A kind of separation equipment for camellia fruit shell and nut

A separation equipment and technology of camellia fruit, applied in the direction of shelling, application, pod removal, etc., can solve the problems of high labor consumption, unfavorable stable production, insufficient shelling, etc., to improve the crushing effect, save labor, and completely shelling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

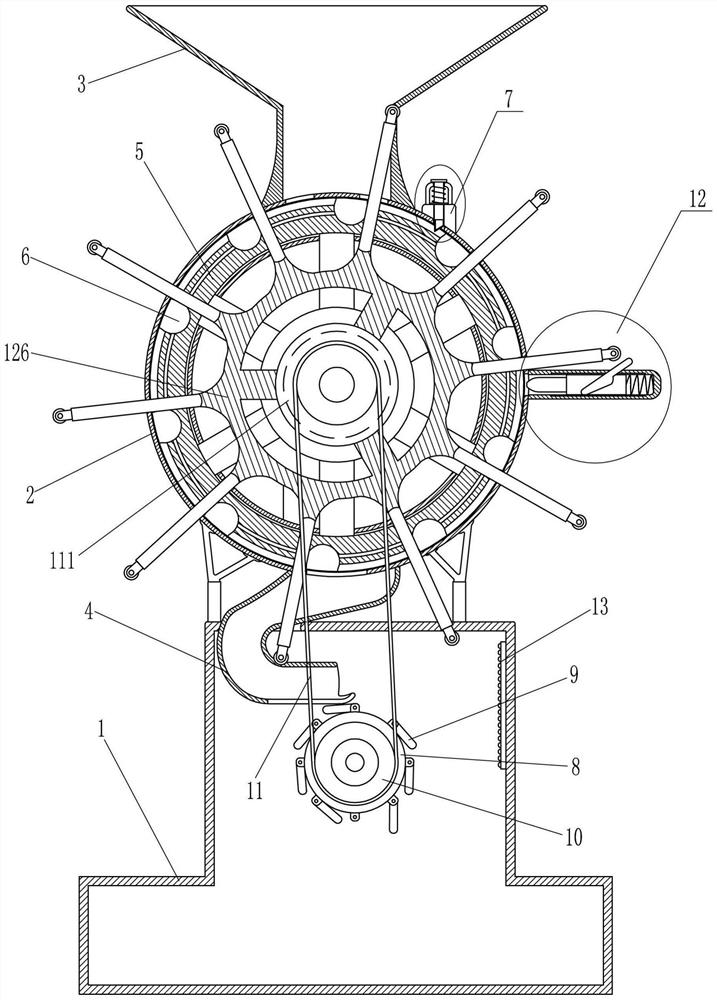

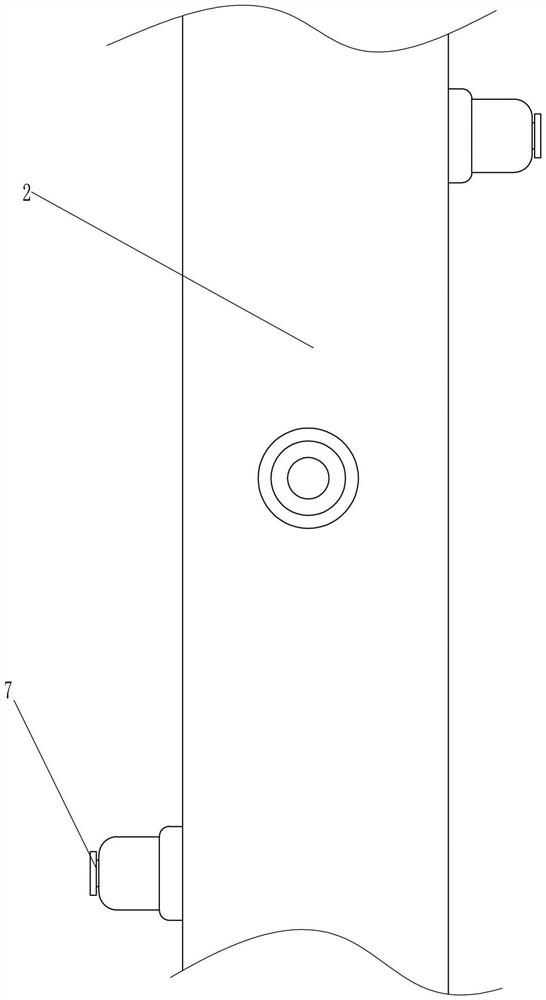

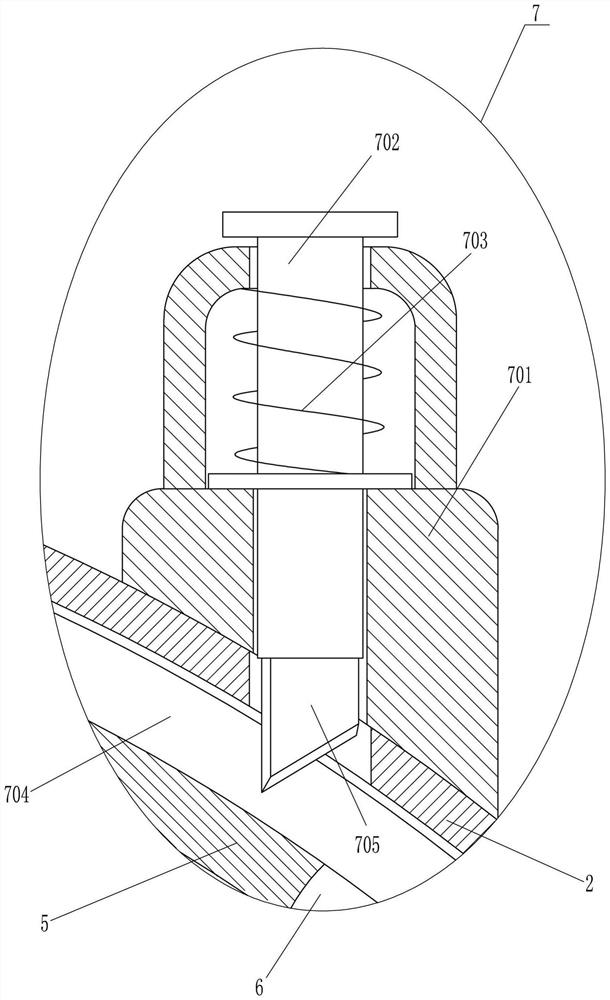

[0018] A kind of separation equipment that is used for camellia fruit shell and nut, as Figure 1-2 As shown, it includes a bottom frame 1, an annular material frame 2, a hopper 3 and a material guide pipe 4. The top of the bottom frame 1 is provided with an annular material frame 2, and the top of the annular material frame 2 is connected to a hopper 3, and the annular material frame 2 is connected by welding. The way is connected with the bottom frame 1 and the hopper 3 respectively, and the thin wall of the joint between the annular material frame 2 and the hopper 3 is provided with a blanking port for falling into the camellia fruit, and the bottom of the annular material frame 2 is connected with a material guide pipe 4, The tail end of the material guide pipe 4 extends into the bottom frame 1, and also includes an annular carrier 5, an opening mechanism 7, a circular plate 8, a pendulum block 9, a sprocket 10, a chain 11 and a motor 111, and the inner rotating type of the...

Embodiment 2

[0023] Such as Figure 4 Shown, also comprise and smash device 12, knock and smash device 12 and include slide frame 121, slide block 122, taper head 123, second spring 124, wedge block 125, ring 126, connecting rod 127 and pulley 128, annular The outer wall of the material frame 2 is connected with a sliding frame 121, the sliding frame 121 is arranged horizontally, and the sliding type inside the sliding frame 121 is provided with a slider 122, and the end of the sliding block 122 close to the ring material frame 2 is connected with a cone head 123, and the cone head 123 runs through the ring Material frame 2 side wall, awl head 123 is used for knocking camellia fruit, and awl head 123 is slidably matched with annular material frame 2, and second spring 124 is connected between slide block 122 and installation frame 701 inner wall, and second spring 124 Located in the slide frame 121, a wedge-shaped block 125 is provided on the front side of the slide block 122, and a circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com