Patents

Literature

256results about "Shuttles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

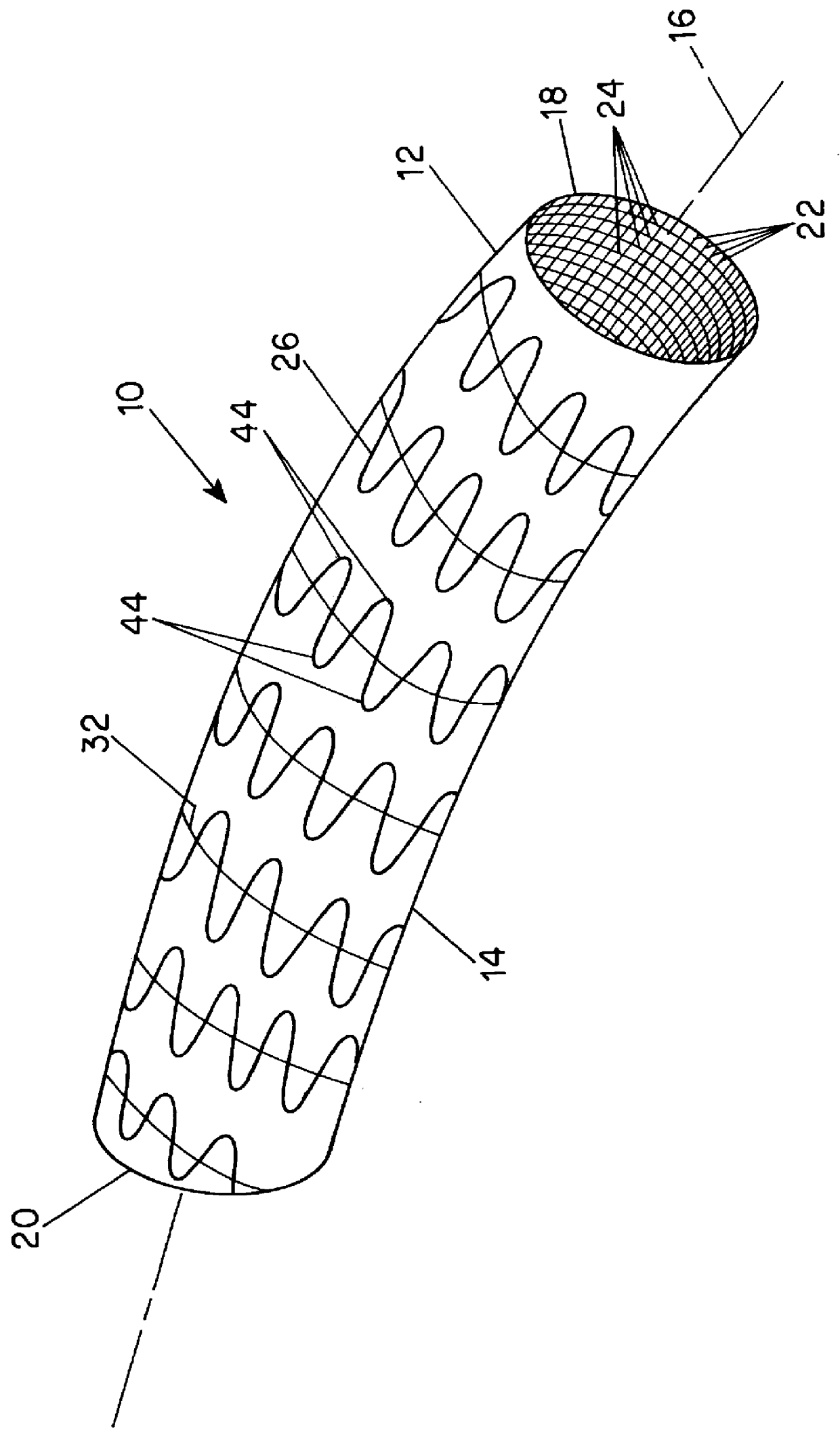

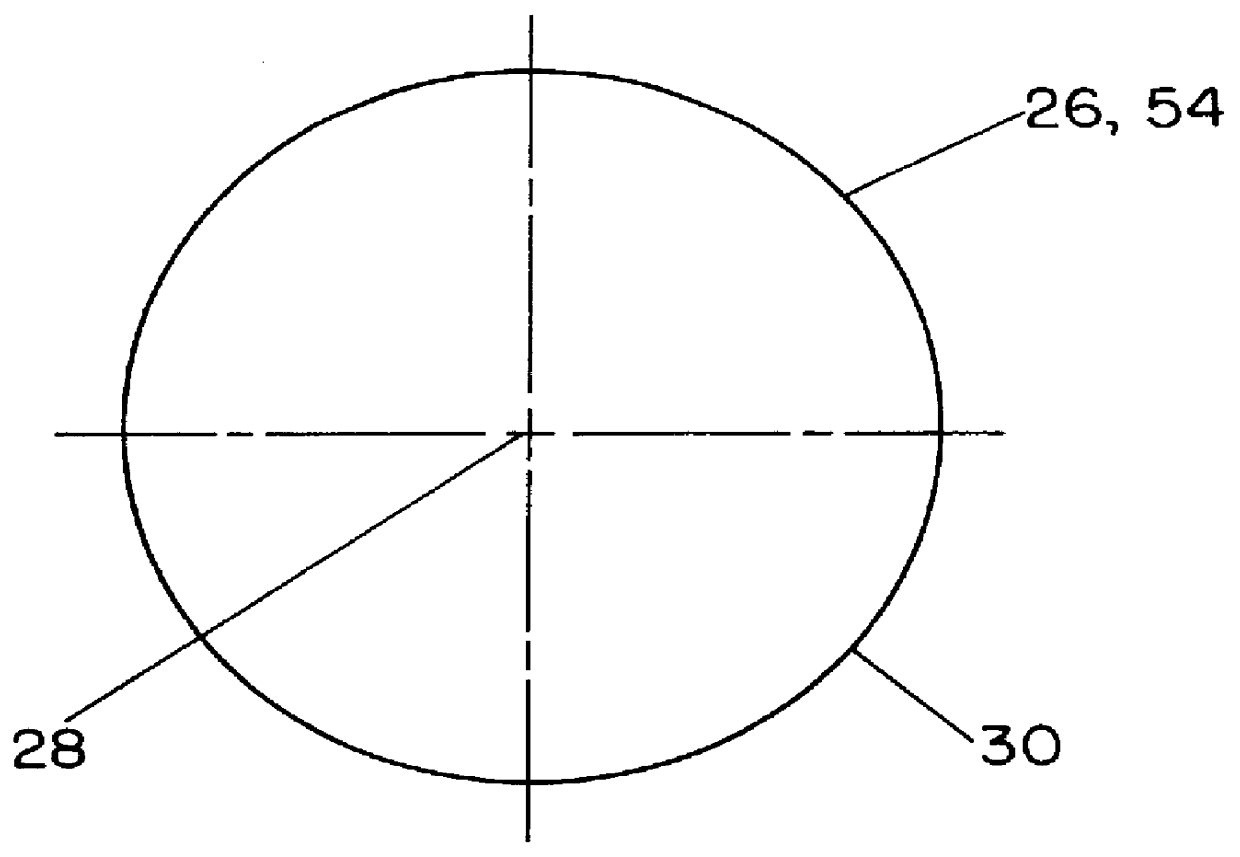

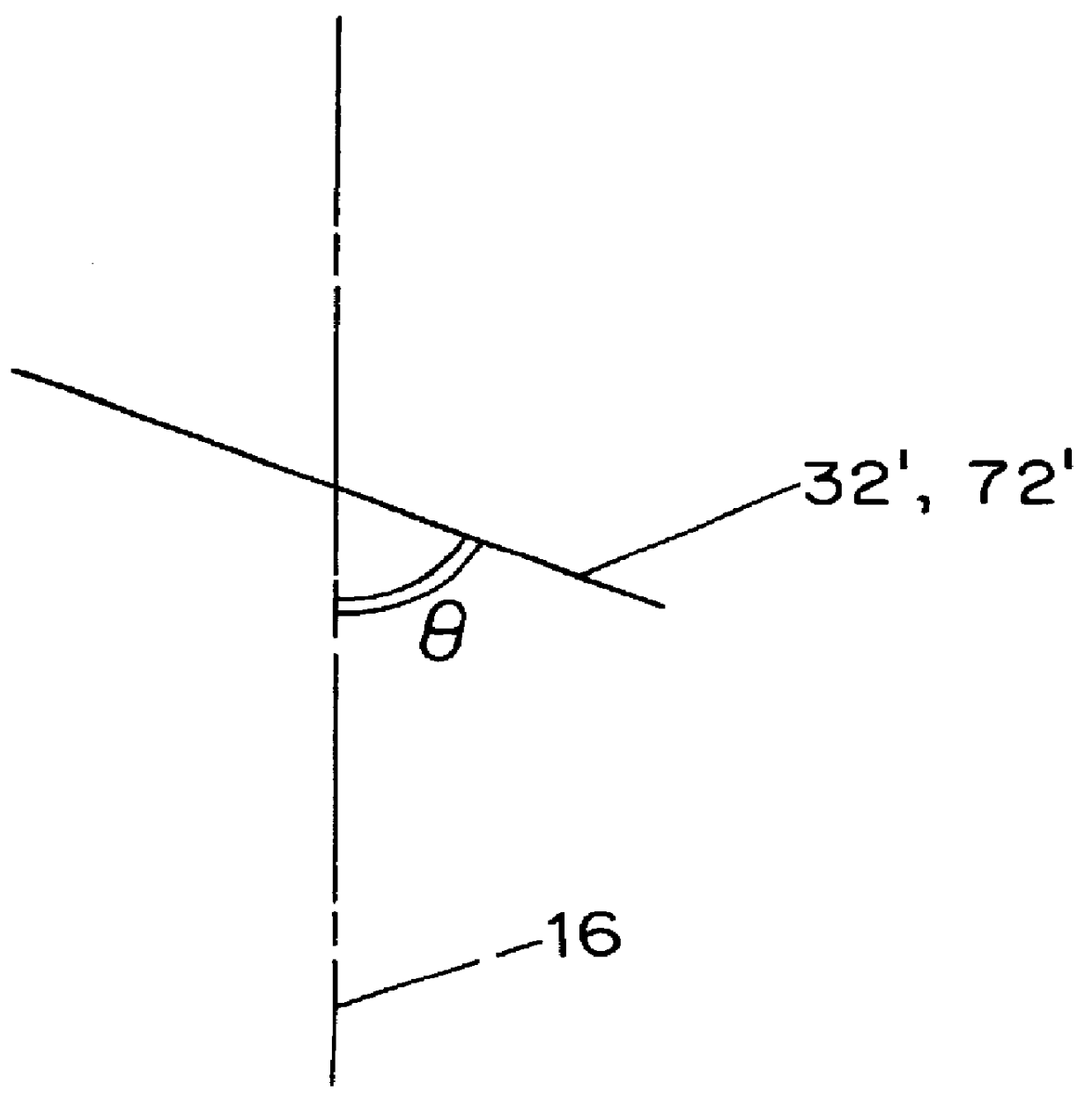

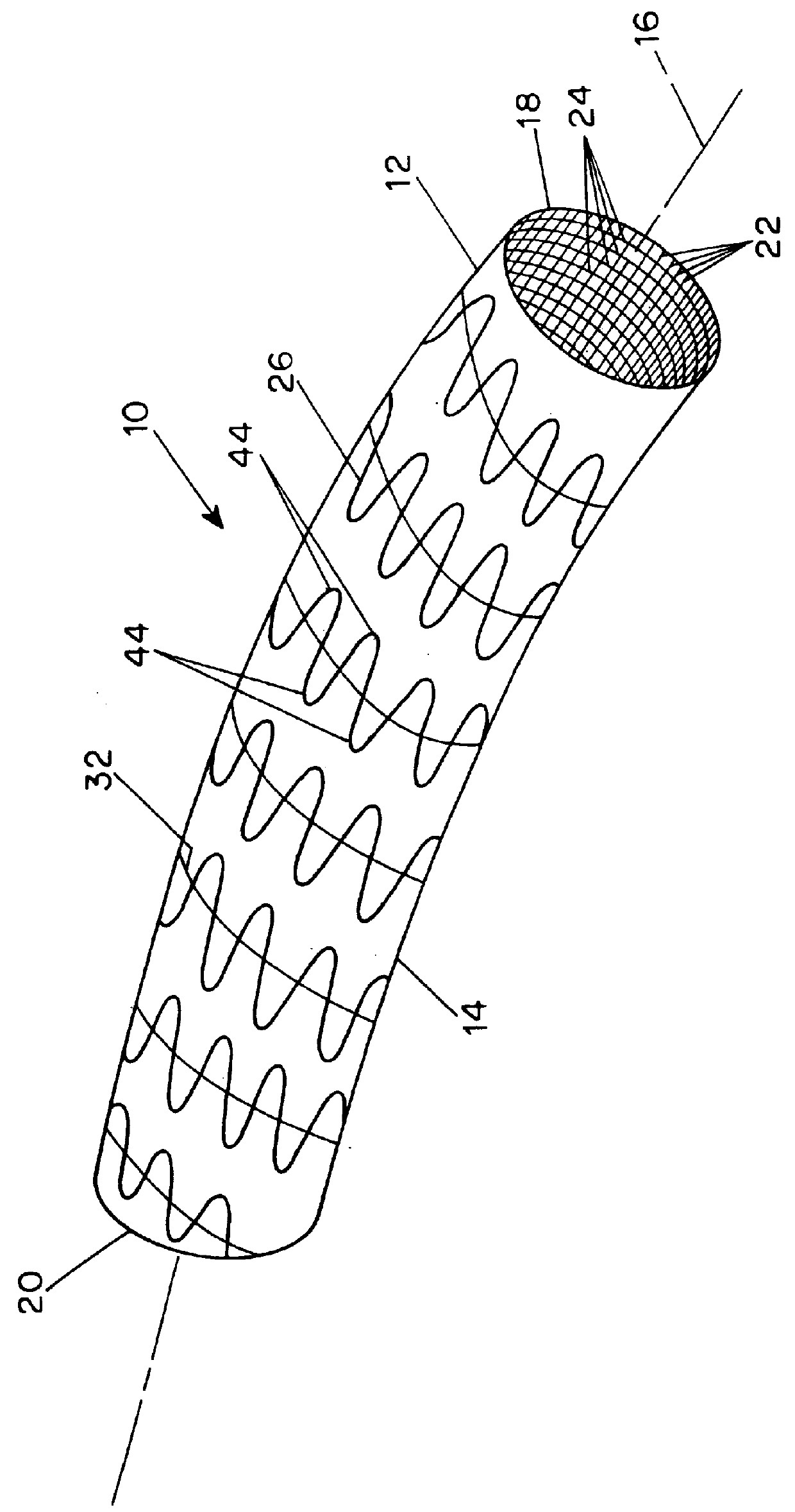

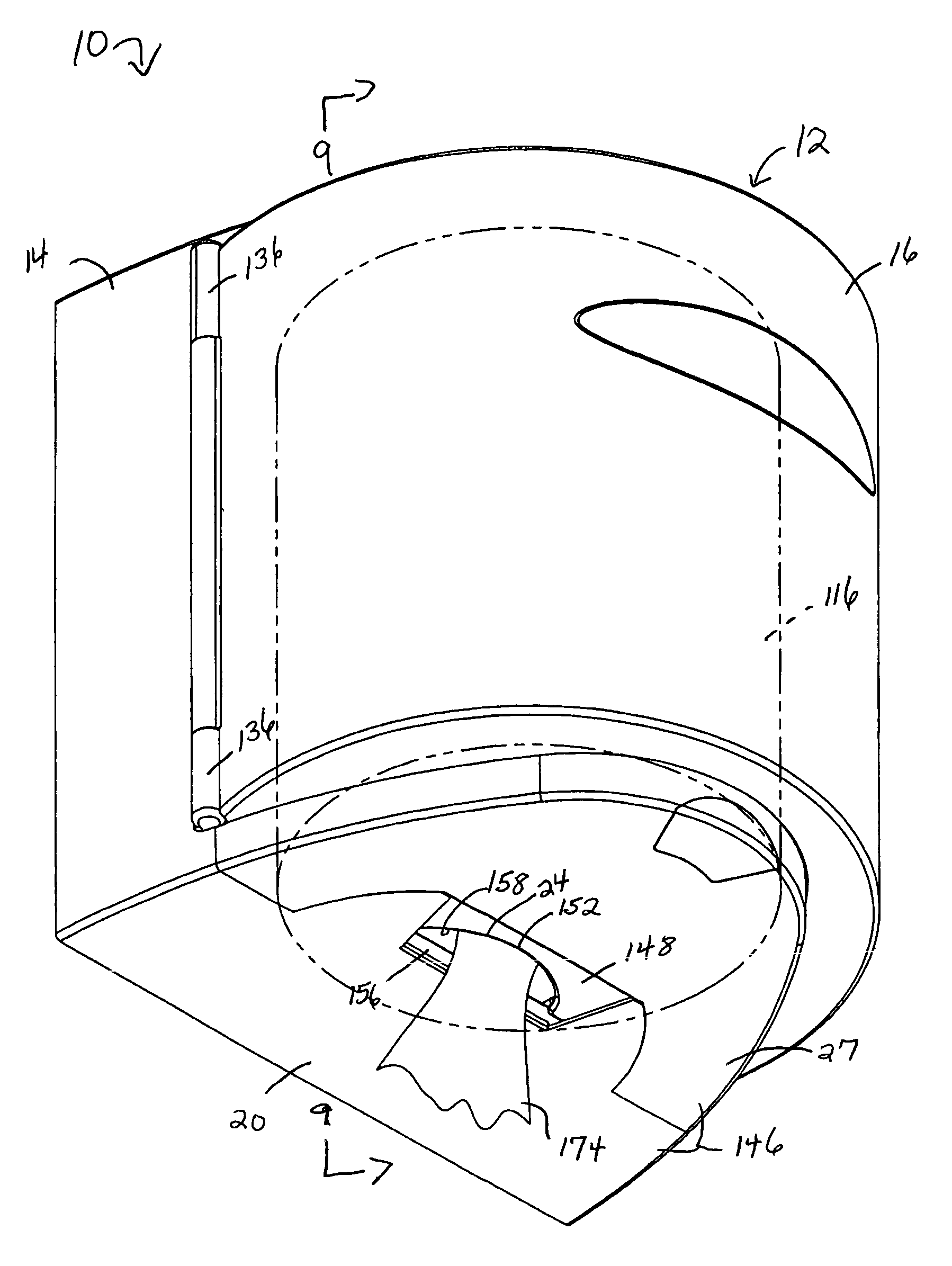

Woven stent/graft structure

A combined stent / graft structure for repair of a body tube in a living body. The structure includes a textile graft adapted to enhance fluid integrity of the body tube and a stent expandable between a first position permitting easy insertion of the stent into the body tube and a second position wherein the stent presses securely against the inside surface of the body tube. The stent includes a first elongate wire-shaped stent member with both a stent member global axis and a stent member local axis, and is integrally secured to the graft by at least one graft yarn of which the graft is formed. Substantial portions of the first stent member global axis form a non-orthogonal angle with the graft main portion axis when projected into a plane containing the graft main portion axis. A woven textile is also part of the invention as is a method of manufacturing such a woven textile, which can be used to produce stent / graft structures according to the invention.

Owner:SECANT MEDICAL

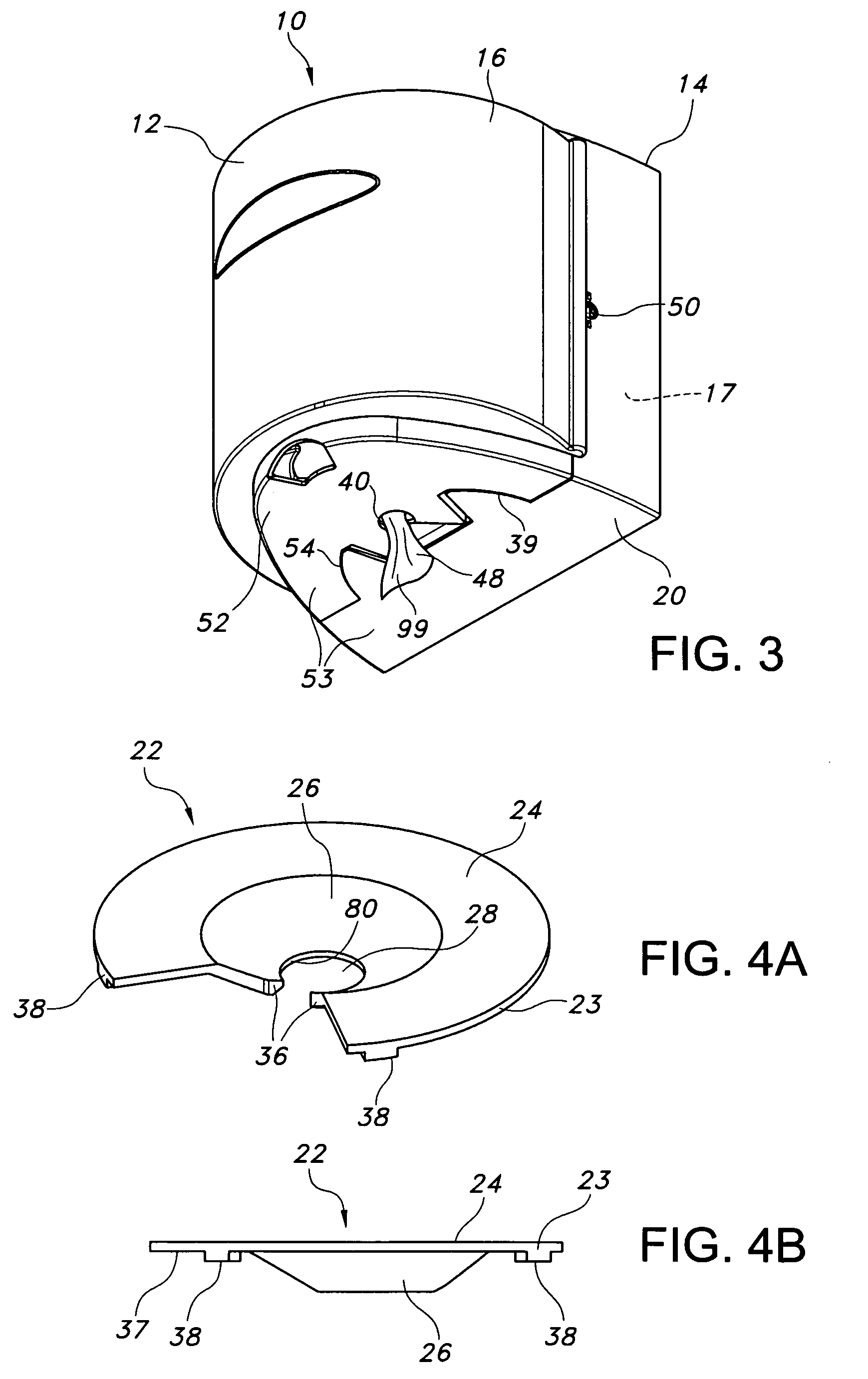

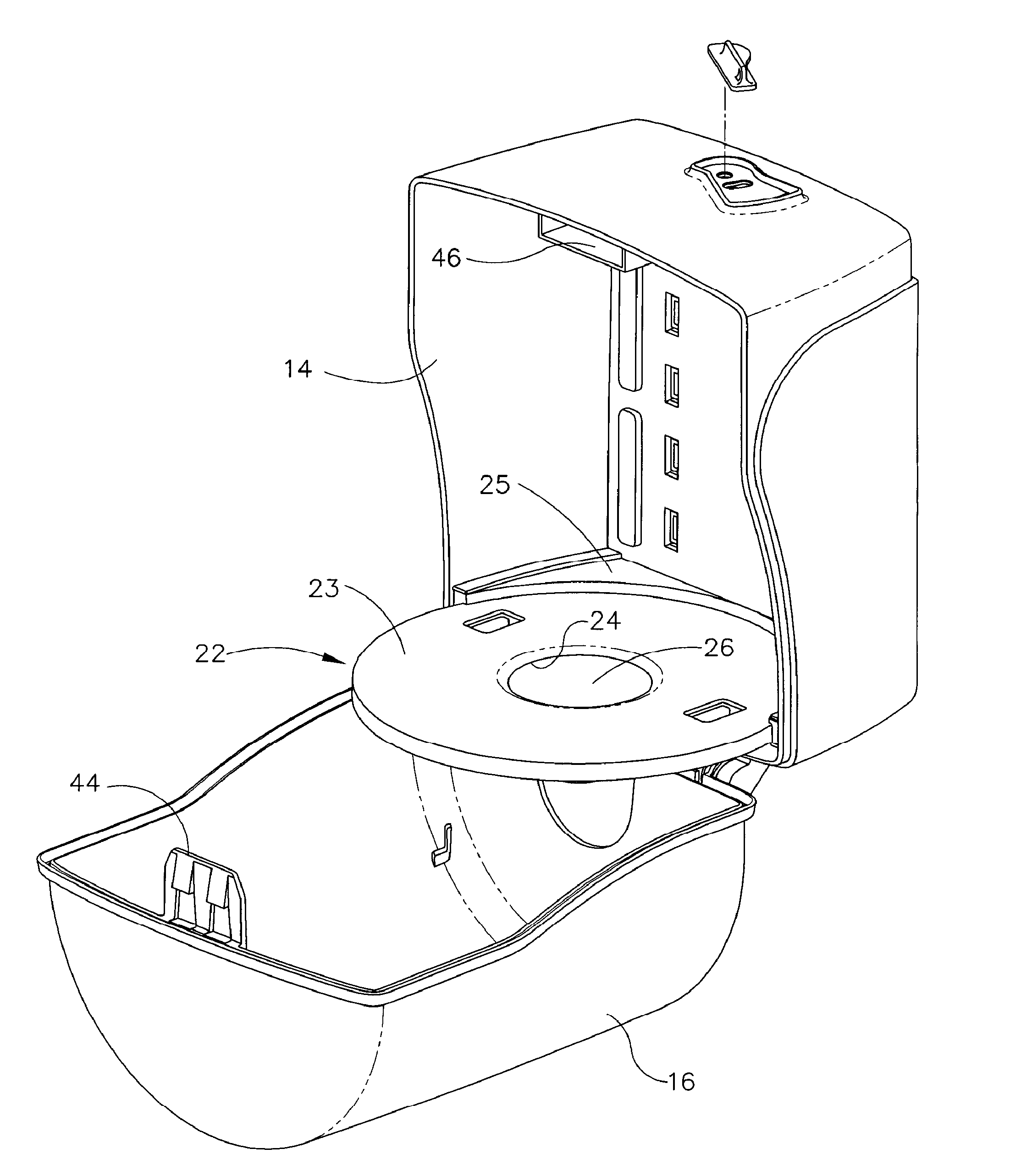

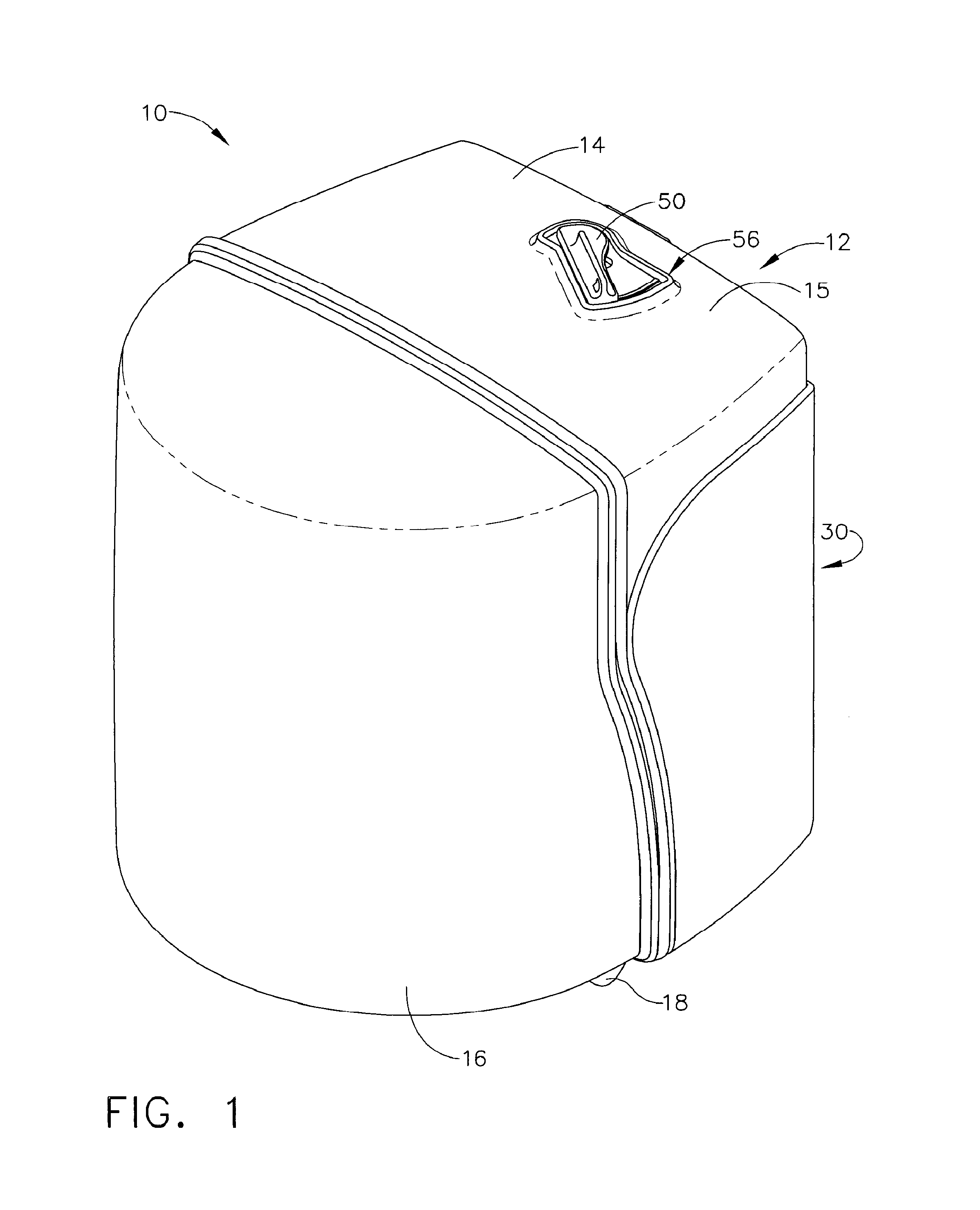

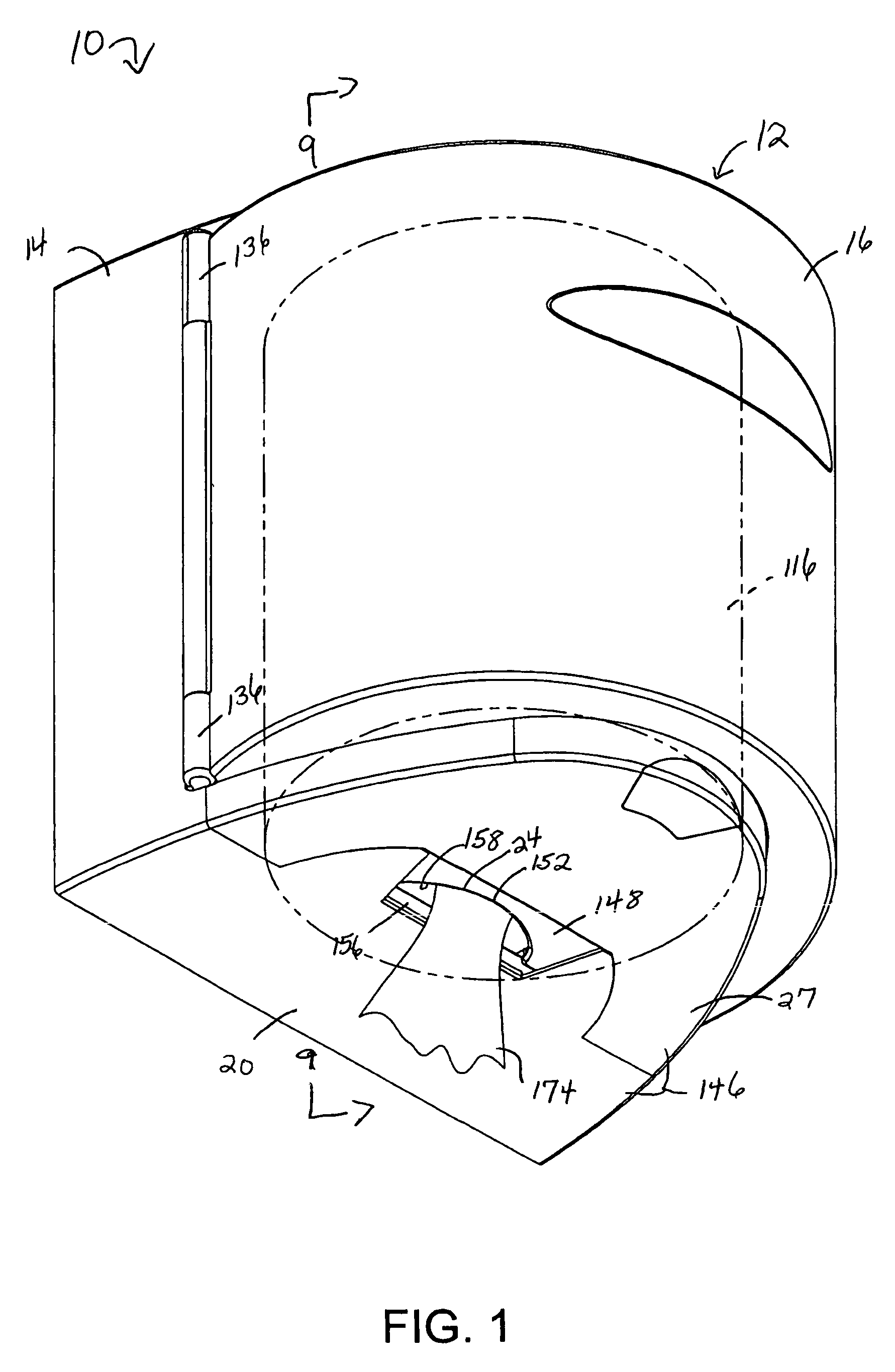

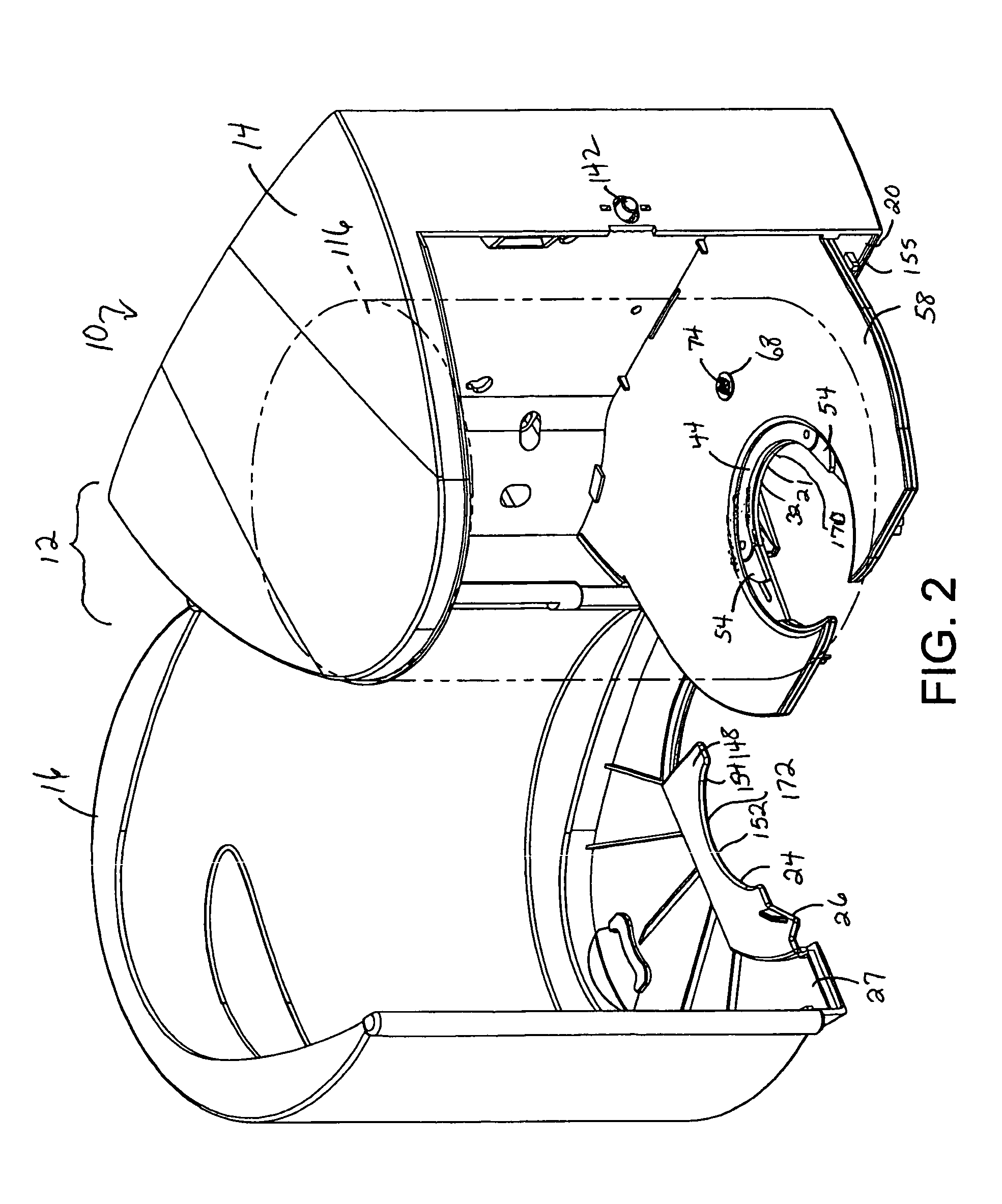

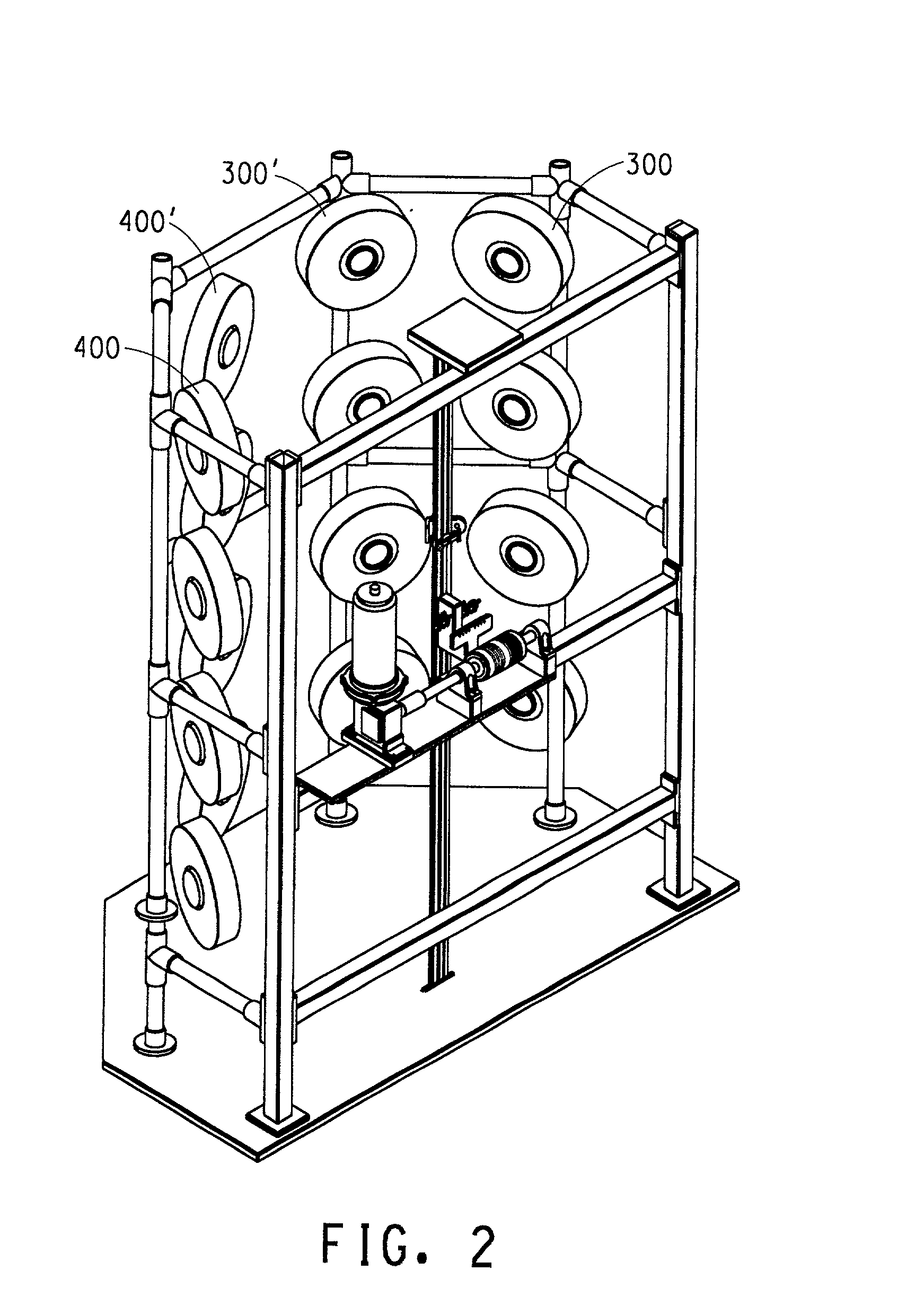

Dispenser for sheet material

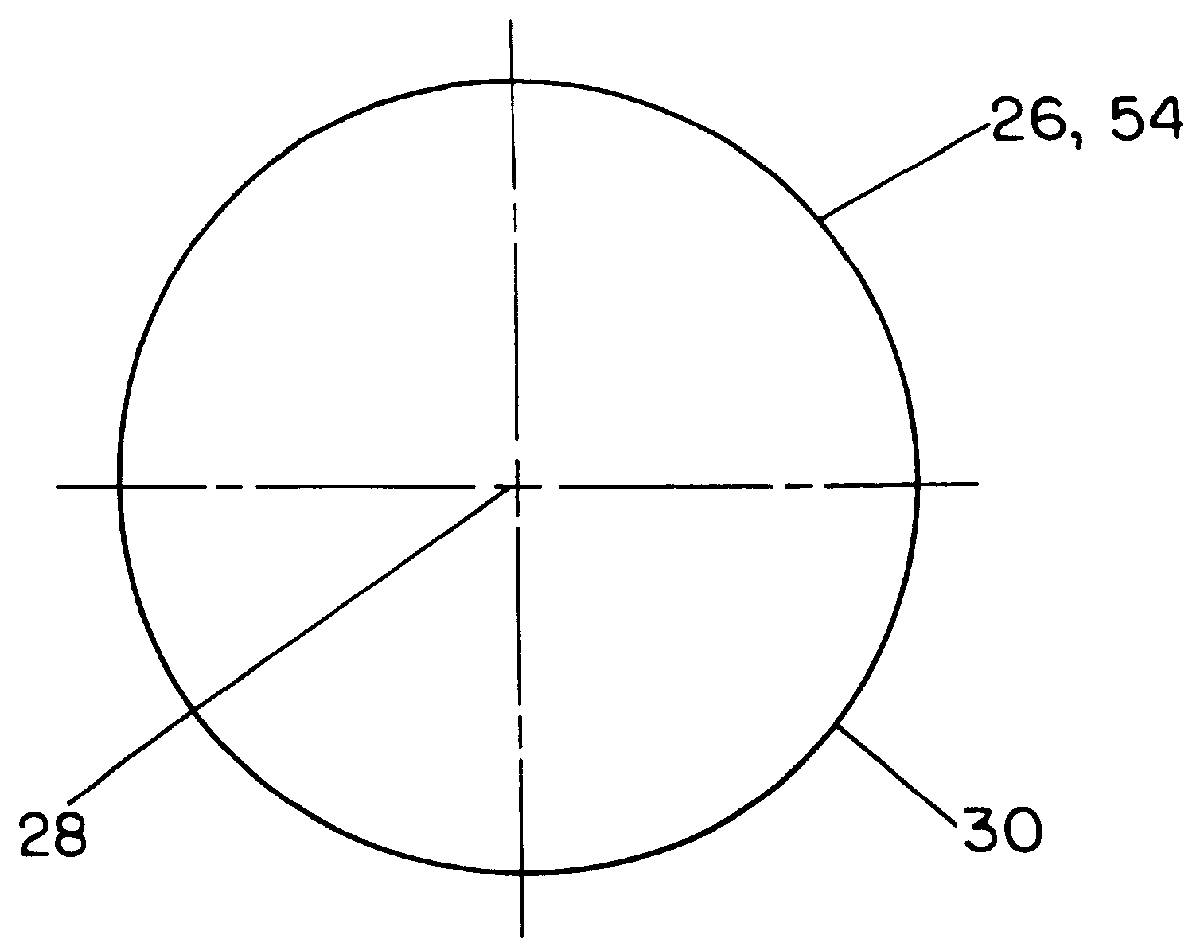

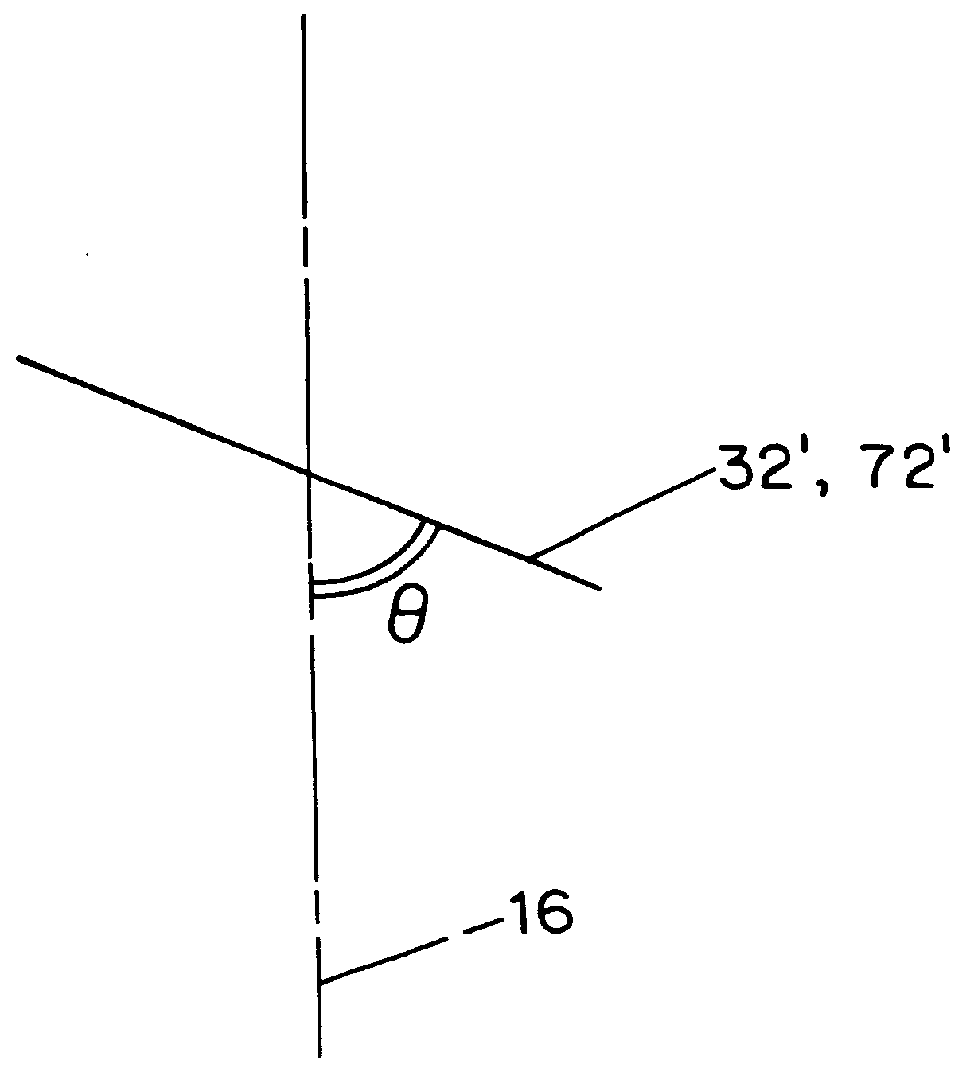

A dispenser adapted to dispense sheet material therefrom is provided and includes a housing including a base and a cover. The base includes a platform configured to support sheet material. The platform includes a dispensing disk and the platform has an outer perimeter intersected by a slot thereby providing an opening into the platform and dispensing disk. The housing is formed to include an exit port spaced apart from the platform and dispensing disk. The cover includes a rotatable disk having a plurality of user interchangeable dispensing slots of differing diameters intersecting an outer periphery of the rotatable disk. Sheet material positioned on the platform flows through the dispensing opening of the dispensing disk and through a selected one of the plurality of dispensing slots. The selected one of the plurality of dispensing slots is aligned with the exit port. The sheet material disposed in the dispenser flows between the opening in the dispensing disk, through at least one space, through the selected one of the plurality of dispensing slots and through the exit port to be dispensed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

