Patents

Literature

43results about How to "Out of complete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

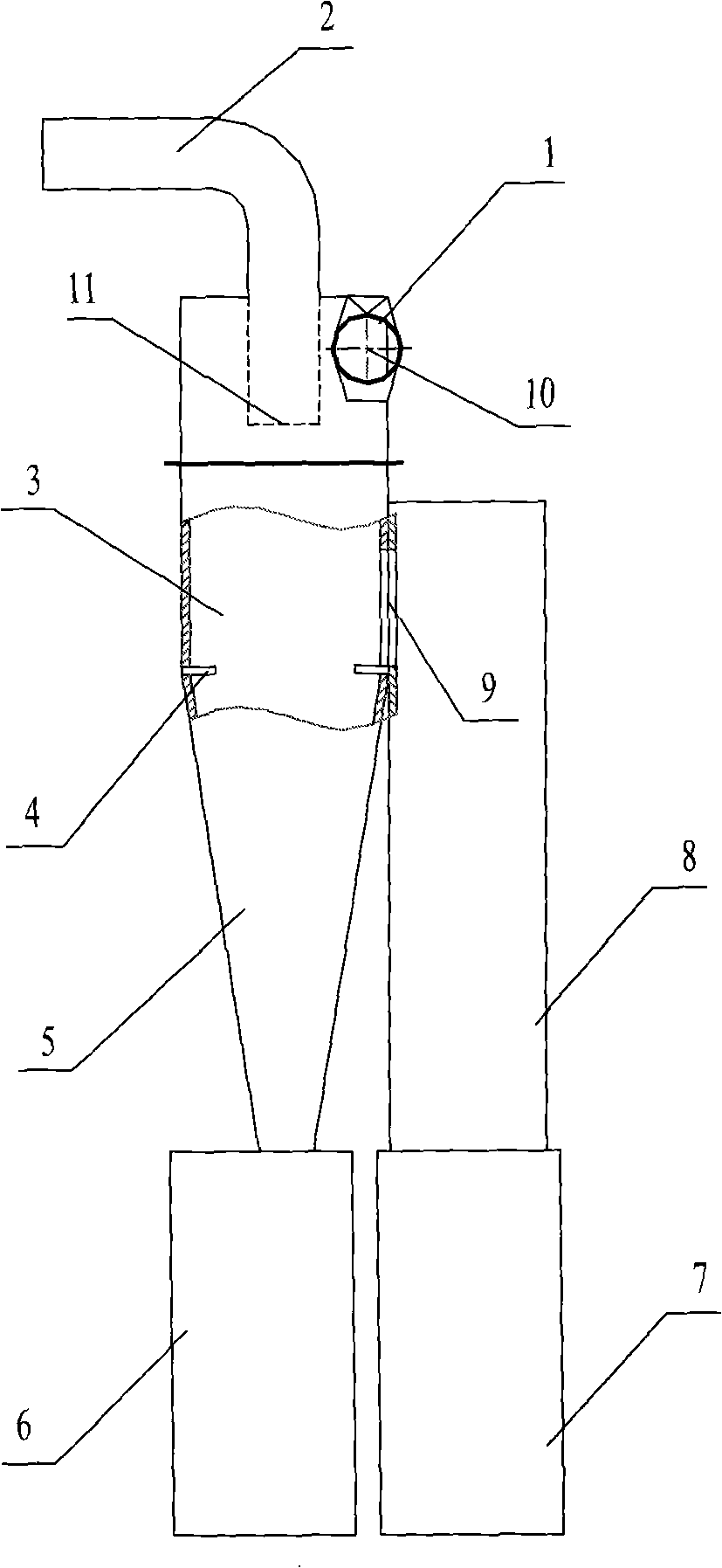

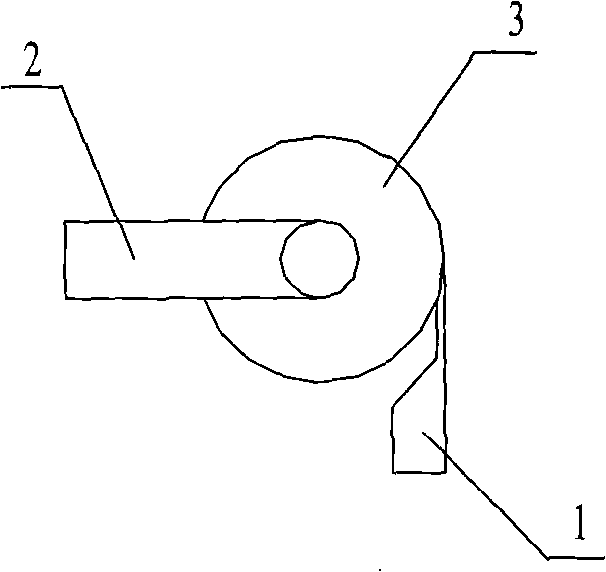

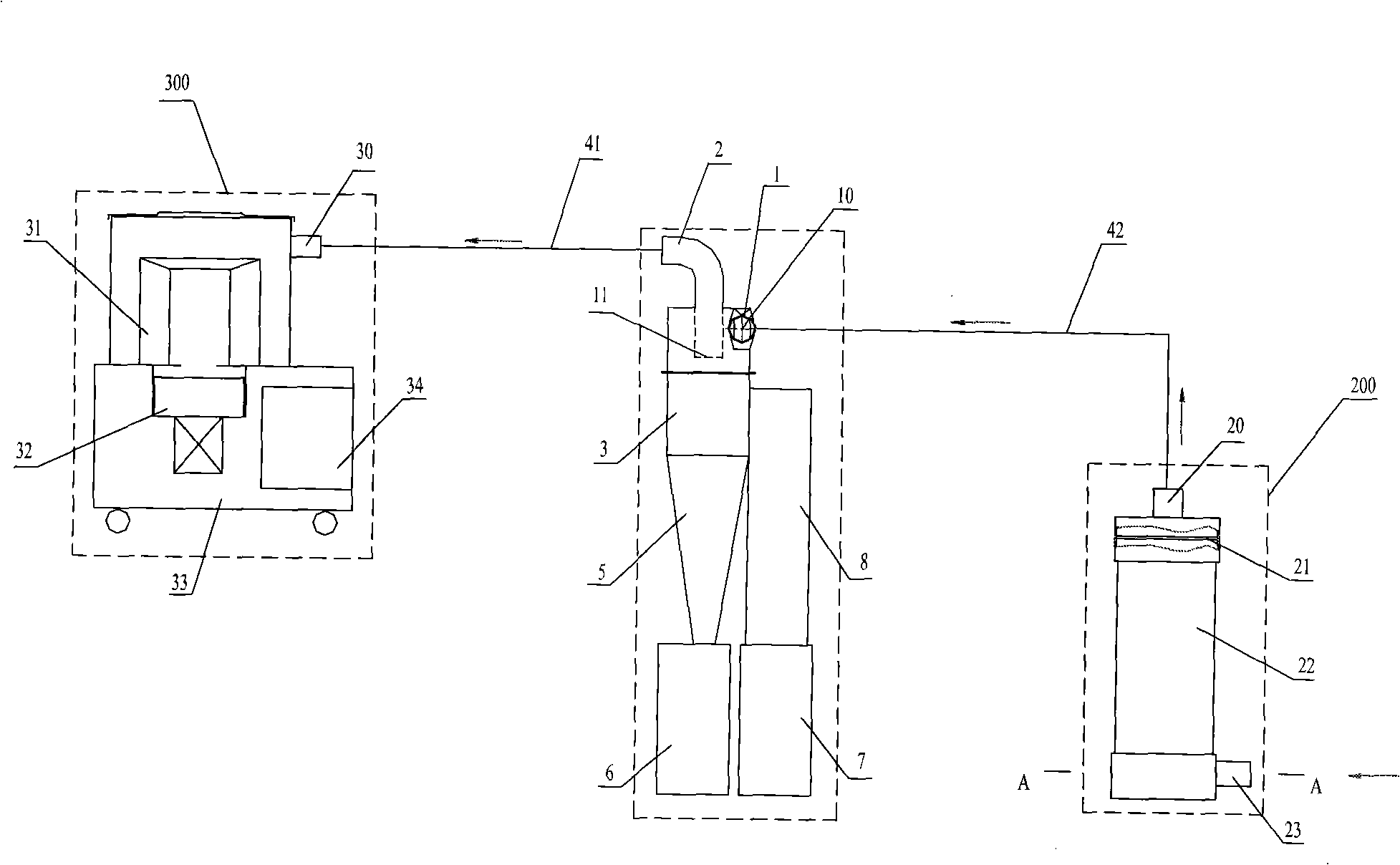

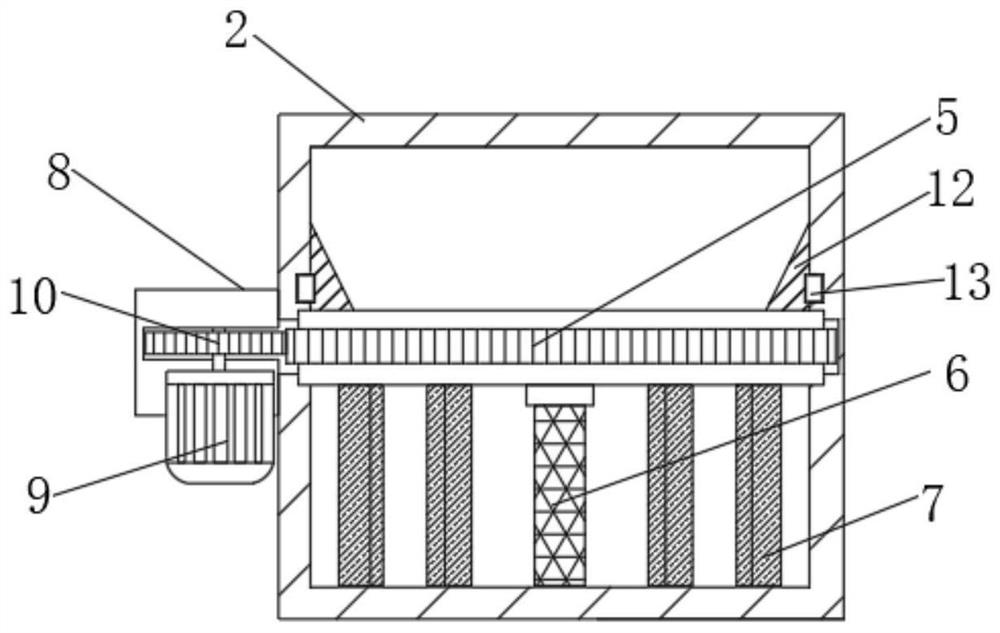

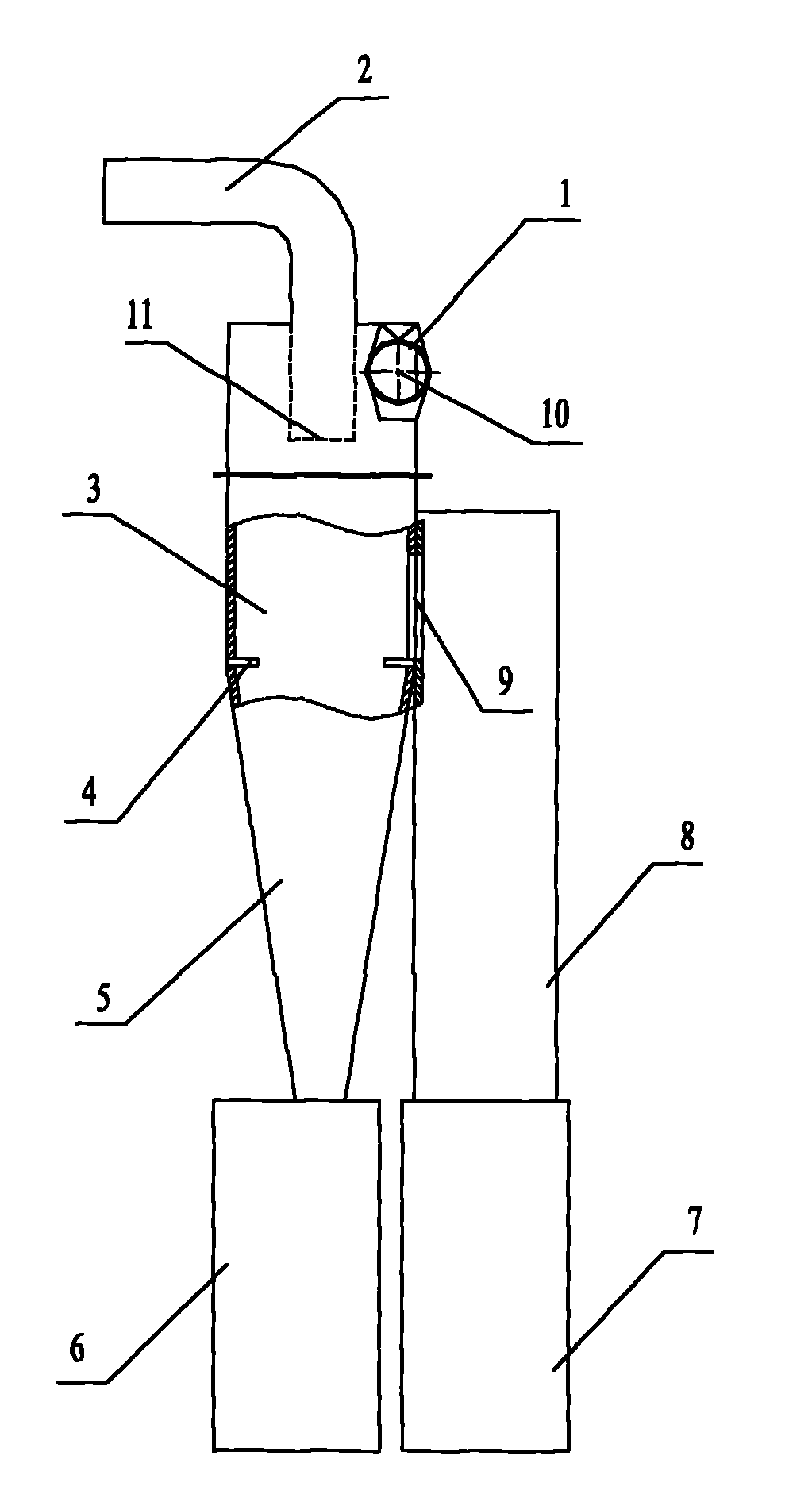

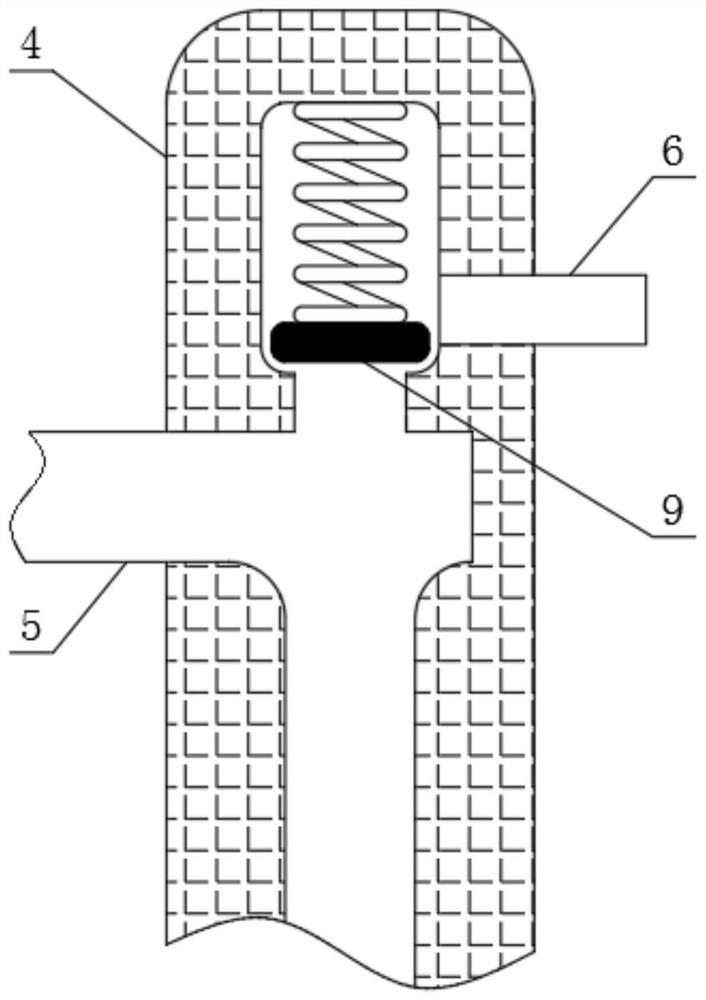

Cyclone separator and spore separation device therewith

InactiveCN101524672ASafe and Low Consumption SystemComplete separationBioreactor/fermenter combinationsBiological substance pretreatmentsAir volumePhencyclone

