Patents

Literature

92results about How to "Convenient drying work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

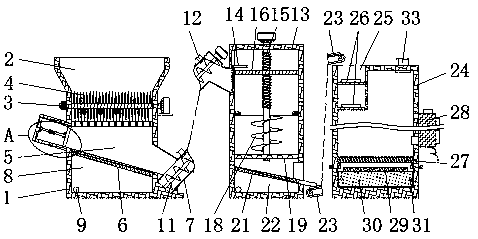

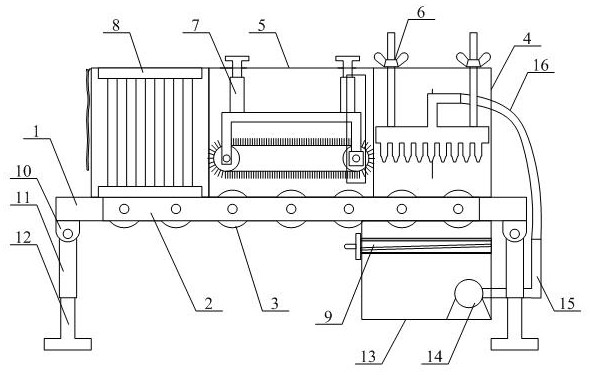

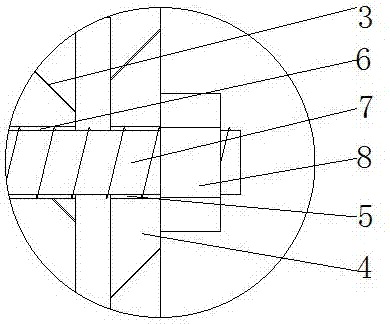

Gauze drying and disinfecting device

InactiveCN109114933AImprove the extrusion effectFully dehydratedDrying solid materials without heatDrying gas arrangementsDrive motorEngineering