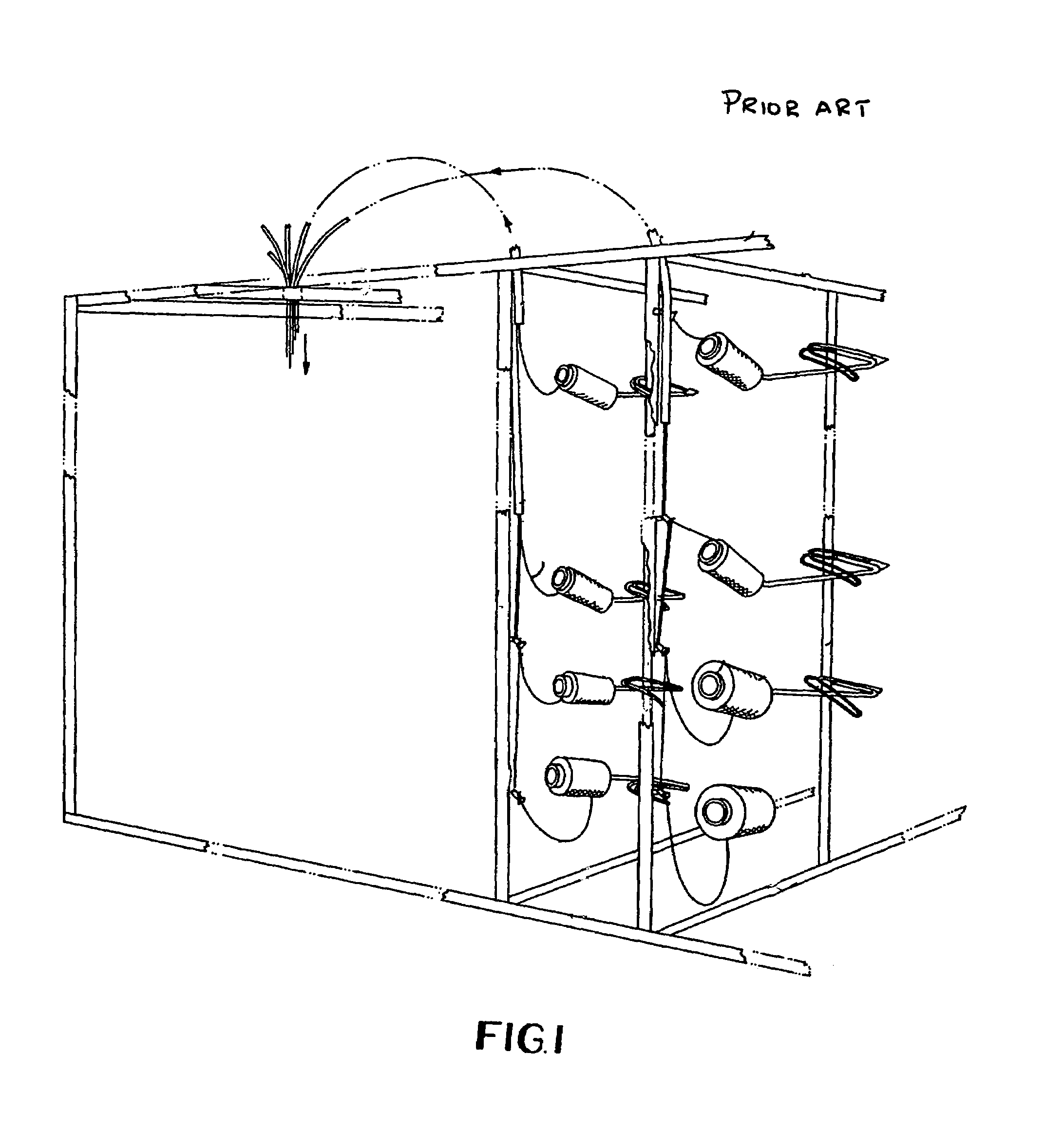

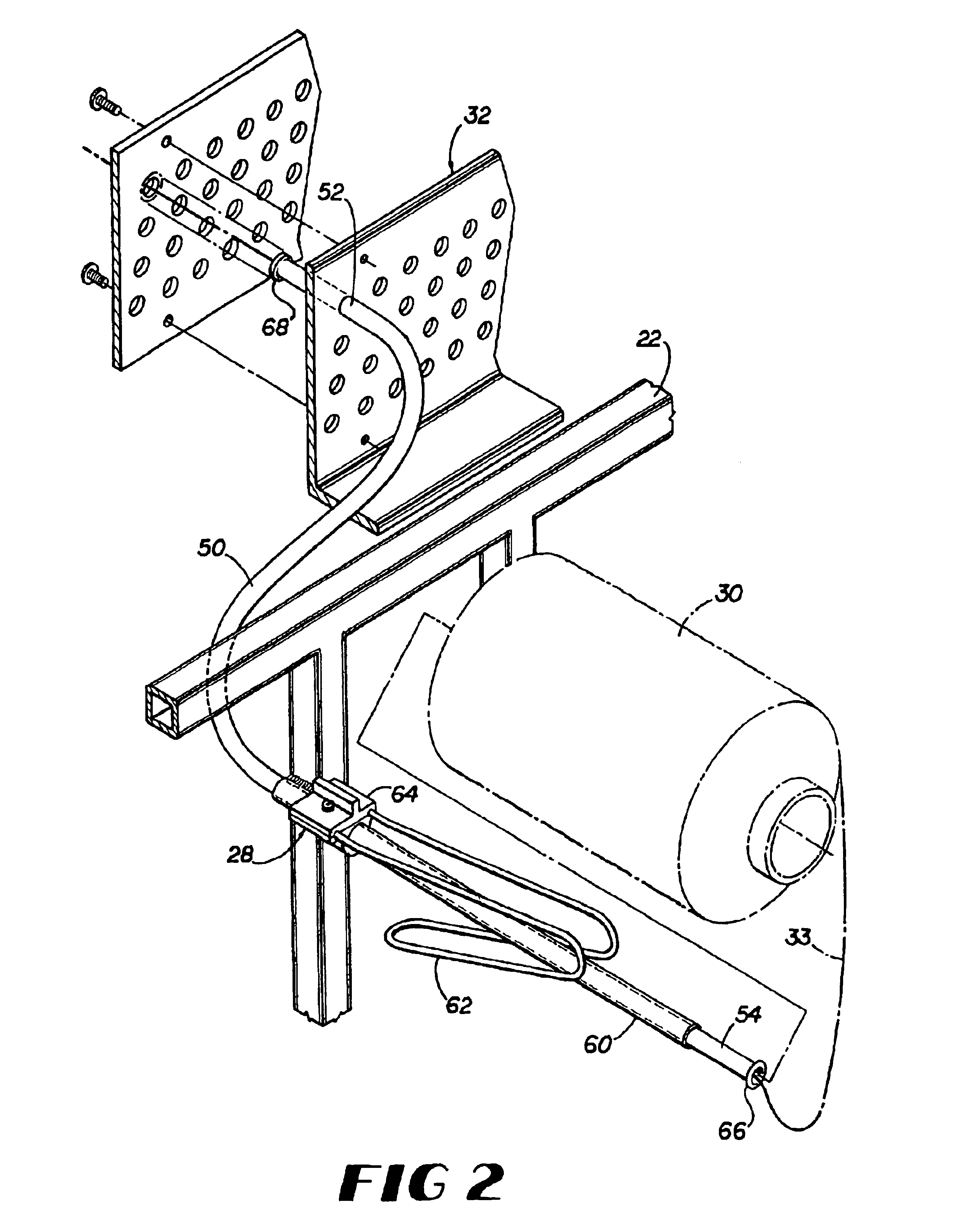

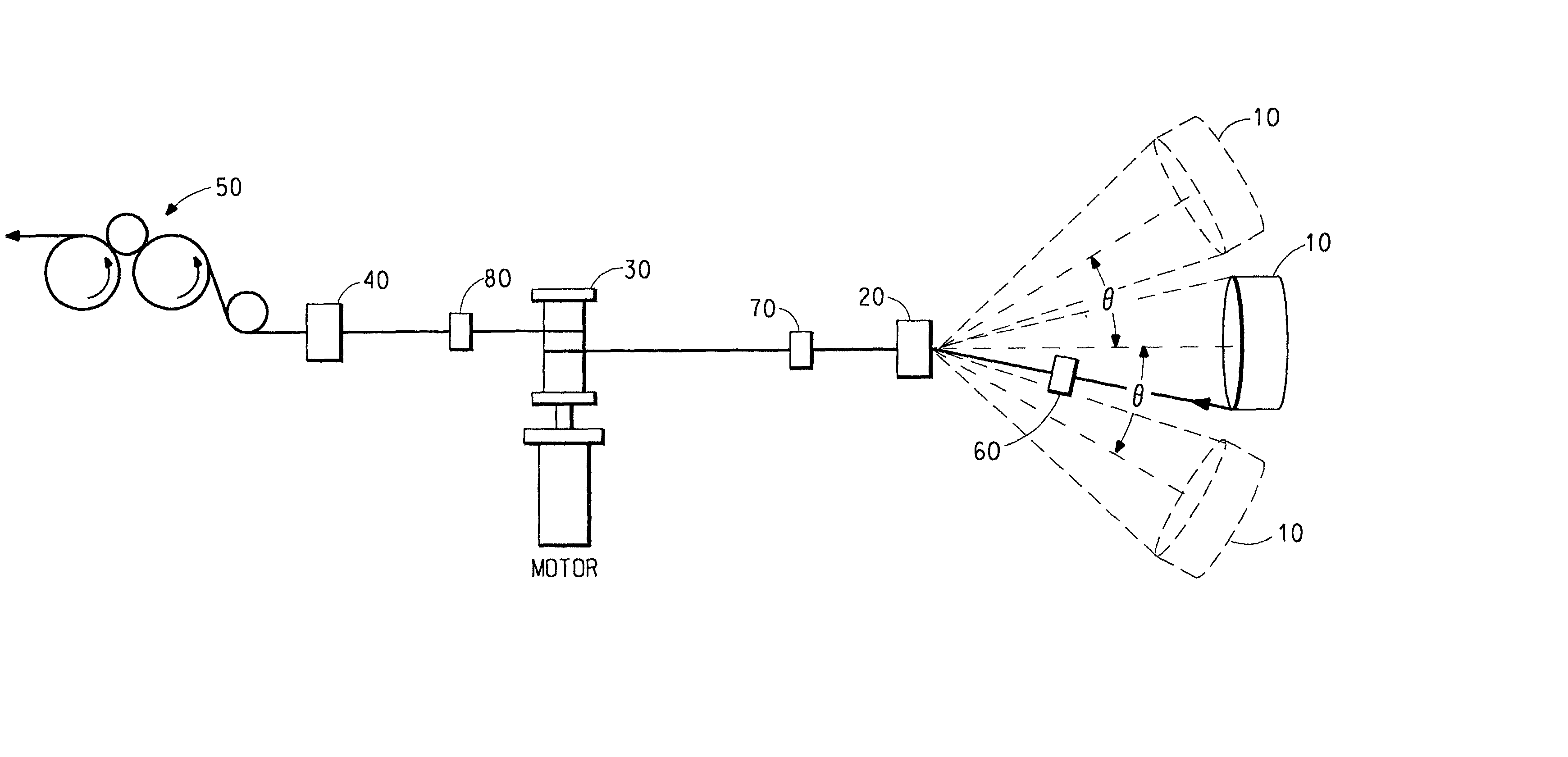

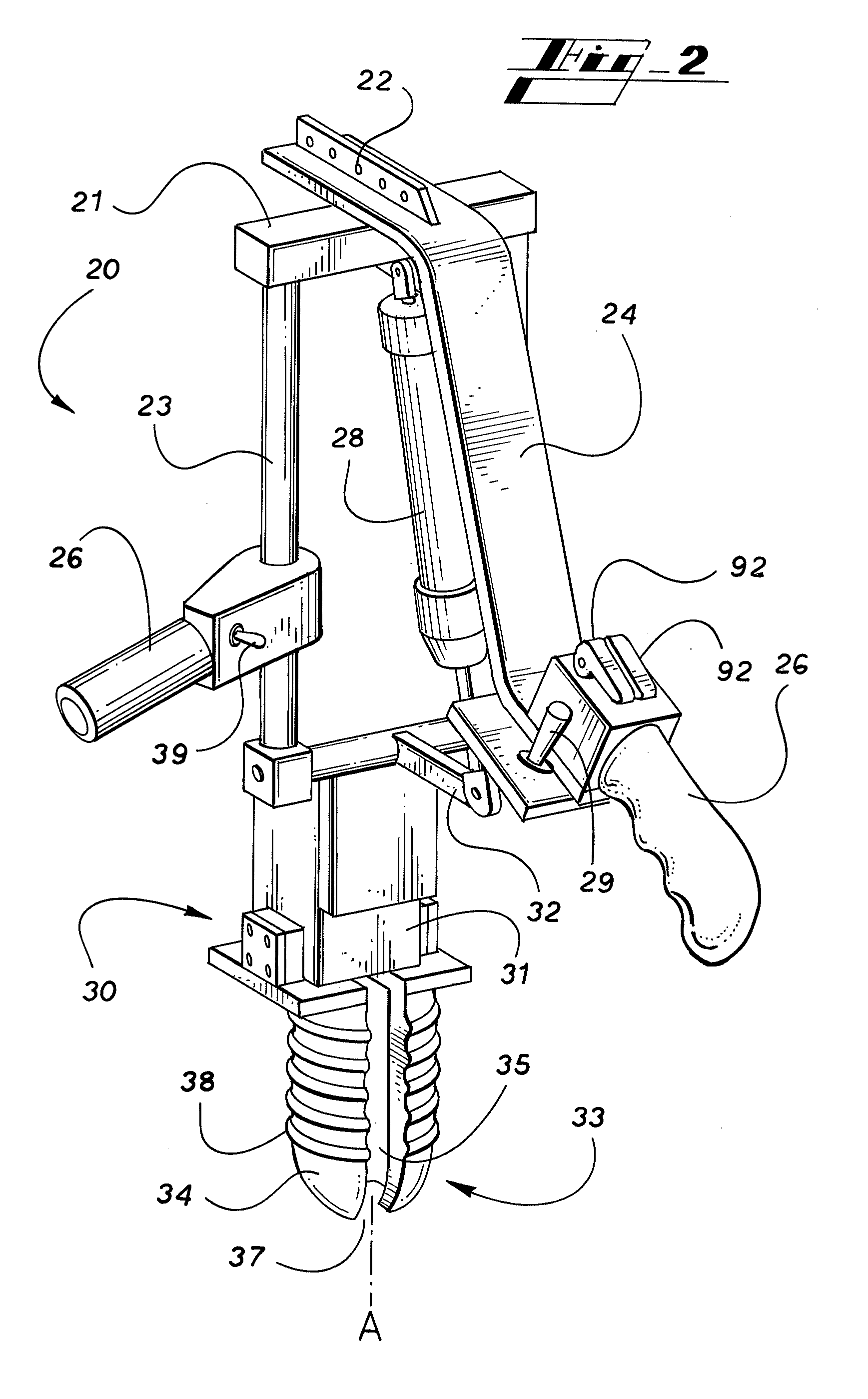

Compact single mandrel creel for over end take-off thread delivery

InactiveUS20070084960A1Fast and reliable methodIncrease the number ofLoomsFilament handlingFiberSmall footprint

The present invention compact creel using the OETO method that accommodates an increased number of packages in a relatively small footprint while providing a straight in-line delivery path in which fiber bends and changes in direction are minimized. In addition, the present invention is a system, apparatus and method for tension control in a fiber feeding system that provides a fast and reliable method for feeding high tack elastomeric thread or fiber from a package to a manufacturing process. Furthermore, the present invention provides a method and apparatus for changing packages on a creel without interrupting the manufacturing process. In particular, the compact creel of the present invention provides for continuous operation of unwinding and fiber delivery by allowing a standby package to be loaded on the same mandrel as an active package that is presently being unwound.

Owner:INVISTA NORTH AMERICA R L

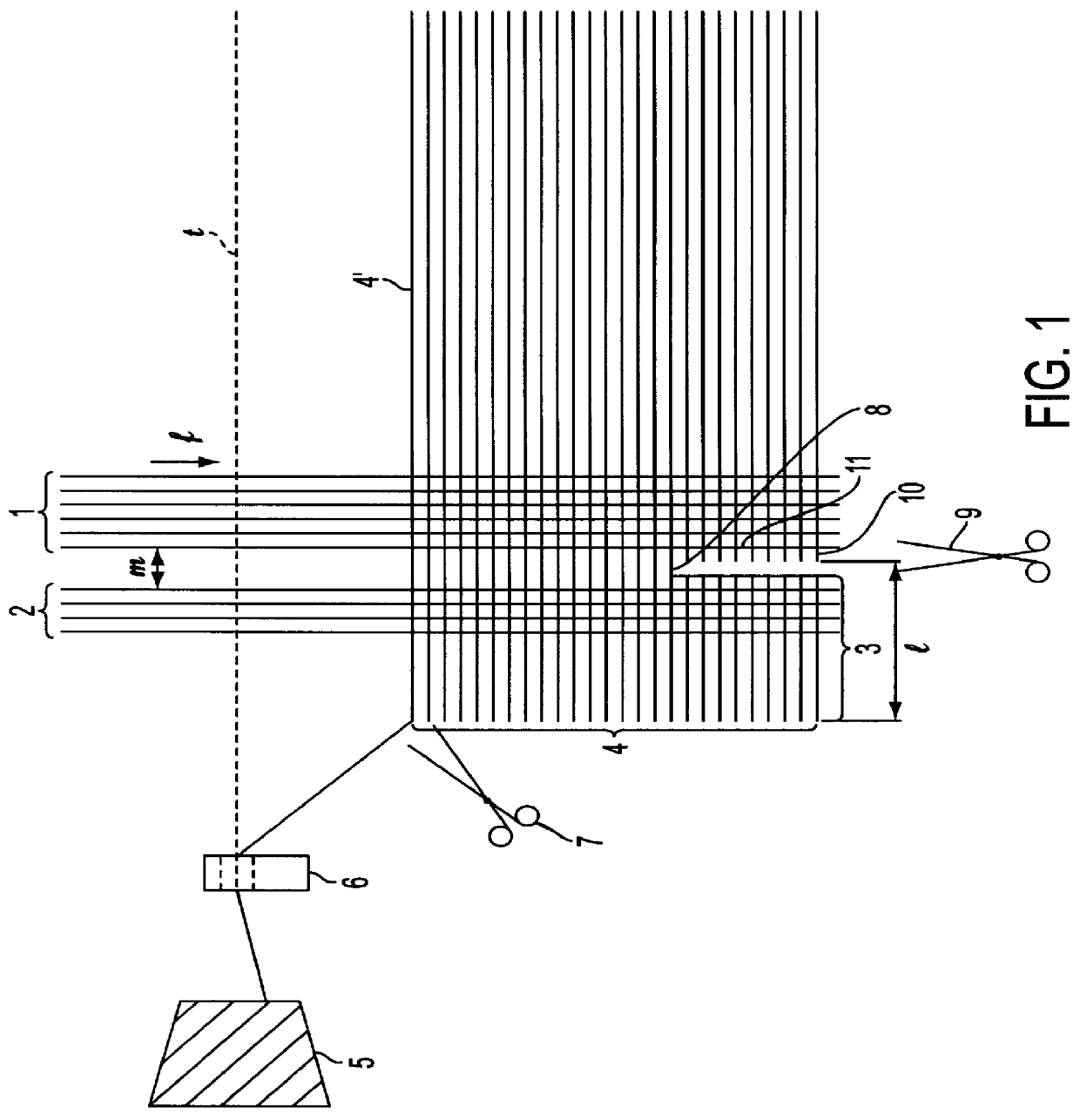

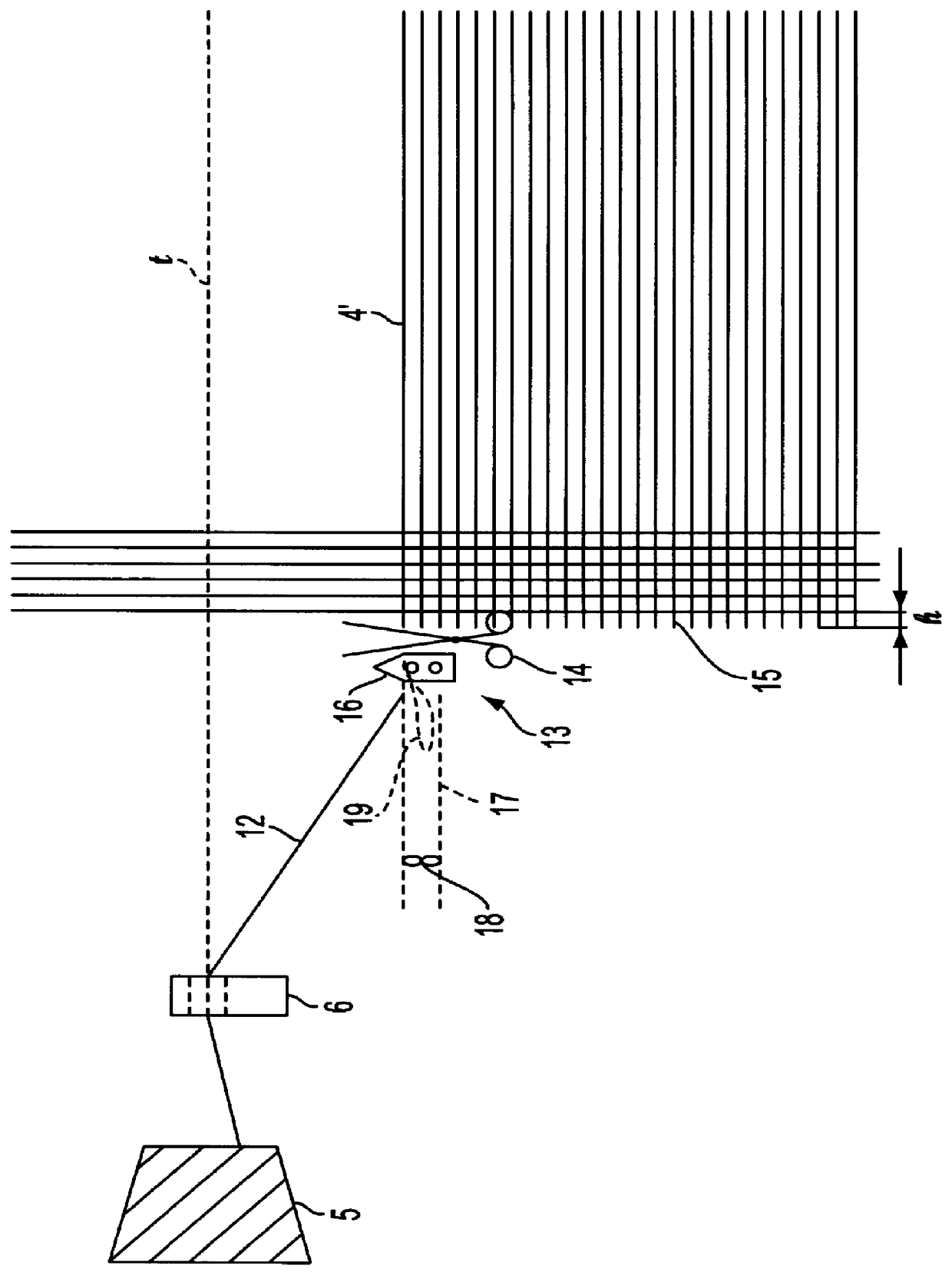

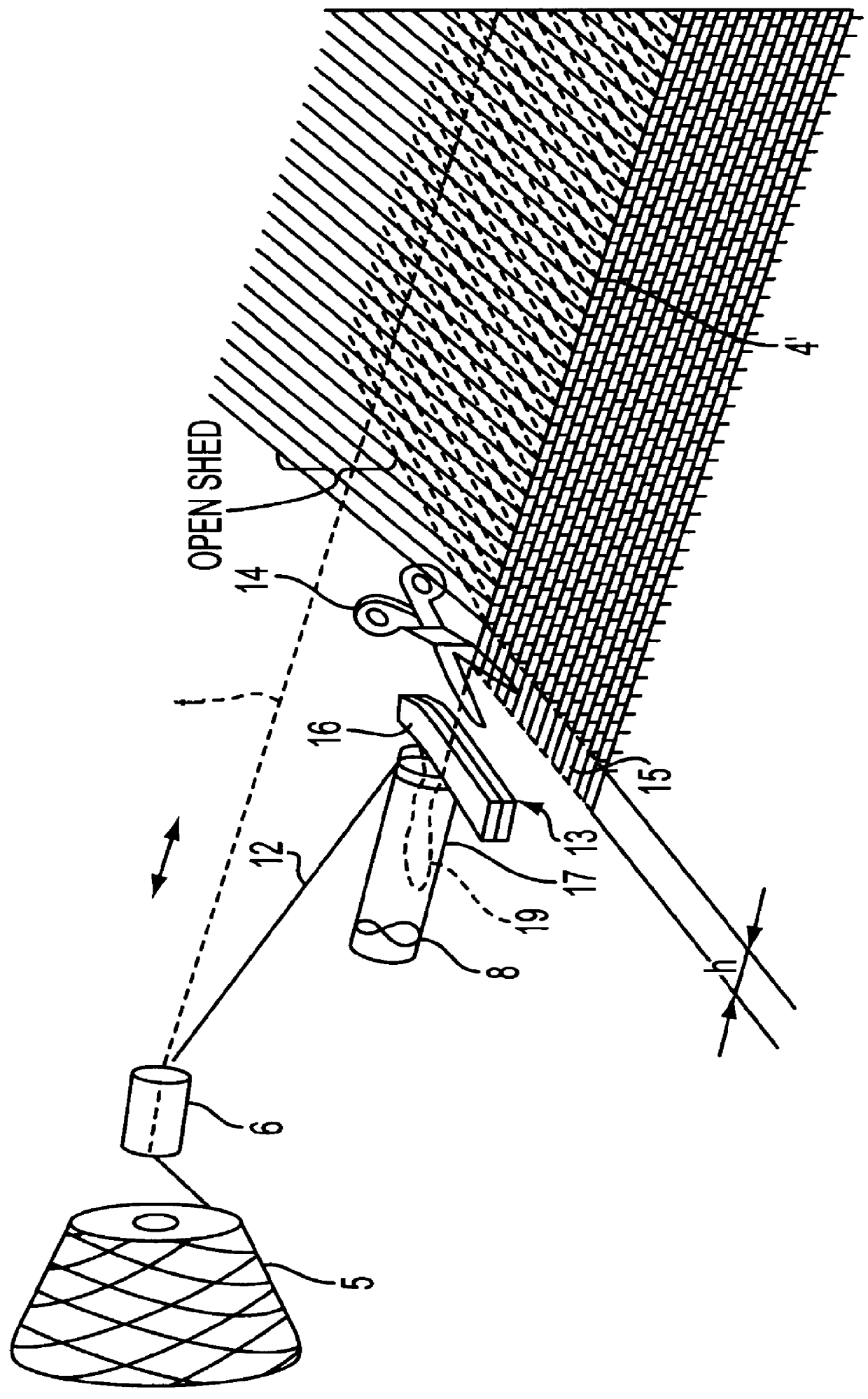

Method for cutting a selvedge of a weft insertion side of a rapier loom

A method for cutting a selvedge on a weft thread insertion side of a rapier loom equipped with a weft thread supply by creating a free space of warp threads arranged separately from a main warp body. The weft thread is inserted through an open shed of the warp body. The inserted weft thread is beaten, and inserted into a holding device which subjects it tension. The wet thread is cut after being beaten and while subject to tension. The end of the weft thread is inserted it into the open shed of the warp after the cutting.

Owner:ISOLA FABRICS SRL

Multiple yarn delivery to a single needle method and apparatus

A textile machine receives a plurality of yarn strands from a yarn supply. A header receives the yarn strands where multiple strands are combined for joint direction to the textile machine. Beams with multiple yarn strands wrapped thereon preferably function as the yarn supply and the header may direct through yarn tubes to a staging header for use by the textile machine. The textile machine is preferably a tufting machine and multiple yarn strands are received by at least one needle of the tufting machine.