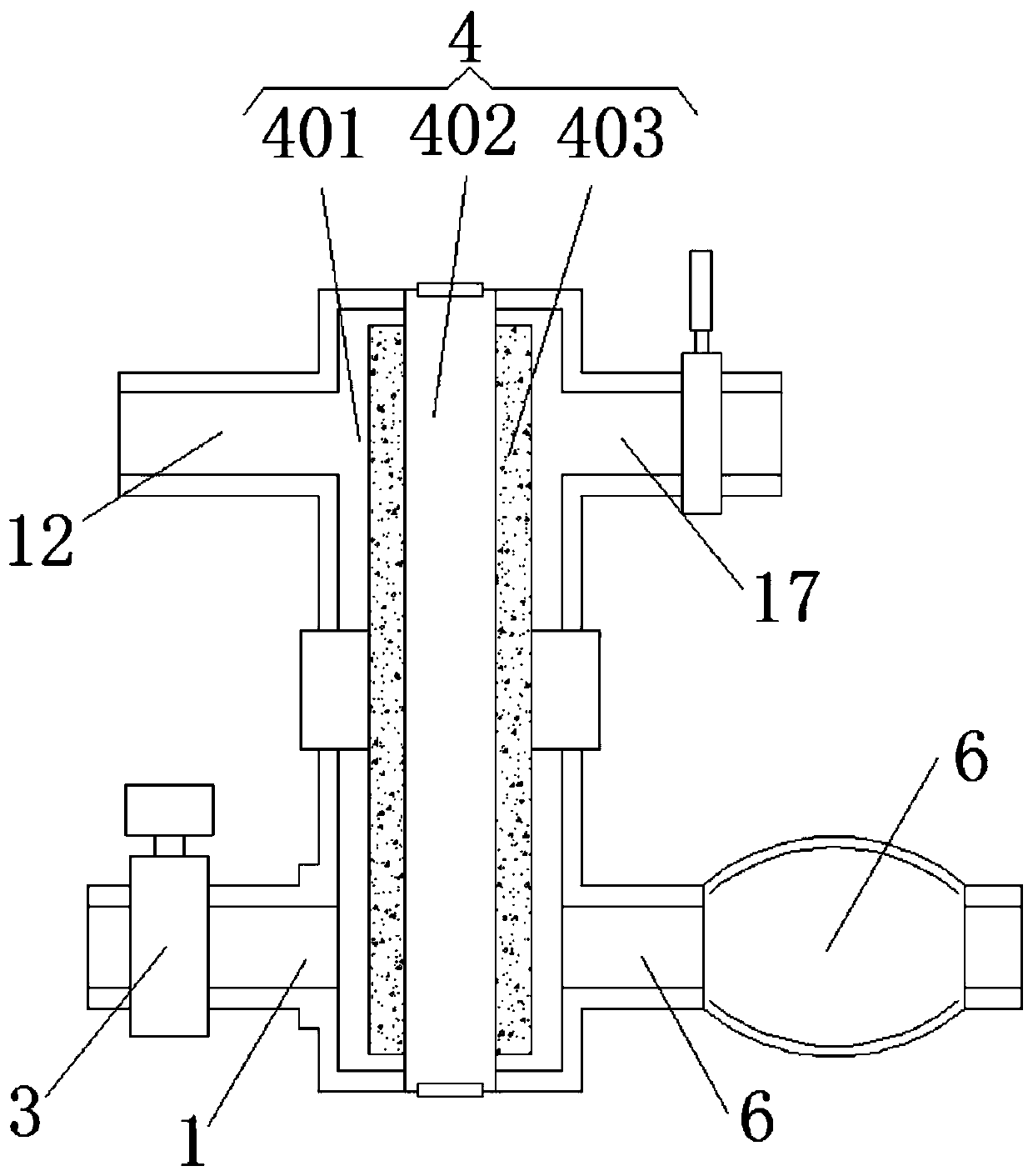

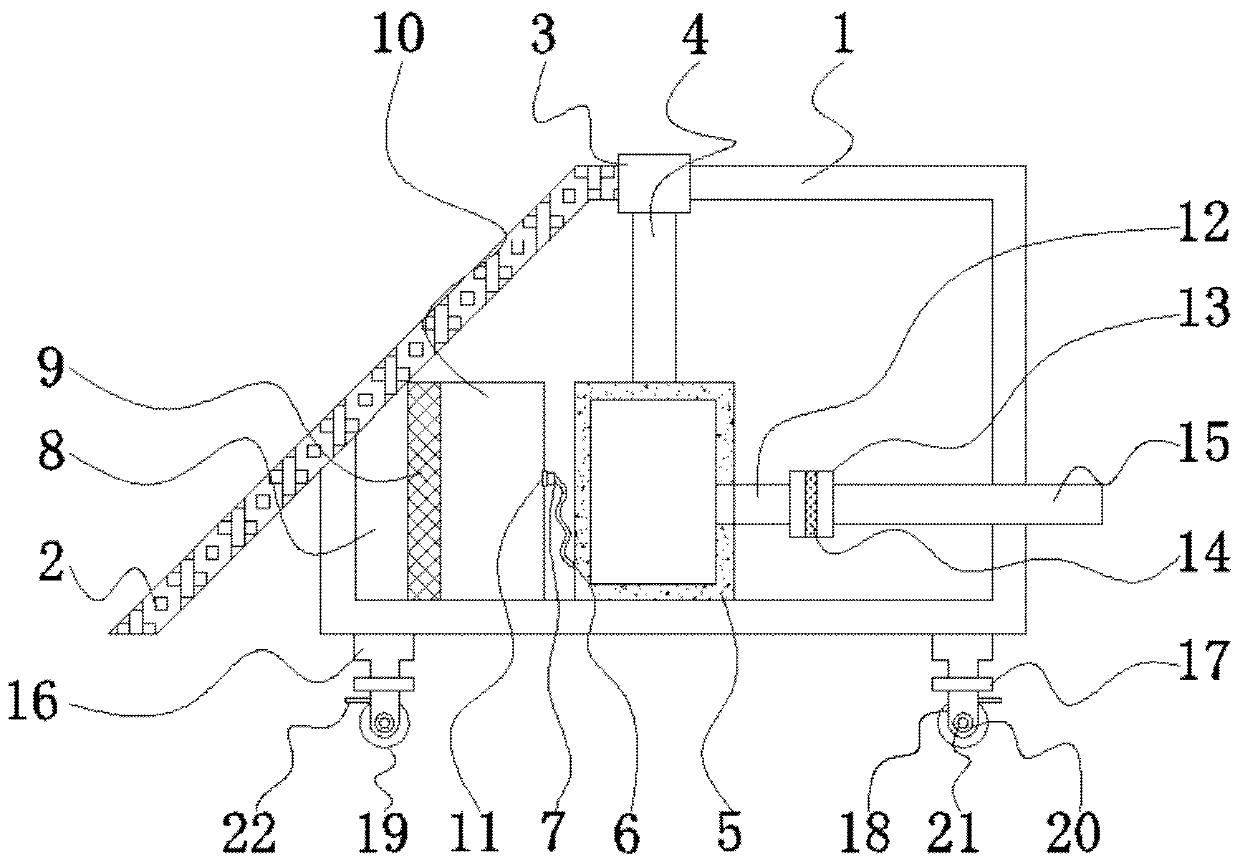

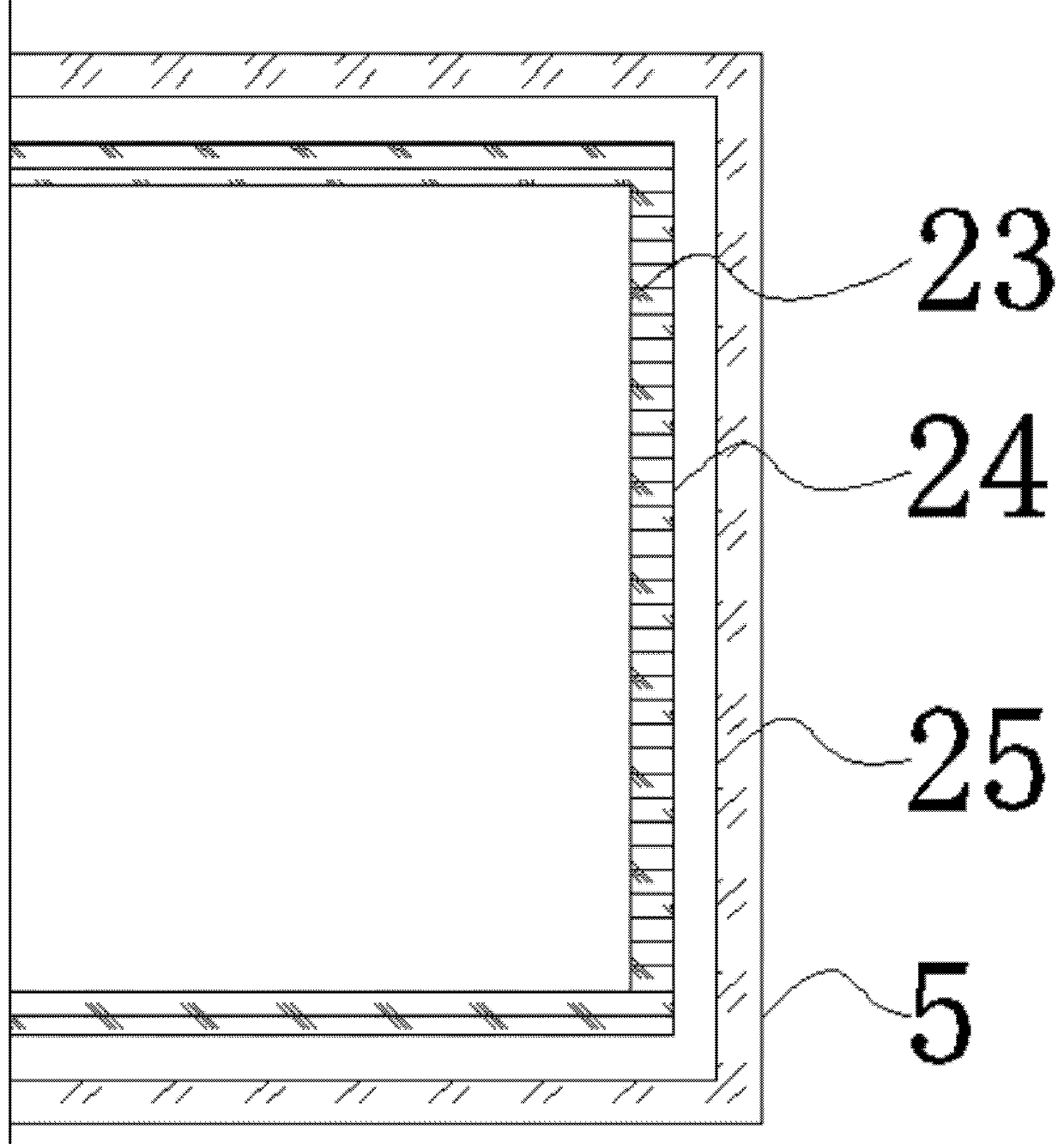

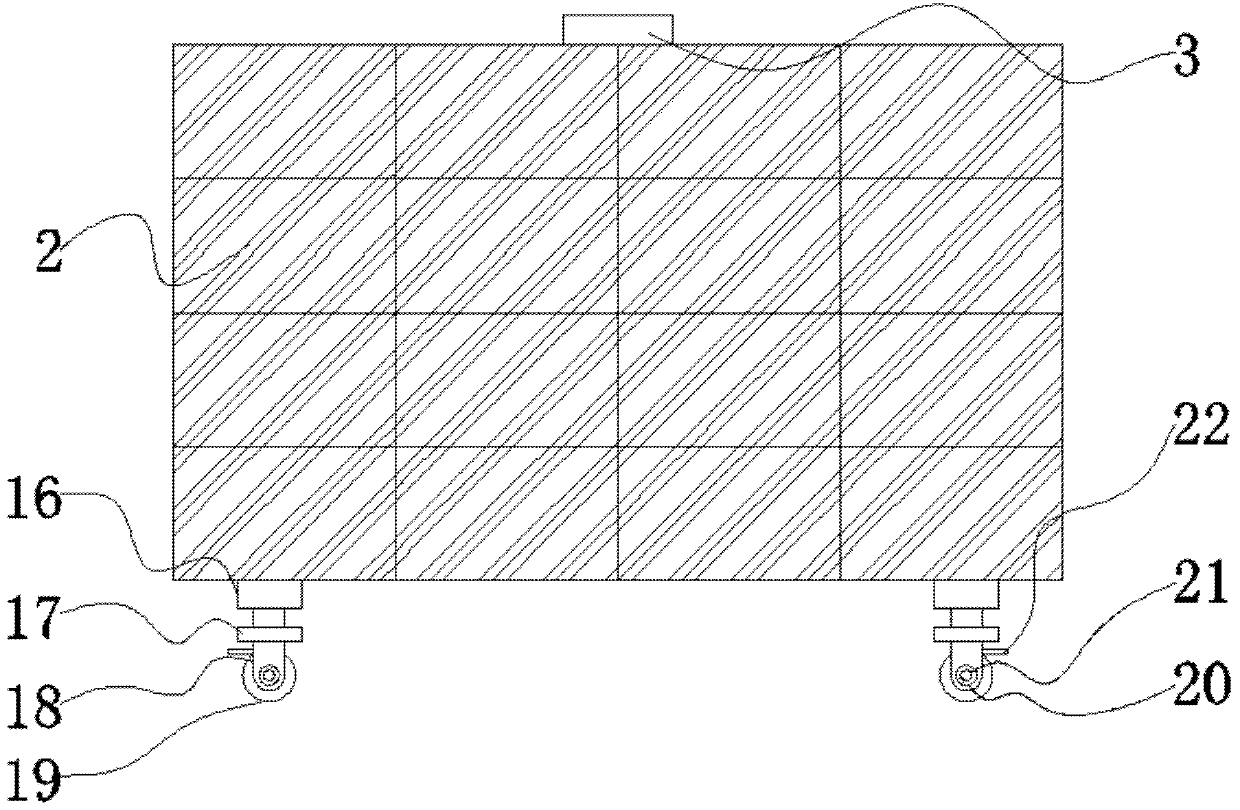

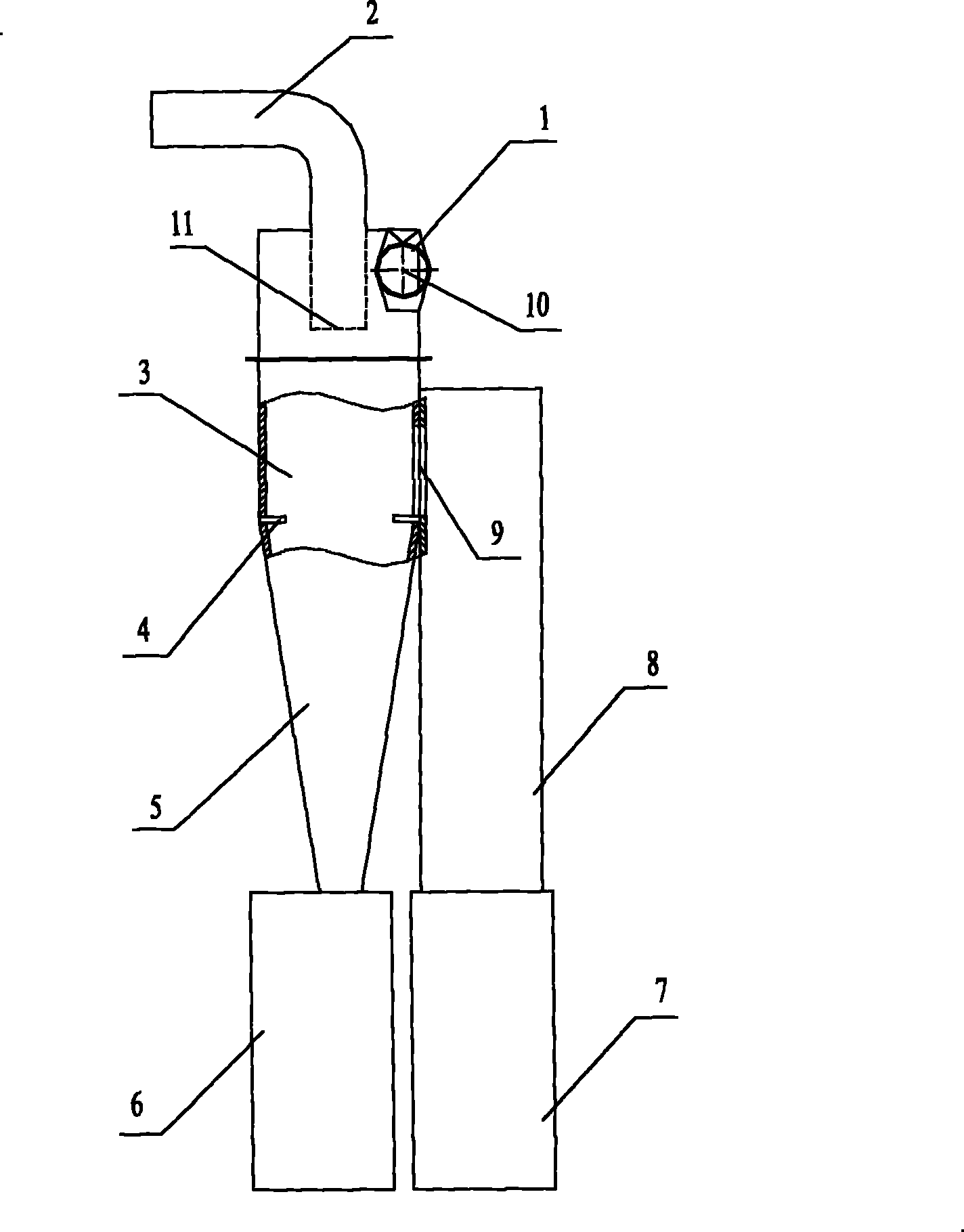

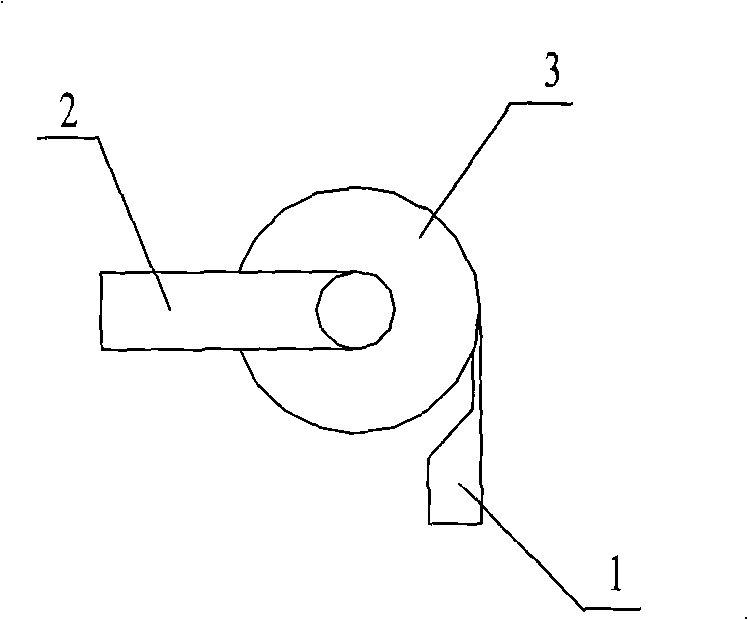

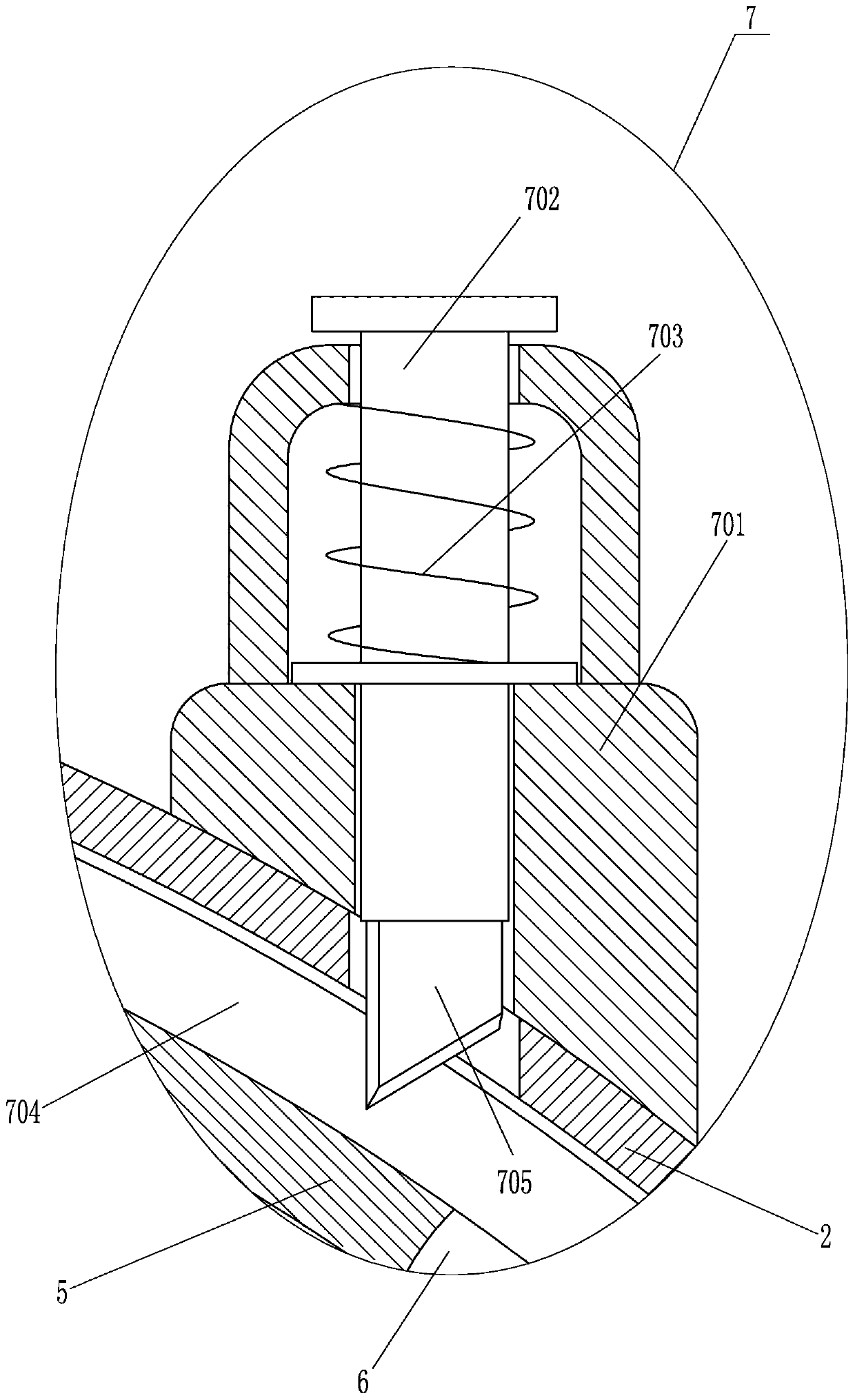

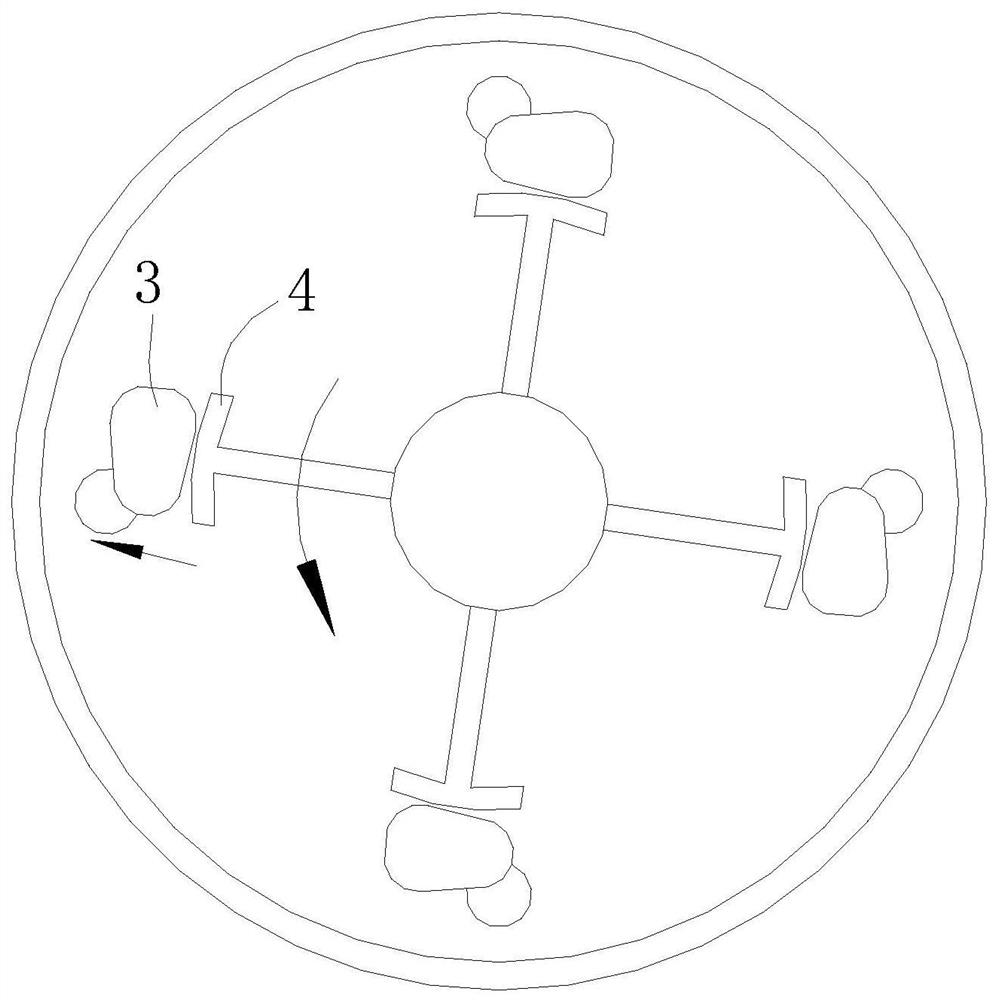

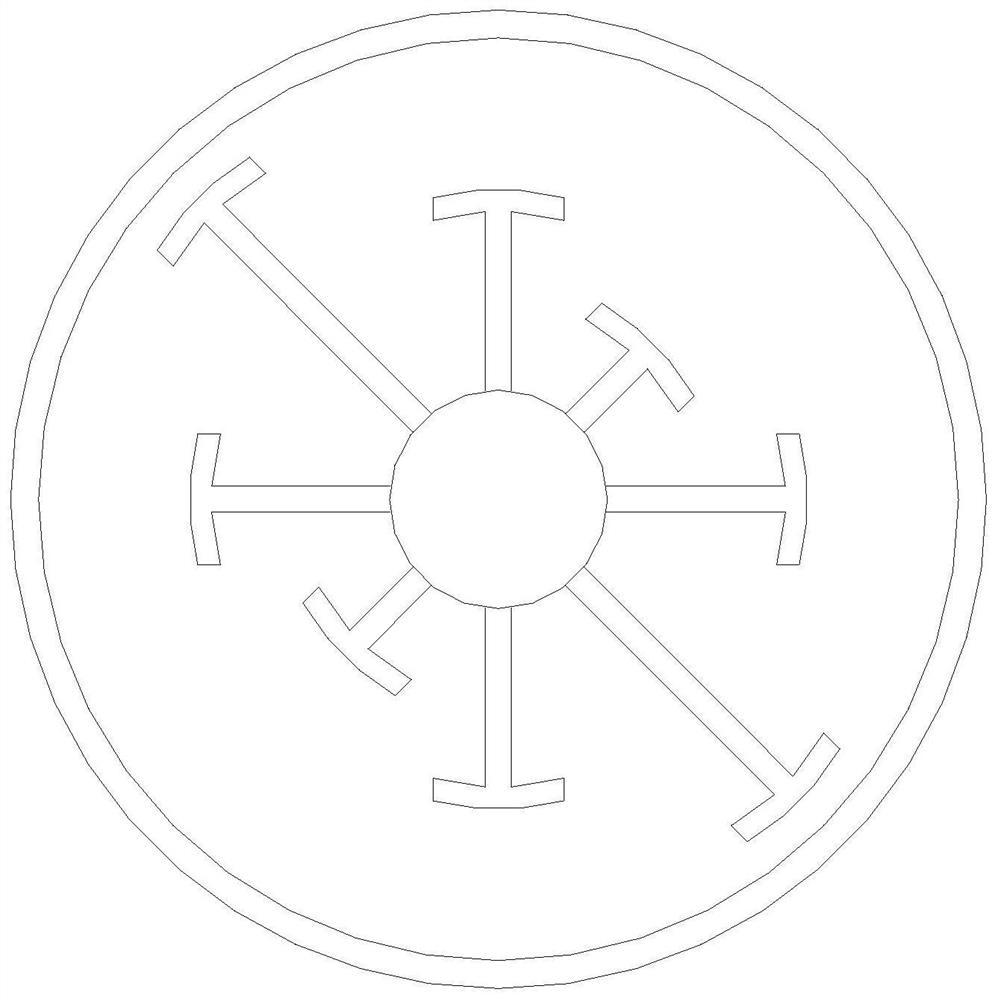

The invention discloses a cyclone separator, comprising a primary separator and a secondary separator (8) which are communicated by a channel (9), the bottom of the primary separator is connected with a primary collection tube (6), the bottom of the secondary separator is connected with a secondary collection tube (7); the top surface of the primary separator is provided with an air outlet channel (2), the side wall of the primary separator is tangentially provided with an air inlet channel (1), the air outlet channel (2) and the air inlet channel (1) are both communicated with the inner cavity of the primary separator; an air volume regulator (10) is arranged inside the air inlet channel (1), and the channel (9) is positioned below the air inlet channel (1). The invention also discloses a spore separation device with the cyclone separator, wherein a blower component (300) is connected with the air outlet channel (2) in a sealing way, and a swirling flow feeder component (200) is connected with the air inlet channel (1) in a sealing way. The spore separation device of the invention can efficiently separate solid fermentation fungal spore.

Owner:ZHEJIANG UNIV

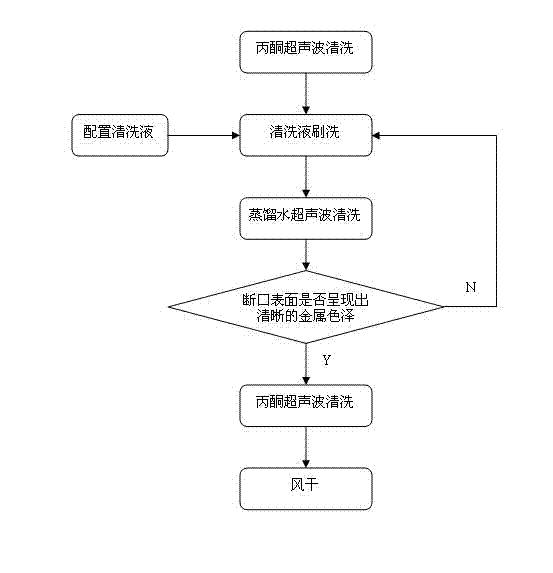

A method of cleaning fractures of steel failed components

InactiveCN104120433AEasy to configureSimple configurationCleaning using liquidsMegasonic cleaningCleaning methods

The invention discloses a method of cleaning fractures of steel failed components and belongs to the technical field of fracture analysis of steel failed components. Aiming at disadvantages of steel failed fracture cleaning methods at present, such as problems of inconvenient preparation of cleaning liquids, poor cleaning effects, and low cleaning efficiency, the method of cleaning the fractures of the steel failed components, which has characteristics of simple cleaning fluid preparation, simple and convenient operation, short consumed time, significant cleaning effects and easy monitoring, is provided. A hydrochloric acid solution is adopted as a cleaning liquid in the method, an ultrasonic wave cleaning technology is used in cooperation, and compact corrosives on the fracture surfaces are conveniently and efficiently removed under the premise of not damaging fracture morphological features. The method is easy to implement, low in energy consumption and suitable for cleaning of various metal failed component fracture surfaces.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

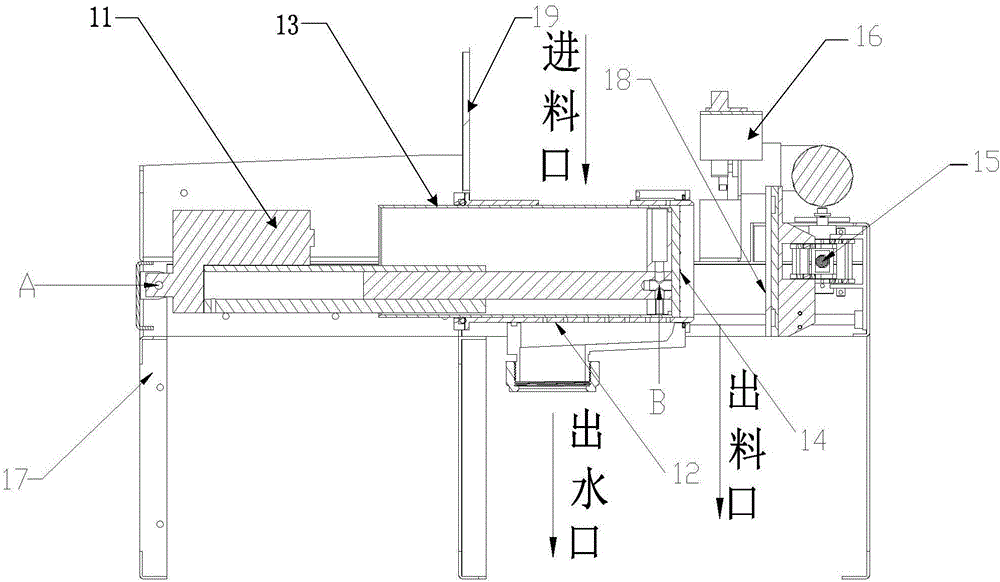

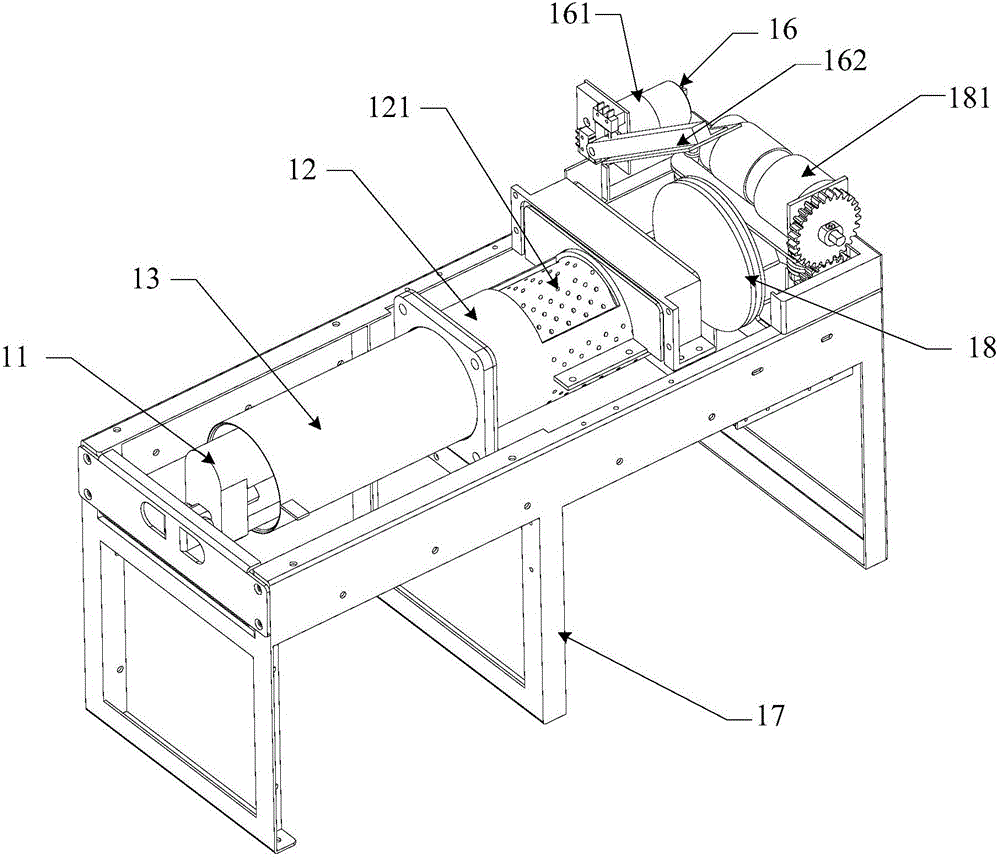

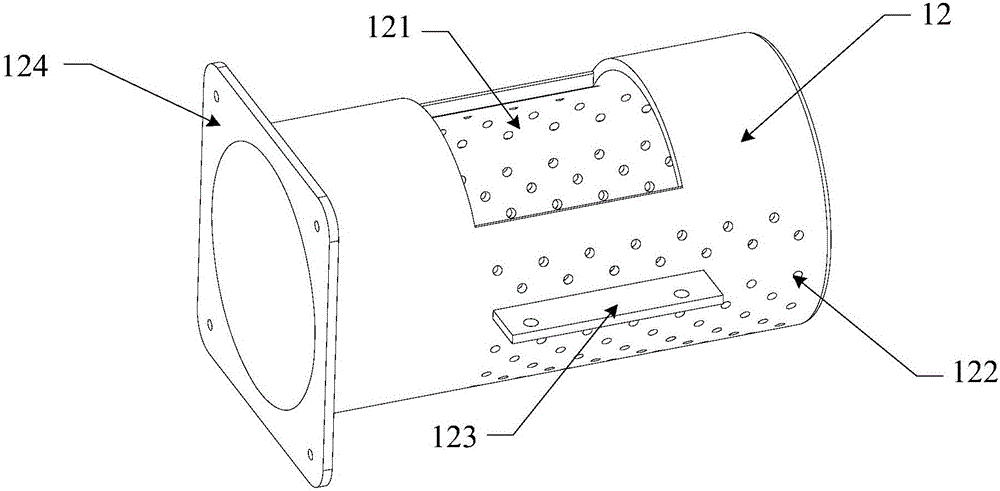

Water removal device for garbage disposal

The invention provides a water removal device for garbage disposal, and the water removal device for garbage disposal is suitable for the field of garbage disposal. The water removal device comprises a water filtering cylinder, a push plate, an ejector plate and a first drive device. The push plate is arranged in the water filtering cylinder. The ejector plate is arranged at one end of the water filtering cylinder. The push plate is connected with the first drive device. The push plate can move in the water filtering cylinder in the axial direction under the drive effect of the first drive device and is used for squeezing garbage in the direction of the ejector plate. A water filtering structure is arranged on the water filtering cylinder and used for draining the squeezed water out of the water filtering cylinder. A feeding opening for feeding is formed in the water filtering cylinder. By the adoption of the water removal device for garbage disposal, miniaturization of garbage disposal equipment can be achieved, and meanwhile a small amount of garbage can be disposed, so that more timely garbage disposal is achieved.

