Intelligent workshop seedling transplanting robot

A robot and workshop technology, applied in the direction of transplanting machinery, planting methods, applications, etc., can solve the problems of not achieving high-efficiency seedling transplanting, small damage to the root system, etc., to avoid excessive gliding that causes rhizomes to break, speed Uniform, avoid rhizome break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

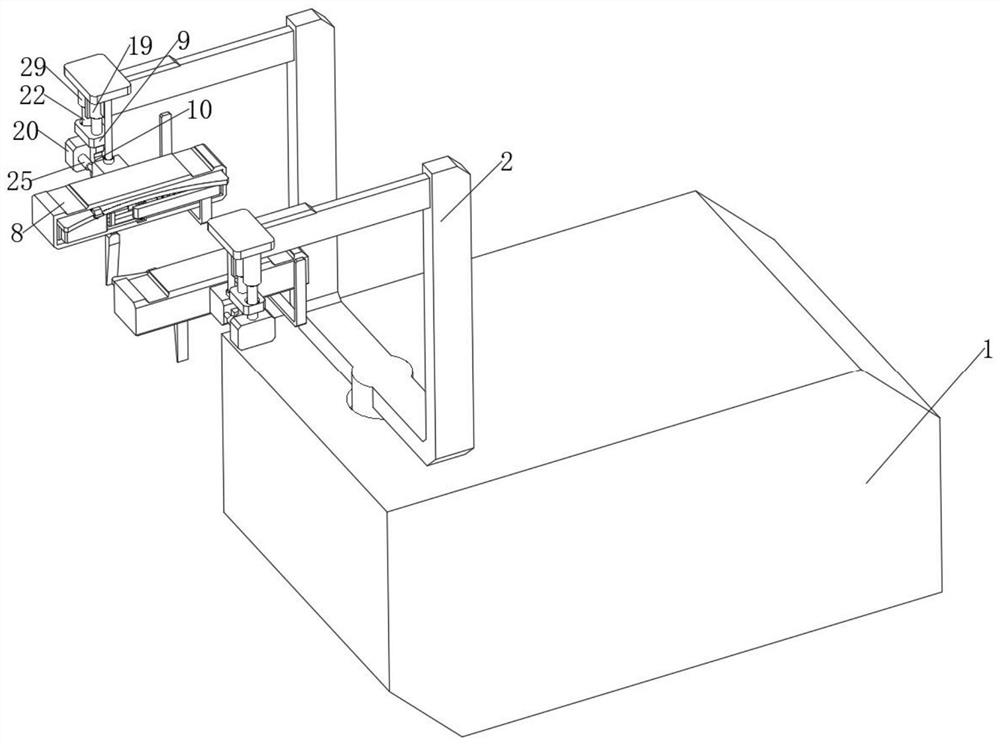

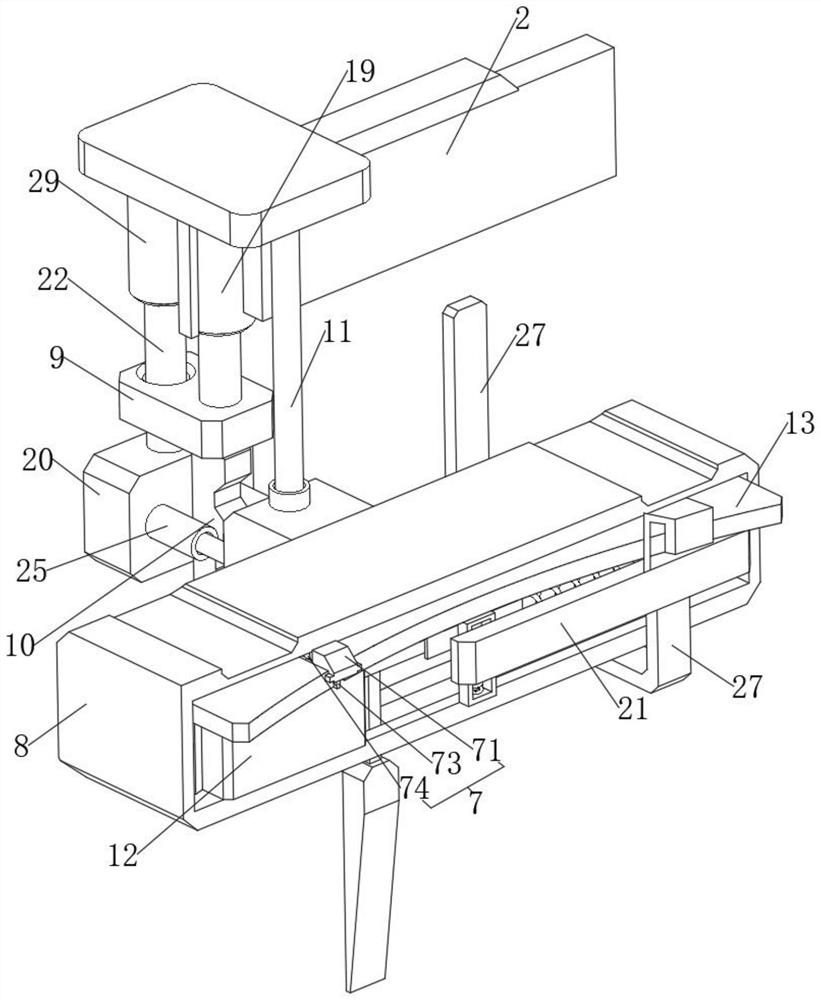

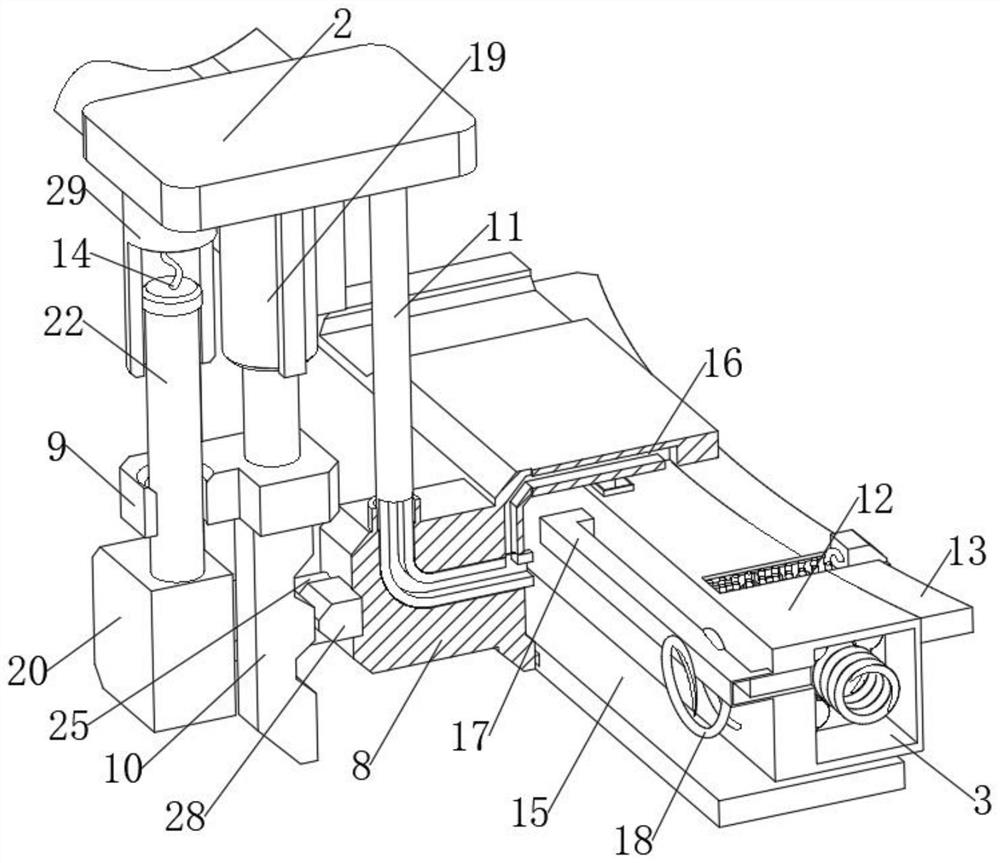

[0028] see Figure 1-3 , an intelligent workshop seedling transplanting robot, including a mobile vehicle 1 and a U-shaped frame 2 on the mobile vehicle 1, a clamping box 8 is connected to the mobile vehicle 1 through a support device, and one side of the clamping box 8 is slidably connected There is a clamping block 12 for clamping the seedling stalk, and a sliding plate 21 is slidably connected on the clamping block 12. The sliding plate 21 is used to stir the seedling stalk to shake, and a trachea 11 is installed on the clamping box 8, and the trachea 11 is used for transmission The high-pressure gas drives the clamping block 12 and the sliding plate 21 to slide;

[0029] The support device includes a sleeve 29 installed on the U-shaped frame 2, the inside of the sleeve 29 is connected to the shaft rod 22 through the first spring 14, the shaft rod 22 is equipped with a support block 20, and the support block 20 is clamped by the telescopic column 25. The box 8 is connected...

Embodiment 2