Owner:MILLIKEN & CO

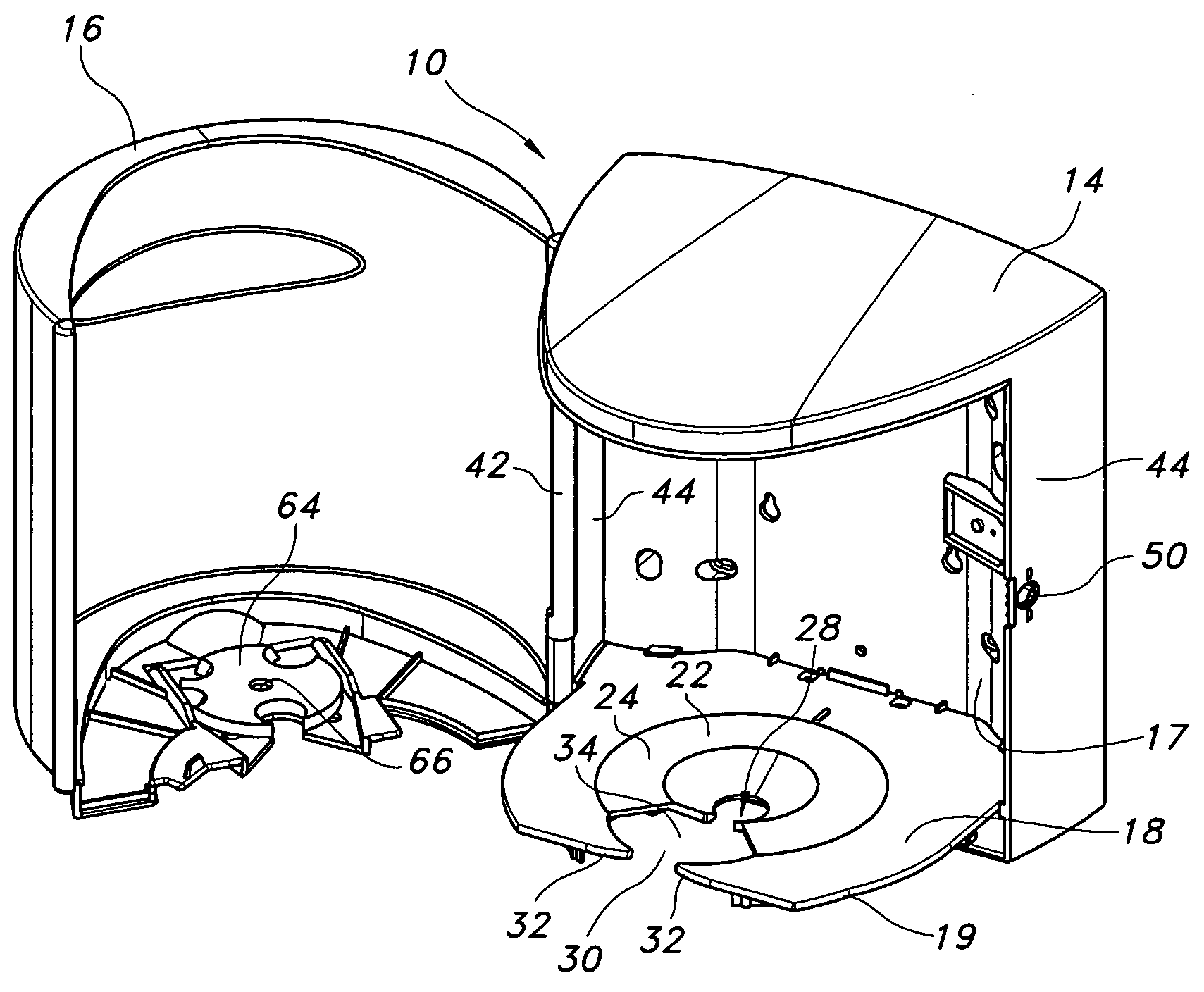

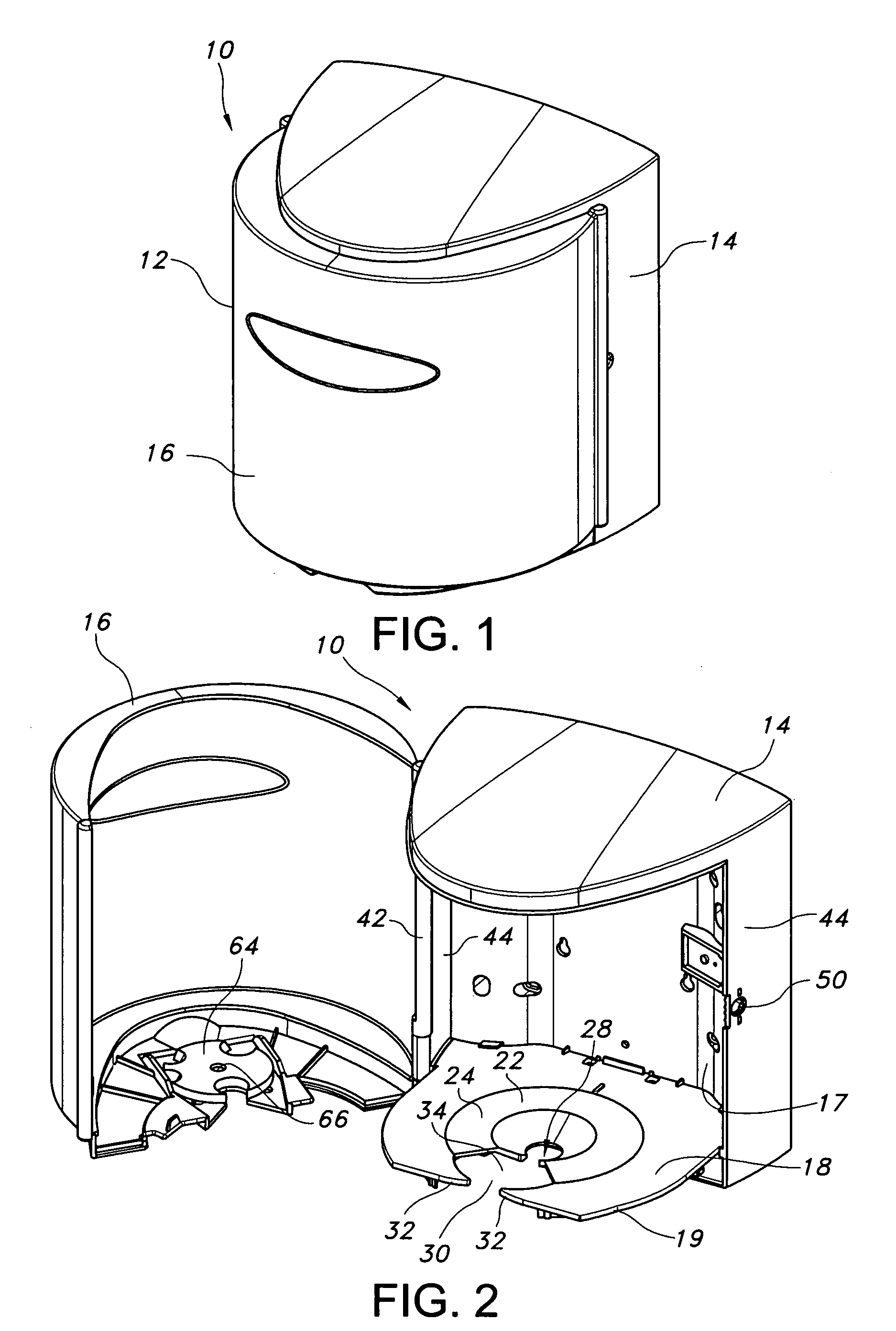

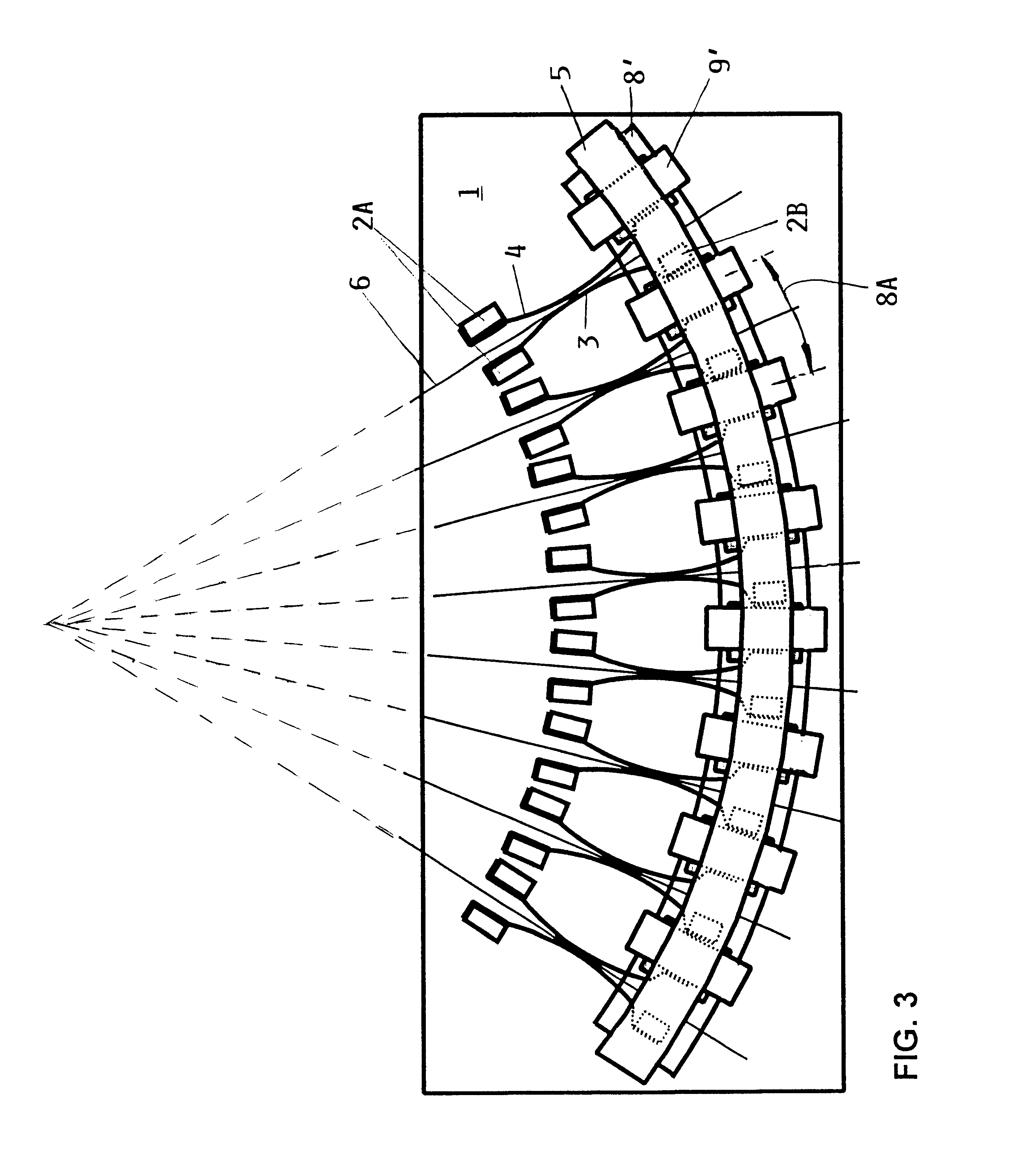

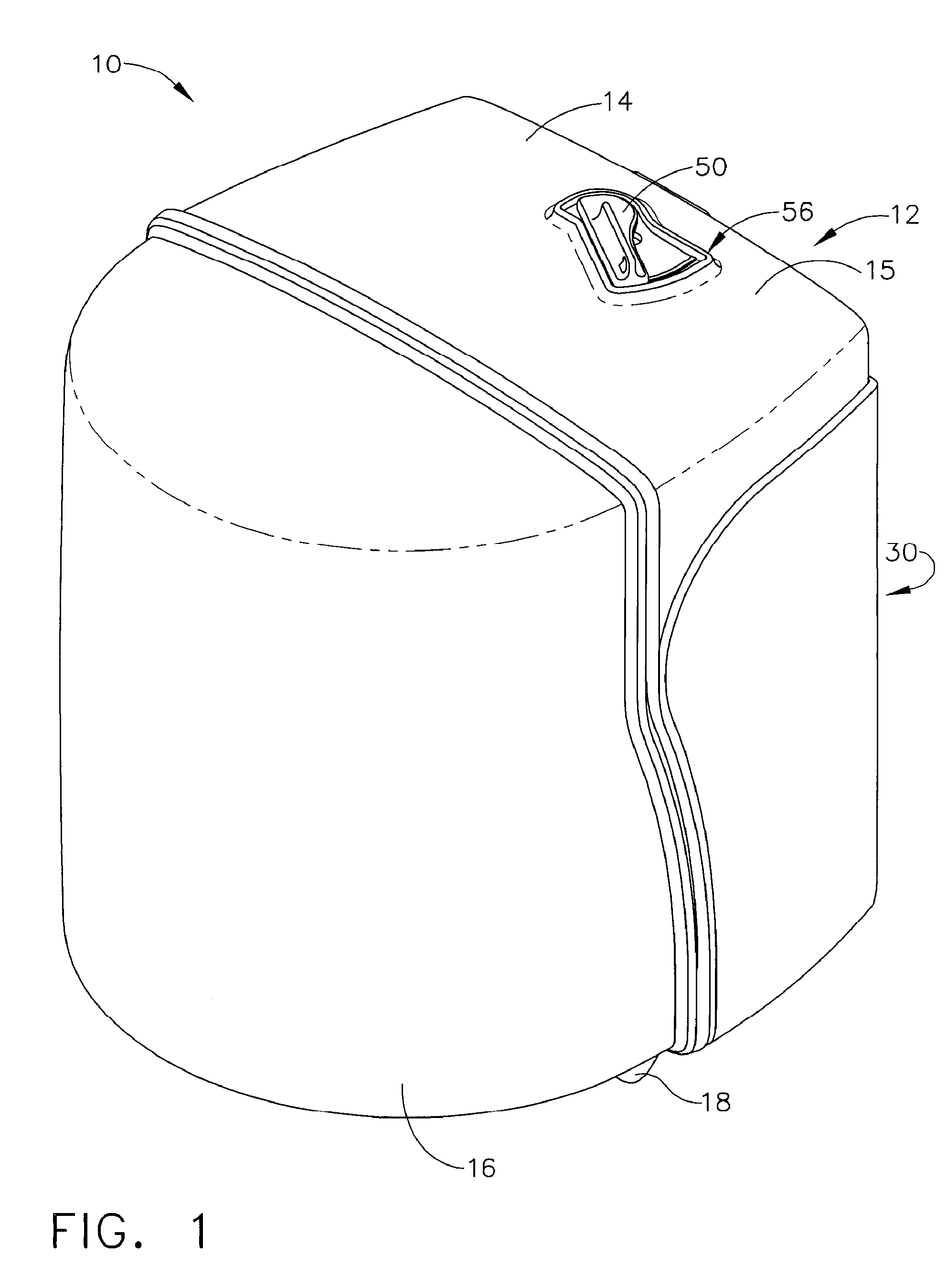

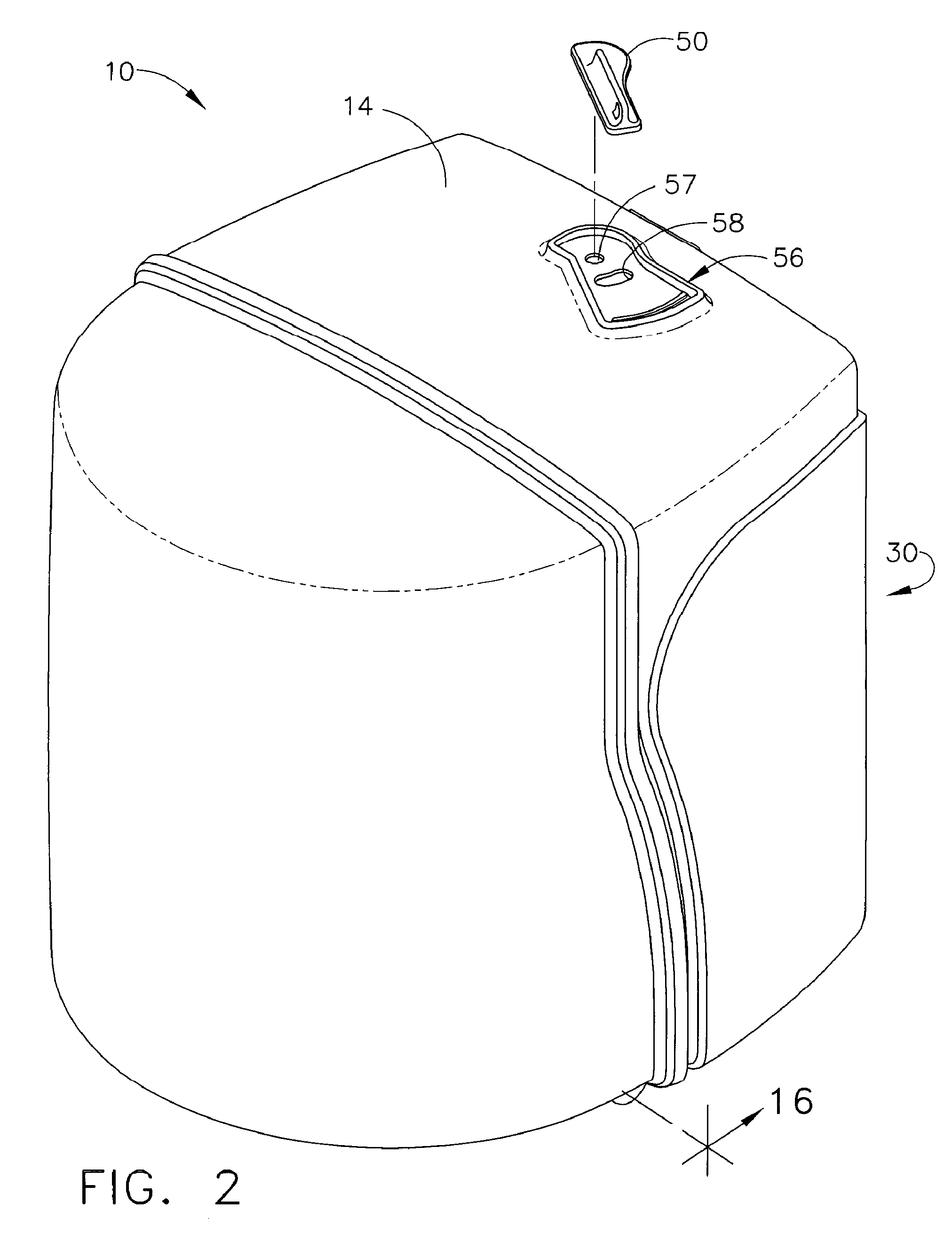

Center-pull paper towel dispenser

A center-pull dispenser for dispensing paper towels from a continuous roll, wherein each individual towel is separated from an adjoining towel by a plurality of perforations. The dispenser comprises a housing having a housing back and a detachable front cover hingedly connected thereto at the lower periphery of said housing back and front cover for opening and closing the housing, a paper support tray removably connected to a lower portion of the housing back and having a centrally located dispensing nozzle, an opening in the lower periphery of the housing through which the towels are dispensed, a detachable wall-mounting member for removably mounting the housing back to a wall, and a locking member for releasably locking the front cover to the housing back and the housing back to the wall-mounting member. In one embodiment, the housing cannot be removed from the wall-mounting member without first unlocking the locking member, and the housing and the housing back are removable from the wall without removing the wall-mounting member from the wall. In another embodiment, the paper support tray comprises locking arms for releasably locking first hinge elements on the lower periphery of said front cover against second hinge elements on the lower periphery of said housing back.

Owner:CINTAS CORP SERVICES INC

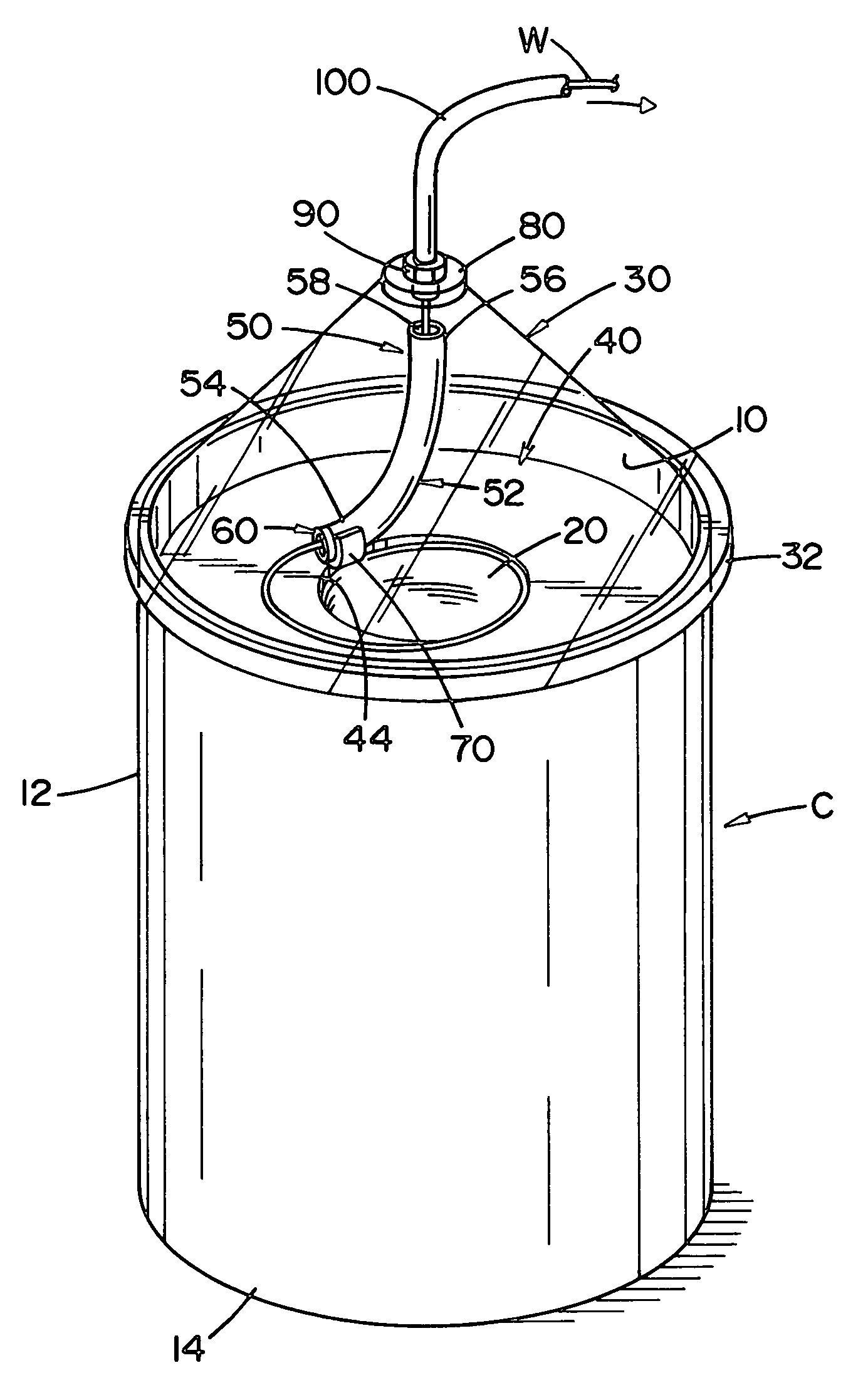

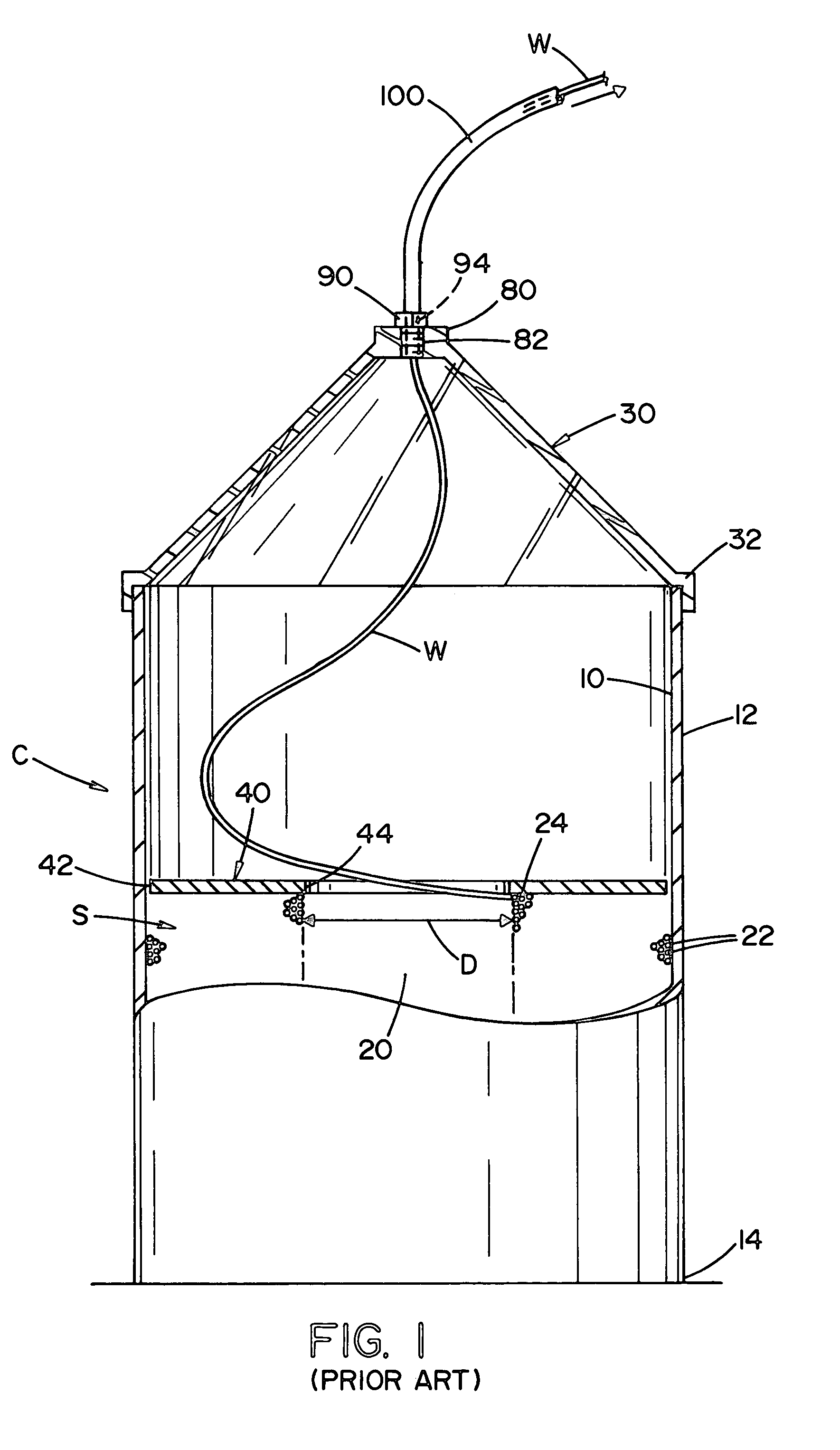

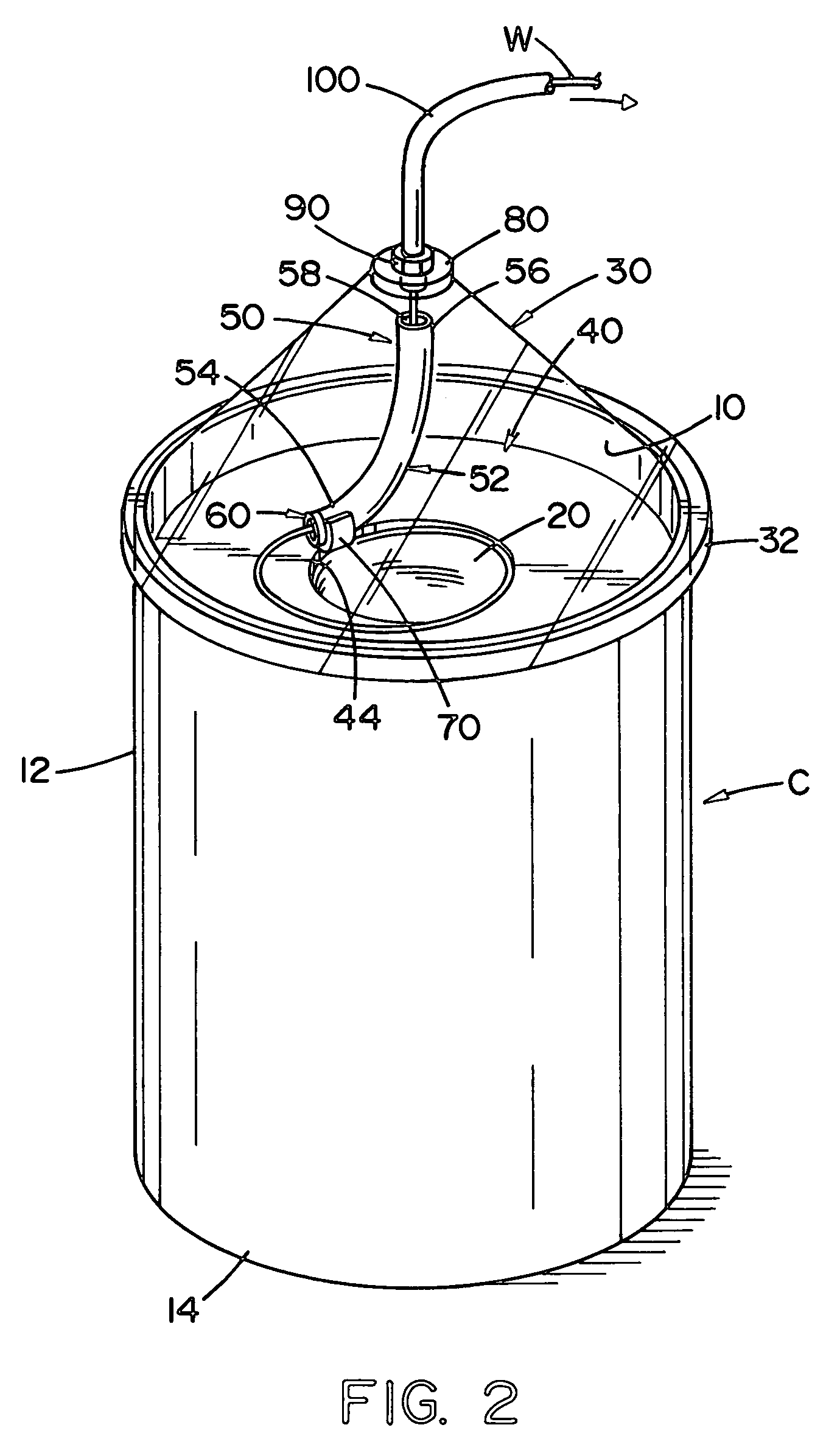

Floating liner

A floating liner for a container of welding wire which floating liner includes a tube having two ends and a passageway extending between the two ends. The floating liner is unsupported between the top of the container and the retaining ring. The floating liner is designed to provide structural support to the wire and added stiffness or rigidity to the wire to inhibit buckling of the wire, knot formation in the wire that can form between the retaining ring and the top of the container. The floating liner has a weight profile that causes one end of the tube to at least partially float above the top surface of a layer of welding wire or retaining ring in the container as the welding wire is paid out of the container.

Owner:LINCOLN GLOBAL INC

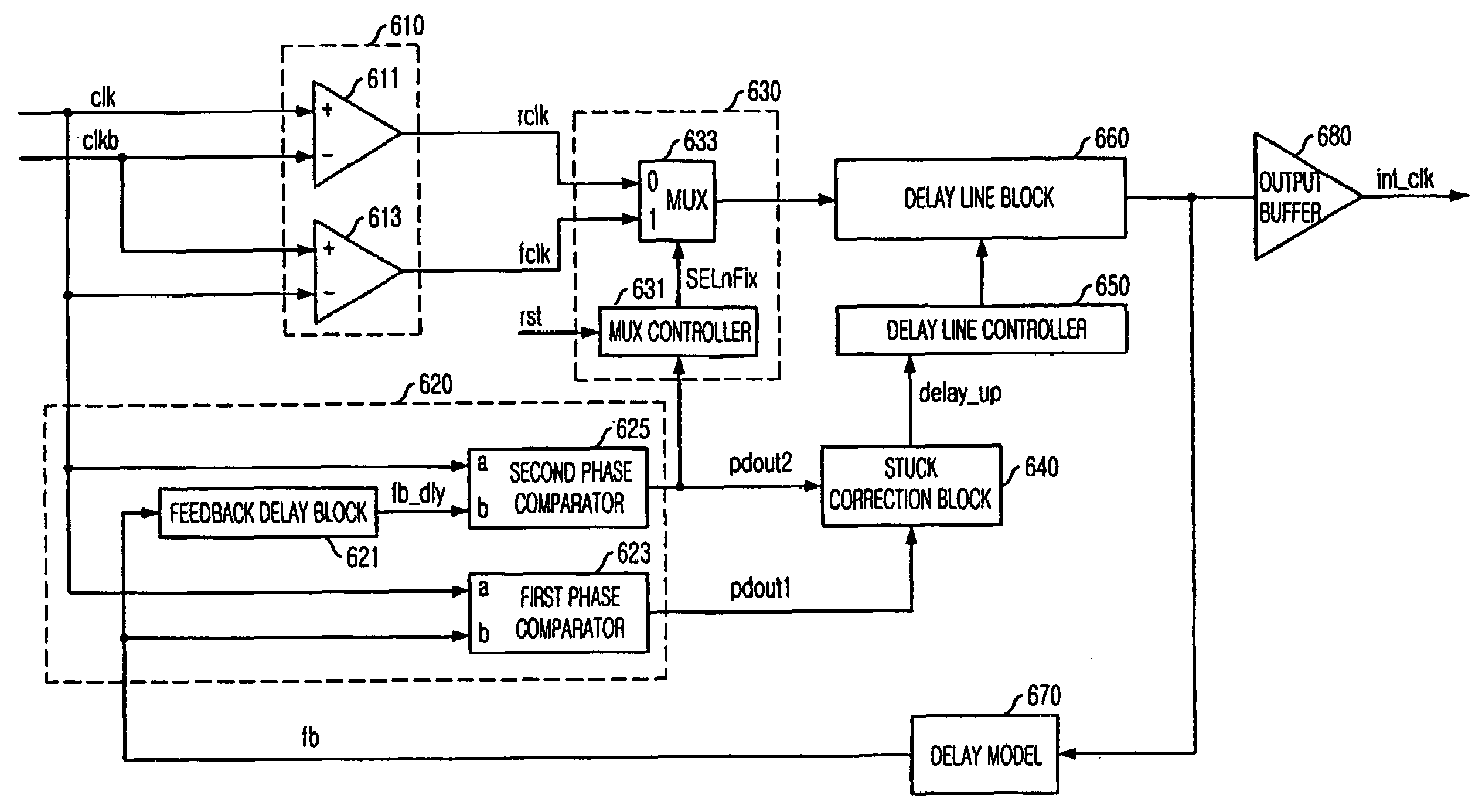

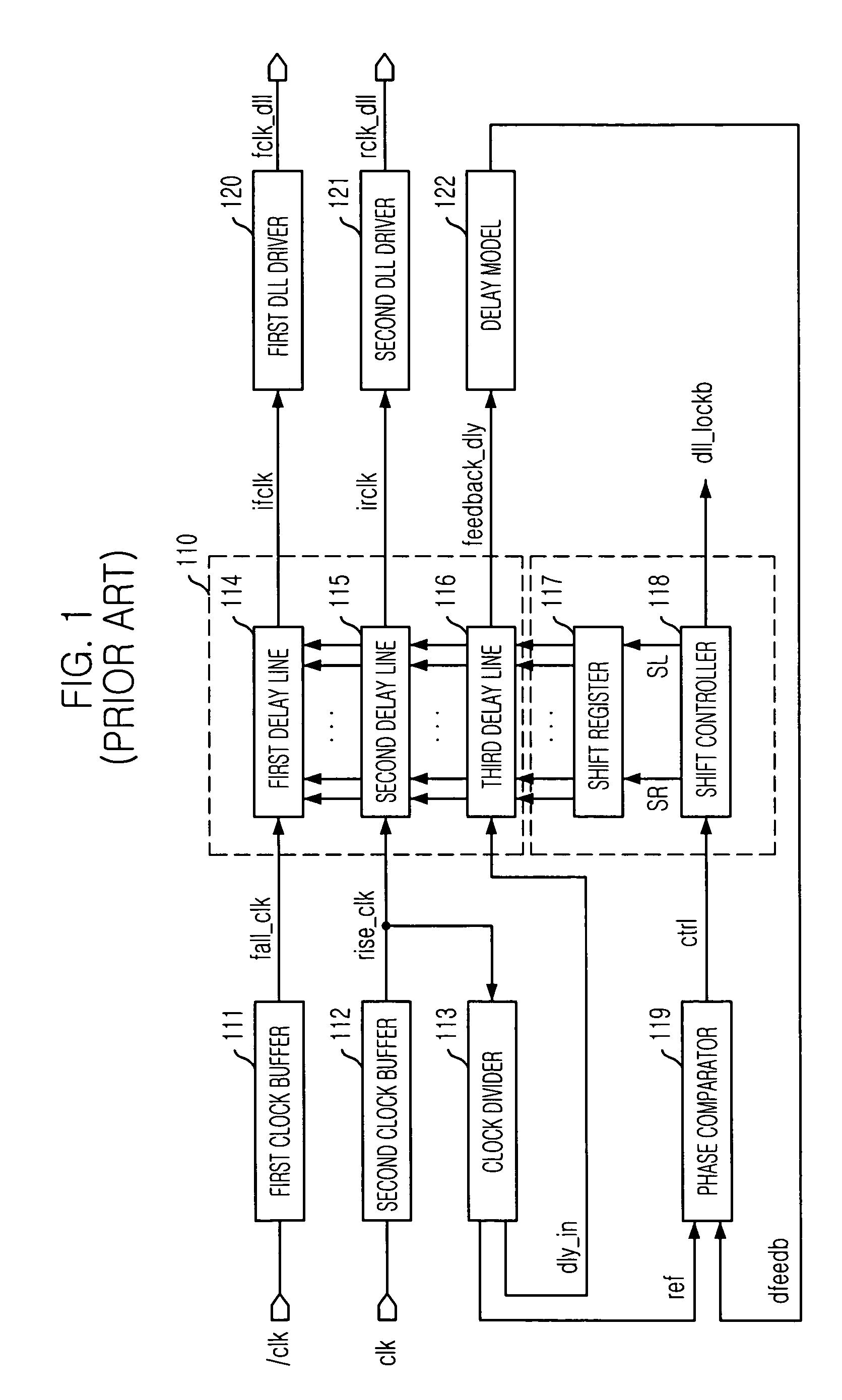

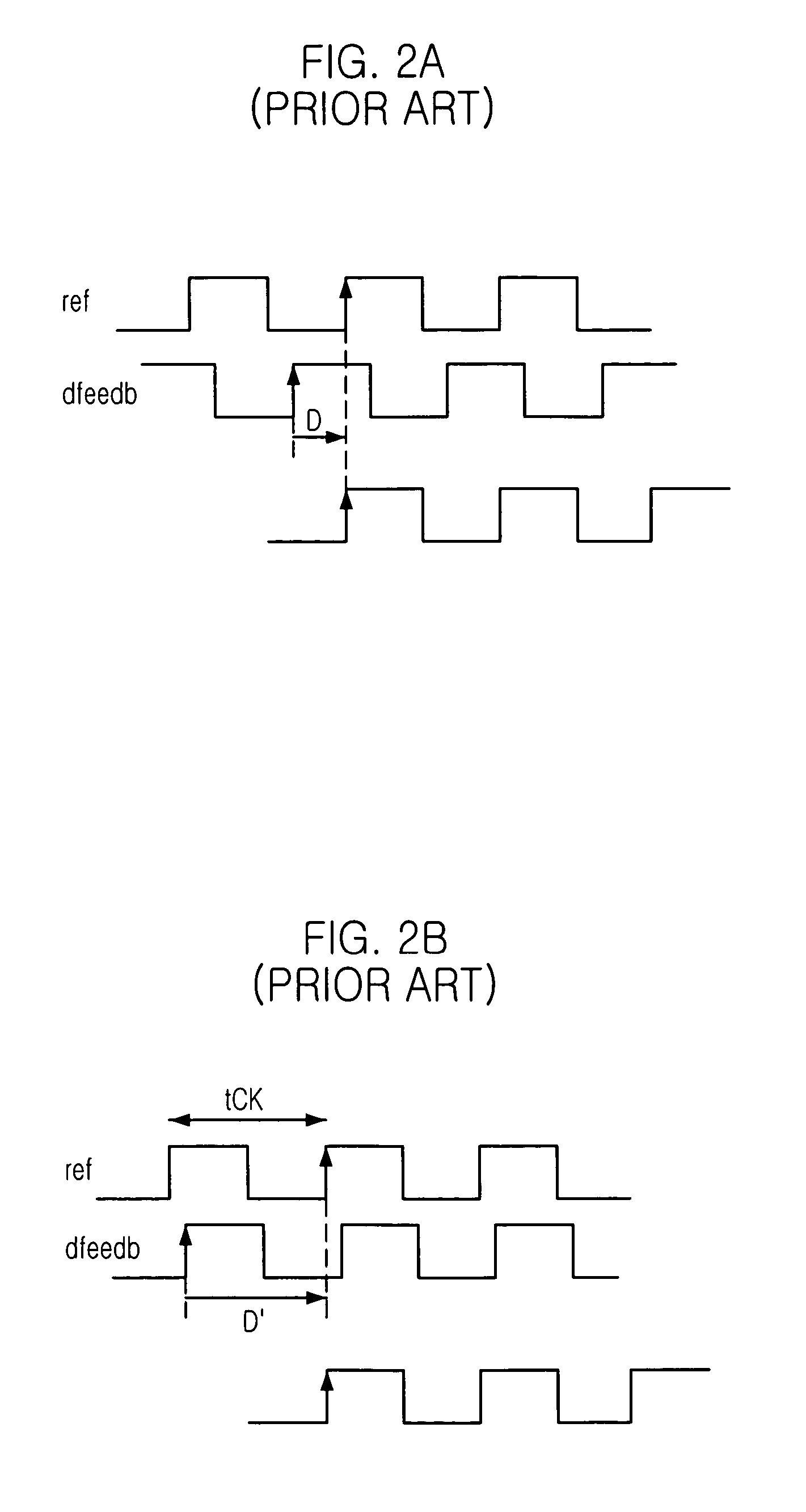

Delay locked loop in semiconductor memory device

A delayed lock loop for preventing a stuck fail in a dead-zone includes a clock buffering block for generating a first and a second internal clock signals; a phase comparison block for delaying a feedback signal by a first predetermined value and for respectively comparing a phase of a delayed feedback signal and a phase of the feedback signal with a phase of the external clock signal; a clock selecting block for selecting one of the first and second internal clock signals based on one comparison result to thereby generate a selected internal clock signal; a stuck checking block for determining a delay value based on the other comparison result; a delay line block for delaying the selected internal clock signal by the delay value; and an output buffer for buffering an outputted signal from the delay line block to thereby generating a DLL clock signal.

