Industrial waste gas treatment and purification system based on big data

A technology of industrial waste gas and purification system, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of insufficient desulfurization and denitrification treatment of industrial waste gas, and achieve the effect of complete contact reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

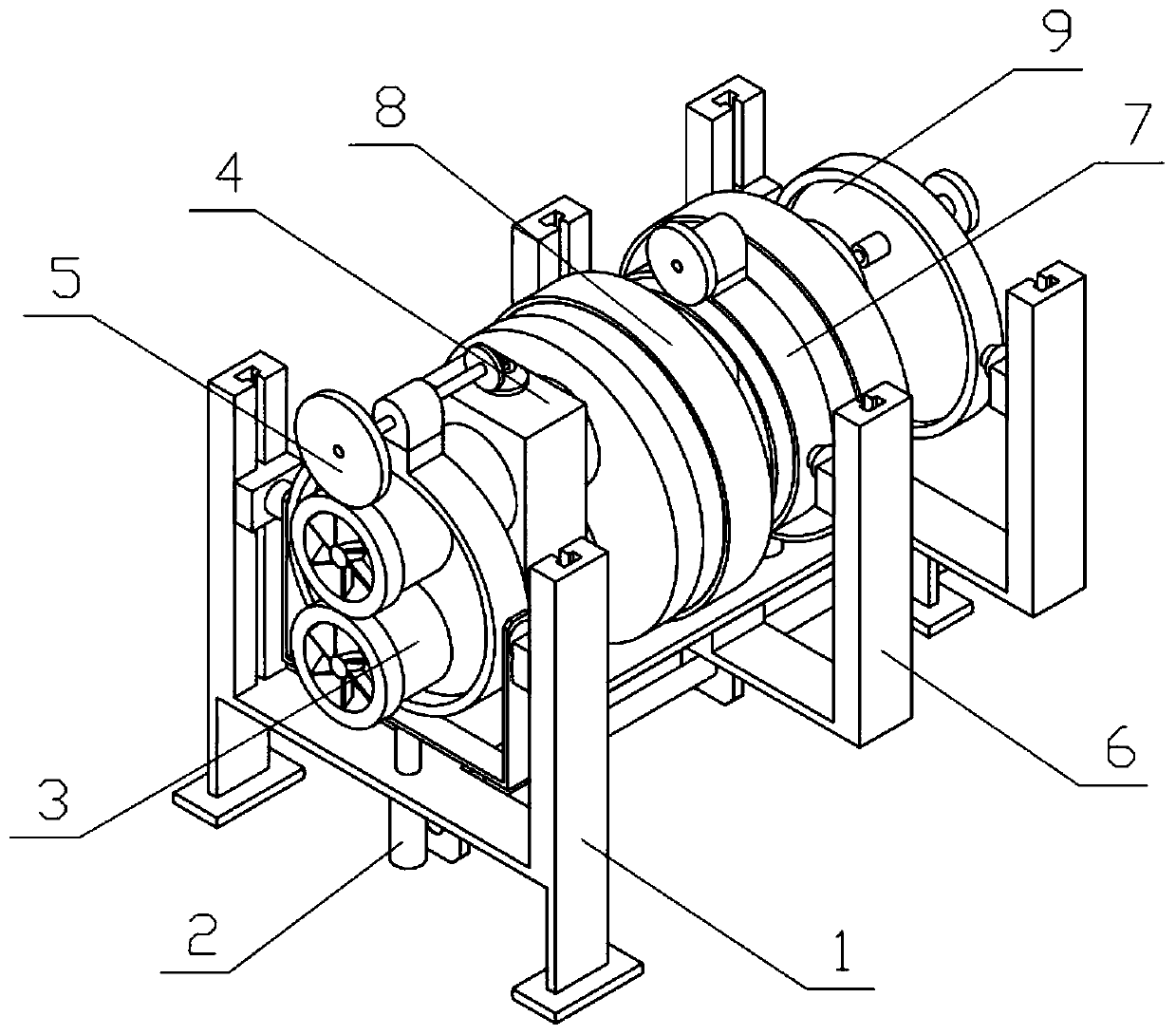

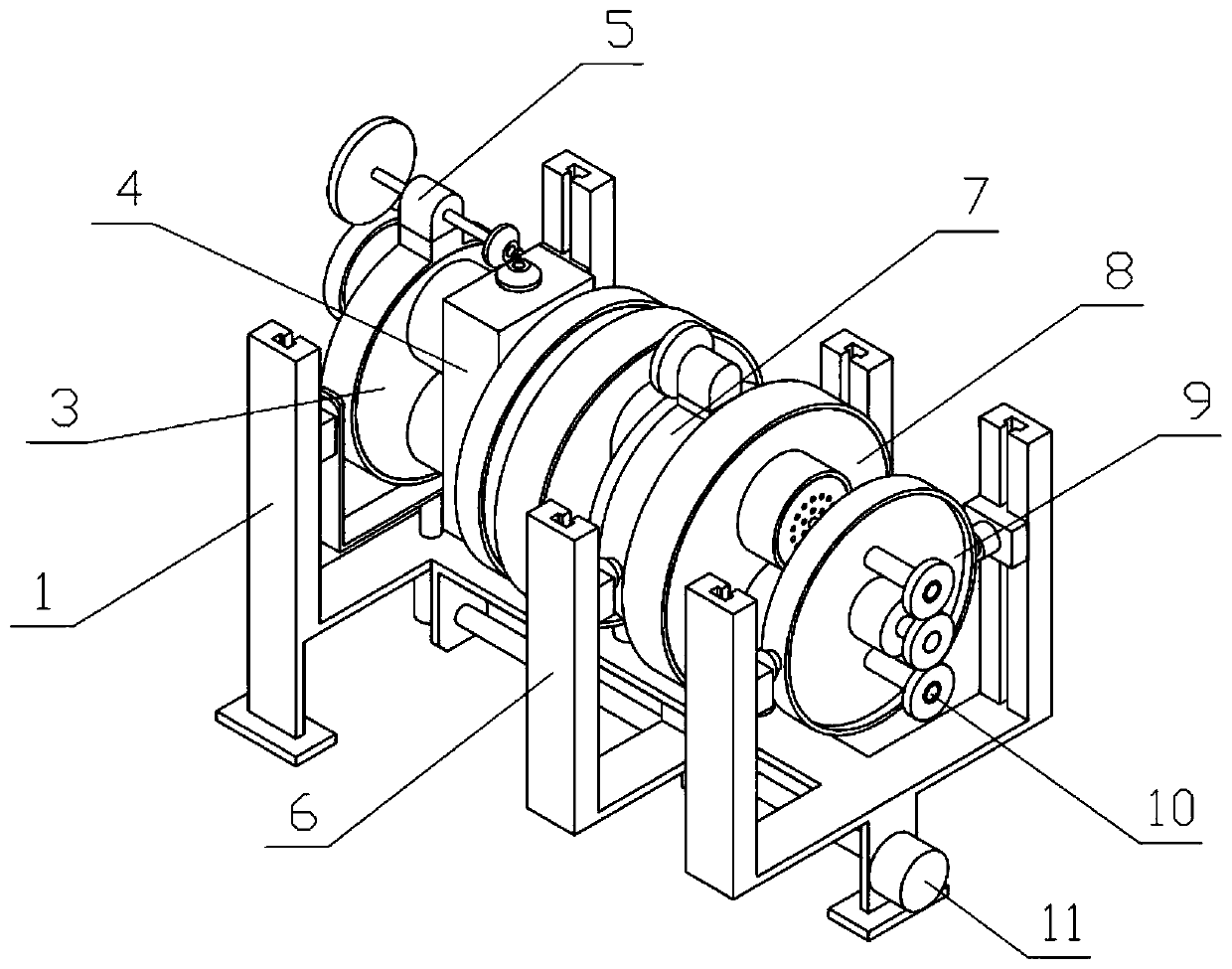

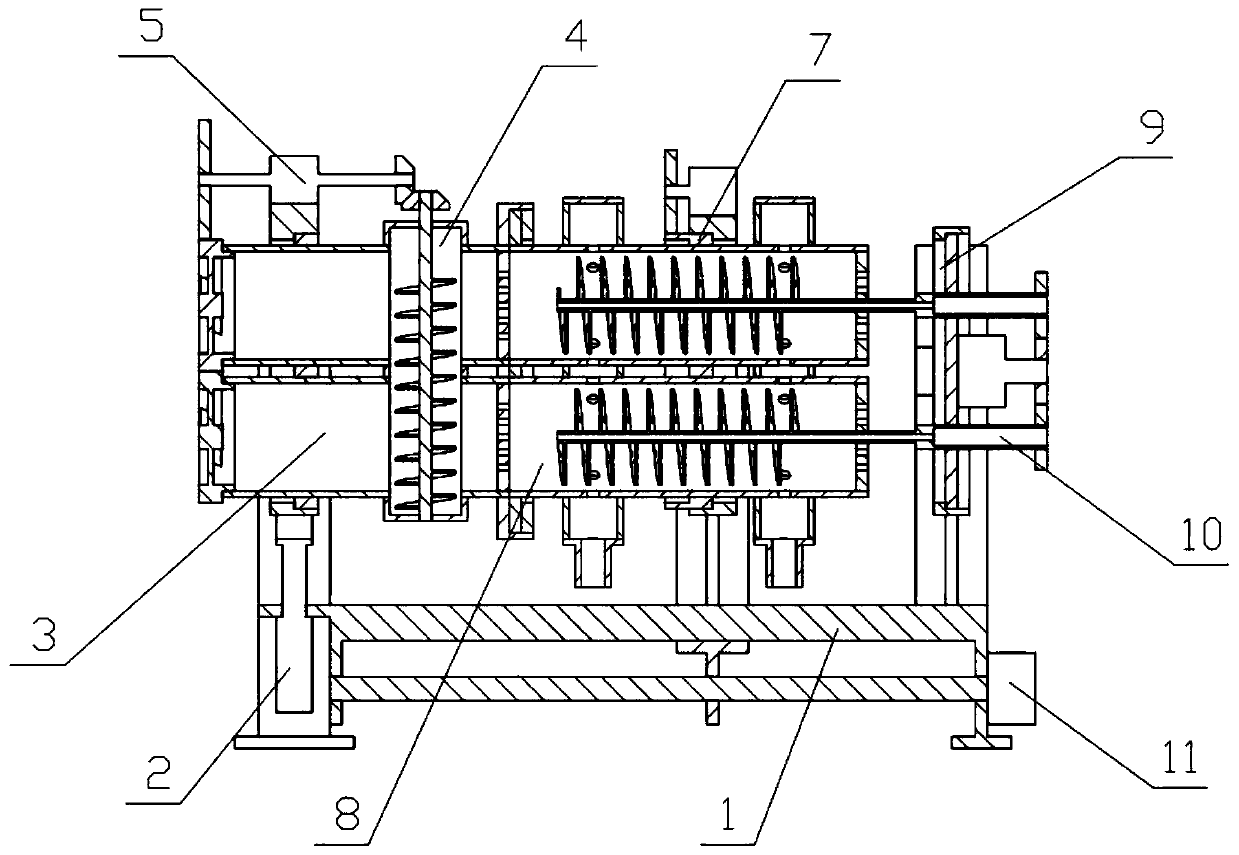

[0040] Combine below Figure 1-16 Describe this embodiment, an industrial waste gas treatment and purification system based on big data, including a device bracket 1, an air suction device 3, a desulfurization device 4, a power mechanism I5, a sliding bracket 6, a swing bracket I7, a denitrification device 8, and a swing bracket Ⅱ9, stirring mechanism 10, pushing mechanism 11, power mechanism Ⅱ12 and power mechanism Ⅲ13, the front end of the device