Cotton rope unwinding device and method for unwinding cotton rope

A technology of unwinding device and wire rope, which is applied in the field of rubber products, can solve problems such as the influence of twist, and achieve the effect of complete untwisting, convenient and quick installation, and active control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

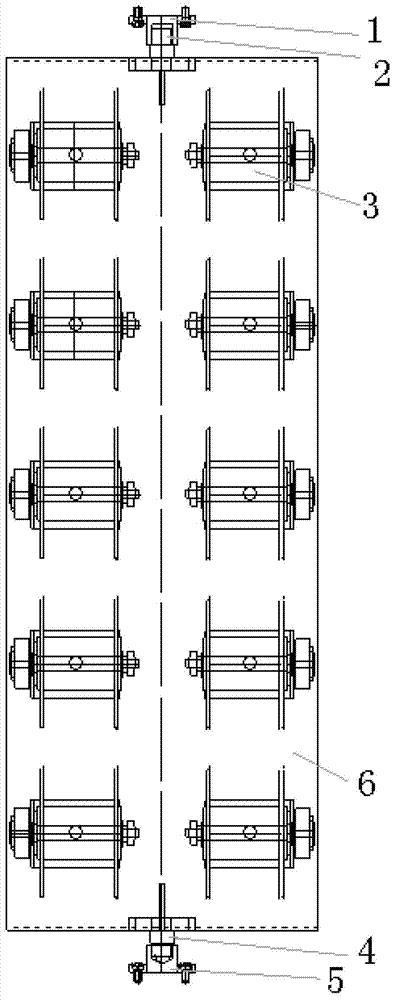

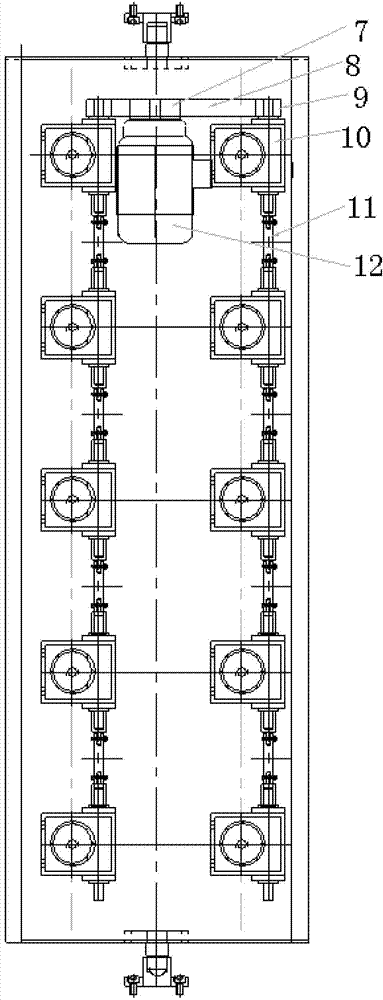

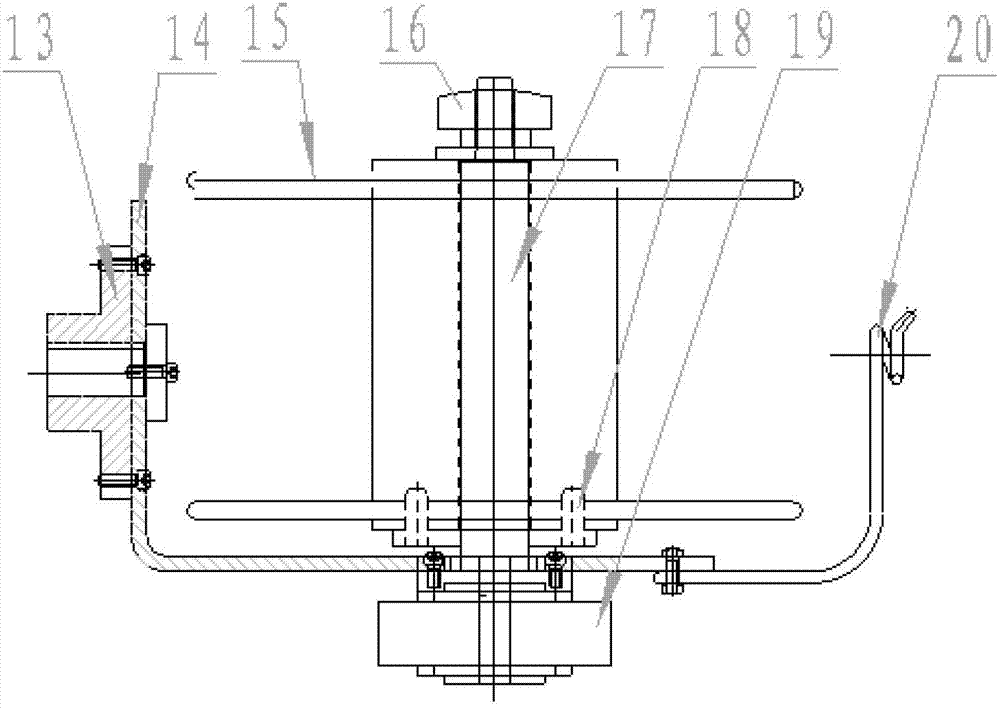

[0043] Embodiment 1: Adopt the above-mentioned mechanism, wherein 16 wire rope guide brackets are set on the mobile car, the winding hose does not move, and the mobile car walks. There are two rows of bobbin assemblies with friction devices on each wire rope guide bracket. Each column includes 5 spool assemblies with friction devices, and 1 variable frequency motor provides untwisting power for 10 spool assemblies with friction devices. The rotation angles or rotation speeds of the 10 bobbin assemblies with friction devices are consistent when they work. When the angle between the wire rope and the winding hose is 30°, according to the formula X=cosα, the twist is calculated to be 0.866, that is, the twist of the steel wire or steel wire rope is 0.866 turns for each rotation of the hose mandrel. Eliminate this twist, and the spool assembly with friction device on the wire rope guide bracket will actively untwist 0.866 turns. There are 16 wire rope unwinding brackets on the mo...

Embodiment 2

[0044] Embodiment 2: adopt the above-mentioned mechanism, 20 wire rope guide brackets are arranged on the fixed frame mechanism, and each wire rope guide bracket has a shaft head that can rotate on it up and down the bracket frame. During work, the wire rope The unwinding