Owner:INTELLECTUAL DISCOVERY CO LTD

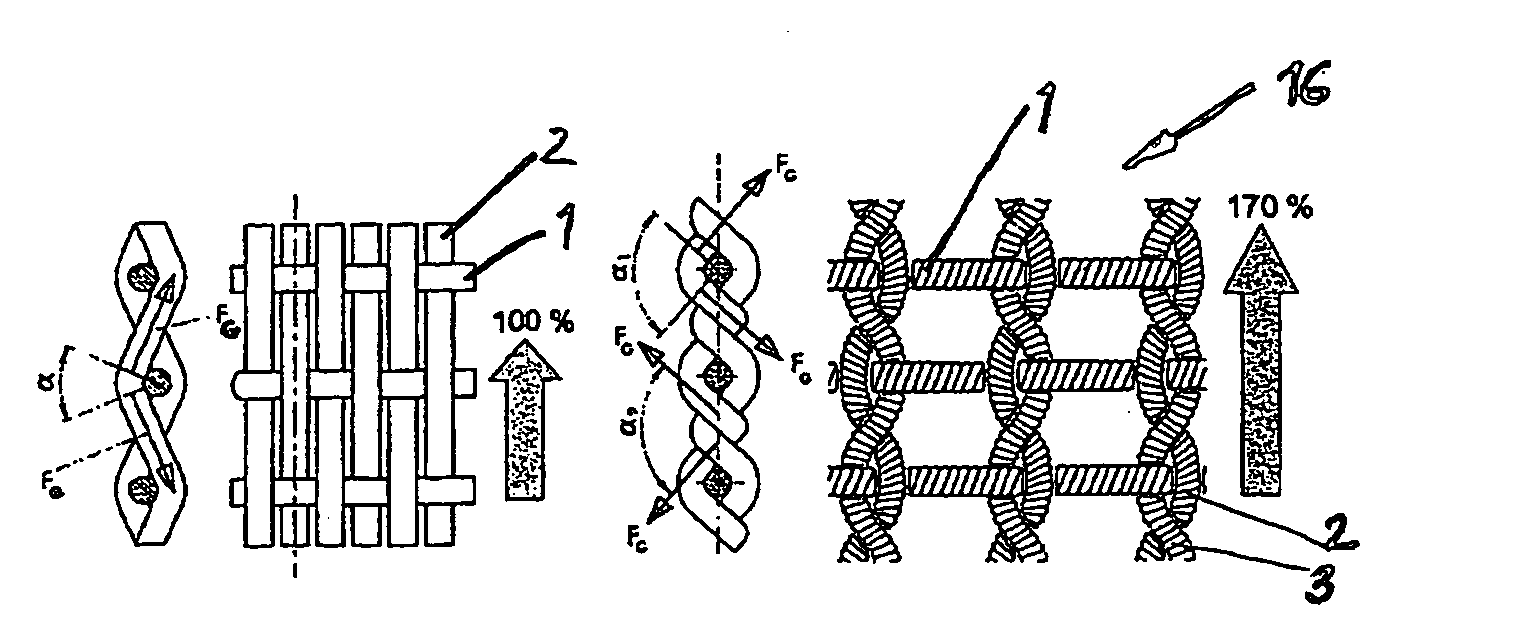

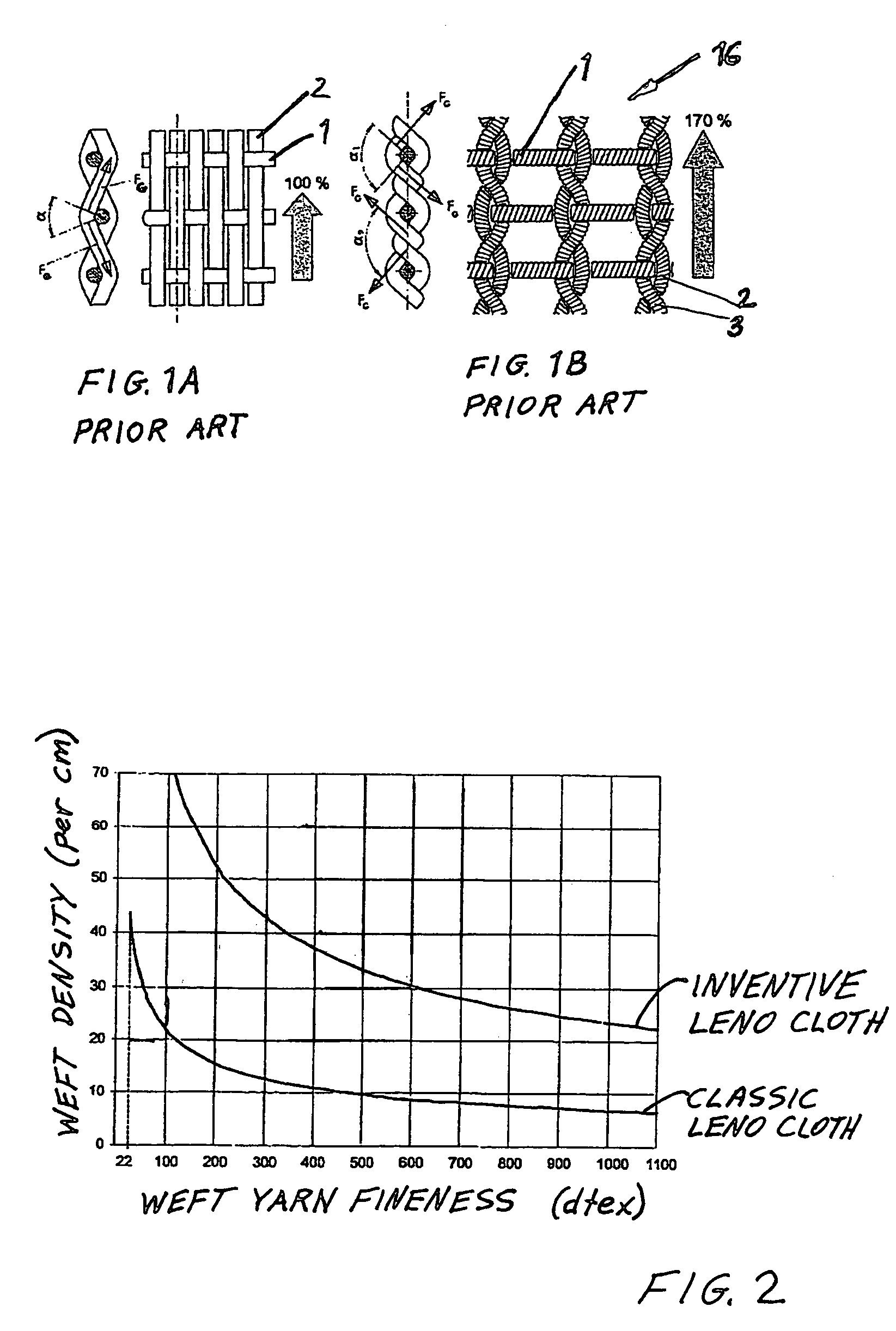

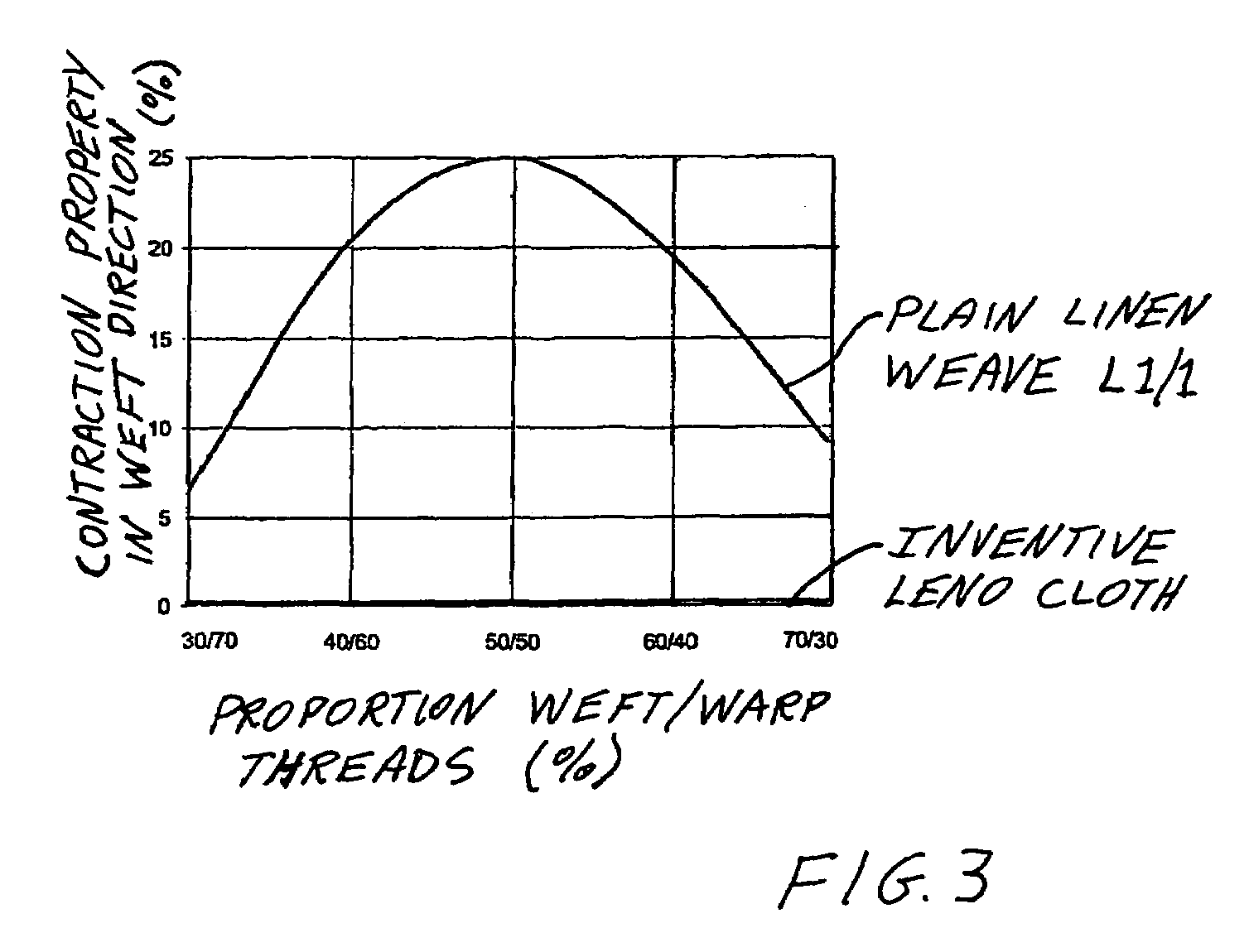

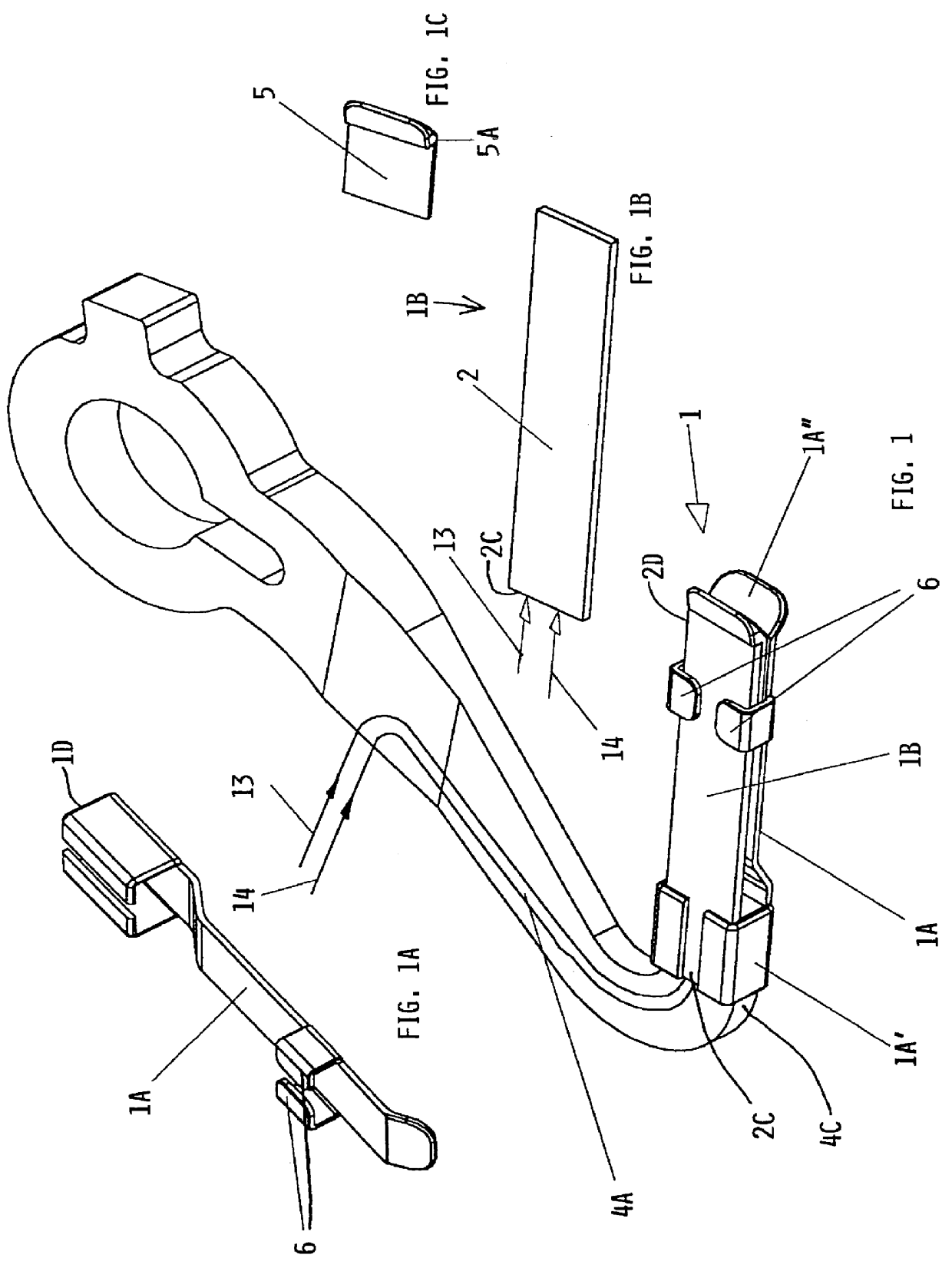

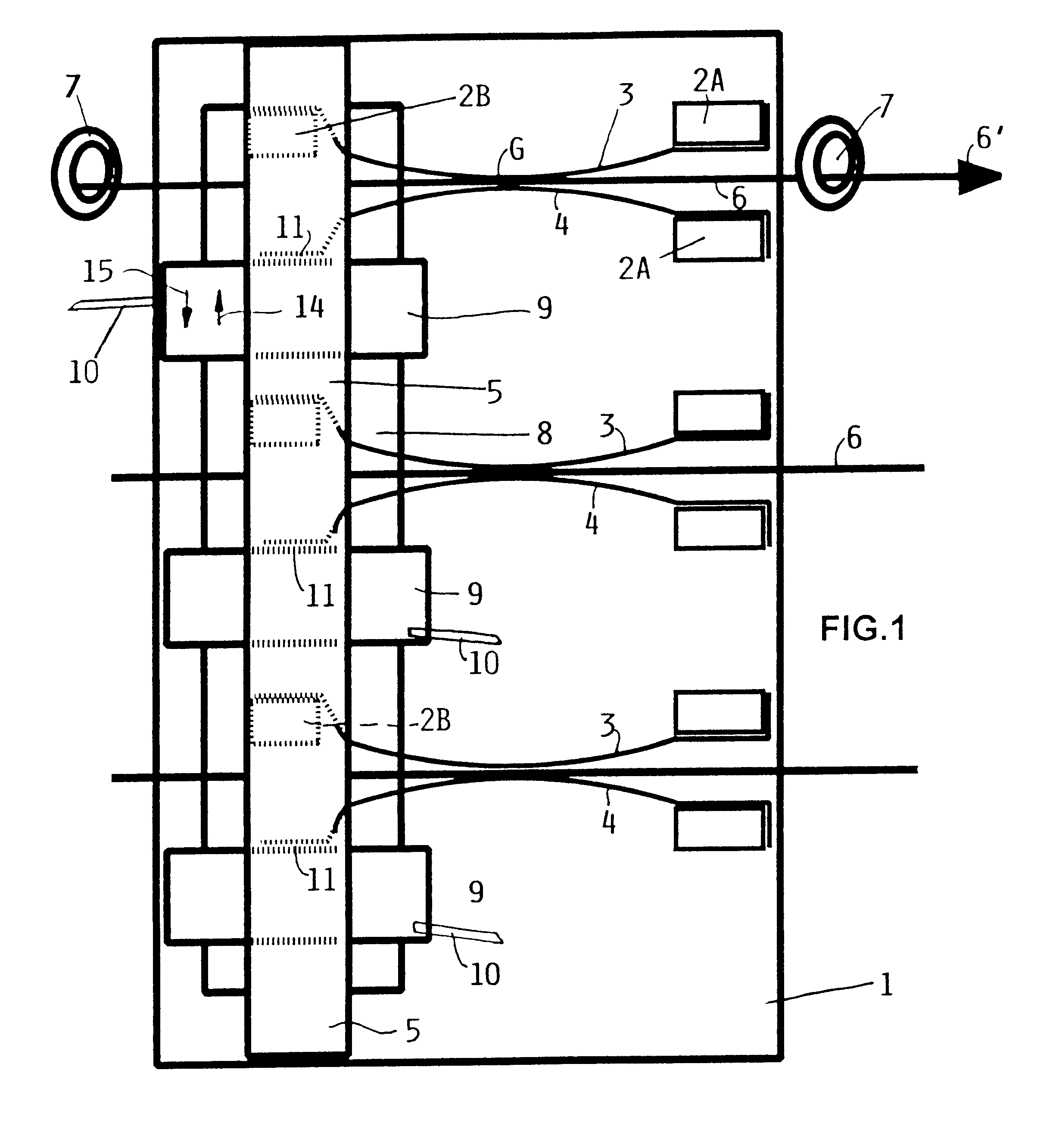

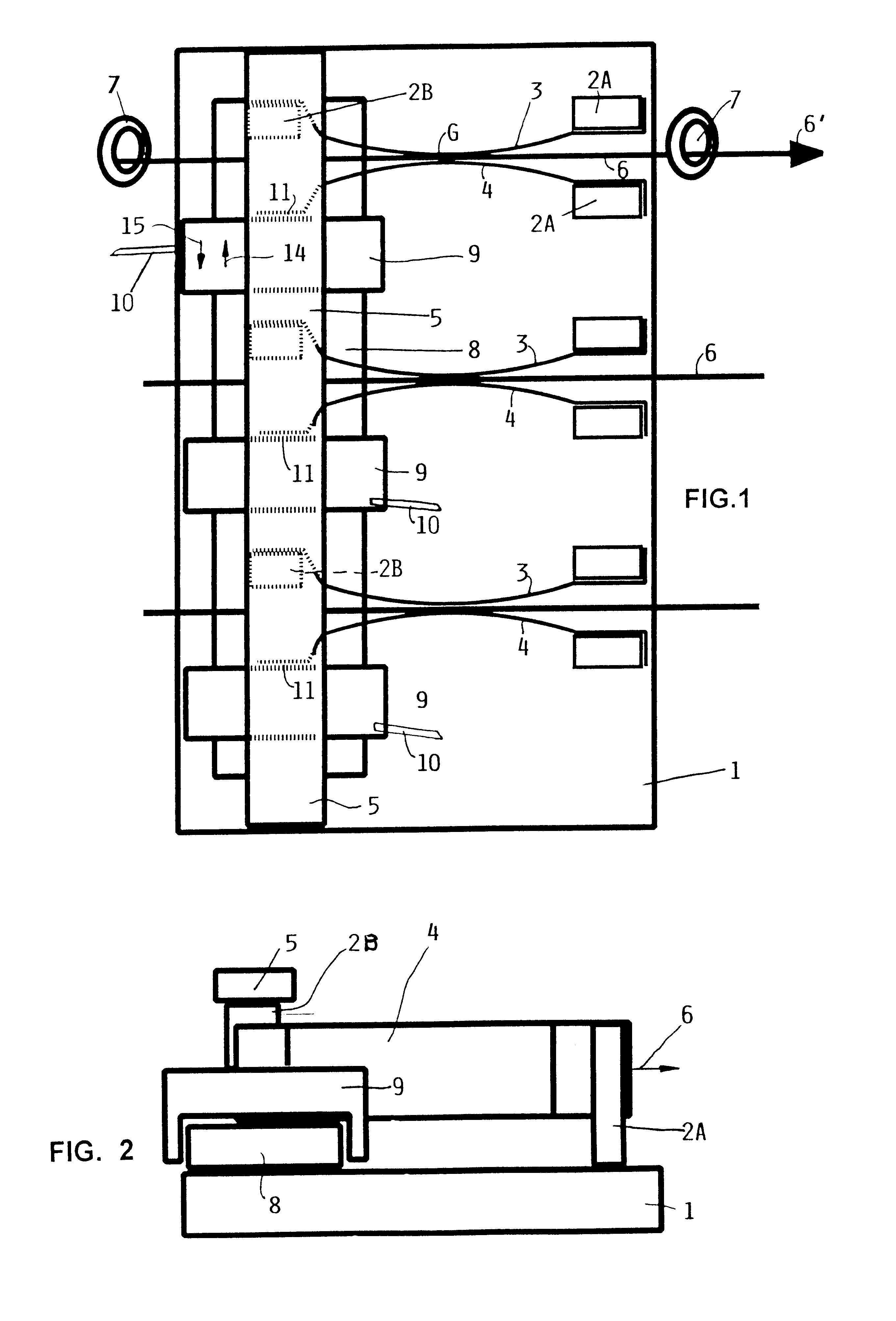

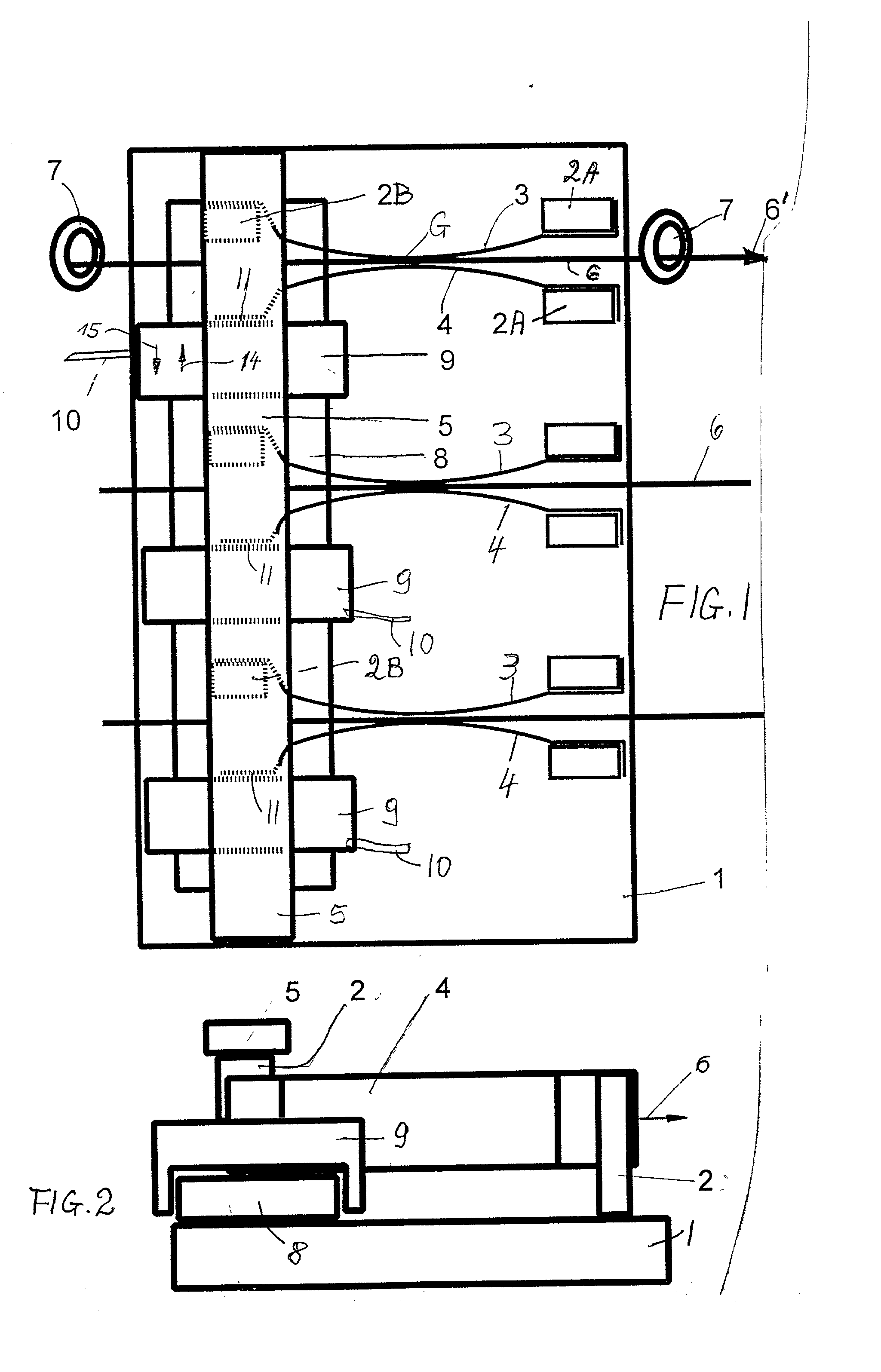

Leno cloth as well as method and weaving machine for production thereof

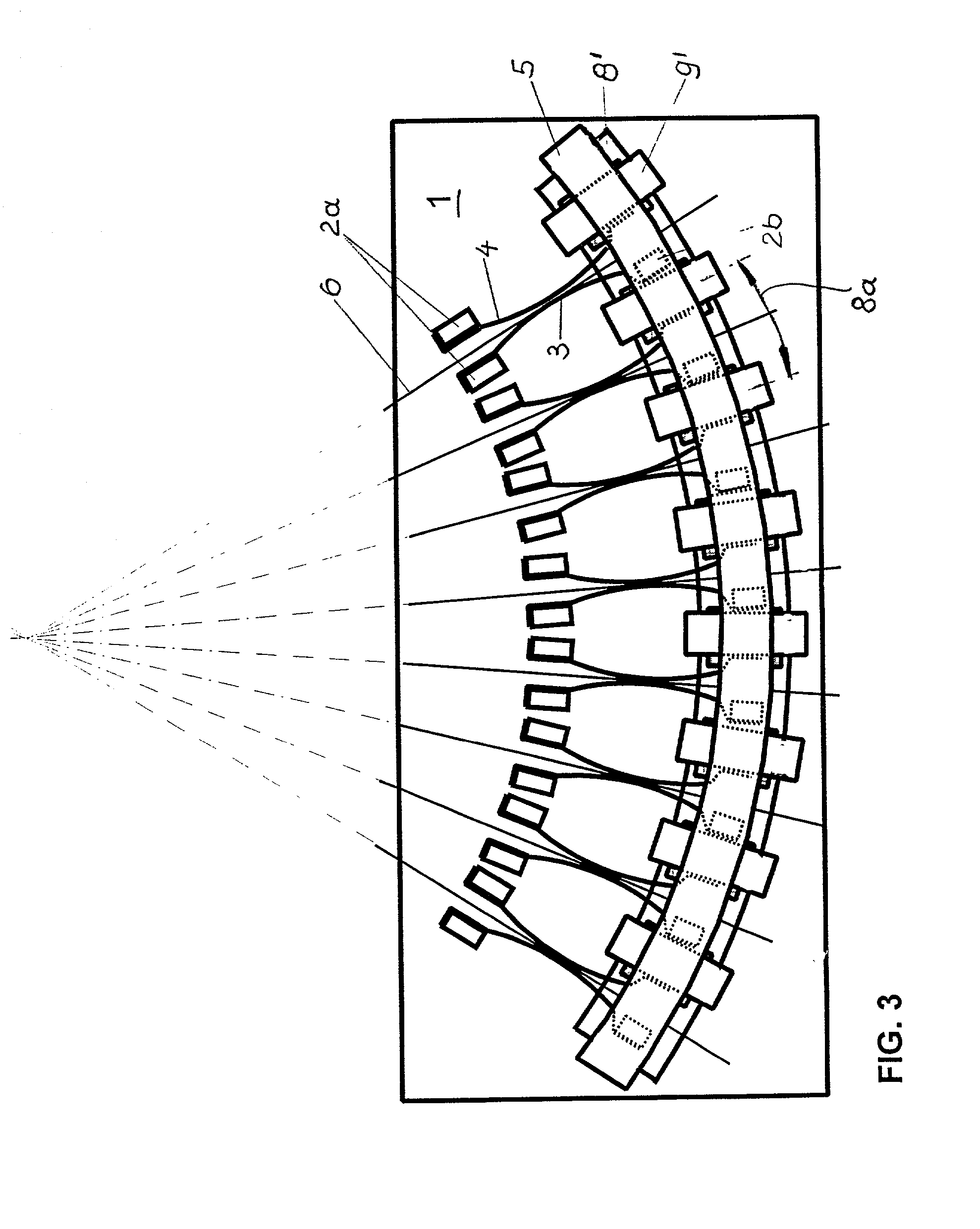

InactiveUS7287553B2Reduce tensionStronger working-in insertion or take-upOrnamental textile articlesLeno shedding mechanismYarnEngineering

A leno cloth is prepared, which comprises at least ground warp threads 1, leno warp threads 3 and weft threads 2, and in which the weft threads 2 and the ground warp threads 1 are arranged essentially interspace free. The weft threads are bound-off by means of the leno warp threads 3, which comprise a clearly lower titer relative to the ground warp threads 1, with such a lower tension relative to the ground warp threads, so that the crossings of the leno warp threads 3 with the ground warp threads 1 that are present due to the binding are arranged in a plane parallel to the plane of the maximum thickness of the weft threads. The leno warp threads 3 comprise a higher working-in or take-up into the woven cloth than the ground warp threads 1. According to a further aspect of the invention, a method for the production of a leno cloth as well as a loom for the carrying out of the method for the production of a leno cloth are described.

Owner:LINDAUER DORNIER GMBH

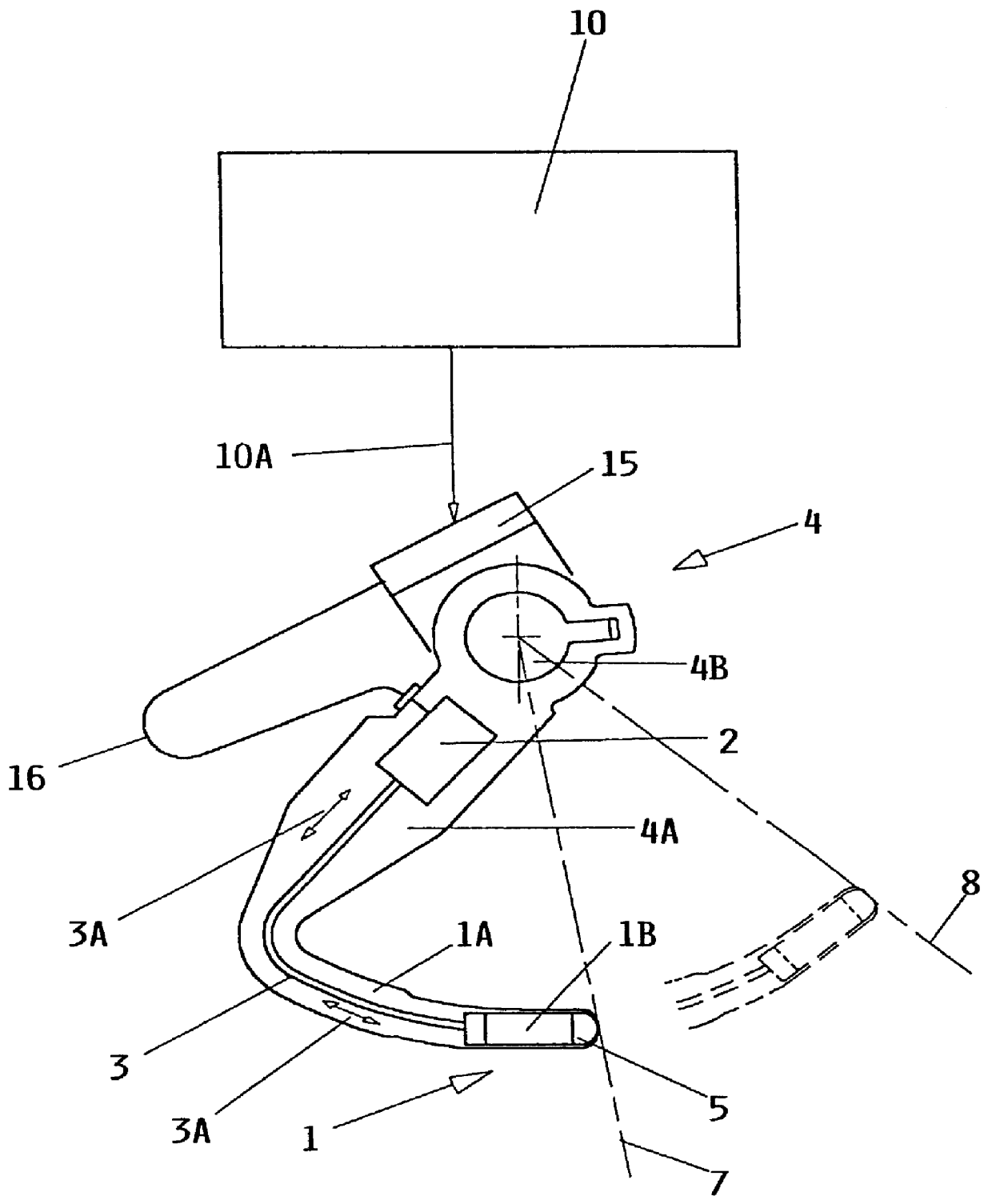

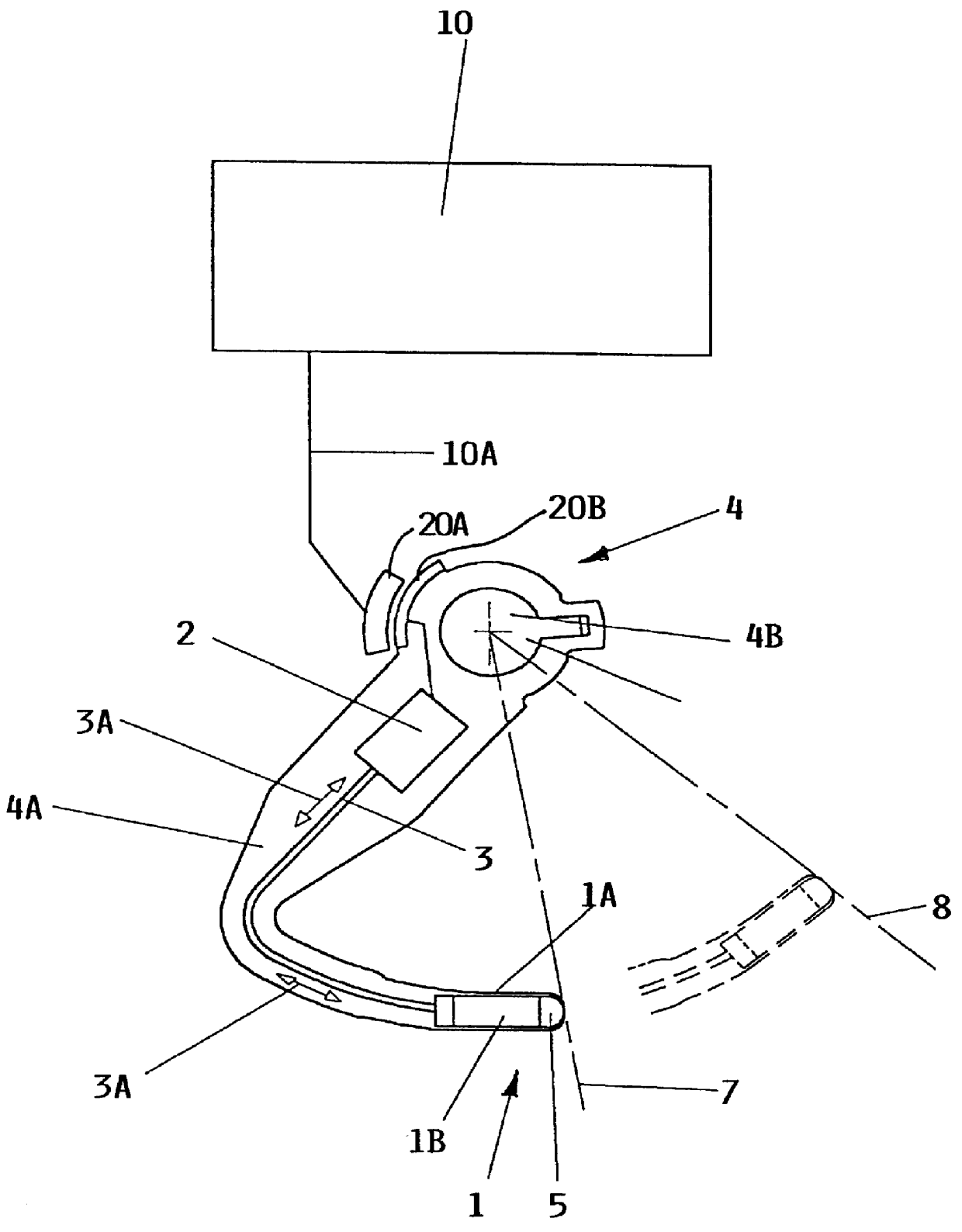

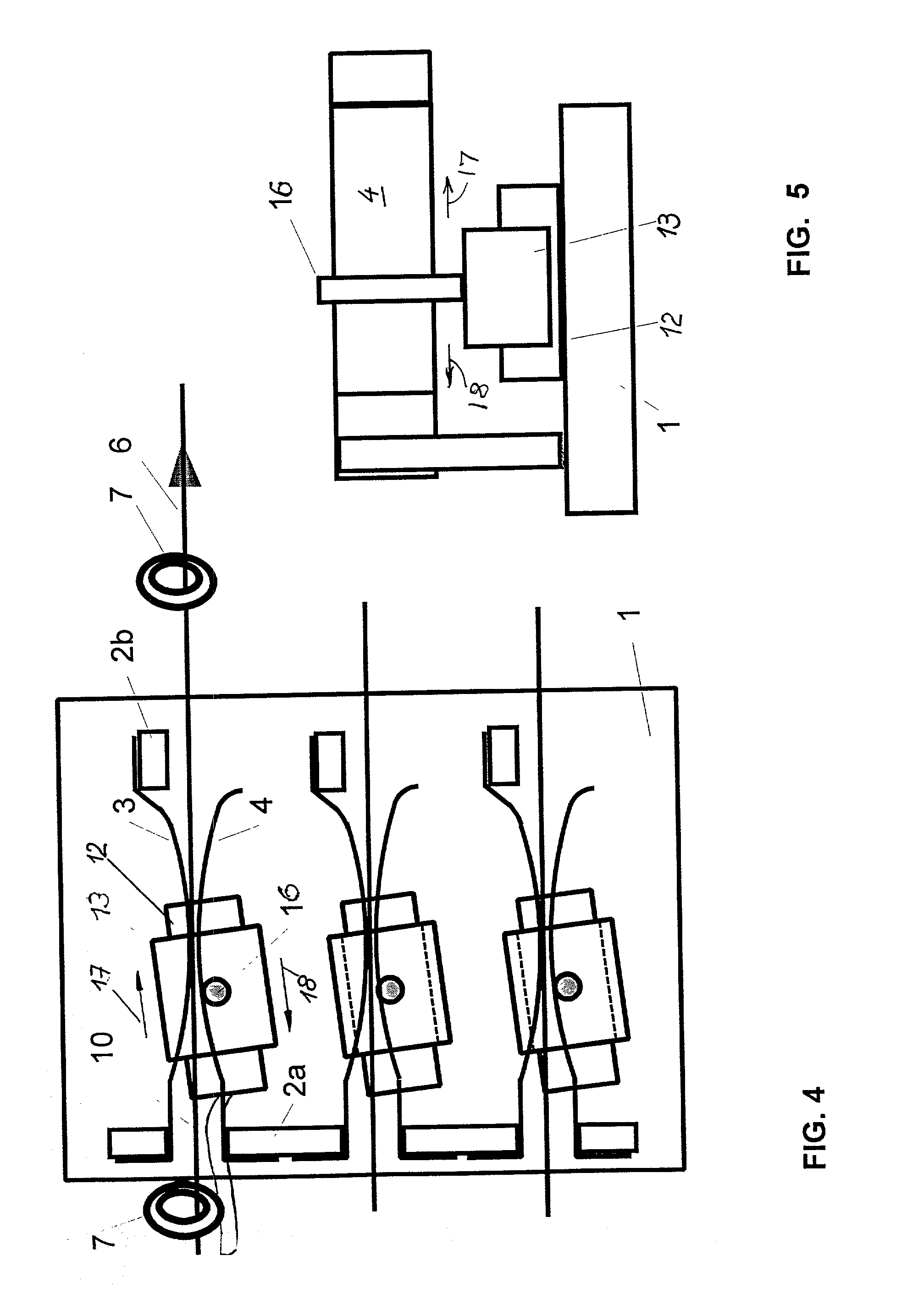

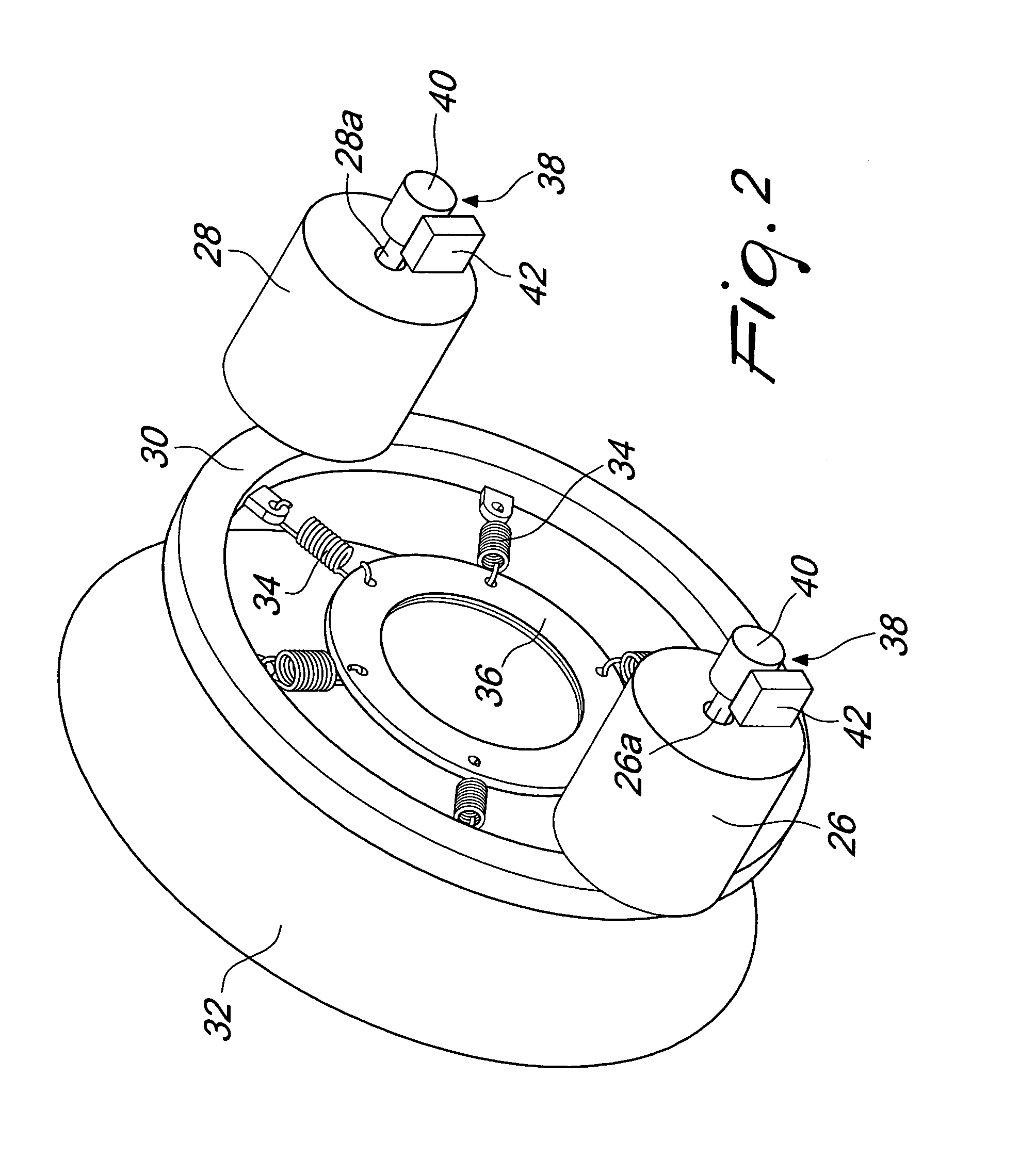

Controllable weft thread presenting and clamping apparatus including an actuated clamp element

A weft thread clamp for a weft thread presenting lever is positively actuated to selectively open or close the clamp and thereby release or hold the weft thread respectively. To achieve this, a second clamp element is movable or deflectable relative to a first clamp element of the clamp. The movable second clamp element may be directly embodied as an actuator, or may be driven by an actuating motion provided by an actuator located remotely from the clamp on the lever. In the latter case, a motion transmission arrangement such as a sheathed push-pull cable or a rod linkage operatively connects the actuator to the movable second clamp element. The actuator may be a piezoelectric, electromagnetic, hybrid pneumatic-electric, or hybrid hydraulic-electric device, or an electric motor. The loom control unit is connected to the actuator for providing control signals thereto.