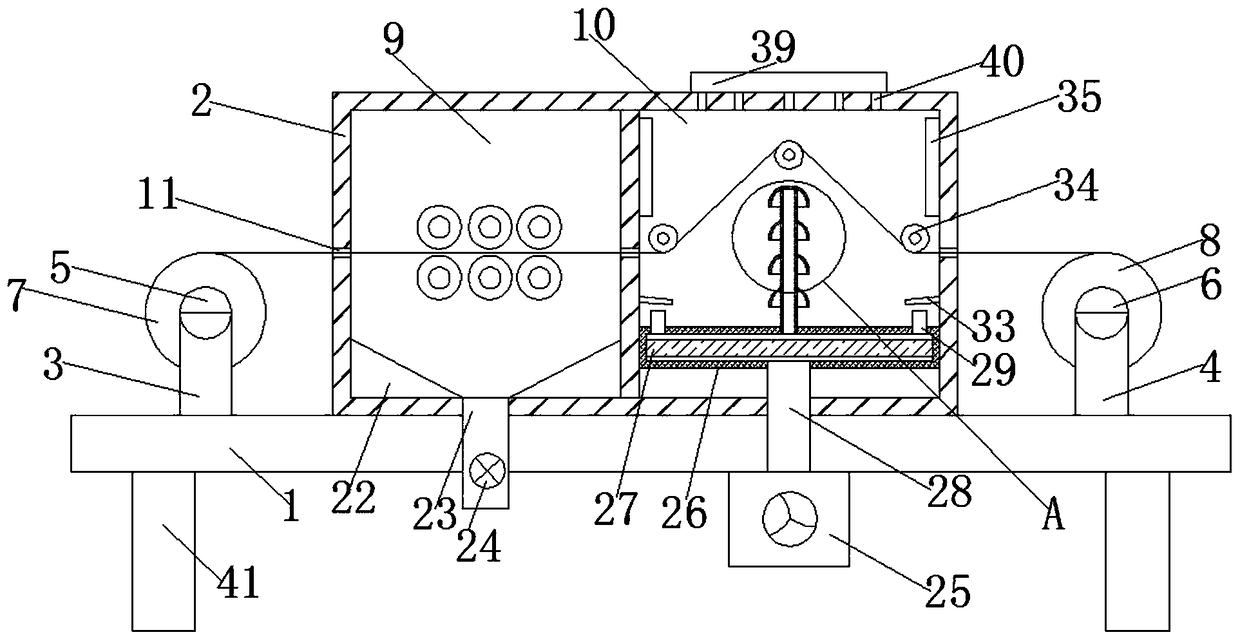

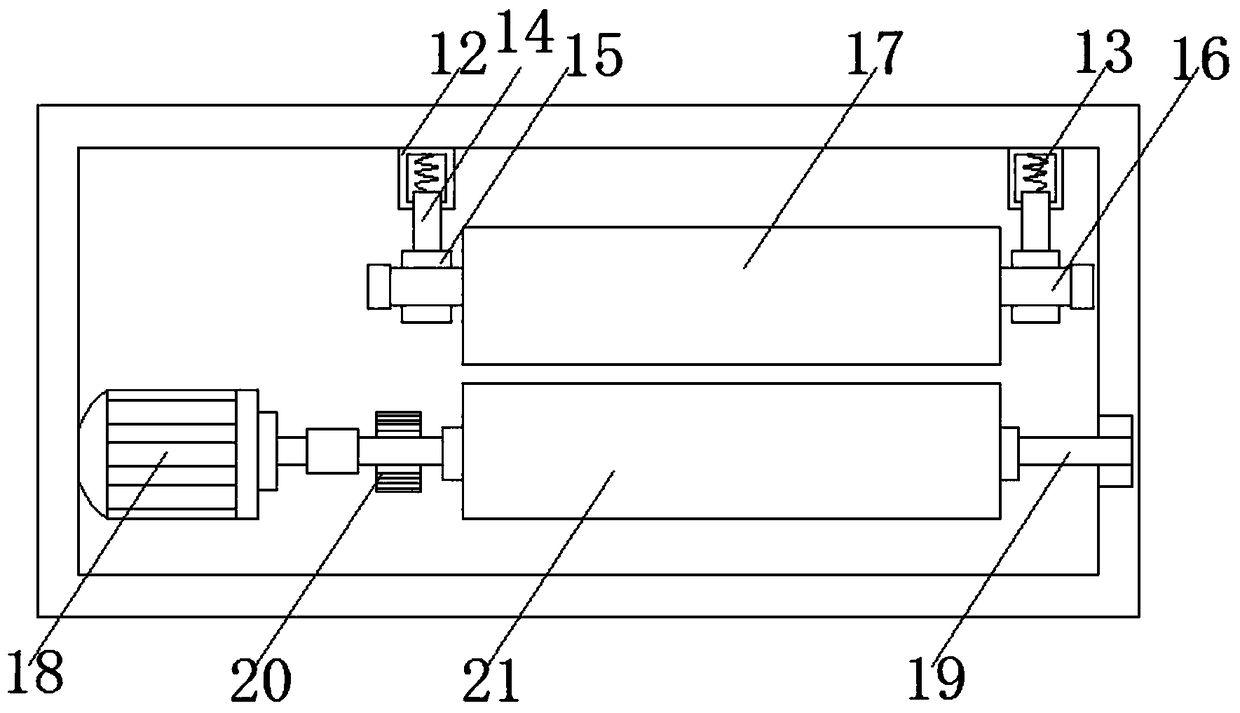

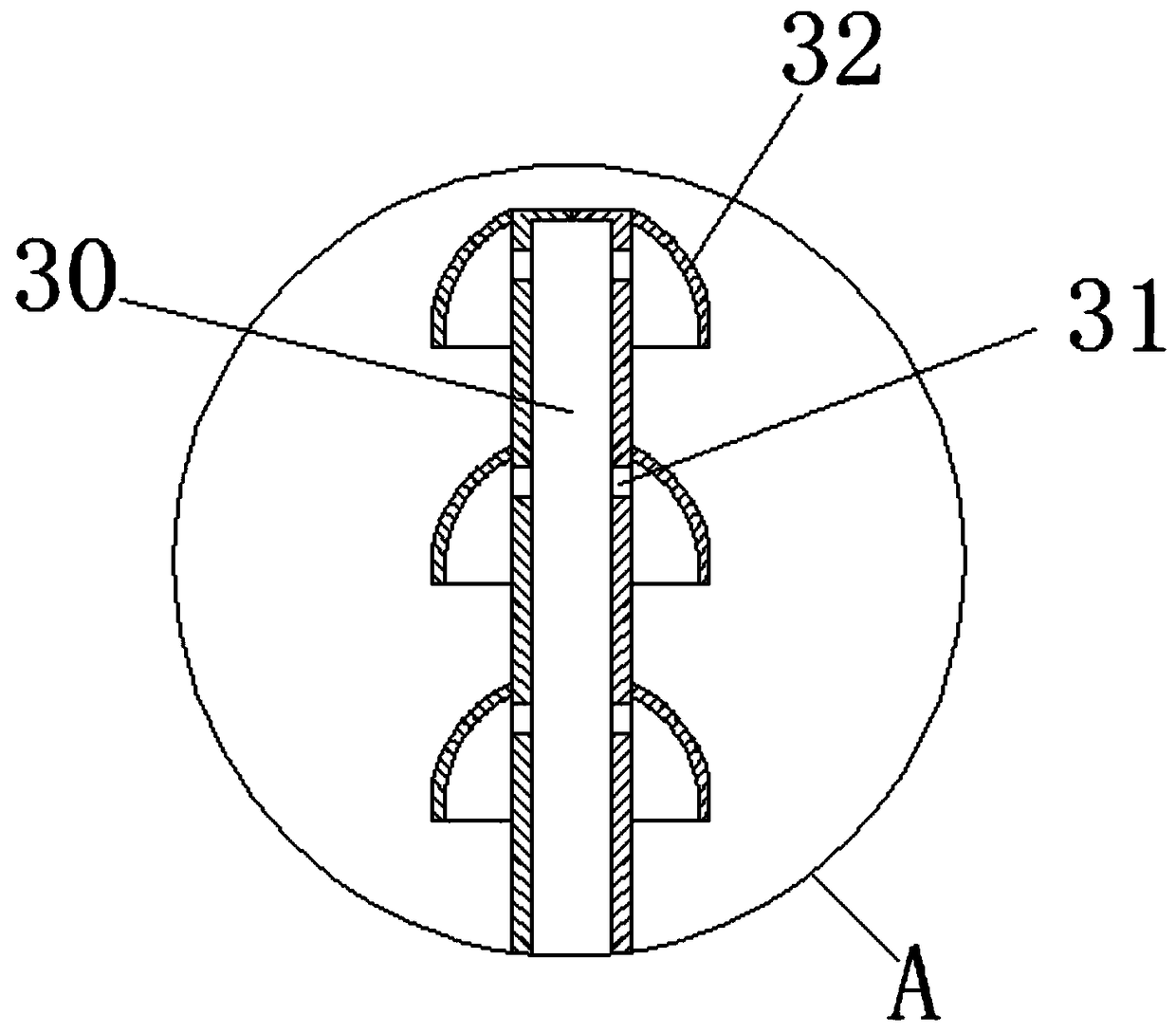

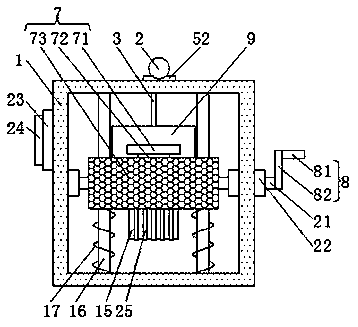

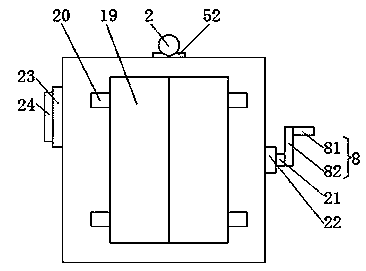

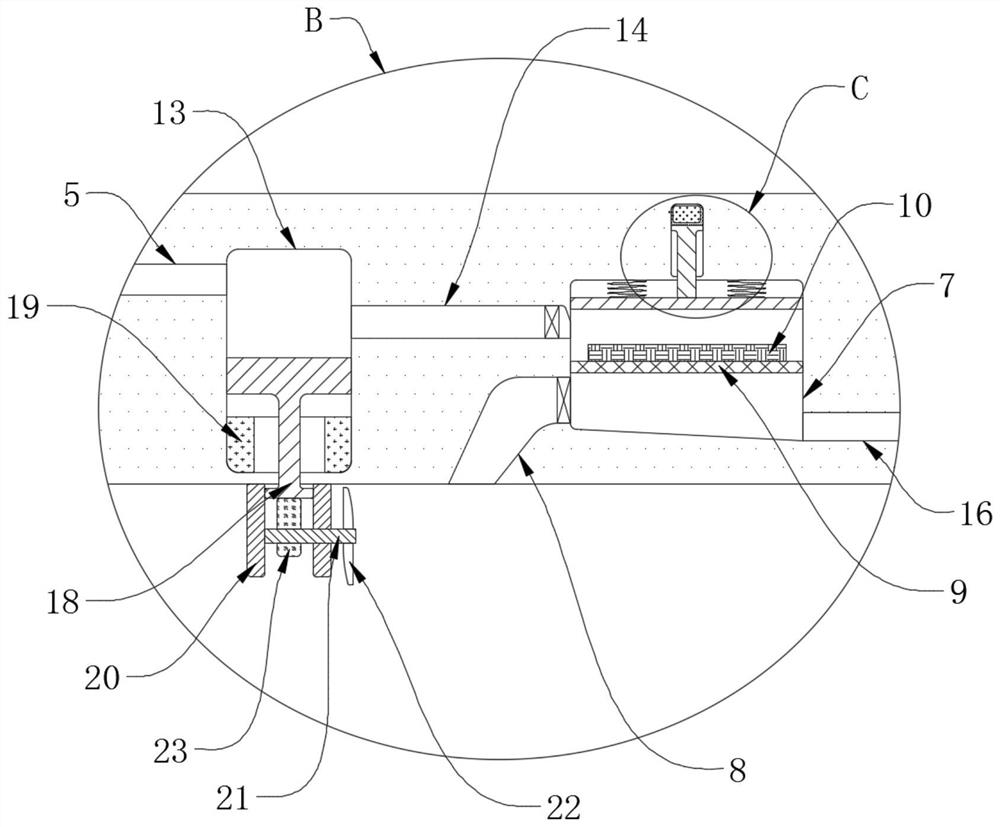

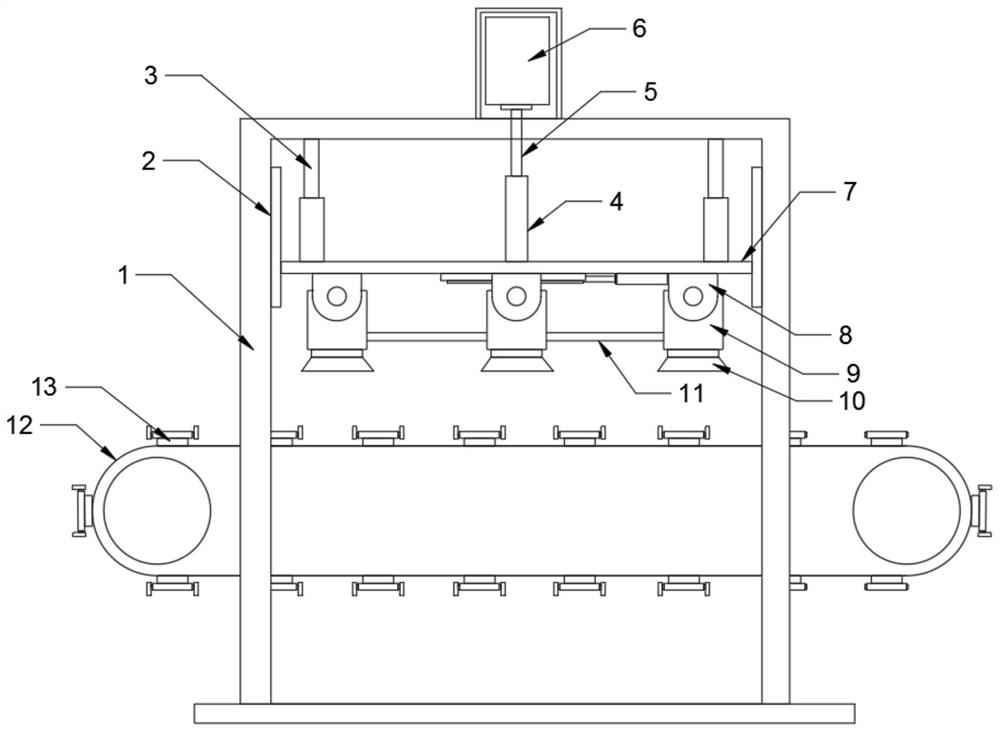

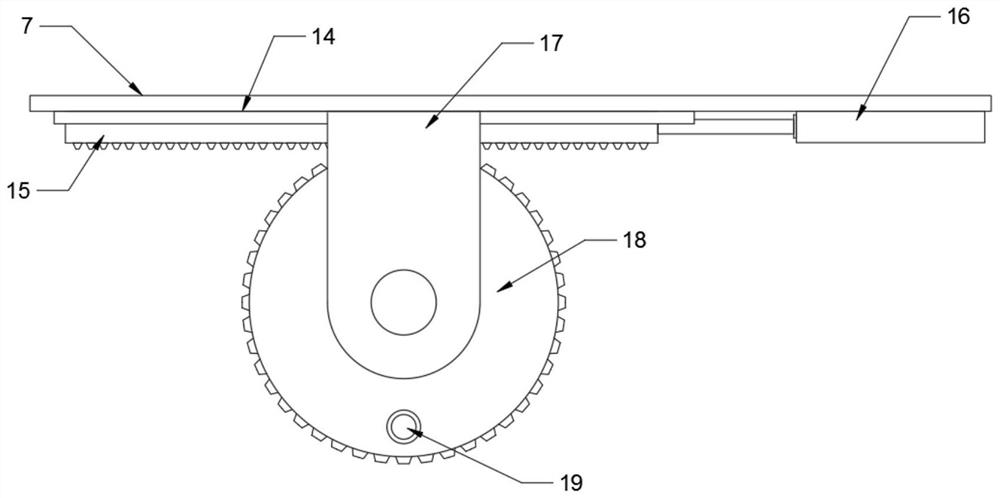

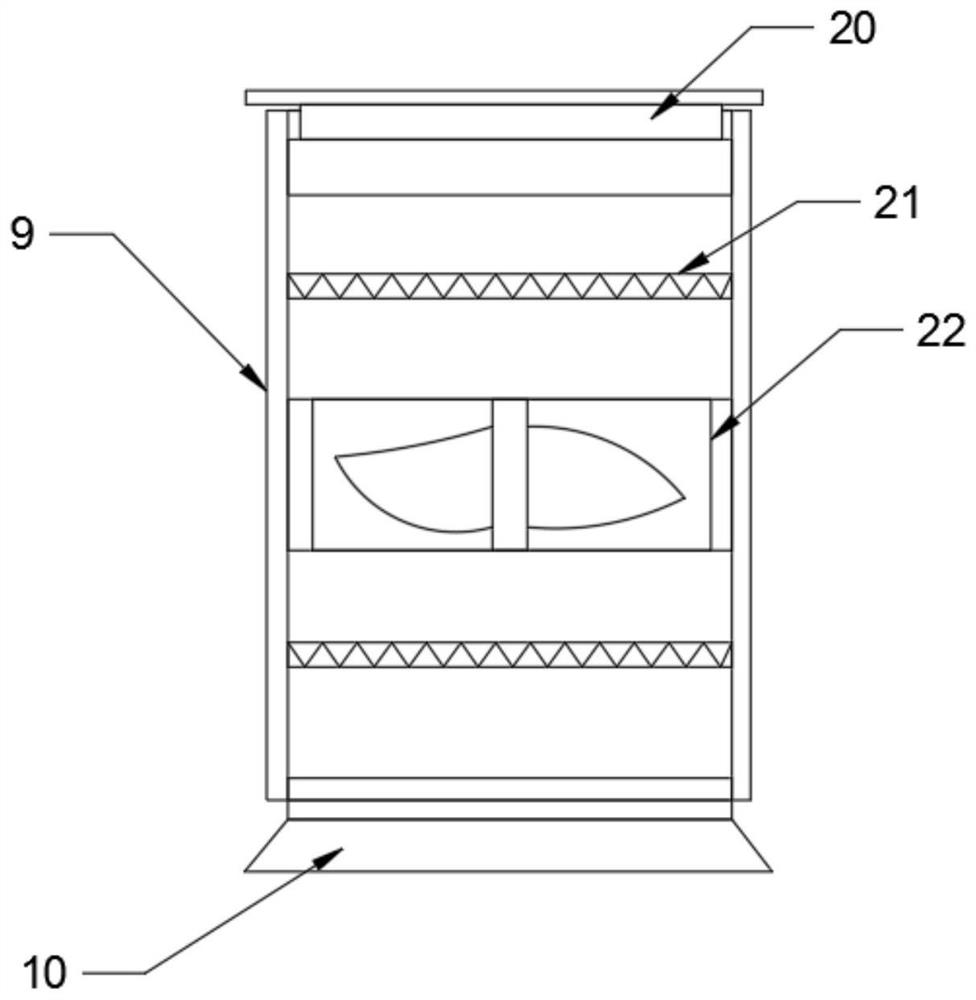

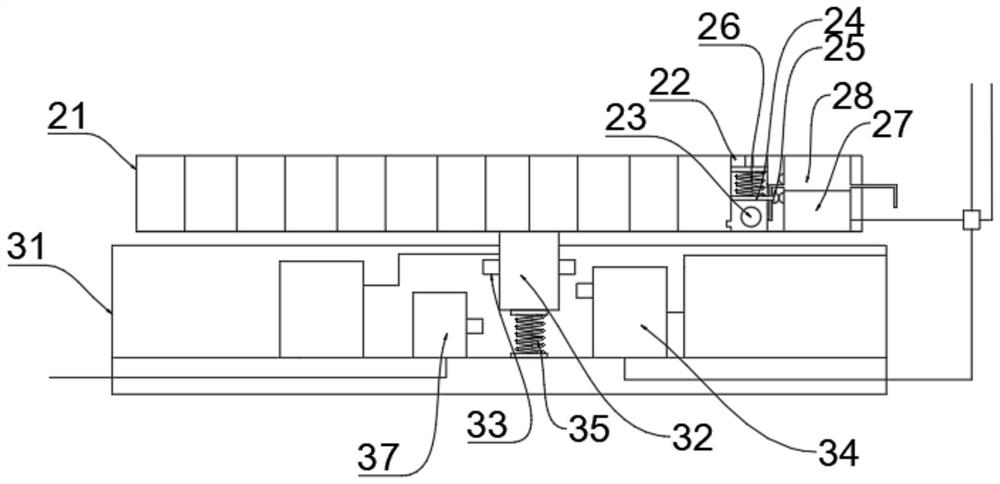

The invention provides a gauze drying and disinfecting device, and relates to the technical field of textile machinery. The gauze drying and disinfecting device comprises a base, the top of the base is fixedly provided with a drying box, a first support and a second support, a material conveying rotating shaft and a material collecting rotating shaft are arranged on the first support and the second support respectively in a penetrating mode, the material conveying rotary shaft and the material collecting rotary shaft are respectively and fixedly provided with a material conveying rotary disc and a material collecting rotary disc, and the drying box is divided into a dehydrating chamber and a drying and disinfecting chamber. According to the gauze drying and disinfecting device, an upper pressing roller, a lower pressing roller, a second roller shaft, a first roller shaft, a driving motor, a transmission gear and an extrusion spring are arranged in a cooperated mode, the driving motor drives one of the second roller shafts to rotate, the lower pressing roller is driven to rotate together through the transmission gear, the corresponding upper pressing roller is driven to rotate in the rotating process of the lower pressing roller, the gauze is dehydrated, the follow-up drying work is facilitated, the squeezing effect of the gauze is increased through the squeezing spring, and dewatering is more sufficient.

Owner:江西美宝利实业有限公司

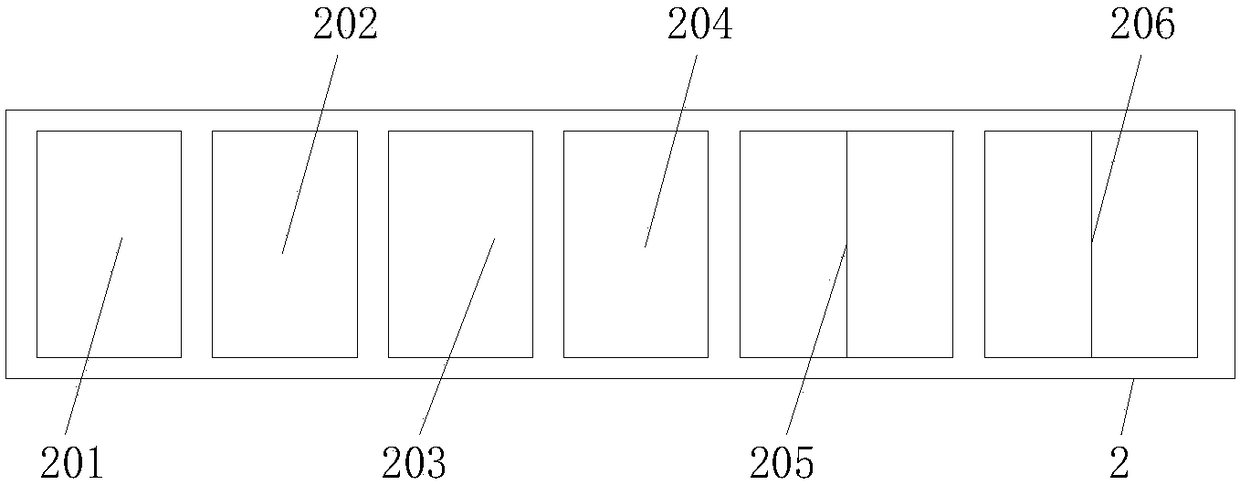

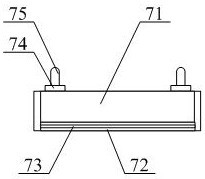

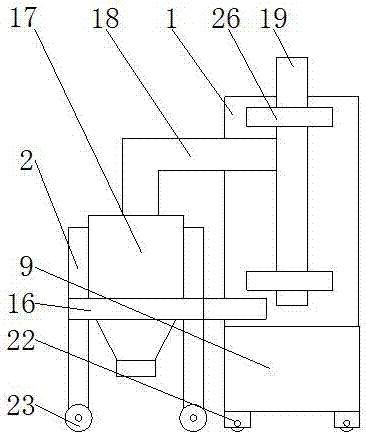

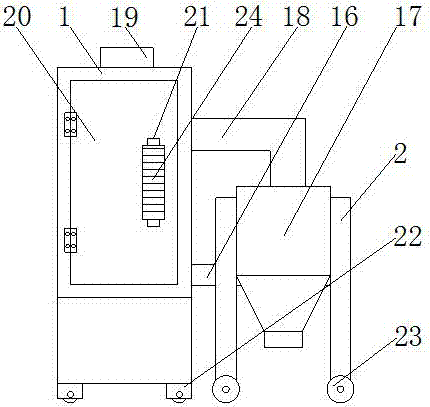

Textile cloth drying rack convenient to use

InactiveCN108360192AIncrease frictionGuaranteed to be stableLiquid/gas/vapor removalTextile treatment carriersFastenerEngineering

The invention discloses a textile cloth drying rack convenient to use. The textile cloth drying rack comprises a base plate, a first sleeve is fixedly connected to the top of the base plate, a slidingrod is arranged in an inner cavity of the first sleeve, the top of the first sleeve is provided with a fastener used in cooperation with the sliding rod, a pin hole is formed inside the sliding rod,a plug is arranged in the inner cavity of the pin hole, one end of the plug penetrates through one side of the first sleeve and extends out of the first sleeve, a supporting rod is fixedly connected to the top of the sliding rod, and the two ends of the supporting rod are sleeved with first sleeves. By cooperatively using the base plate, the first sleeve, the sliding rod, the fastener, the pin hole, the plug, the supporting rod, the second sleeves, an airing rod, a first threaded hole, a second threaded hole and a bolt, the height and using area of the drying rack can be regulated, it is better ensured that the airing work is conveniently performed, and great convenience is brought to usual airing work.

