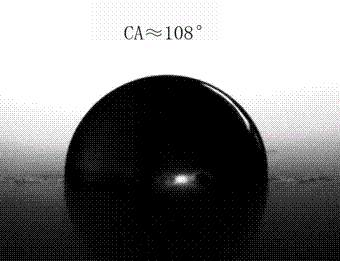

A bionic self-lubricating surface and its preparation and application

A self-lubricating, mass fraction technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of lubricating oil loss, difficult-to-smooth porous surface preparation, etc., to achieve good durability, innovative methods, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

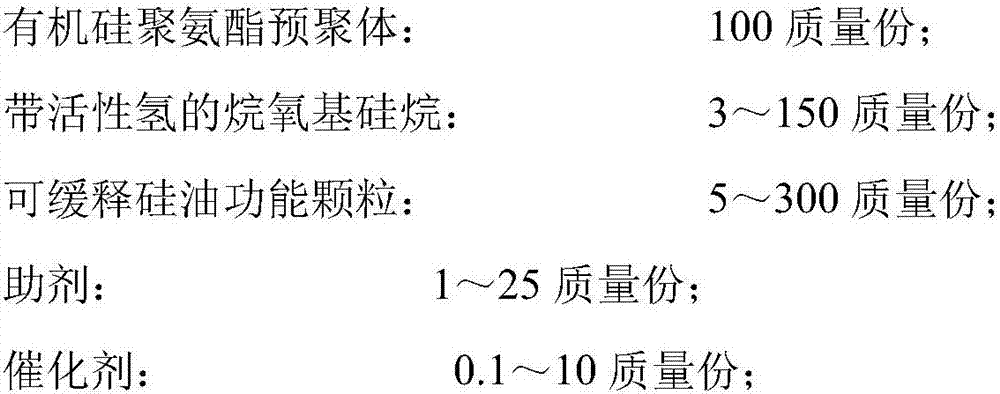

[0033] By mass parts, 100 mass parts of SiO 2 Airgel particles and 900 parts by mass of silicone oil lubricating liquid are mixed, stirred evenly, and filtered to obtain silicone oil-loaded airgel particles, which are functional particles capable of slow-release silicone oil;

[0034] According to the number of parts by mass, 100 parts by mass of silicone polyurethane prepolymer, 10 parts by mass of 3-aminopropyltriethoxysilane, and 0.5 parts by mass of catalyst were stirred and mixed under vacuum, and after the temperature was raised to 40°C, the stirring was continued for 20 minutes. Obtain an alkoxysilane-terminated silicone polyurethane resin; add 100 parts by mass of slow-release silicone oil functional particles, 5 parts by mass of a leveling agent, and 2 parts by mass of a defoamer in the silicone polyurethane resin terminated by an alkoxysilane, After stirring for 200 minutes under vacuum, the material is discharged to obtain a curable self-lubricating resin; the curab...

Embodiment 2

[0037] By mass parts, 100 mass parts of SiO 2 Airgel particles and 1000 parts by mass of silicone oil lubricating liquid are mixed, stirred evenly, and filtered to obtain silicone oil-loaded airgel particles, which are functional particles capable of slow-release silicone oil;

[0038] According to the number of parts by mass, 100 parts by mass of silicone polyurethane prepolymer, 3 parts by mass of 3-aminopropyltrimethoxysilane, and 0.8 parts by mass of catalyst were stirred and mixed under vacuum, and after the temperature was raised to 80°C, stirring was continued for 70 minutes to obtain Alkoxysilane-terminated silicone polyurethane resin; add 200 parts by mass of slow-release silicone oil functional particles, 6 parts by mass of leveling agent, and 1 part by mass of defoamer in the alkoxysilane-terminated silicone polyurethane resin, vacuum After stirring for 100 minutes, the material is discharged to obtain a curable self-lubricating resin; the curable self-lubricating r...

Embodiment 3

[0041] By mass parts, 100 mass parts of SiO 2 Airgel particles are mixed with 800 parts by mass of silicone oil lubricating liquid, stirred evenly, and filtered to obtain silicone oil-loaded airgel particles, which are functional particles capable of slow-release silicone oil;

[0042]According to the number of parts by mass, 100 parts by mass of silicone polyurethane prepolymer, 100 parts by mass of N-aminoethyl-γ-aminopropyltrimethoxysilane, and 0.1 parts by mass of catalyst were stirred and mixed under vacuum, and after the temperature was raised to 50°C, Continue stirring for 60 minutes to obtain an alkoxysilane-terminated silicone polyurethane resin; in the alkoxysilane-terminated silicone polyurethane resin, add 5 parts by mass of slow-release silicone oil functional particles, 5 parts by mass of a leveling agent, and 5 parts by mass of part of defoamer, stirred under vacuum for 10 minutes, and discharged to obtain a curable self-lubricating resin; the curable self-lubri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com