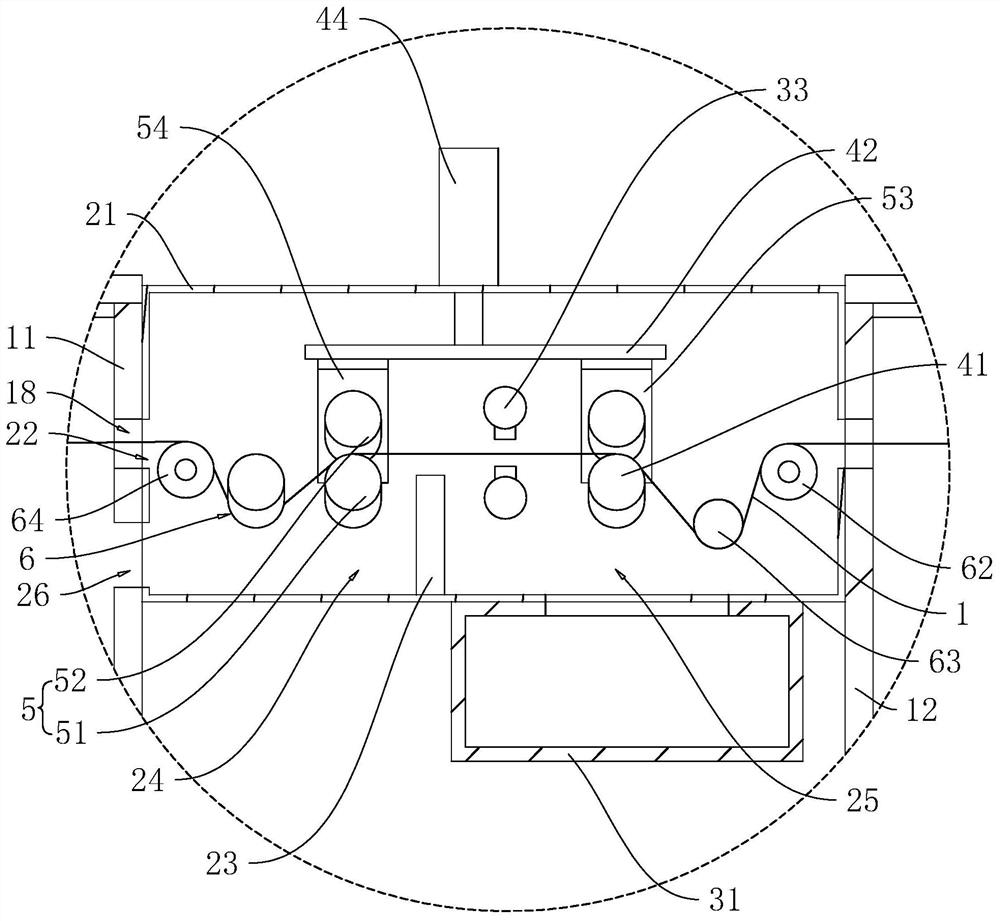

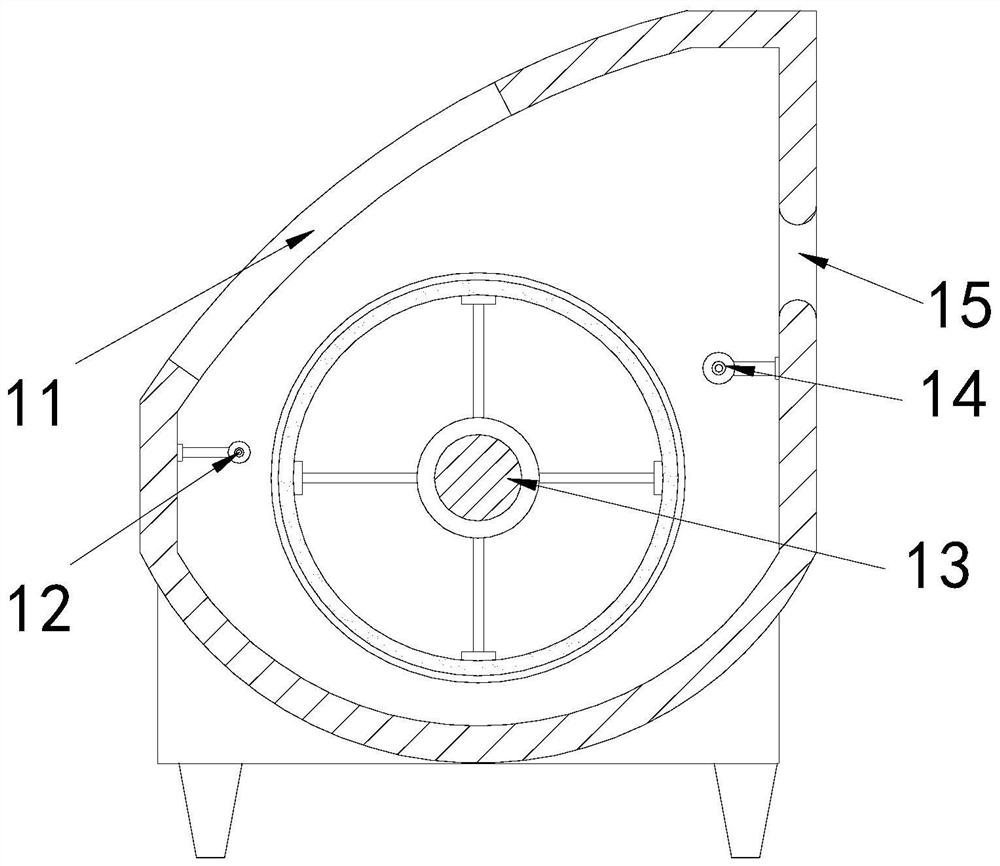

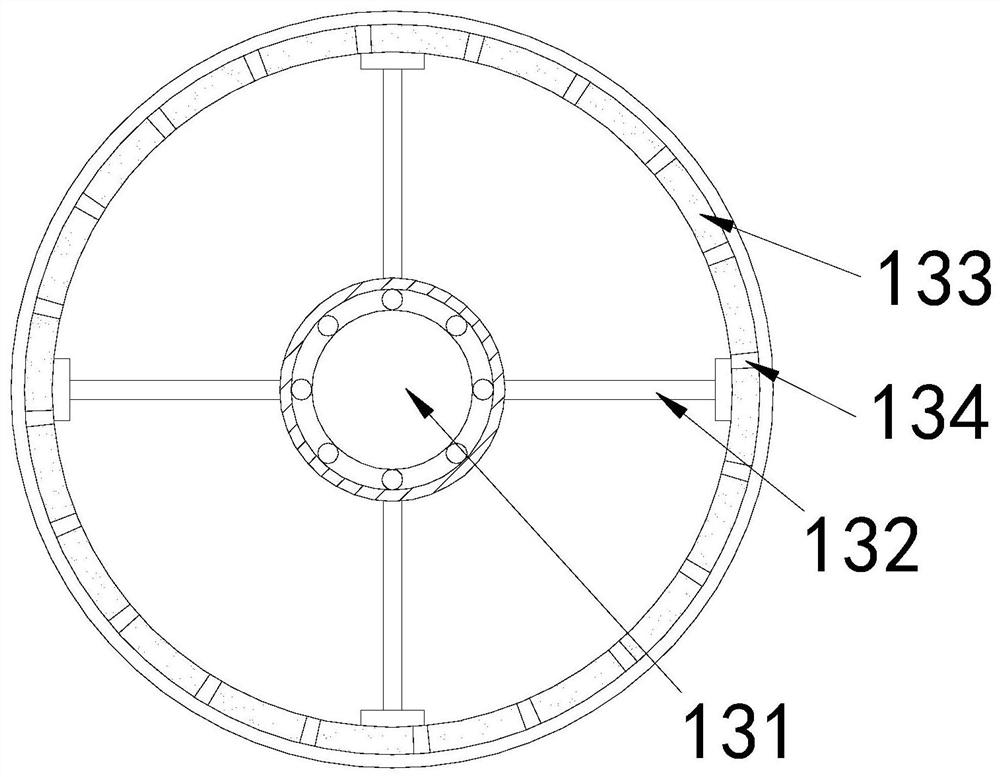

Dyeing machine with relaxation, untwisting and cockling devices

PendingCN109972319AImprove permeabilityConsistent shrinkageTextile treatment untwisting devicesTextile treatment by spraying/projectingFiberHysteresis