Owner:SUZHOU YOUSHENG TEXTILE

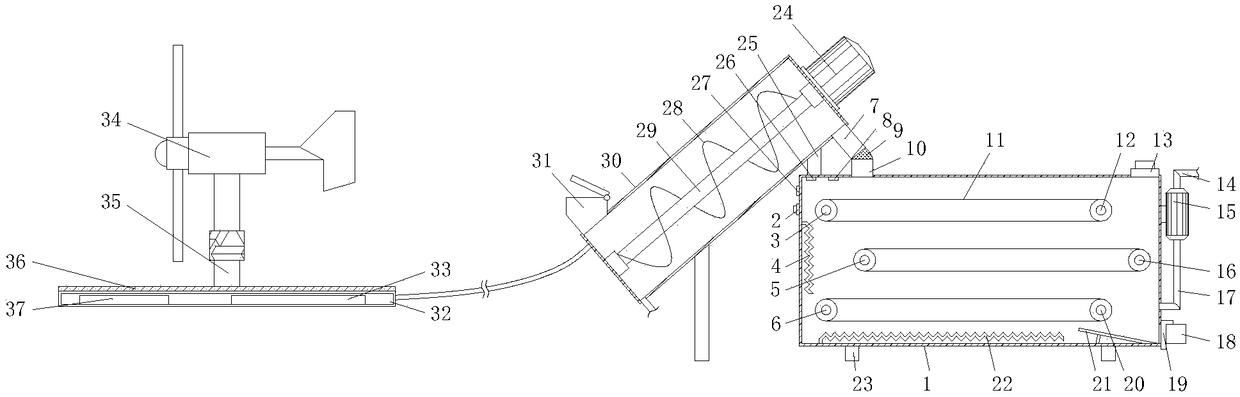

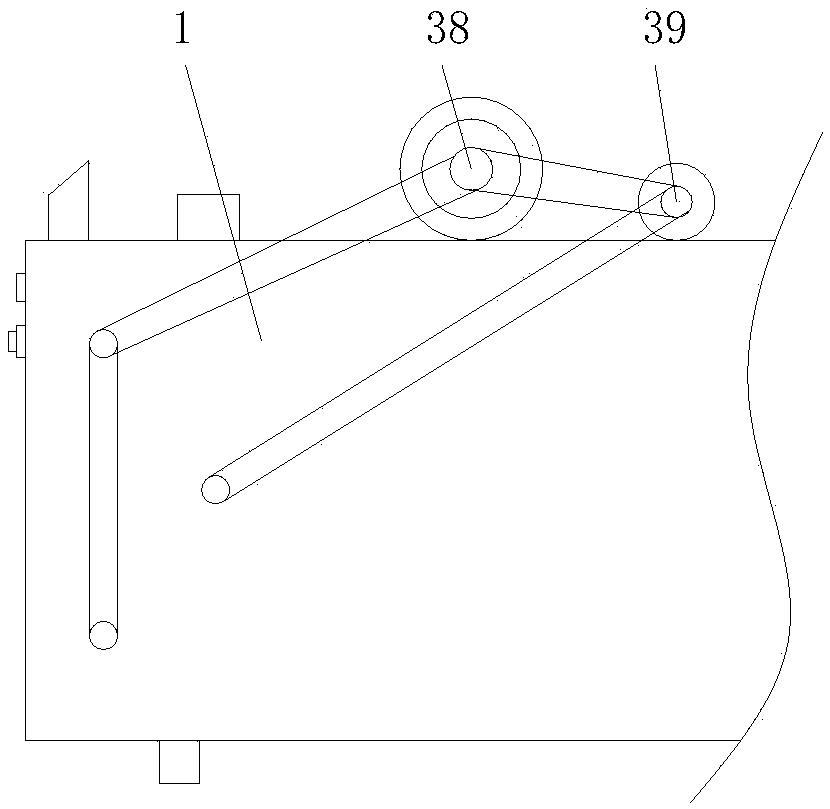

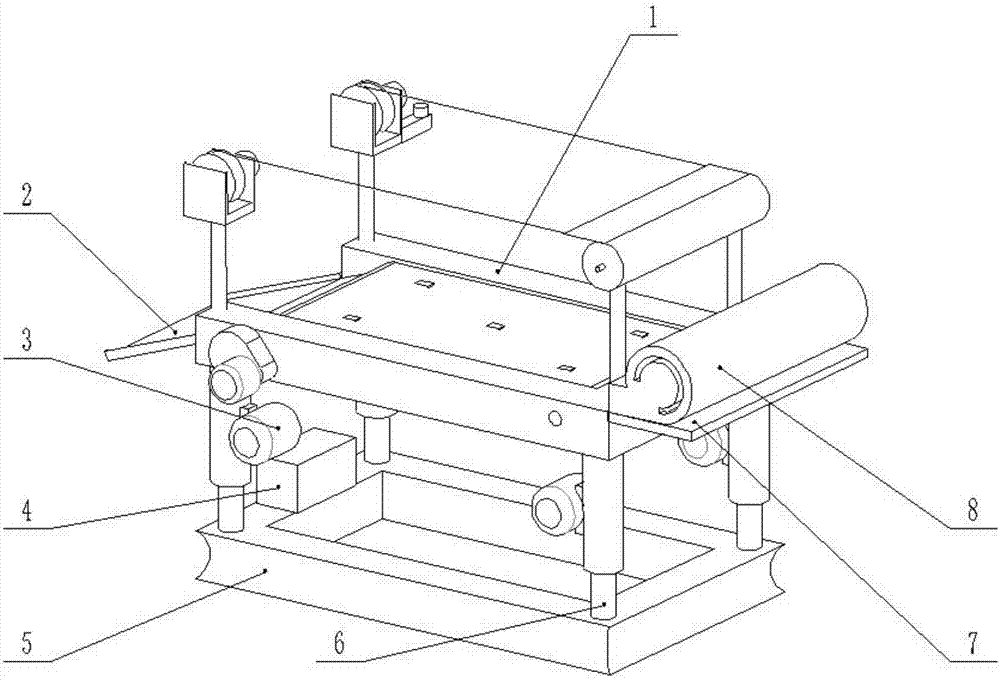

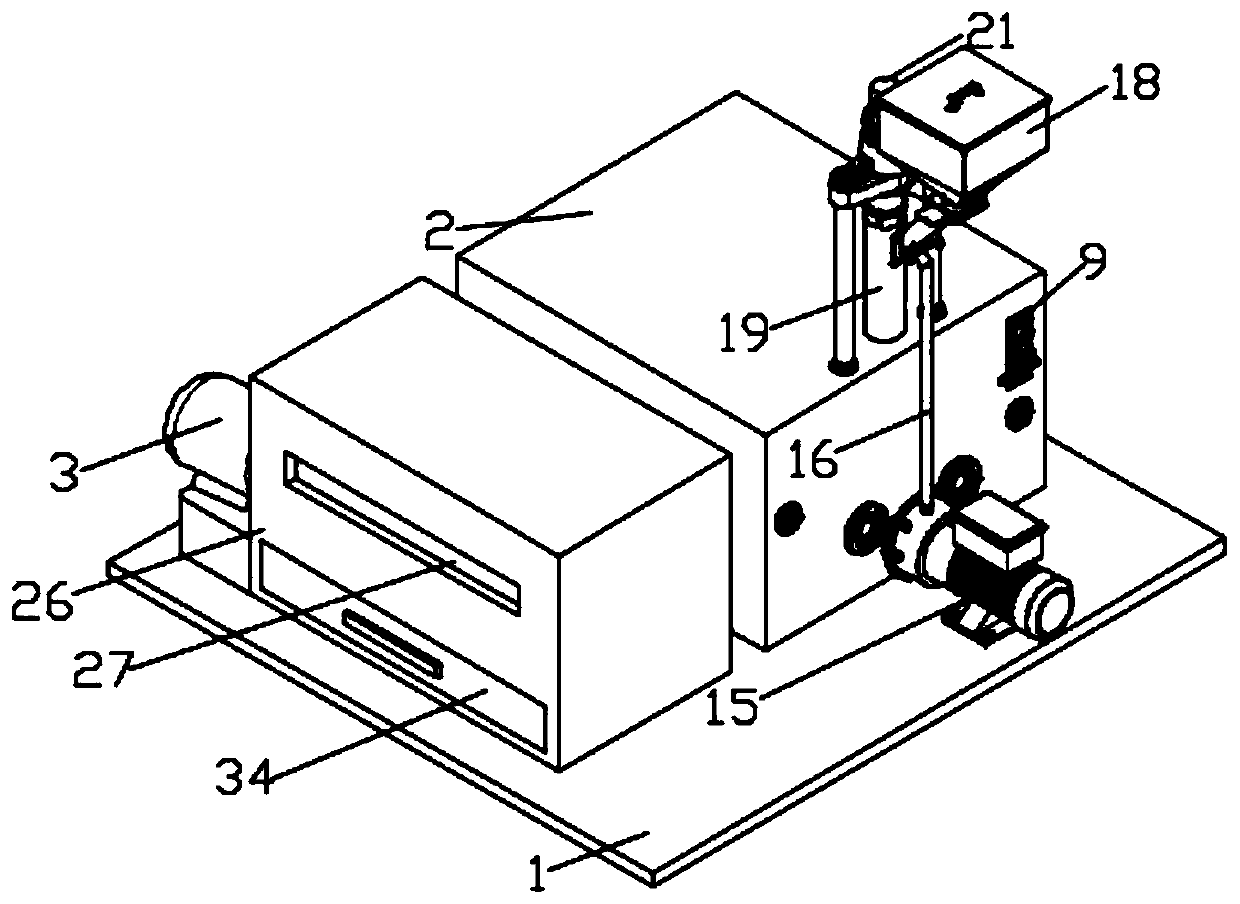

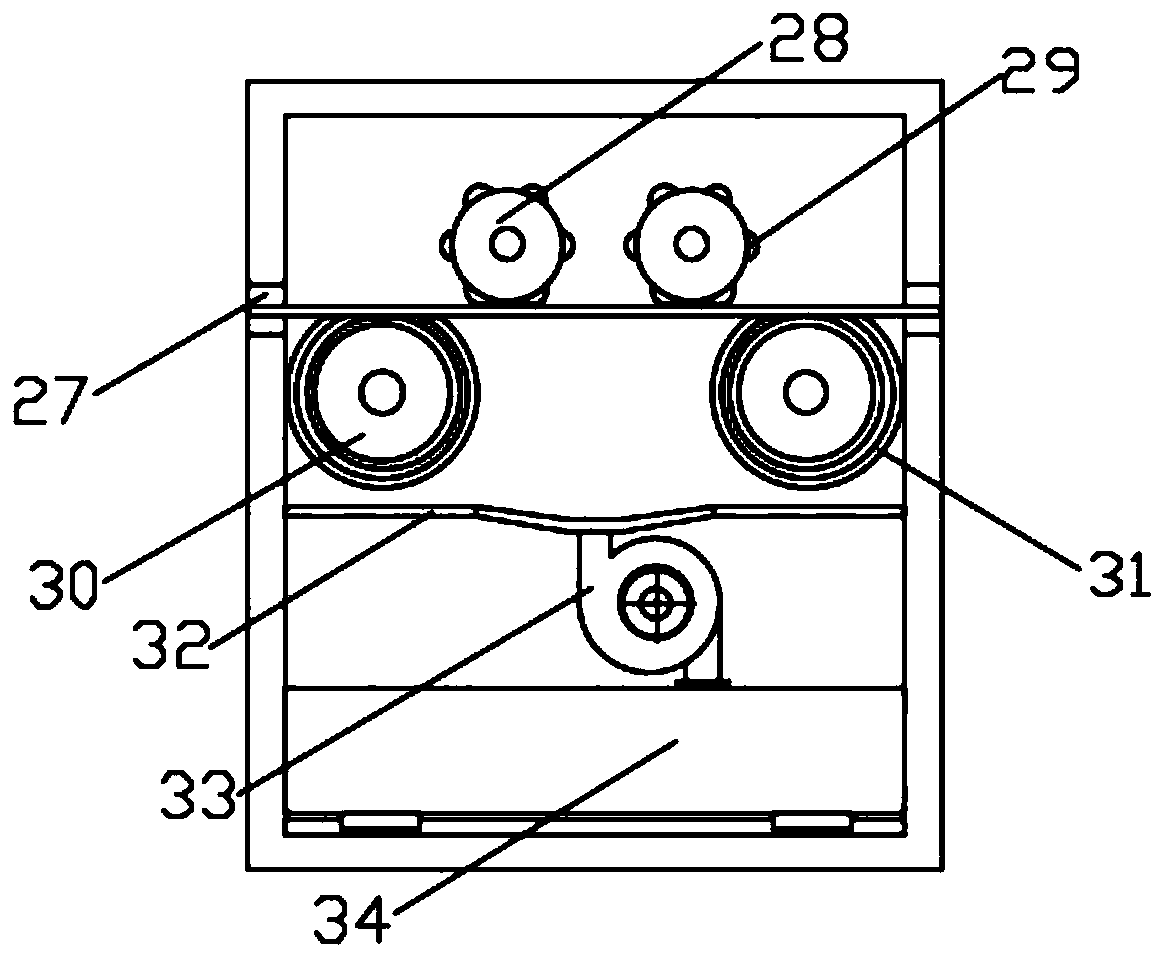

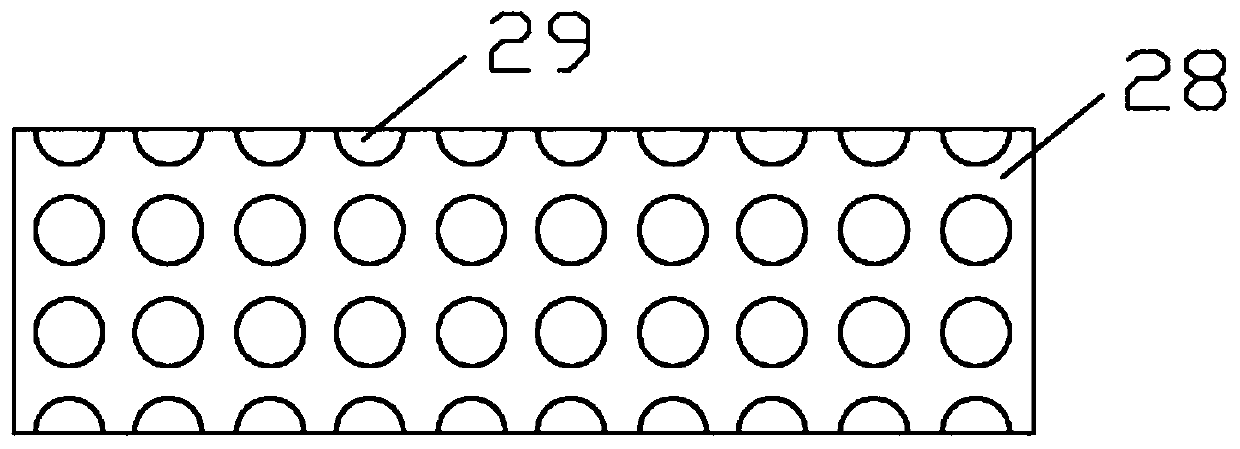

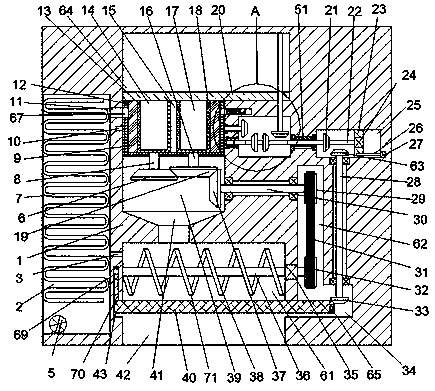

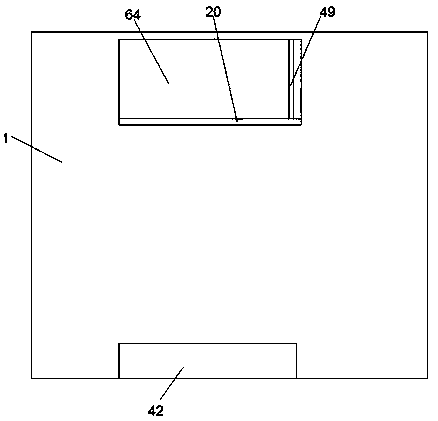

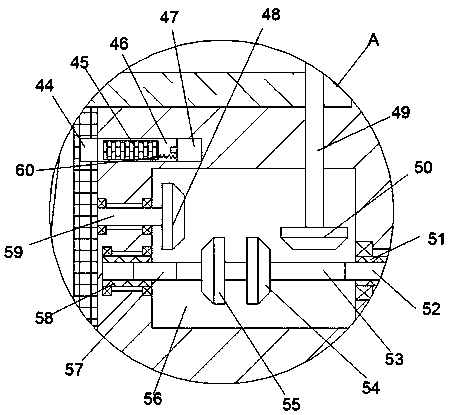

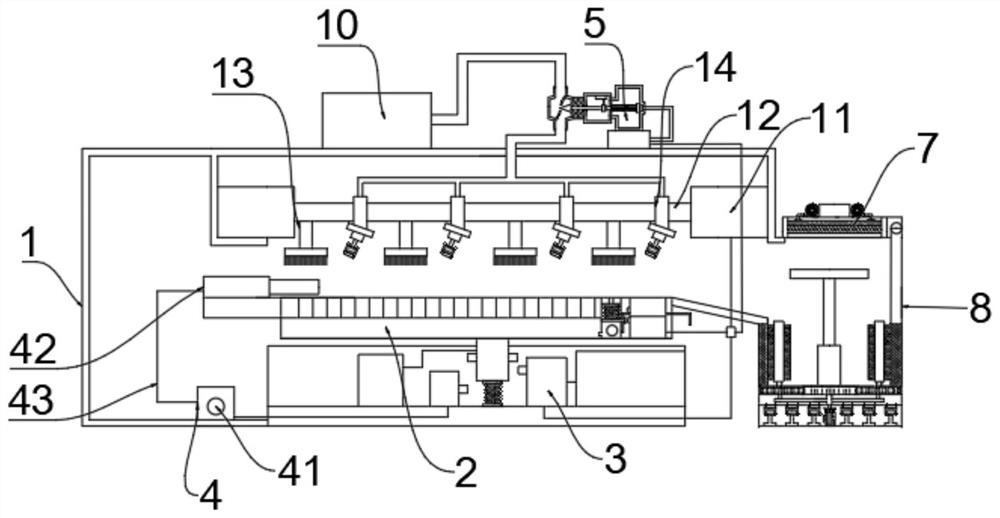

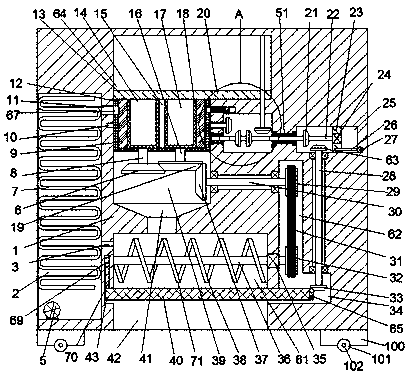

Energy-saving and environmental-friendly drying device

InactiveCN108286895AIncrease travel distancePreheatingBatteries circuit arrangementsDrying gas arrangementsDrive wheelContact time

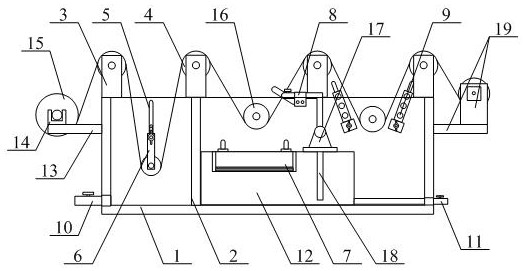

The invention discloses an energy-saving and environmental-friendly drying device. The energy-saving and environmental-friendly drying device comprises a drying tank, a spiral conveying tank and a battery box, wherein a humidity sensor is fixedly connected to the left end of the top part of an inner cavity of the drying tank; a temperature sensor is fixedly connected to the top end of the inner cavity of the drying tank and located on the right side of the humidity sensor; and a first driving wheel and a first driven wheel are sequentially and movably arranged at the upper end of the inner cavity of the drying tank from left to right. According to the energy-saving and environmental-friendly drying device provided by the invention, through the functions of the first driving wheel, the first driven wheel, a second driving wheel, a second driven wheel, a third driving wheel, a third driven wheel, a circulating fan, an air inlet pipe and an air outlet pipe, a displacement distance of a material in the drying tank can be effectively increased, the contact time of the material and hot air in the drying tank is longer, meanwhile, the hot air flow rate in the drying tank can be further improved, the material in the spiral conveying tank can be preheated, and the material drying efficiency is effectively improved.

