A Cable Tensioning Device for Eliminating Backtwist

A technology of tensioning device and stay cable, which is used in cable-stayed bridges, erecting/assembling bridges, bridge parts, etc. The effect of wire cutting and ensuring construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the drawings.

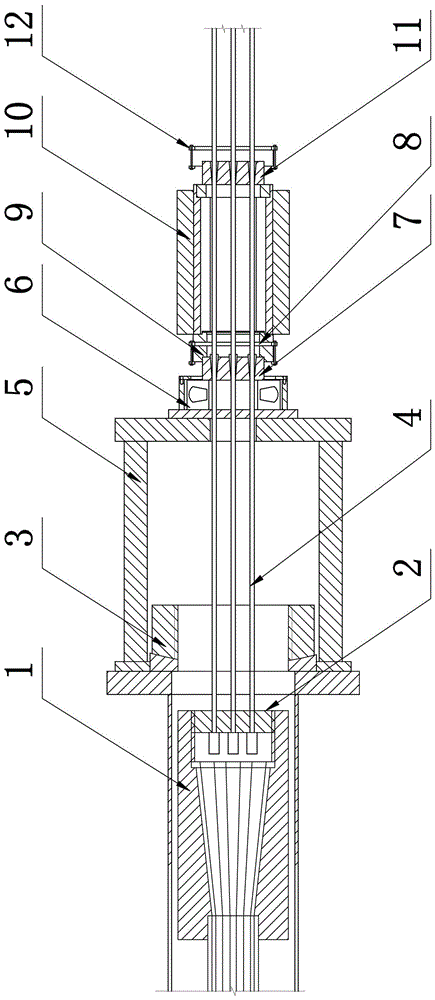

[0011] Such as figure 1 As shown, a stay cable tensioning device that eliminates back-twisting includes stay cable anchor cup 1, connector 2, nut 3, traction steel strand 4, tension support foot 5, and thrust roller bearing 6 , The first tool anchor 7, the first tool anchor limiting component 8, the tool anchor supporting foot 9, the hydraulic jack 10, the second tool anchor 11 and the second tool anchor limiting component 12.

[0012] The following is an embodiment of the present invention:

[0013] Lift the stay cable to the beam surface, connect the traction steel strand 4 to the stay cable anchor cup 1 through the connector 2. The traction steel strand 4 is made of seven steel wires with a nominal diameter of 15.2mm. The number of wires, the number of traction steel strands 4 and the size and technical conditions of the connector 2 need to be designed by technicians according to spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com