A method of cleaning fractures of steel failed components

A component and steel technology, which is applied in the field of cleaning the fracture of steel failure parts, can solve the problems of unsatisfactory cleaning effect of dense corrosion, no calculation method for soaking time, long soaking time (2~4 hours, etc.), and achieve simple configuration Convenience, avoid over-cleaning, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

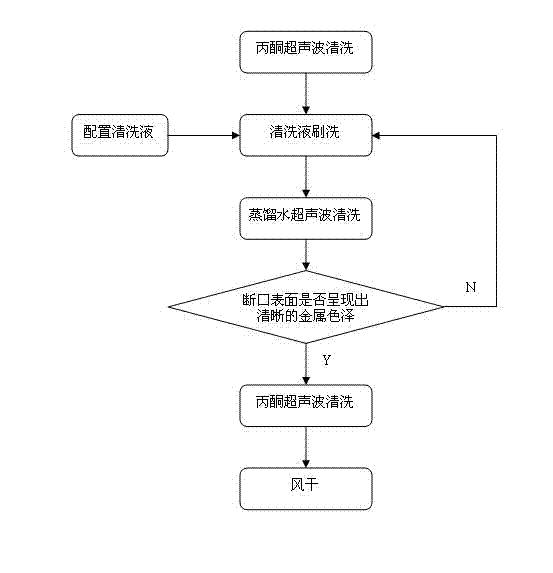

Method used

Image

Examples

Embodiment approach

[0018] Preferred embodiments of the present invention are as follows:

[0019] 1. Embodiment 1

[0020] 1) Configure 100mL of hydrochloric acid aqueous solution with a volume ratio of 3% as the cleaning solution: pour 97mL of distilled water into a dry and clean measuring cylinder, use a burette to absorb 3mL of concentrated hydrochloric acid and drop it into the measuring cylinder, use a glass rod to stir slowly, and configure it so that the volume ratio is 3 % hydrochloric acid aqueous solution, i.e. the cleaning solution of the present invention; use a clean reagent bottle to store the cleaning solution;

[0021] 2) Acetone ultrasonic cleaning: pour clean water into the water tank of the ultrasonic cleaning machine, the water volume is between the highest and the lowest water level, put the steel failure parts to be cleaned into a clean beaker, pour acetone into the beaker until the steel failure is submerged Components, put the beaker into the water tank of the ultrasonic...

Embodiment 2

[0027] The steps and operation method are the same as in Example 1. The specific hydrochloric acid volume ratio of the cleaning solution, the time of ultrasonic cleaning with acetone, the time of ultrasonic cleaning with distilled water, and the repetition times of scrubbing with cleaning solution and ultrasonic cleaning with distilled water are shown in Table 1.

Embodiment 3

[0029] The steps and operation method are the same as in Example 1. The specific hydrochloric acid volume ratio of the cleaning solution, the time of ultrasonic cleaning with acetone, the time of ultrasonic cleaning with distilled water, and the repetition times of scrubbing with cleaning solution and ultrasonic cleaning with distilled water are shown in Table 1.

[0030] Table 1

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com