Owner:罗金山

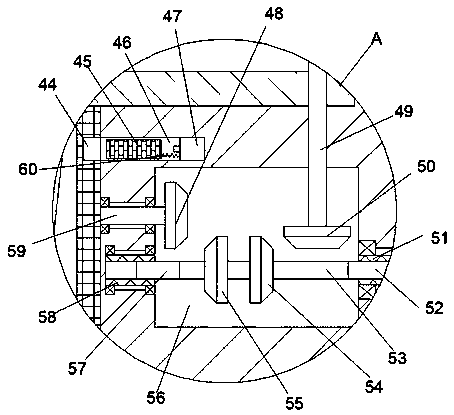

Biomass power generation device and method

The invention discloses a biomass power generation device and method. The device comprises a pulverizer and a stirling generator. A feeding opening is formed in the top end in the pulverizer, a pulverizing blade is arranged on the outer side of a pulverizing roller, the left side of a forming machine is connected with the top end of a raw material pushing machine, the upper portion of the left side of a combustor is arranged on the top end of a conveying belt, and the stirling generator is located on the outer side of the combustor. According to the biomass power generation device and method,raw material pushing is facilitated, conveying work and drying work are synchronously carried out, pressure of raw material extrusion forming can be conveniently ensured, stability after raw materialextrusion forming is ensured, the raw material is not prone to scattering, sufficient combustion of the raw material can be ensured, sufficient using of the raw material is ensured, power generation quality is ensured, production efficiency is improved, waste water, waste gas and waste slag can be treated, pollution emissijon can be reduced, and clean production is facilitated.

Owner:大唐长春热力有限责任公司

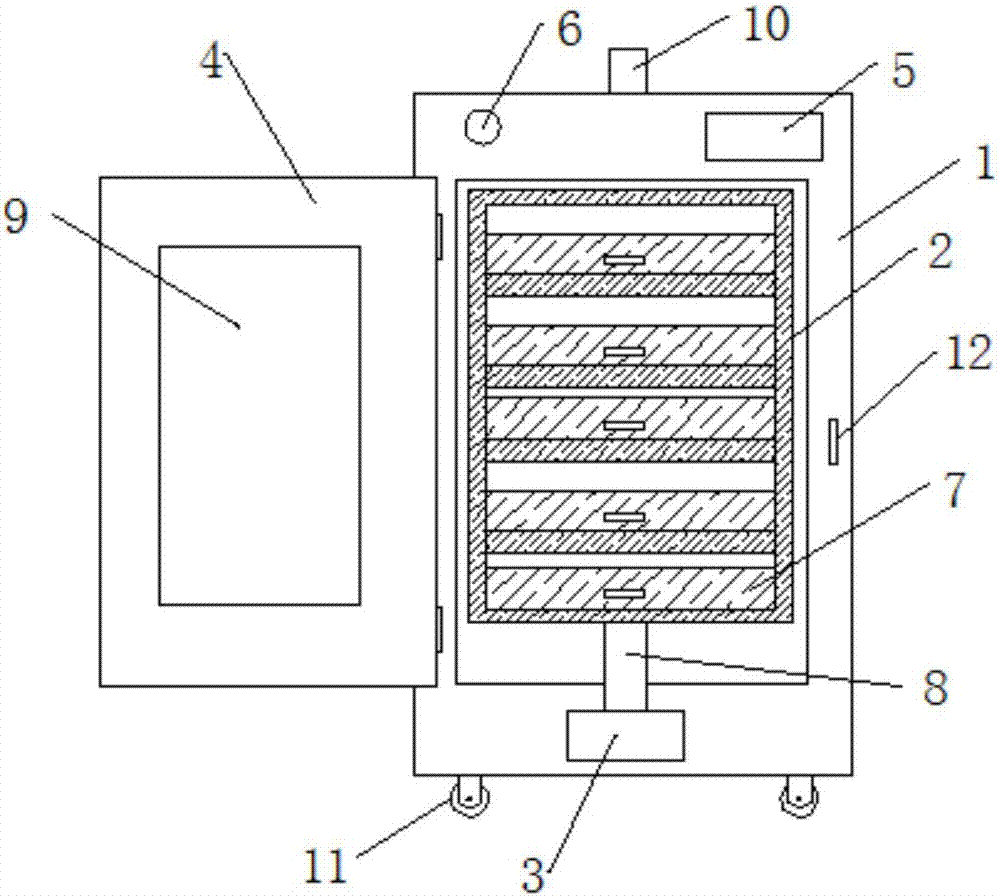

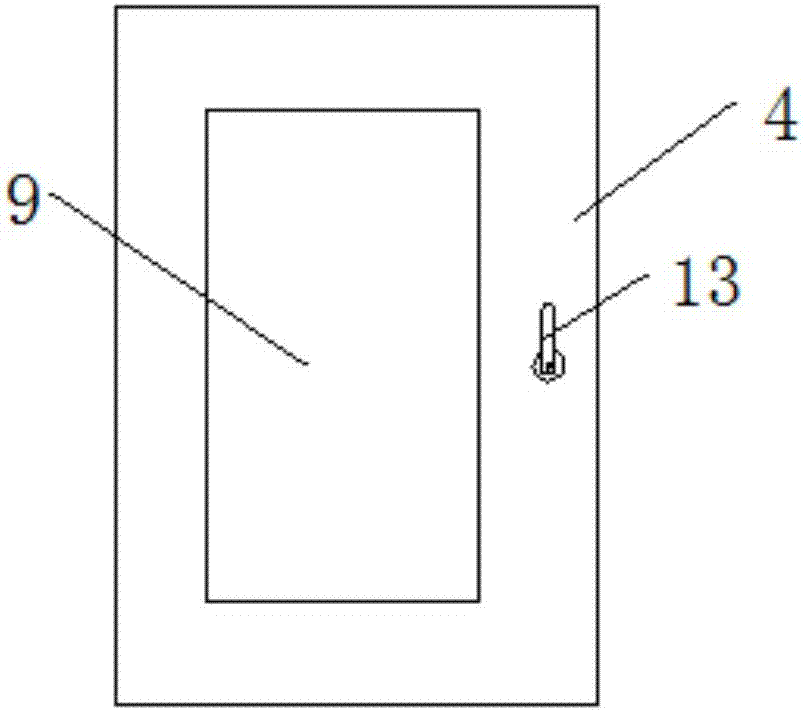

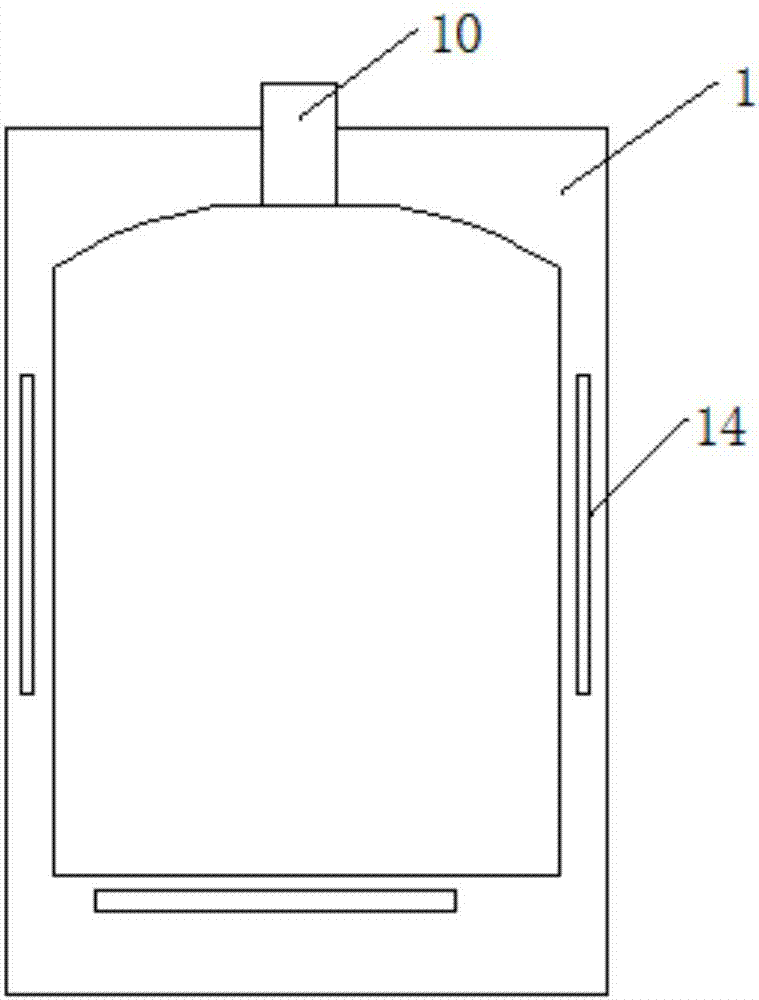

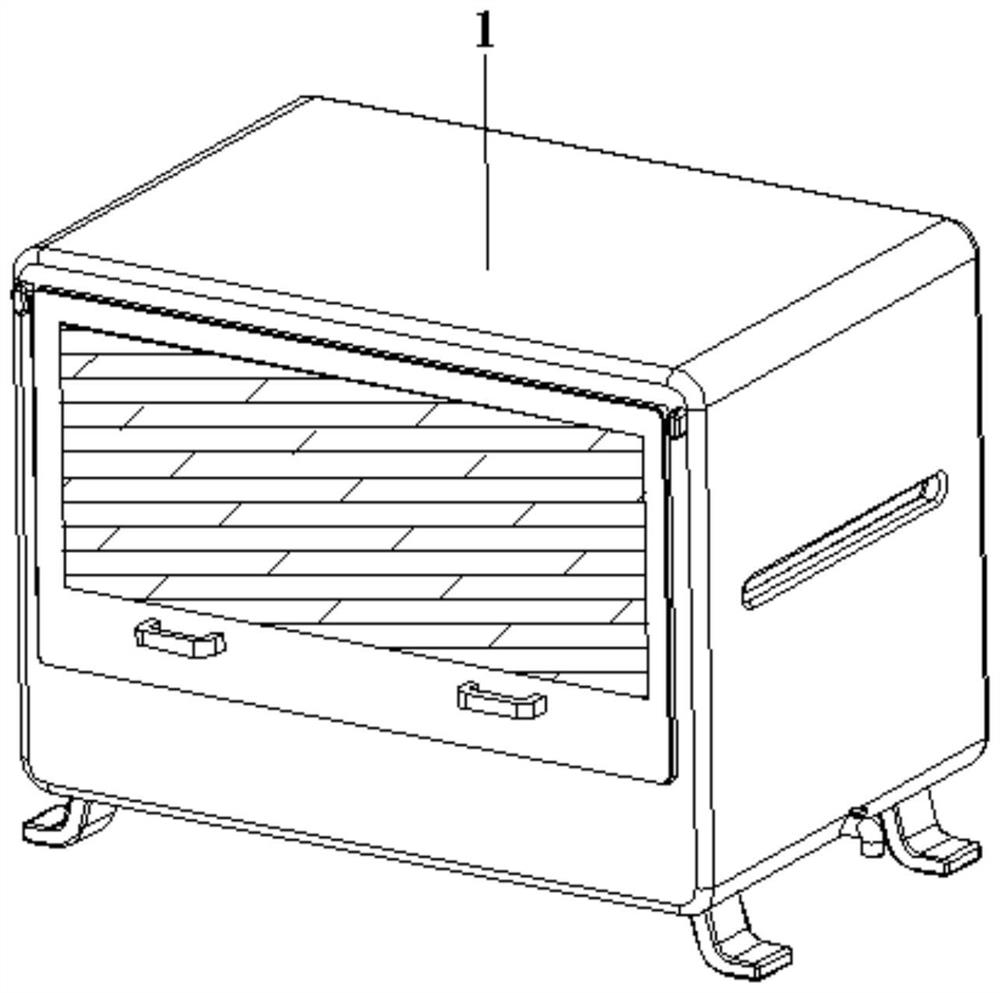

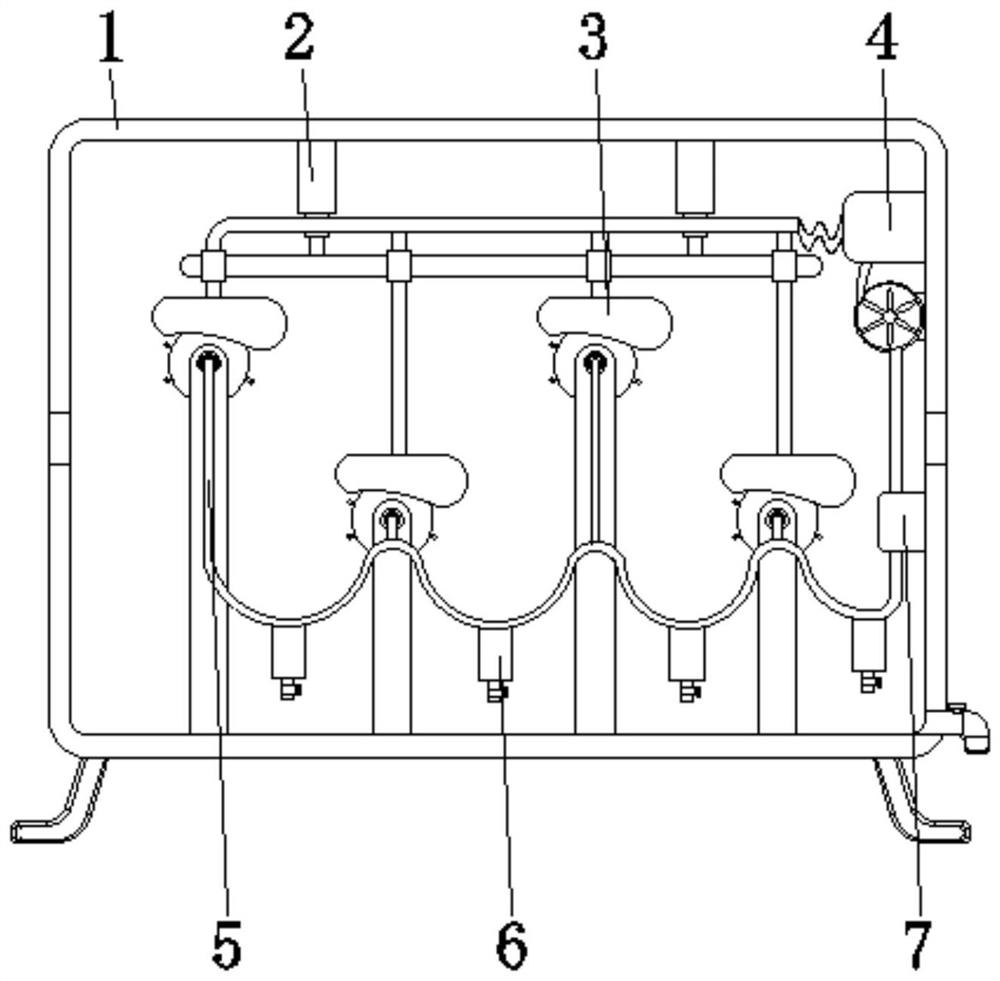

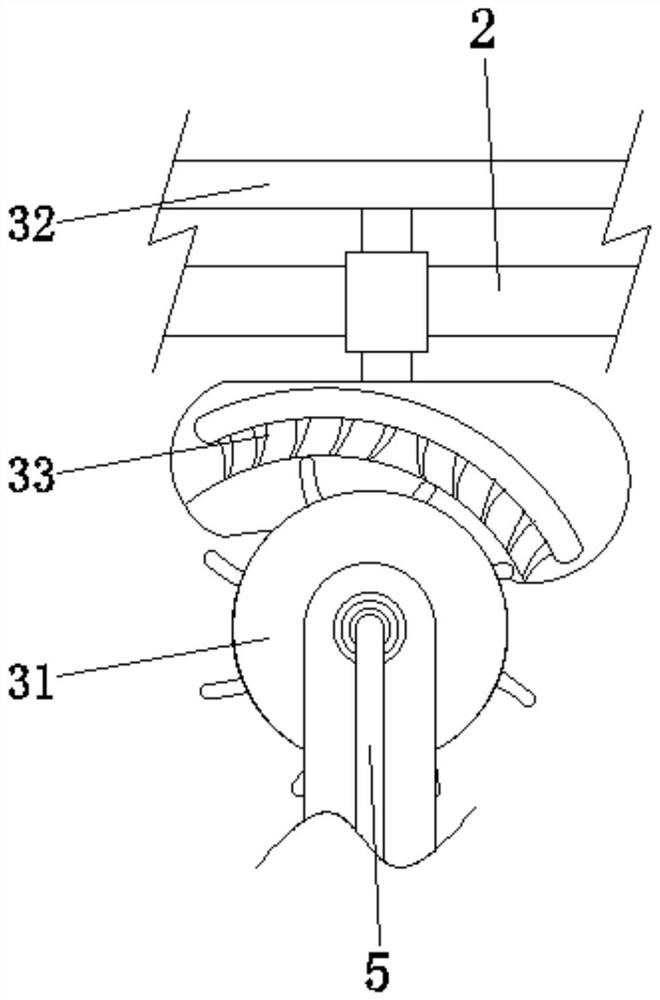

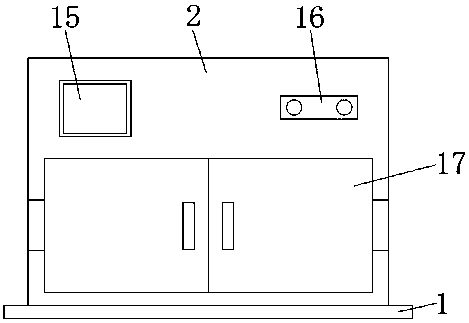

Efficient tea leaf drying device

InactiveCN108007140AConvenient drying workEvenly heatedPre-extraction tea treatmentTea dryingEngineeringExhaust pipe