Owner:深圳市格瑞汉兰科技有限公司

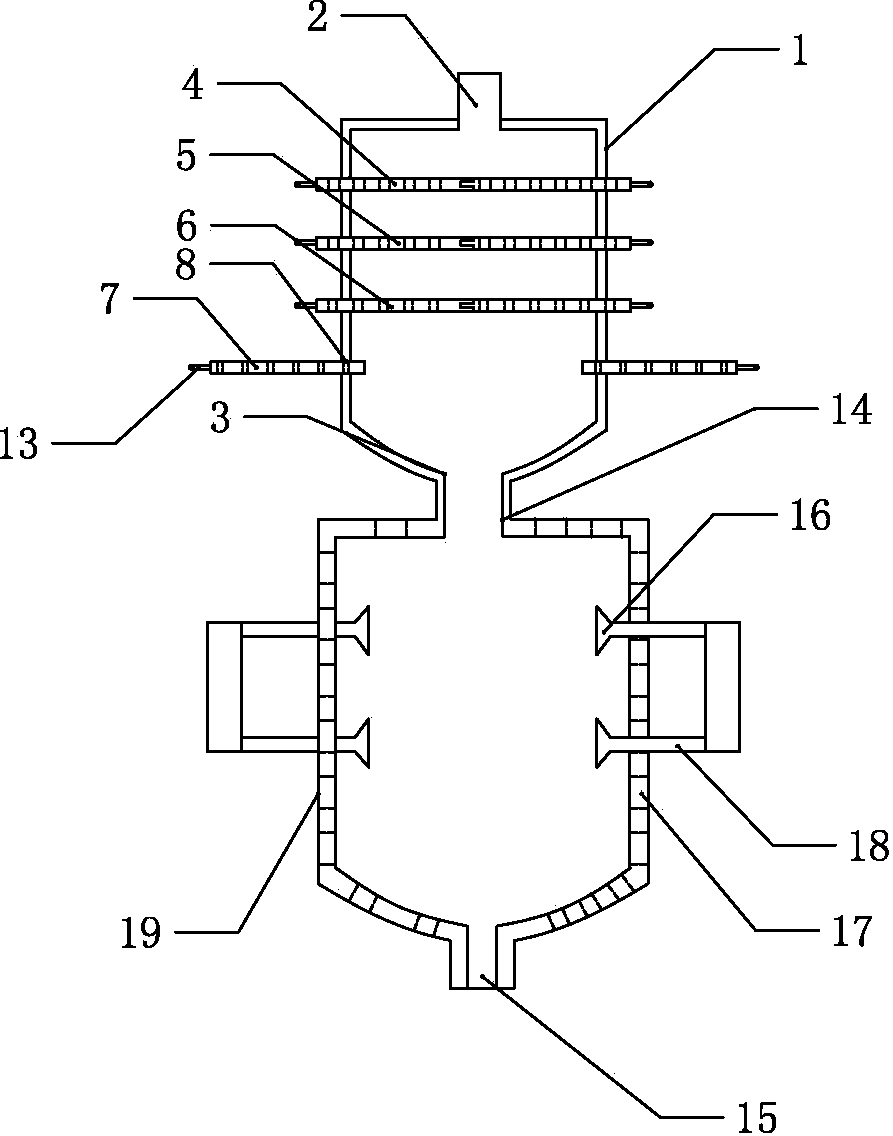

Washing and screening device for peanuts

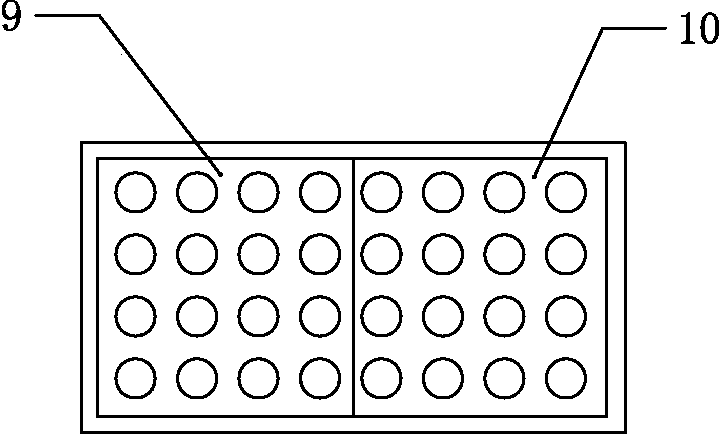

The invention discloses a washing and screening device for peanuts. The washing and screening device comprises a screening tank and a washing tank, the screening tank comprises a screening tank body and a group of screens sequentially arranged in the screening tank from top to bottom, each screen comprises a left screen and a right screen, both the left screens and the right screens penetrate slide holes of the tank wall, the right sides of the left screens and the left sides of the right screens are slidably connected, and the diameters of mesh holes of the screens are declined sequentially from top bottom of the screening tank body. The washing tank comprises a washing tank body, the wall of the washing tank is uniformly provided with vent holes, and dry ice nozzles are arranged on the inner wall of the washing tank body respectively. The washing and screening device for peanuts overcomes the defects that nutrition content of the peanuts runs off, taste becomes unpleasant and only impurities can be screened by the existing screening device. Besides, the provided washing and screening device for the peanuts is capable of screening the peanuts according to size and cleaning the peanuts, the peanuts are good in taste, and loss of the nutrition content is avoided.

Owner:CHONGQING LONGYUE FOOD

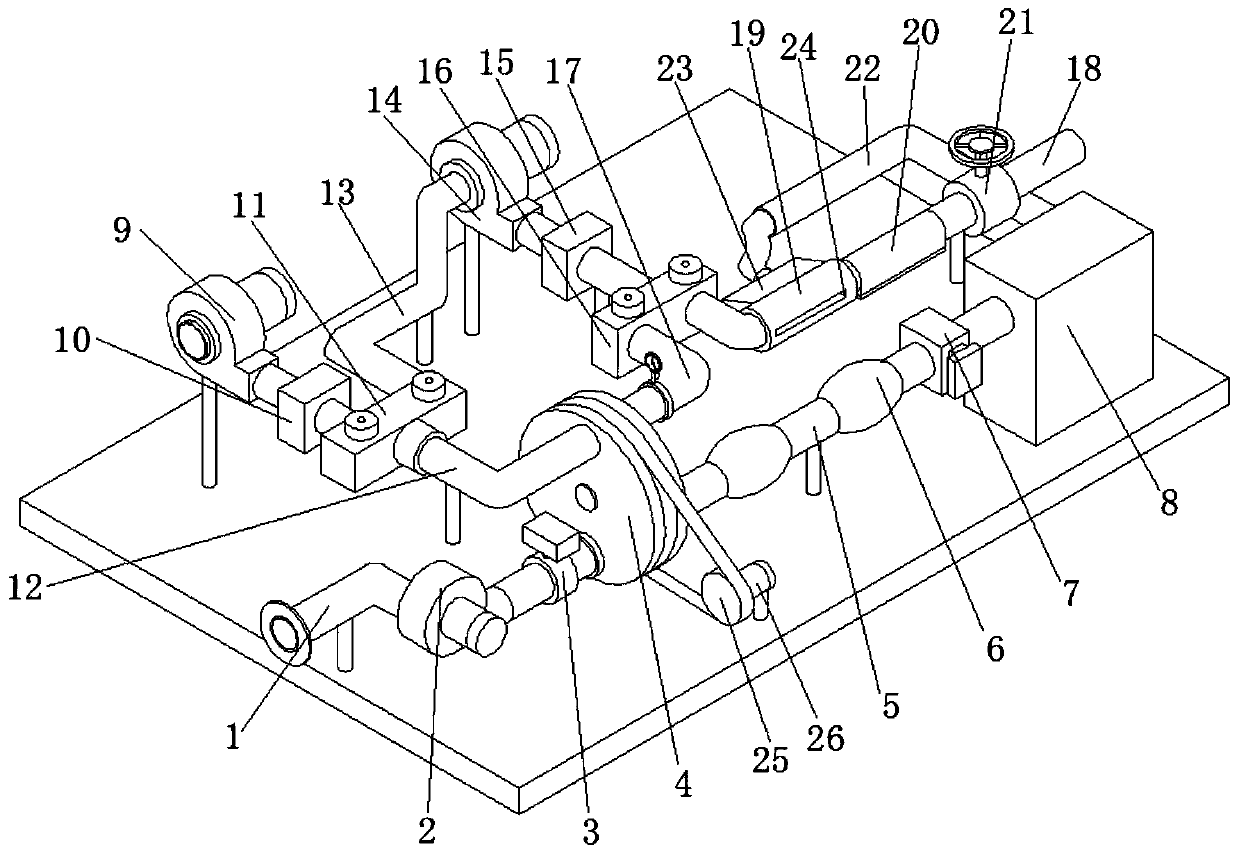

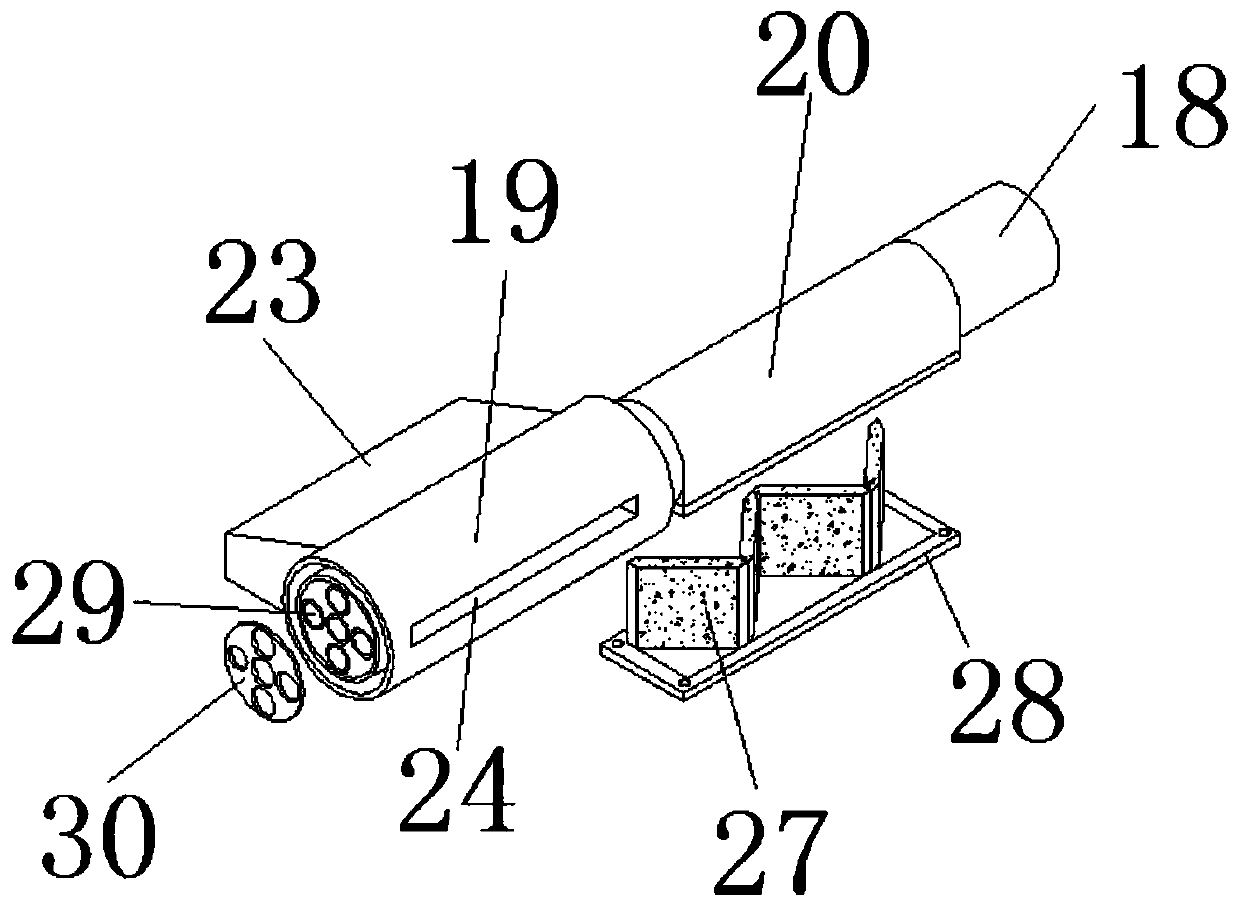

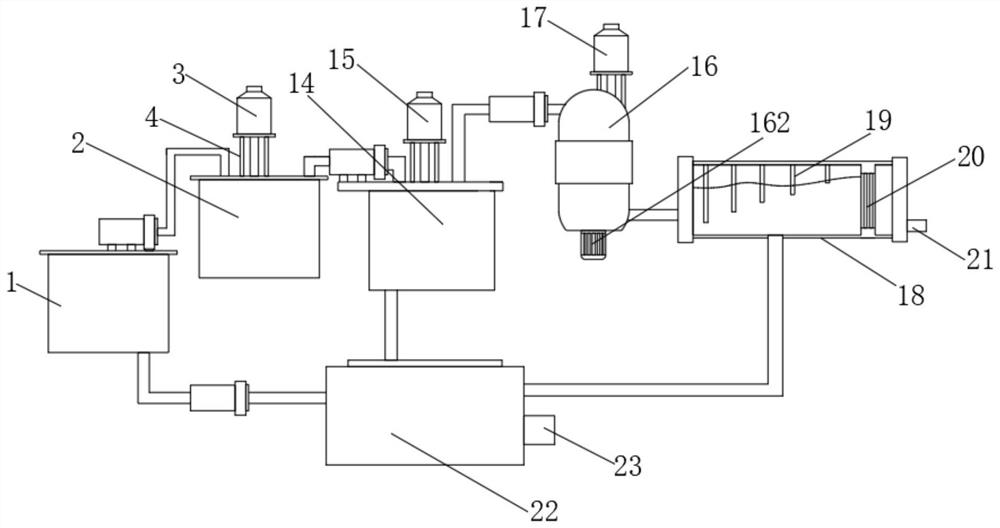

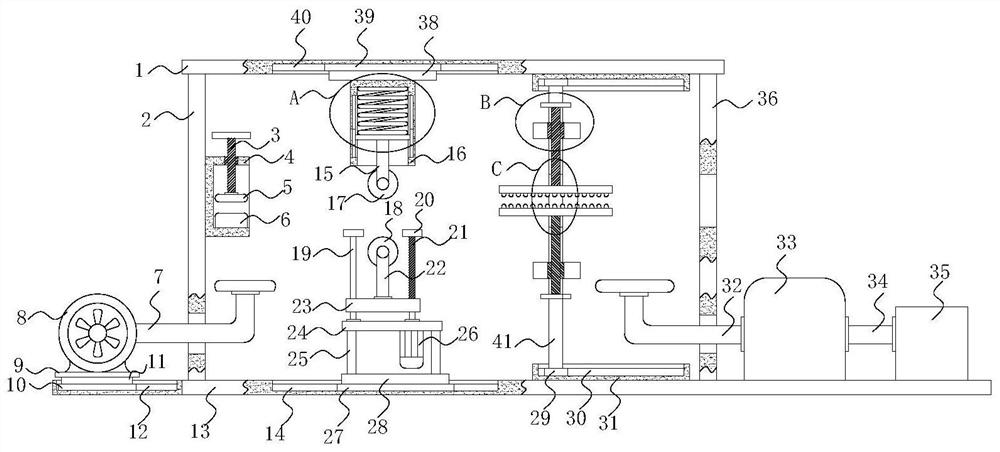

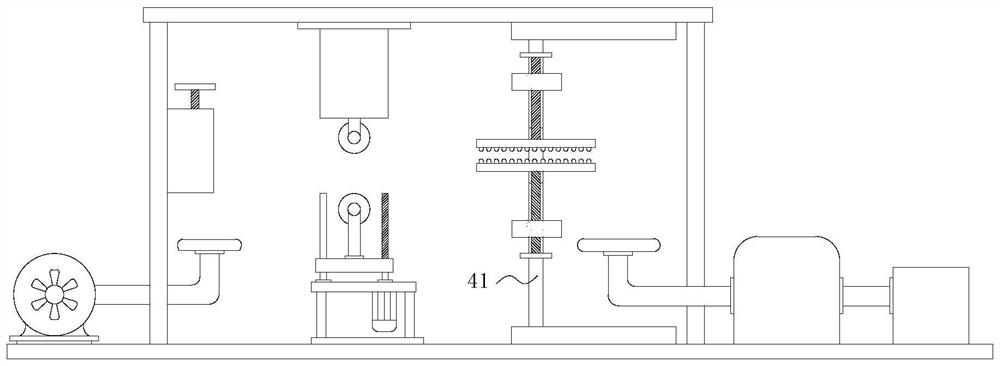

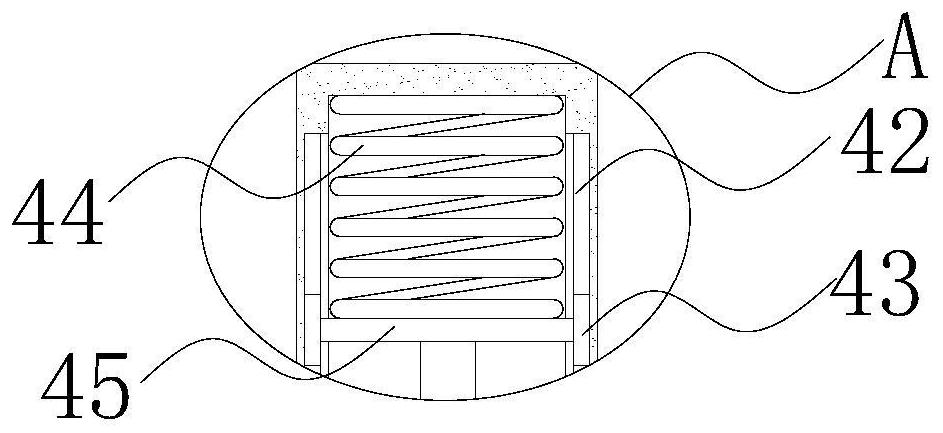

Three-stage treatment equipment for printing and dyeing waste gas

ActiveCN109985501AImprove liquidityIncrease speedDispersed particle separationPhotocatalytic degradationAirflow

The invention discloses three-stage treatment equipment for printing and dyeing waste gas. The equipment comprises a supporting plate, a zeolite concentration device, a waste-gas drying device and a photocatalytic degradation device; the zeolite concentration device, the waste-gas drying device and the photocatalytic degradation device are all installed on the supporting plate. When the equipmentprovided by the invention desorb volatile matter adsorbed on zeolite, firstly a booster fan 2 is utilized to drive hot air to pass through the front surface of a zeolite wheel through a heat exchangepipe 1 to take away concentrated waste gas, the waste gas enters a circulation pipe through a heat exchange pipe 2, the circulation pipe communicates with the heat exchange pipe 1 through adjustment of a two-position three-way solenoid valve 1, a circulation fan is started to drive hot air to pass through the back side of the zeolite wheel through the heat exchange pipe 2, then the hot air entersthe circulation pipe through the heat exchange pipe 1, and the air is blown out by the circulation fan from the circulation pipe, so that the equipment realizes circulating flow of an internal airflow, prevents a new air flow from entering the interior, greatly improves the effects of reducing air and increasing the concentration, and makes the waste gas separated thoroughly through blowing of thepositive and negative surfaces of the zeolite wheel.

Owner:绍兴柯桥佳宇兴腾染整有限公司

Water-saving solar concentrating type distillation seawater desalination device comprising RO (reverse osmosis) system

PendingCN109534585AIncrease light rateImprove conversion efficiencyBatteries circuit arrangementsGeneral water supply conservationDistillationEngineering

The invention discloses a water-saving solar concentrating type distillation seawater desalination device comprising a RO (reverse osmosis) system. The device comprises a frame, two sets of symmetrical fixing bases are fixedly connected to the bottom surface of the frame, a fixing block is fixedly connected to the bottom surface of each fixing base, a support is fixedly connected to the bottom surface of each fixing block, a gasket is arranged on the outer side surface of each support, a pin shaft is arranged in each support, a wheel is arranged on the lower portion of each support, and each wheel is fixedly hinged to the corresponding support through the corresponding pin shaft. According to the water-saving solar concentrating type distillation seawater desalination device comprising theRO (reverse osmosis) system, the wheels are arranged, under the action of the fixing bases, the supports, the fixing blocks, the gaskets, the pin shafts and brake pads, a solar cell panel group can be moved to a place where lighting is convenient, so that the illumination rate is improved, the solar cell panel group is arranged, and under the action of a solar controller, an inverter and a storage battery, the solar energy conversion efficiency is improved.

