Electroplating peeling recovery technology of lithium battery electrode

A recycling method and technology for lithium batteries, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of long cycle, limited addition of conductive agent, poor conductivity, etc., and achieve efficient separation and uniformity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

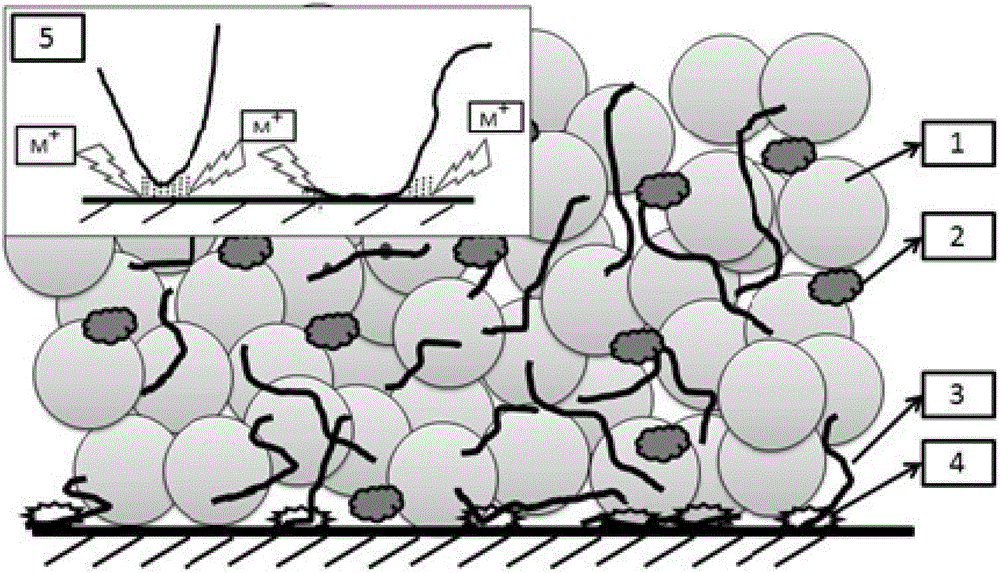

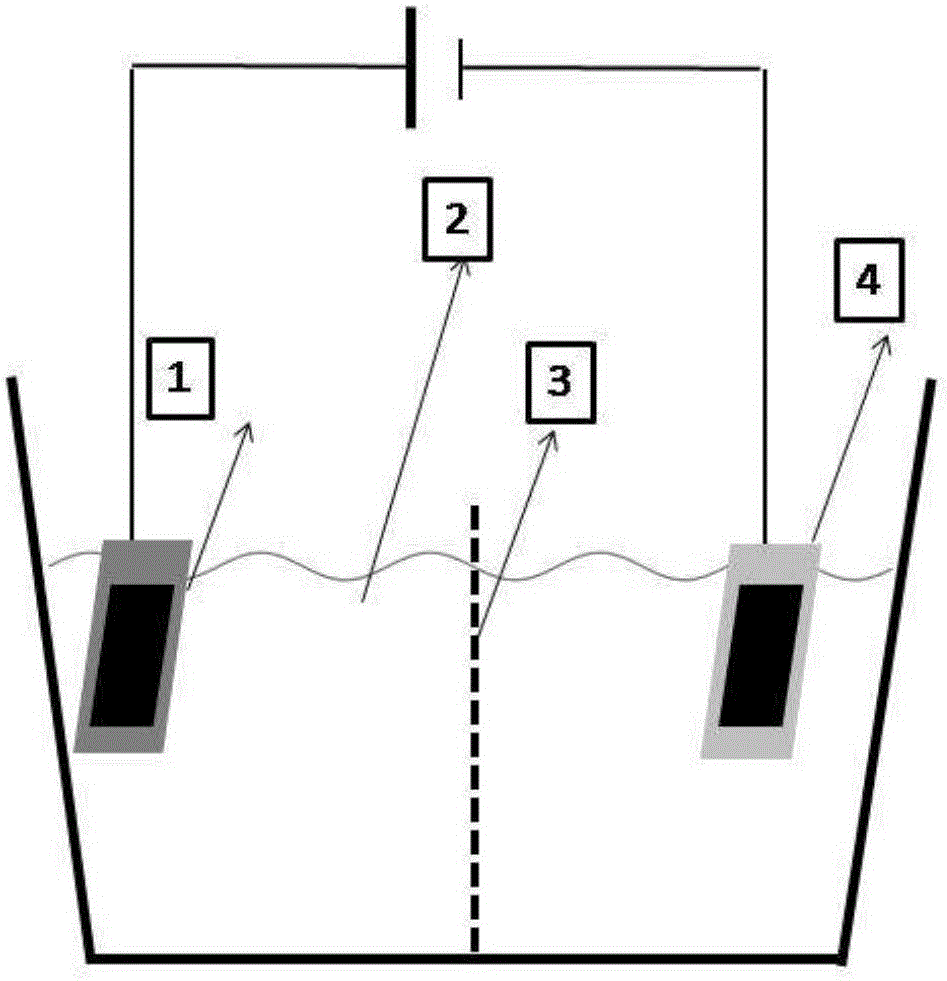

[0031] like figure 1 and figure 2 shown.

[0032] Prepare CuSO with a concentration of 1mol / L 4 Solution 10kg. The pole piece dismantled from a 22.5AH battery, the positive pole piece is 2.25m long and 0.126m wide; the negative pole piece is 2.46m long and 0.123m wide. On the positive terminal of the DC power supply. The DC power supply voltage used is 6V. The pole piece coated with the active material is immersed in CuSO 4 In the solution, a 400-mesh screen is used to isolate the middle, the solution temperature is 0°C, the power in the solution pool is 20 kHz, and the power is 0.1W / cm 2 Ultrasonic, the distance between the two pole pieces is kept at 10cm, the current is 5min, and the DC current is 0.5A, which can achieve the peeling effect. Then rotate the positive electrode sheet so that the other side of the positive electrode coating faces the anode, energize for 5 minutes, and peel off the active material adhered to the other side. The pole pieces were taken out...

Embodiment 2

[0036] A kind of electroplating stripping method of lithium-ion battery electrode recovery, its operation steps are as follows:

