Production line for medicinal material core pulling

A production line and medicinal material technology, applied in the field of pharmaceutical special equipment manufacturing, can solve problems such as inconvenient operation and control, labor-intensive, uneven product quality, etc., and achieve the effect of high product quality, guaranteed product quality, and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

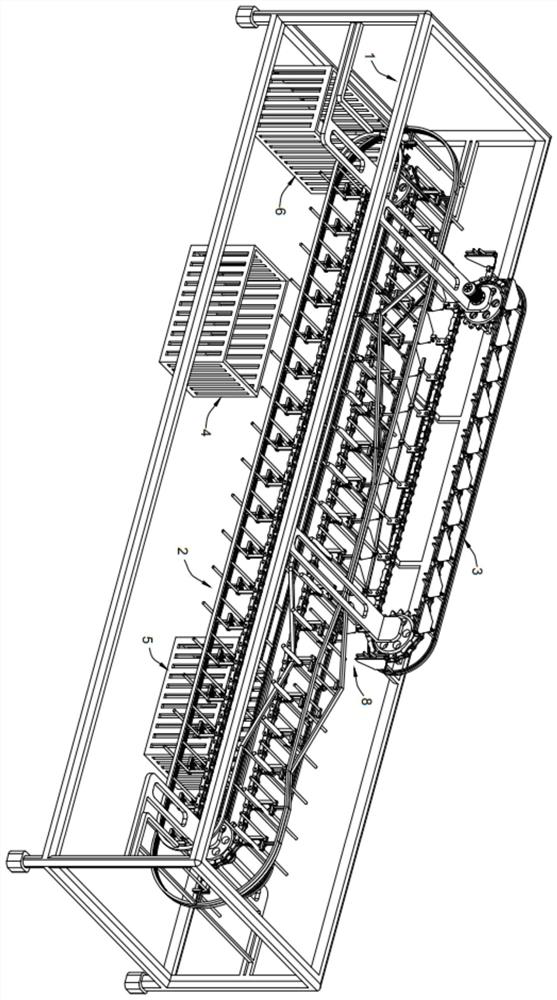

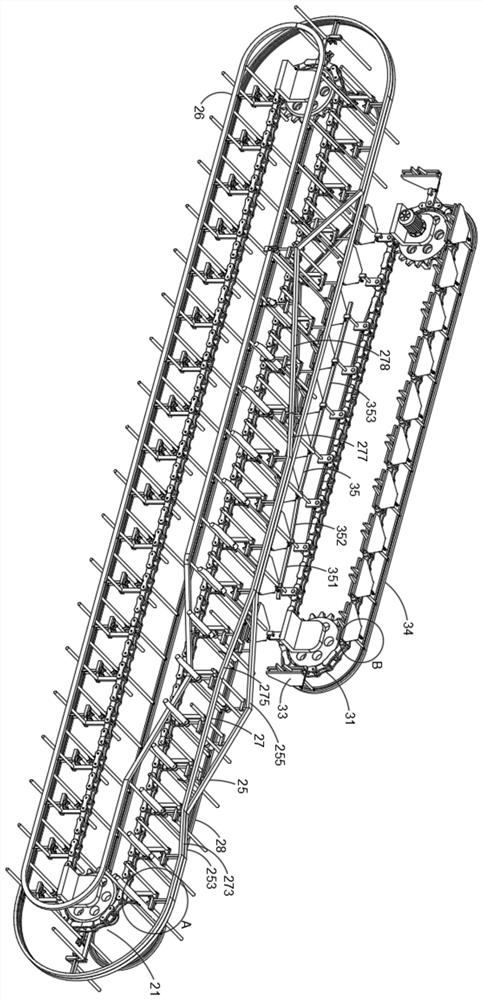

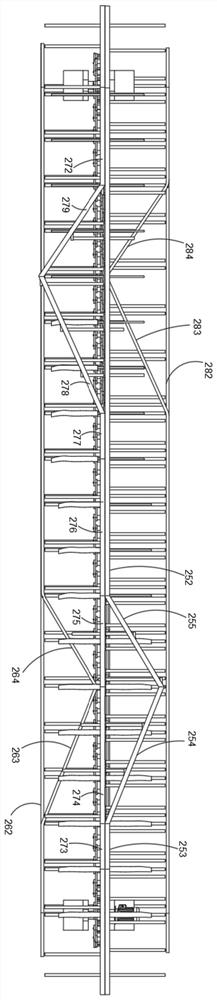

[0044] Such as Figure 1 to Figure 14 As shown, a production line for core-pulling medicinal materials includes a frame 1, and a core-pulling device 2 is provided on the frame 1. The core-pulling device 2 includes a rotary chain a21, which rotates under the drive of the rotary chain a21. The bearing block 22 and the right core-pulling mechanism 23 and the left core-pulling mechanism 24 arranged on the bearing block 22, the clamping device 3 is arranged on the upper side of the core-pulling device 2, and the core-pulling device 2 and the clamping device 3 A clamping channel 8 is formed between them;

[0045] The right core-pulling mechanism 23 includes an upper core-pulling assembly a231 and a lower core-pulling assembly a233, the lower core-pulling assembly a233 carries Morinda officinalis 7, and the left core-pulling mechanism 24 includes an upper core-pulling assembly b241 and a lower core-pulling assembly Component b243, the lower core-pulling component b243 carries Morind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com