Owner:海南自贸区浩天能环境工程有限公司 +1

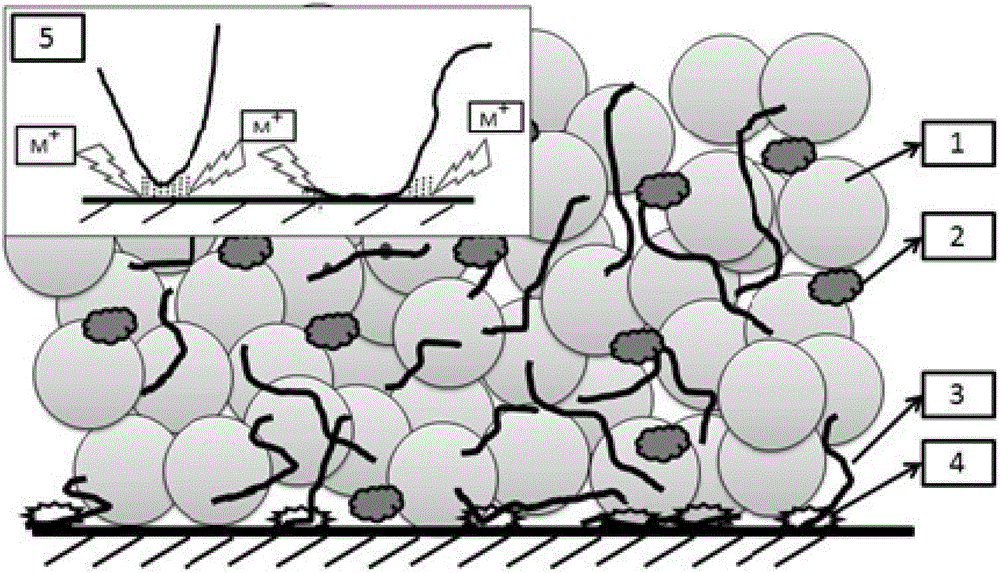

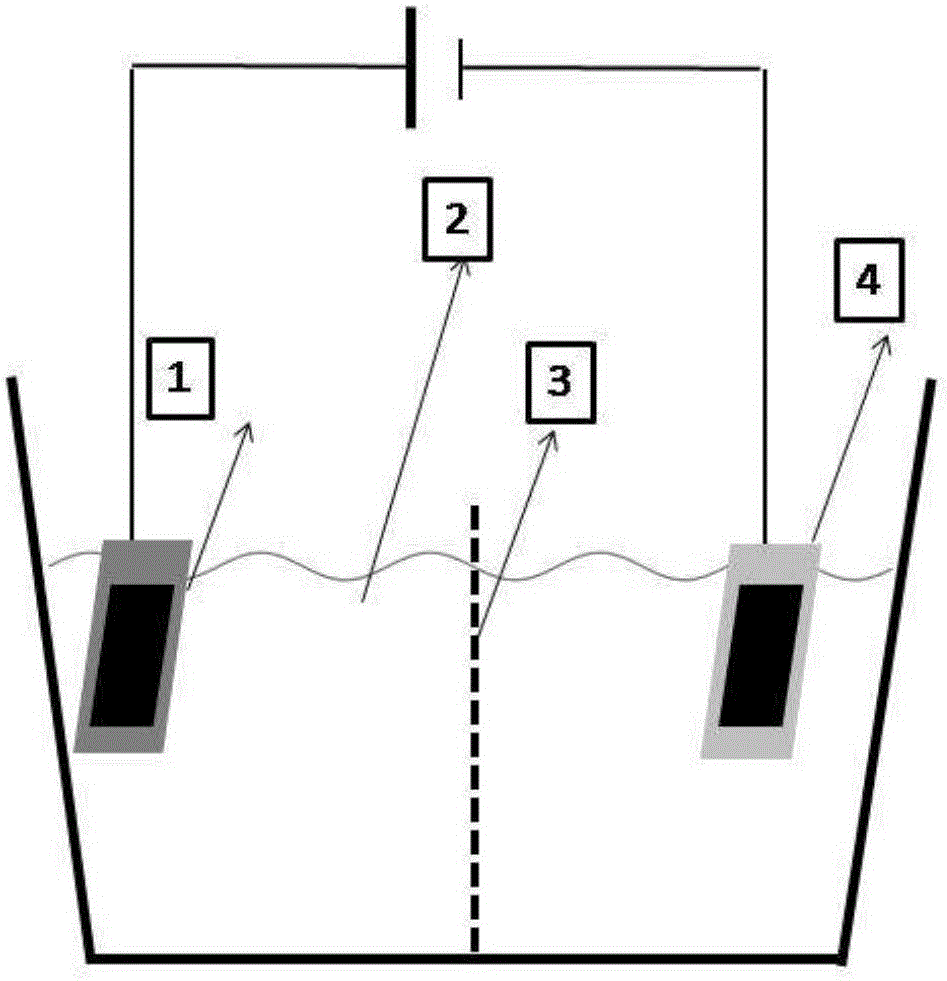

Electroplating peeling recovery technology of lithium battery electrode

ActiveCN106025421AEfficient separationOut of completeWaste accumulators reclaimingBattery recyclingSupersonic wavesEngineering

The invention discloses an electroplating peeling recovery technology of a lithium battery electrode. The electroplating peeling recovery technology comprises the following steps: disassembling and removing a positive plate and a negative plate; taking the positive plate or the negative plate tab as a cathode, taking the negative plate tab as an anode, introducing DC source, performing ultrasonic mixing, then performing electroplating; rotating the positive plate, electroplating the other anode coating surface by facing the anode; taking the positive plate or the negative plate out, filtering the positive plate or the negative plate by a screen mesh to obtain the active substance separating objects, performing deionization washing for 1-5 times, and drying the product and weighing the product. The electroplating peeling recovery technology has the advantages of cleaning and separating the electrode active material with high efficiency, uniformity of the metal ions deposited on the surface is good, bonding effect of an original binder and the surface can be rapidly destroyed, and a purpose of thoroughly disengaging and separating of the active material is reached. According to the invention, supersonic wave concussion with certain power is used, shedding of the active substance from a current collector is accelerated, the obtained anode / cathode active material and a solution are insoluble, and no solid impurity is introduced.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Chemical waste liquid heavy metal residue treatment equipment

InactiveCN111635038AIncrease water outputOut of completeSludge treatmentWater contaminantsHeavy metalsSewage treatment

The invention relates to the technical field of heavy metal treatment. The invention discloses chemical waste liquid heavy metal residue treatment equipment. The equipment comprises a heavy metal waste liquid tank, a neutralization tank, a settling tank, a flocculation tank and a clarification separation tank, wherein the top end of the heavy metal waste liquid tank is connected into the neutralization tank through a pipeline, a first dosing device is arranged above the neutralization tank, a gear disc is rotatably connected to the middle of the neutralization tank, a rotating plate and a water shoveling mixing plate are fixedly mounted at the bottom end of the gear disc, and a plurality of notches are formed in the middle of the gear disc. According to the chemical waste liquid heavy metal residue treatment equipment, at present, heavy metal ions are completely separated in the heavy metal sewage treatment process, long-term continuous operation can be guaranteed, the treatment effectof the device is good, it is guaranteed that heavy metal and added chemicals can be rapidly and evenly mixed, it is guaranteed that a liquid can rapidly reach the standing state, sediment can be rapidly subjected to sedimentation treatment, and the treatment efficiency of the metal ion treatment device is improved.

Owner:广州道源信息科技有限公司

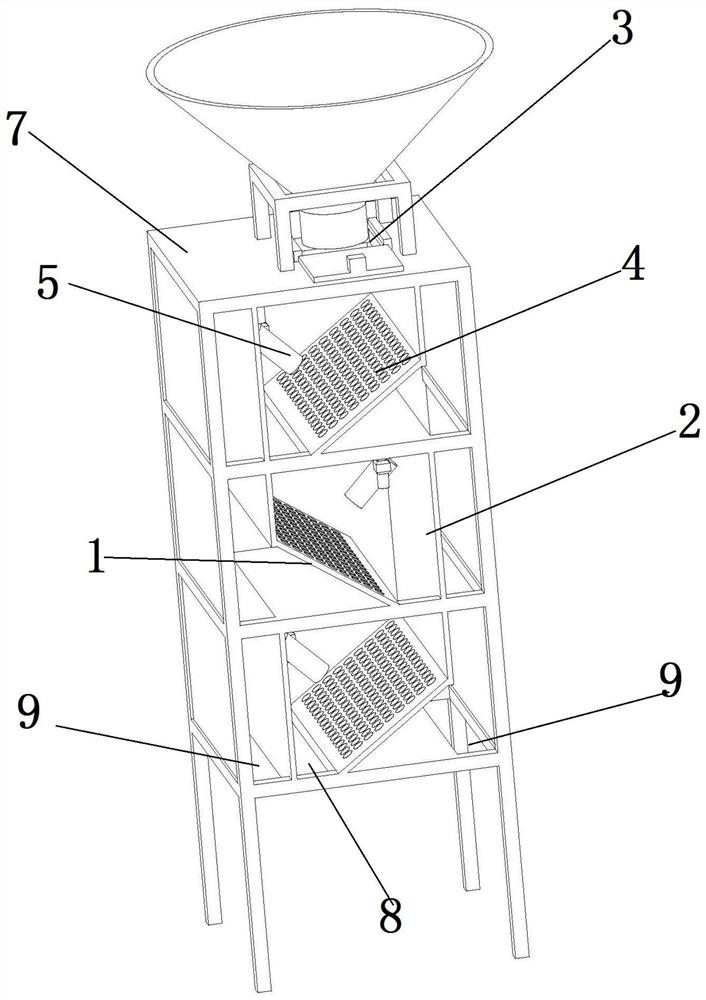

Construction waste screening device for screening iron products

InactiveCN112844587AEasy to absorbEasy to collectMagnetic separationGrain treatmentsEnvironmental engineeringMechanical engineering

The invention discloses a construction waste screening device for screening iron products, and relates to the technical field of construction waste screening devices. The construction waste screening device for screening the iron products comprises a feeding hopper, the lower side of the feeding hopper is fixedly connected with a first support, the lower side of the feeding hopper is fixedly connected with a crushing box body through the first support, the front side and the rear side of the inner wall of the crushing box body are provided with two crushing rollers, the two crushing rollers are horizontally and tangentially arranged, second supports are fixedly connected to the left side and the right side of the crushing box body, and a body box shell is fixedly connected to the lower side of the crushing box body through the second supports. According to the construction waste screening device for screening the iron products, a stirring mechanism can stir construction waste on a material falling plate back and forth, so that the contact rate of the iron products and an electromagnetic plate is increased, the screening efficiency of the electromagnetic plate on the the iron products is improved, and the situation that the iron products is buried, volatilized and blocked by the construction waste and cannot be sucked by the electromagnetic plate is prevented.

Owner:马永华

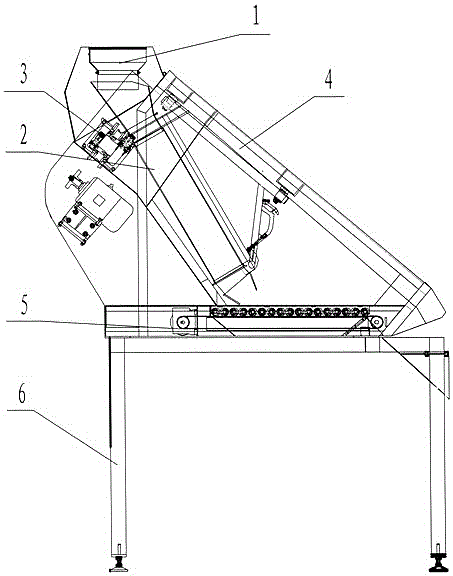

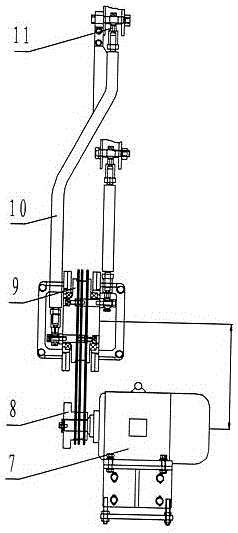

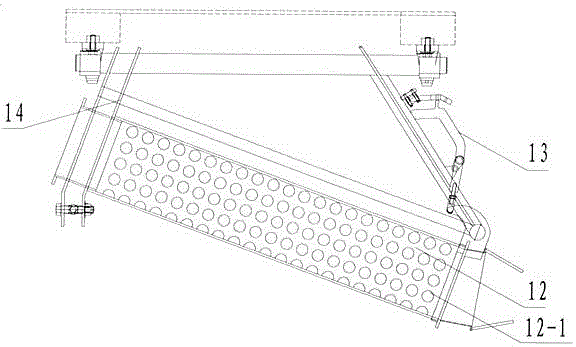

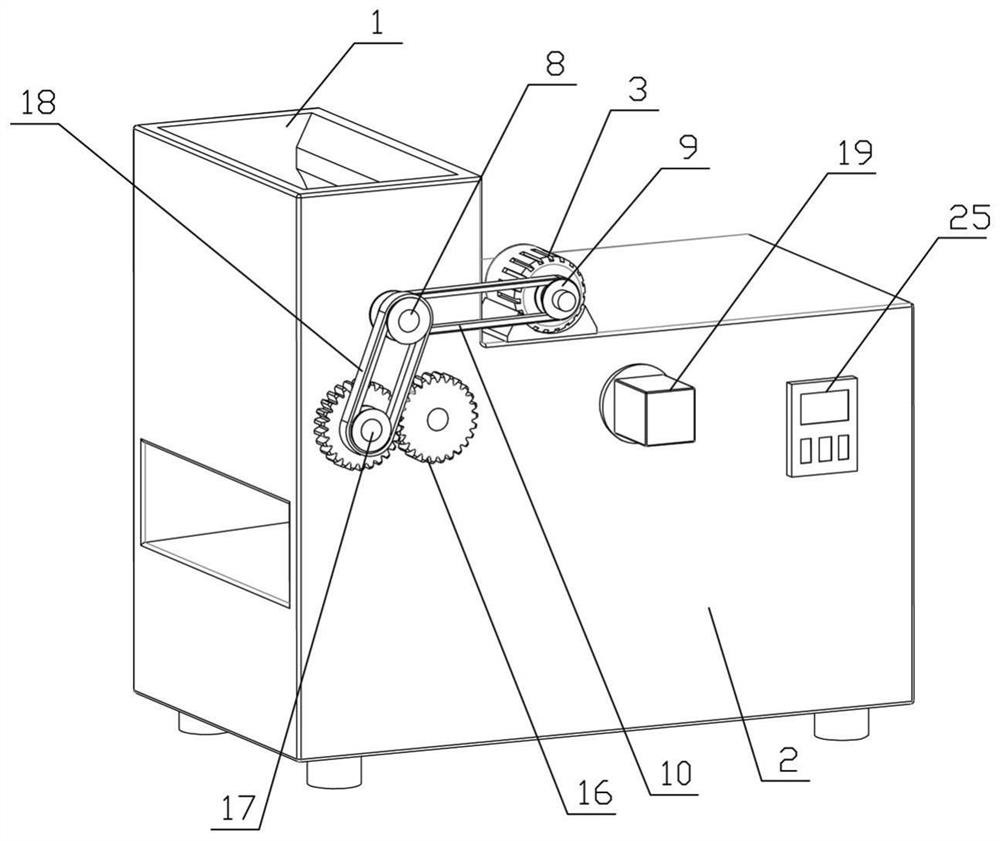

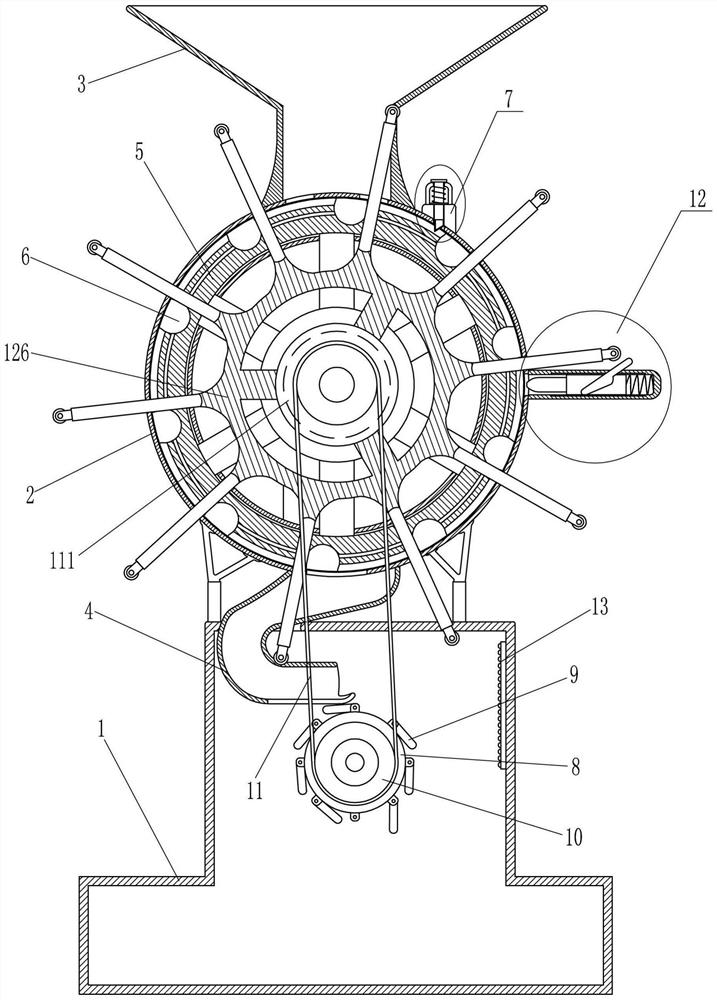

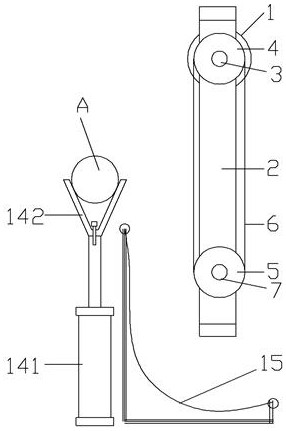

Grape stalk removal device

The invention discloses a grape destemming device, which comprises a frame and a bracket, a hopper is docked under the destemming device, the destemming device is fixed on the upper frame, and a transmission device is fixed on the side of the upper frame, and the transmission device consists of Composed of motor, pulley, pulley, connecting rod and joint bearing, the output shaft on the motor is connected to the pulley, the pulley is connected to another pulley with a belt, and the end of the connecting rod is connected to the screen cylinder through the joint bearing. The destemming device consists of a sieve cylinder, a lever and a bracket. The sieve cylinder is installed obliquely on the bracket. Fruit holes are uniformly arranged on the wall of the sieve cylinder. The roller device is composed of a roller drive motor, a chain, and a roller assembly. The roller drive assembly is It is composed of multiple rollers installed at a certain interval, and there is a gap between each adjacent roller for fruit falling. The rollers are driven by a chain, and the output shaft on the rolling motor is connected to the shaft on the roller. The roller assembly is Staggered installation. It can completely separate the grape grains and grape stems.

Owner:新乡市领先轻工机械有限公司

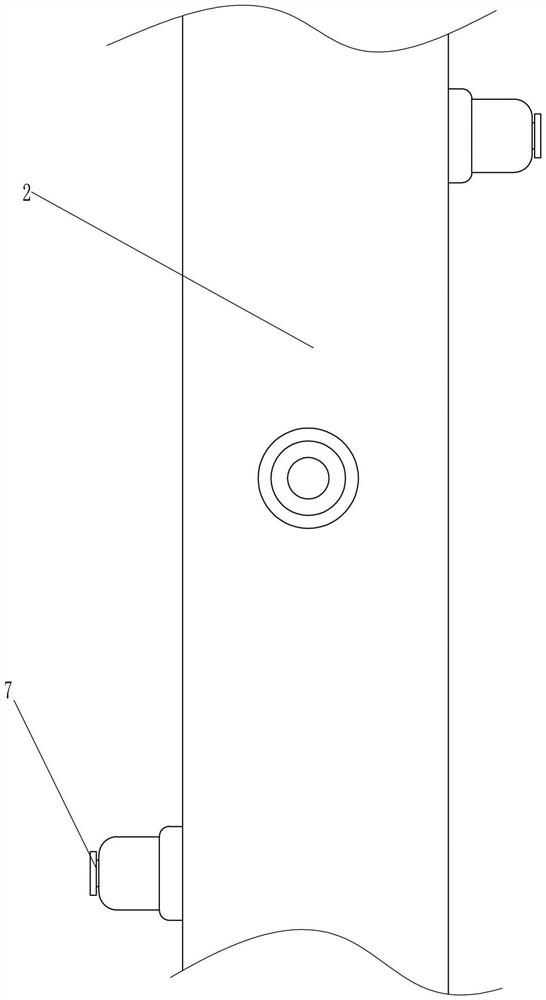

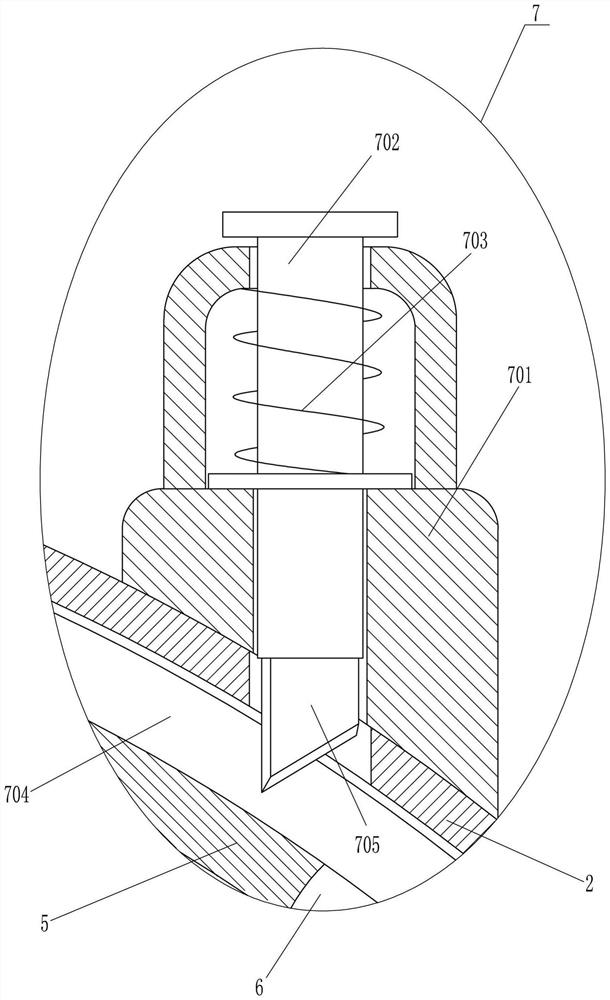

Cyclone separator and spore separation device therewith

InactiveCN101524672BEasy to separateOut of completeReversed direction vortexBiological material testing proceduresSporeCyclone

The invention discloses a cyclone separator, comprising a primary separator and a secondary separator (8) which are communicated by a channel (9), the bottom of the primary separator is connected with a primary collection tube (6), the bottom of the secondary separator is connected with a secondary collection tube (7); the top surface of the primary separator is provided with an air outlet channel (2), the side wall of the primary separator is tangentially provided with an air inlet channel (1), the air outlet channel (2) and the air inlet channel (1) are both communicated with the inner cavity of the primary separator; an air volume regulator (10) is arranged inside the air inlet channel (1), and the channel (9) is positioned below the air inlet channel (1). The invention also discloses a spore separation device with the cyclone separator, wherein a blower component (300) is connected with the air outlet channel (2) in a sealing way, and a swirling flow feeder component (200) is connected with the air inlet channel (1) in a sealing way. The spore separation device of the invention can efficiently separate solid fermentation fungal spore.

Owner:ZHEJIANG UNIV

Industrial waste gas treatment and purification system based on big data

InactiveCN110385021AOut of completeComplete exposure reactionDispersed particle separationSufficient timeSulfur

The invention relates to an industrial waste gas treatment and purification system, in particular to an industrial waste gas treatment and purification system based on big data. The industrial waste gas treatment and purification system comprises a device bracket, an air suction device, a desulfurization device, a power mechanism I, a sliding bracket, a swing bracket I, a denitrification device, aswing bracket II, stirring mechanisms, a pushing mechanism, a power mechanism II and a power mechanism III, thus two desulfurization cylinders and two denitrification cylinders are switched between the communicating state and the closing state to provide time for heating limestone through a heating device arranged in a desulfurization box, and thus industrial waste gas has sufficient time to react with the limestone, and the sulfur in the industrial waste gas is separated more thoroughly; and two stirring mechanisms provide urea and the industrial waste gas to the two denitrification cylinders, air eddy produced when the stirring mechanisms are rotated and pushing of a pushing mechanism make the two denitrification cylinders swing, and a contact reaction between the industrial waste gas and the urea is more thorough since the two denitrification cylinders are located in the eccentric position of the rotation center.

Owner:哈尔滨博觉科技有限公司

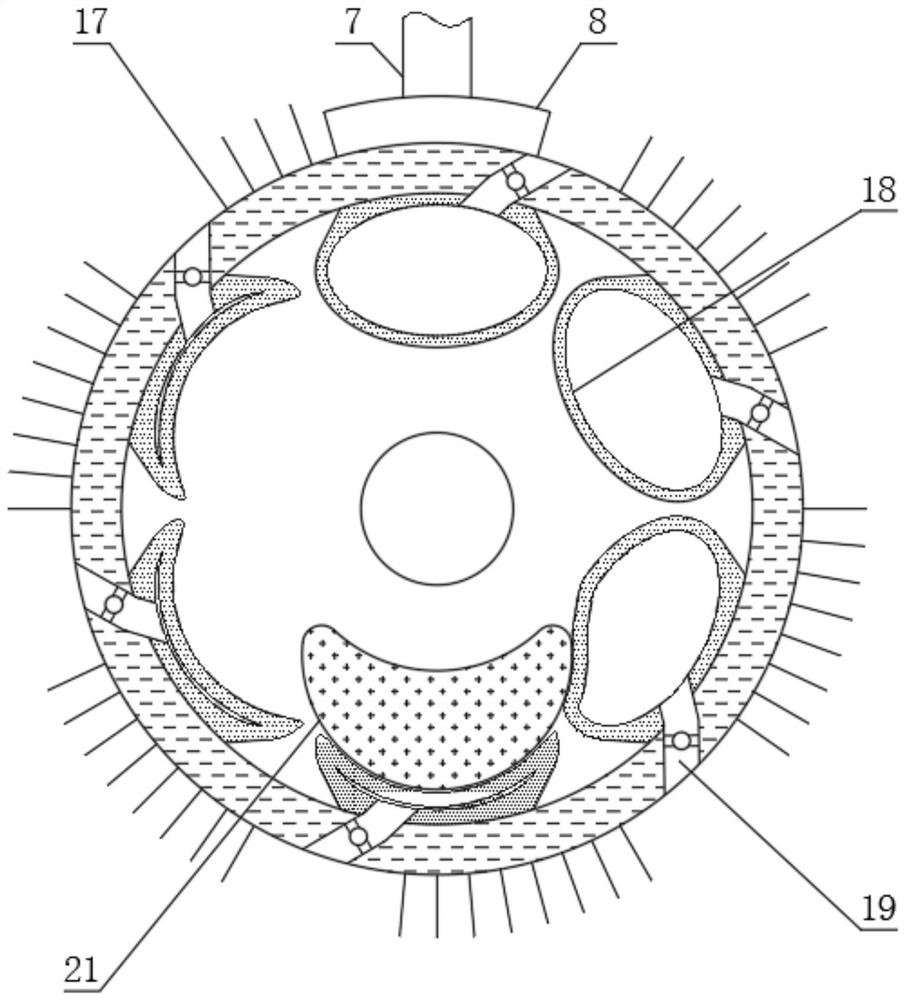

Efficient circuit board dust removal device for mobile communication

InactiveCN112605025AAchieve dust removal effectOut of completeCleaning using toolsCleaning using gasesDust controlBrush

The invention relates to the technical field of mobile communication, and discloses an efficient circuit board dust removal device for mobile communication. The device comprises a box body, the inner bottom wall of the box body is fixedly connected with an air suction cylinder, the interior of the air suction cylinder is movably connected with a piston, and the right side of the piston is fixedly connected with a movable rod. A rotating cylinder is rotatably connected to the inner rear wall of the box body, six annularly-arranged air bags are fixedly connected to the inner side wall of the rotating cylinder, air blowing holes and air inflation holes are formed in the sides, opposite to each other, of the air bags, and an extrusion block is arranged on the lower portion of the interior of the rotating cylinder. When a circuit board moves to the position below the rotating cylinder, the rotating cylinder drives a brush to rotate to remove dust on the circuit board for the first time, meanwhile, the air bags on the lower portion in the rotating cylinder are extruded by the extrusion block, air in the air bags is blown to the circuit board from the air blowing holes to remove the dust on the circuit board for the second time, and therefore the effect of removing the dust on the circuit board in multiple modes is achieved. The dust can be thoroughly separated from the circuit board, and the dust removal effect is better.

Owner:郭宁娣

Paper making technology of distiller's yeast fermented bamboos

InactiveCN108060603AOut of completeImprove toughnessCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpFiberYeast

The invention relates to a paper making technology of distiller's yeast fermented bamboos. The paper making technology solves the problem existing in the prior art that non-cellulose in the bamboos cannot be sufficiently decomposed, a bamboo material also easily damages the fiber of the bamboos when fermented at high temperature, and the strength and tension of paper are influenced. According to the technical scheme, the paper making technology comprises the steps of chopping the bamboos, cutting the bamboos and soaking the bamboos in water; soaking the bamboos in limestone; stacking the bamboos to be cured; turning the bamboos to be aired; fermenting the bamboos; conducting paper making forming after fermentation. The paper making technology is characterized in that distiller's yeast is adopted for fermentation in the step of fermentation, and according to temperature, the fermentation process is controlled within 40-60 days. The paper making technology has the advantages that fermentation can be more thorough, the capability for decomposing cellulose in the fermentation process of the bamboo material can be improved so that the cellulose in the bamboo material can be more thoroughly separated from the non-cellulose, thus bamboo fiber can be better obtained, and the damage to the bamboo fiber is small; moreover, the combining capability of the fiber can also be improved, thusthe tension and the strength of the fiber are greatly increased, and finally, the paper has higher tensile resistance and toughness.

