Three-stage treatment equipment for printing and dyeing waste gas

A treatment equipment and three-stage technology, applied in the field of printing and dyeing waste gas three-stage treatment equipment, can solve the problems of reducing waste gas treatment efficiency and single direction of hot air passage, and achieve the effect of improving cooling effect, increasing speed and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

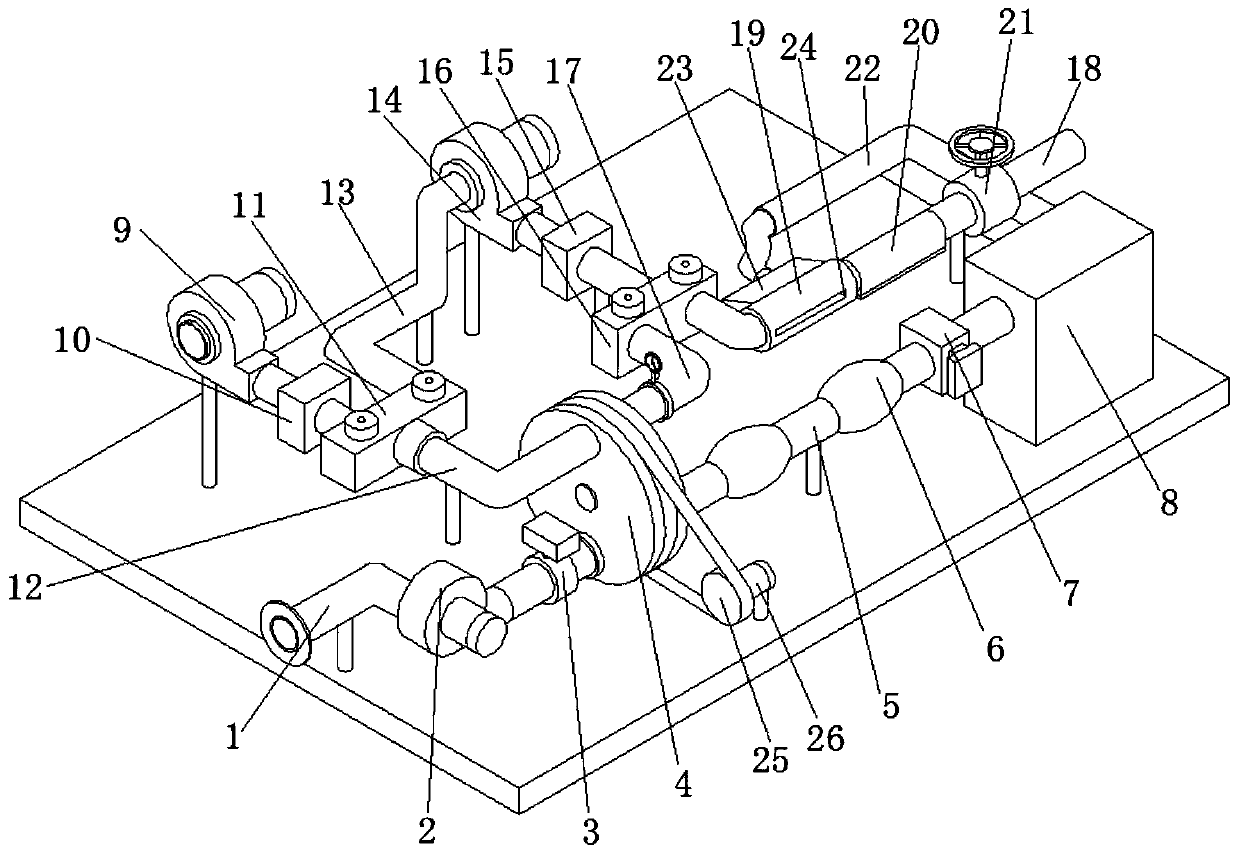

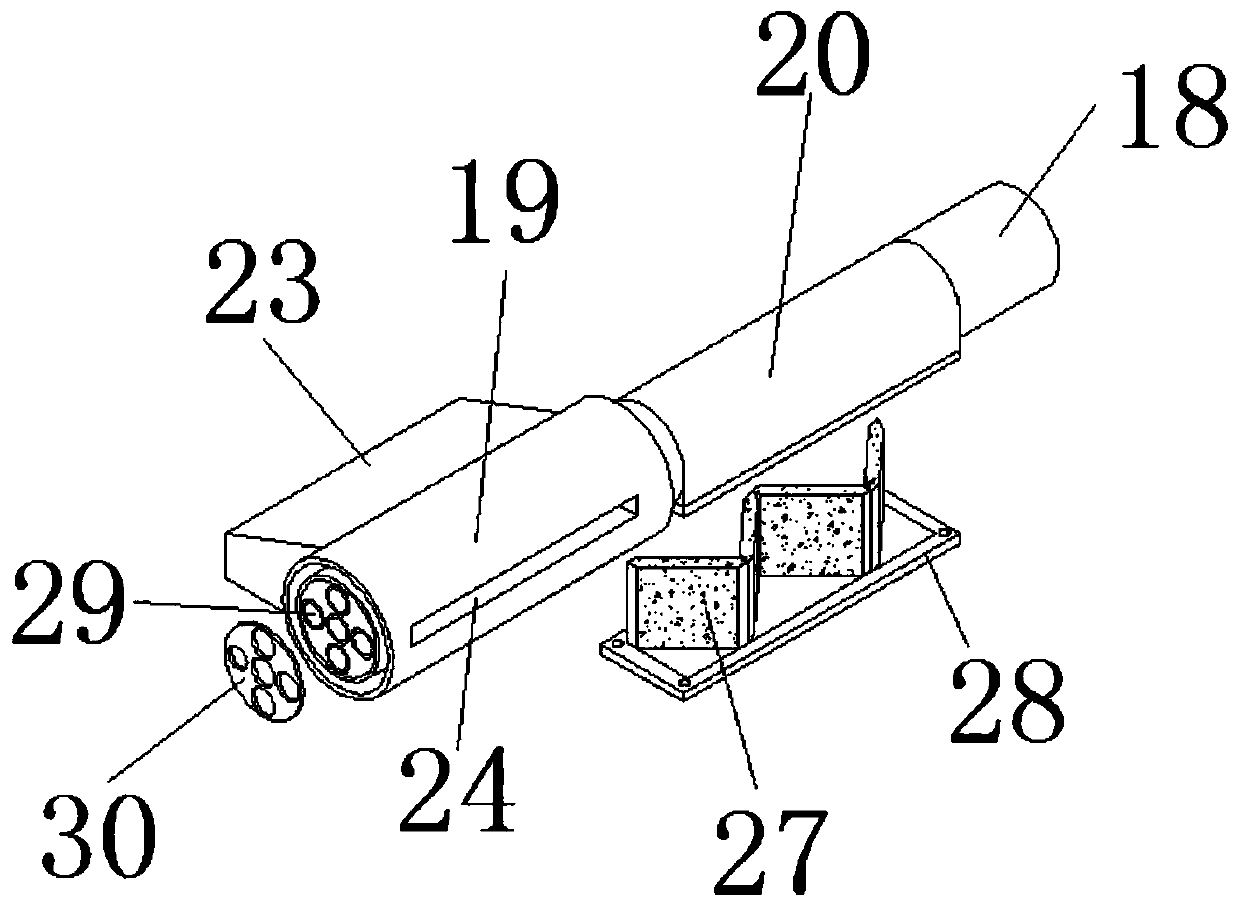

