Dewatering, untwisting and opening equipment for textile printing and dyeing

A textile printing and dyeing and untwisting technology, which is applied in the direction of processing textile material untwisting device, processing textile material equipment configuration, processing textile material drum, etc., can solve cumbersome problems, simplify the mechanical structure, reduce the risk factor, and eliminate the degree of torsion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

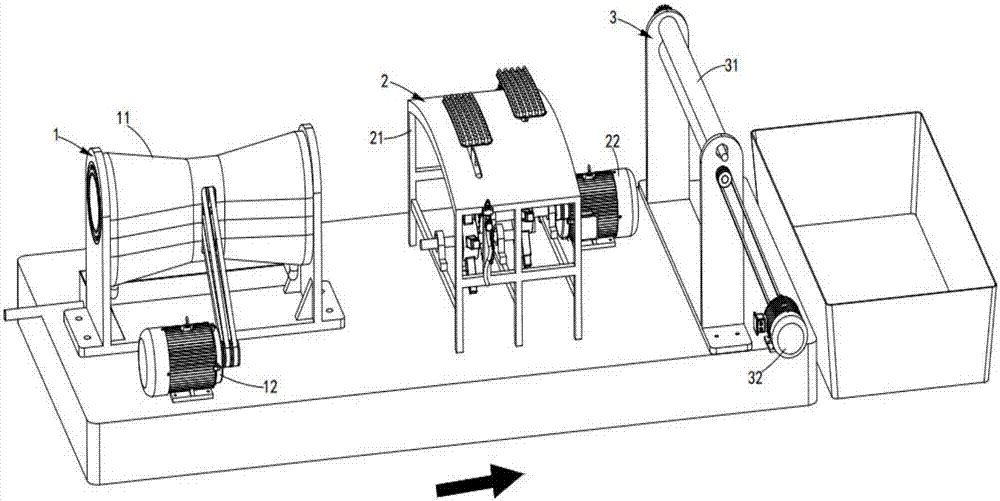

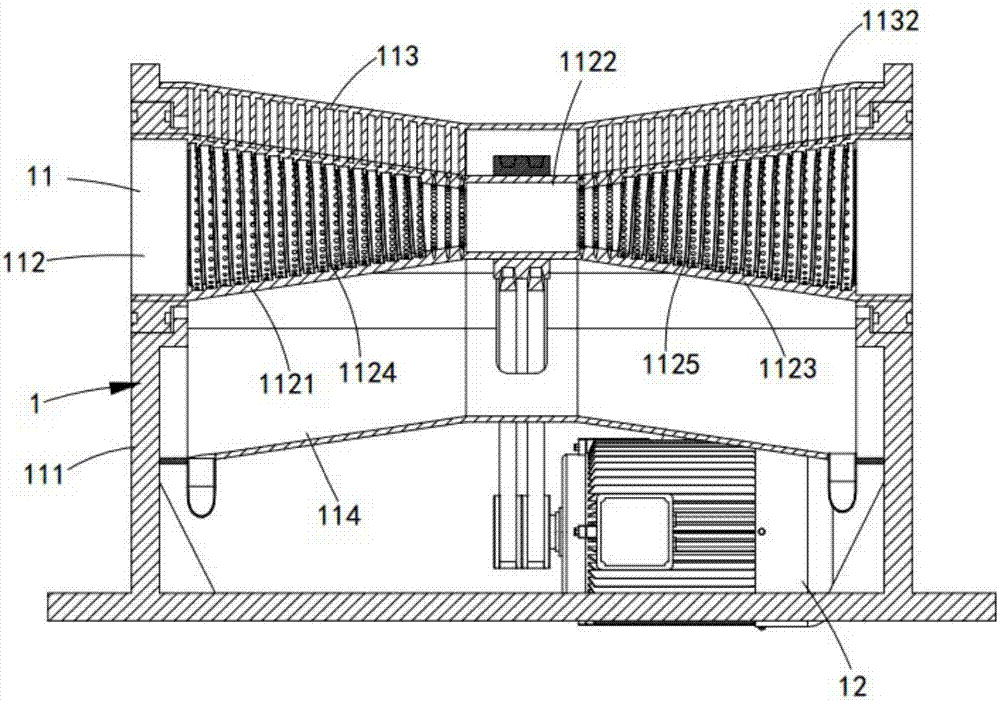

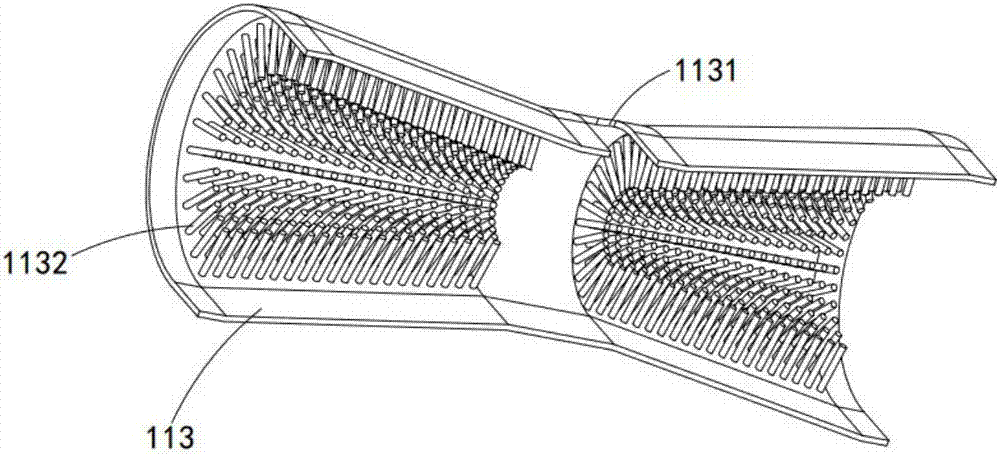

[0061] Such as figure 1 As shown, a textile printing and dyeing dehydration untwisting and opening device, from front to back, includes a spiral untwisting dehydrator 1, a horizontal opening machine 2 and a tractor 3. The spiral untwisting dehydrator 1 includes a spiral untwisting dehydration mechanism 11 and a first driving mechanism 12, the first driving mechanism 12 is arranged on one side of the spiral untwisting dewatering mechanism 11, which drives the spiral dewatering mechanism 12 to dewater the finished textiles by means of belt transmission;

[0062] The horizontal opening machine 2 includes an opening mechanism 21 and a second driving mechanism 22. The second driving mechanism 22 is arranged on the rear side of the opening mechanism 21, which drives the opening mechanism 21 to de-twist and dehydrate the spiral. The textile output from machine 1 is opened;

[0063] The traction machine 3 includes a traction mechanism 31 and a third drive mechanism 32. The third drive mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com