The invention discloses an efficient tea leaf drying device comprising a box, a drying frame and a speed reduction motor. The drying frame is arranged in an inner cavity of the box. The speed reduction motor is fixedly installed at the bottom of the box. The speed reduction motor is rotationally connected with the drying frame through a rotating shaft. The top end of the rotating shaft is fixedlyconnected with the lower bottom end of the drying frame. A plurality of layers of drying trays are inserted in the drying frame from top to bottom. An exhaust pipe is fixedly installed on the top of the box. A cabinet door is hinged to one side of the box. A clamp strip is hinged to the outer surface of the cabinet door. A clamp block matched with the clamp strip is arranged on the box. The clampblock is connected with the clamp strip in a clamped manner. A power switch and a control panel are installed at the upper end of the box in an embedded manner. Electric heating resistor wires are installed on the side walls of the box in an embedded manner. The electric heating resistor wires and the speed reduction motor are both electrically connected with the control panel. The efficient tea leaf drying device is ingenious in concept, reasonable in design, small in size and high in flexibility and practicability and greatly facilitates the drying work of the tea leaves.

Owner:CHONGQING DINGQING TEA IND CO LTD

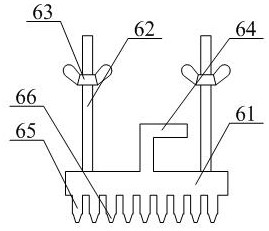

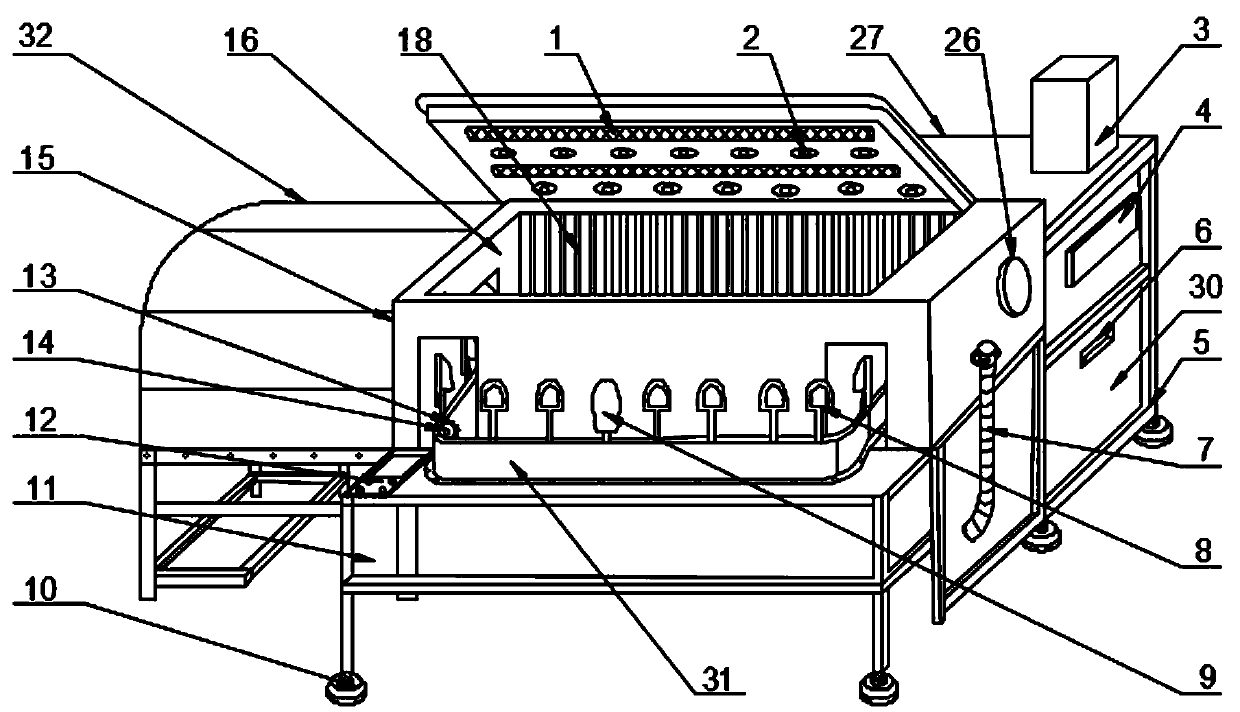

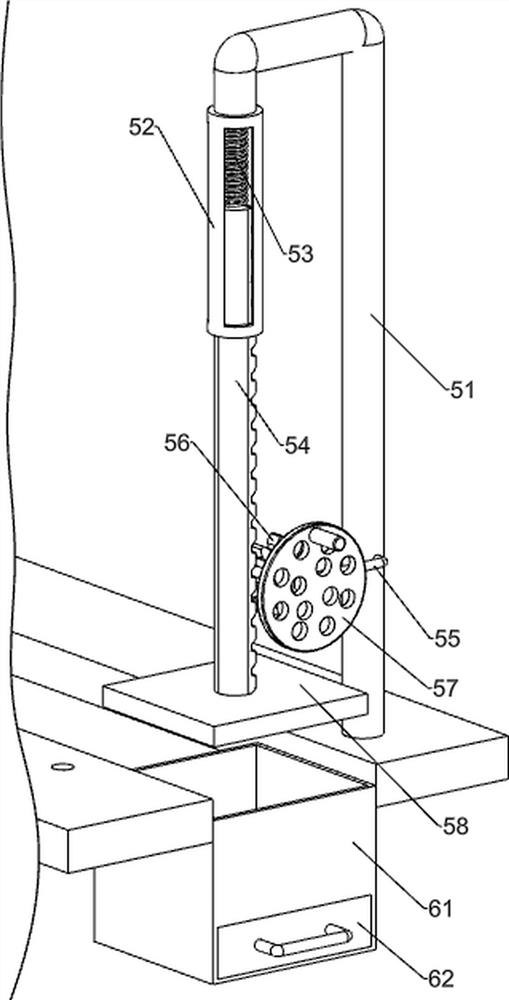

Old template cleaning machine

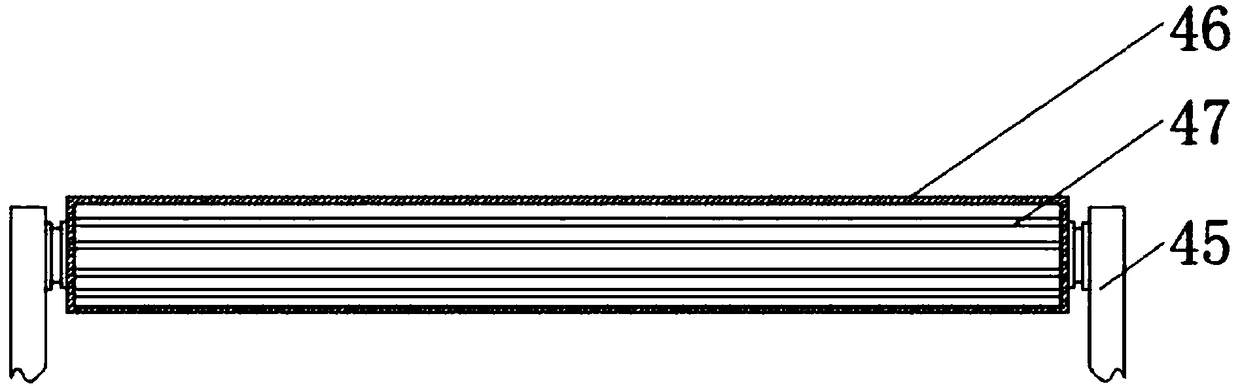

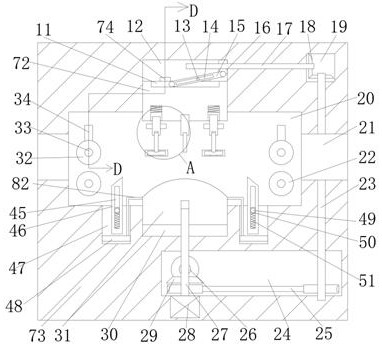

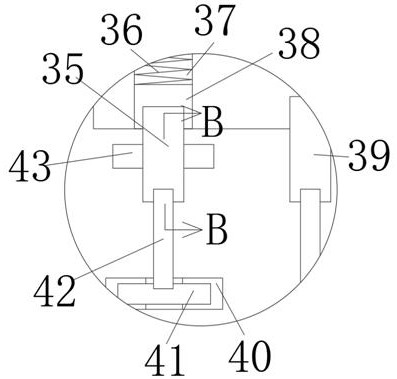

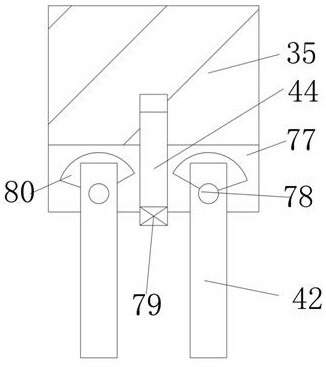

InactiveCN112482757AGood for washingEasy to wipe downDrying solid materials with heatDrying solid materials without heatStructural engineeringMechanical engineering

The invention provides an old template cleaning machine. The old template cleaning machine comprises a cleaning frame, a cleaning hole, a guide roller, a cleaning cover, a fixed cover, a liftable flushing box structure, a rotatable adjusting brushing base structure, a shielding insulation drying cover structure, an insertion filter collecting frame structure, a U-shaped base, a support pipe, an inverted T-shaped base, a first flushing box, a flushing pump, a conveying pipe and a connecting hose, wherein the cleaning hole is formed in the middle position in the cleaning frame; and the guide roller is axially connected into the cleaning hole in sequence from left to right. Through cooperative arrangement of a second flushing box, a connecting pipe, a flushing pipe, a flushing nozzle, the first flushing box, the flushing pump, the conveying pipe and the connecting hose, water is conveyed into the second flushing box through the flushing pump in the use process and is sprayed out by the flushing pipe and the flushing nozzle, so that templates are conveniently flushed in work.

