Waste paper deinking regenerated cultural paper and manufacturing method thereof

A manufacturing method and technology for deinking waste paper, applied in the field of papermaking, can solve the problems that ink particles cannot be directly detected, cannot effectively control air bubbles, and ink particles are not removed cleanly, so as to increase generation time, reduce costs, and change generation. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

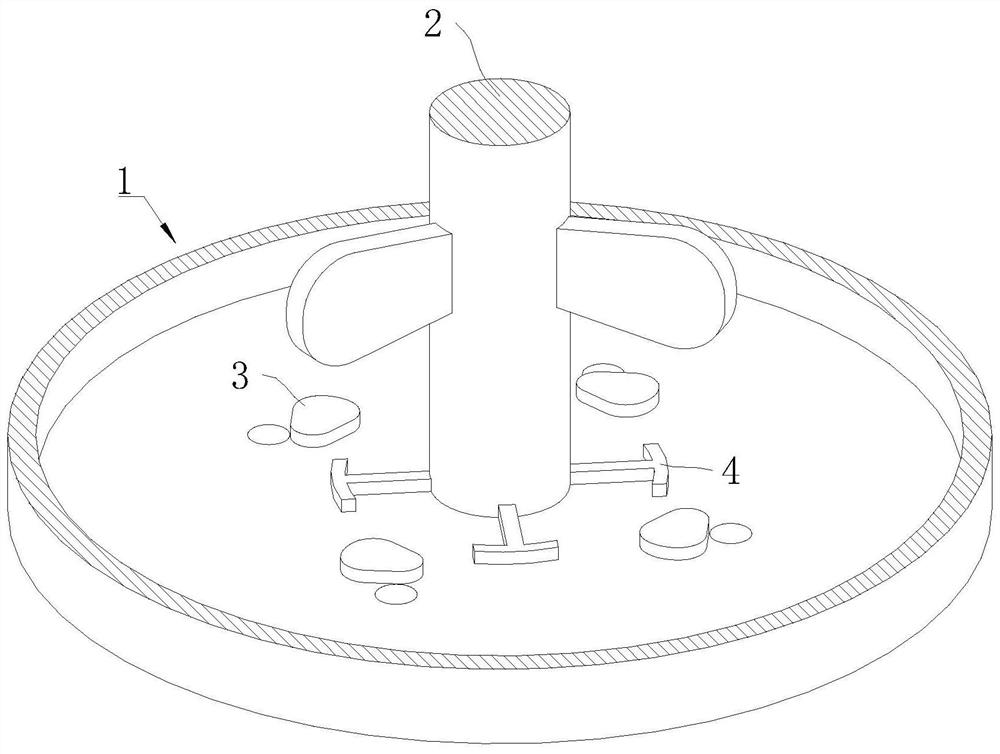

[0057] Specific embodiment one: please refer to Figure 1-2 A kind of manufacturing method of waste paper deinking regenerated culture paper, comprises the following steps:

[0058] S1. Ingredients: waste paper is mixed with water to form waste paper slurry, and the concentration of waste paper slurry is 23-25%;

[0059] S2. Pulping: Put the waste paper slurry in a hydropulper, and add a silicon deinking agent at the same time, so that the waste paper is disintegrated into fibers, and the ink particles in the flakes are dispersed, and large particles of impurities are separated from the fibers;

[0060] S3. Purification: The pulped waste paper pulp is placed in high-consistency slag remover, low-concentration slag remover, compound coarse screen machine, coarse pulp tower, and heavy slag remover to separate large particles of impurities in the pulping process remove;

[0061] S4. Flotation: By introducing air bubbles and surfactants into the purified waste paper slurry, the ...