Owner:ZHEJIANG ZHONGTE INTELLIGENT EQUIP CO LTD

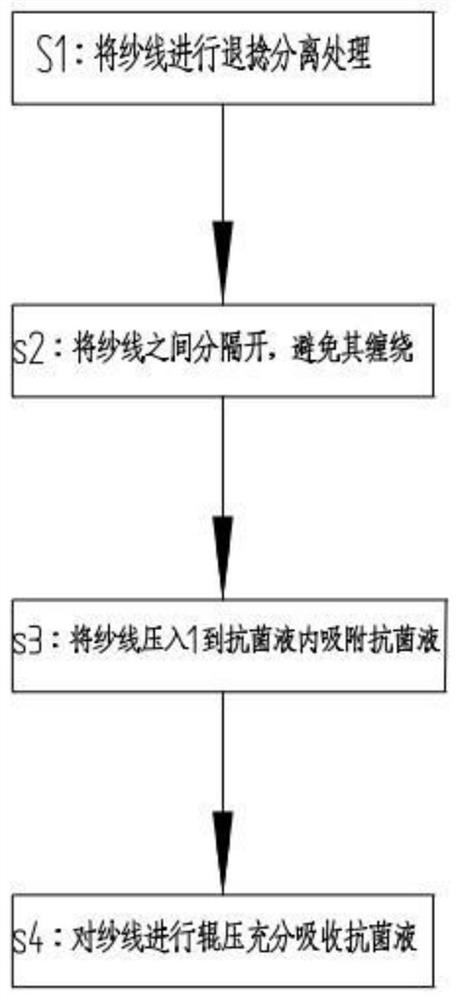

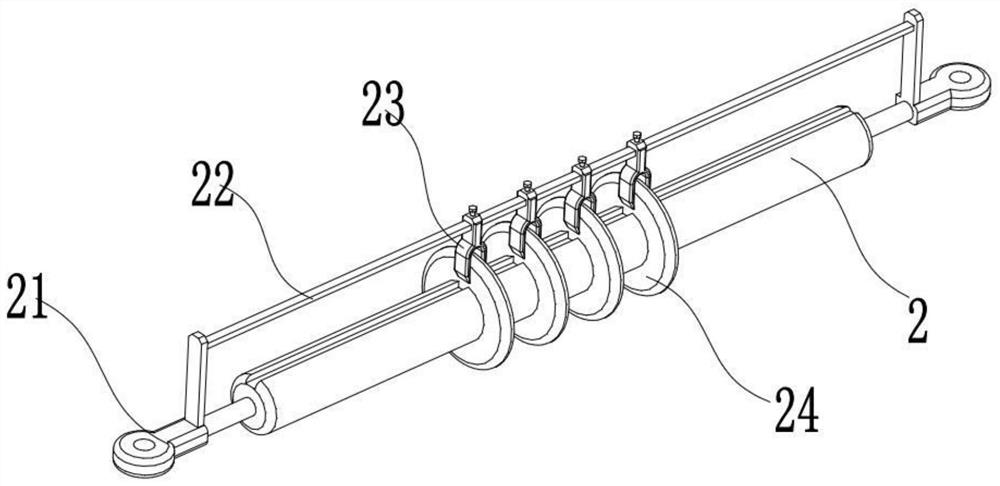

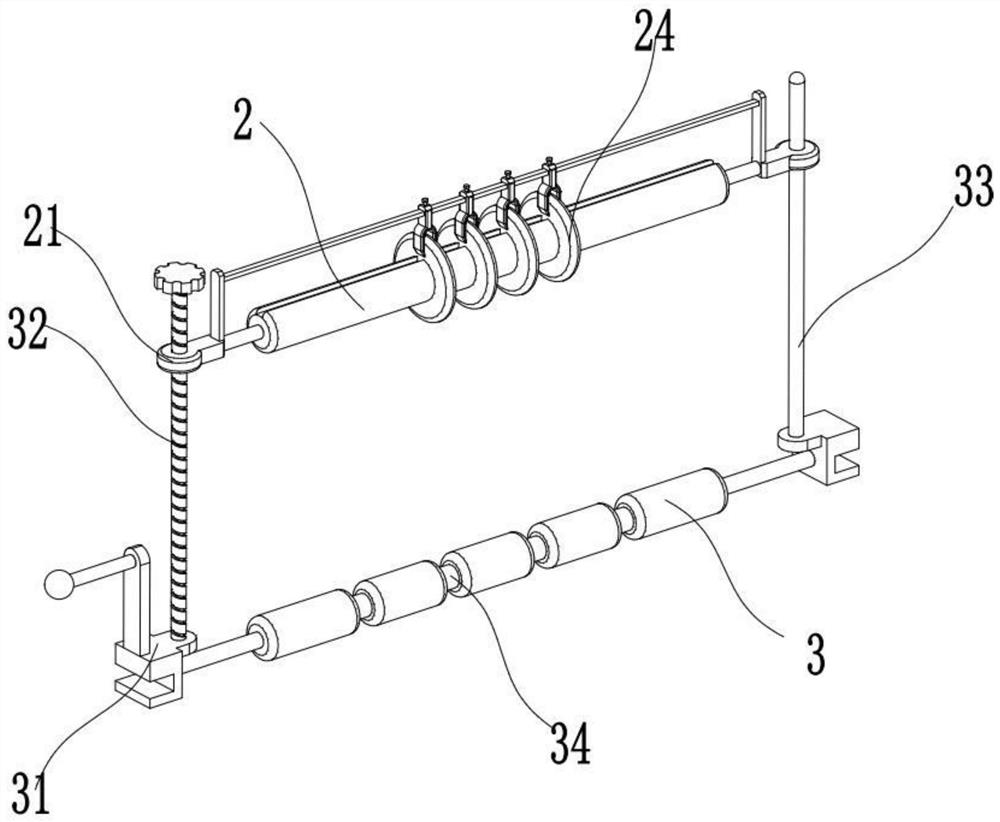

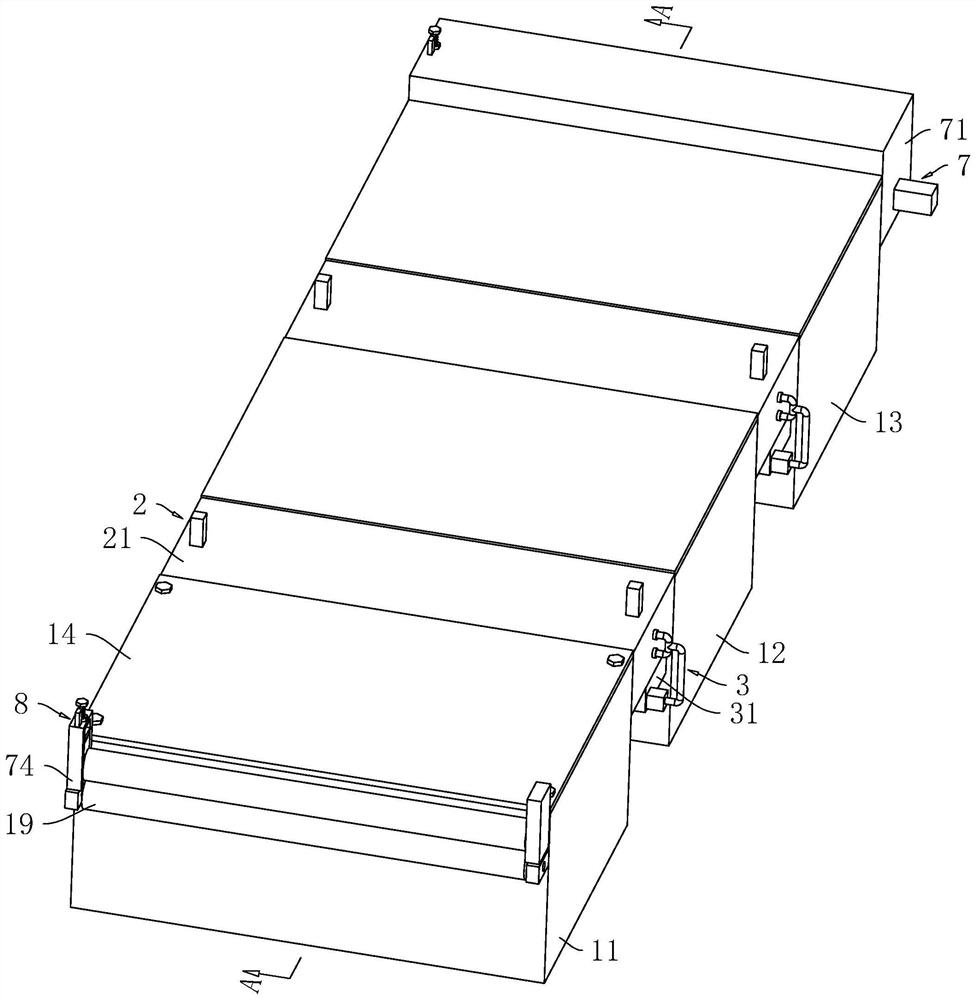

Preparation method of antibacterial yarn

InactiveCN113388982AImprove adsorption capacityFully adsorbedTextile treatment untwisting devicesTextile treatment guiding meansYarnFiber

The invention relates to the technical field of knitted fabrics, in particular to a preparation method of antibacterial yarn. The invention solves the problem that in the background technology, an antibacterial solution cannot be fully adsorbed in multiple twisted yarns which are wound together. The method comprises the following steps of s1, untwisting a plurality of stranded yarns which are formed by mutual cohesion after twisting, so that the plurality of yarns are not wound or cohered together; s2, separating the multiple yarns, so that the multiple yarns are spaced by a certain distance; s3, pressing the plurality of yarns into the antibacterial solution, so that the yarns are immersed into the antibacterial solution, and the surfaces of the yarns are coated with an antibacterial layer; and s4, rolling the yarns, so that the interiors of the yarns fully absorbs