Owner:山东双端数字科技有限公司

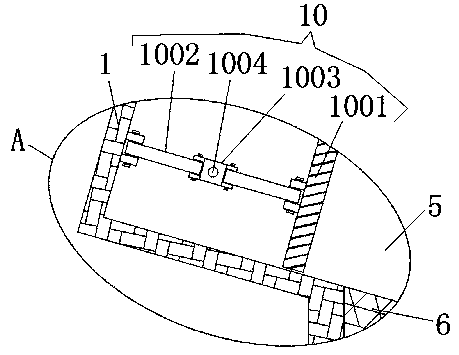

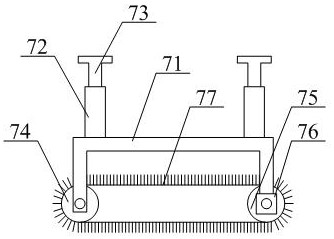

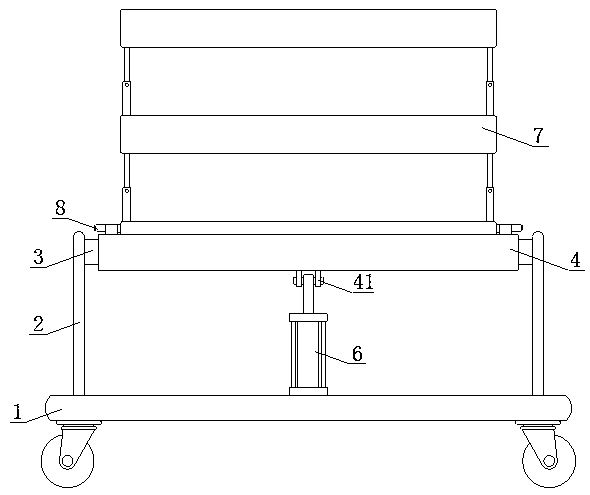

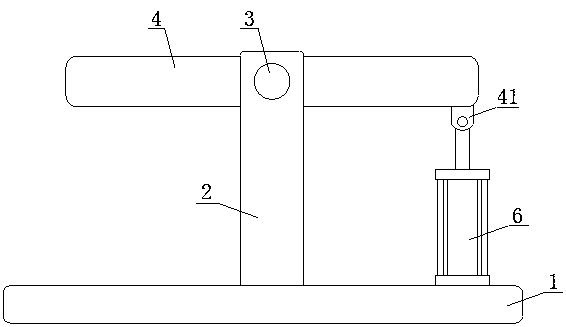

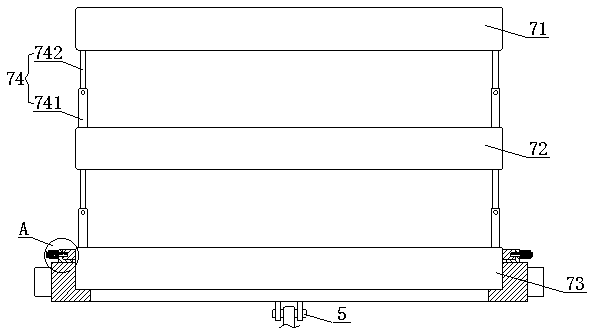

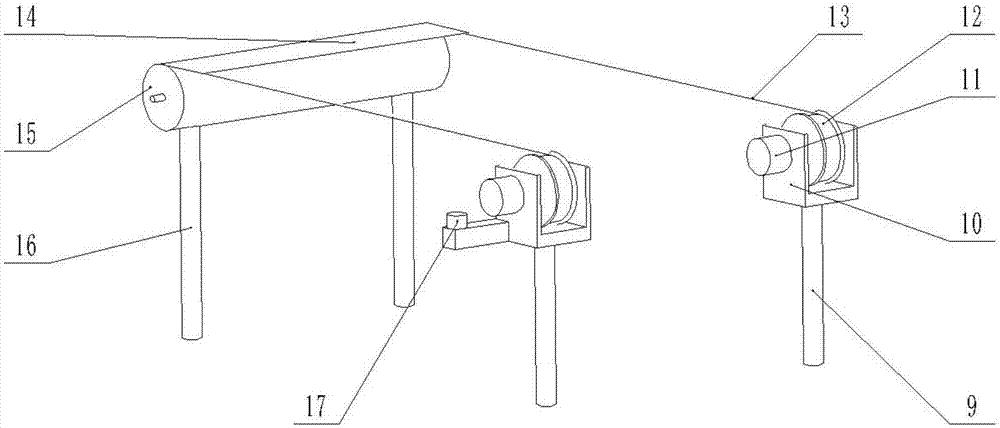

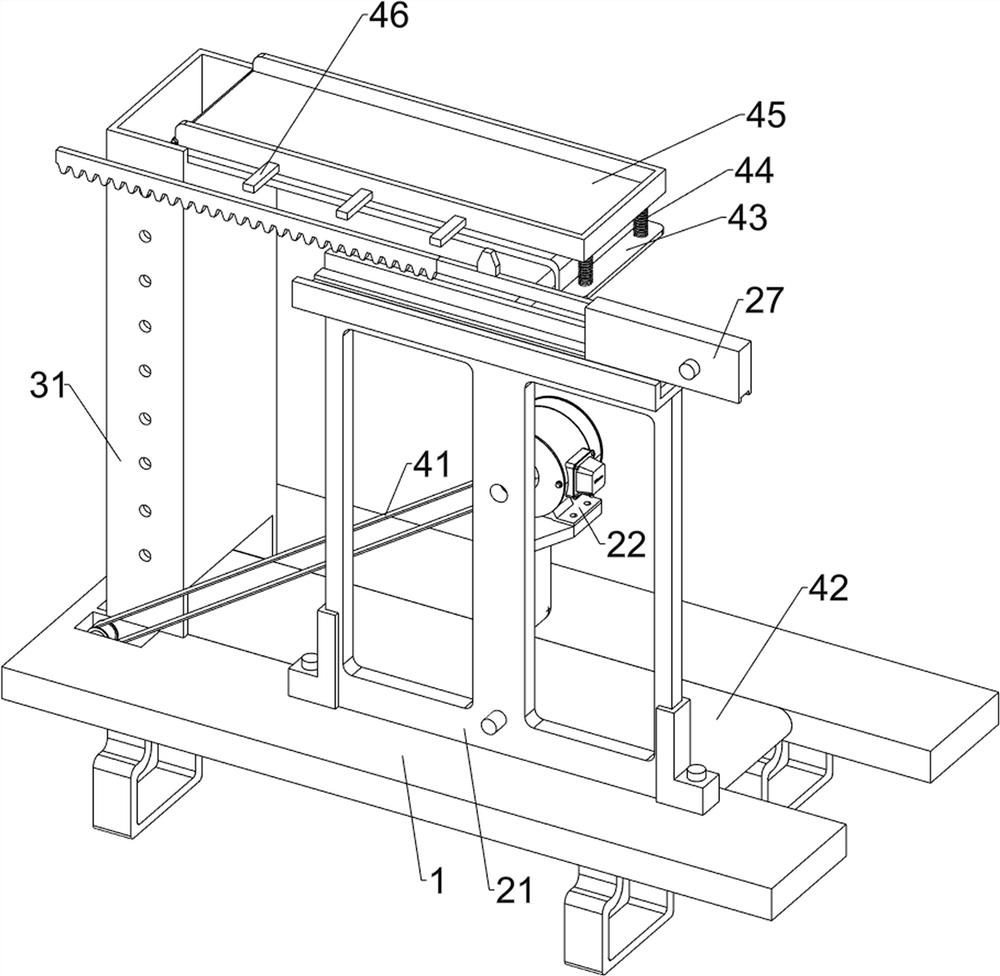

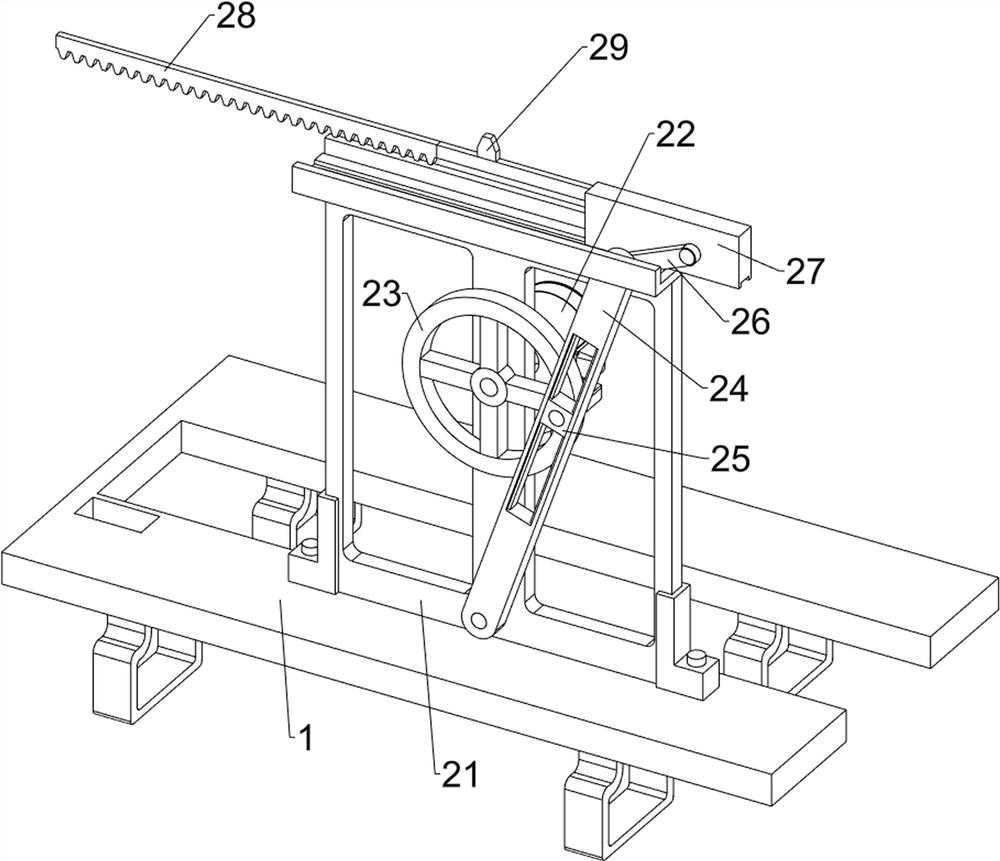

Angle-adjusted layered dried orange peel airing frame

InactiveCN110779289AGood drying effectImprove drying efficiencyDrying machines with local agitationDrying machines with materials at restEngineeringStructural engineering

The invention discloses an angle-adjusted layered dried orange peel airing frame. The angle-adjusted layered dried orange peel airing frame comprises a base; a support column is arranged on the base,and is connected with a mounting frame through a support shaft; a connecting piece is arranged on the lower surface of the mounting frame, and is movably connected with a piston rod of a micro cylinder through a rotating shaft; and an airing mechanism is arranged on the mounting frame, and is connected with a limiting base mounted on the upper surface of the mounting frame through a connecting mechanism. The angle-adjusted layered dried orange peel airing frame can adjust the angle of the airing mechanism through the micro cylinder to achieve good airing effect and high airing efficiency, andcan adjust gaps among an upper-end airing layer, a middle-end airing layer and a lower-end airing layer according to actual demands to achieve the airing work; after completion of airing, a support inner sleeve can be stored into a support outer sleeve, so that the airing mechanism is small in total size and convenient to store; and through a connecting mechanism, the airing mechanism is installedor disassembled conveniently, so that later cleaning of the airing mechanism is convenient.

Owner:江门市新会区和昌隆陈皮茶制品有限公司

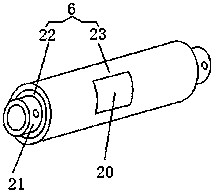

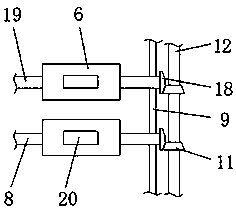

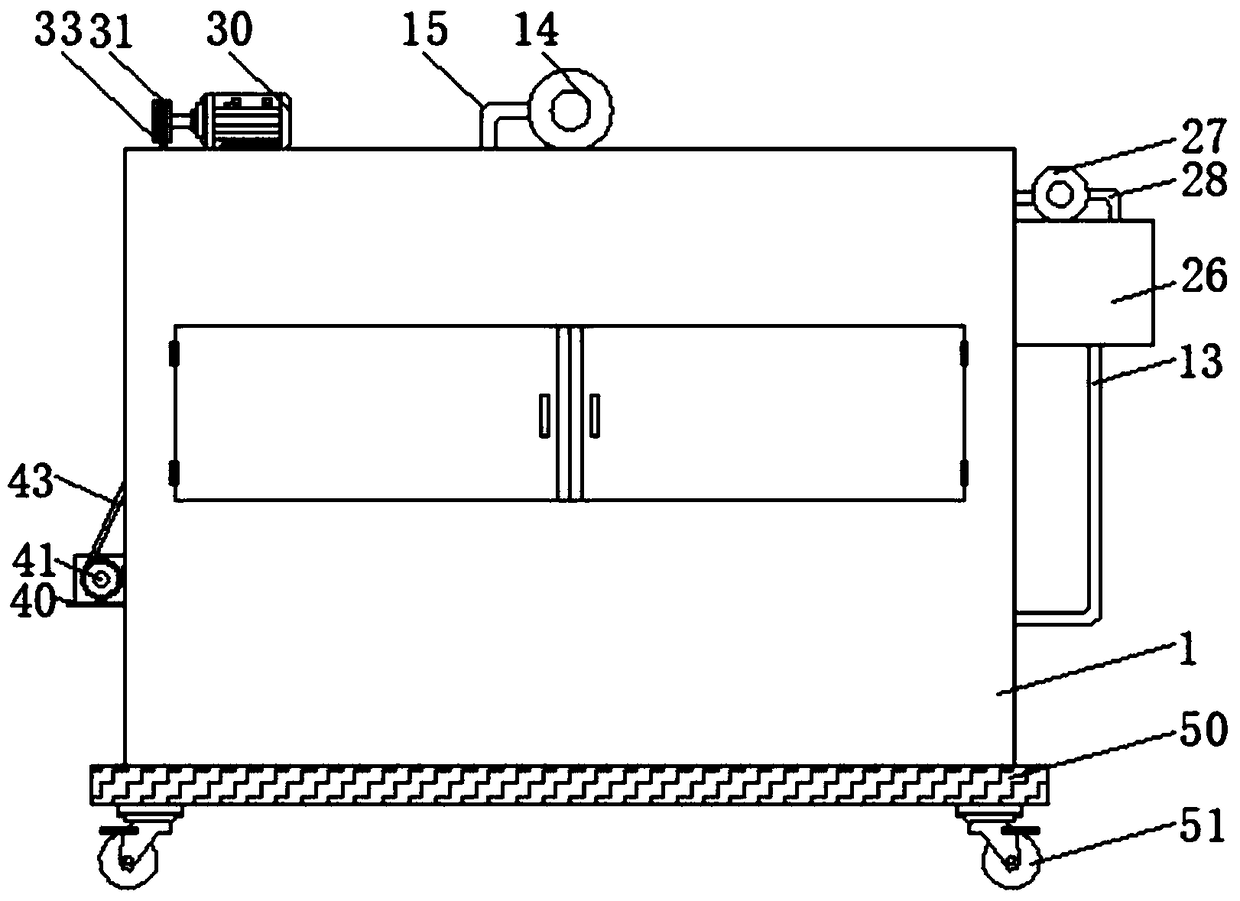

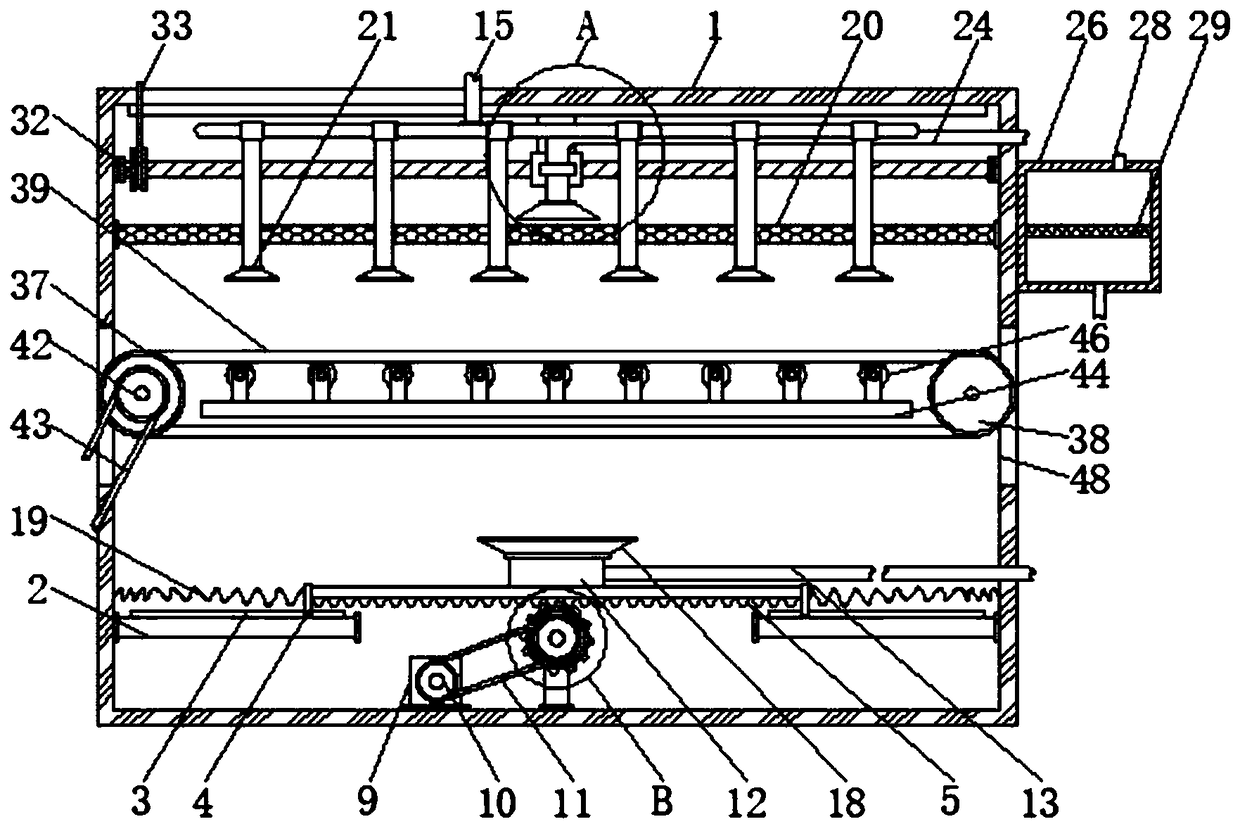

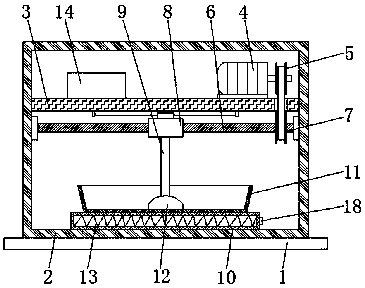

Drying device for plywood production

InactiveCN110671913AGuaranteed fixed effectConvenient drying workDrying gas arrangementsDrying machines with non-progressive movementsElectric machineDrive shaft

The invention discloses a drying device for plywood production. The drying device comprises a box body and a heating air-blowing mechanism, wherein the middle position of the top outer wall of the boxbody is fixedly equipped with a motor box through a bolt; a motor is fixedly arranged on the bottom inner wall of the motor box through a bolt; one end of the output shaft of the motor is in key connection with a transmission shaft; one end of the transmission shaft is positioned inside the box body; one end of the transmission shaft is in sleeve connection with a first bearing; the bottom end ofthe first bearing is welded with a fixed plate; the middle position of the bottom inner wall of the box body is welded with a second bearing; a connecting shaft is spliced on the peripheral inner wall of the second bearing; and the top end of the connecting shaft is welded with a supporting plate. According to the drying device for plywood production disclosed by the invention, one end of plywoodwith specified thickness is separately put into a blocking slot plate, an electric telescopic pole is started, the electric telescopic pole drives a pressure plate to move downwards to be in contactwith the top end of the plywood for extruding and fixing the plywood, so that fixation of each wooden board is guaranteed, and wooden boards are not in contact, and therefore, drying work is convenient.