Owner:ZHEJIANG HUAYUAN ELECTRIC HEAT

Cooking-free heat removal device for waste metal paint layer

PendingCN110434749AEnable recyclingOut of completePolishing machinesGrinding drivesLacquerEngineering

The invention discloses a cooking-free heat removal device for a waste metal paint layer. The cooking-free heat removal device for the waste metal paint layer sequentially comprises a hot depainting mechanism and a scrubbing brush mechanism along the conveying direction of waste plates, wherein the hot depainting mechanism is used for carrying out heat treatment on the waste plates which are slowly fed to enable the metal parts of the waste plates to be heated by the metal parts, the scrubbing brush mechanism comprises at least one pair of steel wire brush rolls which are arranged oppositely and rotate at a high speed; and a gap for allowing the waste plates subjected to heat treatment to slowly pass in a penetrating manner is formed between the roll surfaces of each pair of steel wire brush rolls, and each pair of steel wire brush rolls sequentially performs scrubbing and polishing treatment on the upper surfaces and the lower surfaces of the waste plates subjected to the heat treatment. By utilizing the mode, the separation between the paint layer and the plates is more thorough, and the whole thermal removal process is more environment-friendly and pollution-free.

Owner:王中德

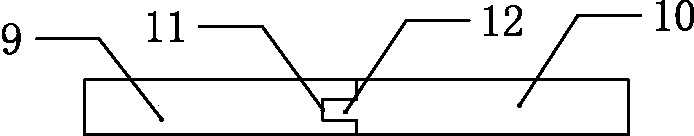

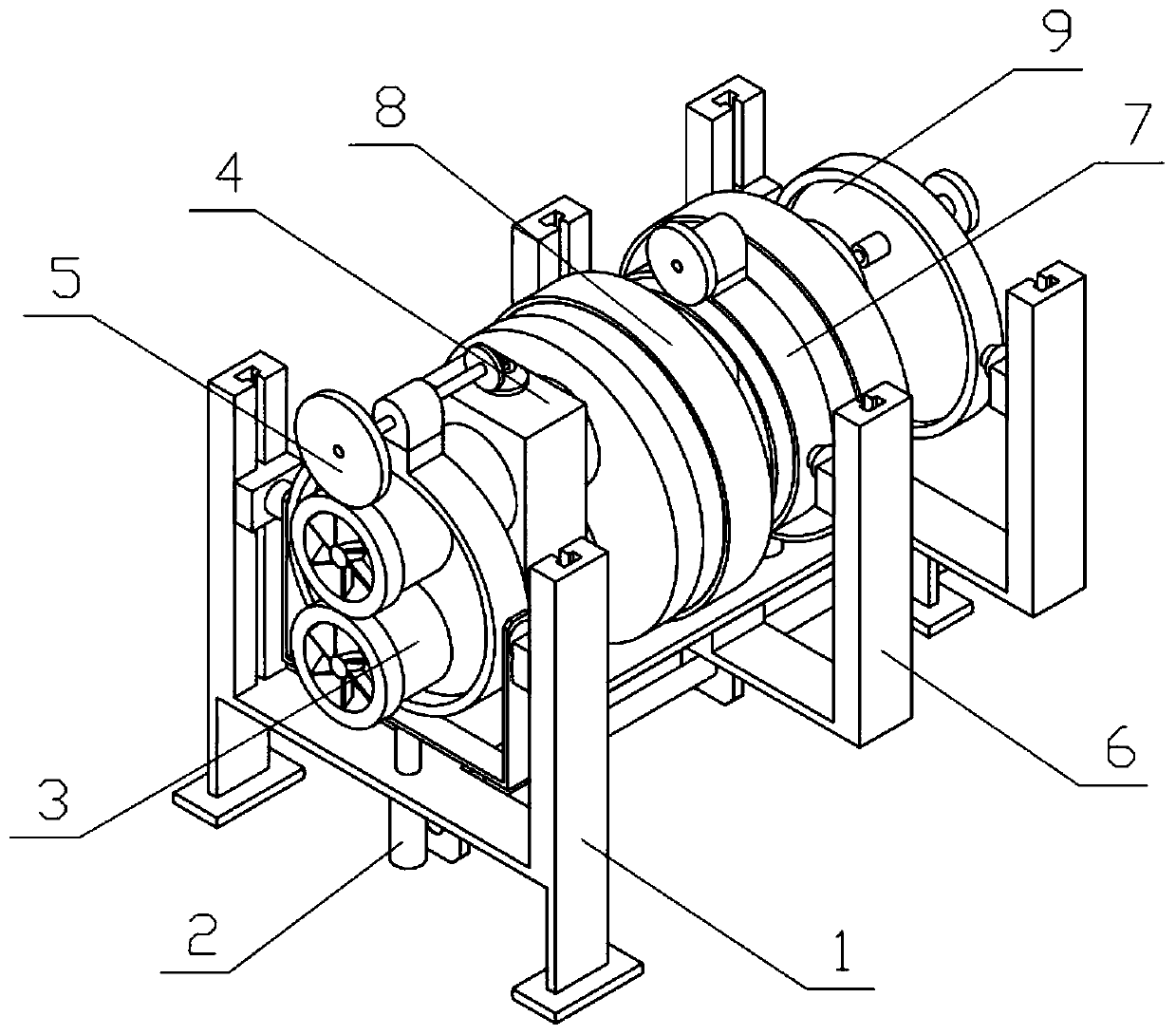

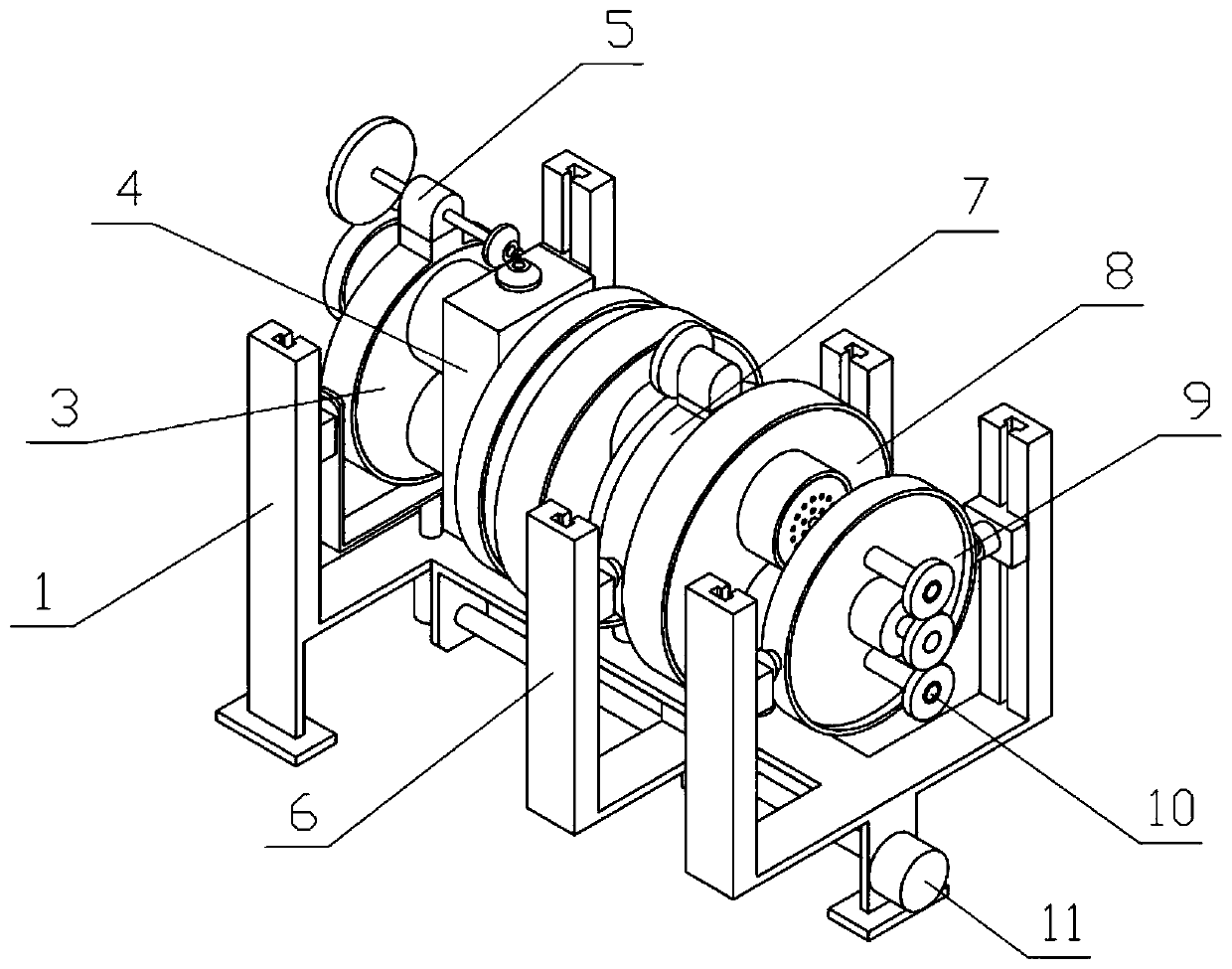

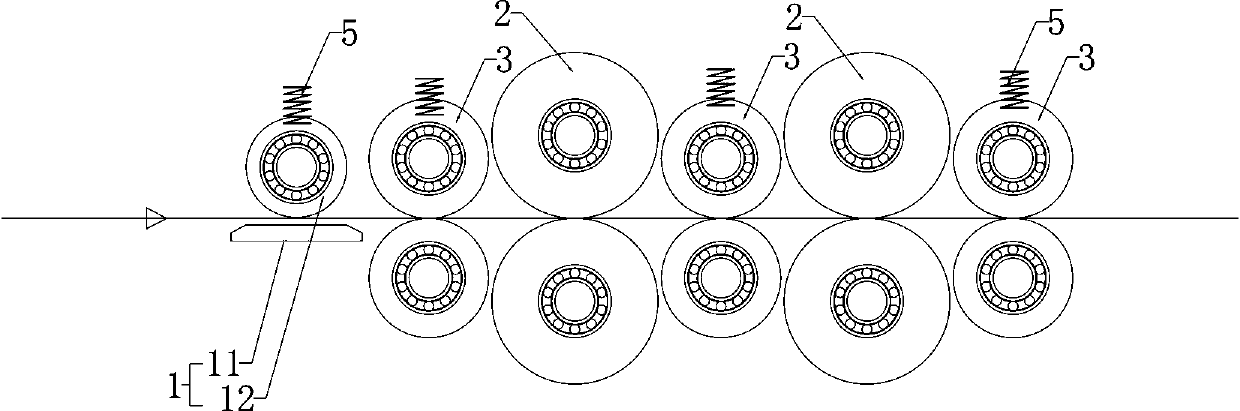

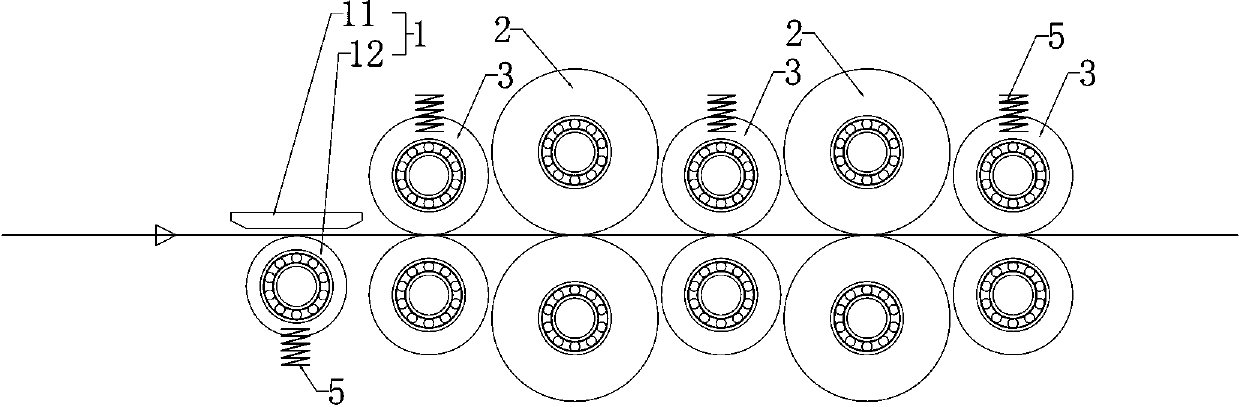

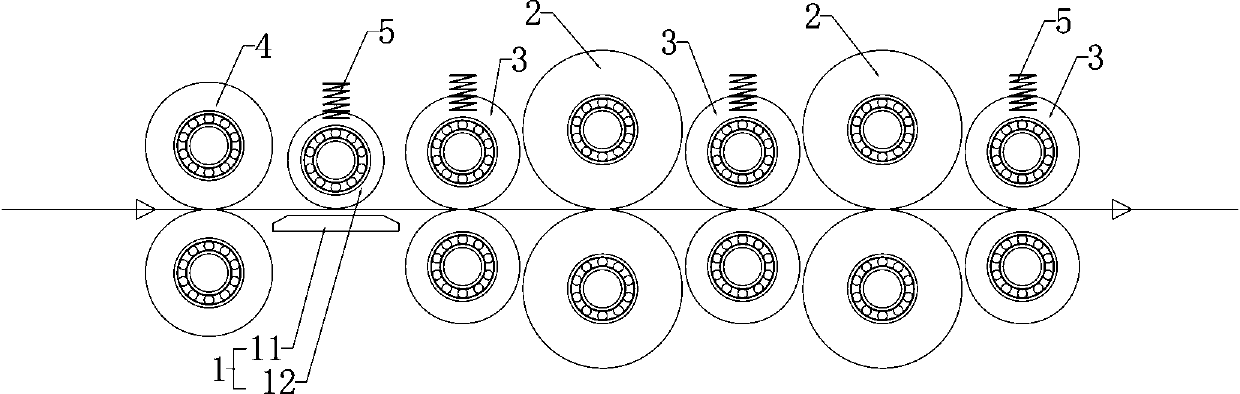

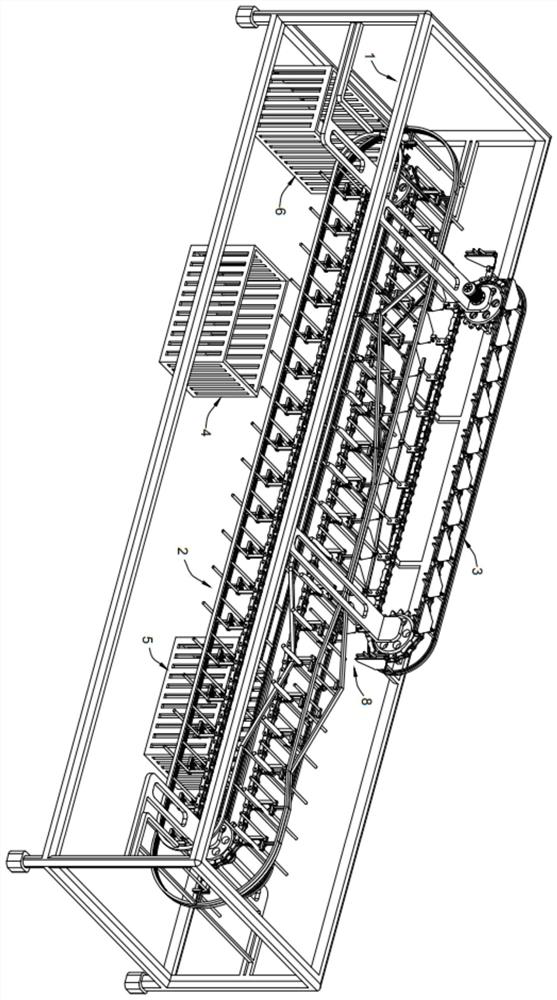

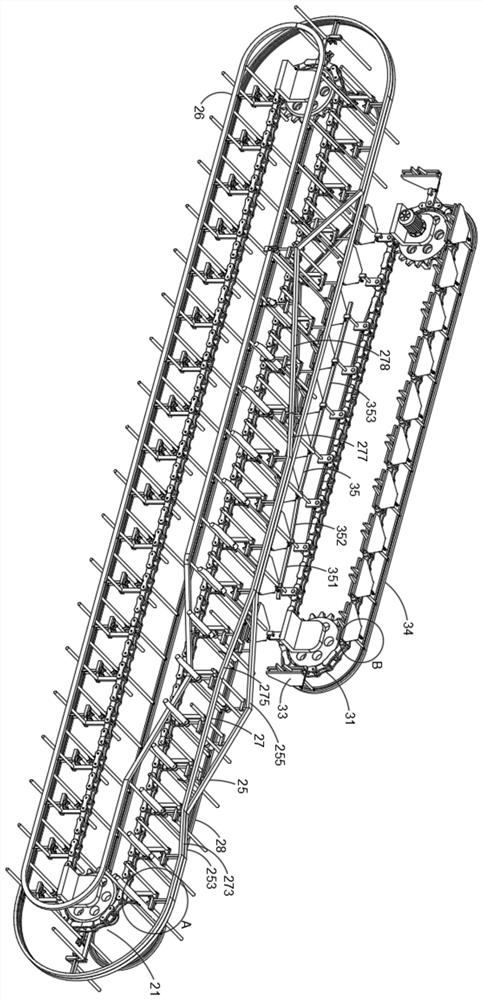

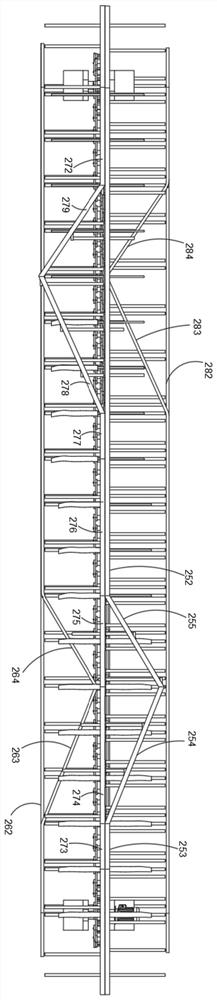

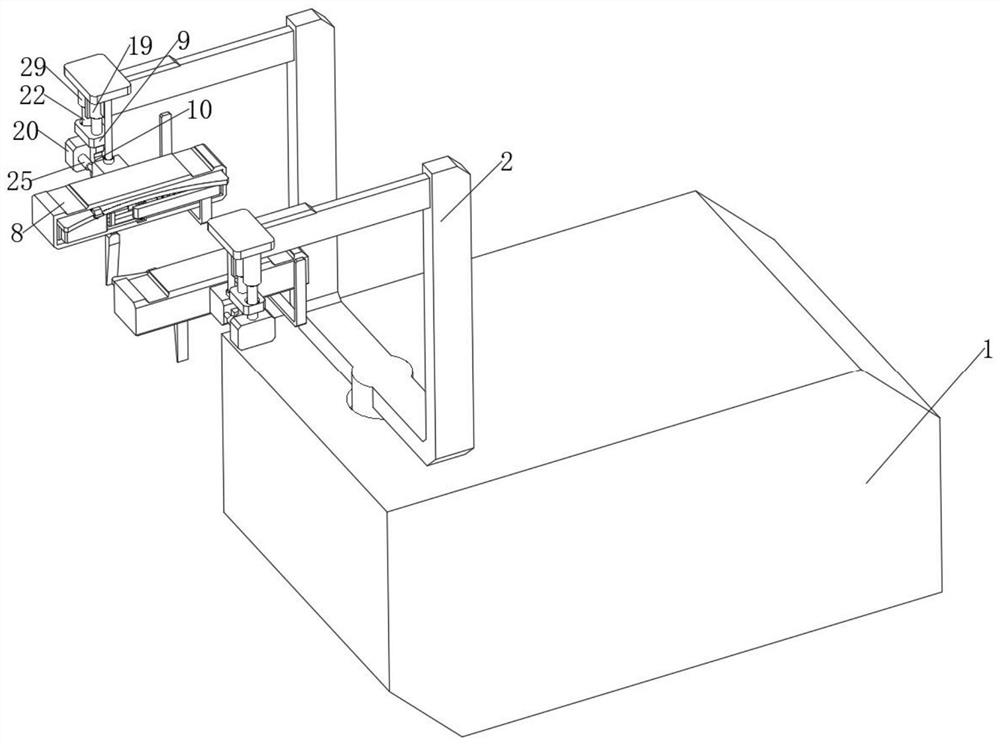

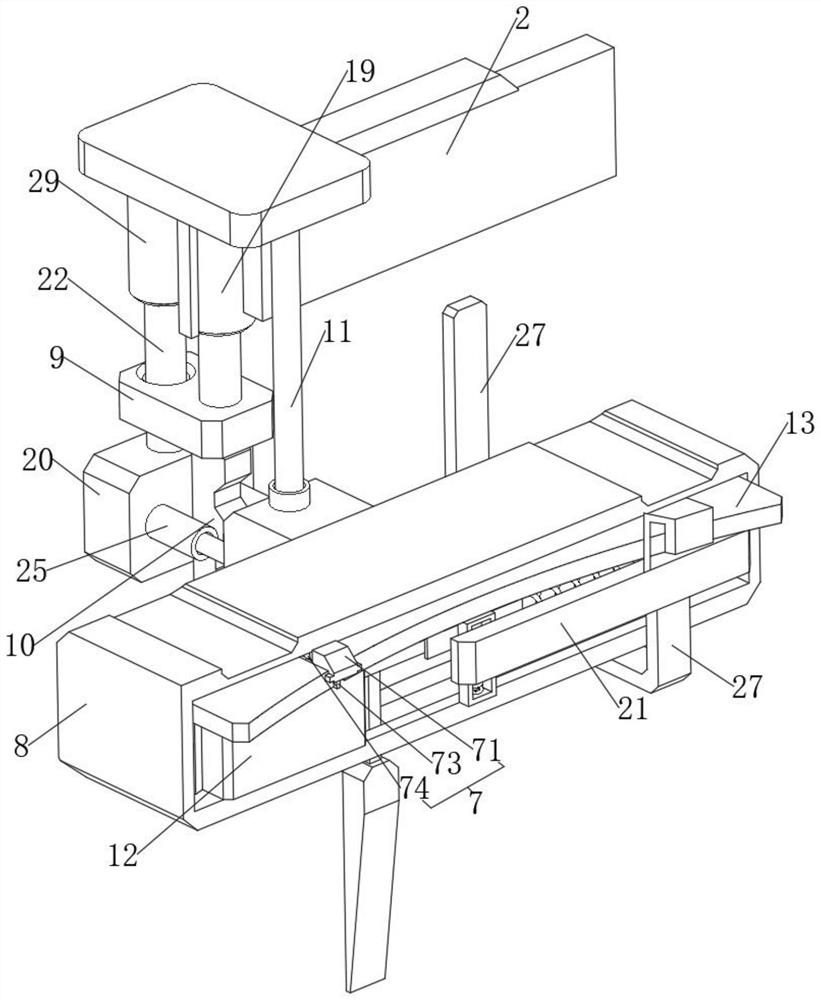

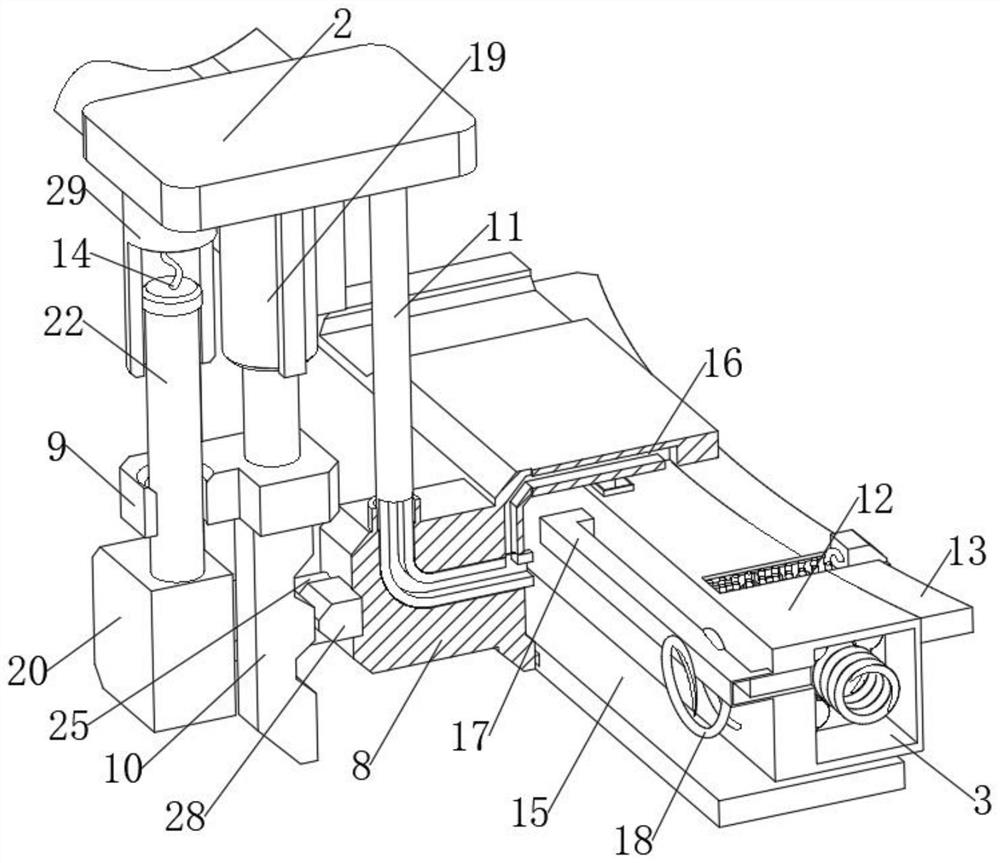

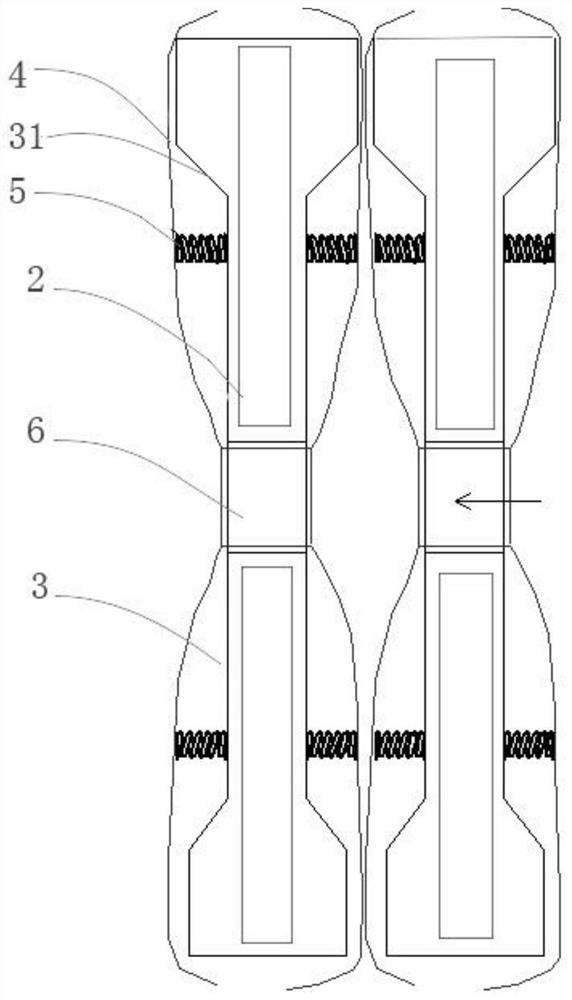

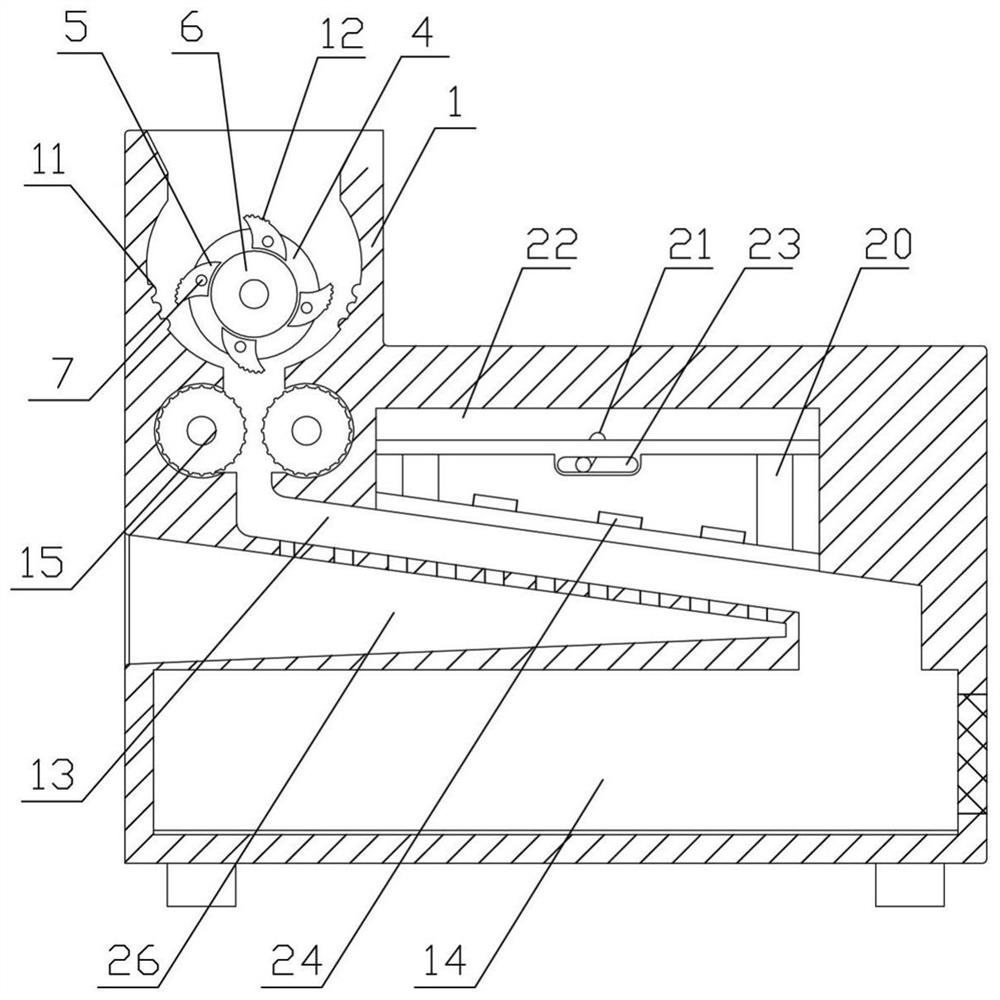

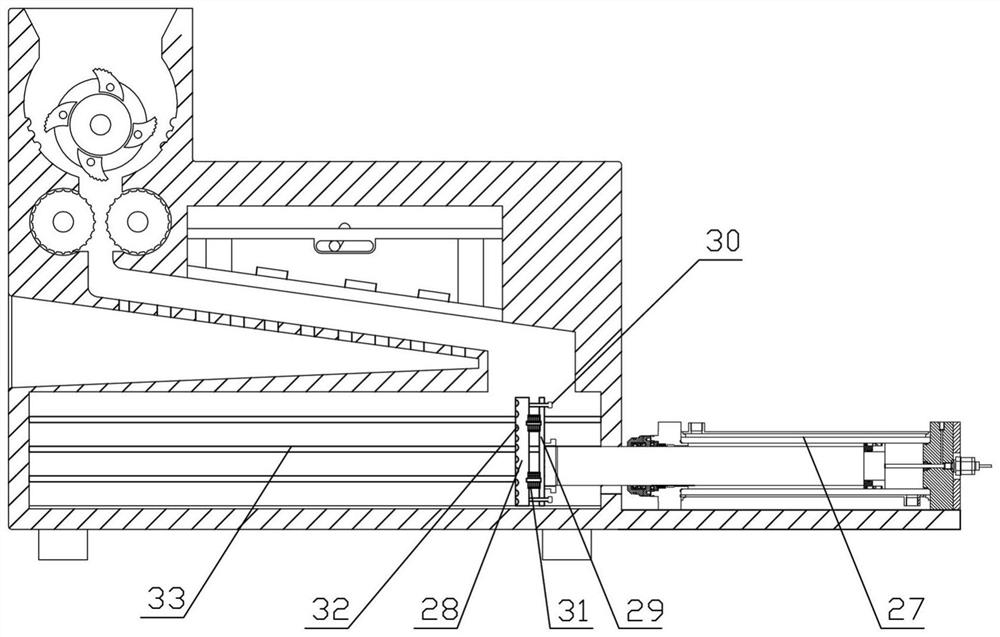

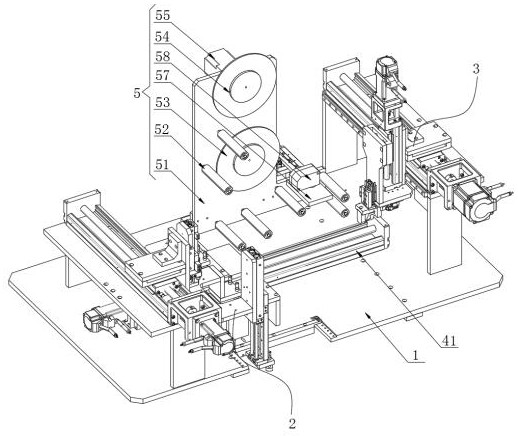

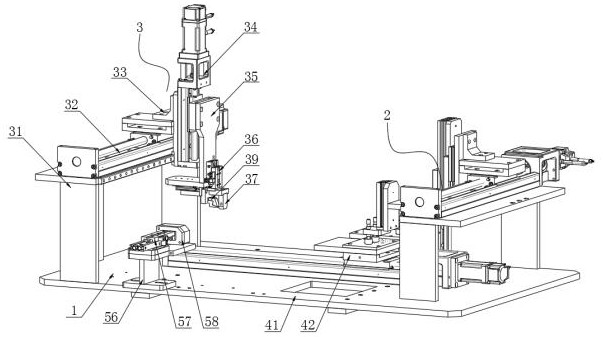

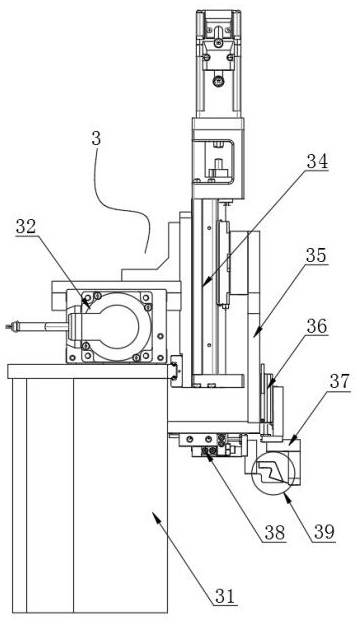

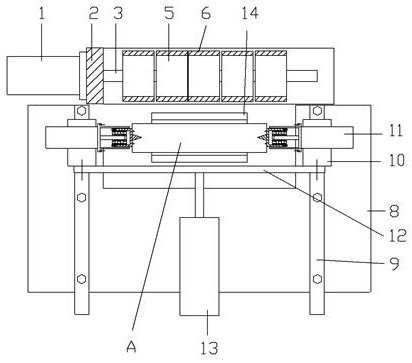

Production line for medicinal material core pulling

PendingCN113509383AImprove efficiencyImprove product qualityPharmaceutical product form changePhysicsMedicinal herbs

The invention relates to a production line for medicinal material core pulling. The production line comprises a rack, a core pulling device is arranged on the rack, the core pulling device comprises a rotary chain a, bearing blocks driven by the rotary chain a to rotate, right core pulling mechanisms and left core pulling mechanisms, the right core pulling mechanisms and the left core pulling mechanisms are arranged on the bearing blocks, and a clamping device is arranged above the side of the core pulling device. A clamping channel is formed between the core pulling device and the clamping device; each right core-pulling mechanism comprises an upper core-pulling assembly a and a lower core-pulling assembly a, the lower core-pulling assembly a bears morinda officinalis, each left core-pulling mechanism comprises an upper core-pulling assembly b and a lower core-pulling assembly b, and the clamping device comprises a rotary chain b and clamping mechanisms driven by the rotary chain b to rotate. The bearing blocks and the clamping mechanisms are in one-to-one correspondence in the vertical direction when the bearing blocks and the clamping mechanisms pass through the clamping channel; the problems that existing morinda officinalis processing consumes manpower, operation and control are inconvenient, and product quality is uneven are solved.

Owner:王文洪

Efficient electrostatic scrap removal device and electrostatic scrap removal method for high-precision filter element

PendingCN113524324AEasy to disengageAvoid secondary pollutionSievingGas current separationFiberProcess engineering