the antibacterial solution. The antibacterial solution used in the step s3 contains 25 parts of nano bamboo carbon fibers, 25 parts of nano silver fibers and 75 parts of natural fabric fibers.

Owner:哈尔滨嗨菲特健康管理有限公司

Desizing, scouring and bleaching combined machine

InactiveCN113493968AImprove deboiling and bleaching effectQuality improvementTextile treatment untwisting devicesLiquid/gas/vapor removal by squeezing rollersProcess engineeringDesizing

The invention relates to a desizing, scouring and bleaching combined machine, and relates to the technical field of cloth treatment. The desizing, scouring and bleaching combined machine comprises a desizing pool, a scouring pool and a bleaching pool; the desizing pool and the bleaching pool are each provided with a cleaning device; and each cleaning device comprises a cleaning box which is arranged on the desizing pool and is provided with a through hole for cloth to pass through, a spraying mechanism which is arranged on the cleaning box and is used for spraying the cloth and removing a solution in the previous process in the cloth, and an extrusion mechanism which is arranged on the cleaning box and used for extruding the cloth. The cloth enters the cleaning box, the spraying mechanism is started to spray the cloth, then the extrusion mechanism extrudes the cloth, and finally the cloth enters the scouring pool to be subjected to the next process, so that the adverse effect of the solution in the previous process on the next process is reduced, the desizing, scouring and bleaching effects of the cloth are improved, and the quality of the cloth is improved.

Owner:舒普林印染有限公司

Extrusion-type dewatering structure for fabric dewatering device

ActiveCN109778463ATextile treatment untwisting devicesLiquid/gas/vapor removal by squeezing rollersPulp and paper industryExtrusion

The invention discloses an extrusion-type dewatering structure for a fabric dewatering device. The structure comprises an extrusion-type dewatering assembly, the extrusion-type dewatering assembly comprises a cylinder and extrusion rings axially arranged in the cylinder in sequence, the fabric can penetrate through the extrusion rings and is extruded, and the diameters of the extrusion rings are gradually decreased in the forward direction of the fabric. In this way, according to the extrusion-type dewatering assembly, through the extrusion rings with gradually-decreased diameters, the fabriccan be extruded step by step, the extrusion effect is improved, and the fabric dewatering effect is improved.

