Novel wood shuttle

A wooden shuttle, a new type of technology, used in shuttles, textiles, textiles and papermaking, etc., can solve the problems of large impact, easy breakage, and large wear, and achieve the effect of overcoming easy wear, changing material limitations, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

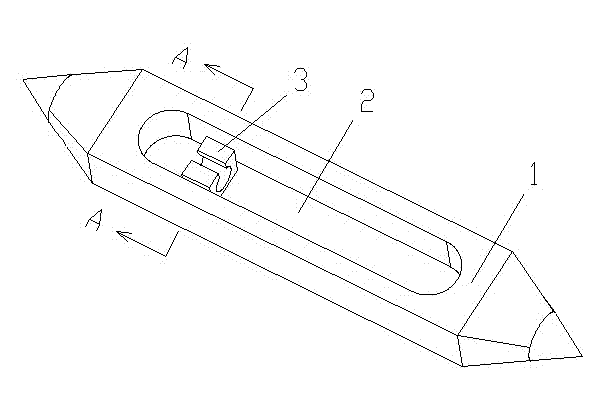

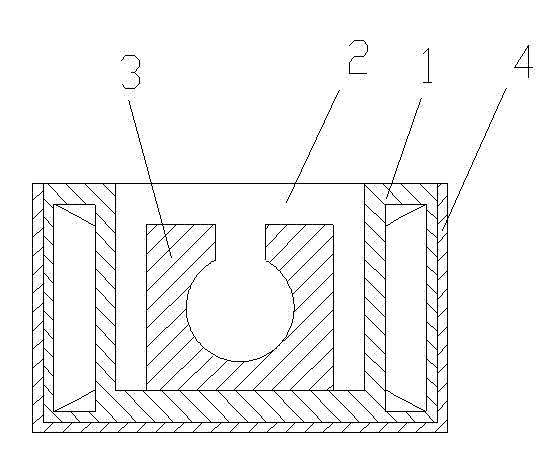

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached Figure 1-2 A kind of novel wooden shuttle of the present invention as shown, comprises wooden shuttle body 1, shuttle groove 2 and weft tube chuck 3, is provided with weft tube chuck 3 in described shuttle groove 2; Described wooden shuttle body 1 The two sides and the bottom are provided with a wear-resistant protective layer 4; the wear-resistant protective layer 4 is a polymer lining layer.

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] The novel wooden shuttle of the present invention changes the material limitation of the traditional wooden shuttle, and can be produced with various woods or wood composite materials, thus reducing the production cost. Since the wear-resistant protective layer is set, the disadvantages of the original wooden shutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com