bracket 1 is vertically slidably connected with the suction device 3, the rear end of the suction device 3 is connected with the desulfurization device 4, and the suction device 3 It communicates with the desulfurization device 4, the suction device 3 is connected with the power mechanism I5, the power mechanism I5 is connected with the suction device 3, the power mechanism I5 is connected with the desulfurization device 4, and the middle part of the device bracket 1 is horizontally connected with a sliding bracket 6. Sliding suppor...

specific Embodiment approach 2

[0042] Combine below Figure 1-16 Describe this embodiment, this embodiment will further explain the first embodiment, the device bracket 1 includes a bottom plate 1-1, a vertical slide rail I1-2, a vertical slide rail II1-3 and a support plate 1-4, the bottom plate 1 Both sides of the rear end of -1 are fixedly connected with vertical slide rails I1-2, both sides of the front end of bottom plate 1-1 are fixedly connected with vertical slide rails II1-3, and the lower end of bottom plate 1-1 is fixedly connected with support plate 1 -4, a pushing mechanism 11 is connected to the support plate 1-4.

specific Embodiment approach 3

[0044] Combine below Figure 1-16 Describe this embodiment, this embodiment will further illustrate the second embodiment, the air suction device 3 includes a swing ring I3-1, a sliding block I3-2, an air suction tube 3-3 and a fan 3-4, and the swing ring I3 The left and right sides of -1 are rotatably connected with sliding block Ⅰ3-2, and the two sliding blocks Ⅰ3-2 are slidably connected to two vertical slide rails Ⅱ1-3 respectively, and the swing ring Ⅰ3-1 is fixedly connected with two suction The inflator 3-3 is connected with a fan 3-4 in rotation on the two air suction cylinders 3-3, and the two fans 3-4 are connected by transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com