mechanism does not move, and the winding hose moves. There are 200 bobbin assemblies with friction devices on the 20 wire rope unwinding brackets, and 20 variable frequency motors provide untwisting power for the 200 bobbin assemblies with friction devices. The angle between the wire rope and the winding hose is 75°. According to the formula X=cosα, the twist is calculated to be 0.2588, that is, the twist of the steel wire or steel wire rope is 0.2588 turns for each rotation of the hose mandrel. To completely eliminate this Twist, the spool assembly with friction device on the wire rope guide bracket should actively pay off 0.2588 turns. The data is sent to the frequency converter by the PLC, and the frequenc...

Embodiment 3

[0046] Embodiment 3: adopt the above-mentioned mechanism, 23 wire rope guide brackets are arranged on the fixed mechanism, each wire rope guide bracket has a shaft head that can rotate on it above and below the bracket frame, during work, the wire rope guide The opening mechanism does not move, and the coiled hose moves, and there are 10 spool assemblies with friction devices on each wire rope guide bracket, and 1 frequency conversion motor provides twisting power for 10 spool assemblies with friction devices. The angle between the wire rope and the winding hose is 54°44'. According to the formula X=cosα, the twist is calculated to be 0.5774, that is, the twist of the steel wire or steel wire rope is 0.5774 turns for each rotation of the hose mandrel. Eliminate this twist, and the spool assembly with friction device on the wire rope guide bracket will actively pay off the wire for 0.5774 turns. The PLC sends the data to the frequency converter, and the frequency converter cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com