Wooden pole polishing machine

A technology of polishing machine and wooden rod, applied in grinding/polishing equipment, grinding machine, metal processing equipment, etc., can solve problems such as affecting processing, difficult alignment of the drum to the center of the wooden rod, and polishing defective products, etc. To achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

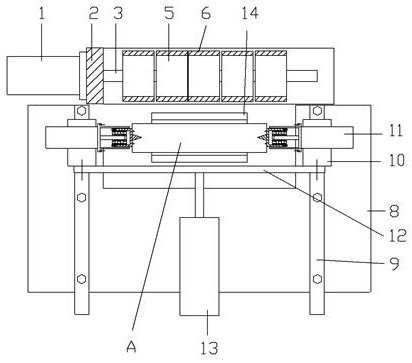

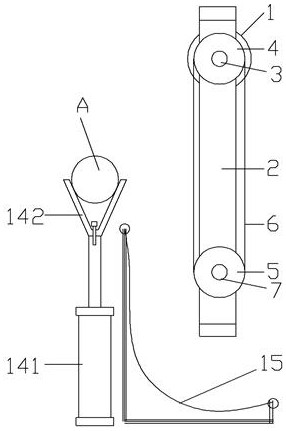

[0018] Example: see Figures 1 to 3 As shown, a wood polishing machine, the motor 1 is fixed on the support 2, the rotating shaft of the motor 1 is fixed with the upper rotating shaft 3; the upper rotating shaft 3 and the lower rotating shaft 7 are installed on the support 2, and the upper rotating shaft 3 is fixed with The driving pulley 4, the driven pulley 5 is fixed on the lower rotating shaft 7, the abrasive belt 6 is tensioned on the driving pulley 4 and the driven pulley 5, two guide rails 9 are fixed on the workbench 8, each guide rail 9 There is a slider 10 on the upper sleeve, and a cylinder clamping device 11 is arranged on the slider 10;

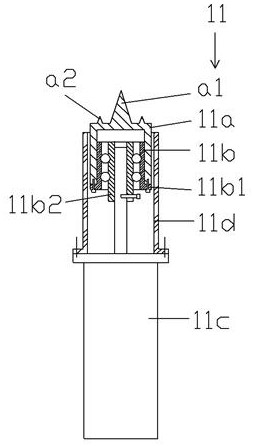

[0019] The structure of the cylinder clamping device 11 is: the middle part of the upper surface of the drum 11a is formed with a main cone a1, and four small cones a2 are distributed in an annular array around the main cone a1; the outer ring of the bearing 11b is formed with an outer The ring rib 11b1, the drum 11a is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com