The invention discloses an efficient electrostatic scrap removal device and electrostatic scrap removal method for a high-precision filter element. The device comprises at least one group of electrostatic scrap removal assembly, each group of electrostatic scrap removal assembly comprises an inclined scrap falling part and a material blocking part which are sequentially arranged in the material flowing direction, a material inlet allowing materials to flow in is formed above each inclined scrap falling part, a plurality of scrap falling holes allowing scraps to penetrate through are formed in the inclined scrap falling part, and an electrostatic gun for removing static electricity of the materials is arranged between the inclined scrap falling part and the material blocking part. The mode that the electrostatic gun is arranged above the scrap falling holes between the inclined scrap falling part and the material blocking part is adopted, and the electrostatic gun is used for conducting static electricity removal and dust removal on falling fiber material bars, so that no static electricity exists between the material scraps and the material bars, and the material scraps can be conveniently separated from the material bars; and the mode that the scrap falling holes are formed in the inclined scrap falling part, and a material falling opening and a scrap falling side are arranged on two sides is adopted, so that the fiber material bars and powdered scraps are thoroughly separated through the material falling opening and the scrap falling side respectively, and the problem of secondary pollution caused by mixing of falling materials and falling scraps due to incomplete separation is solved.

Owner:GUANGDONG XINQIU NEW MATERIAL TECH CO LTD

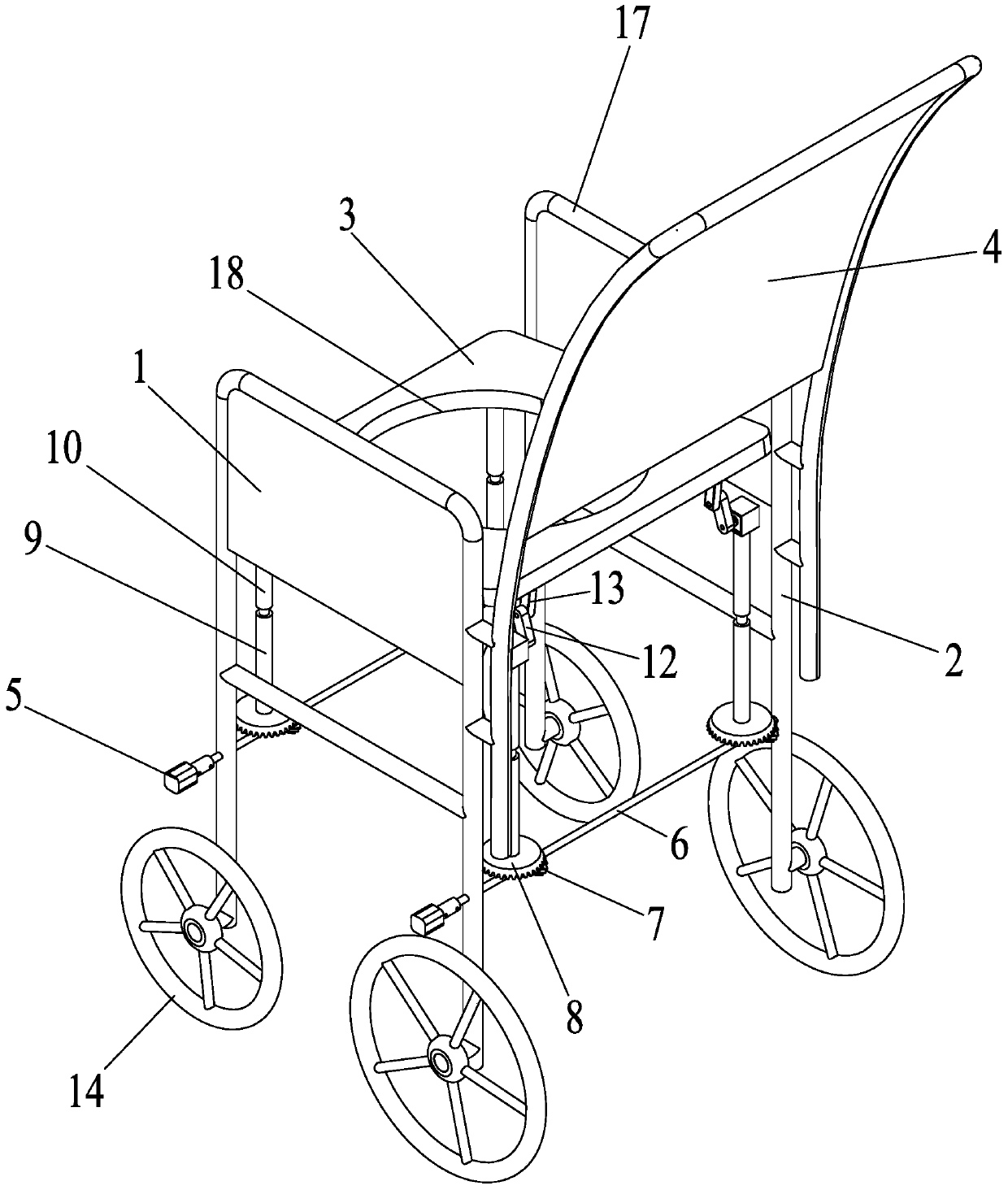

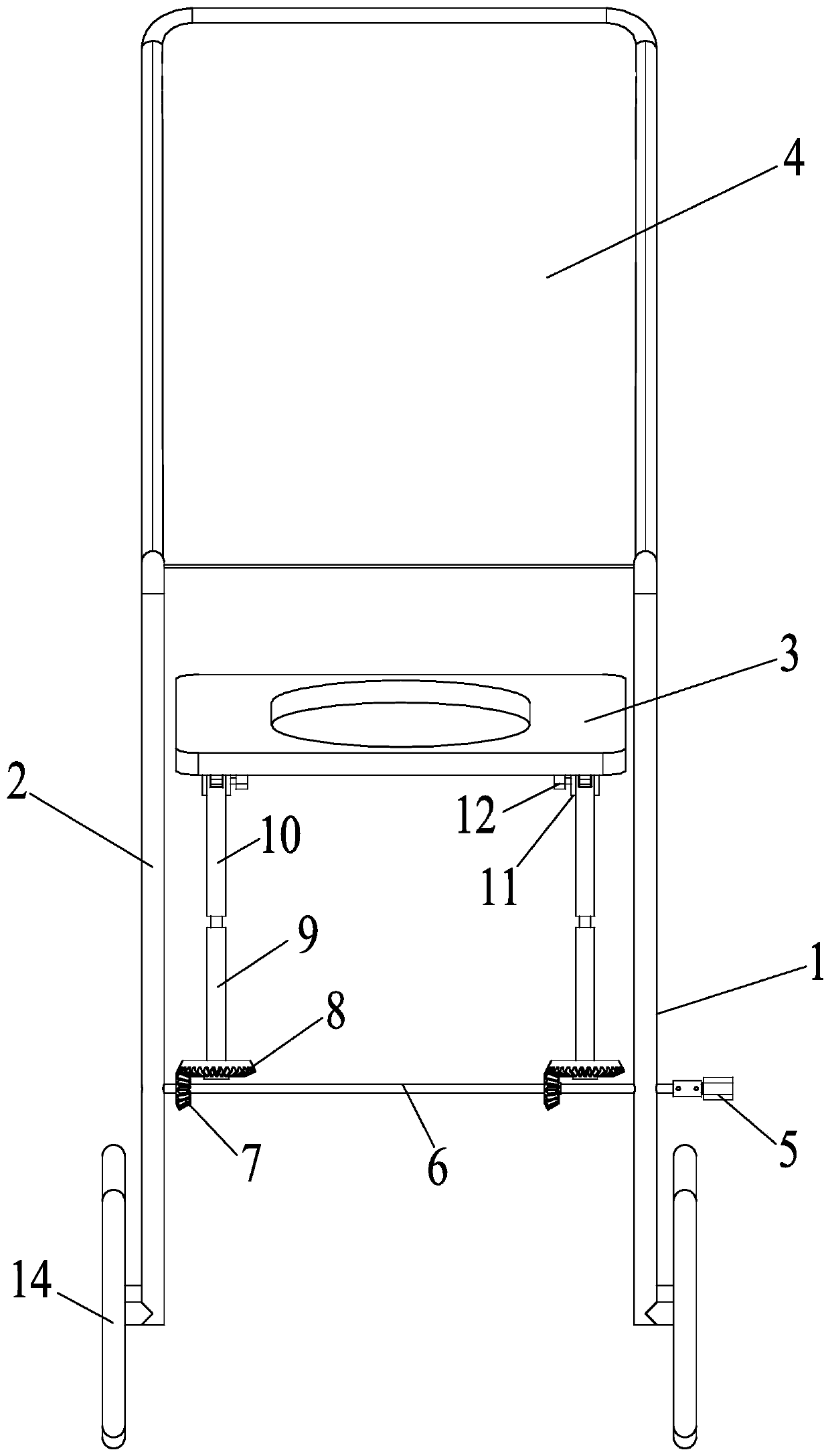

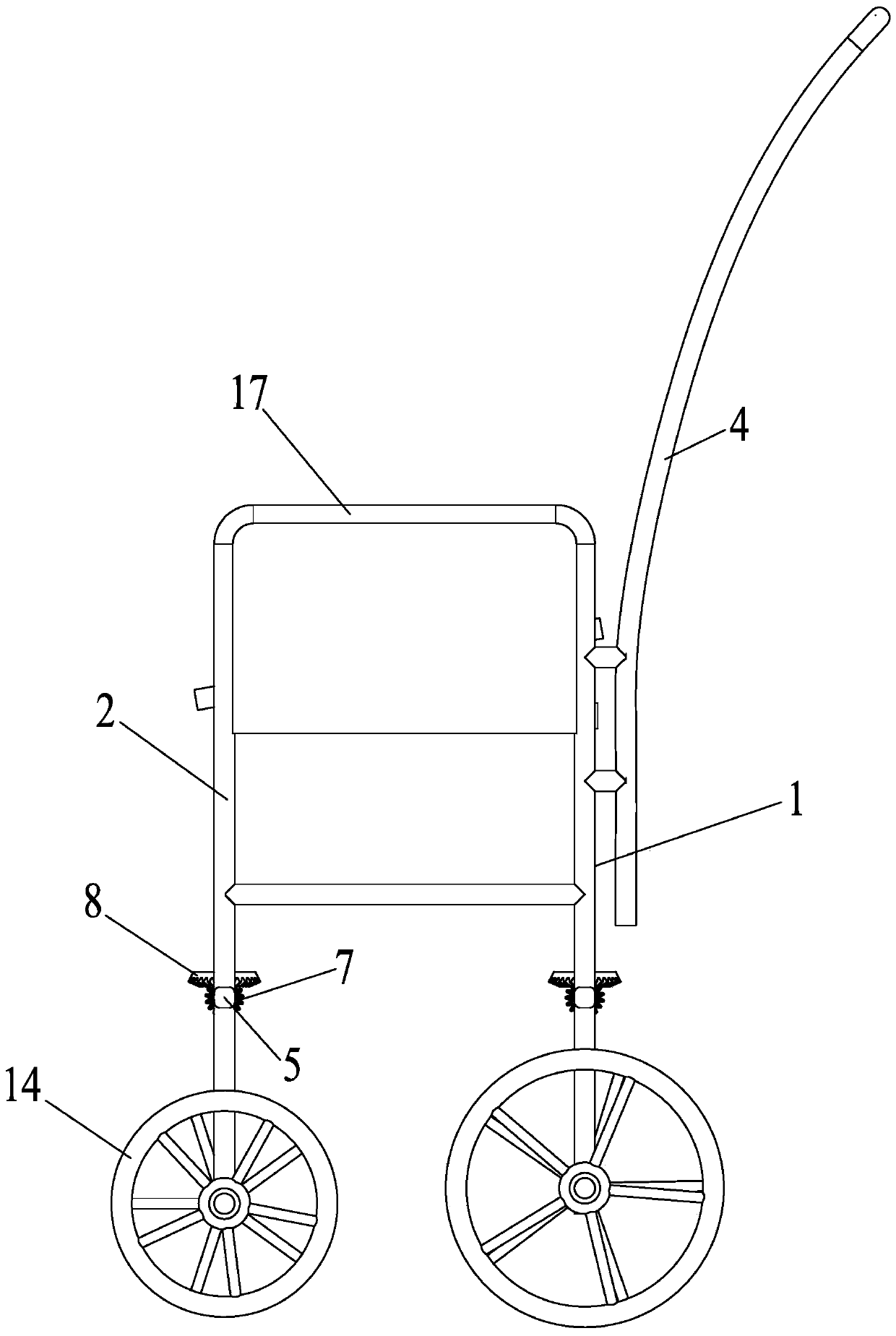

Automatic stretching and retracting device and method for old-age-assisting toilet bowl

ActiveCN111588297AWalk on the groundAdjust speedWheelchairs/patient conveyanceBathroom coversCrankBall screw

The invention discloses an automatic stretching and retracting device and method for an old-age-assisting toilet bowl. The device comprises a seat, a lifting mechanism, a rocker mechanism, a sensing mechanism and a controller. The seat comprises a support, a cushion and a backrest. Each lifting mechanism comprises a rod motor, a driving rod, a first bevel gear, a second bevel gear, a ball screw and a screw sleeve, and each rocker mechanism comprises a rocker motor, a first crank, a second crank, a first sensing mechanism pressure sensor and a second sensing mechanism pressure sensor. The controller firstly drives the cushion to ascend, a change curve of a leg pressing force is drawn, it is finally judged whether the leg pressing force is kept in a constant range or not, if yes, the rotation of the rod motor close to the cushion is stopped, the rotation of the rod motor far away from the cushion is stopped after the inclination angle of the cushion reaches a preset angle, and the rockermotor is finally driven to rotate to enable the cushion to move towards the direction of the person having difficulty in moving. The system is safer and more reliable, does not need to carry other equipment, and is more convenient to use.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

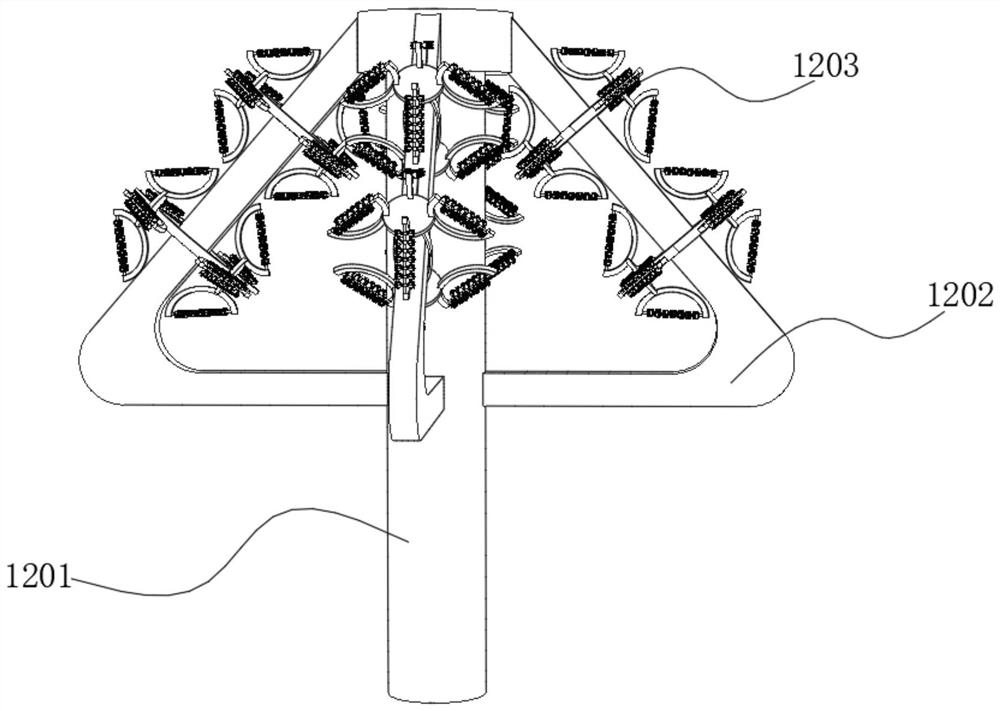

Intelligent workshop seedling transplanting robot

PendingCN113575058AFast transplantAvoid breakingTransplantingAgricultural scienceAgricultural engineering

The invention relates to the technical field of automatic planting, in particular to an intelligent workshop seedling transplanting robot which comprises a moving trolley and a U-shaped frame on the moving trolley, the moving trolley is further connected with a clamping box through a supporting device, one side of the clamping box is slidably connected with a clamping block used for clamping a seedling rod, the clamping block is slidably connected with a sliding plate, the sliding plate is used for stirring the seedling rod to shake, an air pipe is installed on the clamping box and used for conveying high-pressure air through the air pipe to drive the clamping block and the sliding plate to slide, the supporting device comprises a sleeve installed on the U-shaped frame, and the interior of the sleeve is connected with a shaft rod through a first spring. An extrusion block is extruded by a rack to push the clamping box to move left and right in a reciprocating manner, so that the seedling rod is pushed to move by utilizing the reciprocating left and right movement of the clamping box, the connection between rhizomes and the soil is loosened, the phenomenon that the rhizomes are broken to cause poor survival of transplanted seedlings is avoided, and the seedlings can be quickly transplanted into planting cups from hole trays.

