Radial unwinding weft carrier and its radial unwinding method

A weft carrier and unwinding technology, which is applied in textiles, textiles, papermaking, looms, etc., can solve the problems of non-wear resistance and weft yarns that cannot be twisted, so as to reduce wear, reduce loose edges, and reduce yarn consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

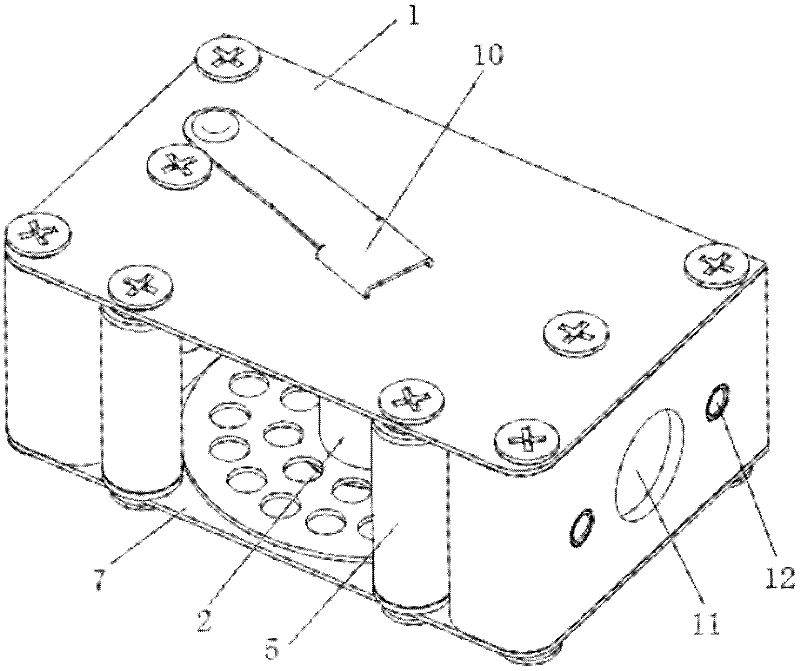

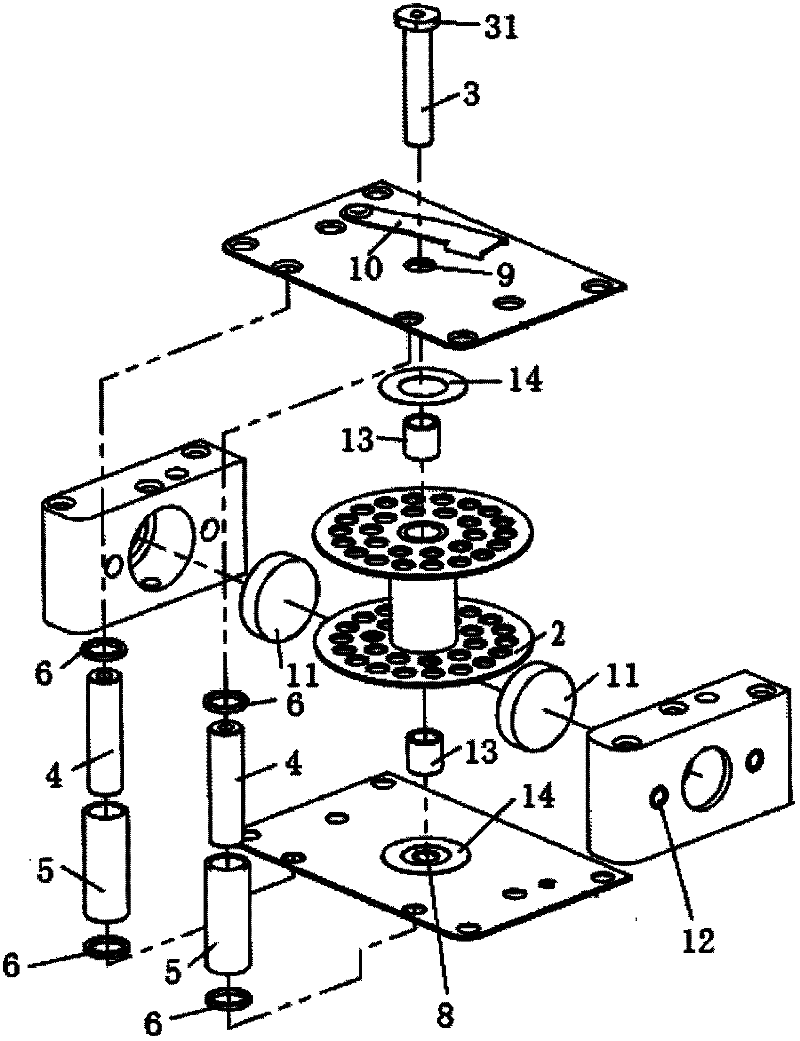

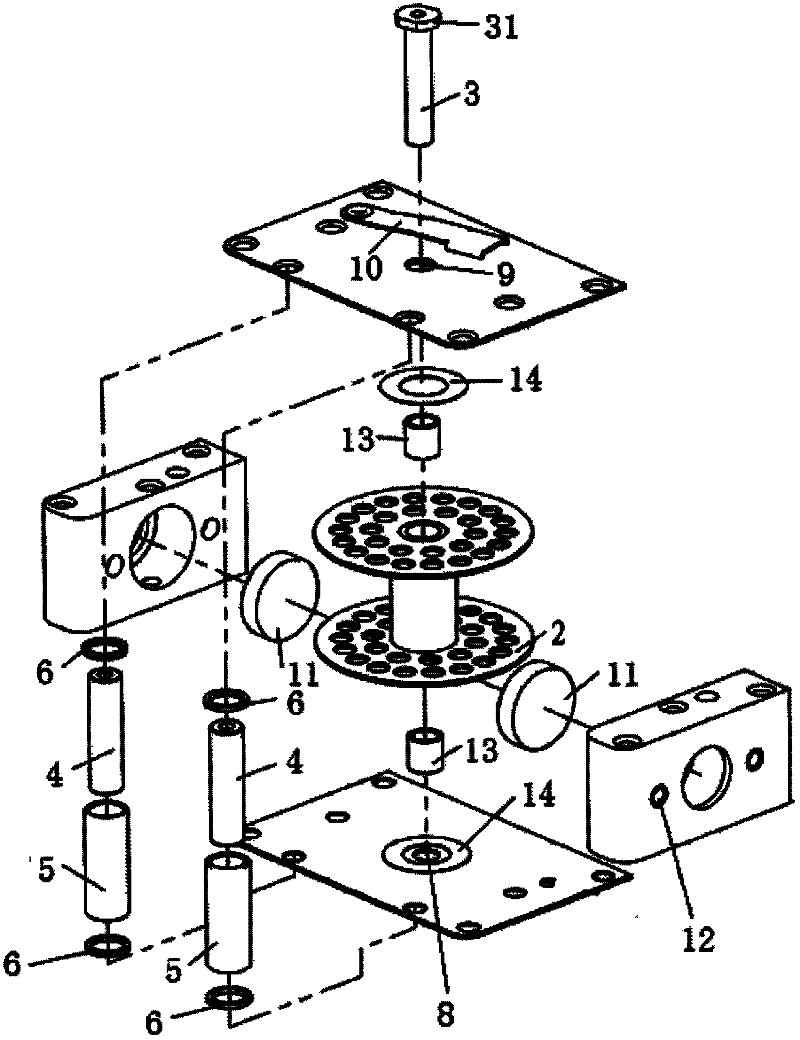

[0022] like figure 1 , 2 As shown, the radial unwinding weft carrier of the present invention includes a shuttle box 1 and a weft storage device located in the shuttle box 1, and a yarn outlet 7 is provided on the side of the shuttle box 1 for installing and dismounting the weft storage device And extract weft yarn, storage weft device comprises yarn storage shaft 2 and the mandrel 3 that is positioned at storage yarn shaft 2, mandrel 3 is fixed in the shuttle box 1 by clamping device, and storage yarn shaft 2 can rotate on mandrel 3.

[0023] The lower surface of shuttle box 1 inside is provided with through hole 8, is used to place mandrel 3, and the upper surface of shuttle box 1 is provided with through hole 9, and mandrel 3 one end is provided with flange 31, and the other end is inserted into through hole 9, clips The tightening device is located on the flange 31. Both ends of the mandrel 3 are covered with damping washers 14 for preventing the yarn storage shaft 2 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com