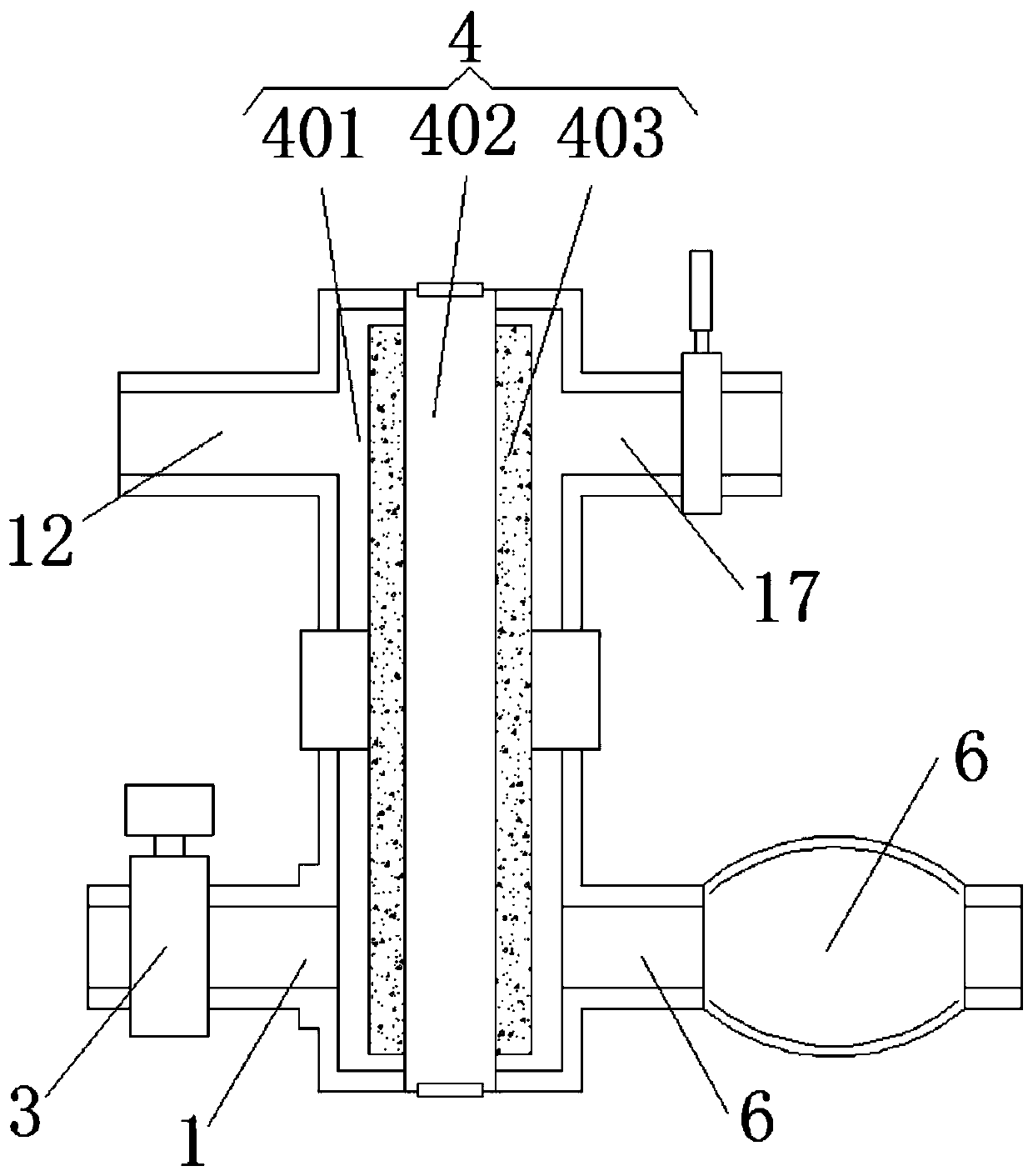

[0025] Embodiment: a kind of printing and dyeing exhaust gas three-stage treatment equipment, such as Figure 1-Figure 4As shown, it includes a support plate, a zeolite concentration device, a waste gas drying device and a photocatalytic degradation device. The zeolite concentration device, the waste gas drying device and the photocatalytic degradation device are all installed on the support plate. , electric butterfly valve 3, zeolite rotating mechanism 4, exhaust pipe 5, booster fan 2 9, electric heating component 10, two-position three-way solenoid valve 11, heat exchange pipe 12, circulation pipe 13, circulation fan 14, Electric heating component 2 15, two-position three-way solenoid valve 2 16 and heat exchange pipe 2 17, the intake pipe 1 is connected to the zeolite rotating mechanism 4, and a booster fan is installed on the outer wall of the intake pipe 1 near the air inlet 12. An electric butterfly valve 3 is installed on the outer wall of the intake pipe 1 close to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com