Owner:SHANGHAI BANGBO MODERN AGRISCI

A waste silk cleaning device for textile cloth processing

ActiveCN110835820BConvenient drying workImprove convenienceMechanical cleaningPressure cleaningElectric machineryEngineering

The invention discloses a waste silk cleaning device for textile fabric processing, and relates to the field of textile fabric waste silk cleaning. The waste silk cleaning device for textile cloth processing includes a bottom plate, the top outer surface of the bottom plate is fixedly installed with a first side frame, a second side frame, a fixing plate, a vacuum cleaner and a collection box, and the inside of the bottom plate is provided with a The second chute, the inside of the second chute is slidingly installed with a second slider, the top of the second slider is fixedly installed with an auxiliary seat, the top outer surface of the auxiliary seat is fixedly installed with an auxiliary plate, and the top outer surface of the auxiliary plate is fixed A support plate is installed, the bottom outer surface of the support plate is fixedly installed with a motor, the top outer surface of the support plate is fixedly rotated and installed with a screw rod and a limit rod is fixedly installed, and the output shaft of the motor runs through the support plate and is fixedly connected with the screw rod. . The invention replaces the traditional way of manually cleaning the waste silk of textile fabrics, improves the work efficiency of workers, and reduces the work intensity.

Owner:安徽省拥家户外用品科技有限公司

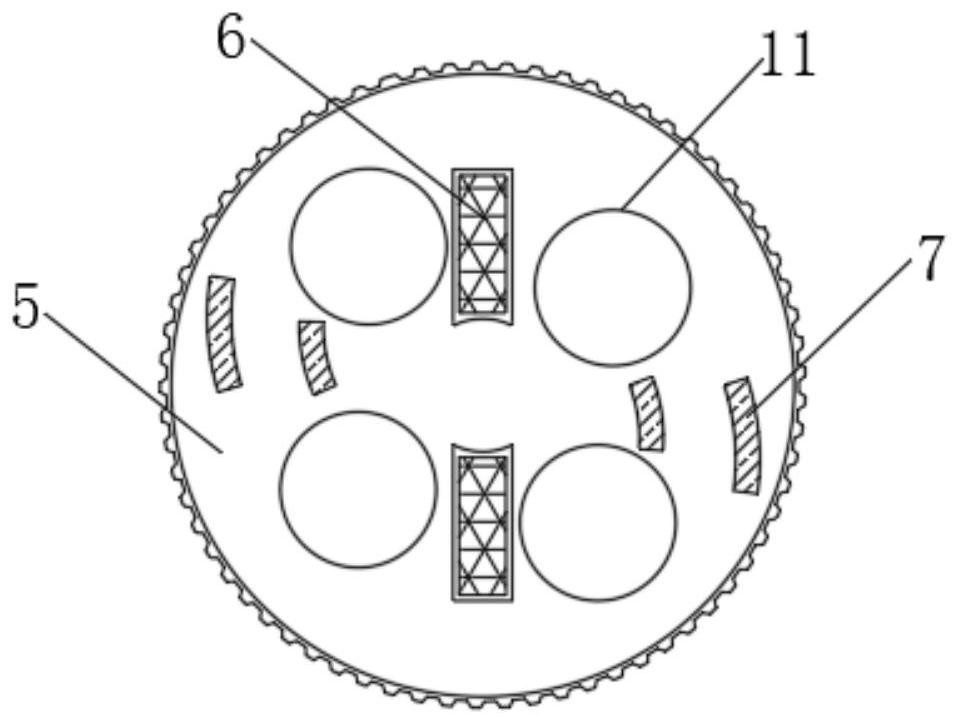

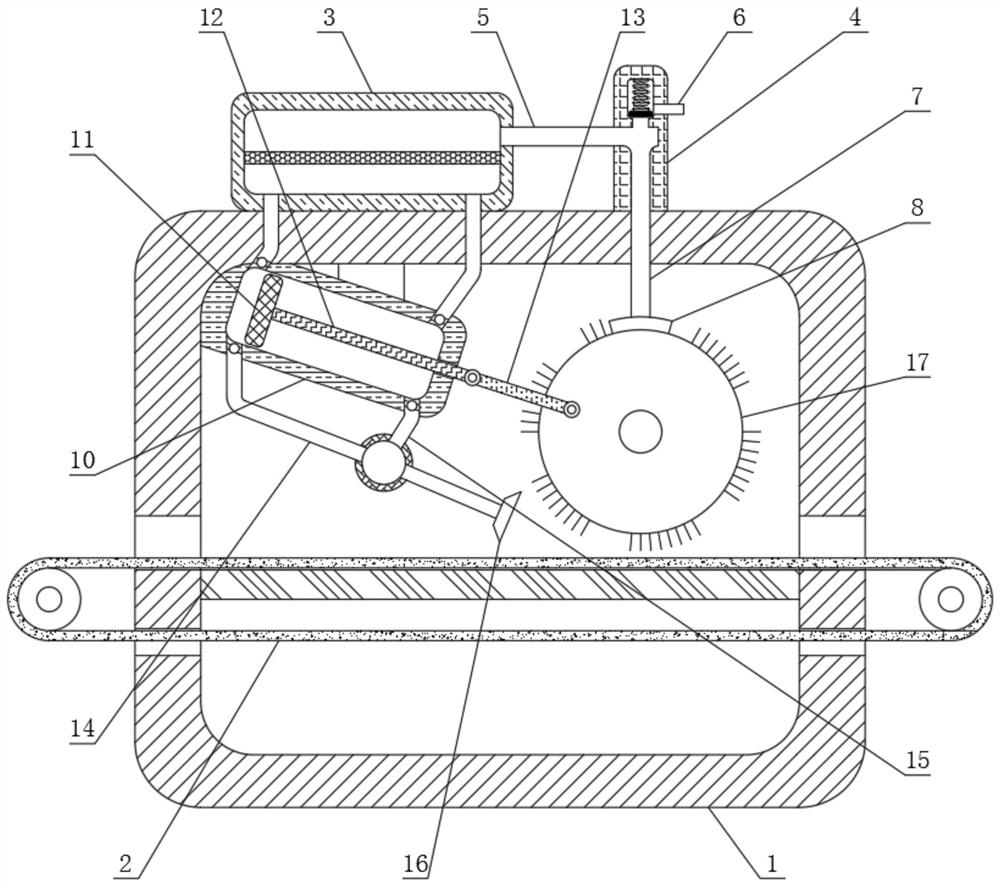

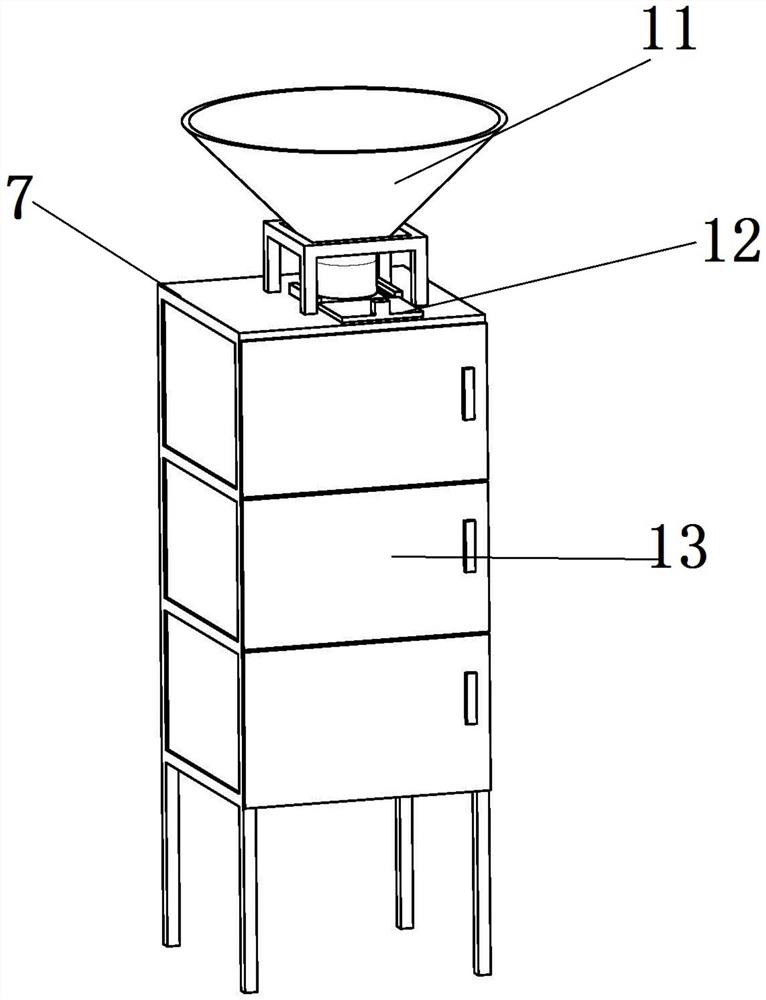

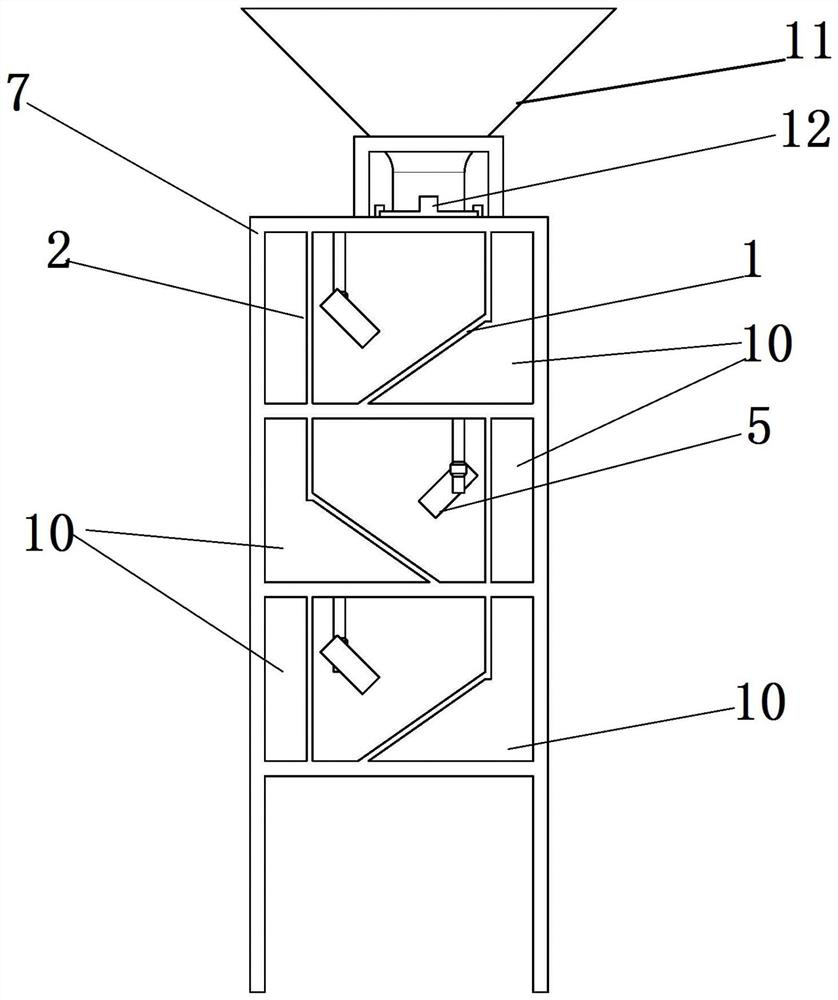

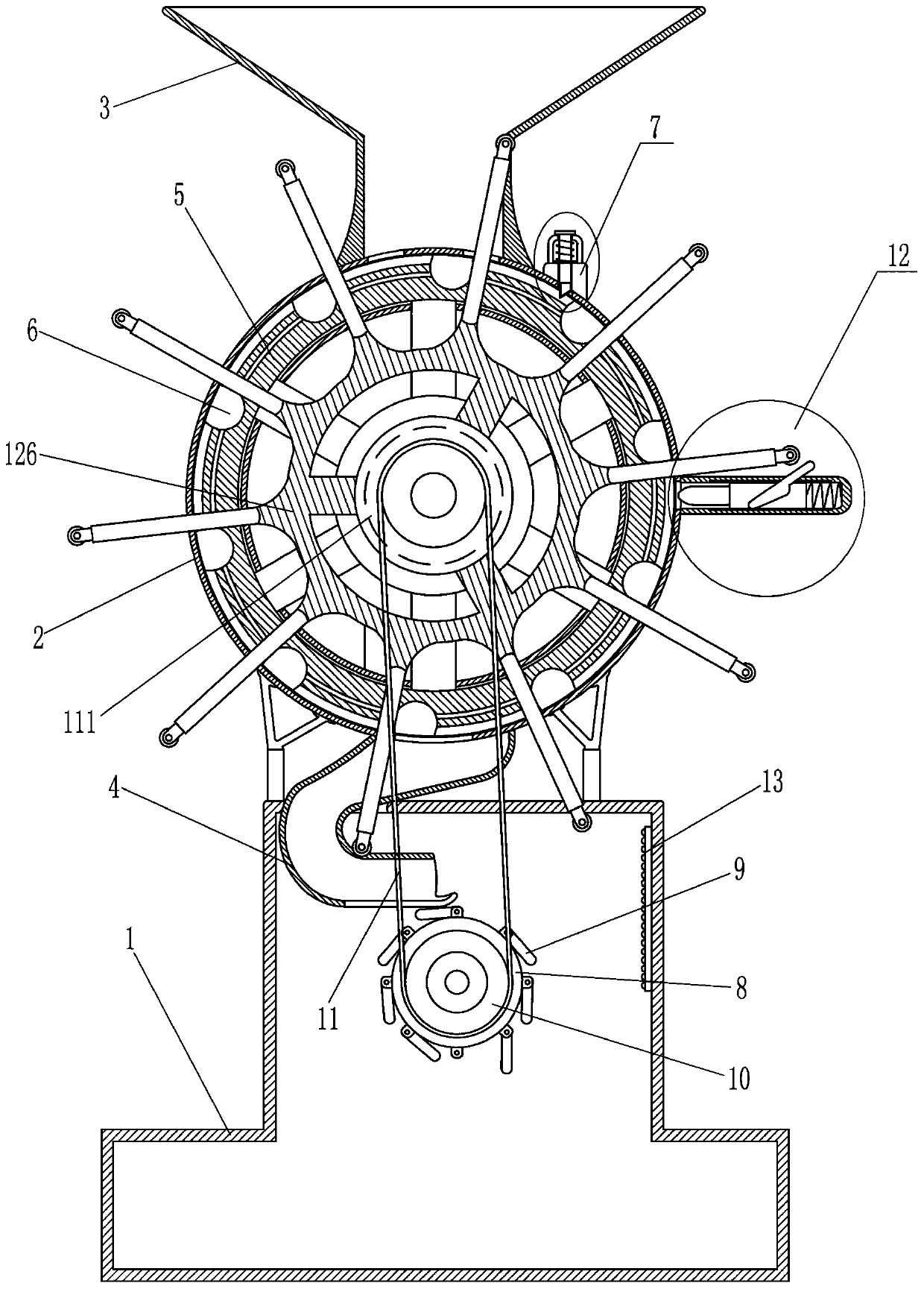

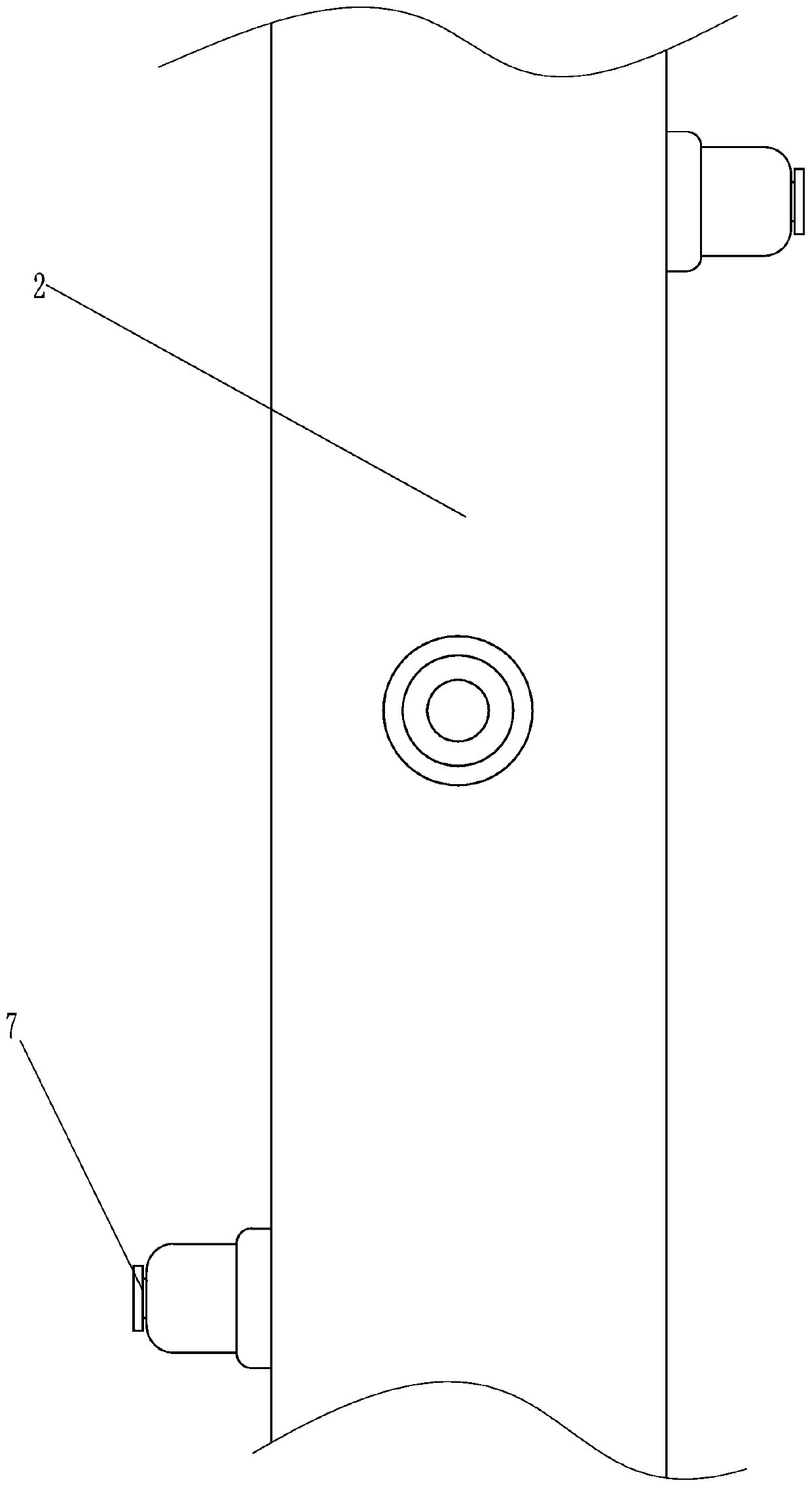

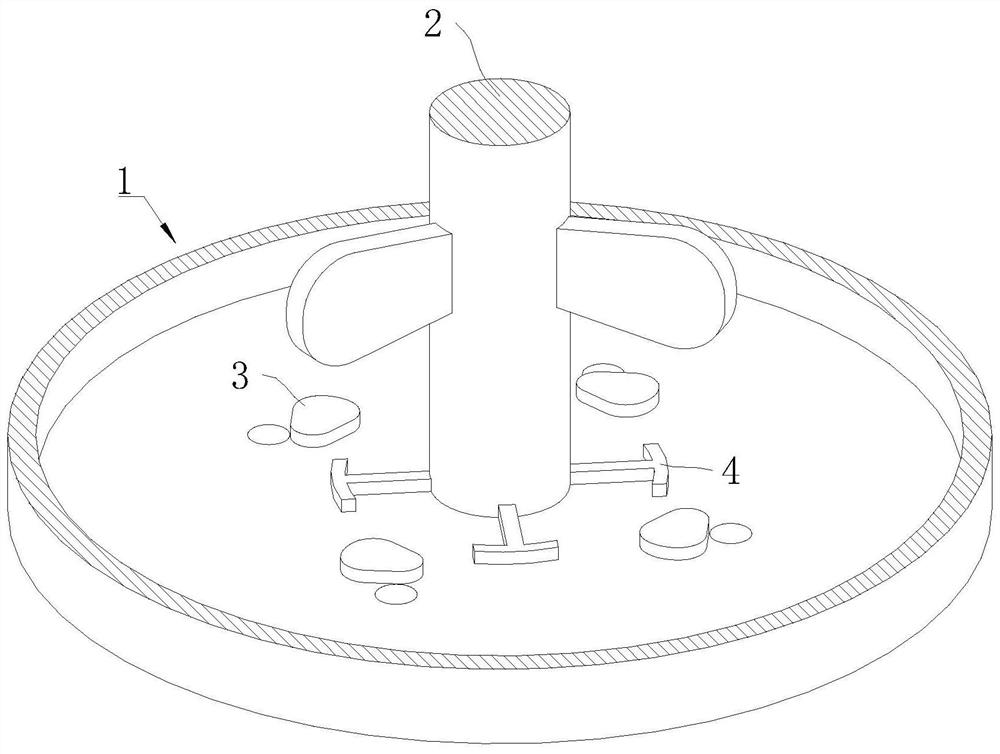

Separation device for shells and kernels of camellia fruits

ActiveCN110934309AOut of completeImprove crushing effectHuskingHullingEngineeringMechanical engineering

The invention relates to a crusher, specifically to a separation device for shells and kernels of camellia fruits. The invention is to solve a technical problem of designing a device which is used forseparating the shells and the kernels of the camellia fruits, can save manpower in use, is applicable to mass production and can stably remove the shells. The separation device for the shells and thekernels of the camellias comprises a bottom frame, an annular material frame, a material hopper, a material guide pipe, an annular carrier and the like, wherein the annular material frame is arrangedat the top part of the bottom frame; the material hopper is connected with and arranged at the top part of the annular material frame; and a material falling opening used for allowing the camellia fruits to fall is arranged on the thin wall of the joint of the annular material frame and the material hopper. According to the invention, the camellia fruits are opened through an opening mechanism; after the camellia fruits are opened by the opening mechanism, the camellia fruits are broken by a breaking unit, so the kernels of the camellia fruits are separated from the shells; thus, the kernelsof the camellia fruits are conveniently separated from the shells subsequently; only the camellia fruits need to be poured into the material hopper when the separation device is used; operation is simple; and labor is saved.