Owner:LINDAUER DORNIER GMBH

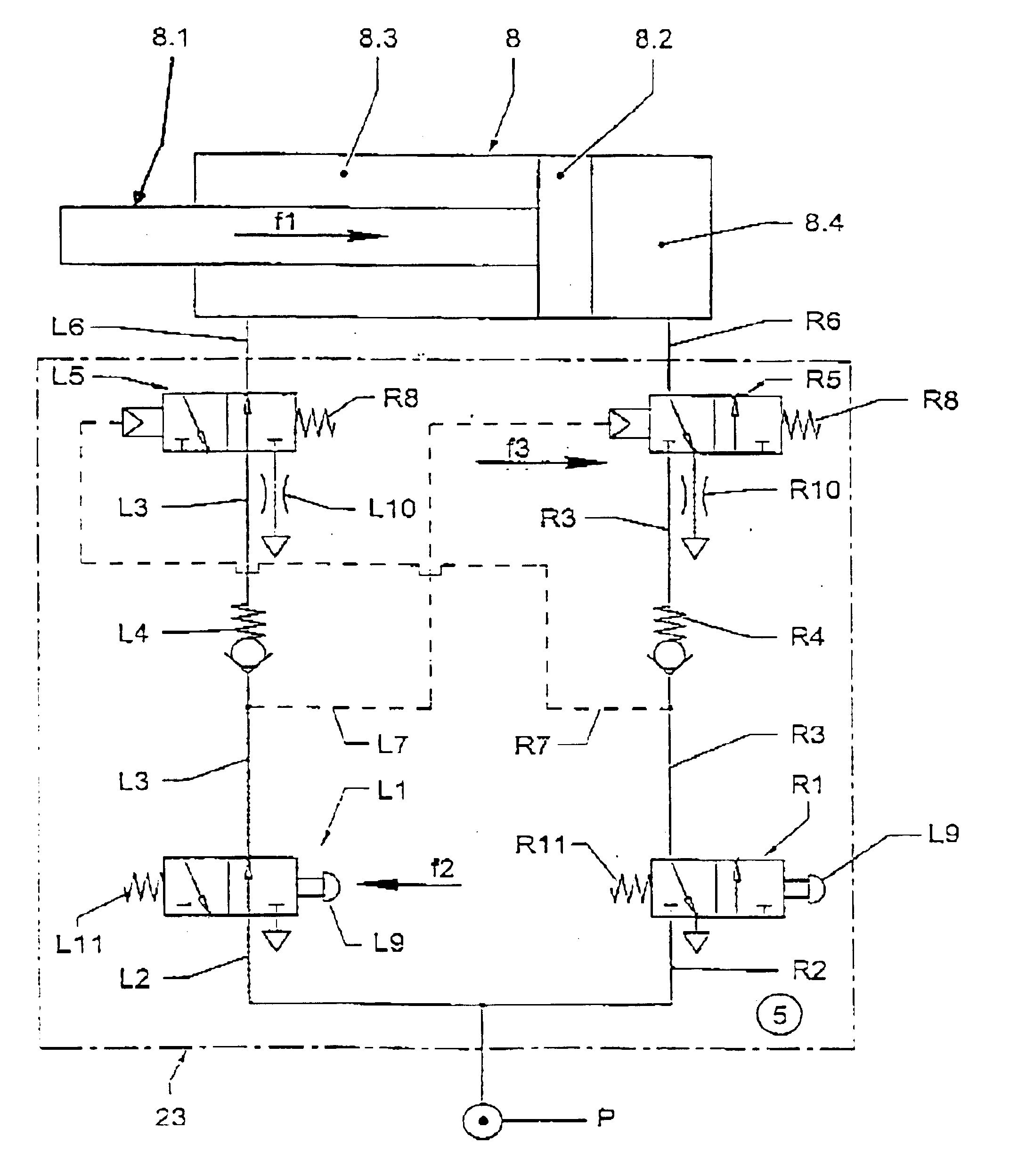

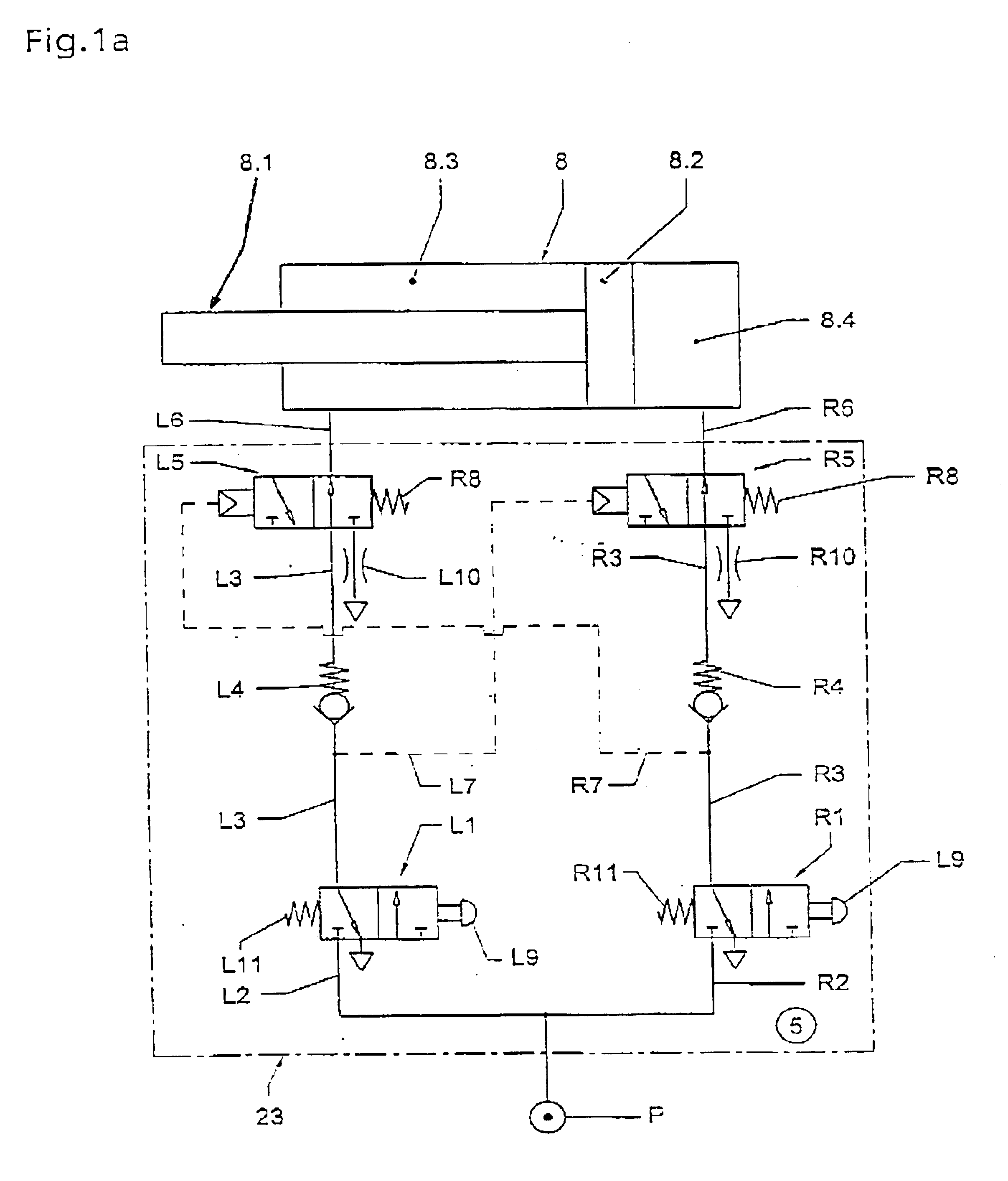

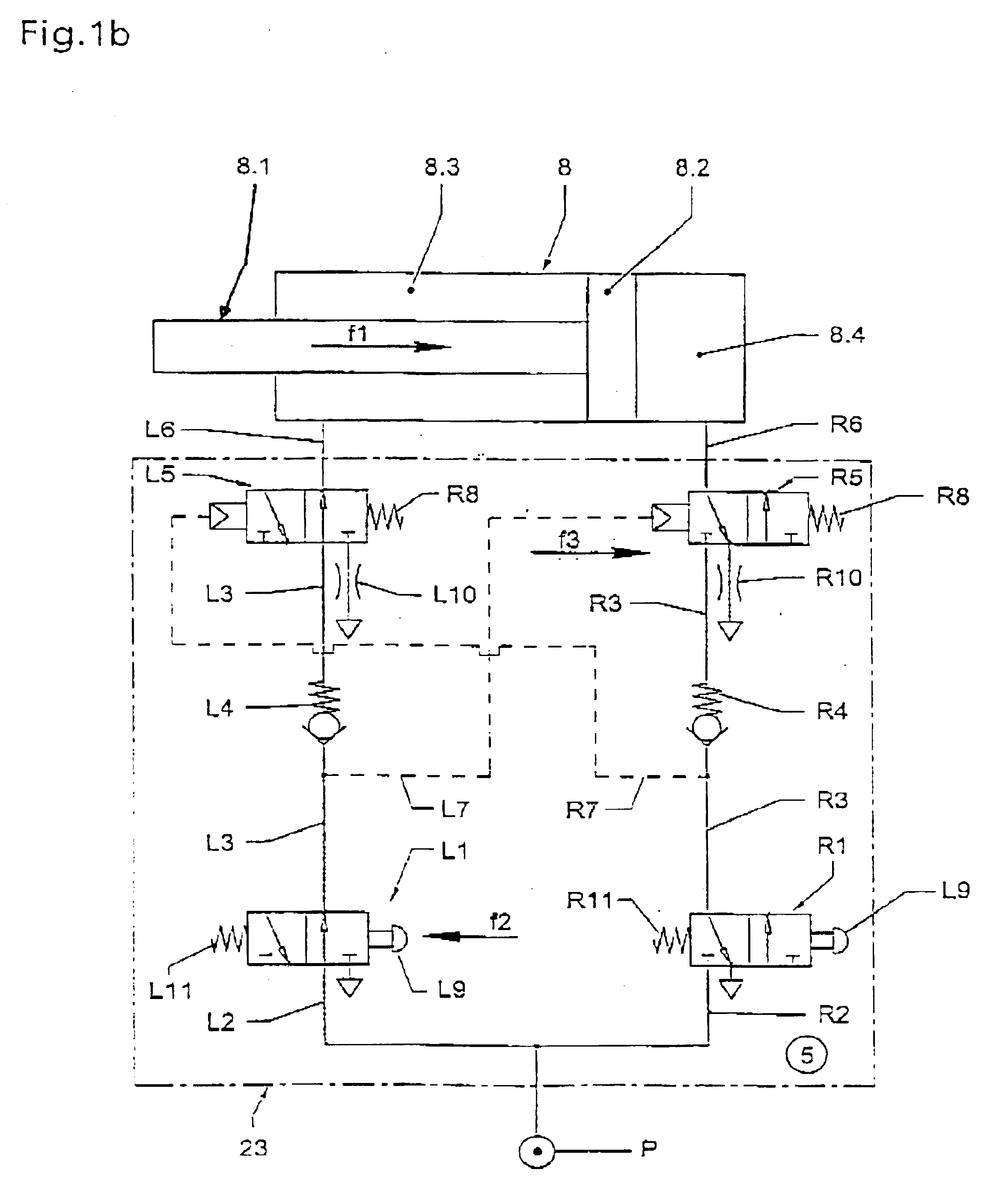

Actuating valve for bidirectional pneumatic cylinder and use of such actuating valve for bobbin creels controlled by pneumatic cylinders

InactiveUS6848641B2Reduce decreaseCompact configurationServomotor componentsServomotorsBobbinControl line

An actuating valve has two relay valves connected to a compressed air source and a pneumatic cylinder with two pressure chambers. When one relay valve is actuated, one pressure chamber is pressure-loaded and the other is relieved. Two 3 / 2 port directional control valves are arranged upstream of the pneumatic cylinder. Two check valves are positioned in branch lines connecting the relay valves and the directional control valves. A control line connects the branch line to the other directional control valve, respectively. The directional control valves are moveable between a first position allowing compressed air to pass and a pressure relief position. When the relay valves are inactive, the directional control valves are in the first position and the relay valves are in a venting position for the branch lines. When one relay valve is actuated, it assumes a position allowing passage of air to the branch line connected to it.

Owner:ZHUOLANG INTELLIGENT MACHINERY CO LTD

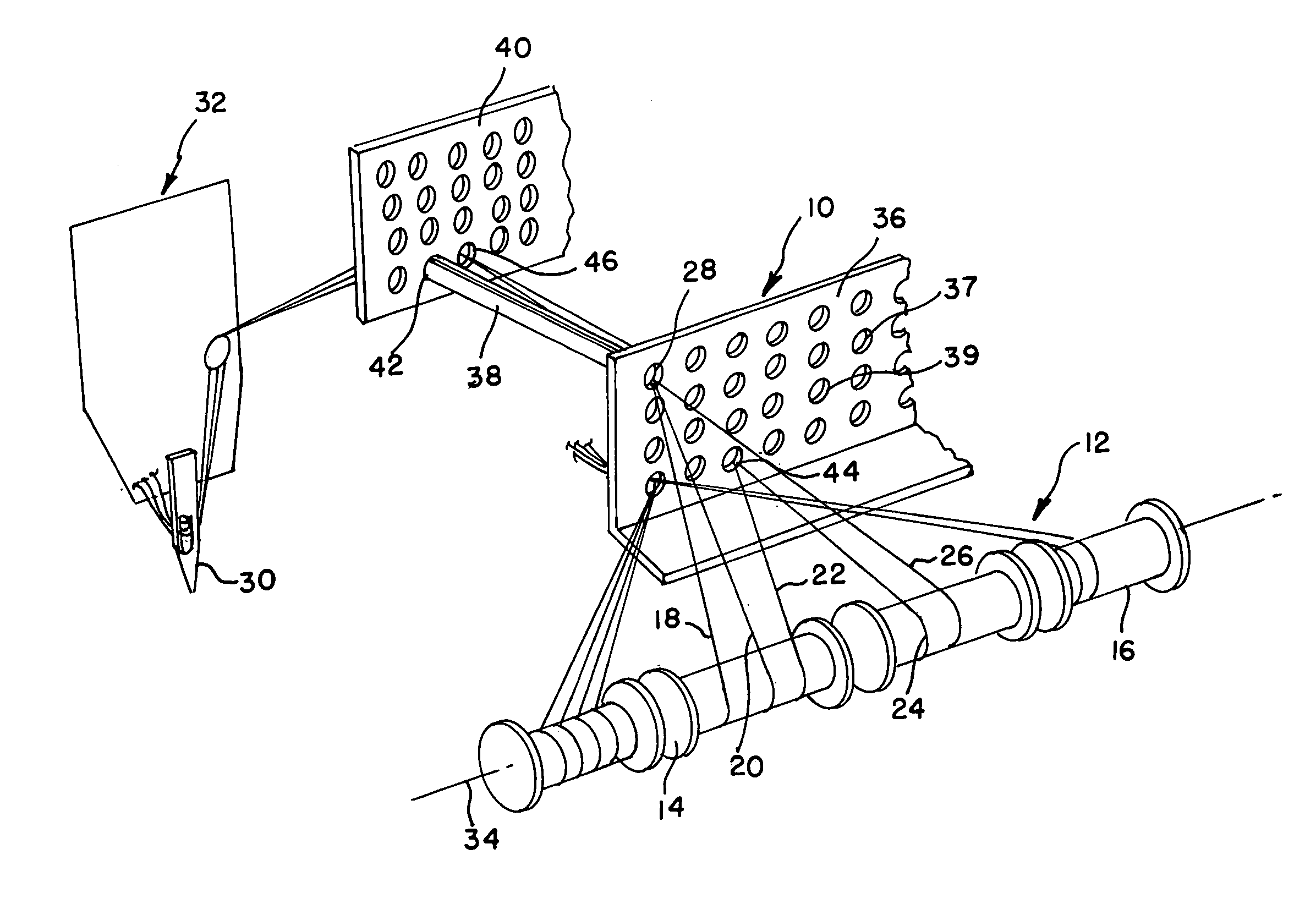

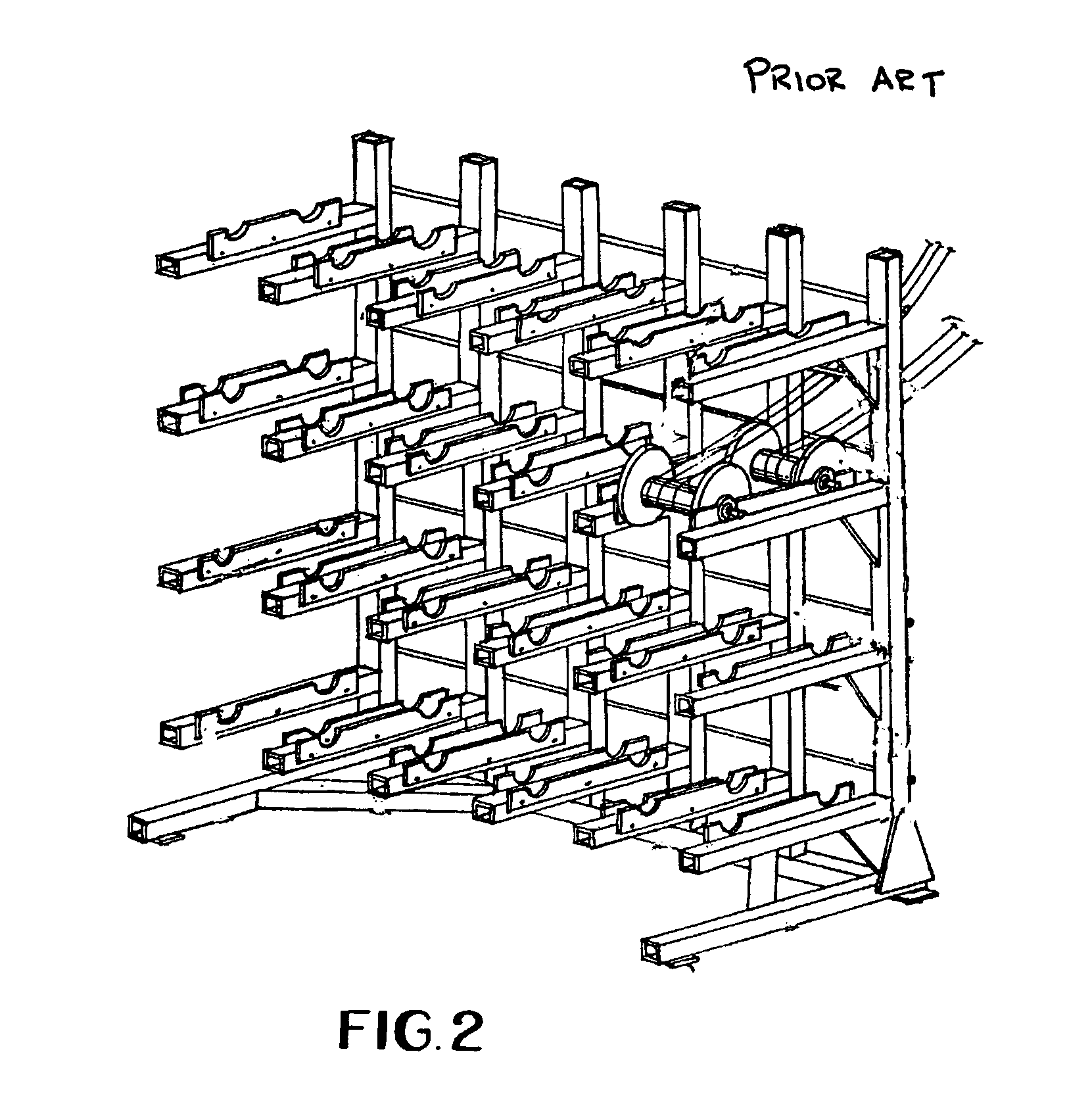

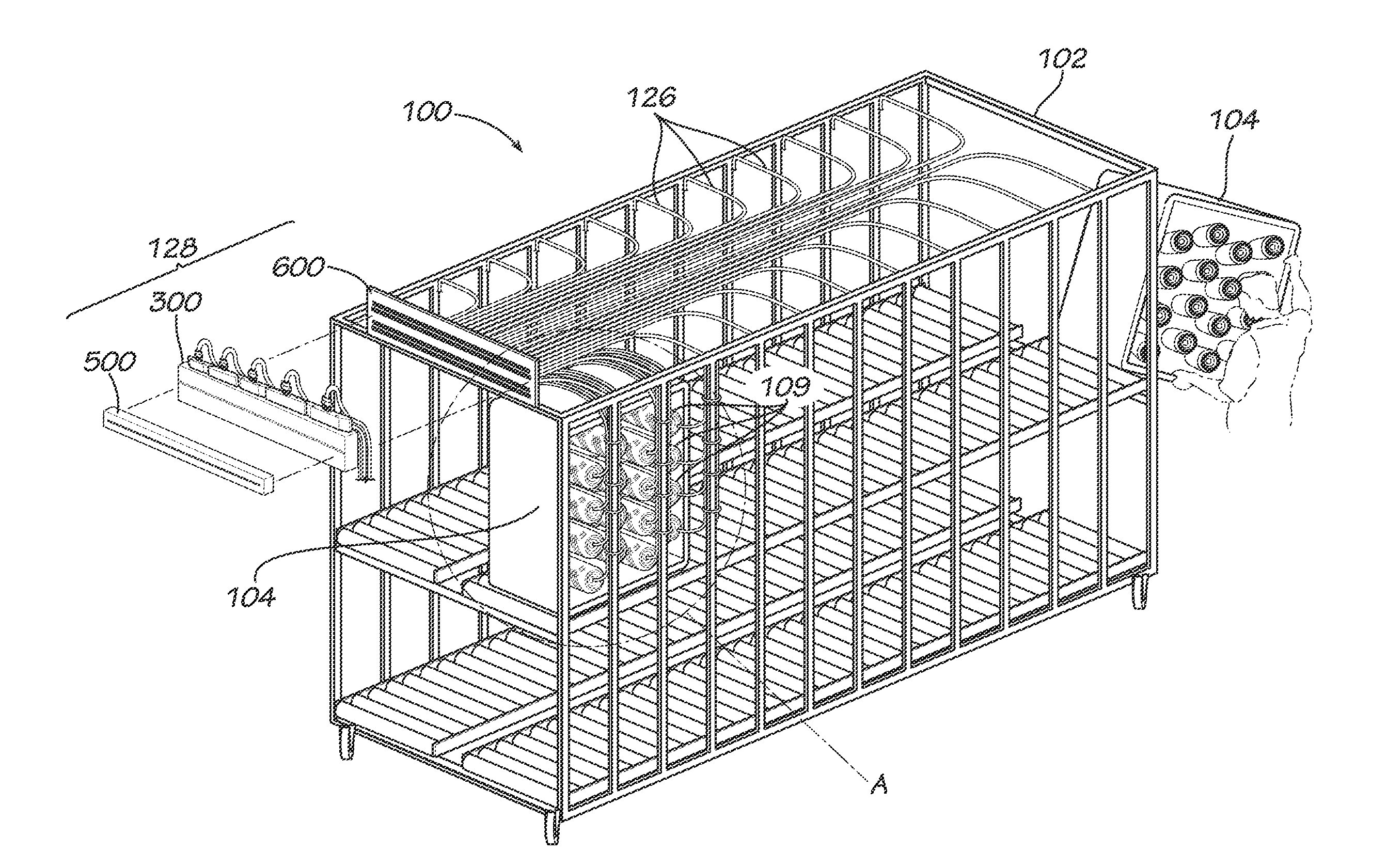

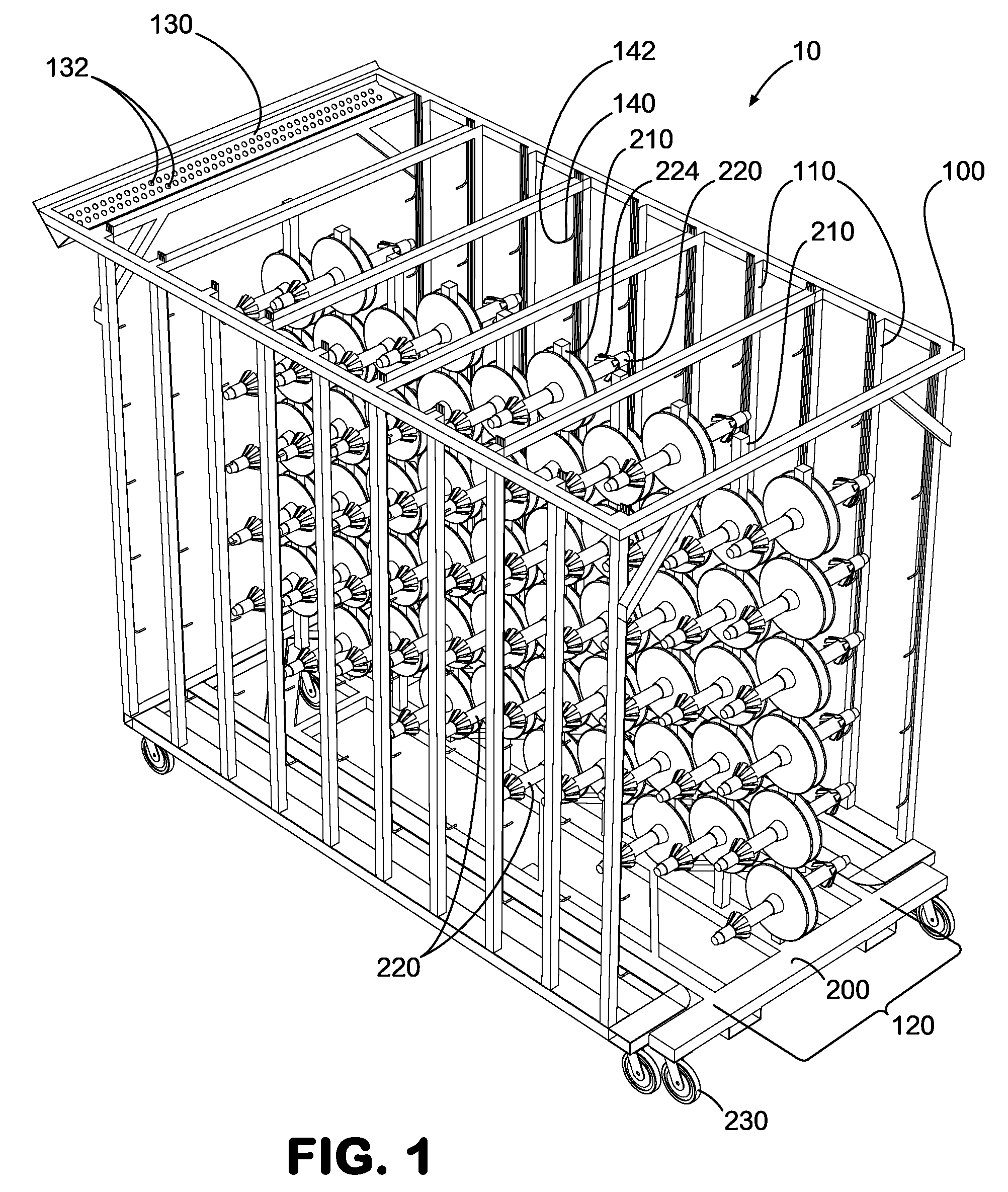

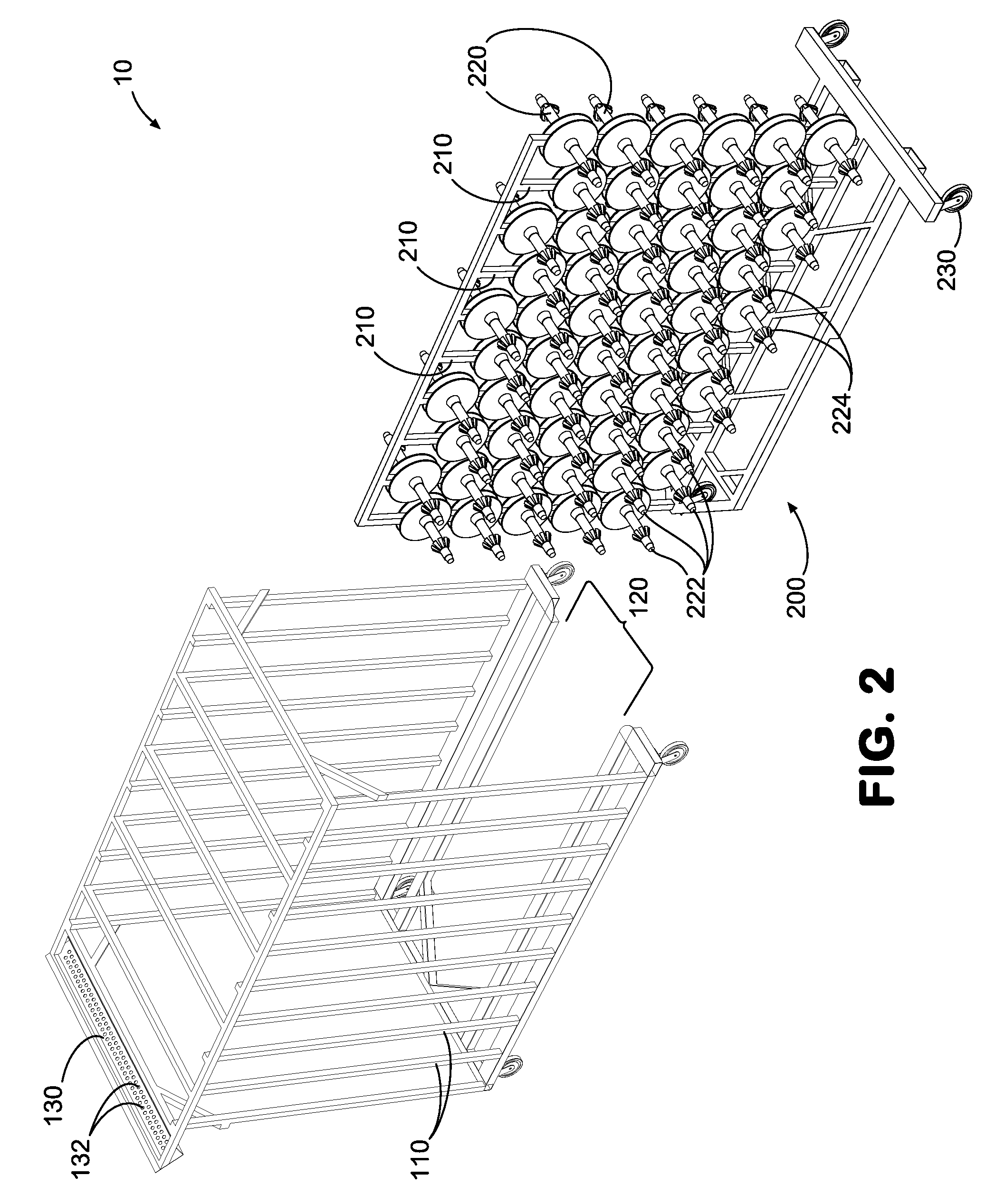

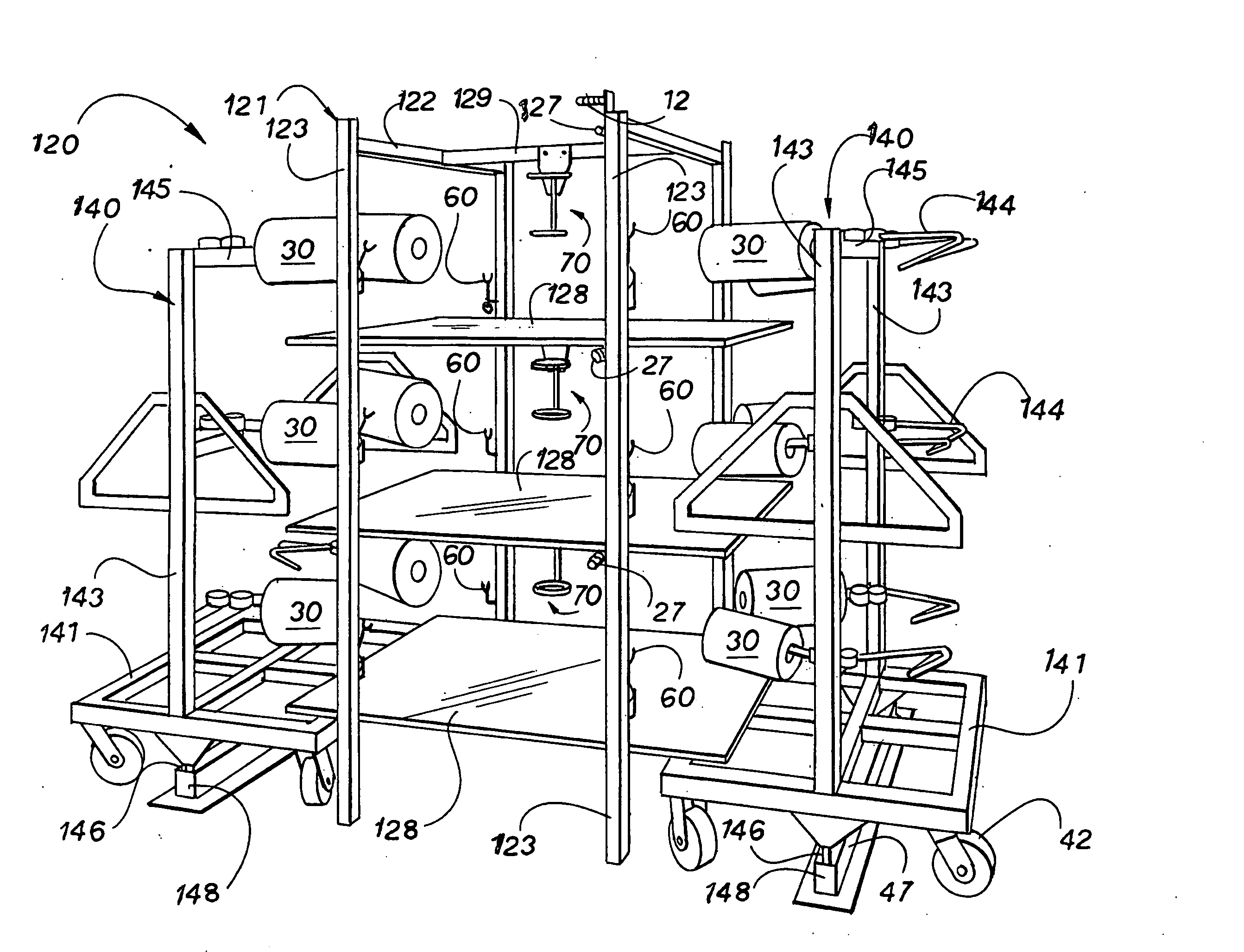

Portable Creels With Insertable Yarn Trays and Improved Headers and Yarn Handling Methods

Creels having frames configured to receive one or more trays of yarn packages. The trays of yarn packages are removable from the frame and can be loaded with packages of yarn when not inserted into the frame. Separately loading trays with yarns can simplify and provide other benefits with respect to the process of loading a creel with yarn packages. Also disclosed is an assembly that is positioned with respect to a detachable header and a stationary header on a creel and that comprises an air flow unit that causes yarns to move through to an alignment mechanism that aligns the yarns for attachment to yarns already feeding into a tufting machine.

Owner:INTERFACE INC

Dispenser for sheet material

Owner:KIMBERLY-CLARK WORLDWIDE INC

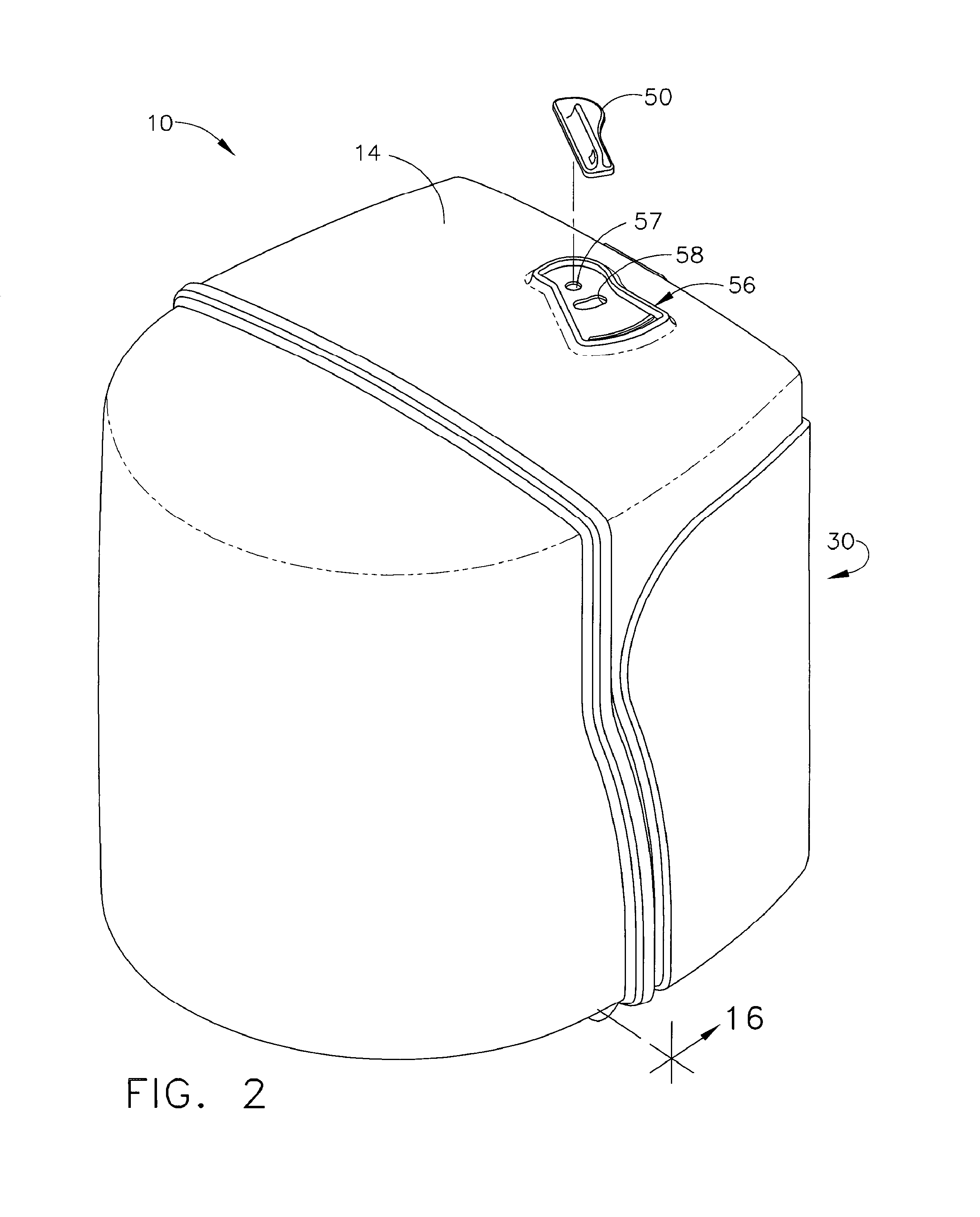

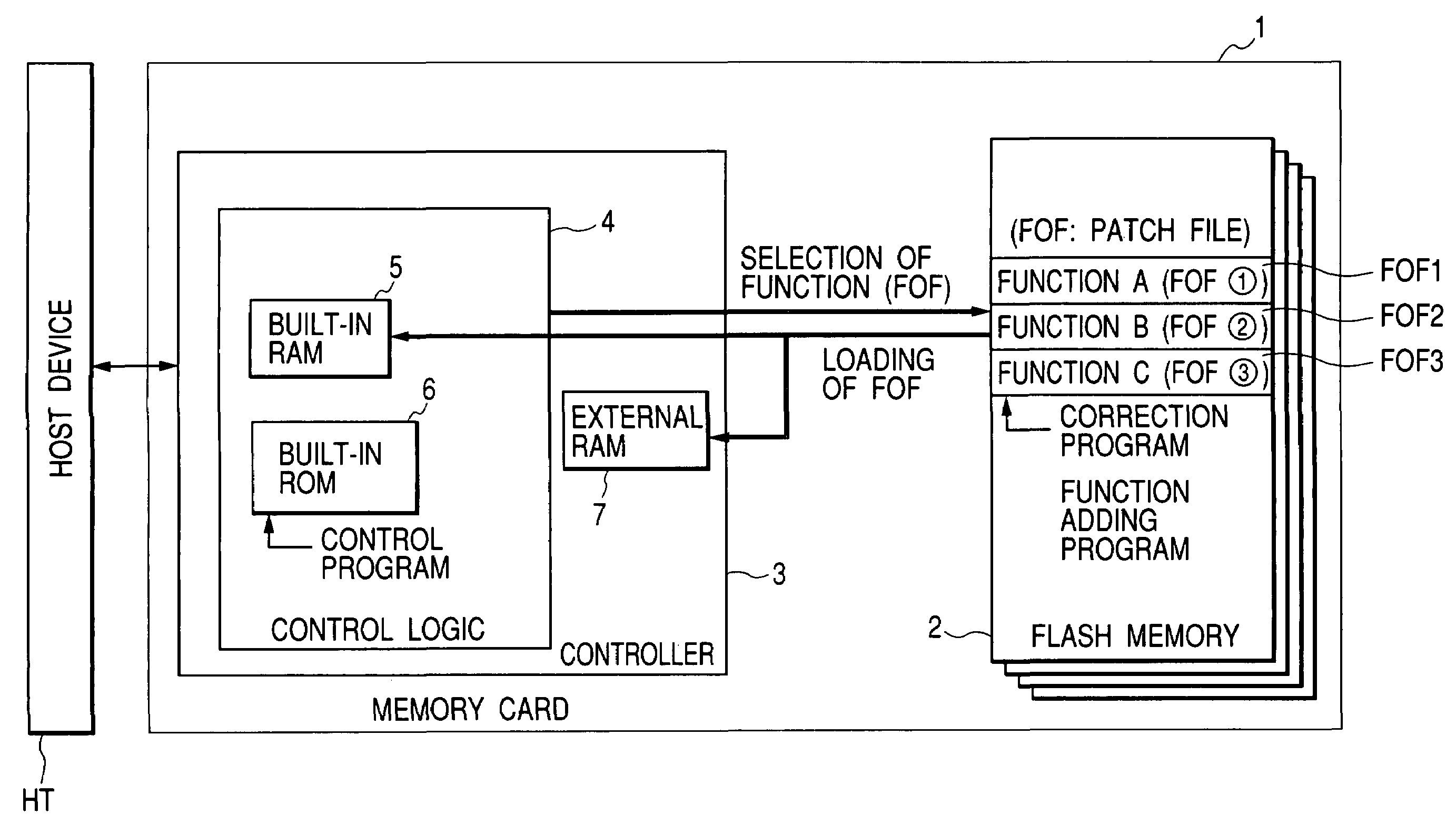

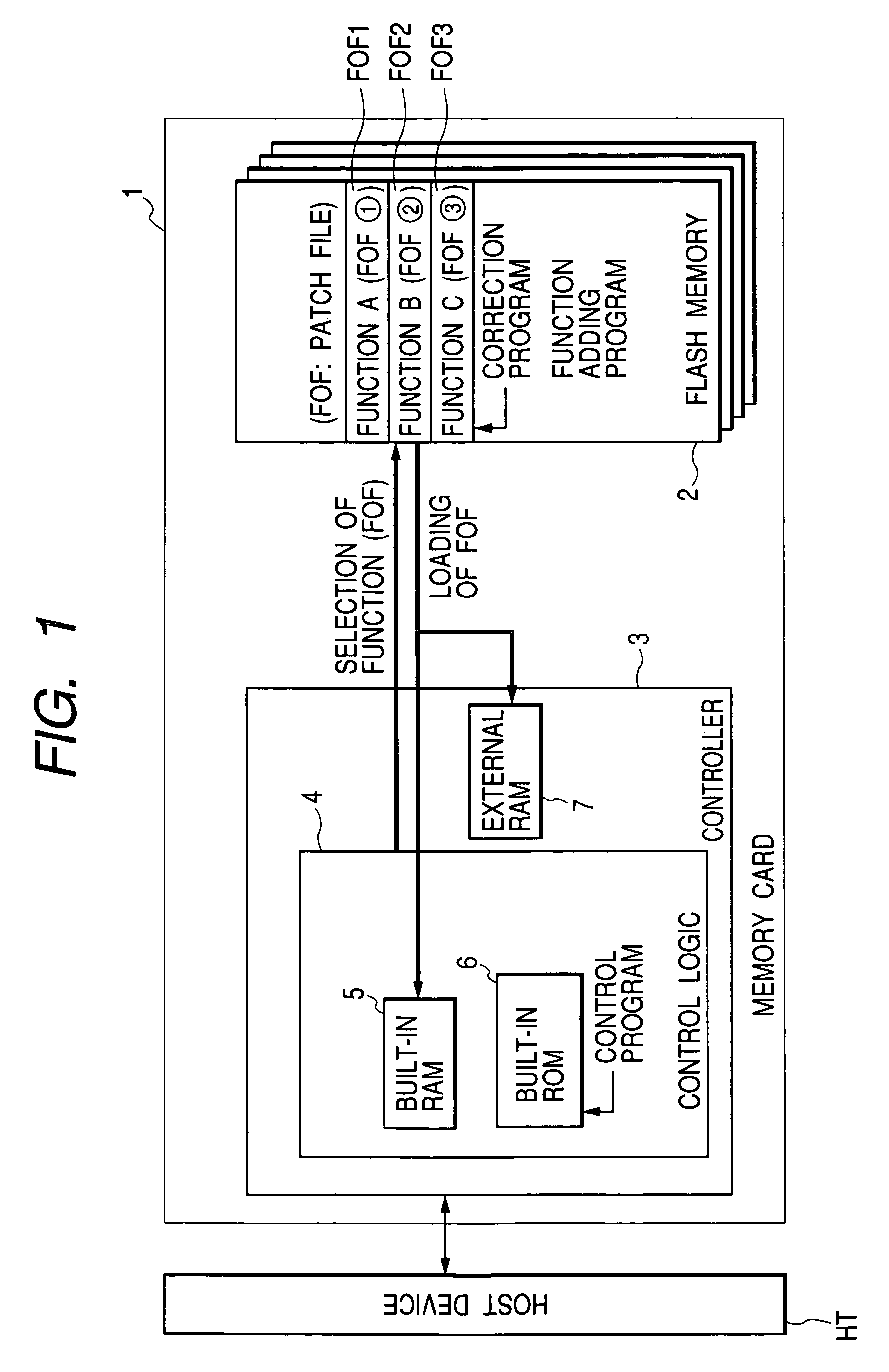

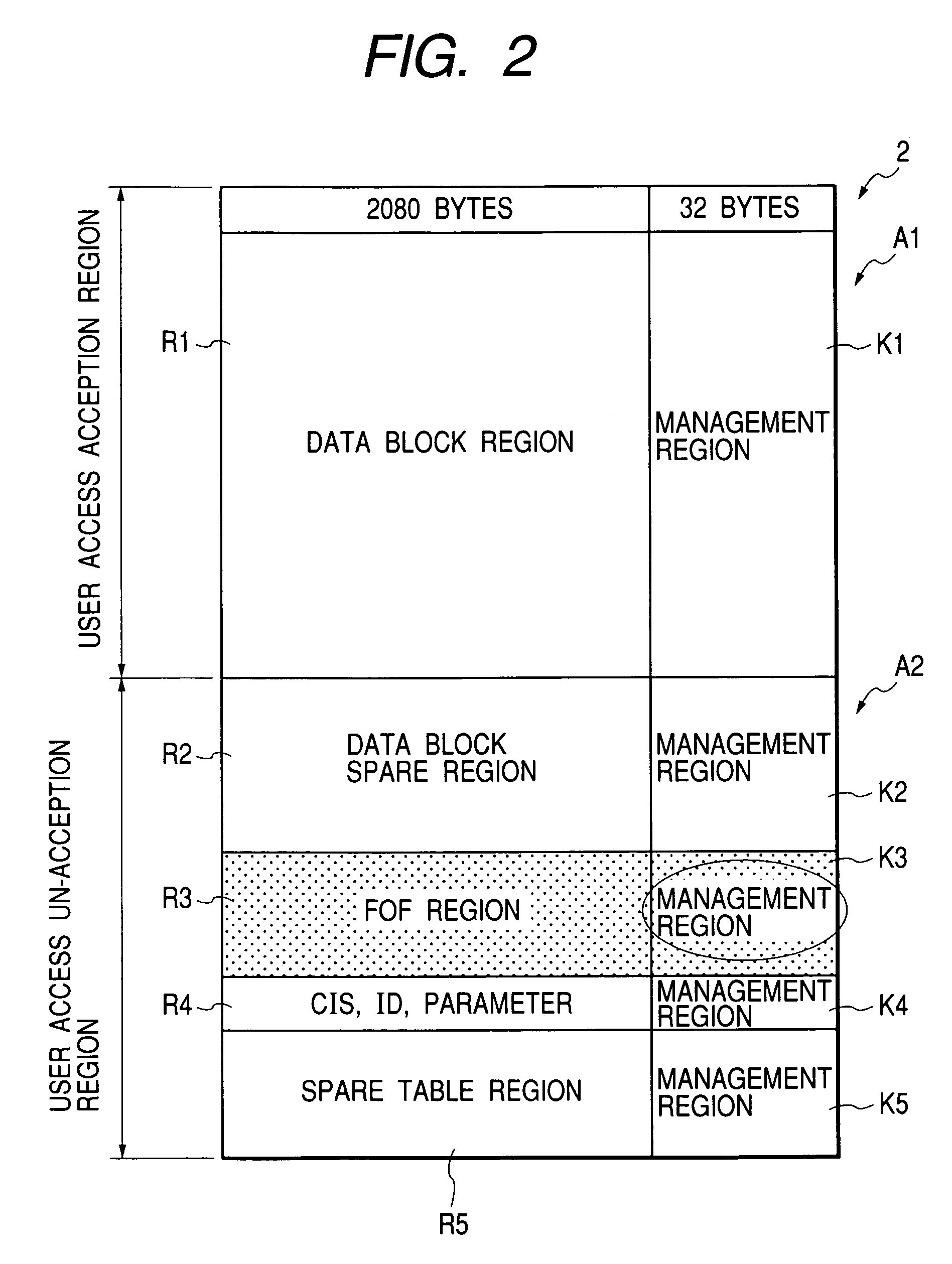

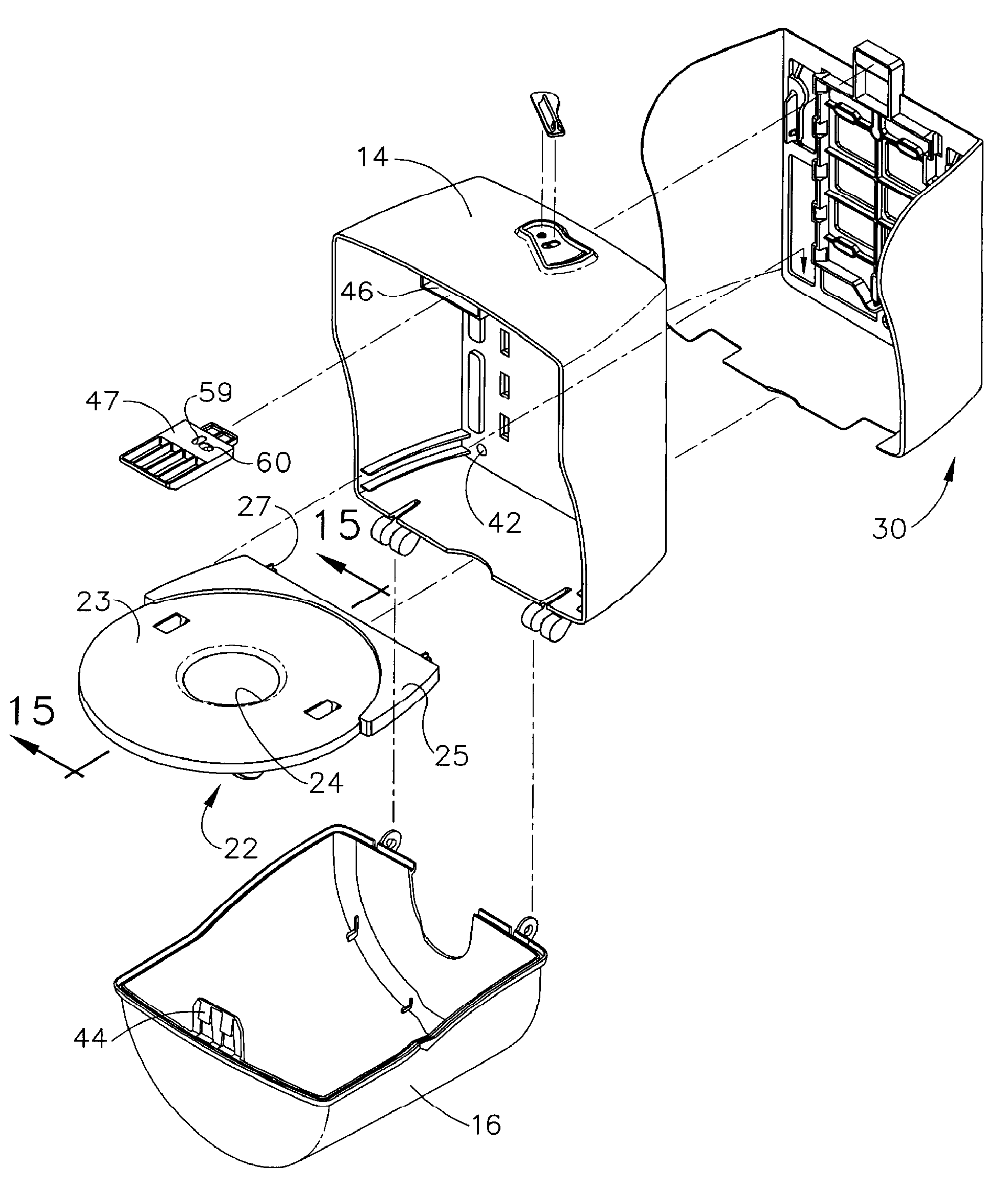

Nonvolatile memory card

The present invention provides a nonvolatile memory card in which a program is added, modified, changed, or the like by selecting arbitrary firmware on a flash memory from a plurality of pieces of firmware on flash memories. In a memory card, in addition to a program stored in a built-in ROM, firmware on flash memories as programs for adding, changing, modifying, or the like of a function such as a patch program are stored. Firmware on a flash memory which is desired to be made valid is set in a parameter sector or the like and is loaded into an external RAM, and the CPU of a control logic executes a process.