specific Embodiment 2

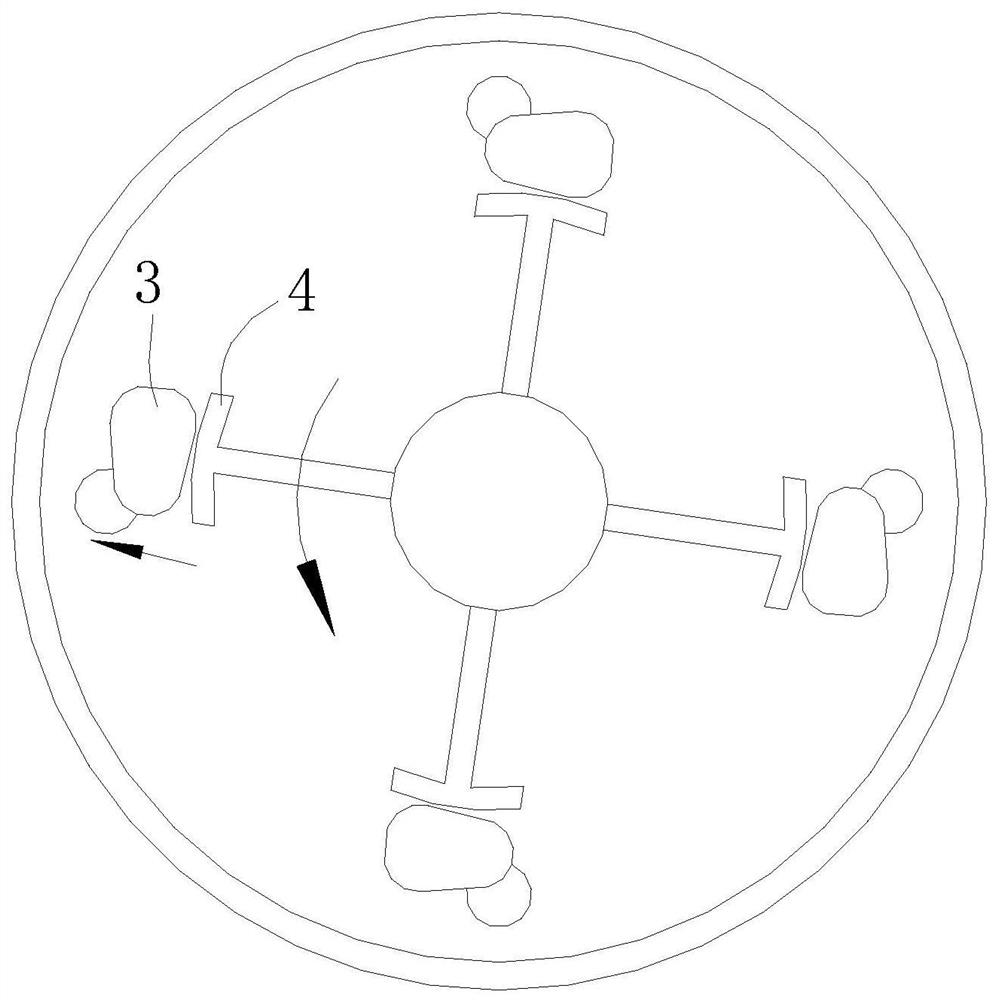

[0074] Specific embodiment two: on the basis of specific embodiment one, please refer to image 3 A method for manufacturing waste paper deinking recycled cultural paper, the bottom wall of the flotation tank 1 has a multi-layer air outlet ring, each layer of air outlet rings includes a plurality of uniformly distributed air holes 101, and the multi-layer air outlet rings are formed by a plurality of concentric circles The form distribution; the concentric circle is coaxial with the main axis 2;

[0075] The abutment block 401 has a variety of specifications, and the length of the connecting rod of the abutment block 401 of different specifications is different, and the number of specifications corresponds to the number of layers of the air outlet circle; the range of motion of the abutment block 401 of each specification covers the corresponding air outlet circle. The position of the movable end of the cam in the free state.