[0033] This embodiment is an improvement made on the basis of Embodiment 1, according to Figure 1-5 As shown, a first piston cavity 15 is formed between the clamping block 12 and the clamping box 8, the first piston cavity 15 is used to store the gas sprayed by the gas pipe 11, and the clamping block 12 is connected to the clamping box 8 through a second spring 18 , the inner wall of the clamping box 8 is also provided with an air delivery groove 16, the air delivery groove 16 is connected with the air pipe 11, and a pushing part 3 is also arranged in the clamping block 12, and the pushing part 3 is used to drive the sliding plate 21 to slide, and the clamping A transmission pipe 17 is also installed on the holding block 12, and the transmission pipe 17 is used to receive the gas sprayed by the air delivery tank 16, and the transmission pipe 17 communicates with the pushing part 3;

[0034] The inside of the shown clamping block 12 is provided with an air outlet hole 23 for c...

Embodiment 3

[0039] This embodiment is an improvement made on the basis of Embodiment 2, according to Figure 1-6 As shown, the inside of the clamping block 12 is also equipped with an adjustment component 6, the adjustment component 6 is used to limit the sliding distance of the piston plate 33, the adjustment component 6 includes a first one-way tooth 64 that is rotatably connected to the push rod 34, and the push rod 34 is also equipped with a first retaining bar 65, the inside of the clamping block 12 is connected with a gear 24 by a short shaft, and the gear 24 is meshed with the bar groove 62, and the short shaft is also connected with an eccentric gear 99, and the shaft of the eccentric gear 99 The center is far away from the axis center of the short shaft, and the inside of the clamping block 12 is also slidably connected with a gear bar 61. The gear bar 61 is connected with the clamping block 12 through the fifth spring 63. The gear bar 61 is equipped with meshing teeth 66, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com