Owner:湖北天莱木业有限公司

Intelligent multifunctional airing device

ActiveCN106969615AConvenient drying workPrevent oversunDrying gas arrangementsDrying machines with non-progressive movementsMicrocontrollerEngineering

The invention discloses an intelligent multifunctional airing device, and belongs to the field of daily necessities. Damping springs are fixed to a base. A vibration platform is fixed to the upper ends of the damping springs. Vibration motors are arranged below the vibration platform. An air blower supporting plate is hinged to one side of the vibration platform. An air blower is fixedly connected to the upper portion of the air blower supporting plate. Automatic unloading shafts are installed in the vibration platform. An airing plane is installed between the two automatic unloading shafts. Winding motors are installed on one sides of motor fixing supports, output shafts of the winding motors are connected with wire winding wheels, steel wire ropes are wound on the surfaces of the wire winding wheels, and weather cloth is connected with the steel wire ropes. According to the intelligent multifunctional airing device, a coordination part can work automatically through various sensors and a single chip microcomputer control module, grain airing is greatly facilitated, the labor force is liberated, and the problems of preventing rain, excessive airing and the like of crops are solved.

Owner:宣城金博伟家居智能科技有限公司

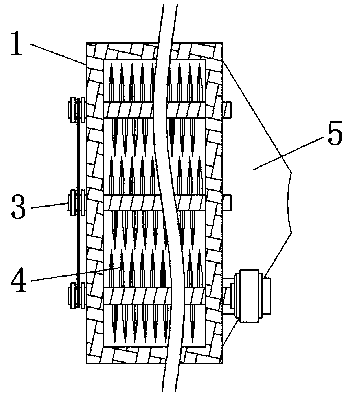

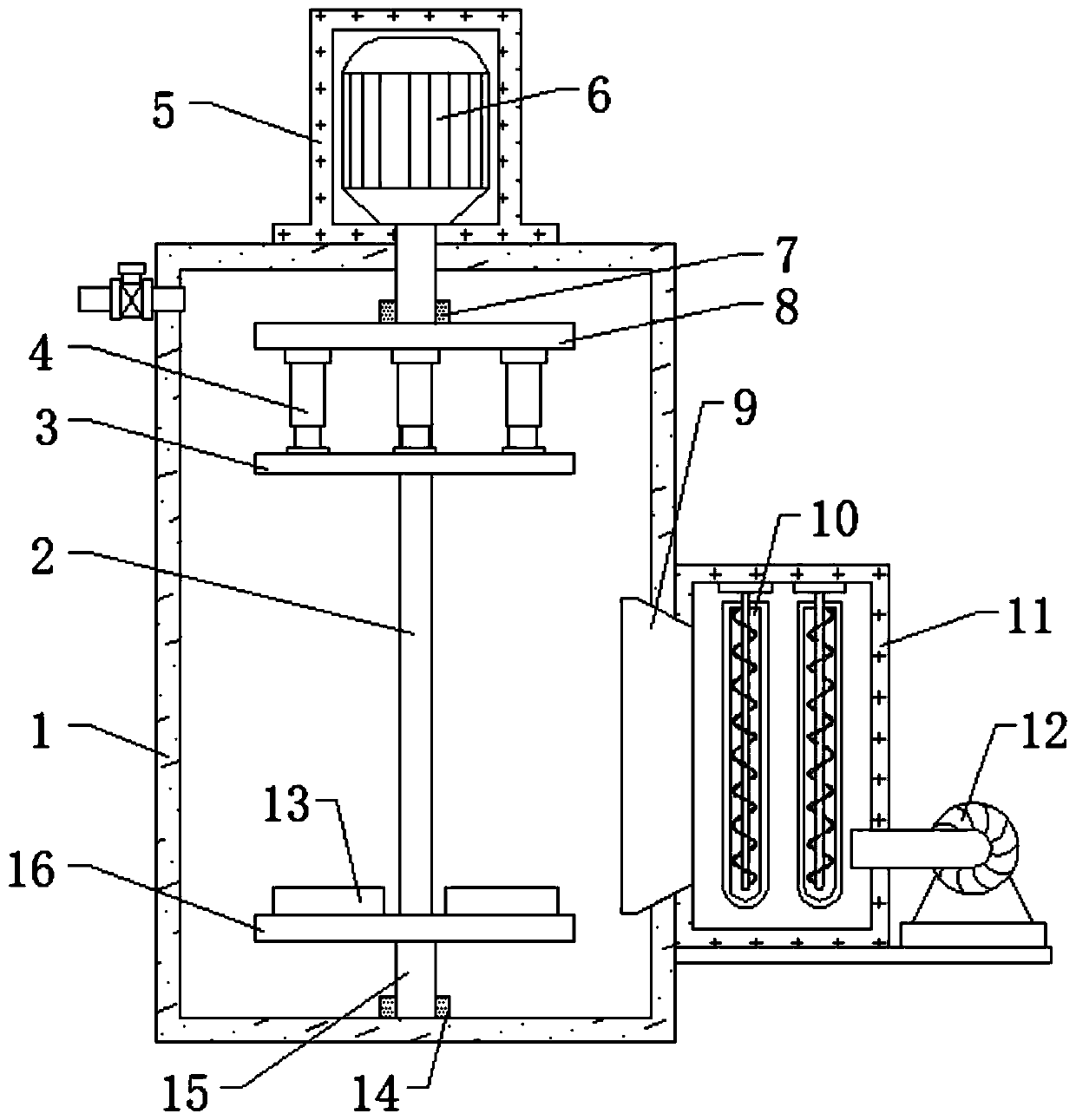

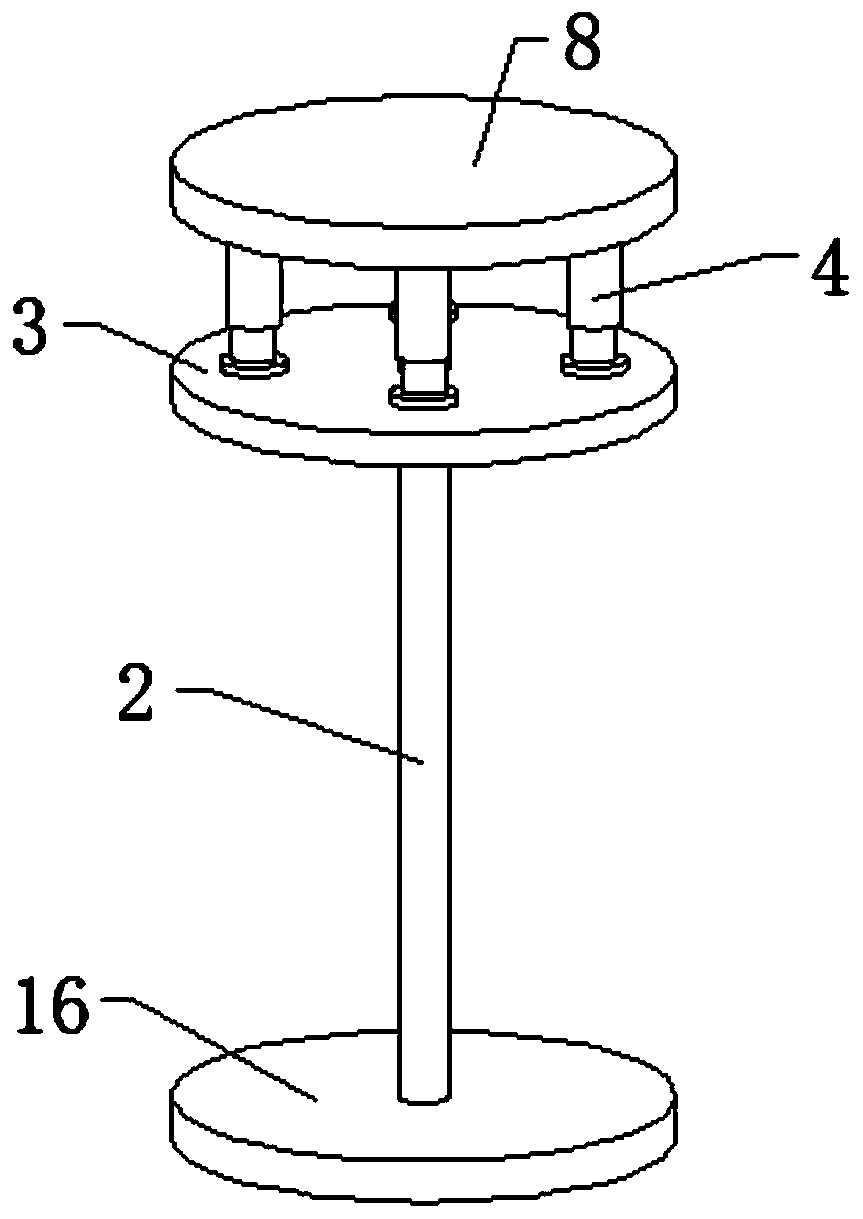

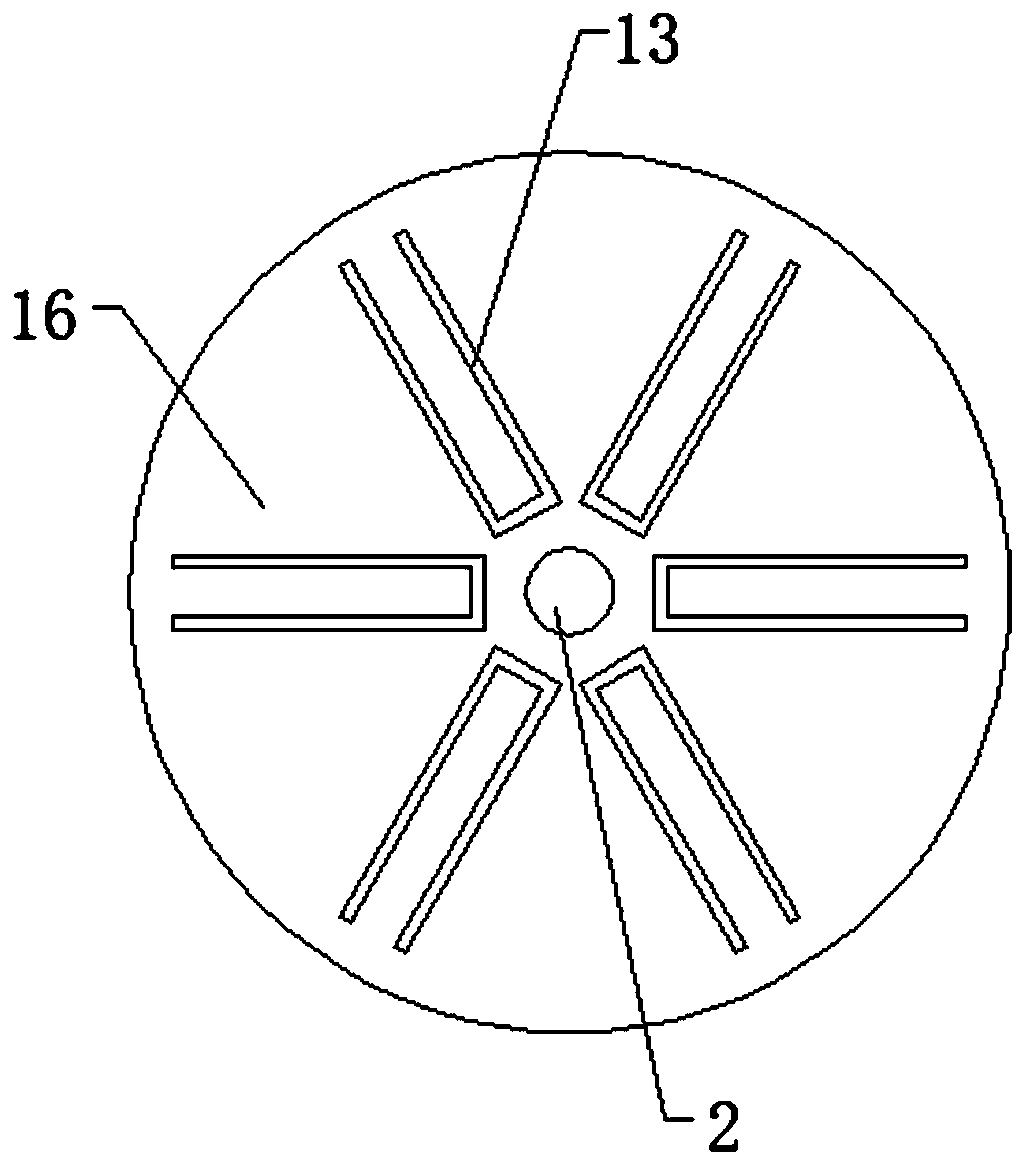

Rapid drying device for bamboo chopsticks

PendingCN108679962AUniform temperatureSimple and reasonable structureDrying gas arrangementsDrying machines with non-progressive movementsEngineeringDrive shaft

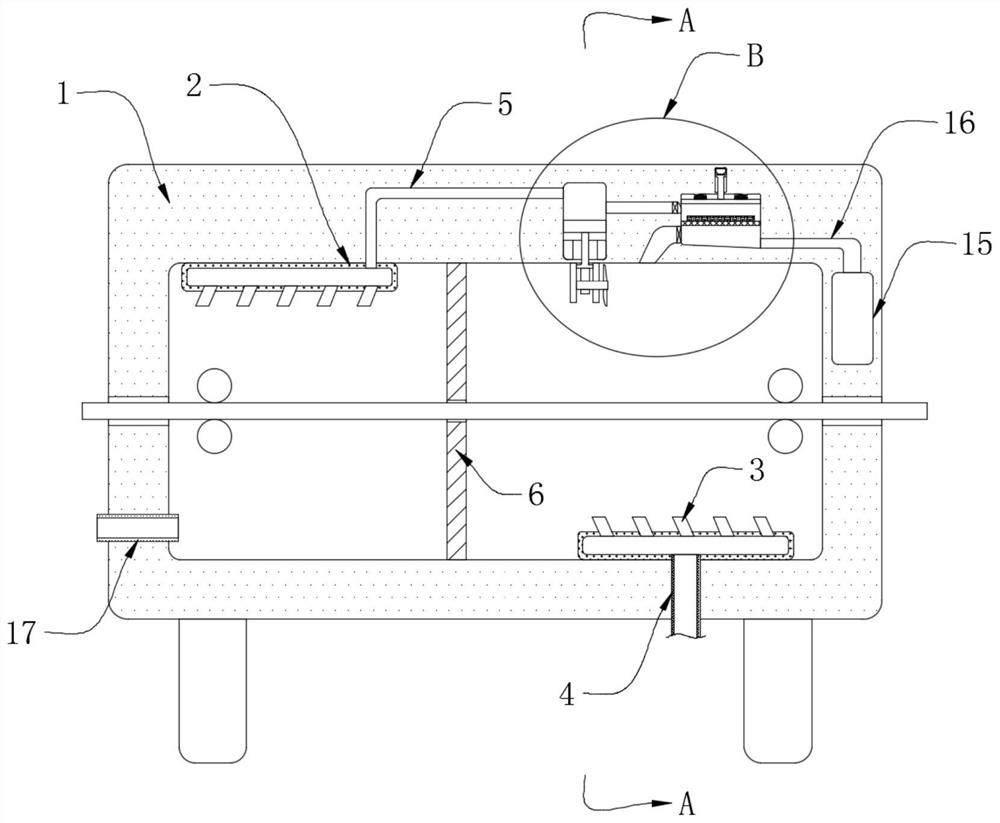

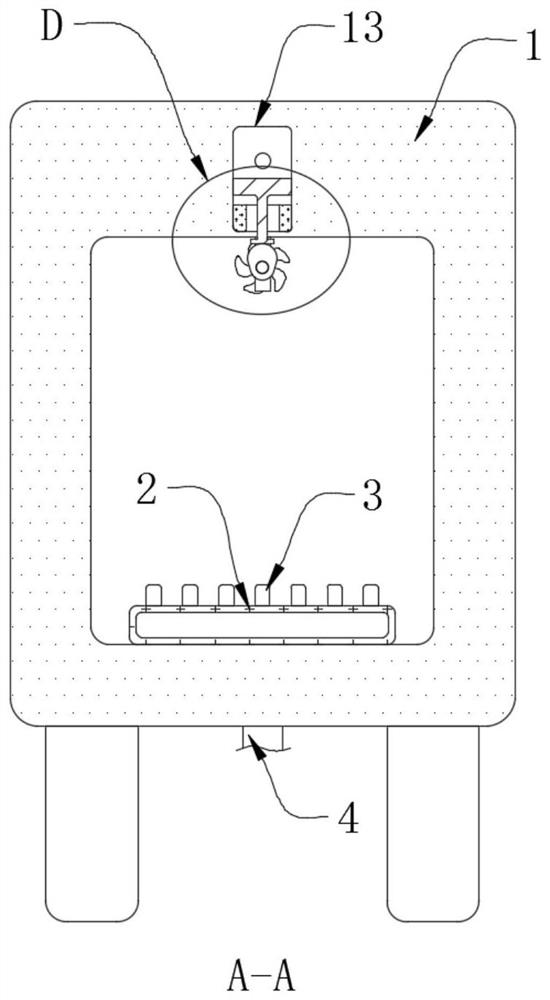

The invention discloses a rapid drying device for bamboo chopstick. The rapid drying device comprises a device body, the device body is internally provided with two groups of raised vertical partitionplates, and the internal space of the device body is divided into a dehumidifying chamber, a drying chamber and a drive chamber by the two groups of partition plates. The drive chamber is internallyprovided with a group of raised vertical drive shafts, the bottom ends of the drive shafts are rotatably installed at the bottom end of the drive chamber through bearings, and the top ends of the drive shafts penetrate through the top end of the drive chamber and are fixedly connected with the output end of a rotating motor. The rotating motor is fixed to the top end of the device body, and two groups of first bevel gears are fixedly installed on circumferential rod bodies of the drive shafts. A first rotating shaft and a second rotating shaft are sequentially and horizontally arranged in thedrying chamber from bottom to top, and the left end of the first rotating shaft and the left end of the second rotating shaft are rotatably installed on the first group of partition plates through bearings. The rapid drying device for the bamboo chopsticks has the advantages of high drying efficiency and good drying effect, and can be widely promoted and used.