Owner:RENESAS ELECTRONICS CORP

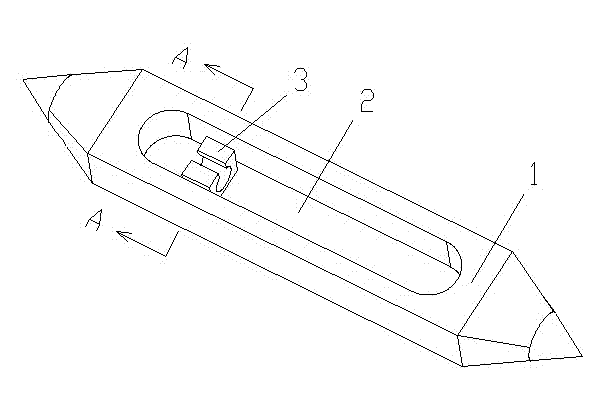

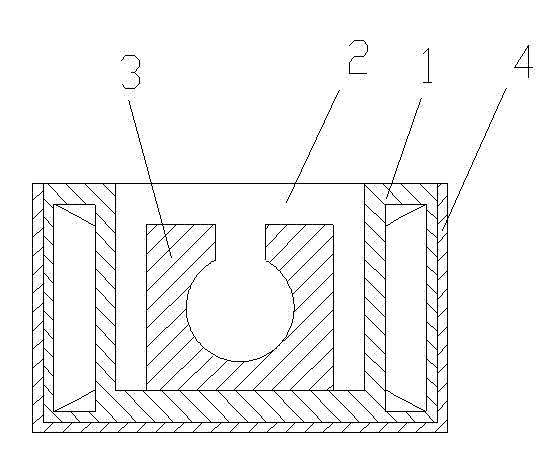

Novel wood shuttle

InactiveCN102767044AOvercome the disadvantages of easy wear and tearExtended service lifeShuttlesSynthetic materialsWear resistant

The invention discloses a novel wood shuttle, comprising a wood shuttle body, a shuttle groove and a quill chuck, wherein the quill chuck is arranged in the shuttle groove; two sides and bottom of the wood shuttle body respectively are provided with a wear resistant protection layer; and the wear resistant protection layers are high polymer liner plate layers. The novel wood shuttle provided by the invention can change limit for materials of the traditional shuttle, and can be produced by various woods or wood synthetic materials so as to reduce production cost. Due to arrangement of the wear resistant protection layers, the defects that the former wood shuttle is worn and cracked easily are overcome, and service life of the wood shuttle is prolonged.

