Processing method of semi-fermented steamed green tea

A processing method and technology of steaming green tea, applied in chemical instruments and methods, tea treatment before extraction, detergent compounding agent, etc., can solve problems such as difficulty in grasping the degree of frying green tea, low yield of fresh leaf tea, and difficult temperature control , to achieve the effect of promoting the uniform distribution of water, reducing the grassy smell and enriching the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

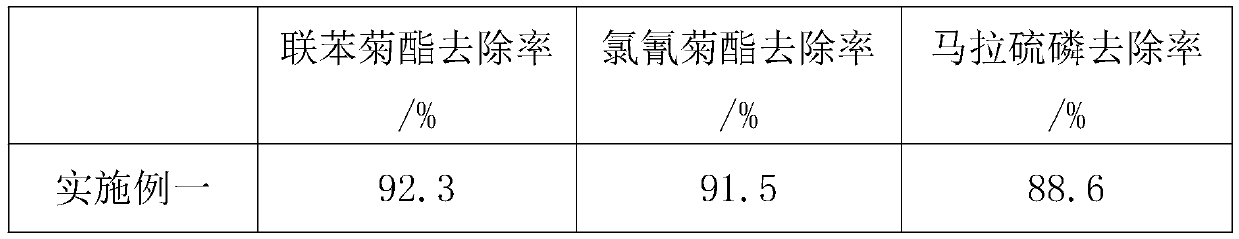

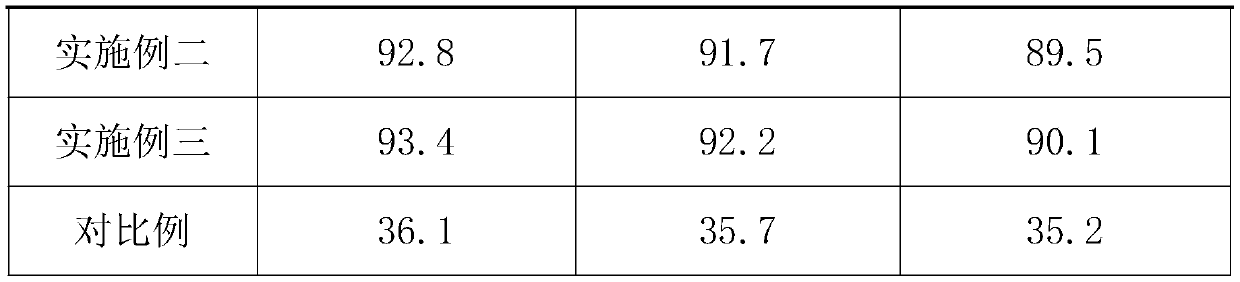

Embodiment 1

[0028] A processing method of semi-fermented steamed green tea, comprising the following steps:

[0029] Step 1. Tender harvesting: picking the fresh leaves of the small-leaf tea tree, one bud, one and two leaves as raw materials, immerse the picked fresh leaves in the finishing solution to remove the residual pesticides on the surface of the fresh leaves, soak for 15 minutes, take them out, rinse with water and drain the water , wherein the finishing solution is composed of the following raw materials in parts by weight: 2 parts of C12-14 alkyl glycosides, 1.2 parts of Scutellaria baicalensis extract, 0.3 parts of tea saponin, 0.2 parts of dipotassium hydrogen phosphate, and 85 parts of water;

[0030] Step 2, withering: spread the picked fresh leaves evenly in the sun for 5 minutes, then place them in a cool place for natural withering for 2 hours, with the water loss rate of fresh leaves reaching 8-12% as the standard;

[0031] Step 3. Mixing: Mix and shake the withered fre...

Embodiment 2

[0041] A processing method of semi-fermented steamed green tea, comprising the following steps:

[0042] Step 1. Tender harvesting: pick the fresh leaves of small-leaved tea trees, one bud, one and two leaves as raw materials, soak the picked fresh leaves in the finishing solution to remove the residual pesticides on the surface of the fresh leaves, take them out after soaking for 20 minutes, rinse with water and drain the water , wherein the finishing solution is composed of the following raw materials in parts by weight: 4 parts of C12-14 alkyl glycosides, 1 part of Scutellaria baicalensis extract, 0.2 parts of tea saponin, 0.3 parts of dipotassium hydrogen phosphate, and 90 parts of water;

[0043] Step 2. Withering: spread the picked fresh leaves evenly in the sun for 6 minutes, and then place them in a cool place for natural withering for 2.5 hours. The water loss rate of fresh leaves reaches 8-12% as the standard;

[0044] Step 3. Mixing: Mix and shake the withered fresh...

Embodiment 3

[0054] A processing method of semi-fermented steamed green tea, comprising the following steps:

[0055] Step 1. Tender harvesting: pick the fresh leaves of small-leaf tea trees, one bud, one and two leaves as raw materials, soak the picked fresh leaves in the finishing solution to remove the residual pesticides on the surface of the fresh leaves, take them out after soaking for 30 minutes, rinse with water and drain the water , wherein the finishing solution is composed of the following raw materials in parts by weight: 6 parts of C12-14 alkyl glycosides, 0.8 parts of Scutellaria baicalensis extract, 0.1 parts of tea saponin, 0.4 parts of dipotassium hydrogen phosphate, and 95 parts of water;

[0056] Step 2, withering: spread the picked fresh leaves evenly in the sun for 8 minutes, then place them in a cool place for natural withering for 3 hours, with the water loss rate of fresh leaves reaching 8-12% as the standard;

[0057] Step 3. Mixing: Mix and shake the withered fres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com