Owner:湖南亚美茶油股份有限公司

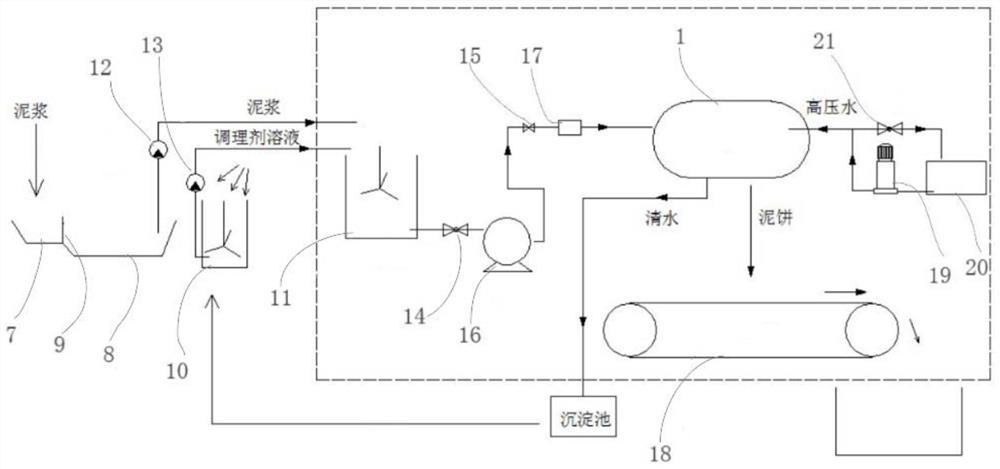

A kind of mud solid-liquid separator and process

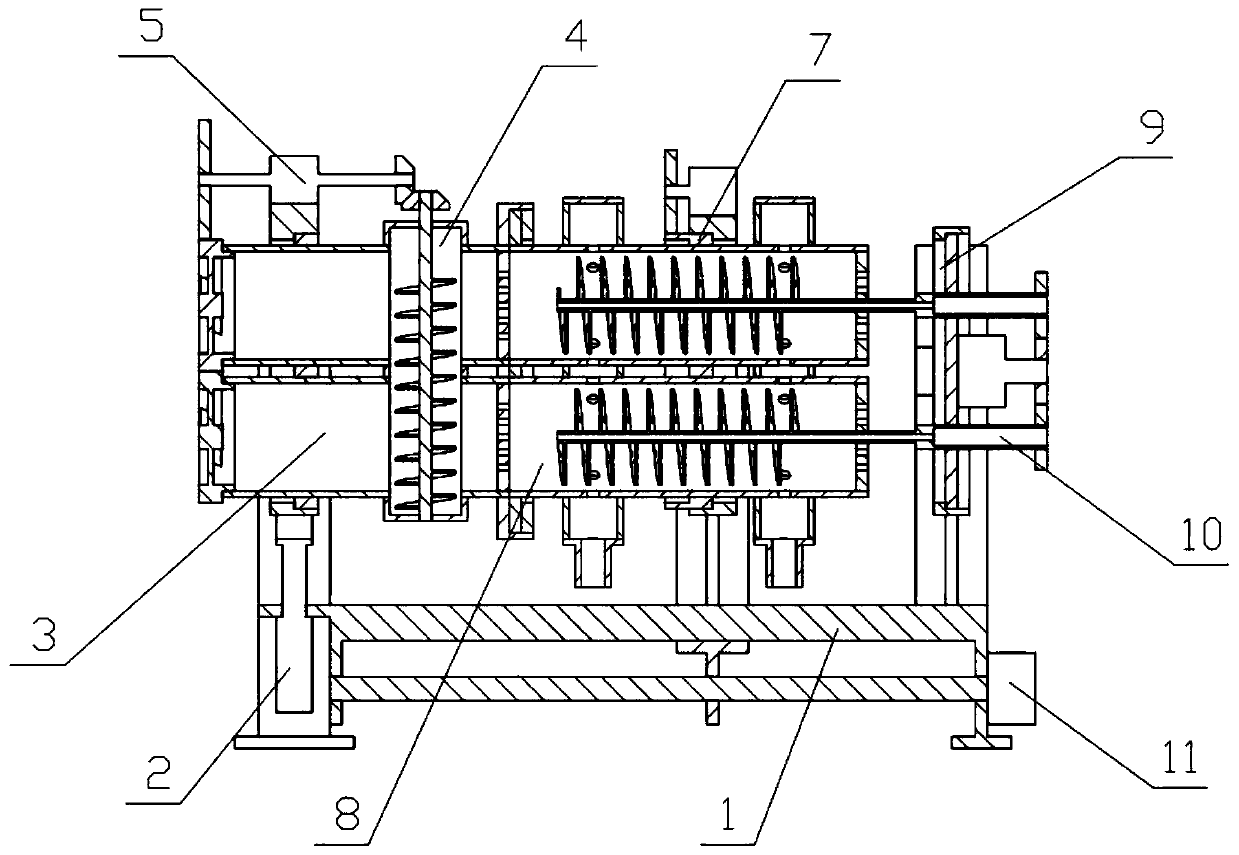

ActiveCN110078341BEffective attachmentAvoid stickingSludge treatmentSpecific water treatment objectivesFiltrationProcess engineering

The invention relates to a mud solid-liquid separator and a process, belonging to the technical field of sewage filtering equipment. The mud solid-liquid separator includes a filter press. A filter plate is installed inside the filter press. Grooves are arranged on the outer surface of the filter plate. Two adjacent filter plates are periodically attached to each other, and the grooves in between are periodically closed to form a filter plate. The outside of the groove is covered with filter cloth, and there is a spring between the groove and the filter cloth; the process includes primary filtration, adding conditioner, pressure filtration and recovery, etc. The present invention uses a spring to eject the mud cake on the outside of the filter cloth. The spring not only changes the continuous curved surface of the filter cloth by its jacking action, so that the mud cake cannot be effectively attached, but also the instantaneous pushing effect of the spring force can effectively bounce the mud cake. From the beginning, the inertia is used to separate from the filter cloth, avoiding the adhesion of the sticky mud cake, reducing the frequent cleaning of the equipment, and greatly improving the continuity of production.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

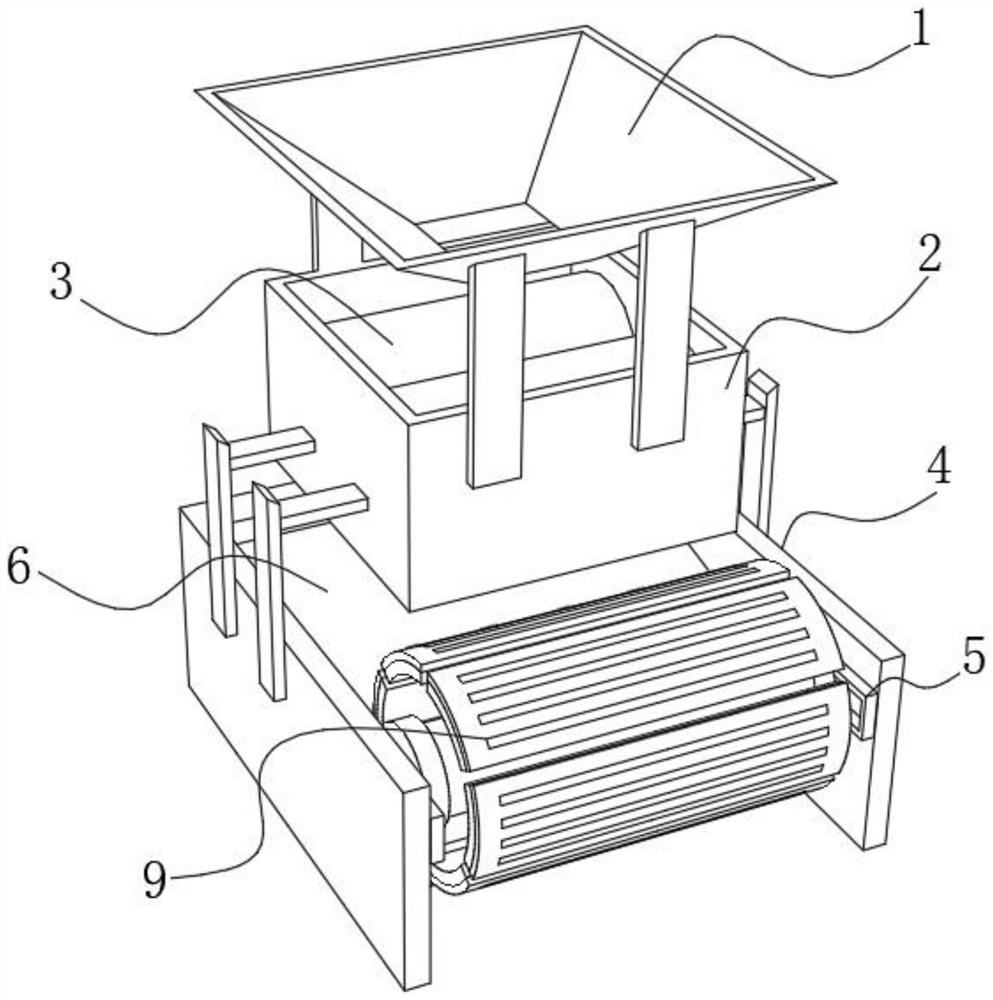

Reinforcing bar engineering waste recycling device

InactiveCN113695049AEasy to collectEasy for secondary recyclingGrain treatmentsElectric machineryRebar

The invention discloses a reinforcing bar engineering waste recycling device. The reinforcing bar engineering waste recycling device comprises a hopper (1), a shell (2) and a first driving motor (3); a first crushing mechanism is arranged in the hopper (1); and a sliding way (13), a collecting cavity (14), a second crushing mechanism and a third crushing mechanism are arranged in the shell (2), the sliding way (13) is obliquely arranged, and the two ends of the sliding way (13) communicate with the hopper (1) and the collecting cavity (14) correspondingly. By means of the device, cement blocks on the outer sides of reinforcing bars can be crushed in a multi-stage manner, crushing is more thorough, the reinforcing bars and the cement blocks are separated more thoroughly, and unified collection and secondary recycling of the reinforcing bars are convenient.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

Processing method of semi-fermented steamed green tea

PendingCN111406808AIncrease contentStrong tasteInorganic/elemental detergent compounding agentsPre-extraction tea treatmentGreen teasProcess engineering

The invention relates to the technical field of tea processing, and provides a processing method of semi-fermented steamed green tea. The processing method comprises the steps of tender picking, withering, stirring, standing, steaming, heat dissipation, dehumidification, rolling, primary drying, secondary rolling, secondary drying and aroma enhancement; the produced tea not only has the advantagesof steaming, but also achieves the effect of converting aroma generated in stir-frying through subsequent aroma enhancement, so that the processed tea is not only rich in inclusion but also rich in taste, and the steaming technology is adopted to solve the problems that the fixation temperature is not easy to regulate and control, the fixation degree is not easy to master, the yield is low due toexcessive water loss of fresh leaves in the fixation process and the like in the existing stir-frying technology.

Owner:温文溪

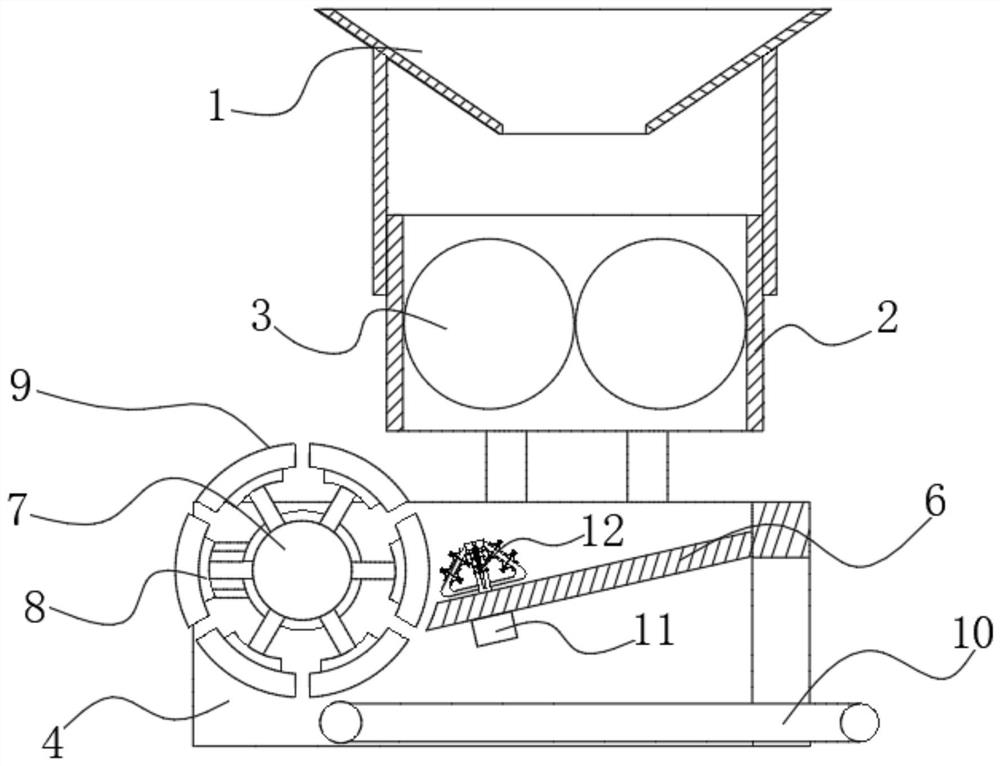

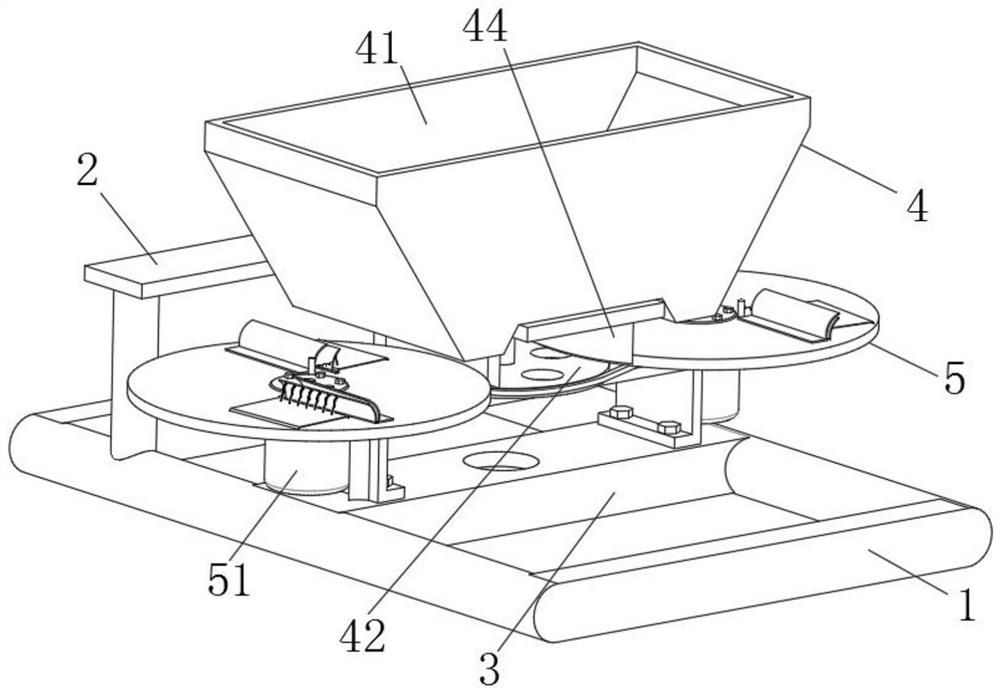

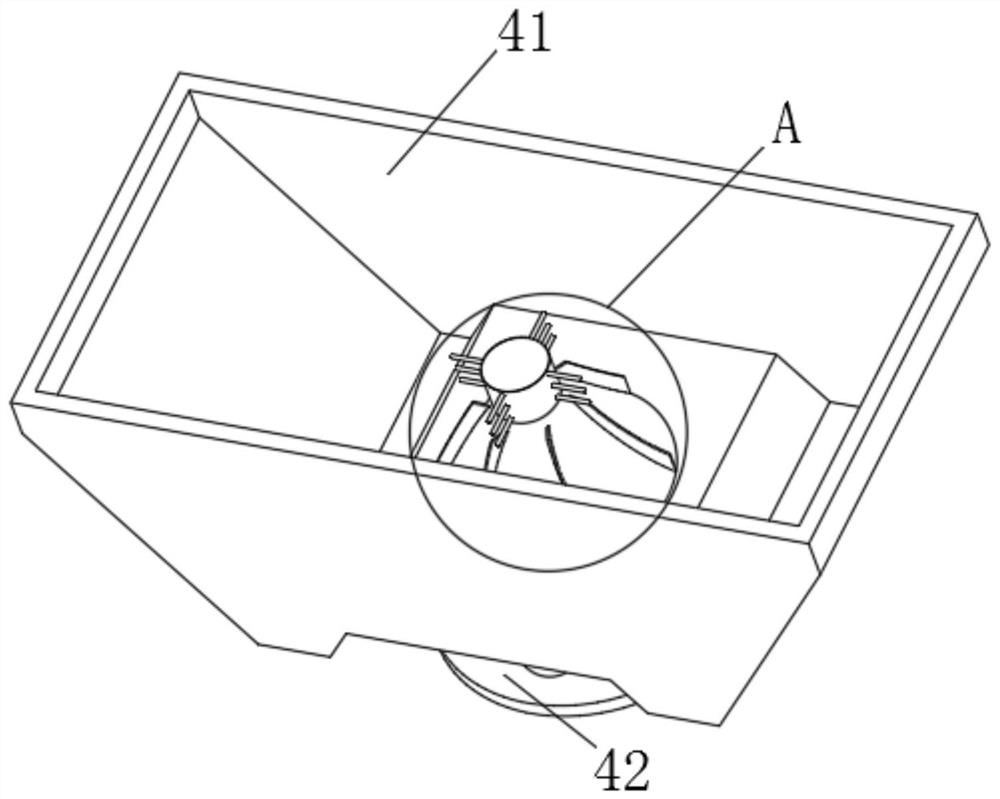

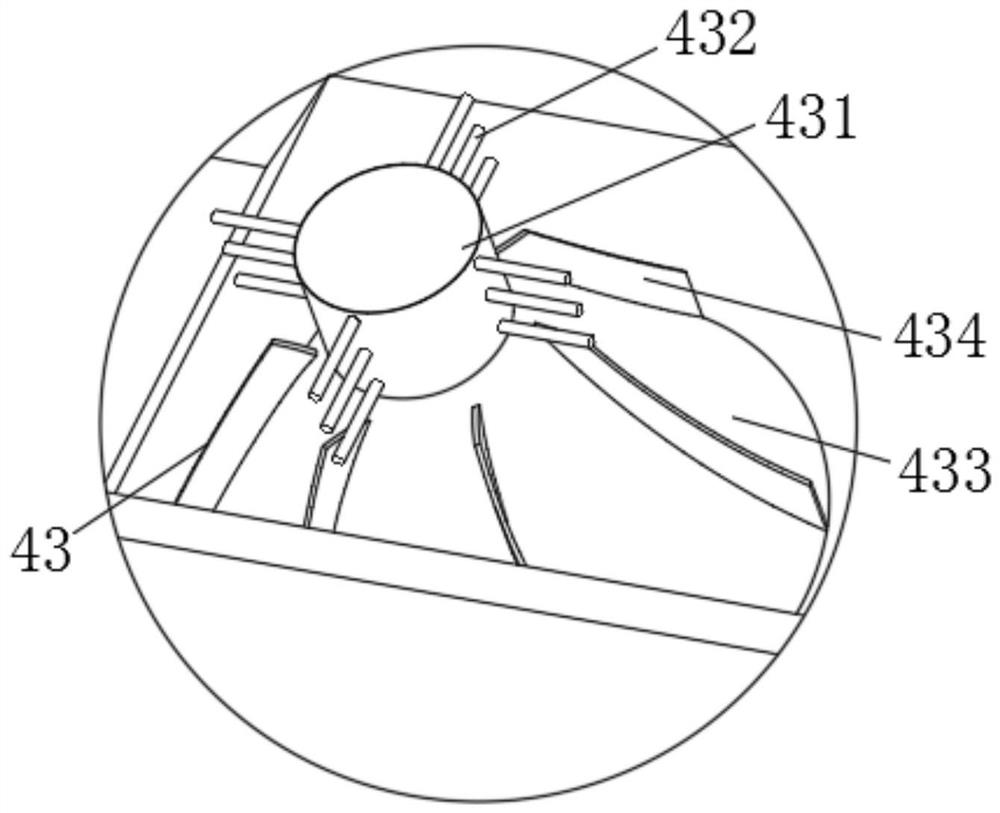

Double-disc fertilizer spreading mechanism for self-propelled plant protection machine

PendingCN114175900AAvoid impact on spreading efficiencyAvoid affecting work efficiencyFertiliser distributersAgricultural scienceAgricultural engineering

The invention discloses a double-disc fertilizer spreading mechanism for a self-propelled plant protection machine, and relates to the technical field of agricultural machinery. The double-disc fertilizer spreading mechanism for the self-propelled plant protection machine comprises a base, a fixing frame is fixedly installed at the position, close to the back face, of the top of the base, a T-shaped structural steel plate is arranged at the upper end of the fixing frame, a fixing plate is fixedly installed in the center of the top of the base, and vertical fixing blocks are fixedly installed at the left end and the right end of the top of the fixing plate; a feeding mechanism is arranged at the position, close to the center of the top of the base, of the top of the fixing frame, a throwing mechanism is arranged at the upper end of the fixing plate, and the feeding mechanism comprises a storage barrel, a movable disc, a rotating piece and two arc-shaped plates. According to the double-disc fertilizer spreading mechanism for the self-propelled plant protection machine, the feeding mechanism and the spreading mechanism are arranged, fertilizer is spread to the outer side of the spreading disc, the fertilizer in the center of the spreading disc is pushed to the outer side, and the situation that the fertilizer is accumulated in the center of the spreading disc, and the spreading efficiency of the device is affected is avoided.

Owner:HUAIAN ZHONGDING MACHINERY MFG CO LTD

Waste paper deinking regenerated cultural paper and manufacturing method thereof

The invention discloses waste paper deinking regenerated cultural paper and a manufacturing method thereof, and belongs to the field of papermaking. The invention relates to a manufacturing method of waste paper deinking regenerated cultural paper. The manufacturing method comprises the following steps: S1, preparing materials: mixing waste paper with water to form waste paper pulp; s2, pulping: defibering the waste paper into fibers, and dispersing sheet ink particles; s3, purification: removing large-particle impurities separated in the pulping process; the viscous impurities gather on the upper layer of the waste liquid pulp and are scraped away by a scraping plate, the fifth step of concentration, the waste paper pulp is concentrated, and the sixth step of heat dispersion, the concentrated and heated waste paper pulp is introduced into a heat dispersion machine; s7, bleaching: introducing the waste paper pulp into a bleaching tower; s8, making paper: regenerating the cultural paper; when sticky impurities in waste paper pulp are removed through flotation, the size of bubbles can be automatically adjusted, the generation frequency of the bubbles of all the sizes can be automatically adjusted, and it is effectively guaranteed that sticky substances of all the sizes in the pulp are removed.

Owner:五洲特种纸业(江西)有限公司

Full-automatic adhesive film attaching machine of display module

PendingCN111960170AOut of completeAvoid the problem of missing stickersConveyor partsArticle deliveryFixed frameDisplay device

The invention discloses a full-automatic adhesive film attaching machine of a display module and relates to the technical field of automatic equipment. The full-automatic adhesive film attaching machine comprises a bottom plate. The left side and the right side of the top of the bottom plate are fixedly connected with a feeding and discharging mechanism and a film attaching mechanism correspondingly. A transfer mechanism is fixedly connected to the middle of the top of the bottom plate, and an adhesive film feeding mechanism is fixedly connected to the rear side of the top of the bottom plate.The film attaching mechanism comprises a first fixing frame fixedly connected with the top of the bottom plate, and a first transverse moving linear guide rail is fixedly connected to the top of thefirst fixing frame. A first main slipping frame is fixedly connected to the top of a first transverse moving linear guide rail sliding block. By means of the full-automatic film attaching machine, thefirst transverse moving linear guide rail is matched with a first main linear guide rail so that a pressing block and a film shoveling structure can be moved above an adhesive film, then a film shoveling structure is flatly pushed so that the adhesive film can be shoveled off from release paper, then the pressing block is pressed downwards, and the adhesive film is clamped and then moved to a workpiece for film attaching. By means of the device, it can be ensured that the adhesive film is thoroughly disengaged from the release paper, and the problem of missing attaching is avoided.

Owner:东莞市泰宇达光电科技有限公司

A kind of separation equipment for camellia fruit shell and nut

Owner:湖南亚美茶油股份有限公司

Wooden pole polishing machine

InactiveCN111993235AOut of completeFacilitate subsequent processingBelt grinding machinesGas cylinderPiston rod

The invention discloses a wooden pole polishing machine. A slide block is in plug bush on each guide rail, and a gas cylinder clamping device is arranged on the slide block; the structure of each gascylinder clamping device is as follows: a main pointed cone is formed on the middle part of the upper surface of a rotary barrel, and four small pointed tapered rings are distributed around the main pointed cone in the form of a ring-shaped array; an outer ring blocking side is formed on the outer ring of a bearing, a rotary barrel is in plug bush on the outer ring of the bearing, the rotary barrel is fixed to the outer ring blocking side through a bolt; a piston rod of a gas cylinder is fixed to the inner ring of the bearing through a bolt; the rotary barrel is in plug bush in a sleeve, and the sleeve is fixedly arranged on the gas cylinder; a primary gas cylinder is fixedly arranged on a workbench, a connecting plate is fixed to a piston rod of a main gas cylinder, left and right ends ofthe connecting plate are each fixed to one slide block, and the gas cylinder is fixedly arranged on the slide blocks; and a bracket and a workbench are fixed together, and an abrasive belt and a wooden pole are opposite. The center of the wooden pole and the center of the rotary barrel are aligned to clamp, so that the wooden pole can be completely separated from the rotary barrel after polishingis accomplished, and therefore, follow-up process processing is convenient.

Owner:HUZHOU CHAOYU WOOD TOOLS

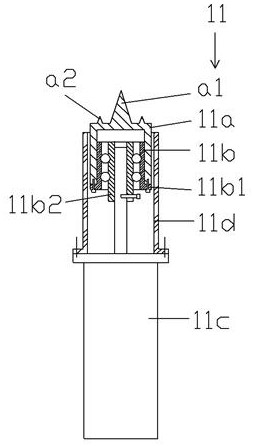

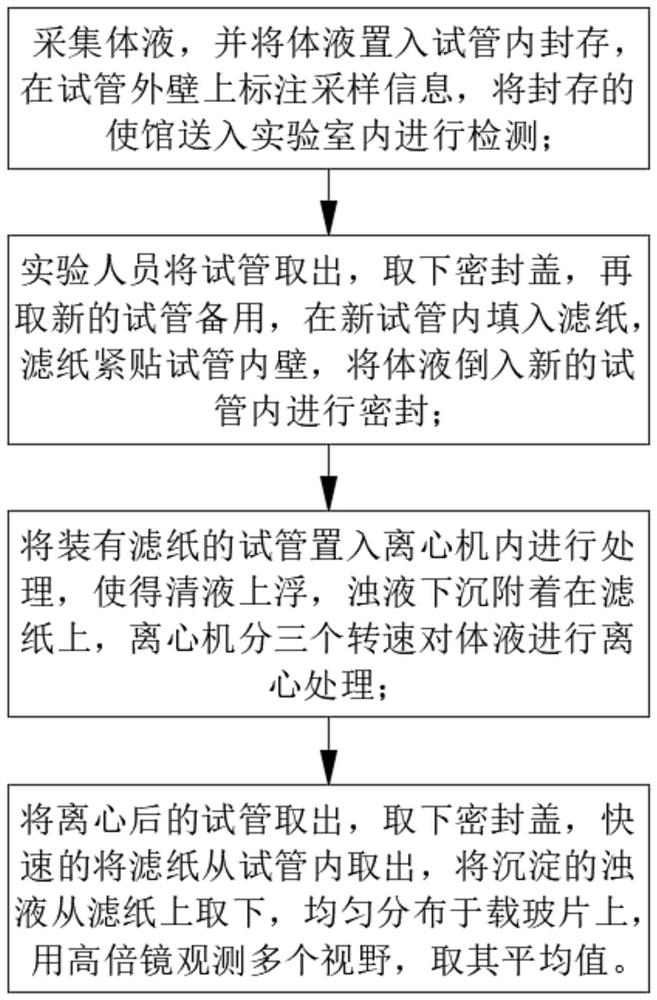

Inspection method for clinical test items

PendingCN113341118AUniform precipitationRapid precipitationPreparing sample for investigationBiological testingClinical testsFilter paper

The invention discloses an inspection method for clinical test items and belongs to the technical field of medical examination technologies. The method comprises the following steps that: body fluid is collected, the body fluid is sealed in a test tube, sampling information on the outer wall of the test tube is marked, and the sealed body fluid is sent into a laboratory so as to be detected; an experimenter takes out the test tube, takes down a sealing cover, takes a new test tube for later use, fills filter paper into the new test tube, tightly attaches the filter paper to the inner wall of the test tube, and pours the body fluid into the new test tube and seals the new test tube; the test tube filled with the filter paper is put into a centrifugal machine for treatment, so that clear liquid floats upwards, turbid liquid sinks and is attached to the filter paper, and centrifugal treatment is performed on the body fluid by a centrifugal machine at three rotating speeds; and the centrifuged test tube is taken out, the sealing cover is taken down, the filter paper is rapidly taken out of the test tube, and the precipitated turbid liquid is taken down from the filter paper. According to the method, the detection efficiency is improved, the body fluid can be uniformly precipitated by adjusting the rotating speed of the centrifugal machine, and the detection accuracy is improved.

Owner:长沙山水医学检验所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com