Owner:SUZHOU SHENGLONG SILK EMBROIDERY

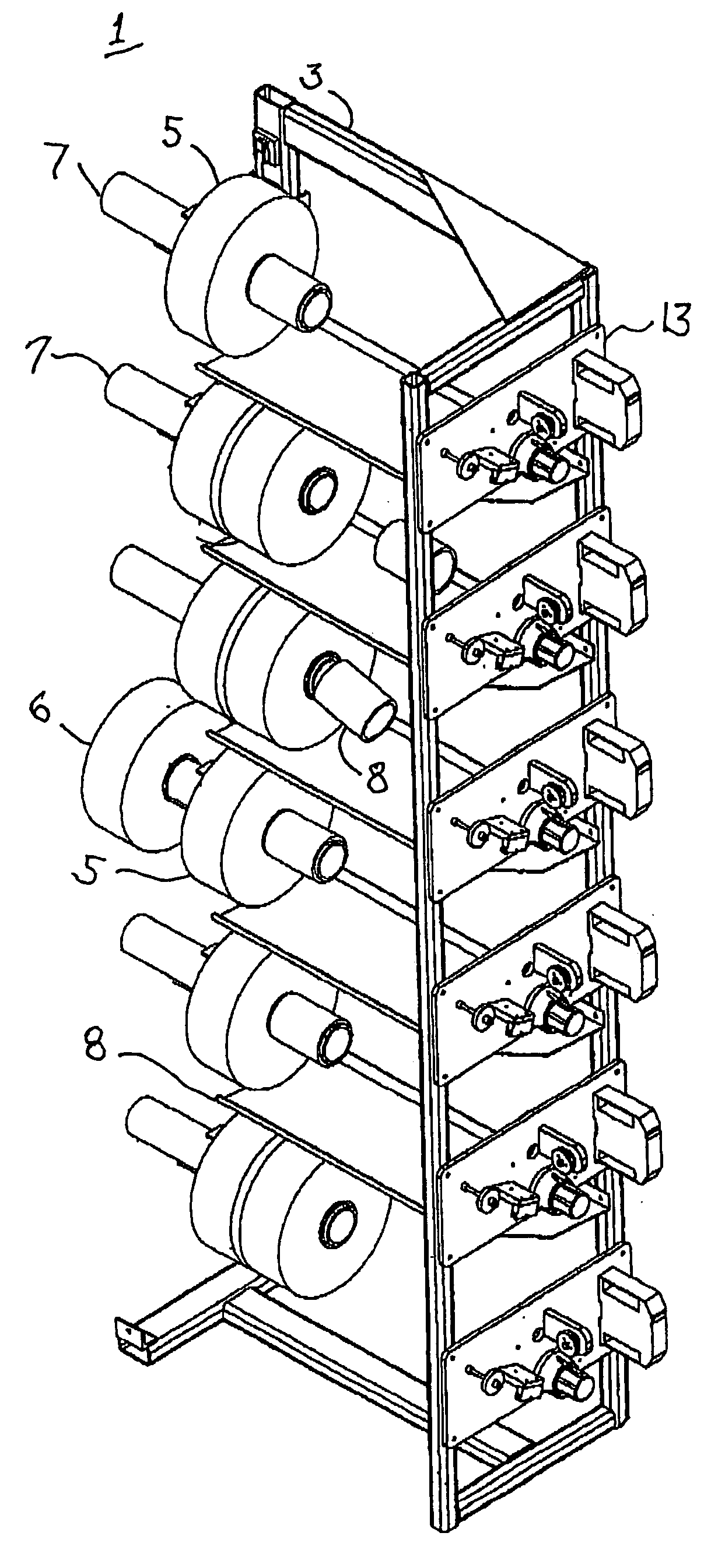

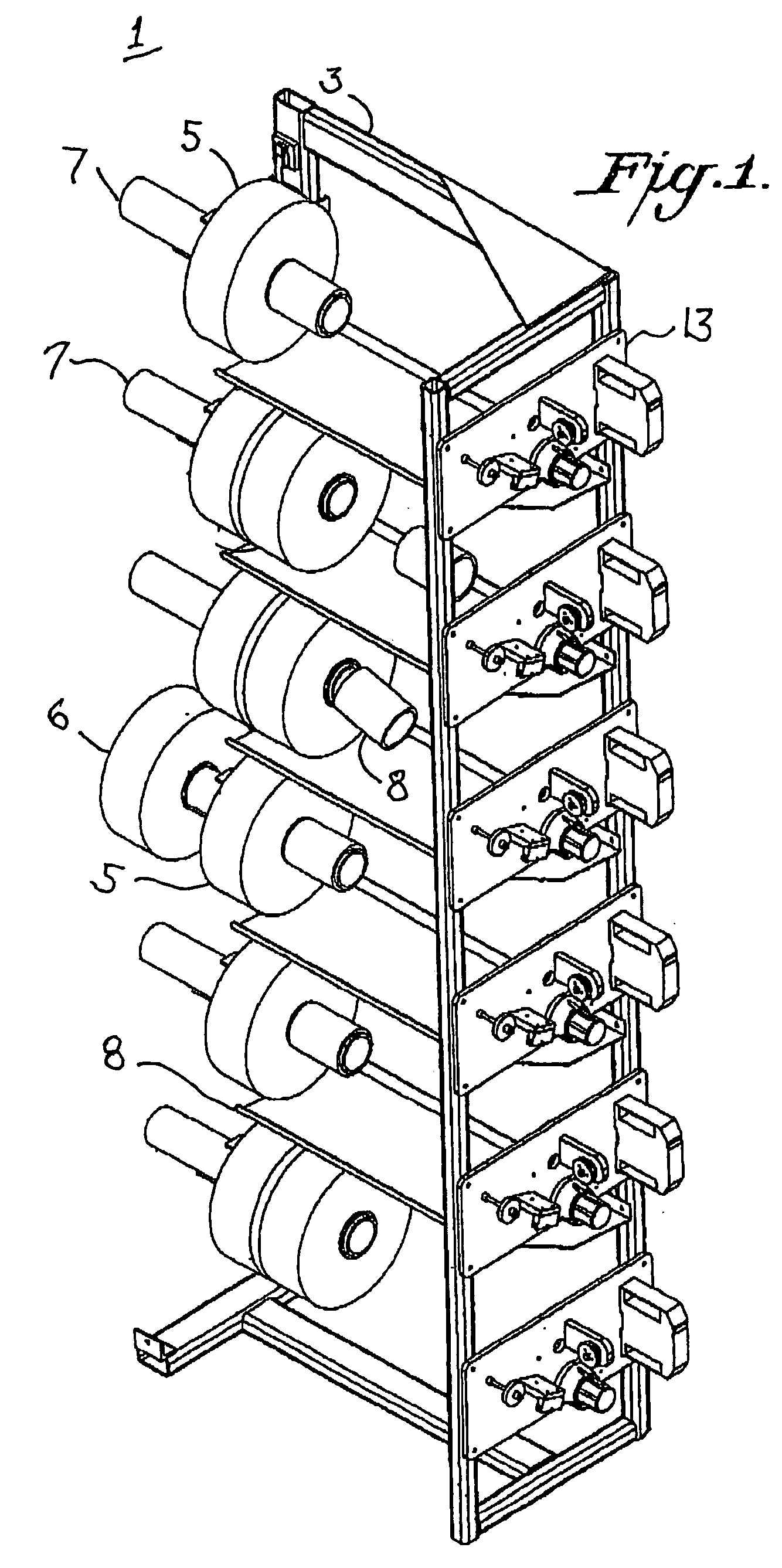

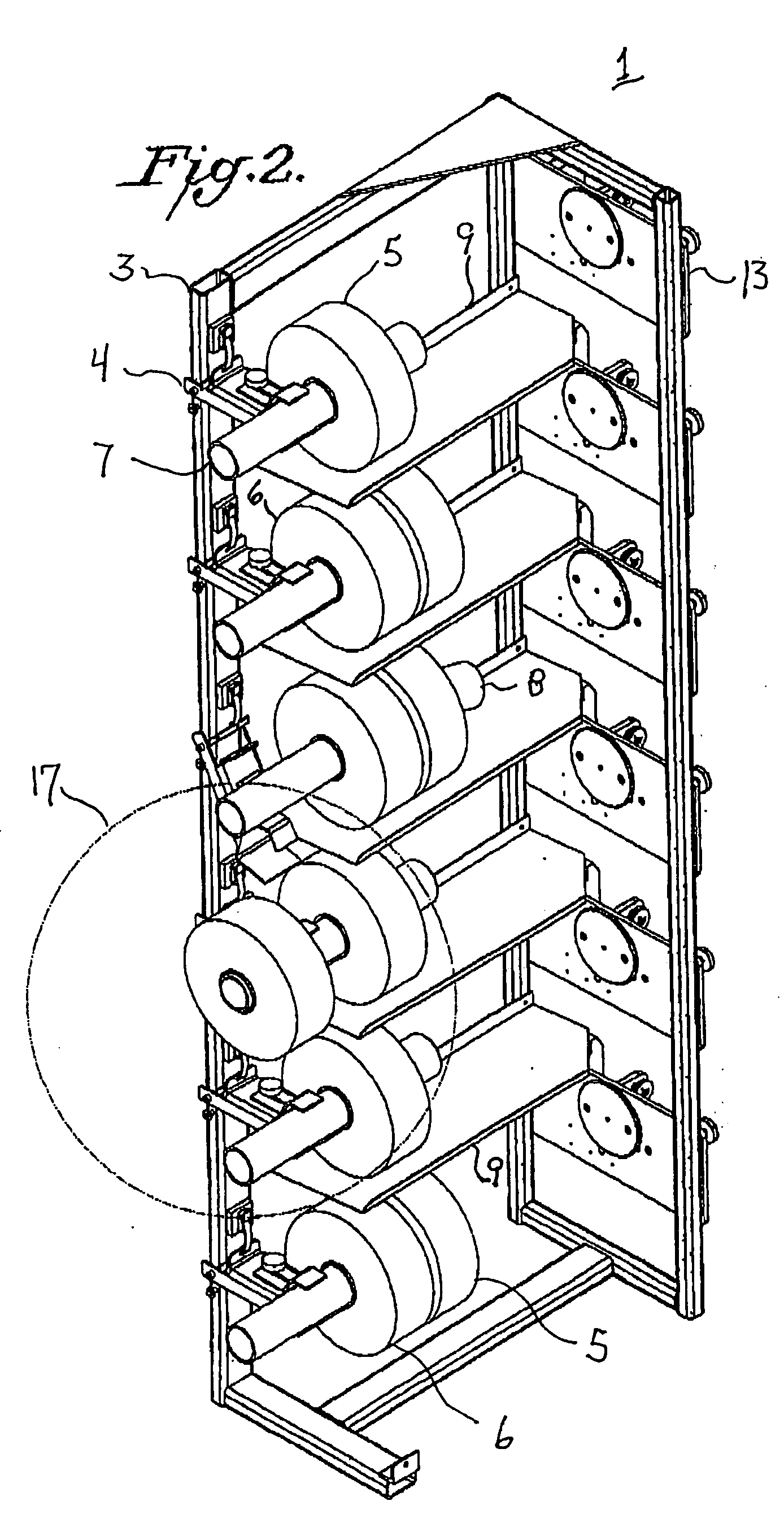

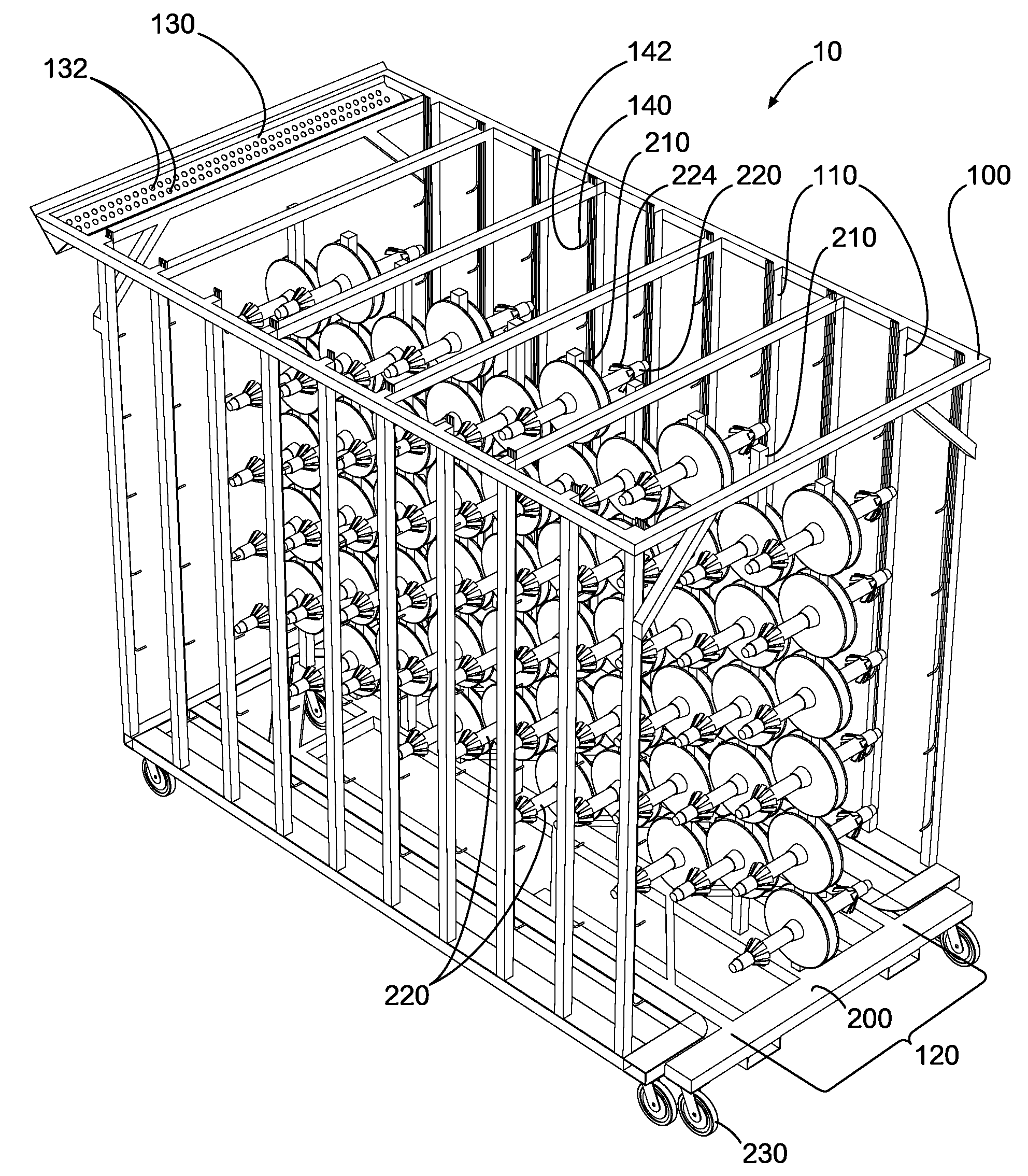

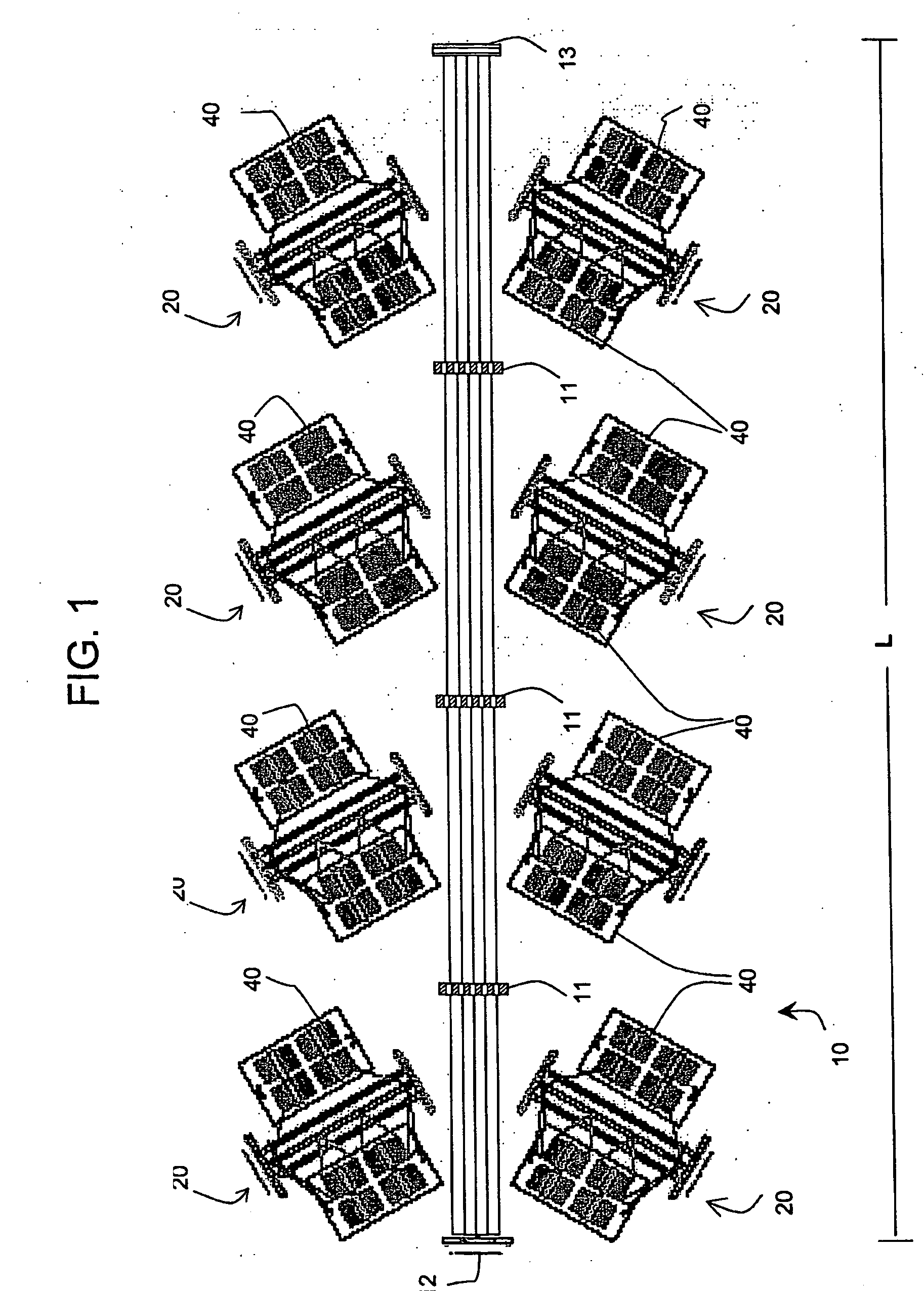

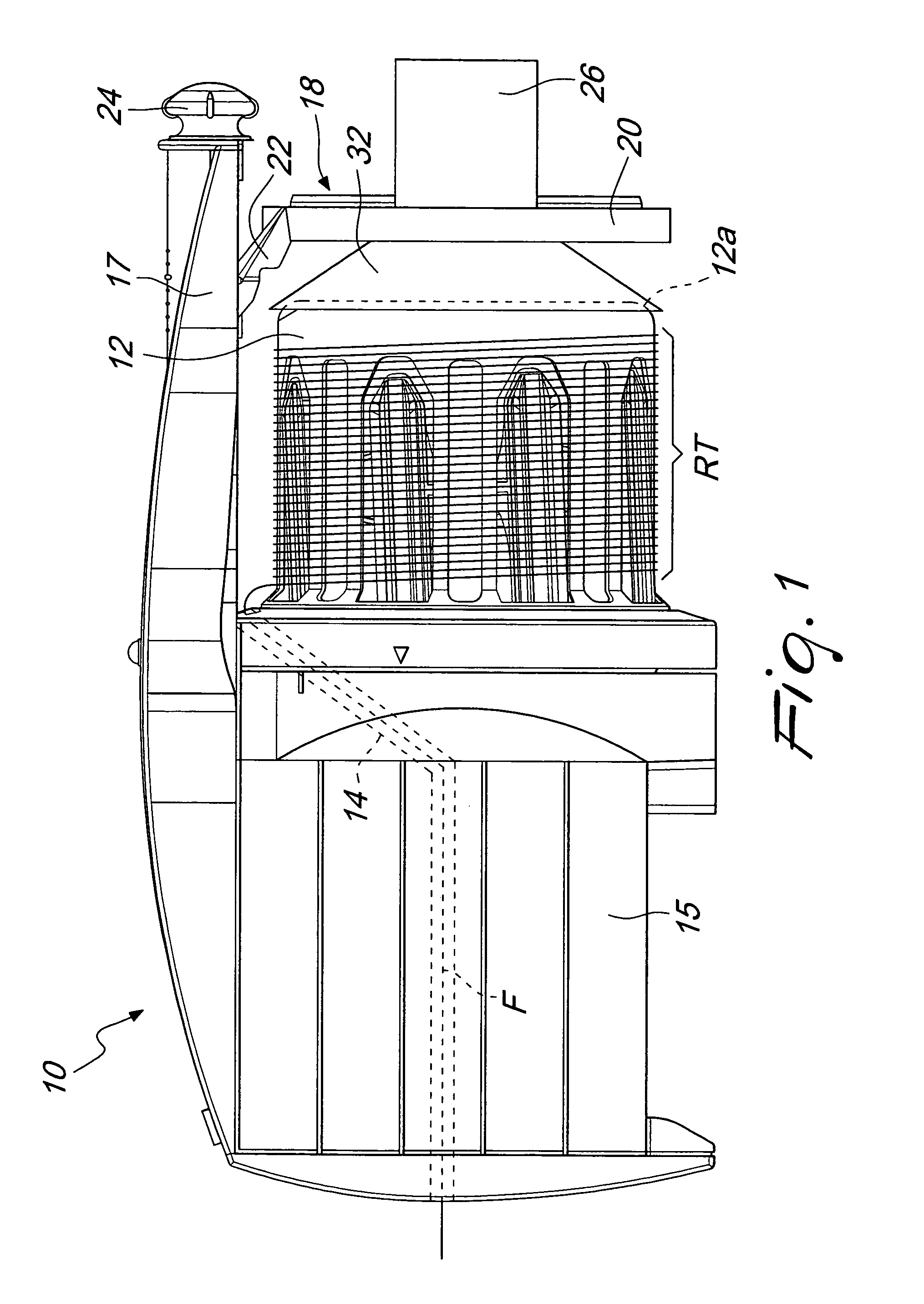

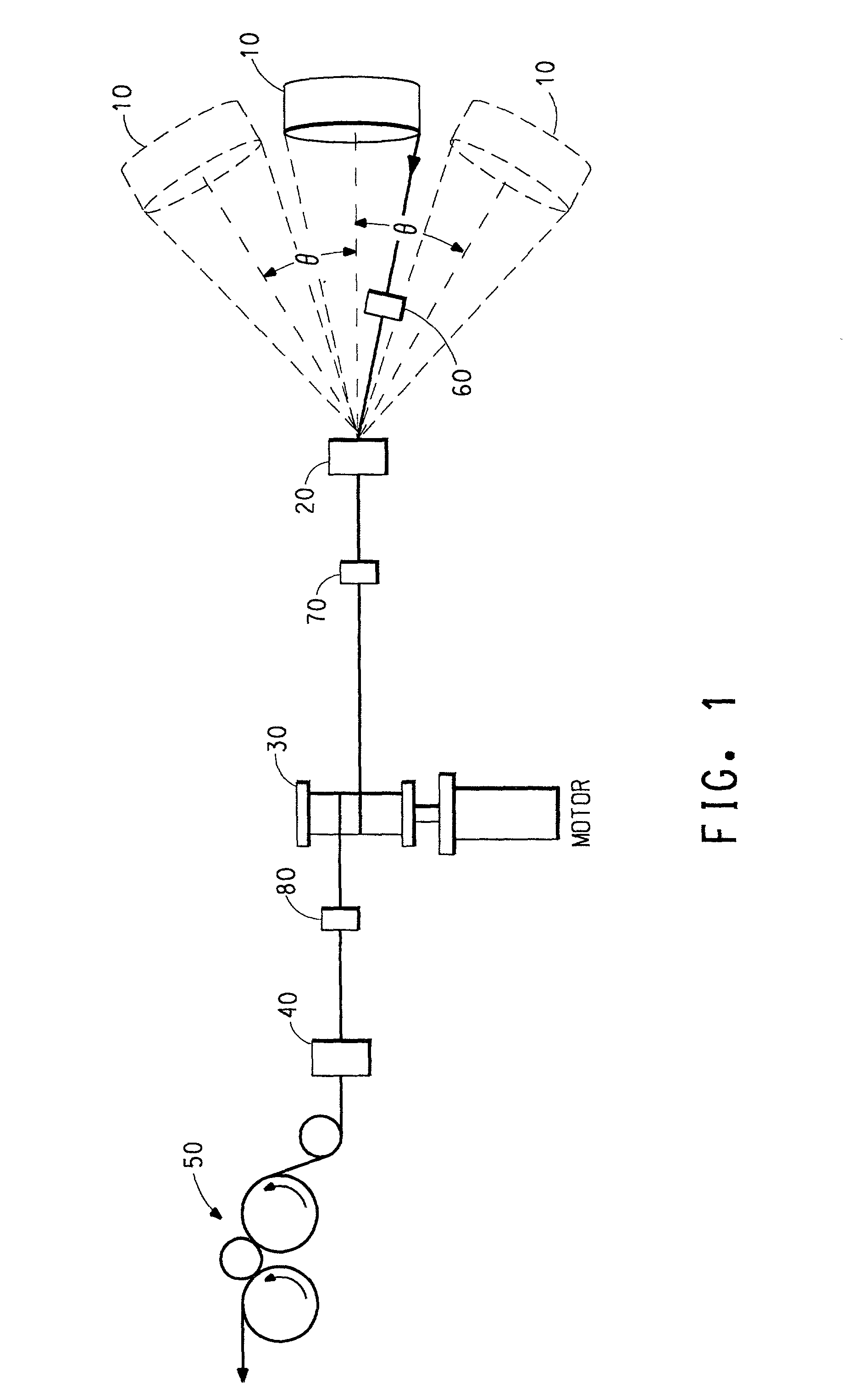

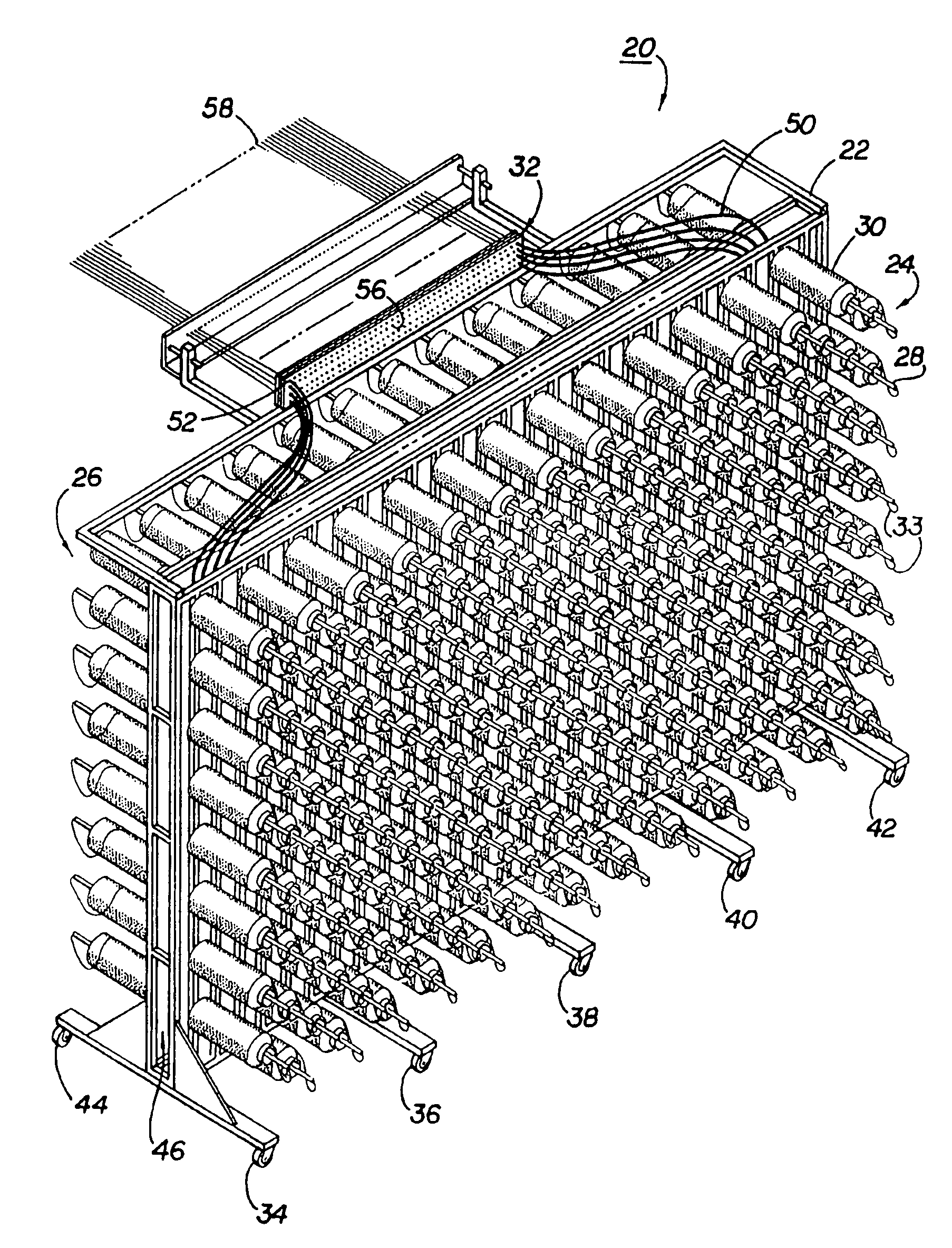

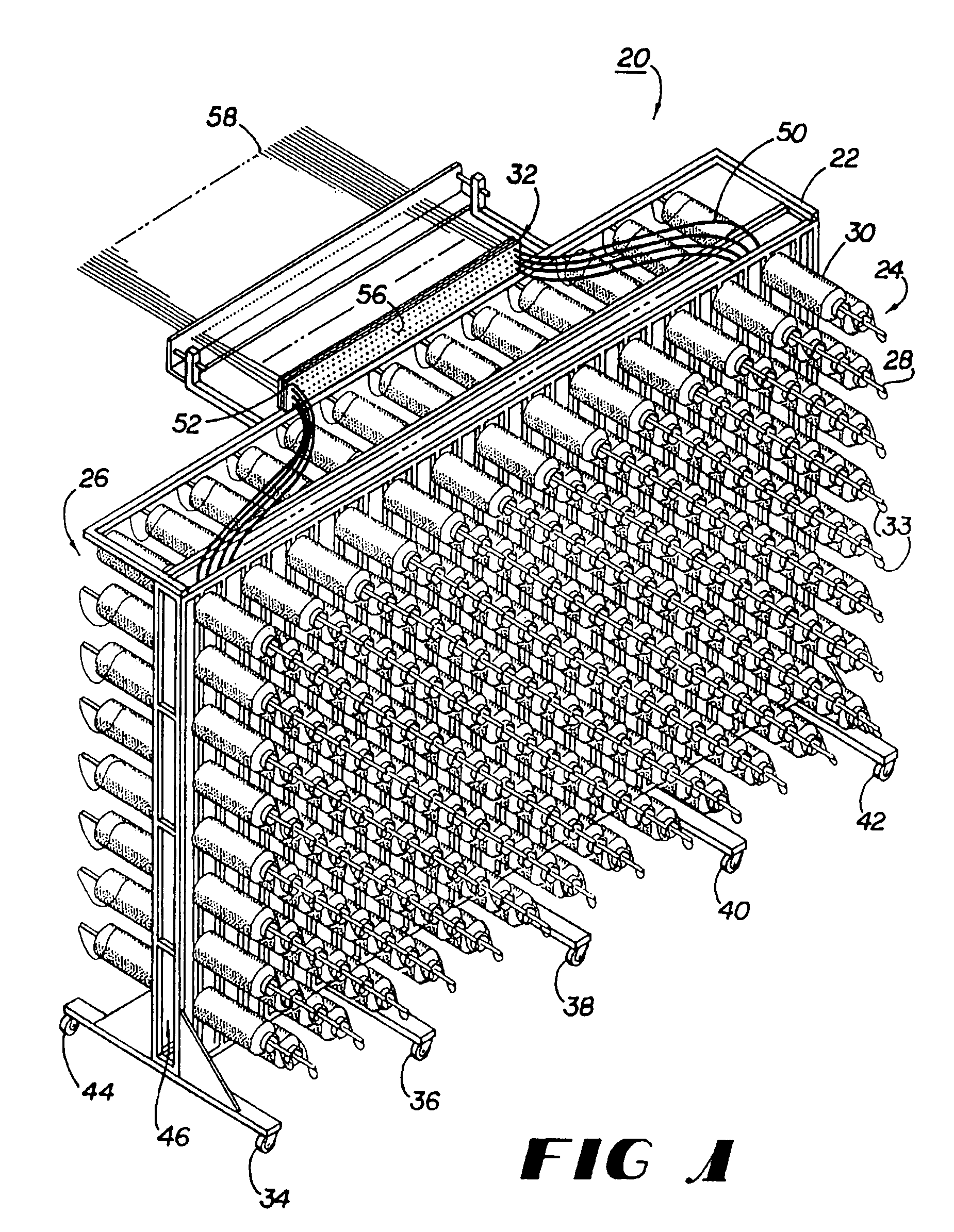

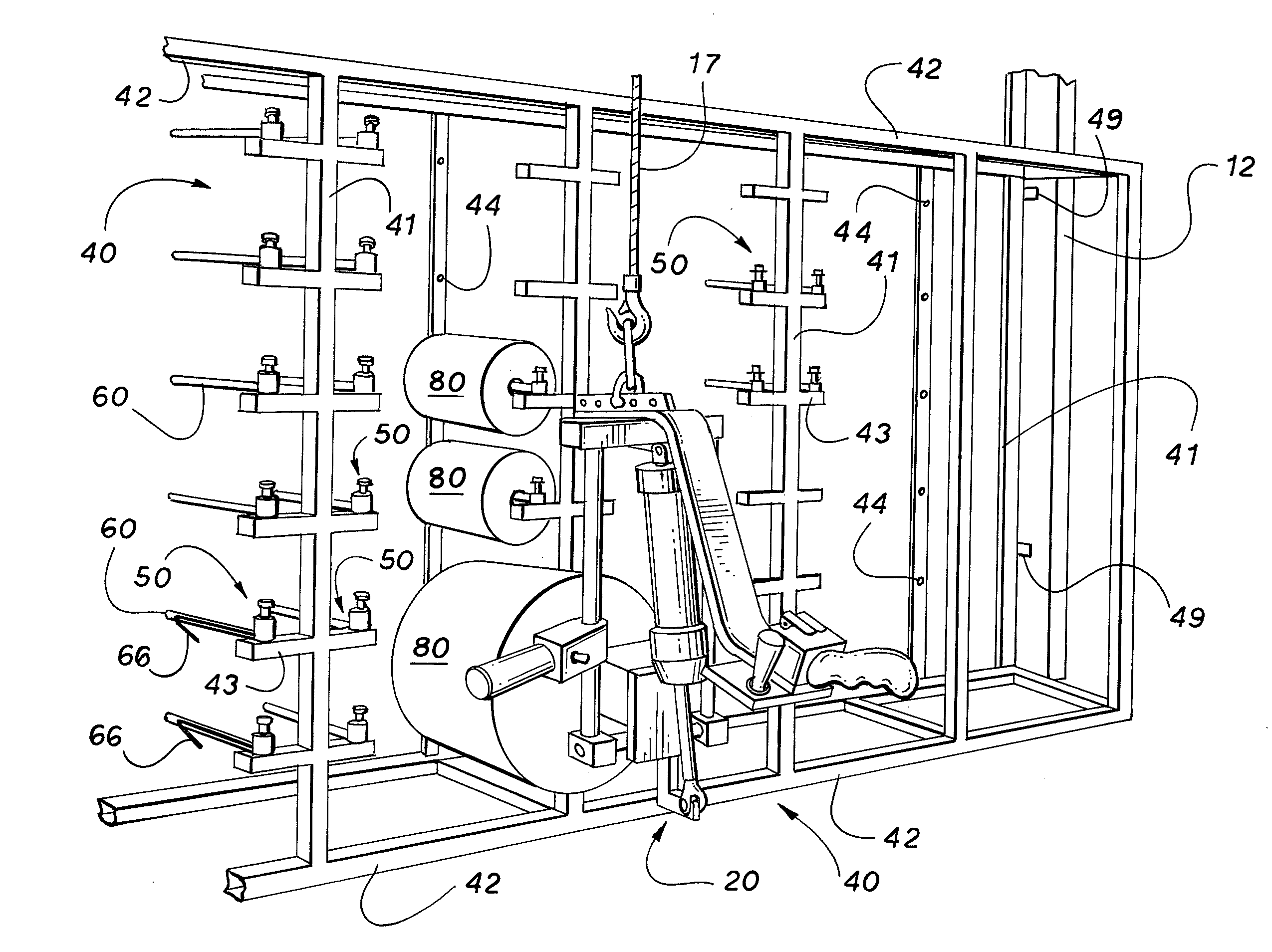

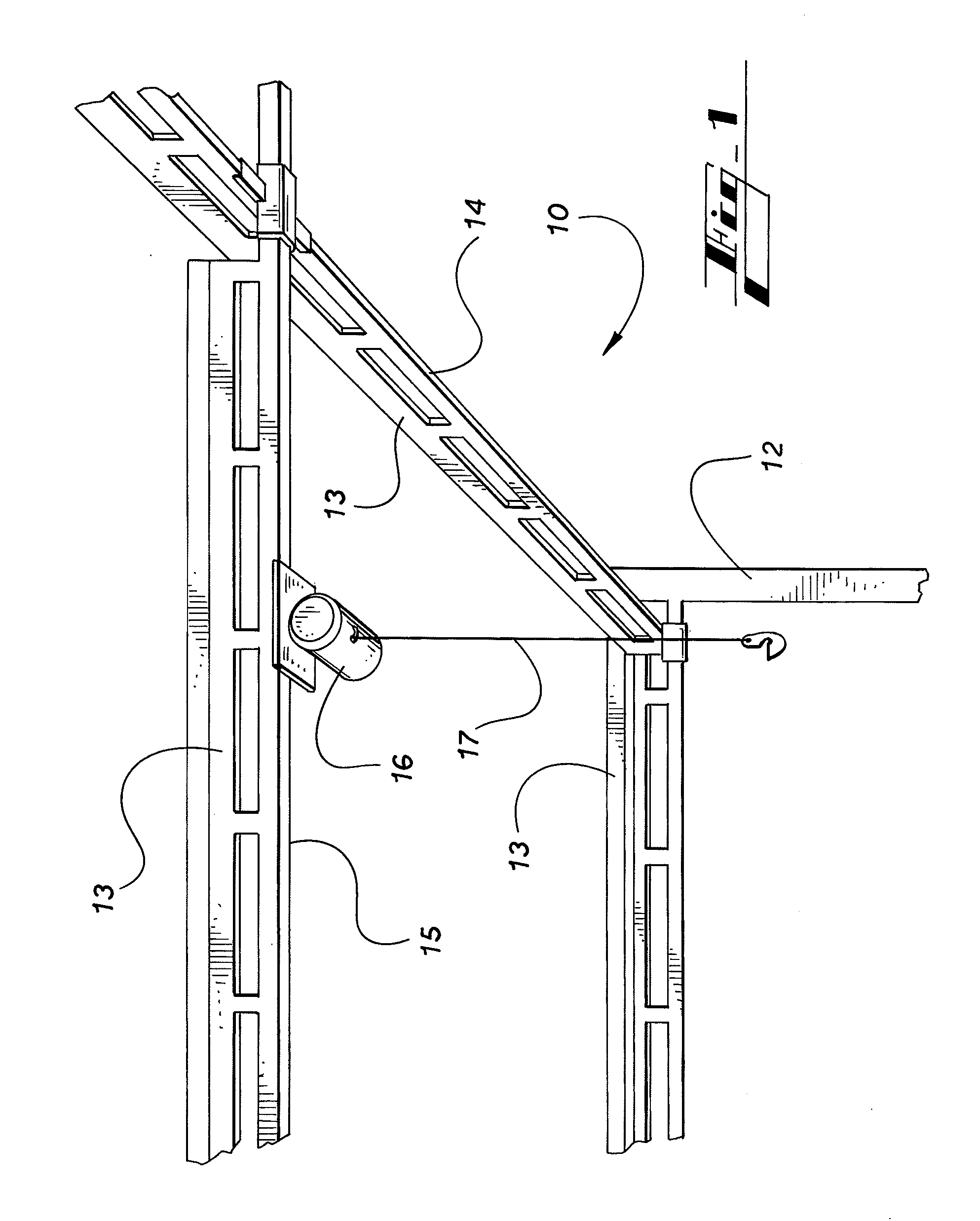

Modular creel

A portable creel for organizing yarn packages and directing yarn to a tufting machine. A portable creel provides flexibility for carpet manufactures in that operators can pre-load portable creels with yarn packages for future runs and move them into position when needed. In one aspect, the portable creel comprises an outer frame and a movable inner frame. The inner frame is configured to hold a plurality of yarn packages and the outer frame comprises a plurality of tubes configured to direct the yarn from the yarn packages to a header. The header, in turn, directs the yarn from the portable creel to specific portions of a tufting machine.

Owner:COLUMBIA INSURANCE CO

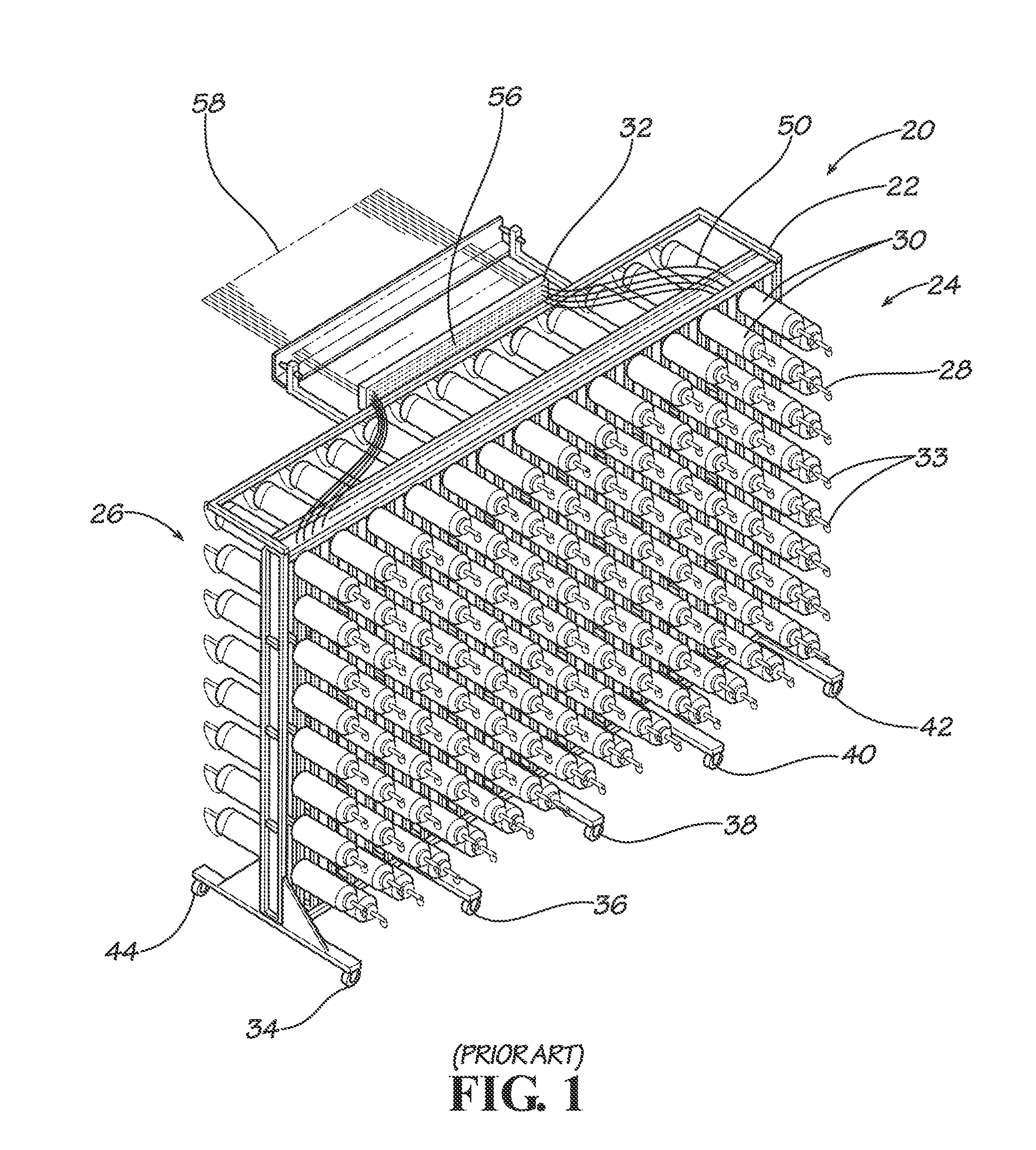

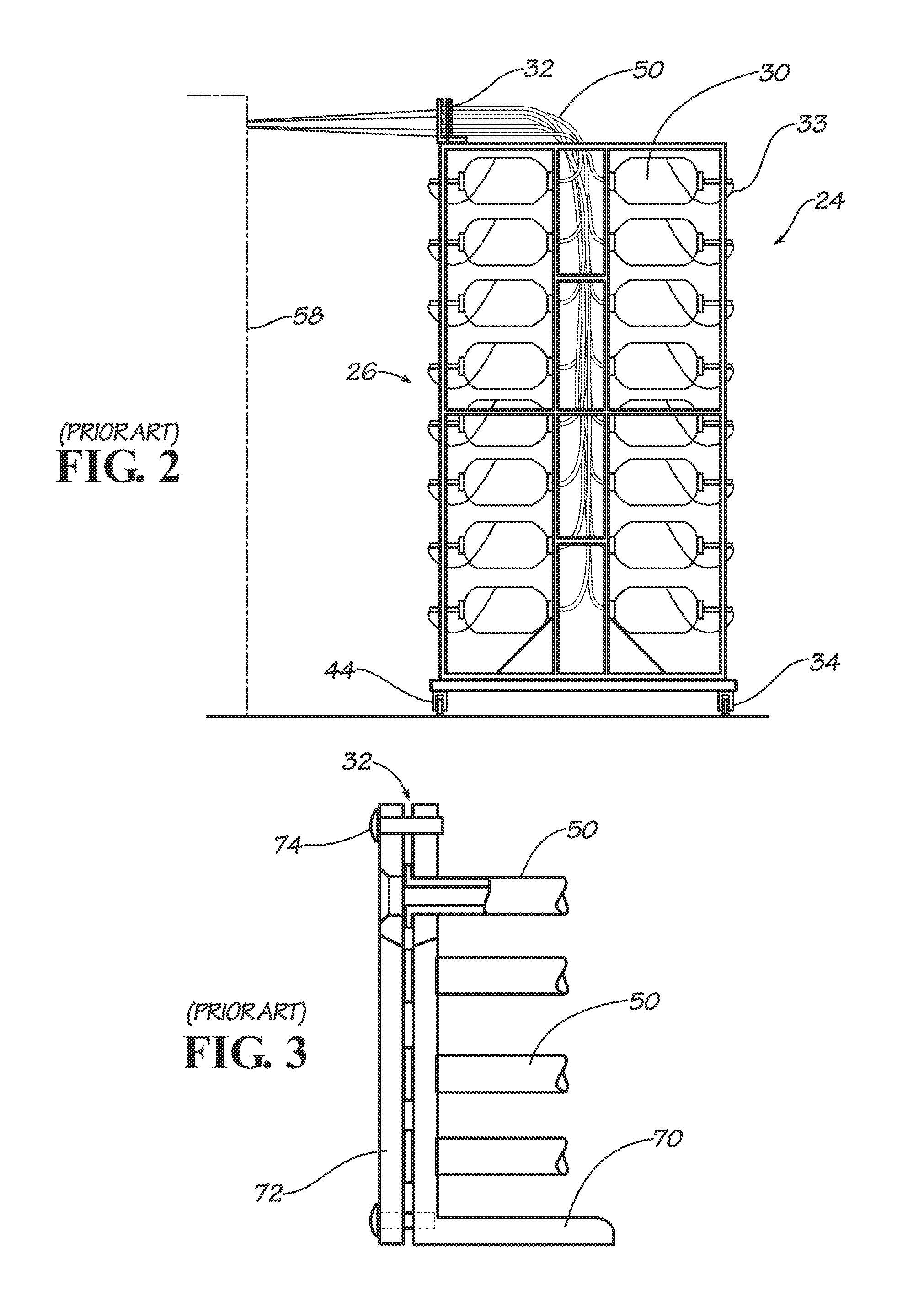

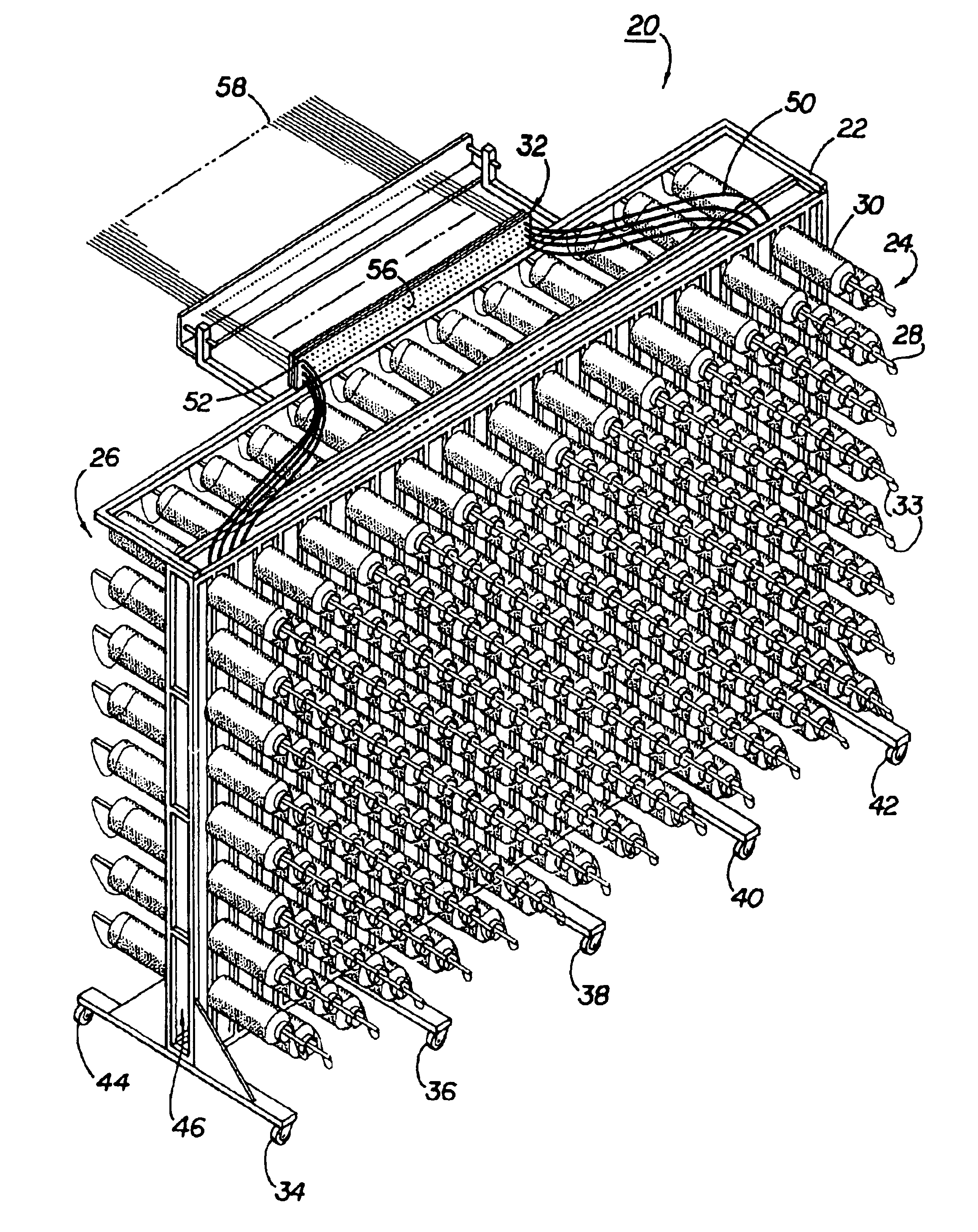

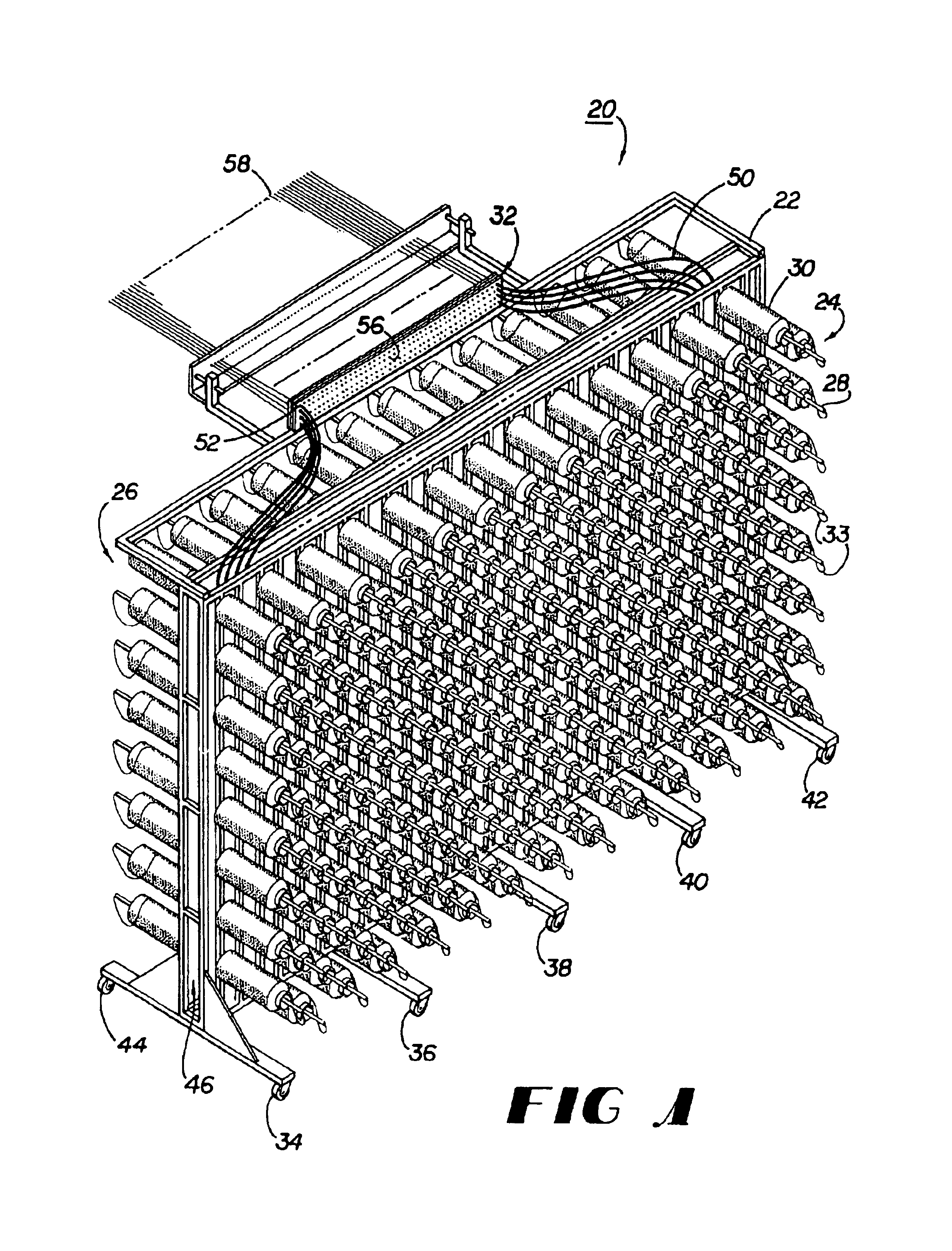

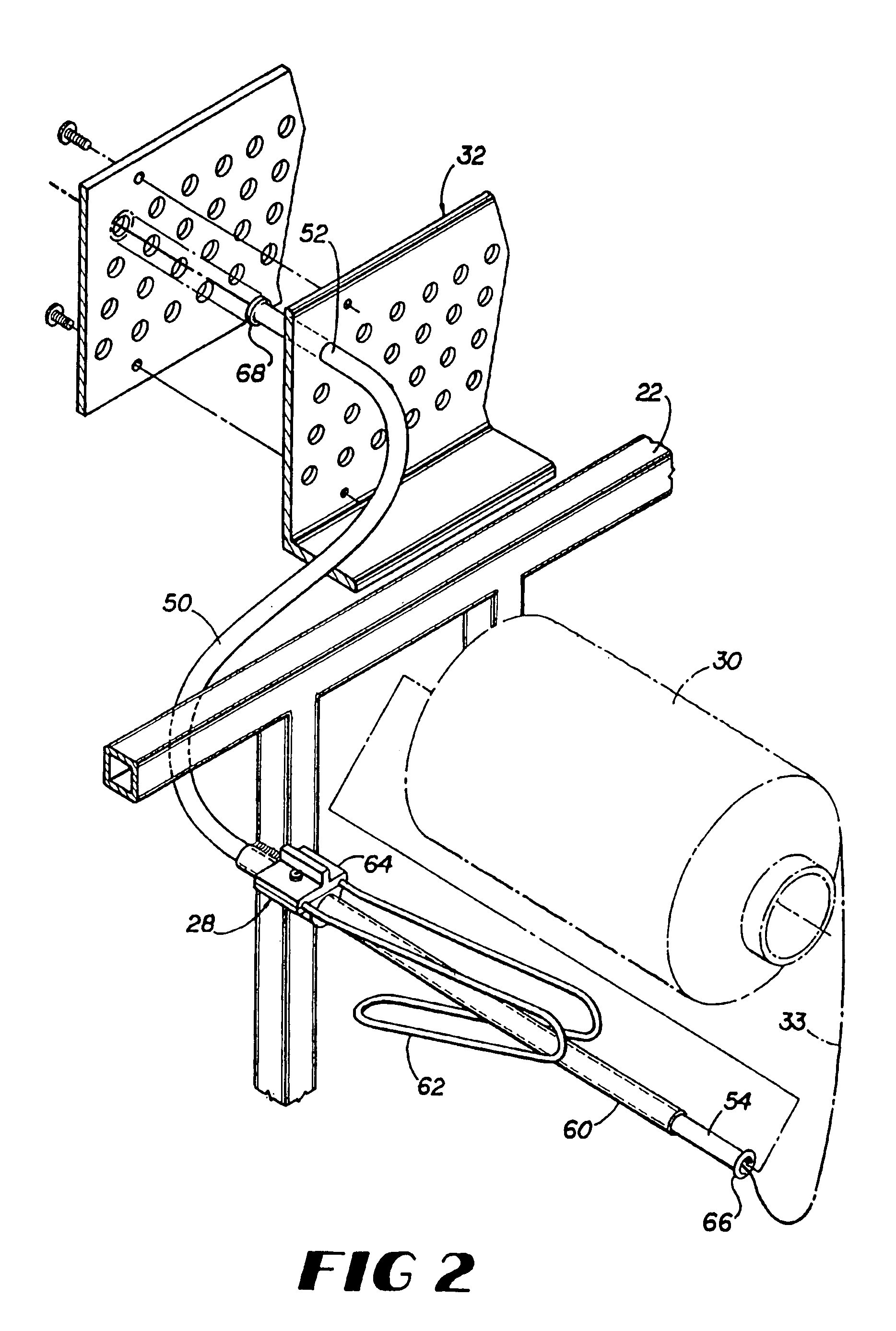

Compact creel

InactiveUS7004415B2Reduces yarn wasteImprove finished product qualityTufting apparatusFilament handlingYarnBobbin

A highly mobile, compact creel that utilizes frames for holding yarn packages (or bobbins) for feeding yarn to a tufting machine. Each frame includes holders affixed to the frame for holding yarn packages facing front and back, a header attachable to the frame for directing yarn from the yarn packages to the tufting machine, and anti-static flexible tubing for leading yarn from the holders to the header. The header provides for aligning all the yarn ends in the same plane to join them to ends already threaded into the tufting machine. An optional frame overlay upright having a ring affixed thereto and strands threaded through the ring prevents yarn from upper yarn packages from falling onto tubes holding lower yarn packages causing yarn entanglement.

Owner:INTERFACE INC

Thread brake system with a linear electric motor for weaving looms

At least one of two flexible leaf springs that form a thread gap is controlled by a linearly moveable element of a linear motor or drive. Multi-thread brakes are formed by assembling a plurality of such brakes on a common support whereby a single stator may cooperate with a plurality of linearly moveable armatures forming a corresponding plurality of thread brakes or each thread brake may have its own stator and its own armature arranged in a row either linearly or along a curved support, whereby a compact structure is achieved.

