Preparation method of cyclohexene catalyst, as well as preparation method and device of cyclohexene

A cyclohexene and catalyst technology, which is applied in the field of chemical raw material preparation, can solve the problems of separation of granular catalyst and reaction solution, difficult application of catalyst, loss of catalyst, etc., and achieve uniform distribution of active components, easy industrial production, and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

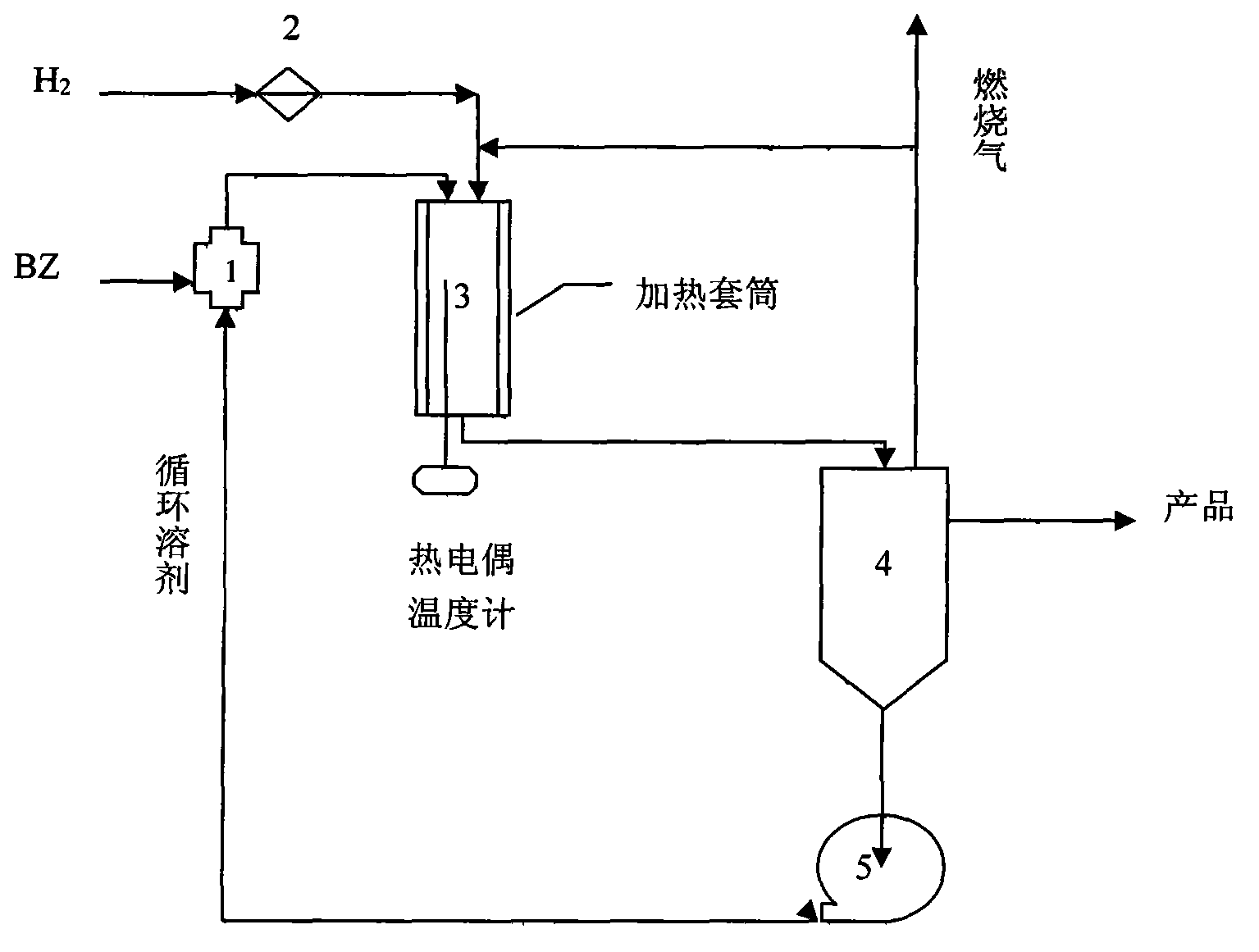

Image

Examples

preparation example Construction

[0017] The preparation method of cyclohexene catalyst, catalyst is made up of active component A, auxiliary agent M and carrier, and preparation method is: with ACl 3 ·nH 2 O is the precursor of the active component A, the soluble salt is used as the precursor of the auxiliary agent M, and then the carrier is added. The mass percentage of each component is: based on the carrier, the active component A is 3 to 10% of the carrier, and the auxiliary agent M is 10-20% of the active component A; add an organic solvent and stir evenly to obtain a solution, then stir and evaporate to dryness to remove organic matter to obtain a solid powder, which is compressed into a tablet to obtain a solid catalyst.

[0018] The additive M is one or two compounds of Zn, Fe, Ni, La. ZnSO is preferred 4 , FeSO 4 .

[0019] The carrier is one or a mixture of Si, Al, Co, Cr, Ti, Zr oxides. ZrO is preferred 2 , SiO 2 、Al 2 o 3 .

[0020] The organic solvent is one of hexanediol, formaldehyde ...

Embodiment approach 1

[0031] First add 9.5g of carrier (SiO 2 / ZrO 2 =1:4) into about 50ml of hexanediol solution, heated to 160°C in an oil bath, stirred the carrier solution for 1 hour, and then added 1.295 ACl 3 ·nH 2 O, after stirring for 3 h, the temperature was raised to 250° C., stirred and evaporated to dryness, and the organic solution was removed to obtain a gray powdery substance.

[0032] The powder was compressed into 30-mesh granules and loaded into a fixed-bed reactor with a volume of 20 ml.

[0033] Before the reaction, first raise the temperature to 350°C, and pass H under the pressure of 0.2MPa 2 , the flow rate is 20ml / min, and the reduction operation is carried out for 8h.

[0034] After confirming that the restoration is complete, H 2 The flow rate is increased to 1000mi / min, the system pressure is increased to 4.0MPa, when the temperature reaches 150°C, 2.0wt% ZnSO is introduced into the reactor 4 The aqueous solution (pH=5.5) was pretreated for 4 hours, and then benzene...

Embodiment approach 2

[0036] First add 9.5g of carrier (SiO 2 / ZrO 2 =1:4) into about 50ml of hexanediol solution, heated to 160°C in an oil bath, and after the carrier solution was stirred for 1h, 1.295g of ACl was added 3 ·nH 2 O, 0.129g ZnCl 2 After stirring for 3 h, the temperature was raised to 250° C., stirred and evaporated to dryness, and the organic solution was removed to obtain a gray powdery substance.

[0037] The powder was compressed into 30-mesh granules and loaded into a fixed-bed reactor with a volume of 20 ml.

[0038] Before the reaction, first raise the temperature to 350°C, and pass H under the pressure of 0.2MPa 2 , the flow rate is 20ml / min, and the reduction operation is carried out for 8h.

[0039] After reduction, H 2The flow rate is raised to 1000ml / min, the system pressure is raised to 4.0MPa, and when the temperature reaches 150°C, 2.0wt% ZnSO is introduced into the reactor 4 The aqueous solution (pH=5.5) was pretreated for 4 hours, and then benzene was introduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com