[0076] The connecting rods corresponding to the ...

specific Embodiment 3

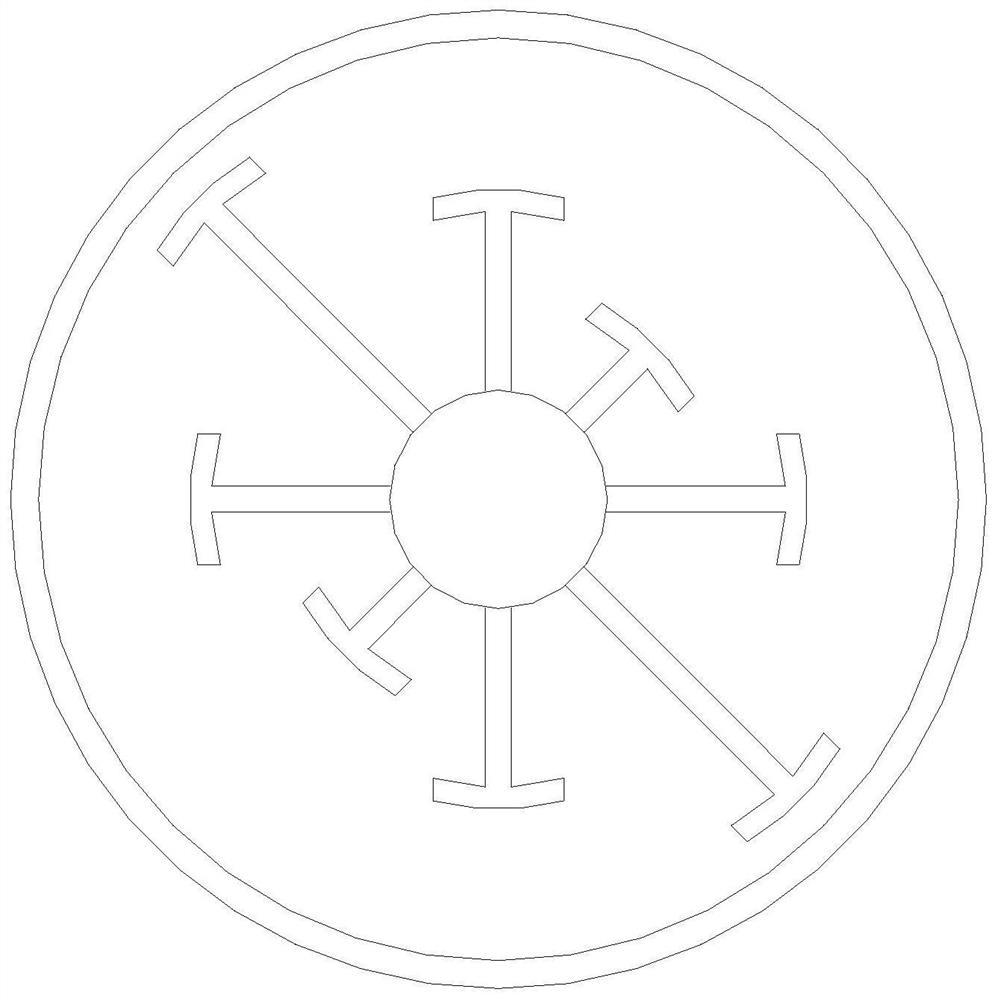

[0077] Specific embodiment three: different from specific embodiment two, please refer to Figure 4 A manufacturing method of waste paper deinking recycled cultural paper, the abutment block 401 has only one specification, that is, the abutment block 401 only drives the cam corresponding to the air hole 101 of the air outlet ring closest to the main shaft 2; the air outlet ring of each layer The number of air holes 101 is consistent, and the air holes 101 of different air outlet rings are all located on the same straight line, and the cams of the air holes 101 located on the same straight line are connected by brackets. When the cam closest to the main shaft 2 rotates, the bracket drives the remaining cams to Rotate to the same time, effectively avoid too many connecting rods hindering the rise of bubbles, and increase the combination rate of bubbles and ink particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com