Owner:JIANGSU HUAYI GARMENT CO LTD

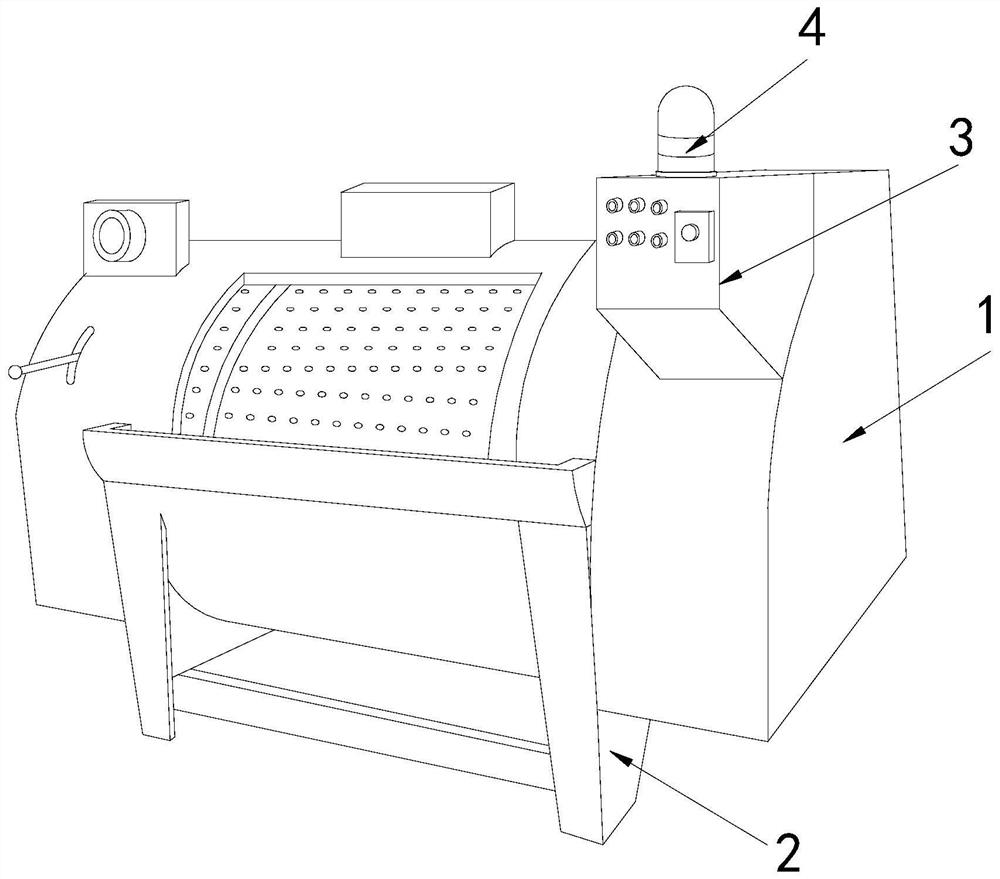

Textile printing and dyeing machine for textiles

InactiveCN112048857AFor quick outflowKeep it openTextile treatment untwisting devicesTextile treatment machine arrangementsTextile printerEngineering

The invention discloses a textile printing and dyeing machine for textiles. The textile printing and dyeing machine structurally comprises a main body, supporting legs, a control panel and an alarm lamp, wherein one supporting leg is arranged at each of the four ends of the bottom of the main body, the control panel is located on the upper portion of the front end of the main body, the alarm lampis arranged at the top end of the main body, the main body comprises a feeding port, a guiding roller, a roller, a material squeezing roller and a discharging port, the material squeezing roller comprises a supporting arm, clamping blocks, a circulating groove and a concentrating groove, the circulating groove comprises a rotating column, a circular ring body, fixing rods, material passing groovesand communicating grooves, and each communicating groove comprises a groove body, a flow guiding block and a one-way hole. According to the textile printing and dyeing machine, the hole diameter of the material squeezing roller is arranged to be gradually reduced from the middle to the two ends, so that when the material squeezing roller drives cotton cloth to operate, the cotton cloth can be expanded towards the two ends, and the situation that the dye is not uniformly squeezed out due to wrinkles of the cotton cloth in the material squeezing roller is avoided.