Owner:LINDAUER DORNIER GMBH

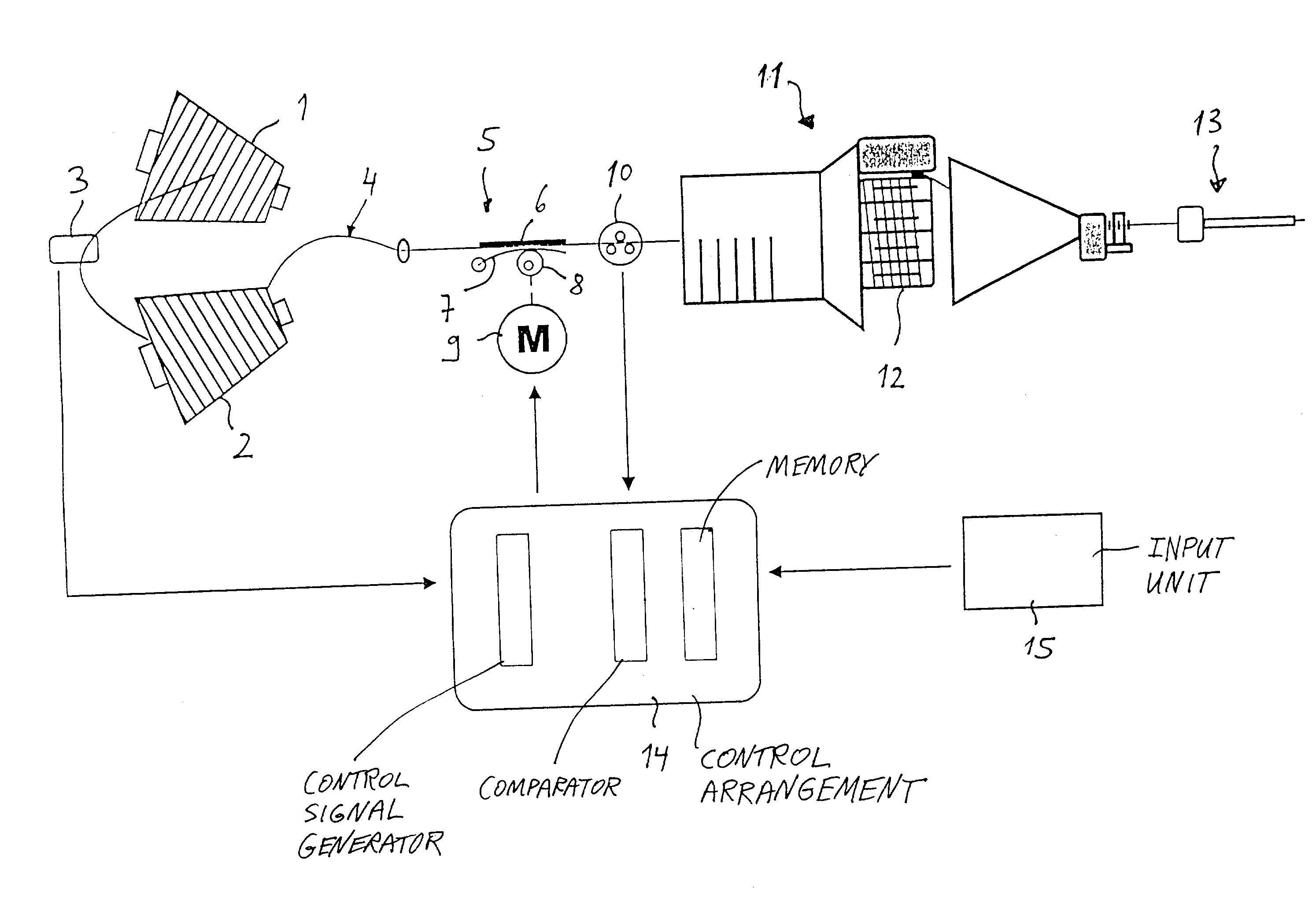

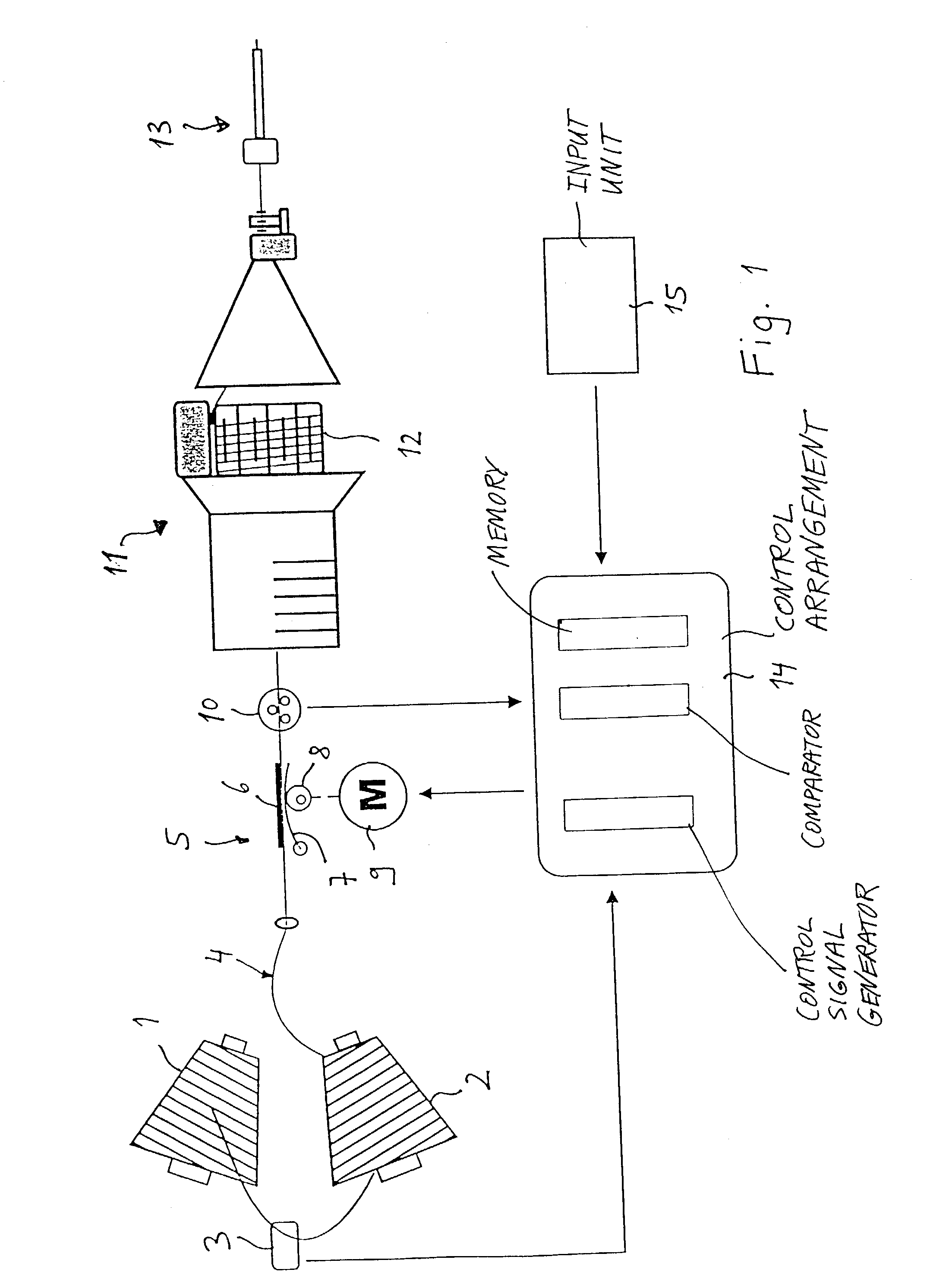

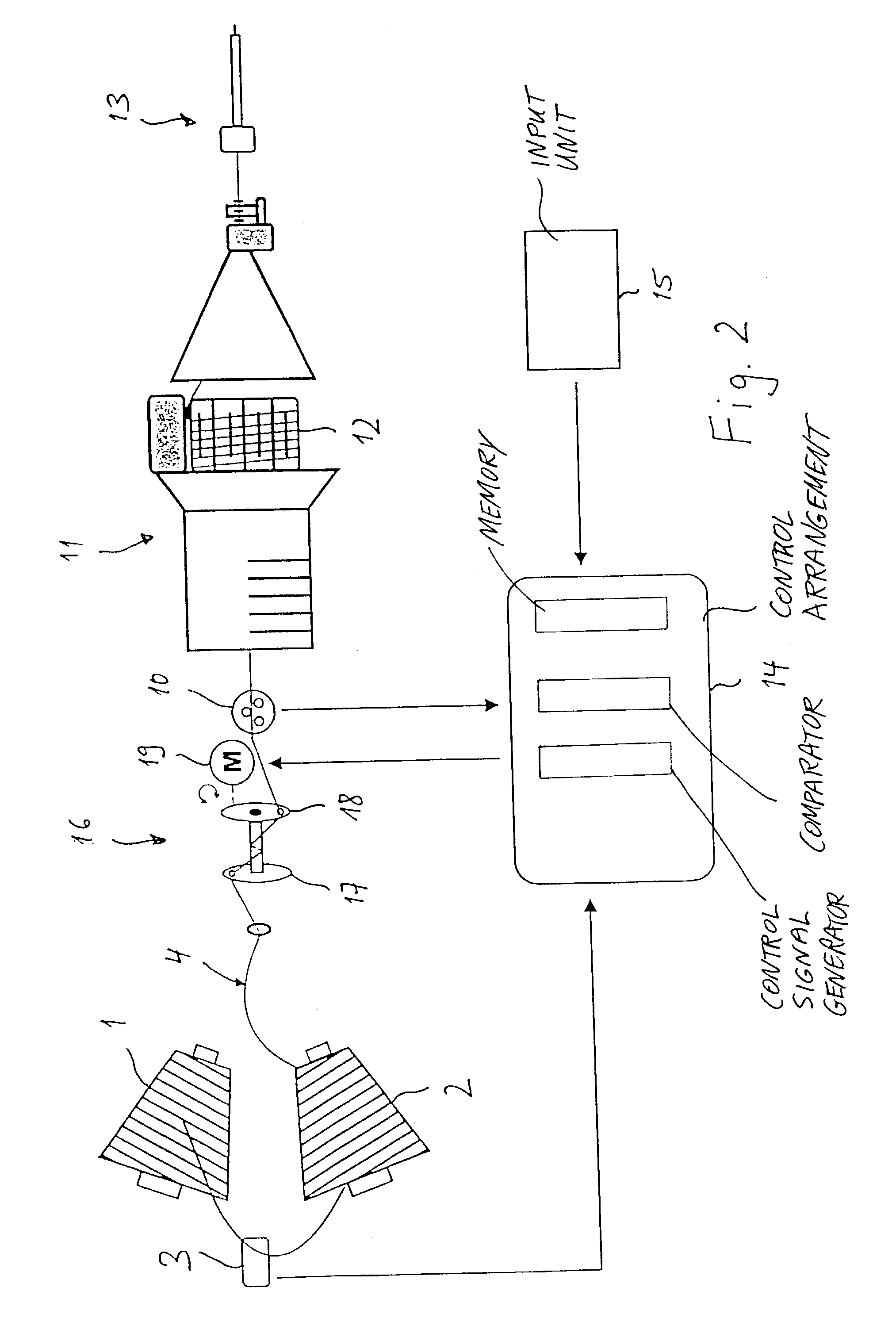

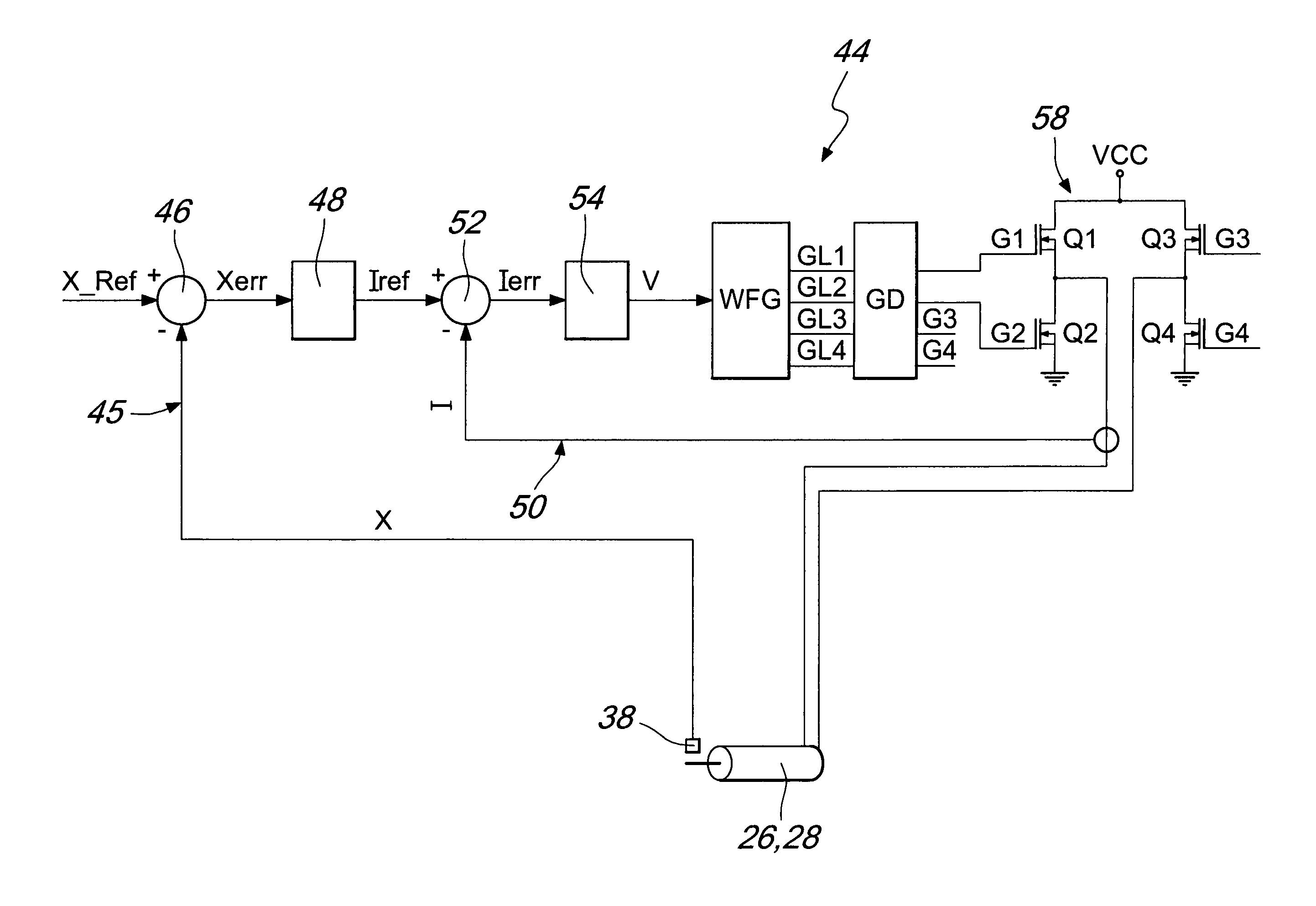

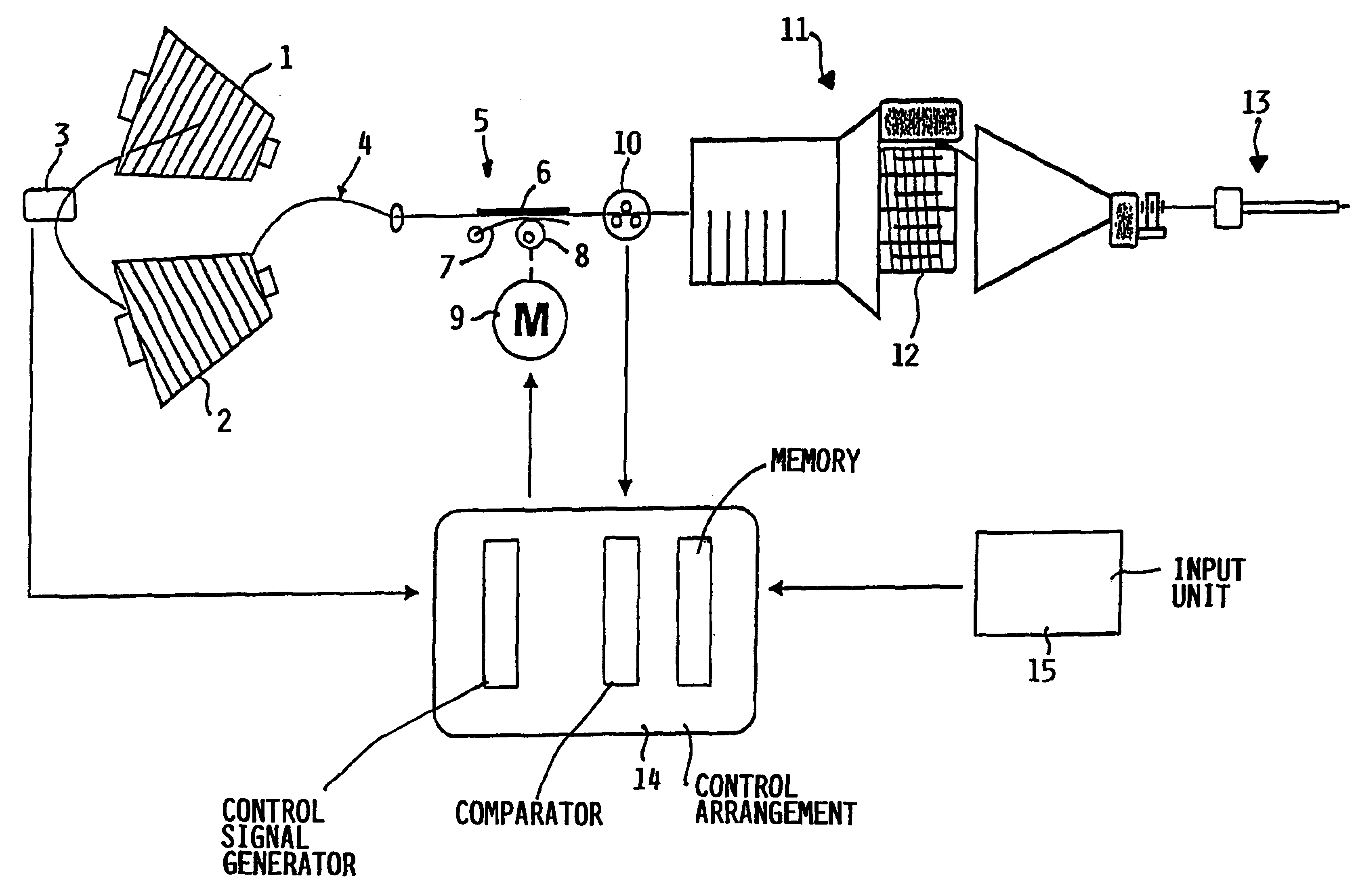

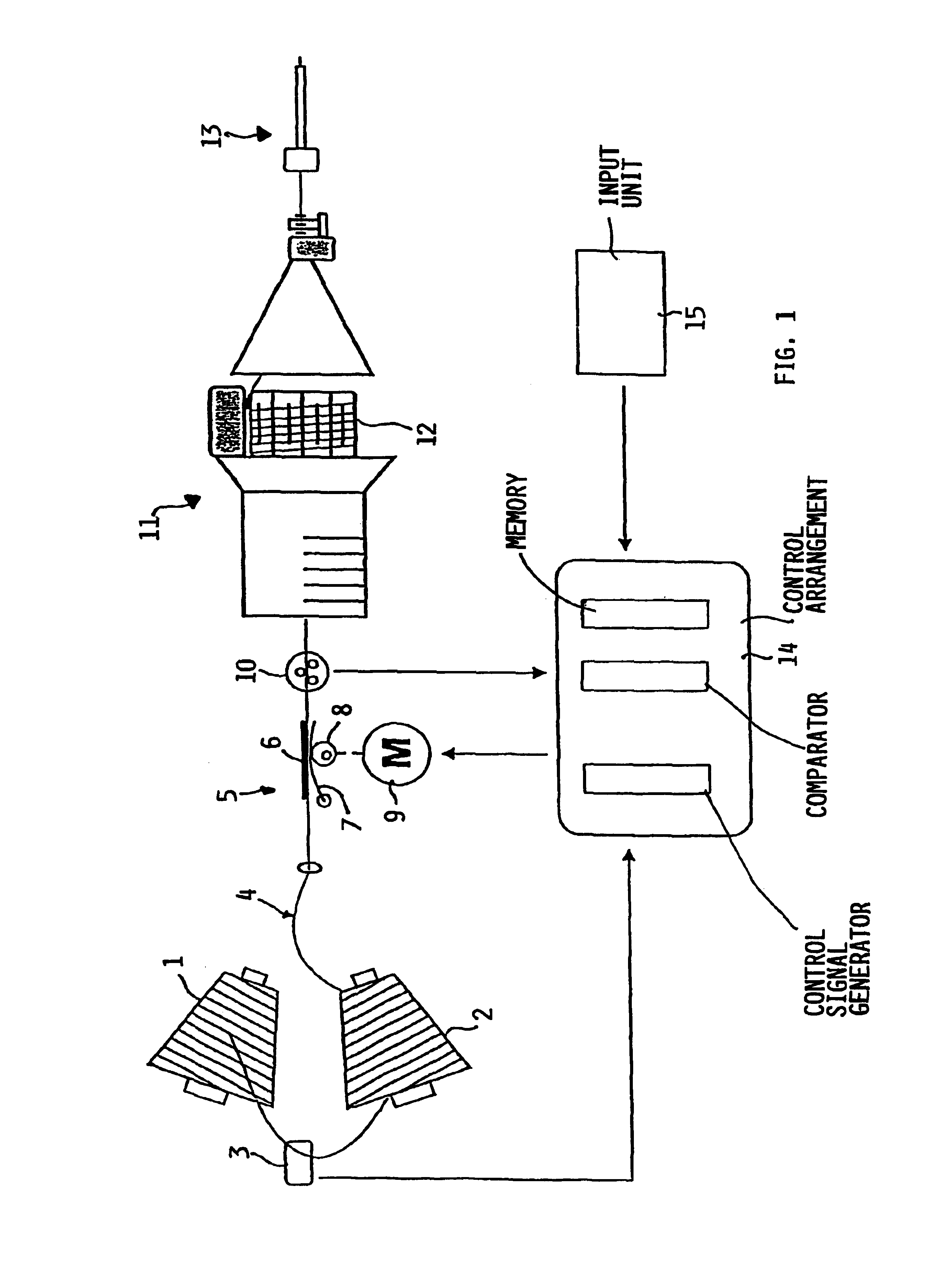

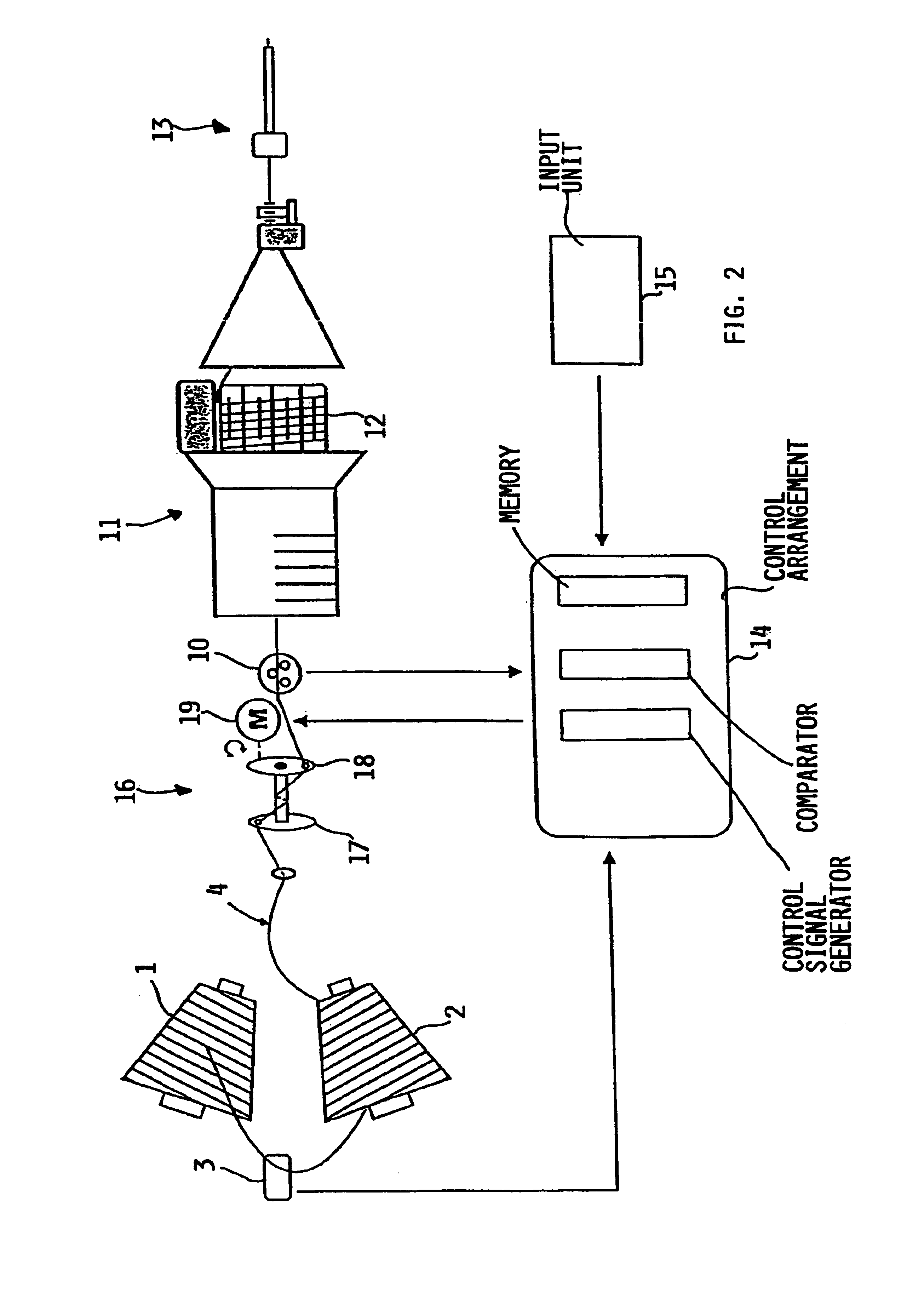

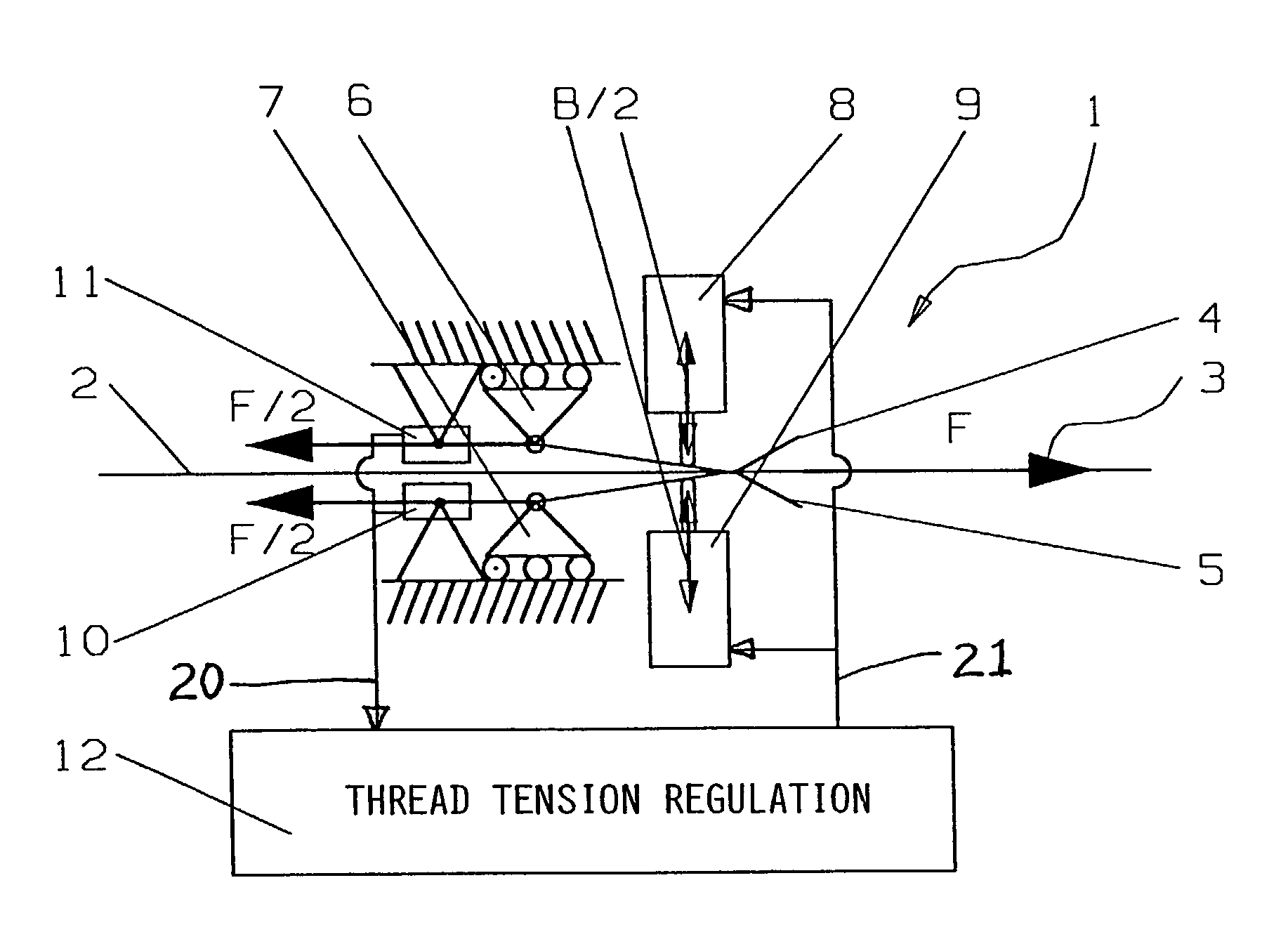

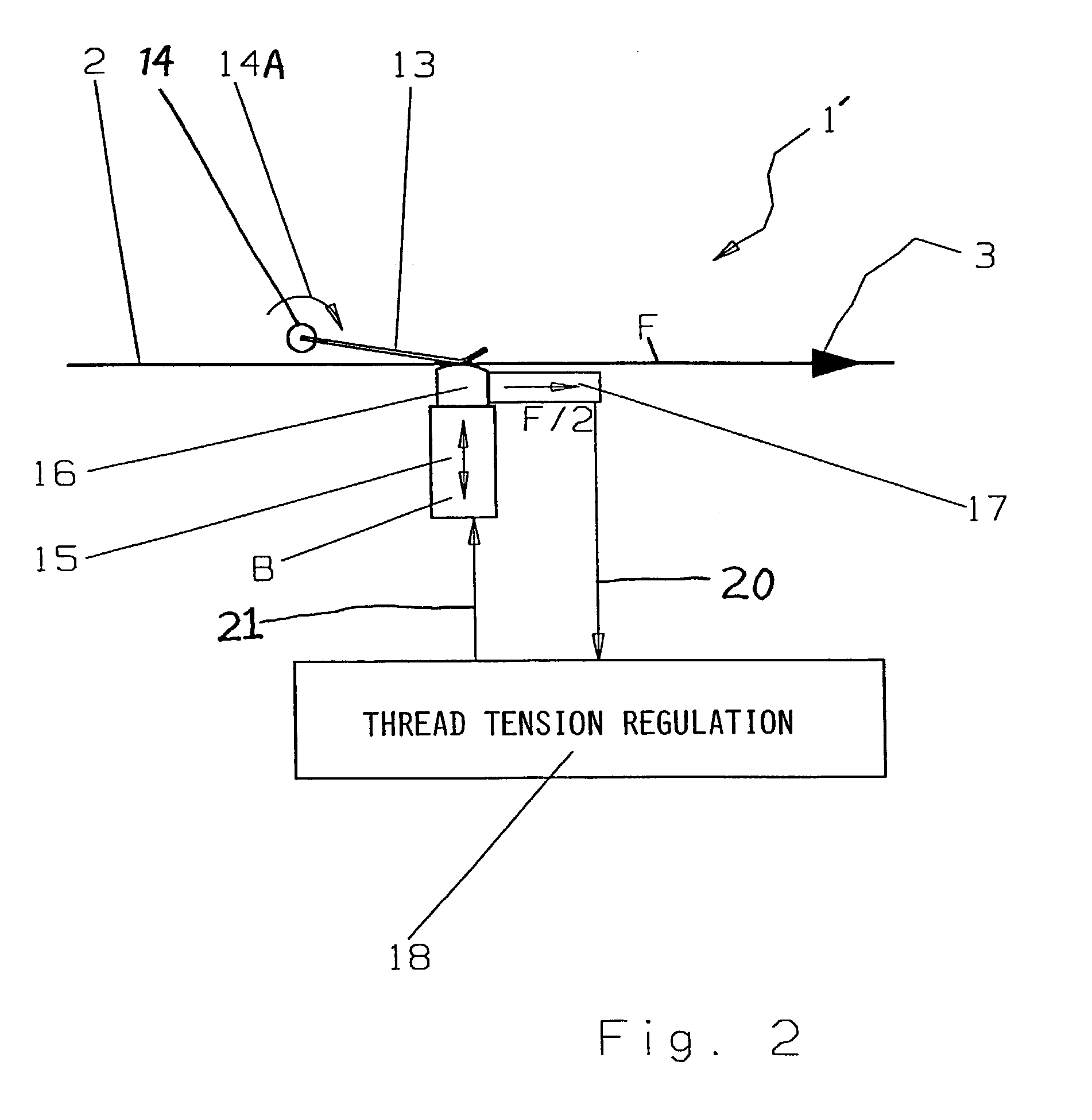

Method and apparatus for variably braking the weft thread between a supply spool and a thread store in a loom

A supply spool supplies a weft thread through an adjustable actuated thread brake and a thread tension sensor to a weft thread accumulator, from which an accumulated insertion length of the thread is provided to a weft insertion device. The tension sensor provides a measured actual thread tension signal to a control arrangement, which compares the actual tension to a selected rated tension, and, dependent on the deviation therebetween, provides a control signal to an actuator of the thread brake, so that the actual thread tension constantly corresponds to the selected rated tension. Another sensor provides a signal indicating a change from an empty spool to a full spool. Responsive thereto, the control arrangement actuates the thread brake to an adjustable starting brake setting as a coarse adjustment. Then the self-regulating fine adjustment is continued. A constant winding tension and thread accumulation length are achieved in the thread accumulator.

Owner:LINDAUER DORNIER GMBH

Thread brake for weaving looms

At least one of two flexible leaf springs that form a thread gap is controlled by a linearly moveable element of a linear motor or drive. Multi-thread brakes are formed by assembling a plurality of such brakes on a common support whereby a single stator may cooperate with a plurality of linearly moveable armatures forming a corresponding plurality of thread brakes or each thread brake may have its own stator and its own armature arranged in a row either linearly or along a curved support, whereby a compact structure is achieved.

Owner:LINDAUER DORNIER GMBH

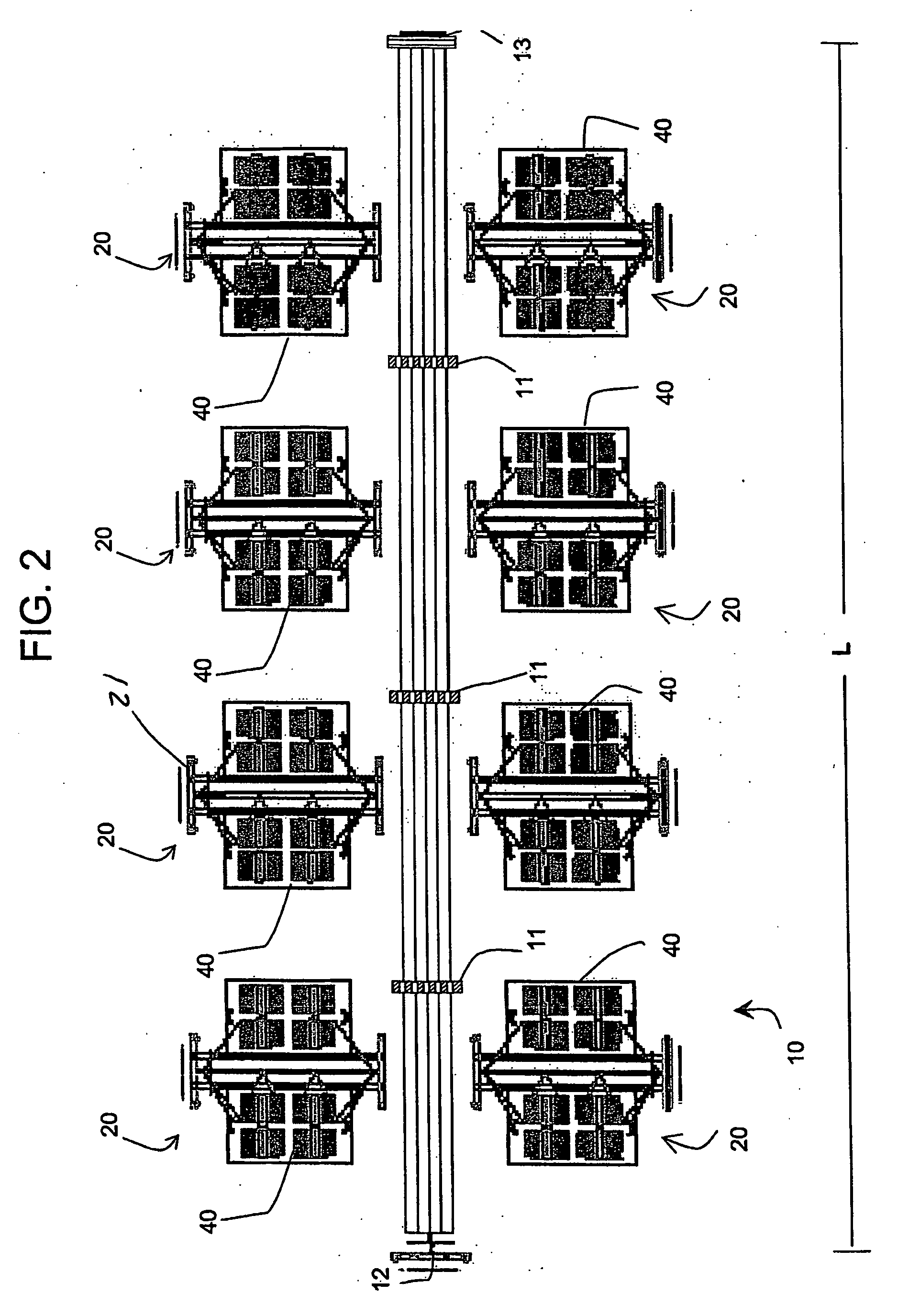

Creel Magazine Supply System and Method

InactiveUS20090101749A1Improve efficiencyReduce complexityFilament handlingCreelsEngineeringMechanical engineering

A creel magazine for continuously delivering packaged stranded material to a manufacturing process. A plurality of magazines linearly disposed in substantially parallel alignment are alternately supplied stranded materials fed to the manufacturing process from movable magazine cartridges supporting packages of stranded materials form either side of the magazine frame. The apparatus and method provide for sequential delivery of stranded materials from packages supported by cartridges at the sides of the magazines, intermediate replenishment of the depleted cartridges with cartridges loaded with replenished packages.

Owner:AUTOMATED CREEL SYST

Control unit for yarn-braking devices in weft feeders for looms, and tuning method therefor

InactiveUS7584014B2Improve automationShort execution timeLoomsFilament handlingYarnReference current

Owner:L G L ELECTRONICS

Unwinder for as-spun elastomeric fiber

The invention provides an over-end take off device (OETO) for unwinding elastomeric fiber. The invention further provides a method for unwinding elastomeric fiber for downstream processing.

Owner:THE LYCRA CO LLC

Center-pull paper towel dispenser

A center-pull dispenser for dispensing paper towels from a continuous roll, wherein each individual towel is separated from an adjoining towel by a plurality of perforations. The dispenser comprises a housing having a housing back and a detachable front cover hingedly connected thereto at the lower periphery of said housing back and front cover for opening and closing the housing, a paper support tray removably connected to a lower portion of the housing back, the tray having a centrally located dispensing nozzle and at least one locking element for releasably locking at least one first hinge element on the lower periphery of the front cover to at least one second hinge element on the lower periphery of the housing back, an opening in the lower periphery of said housing through which the towels are dispensed, and a wall-mounting member for removably mounting the housing back to a wall. In one embodiment, the paper support tray comprises locking arms for releasably locking first hinge elements on the lower periphery of said front cover against second hinge elements on the lower periphery of said housing back. In another embodiment, the dispenser comprises a locking member for releasably locking the front cover to the housing back and the housing back to the wall-mounting member.

Owner:CINTAS CORP SERVICES INC

Method and apparatus for variably braking the weft thread between a supply spool and a thread store in a loom

A supply spool supplies a weft thread through an adjustable actuated thread brake and a thread tension sensor to a weft thread accumulator, from which an accumulated insertion length of the thread is provided to a weft insertion device. The tension sensor provides a measured actual thread tension signal to a control arrangement, which compares the actual tension to a selected rated tension, and, dependent on the deviation therebetween, provides a control signal to an actuator of the thread brake, so that the actual thread tension constantly corresponds to the selected rated tension. Another sensor provides a signal indicating a change from an empty spool to a full spool. Responsive thereto, the control arrangement actuates the thread brake to an adjustable starting brake setting as a coarse adjustment. Then the self-regulating fine adjustment is continued. A constant winding tension and thread accumulation length are achieved in the thread accumulator.

Owner:LINDAUER DORNIER GMBH

Compact creel

InactiveUS7316366B2Reduces yarn wasteImprove finished product qualityTufting apparatusFilament handlingYarnBobbin

A highly mobile, compact creel that utilizes frames for holding yarn packages (or bobbins) for feeding yarn to a tufting machine. Each frame includes holders affixed to the frame for holding yarn packages facing front and back, a header attachable to the frame for directing yarn from the yarn packages to the tufting machine, and anti-static flexible tubing for leading yarn from the holders to the header. The header provides for aligning all the yarn ends in the same plane to join them to ends already threaded into the tufting machine. An optional frame overlay upright having a ring affixed thereto and strands threaded through the ring prevents yarn from upper yarn packages from falling onto tubes holding lower yarn packages causing yarn entanglement.

Owner:INTERFACE INC

Yarn Braking Device

InactiveUS20080296425A1Eliminate negative effectsSimple structureLoomsFilament handlingYarnAxial force

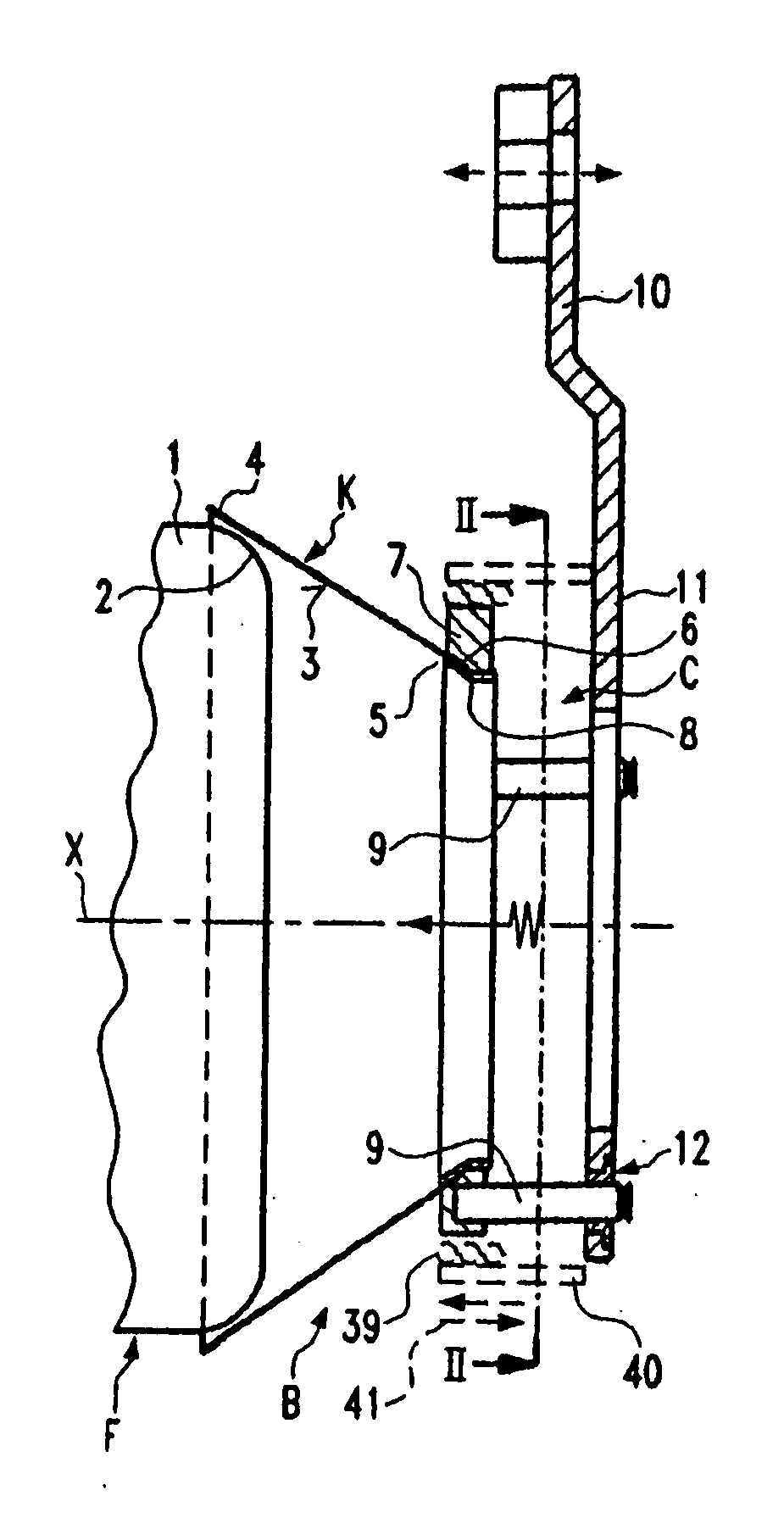

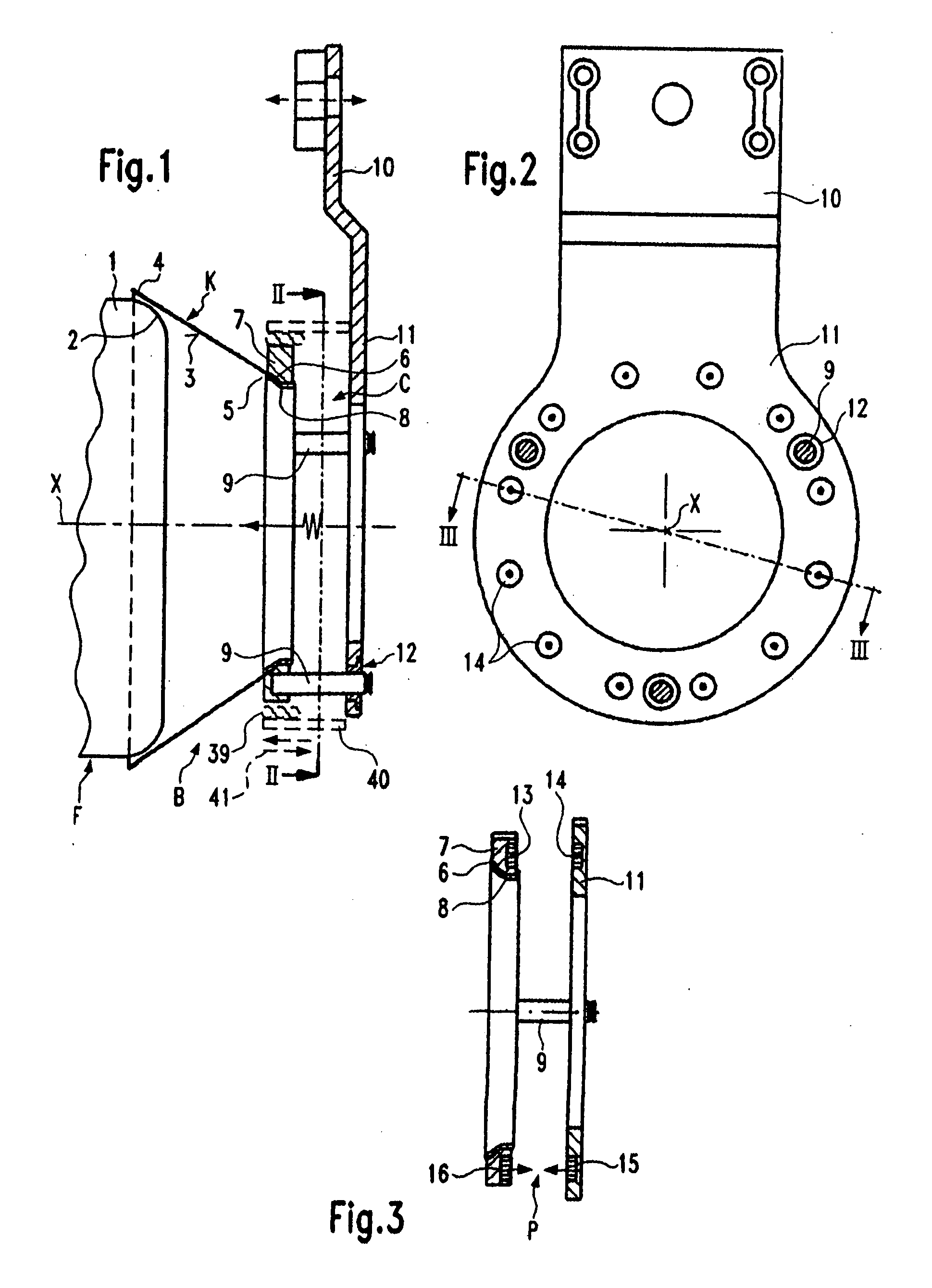

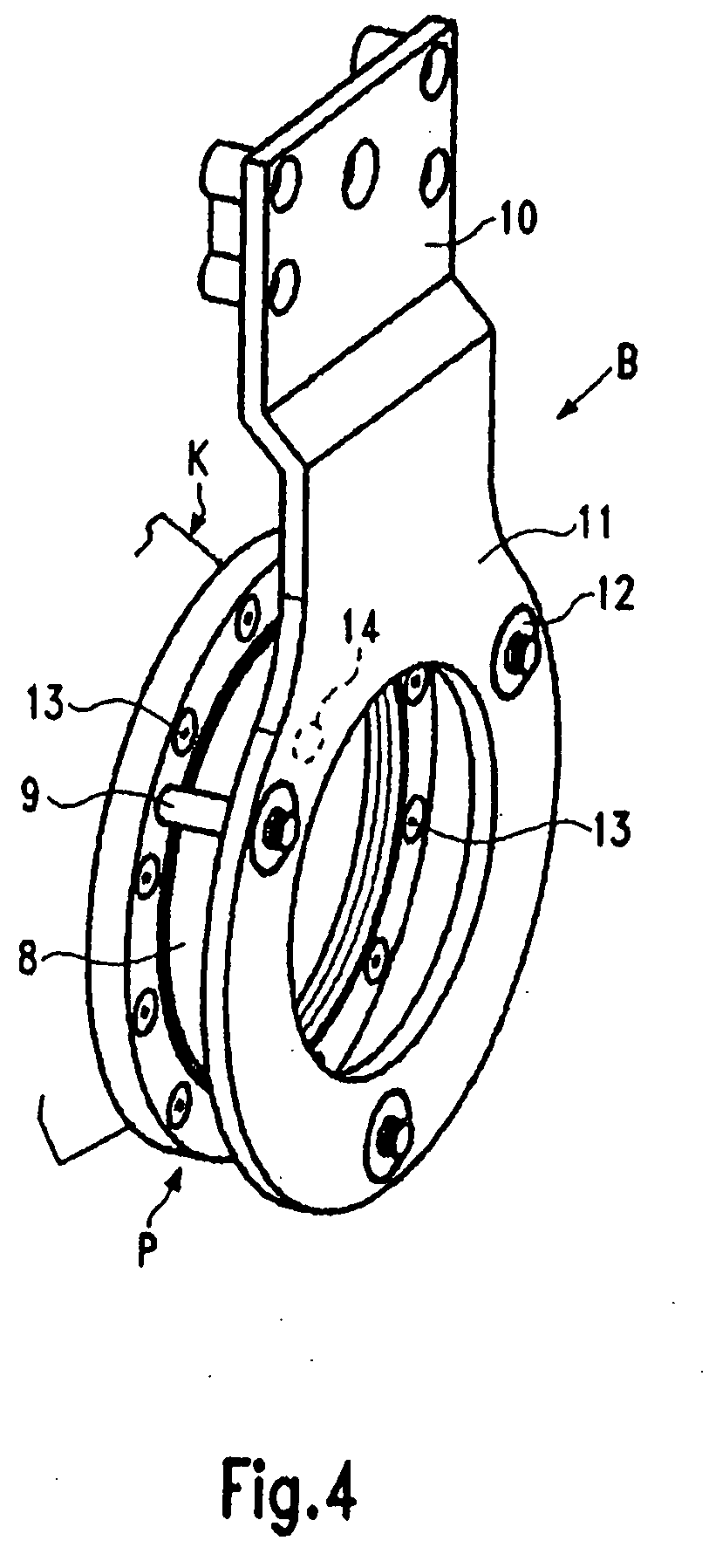

The invention relates to a yarn tensioning device (B) comprising a braking body (K) embodied in the form of a truncated conical jacket (3) which is coaxially positioned on the rounded discharge end (2) of a storage body (1) and is pushed to a small diameter end (5) by the elastic axial force defining a braking effect between the braking body and the discharge end (2), an axial force generator (P) disposed between a fixed holding element (10) and the braking body and a centering device (C) provided with a radial working direction and disposed between the holding element (10) and the braking body, wherein said axial force generator (P) consists of at least one pair of axially superimposed permanent magnets, an intermediate slit is arranged between said permanent magnets and the centering device (C) which is embodied in the form of a axial slide guideway (9, 12, 24, 23) which is structurally and functionally separated from the permanent magnet pair or contactlessly formed thereby.

Owner:IRO AB

Pivoting package support

InactiveUS20080173742A1Relieving musculo-skeletal stressEfficiencyFilament handlingCreelsYarnVertical axis

A yarn package support for a creel has a support arm that is pivotal about a vertical axis between a loading position and a use position. In the loading position, the package support arm is positioned to load a spool of stranded material, such as yarn or thread. In the use position, the spool and support arm are positioned so that the yarn may be feed into a weaving apparatus. The pivot arrangement permits a laborer to reposition the support arm in a single handed action.

Owner:AUTOMATED CREEL SYST

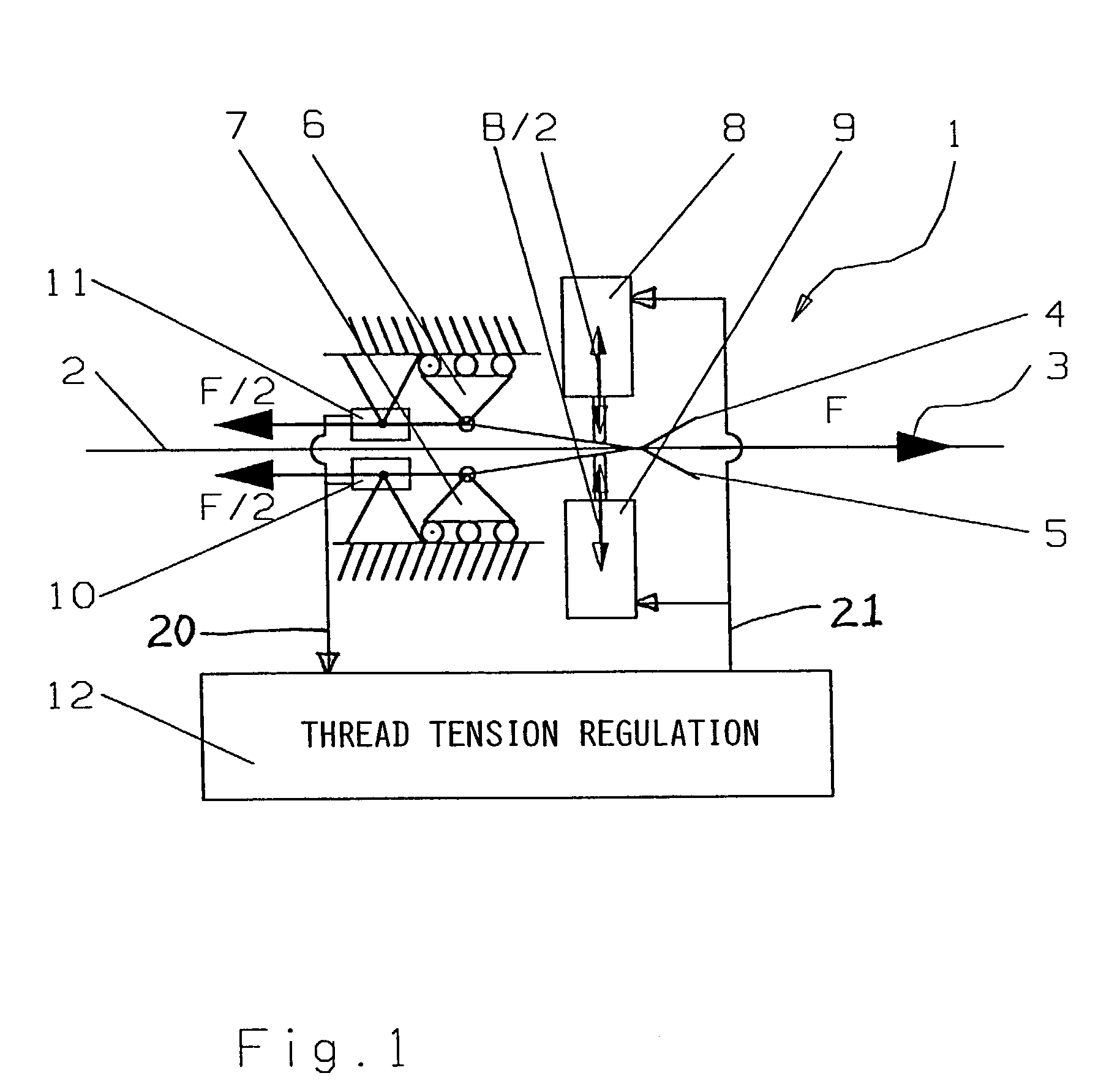

Thread tension regulation in a thread brake device and method in a textile processing machine

InactiveUS7077168B2Load minimizationReduce mechanical loadLoomsFilament handlingPiezoelectric actuatorsEngineering

A thread brake arrangement for use in a textile processing machine includes two brake elements with the thread running there between. An actuator, preferably a piezoelectric actuator, variably actuates one of the brake elements relative to the other to exert an adjustable braking force onto the thread. The thread exerts a reaction force in the thread running direction onto the brake elements. At least one of the brake elements is movably supported to be movable along the thread running direction, and is mechanically coupled to a force transducer that measures the reaction force, which is proportional or equal to the thread tension force. A regulating arrangement receives the measured force signal, and controls the actuator to adjust the adjustable brake element, so as to vary the applied braking force and thus regulate the arising thread tension responsive to and dependent on the measured reaction force.

Owner:LINDAUER DORNIER GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com