[0037] Prepare CuSO with a concentration of 0.1mol / L 4 Solution 10kg. The pole piece dismantled from a 22.5AH battery, the positive pole piece is 2.25m long and 0.126m wide; the negative pole piece is 2.46m long and 0.123m wide. On the positive terminal of the DC power supply. The DC power supply voltage used is 4V. The pole piece coated with the active material is immersed in CuSO 4 In the solution, a 200-mesh screen is used to isolate the middle, the solution temperature is 50°C, the power added to the solution pool is 40 kHz, and the power is 1W / cm 2 Ultrasonic, the distance between the two pole pieces is kept at 100cm, and the power is applied for 20 minutes, and the DC current is 0.1A, which can achieve the peeling effect. Then turn the positive electrode sheet so that the other side of the positive electrode coating faces the anode, power...

Embodiment 3

[0041] A kind of electroplating stripping method of lithium-ion battery electrode recovery, its operation steps are as follows:

[0042] Prepare CuSO with a concentration of 0.01mol / L 4Solution 10kg. The pole piece dismantled from a 22.5AH battery, the positive pole piece is 2.25m long and 0.126m wide; the negative pole piece is 2.46m long and 0.123m wide. On the positive terminal of the DC power supply. The DC power supply voltage used is 150V. The pole piece coated with the active material is immersed in CuSO 4 In the solution, a 600-mesh screen is used to isolate the middle, the solution temperature is 90°C, the power added to the solution pool is 25 kHz, and the power is 0.15W / cm 2 Ultrasonic, the distance between the two pole pieces is kept at 1cm, and the current is 0.6A after energizing for 1min, which can achieve the peeling effect. Then turn the positive electrode sheet so that the other positive electrode coated surface faces the anode, power on for 1 min, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com