Owner:北京弘福阁酒店管理有限公司

Cloth washing machine and washing method of cloth

InactiveCN108796896AEasy to storeModerate tensionTextile treatment untwisting devicesLiquid/gas/vapor removalPulp and paper industryWater washing

The utility model relates to a cloth washing machine and a washing method of cloth and aims at overcoming the defects in the prior art that when the cloth is twisted on rotating rollers in a hemp ropeshape for washing, the washing time is long, the washing effect is poor, colors of the cloth are likely to be mixed since the wet cloth is stacked for a long time, and the quality of the cloth is influenced. The provided cloth washing machine comprises a washing tank, cloth conveying devices penetrating through the washing tank, a cloth receiving bin and a group of heating and drying rollers. Theheating and drying rollers are arranged on the cloth conveying devices between the washing tank and the cloth receiving bin, the cloth is unfolded and conveyed horizontally along a conveying roller and the heating and drying rollers. A washing method of the cloth is also provided, and cloth washing is conducted on the basis of the cloth washing machine. The method includes the following steps that A, the cloth is unfolded and conveyed horizontally to the washing tank for washing; B, the cloth is conveyed to the heating and drying rollers, and the heating and drying rollers are used for dryingthe cloth; C, the cloth is conveyed into the cloth receiving bin. According to the cloth washing machine and the washing method of the cloth, cleaning is conducted completely, the effect of removingresidual ink is good, storage of the dried cloth for a long time is facilitated, and the cloth washing machine and the washing method are suitable for being used for washing the cloth.

Owner:深圳同益新中控实业有限公司

Polyester-mixed cotton cloth mercerizing machine and mercerizing process

InactiveCN112080880AQuality improvementReduce contentMercerising of indefinite length fabricsTextile treatment untwisting devicesPolyesterCotton cloth

The invention relates to a polyester-mixed cotton cloth mercerizing machine and a mercerizing process. The mercerizing machine comprises a rack, wherein a first removing mechanism is arranged on the rack, and the first removing mechanism comprises a spraying box, a spraying device and a driving device; and the spraying box is arranged on the rack and contains cleaning liquid, the spraying device is arranged on the spraying box and sprays cloth, the spraying device comprises a spraying pump and a spraying pipe, the spraying pump is arranged on the spraying box, the spraying pipe is arranged onthe spraying box, a pipe opening of the spraying pipe faces the cloth, the driving device is arranged on the spraying box, the driving device comprises a driving roller and a driving piece, the driving roller is rotatably arranged on the spraying box and abuts against the cloth, and the driving piece is arranged on the spraying box and connected with the driving roller. The spraying pump is started to enable the cleaning liquid to be sprayed onto the cloth, so that alkali liquor on the cloth is cleaned up, the content of the alkali liquor when the cloth enters the next procedure is reduced, the influence of the alkali liquor on the next procedure is reduced, and the quality of the cloth is improved.

Owner:嵊州市新剡东印染股份有限公司

Scutching equipment for water-soluble chitosan textile processing

PendingCN112458670AQuality improvementGood effectTextile treatment untwisting devicesLiquid/gas/vapor removal by gas jetsStructural engineeringDrive motor

The invention discloses scutching equipment for water-soluble chitosan textile processing. The equipment comprises a scutching box, wherein supporting legs are welded to the four corners of the bottomof the scutching box, a servo motor is installed on the upper portion of the outer wall of one side of the scutching box through bolts, an output shaft of the servo motor is connected with a two-wayscrew through a coupler, the two-way screw is sleeved with two threaded sleeves, limiting rods are welded to the outer walls of the tops of the two threaded sleeves correspondingly, limiting grooves are formed in the inner wall of the top of the scutching box, the outer walls of the top ends of the limiting rods are slidably connected with the inner walls of the tops of the limiting grooves, hot air boxes are welded to the outer walls of the bottoms of the two threaded sleeves correspondingly, and hot air mechanisms are arranged in the two hot air boxes. Through cooperative use of the hot airboxes, a damp-proof cover, a driving motor, a transmission shaft, a driving bevel gear, a driven bevel gear, air blowing fan blades and an electric heating wire, cloth can be continuously dried in thescutching process, and therefore the probability of the cloth wrinkling phenomenon after scutching can be reduced.

Owner:SUZHOU DEHEYAXIN TEXTILE NEW MATERIAL TECH CO LTD

Automatic fabric opening device

The invention relates to an automatic fabric opening device. The left side and the right side of a rope-shaped fabric are blown open through an air injection method, and the fabric is made to return to the flat state. A fabric stretching device is mainly a uniquely designed air bellow, the rope-shaped fabric enters the air bellow from an inlet in the upper portion of the air bellow, the front sideand the rear side of the air bellow are each provided with an inlet for injected air to enter, the injected air passes through a specially designed air window in the air bellow, the surface of the rope-shaped fabric is blown from the front and the rear to generate dragging force, and the fabric is opened left and right; and a long and narrow outlet is formed in the bottom of the air box, so thatthe opened fabric is discharged to be connected with a downstream treatment procedure. According to the device, high automation is used for replacing manpower to treat the fabric opening procedure, time and labor are saved, comprehensive automation of dyeing machinery can be facilitated, and the device has extremely high application value.

Owner:FONGS NAT ENG (GUANGDONG) CO LTD

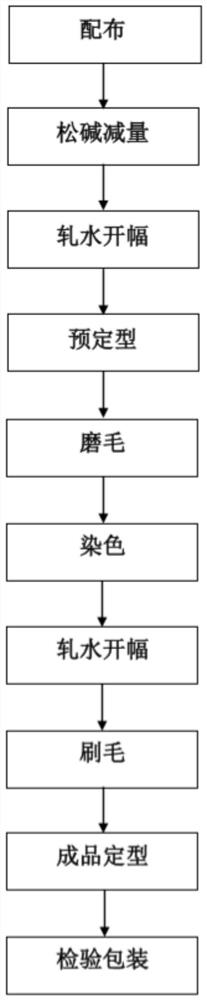

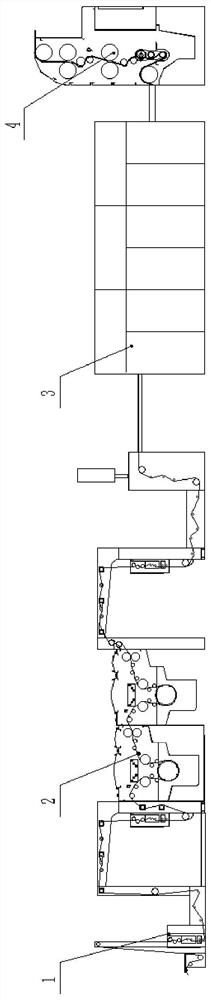

Production process of dotted sanded fluff

PendingCN112981799AReduce pollutionShort holding timeTextile treatment untwisting devicesHeating/cooling textile fabricsEngineeringProcess engineering

Owner:浙江丰林染整有限公司

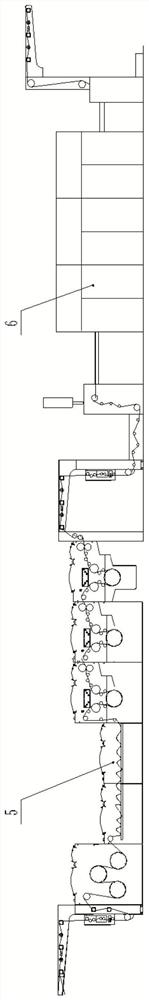

Textile dyeing and finishing integrated production system with high-frequency oscillation structure

InactiveCN112779706AGood synchronous performanceSmall footprintTextile treatment untwisting devicesHeating/cooling textile fabricsColour fastnessProcess engineering

The invention discloses a textile dyeing and finishing integrated production system with a high-frequency oscillation structure, and belongs to the technical field of textile fabric production. The system comprises a scutching unit, an oil removing and washing unit, a preheating and setting unit, a film forming and mangling device, a post-dyeing washing unit and a heat setting unit, wherein the scutching unit is connected with the oil removing and washing unit; the oil removing and washing unit is connected with the preheating and setting unit; the preheating and setting unit is connected with the film forming and mangling device; the film forming and mangling device is connected with the post-dyeing washing unit; and the post-dyeing washing unit is connected with the heat setting unit. According to the textile dyeing and finishing integrated production system with the high-frequency oscillation structure, dye liquor fully permeates into fabric fibers through high-frequency oscillation, so that dyeing is more uniform, no white core exists, the color fastness is good, and the color is bright.

Owner:广东亚生新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com