Owner:湖南奇宏林业股份有限公司

Cloth dryer for knitted fabric production

InactiveCN109341304AImprove work efficiencyEfficient dryingDrying gas arrangementsDrying machines with progressive movementsEngineering

The invention discloses a cloth dryer for knitted fabric production and relates to the technical field of cloth production. The cloth dryer for knitted fabric production comprises a tank; transverse boards are fixedly connected to the bottoms of the two sides of the inner wall of the tank; sliding rails are fixedly connected to the tops of the two transverse boards; sliding blocks are slidably connected to the tops of the two sliding rails; a toothed board is fixedly connected between the opposite sides of the two sliding blocks; a vertical board is fixedly connected to the bottom of the innerwall of the tank; and the surface of the vertical board is rotationally connected with a gear meshing with the toothed board. According to the cloth dryer for knitted fabric production, as the top ofthe toothed board is fixedly connected with a vertical pipe, knitted fabric can be quickly and efficiently dried, and therefore, great convenience is brought to workers during knitted fabric drying;and as the top of one side of the tank is fixedly connected with a filter tank, the loss of heat is reduced, heat can be recycled, the resources are greatly saved, and reasonable utilization of the resources is achieved.

Owner:宜城成雄织造有限公司

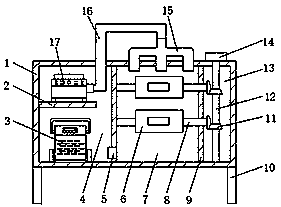

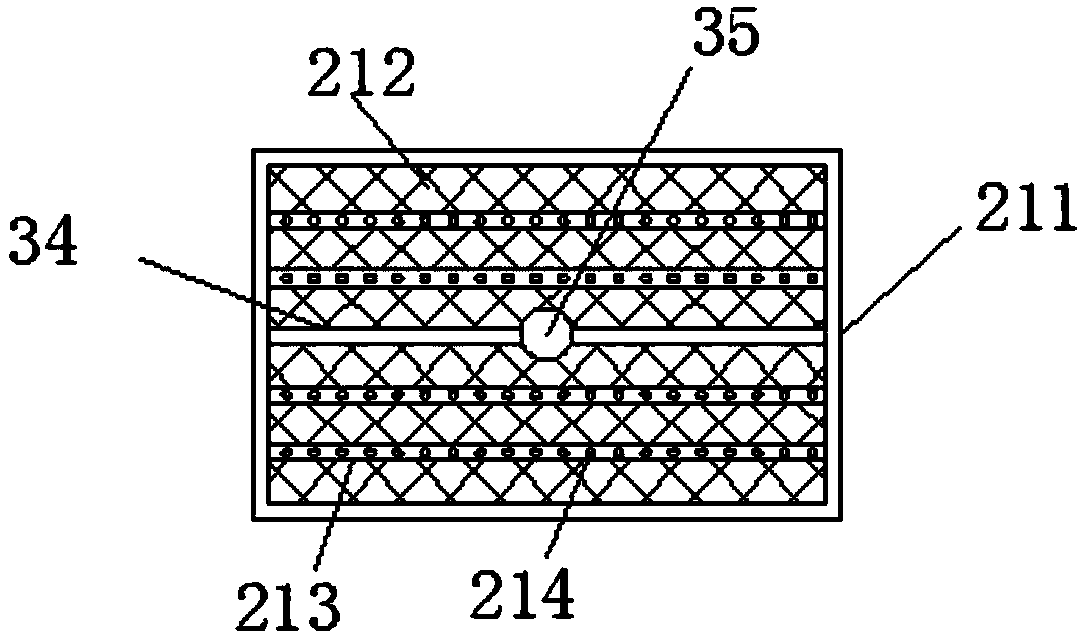

Textile drying control detection device

InactiveCN112082356ASimple structureEasy to operateTextile testingDrying machines with progressive movementsStructural engineeringMechanical engineering

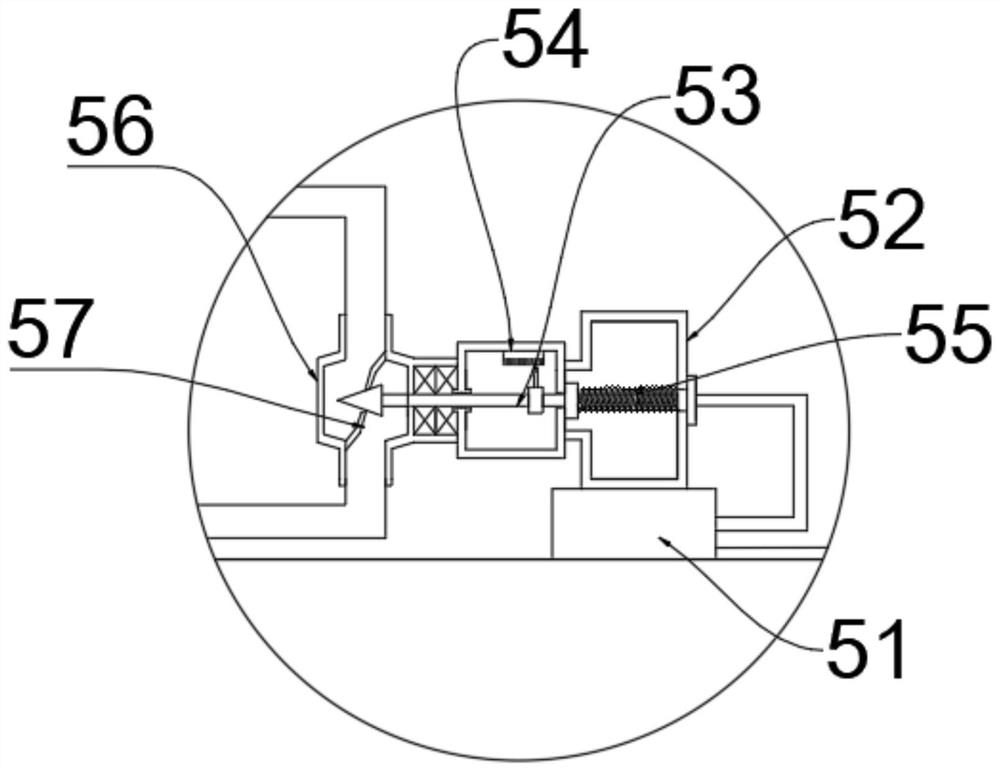

The invention discloses a textile drying control detection device. The textile drying control detection device comprises a box body, wherein a working cavity is formed in the box body; the left side and the right side of the working cavity are communicated with through holes penetrating through the box body; a lifting groove with an upward opening is formed in the bottom wall of the working cavity; a cambered surface block is mounted in the lifting groove in a sliding manner; reciprocating swing grooves with upward openings are symmetrically formed in the bottom wall of the working cavity andin the left side and the right side of the lifting groove; swing shafts extending front and back are rotationally mounted on the rear side walls of the reciprocating swing grooves; the swing shafts are connected with inclined surface swing rods extending into the working cavity; movable grooves penetrating front and back are formed in the inclined surface swing rods; the swing shafts are fixedly connected with fixed blocks in the inclined surface swing rods; and the fixed blocks are in sliding fit with the inner walls of the movable grooves. The device is simple in structure and convenient tooperate; a movable roller and the inclined surface swing rods move through movement between the cambered surface block and a supporting block, so that textiles are supported and fixed.

Owner:台州椒江迈进针织有限公司

Antibacterial and disinfectant ultra-soft floor wet wipe and preparation method thereof

The invention discloses an antibacterial and disinfectant ultra-soft floor wet wipe and a preparation method thereof. Antibacterial and disinfectant liquid prepared by uniformly mixing cetyl pyridinium chloride, phenoxyethanol, glycerol, benzalkonium chloride, chamomile extracting solution, olive oil, citric acid and deionized water has god sterilization and disinfection effects; meanwhile, a carding fiber net, a modified hot melt fiber net, a hot rolled fiber net absorption layer and a water absorption fiber layer are subjected to spunlace reinforcement so that the winding of the whole is firm; no layering phenomenon occurs; and a prepared semi-finished product wet wipe has good permeability and softness. The antibacterial and disinfectant liquid at the bottom of a dip dyeing box is pumped by a water pump and is discharged to a connecting pipe through a liquid extraction pipe; the antibacterial and disinfectant liquid enters a liquid discharging pipe through the connecting pipe; an output shaft of a second motor drives a driving shaft to rotate; the driving shaft drives a shaft sleeve arranged on the surface to rotate; the shaft sleeve drives a stirring rod to stir the antibacterial and disinfectant liquid; and meanwhile, a scale removal pad is driven to remove scales on the inner wall of the liquid discharging pipe.

Owner:铜陵麟安生物科技有限公司

Grain cleaning device with drying function

InactiveCN108787563AEasy to drySpeed up dryingDrying gas arrangementsCleaning using liquidsAgricultural engineeringHeater Rod

The invention discloses a grain cleaning device with a drying function. The grain cleaning device with a drying function comprises a shell and a material storage device, wherein a feeding hole is formed in the right side face of the shell, two cover plates are arranged on the right side face of the feeding hole, and the two cover plates are movably connected with the right side face of the shell through two hinges respectively, and the upper surface of the shell is fixedly connected with the lower surface of the driving device, rope discs are fixedly connected to the left end and the right endof the driving device, the outer surface of the rope disc is wound with a traction rope, and the traction rope is positioned in a through hole formed in the upper surface of the shell, and the bottomend of the traction rope is fixedly connected with the upper surface of the water tank. According to the cleaning device for the grain with the drying function, a water pump, a motor and a rope disc,a stay cord, a water pipe, a spray head, an air blower and a heating rod are arranged in a cooperating mode, the processing efficiency and the processing quality of people on the grains are improved,and therefore people can clean and dry the grains in real time, so that the labor cost is effectively saved, and the working efficiency of people is improved.

Owner:芜湖孺子牛节能环保技术研发有限公司

Drying box for textile fabric processing

PendingCN112923703AAchieve separationPlay a protective effectDrying gas arrangementsDrying chambers/containersEngineeringEnvironmental geology

The invention discloses a drying box for textile fabric processing. The drying box comprises a drying box body, wherein two air collecting blocks are arranged in the drying box body, a plurality of nozzles are arranged in the two air collecting blocks, an air inlet pipe communicating with the outside of the drying box body is inserted into the inner bottom of one air collecting block, a communicating pipe is inserted into the inner top of the other air collecting block, a partition plate is welded to the inner wall of the drying box, a treatment cavity with the inner bottom obliquely arranged is formed in the upper end of the drying box, the treatment cavity communicates with the drying box through an air inlet groove, and a treatment device is arranged in the treatment cavity. The drying box has the advantages that water in hot air flow is absorbed by utilizing the water absorption of sponge, and the water in the hot air flow can be quickly separated, so that the treated hot air flow does not contain water, water does not exist when the hot air is discharged, the environment around the drying box can be protected to a certain extent, and the sponge is used for absorbing water, so that the cost is lower.

Owner:何鑫鑫

Rapid drying device for LED shell machining material

InactiveCN112432484AImprove stabilityEnsure stabilityDrying gas arrangementsDrying machines with progressive movementsElectric machineRolling-element bearing

The invention discloses a rapid drying device for an LED shell machining material. The rapid drying device comprises a fixing frame, a conveying belt and fans, wherein sliding rails are arranged on the left side and the right side of the upper end of the inner side of the fixing frame, a supporting frame is arranged on the inner sides of the sliding rails, a fixing barrel is installed in the middle of the top end of the supporting frame, a rotating motor is installed in the middle of the top end of the fixing frame, and a threaded rod is installed at the front end of a rotating shaft of the rotating motor; first rotating frames are mounted in the middle of the bottom end of the supporting frame, a cylinder is installed on the inner side of each first rotating frame, a filter screen is installed at the top end of the inner side of each cylinder, a fan is installed in the middle of the inner side of each cylinder, heating wires are installed at the upper end and the lower end of each fan, and an air outlet is formed in the bottom end of each cylinder; and a guide rail and a rack are installed on the rear side of the bottom end of the supporting frame, a telescopic motor is arranged at the right end of the rack, second rotating frames and gears are installed on the outer side of the guide rail, rolling bearings are installed on the outer edges of the gears, and connecting rods aremounted on outer sides of the rolling bearings. The rapid drying device is reasonable in structure, LED shells can be conveniently fixed and dried, so that the drying is uniform, then the drying efficiency is effectively improved, and the drying effect is good.

Owner:SUZHOU XUNNENG OPTOELECTRONICS TECH CO LTD

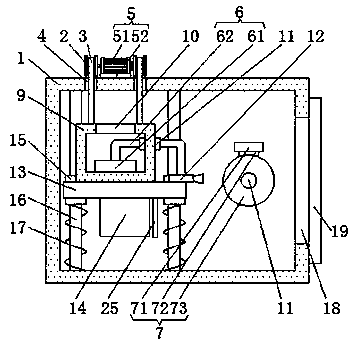

Tobacco dryer

InactiveCN108669618AAvoid pollutionConvenient drying workTobacco preparationElectric heatingEngineering

The invention discloses a tobacco drier. The tobacco drier comprises a main box body; the main box body is provided with an electric heating cavity extending upwards and downwards; a heating mechanismis arranged in the electric heating cavity; the position, located on the right side of the electric heating cavity, of the end surface of the front side of the main box body is provided with a pressing plate groove extending backwards; an opening of the pressing plate groove faces forwards; a pressing plate mechanism is arranged in the pressing plate groove; the end wall of the bottom, close to the left side, of the pressing plate groove is provided with a first working cavity extending downwards; the position, at the bottom of the first working cavity, of the main box body is provided with asecond working cavity extending leftwards and rightwards; the position, between the first working cavity and the second working cavity, of the main box body is provided with a funnel cavity; a stirring mechanism is arranged in the second working cavity; the position, at the bottom of the second working cavity, of the main box body is provided with a discharging groove; the bottom of the second working cavity is communicated with the top of the discharging groove; and the bottom of the discharging groove is provided with an opening, and the bottom of the discharging groove is communicated withthe outside.

Owner:张叶莎

Ultrasonic cleaning device

InactiveCN112517467AEasy to cleanAvoid enteringHollow article cleaningDrying gas arrangementsElectric machineryEngineering

The invention discloses an ultrasonic cleaning device. The ultrasonic cleaning device comprises a machine body, a cleaning device body and a control device, wherein the ultrasonic cleaning device bodyis arranged on the side face of the cleaning device body, a motor and a rotating shaft are arranged above the cleaning device body, the rotating shaft is connected to the output end of the motor, a plurality of rolling brushes are connected to the side face of the rotating shaft, the side face of the rotating shaft is slidably connected to a plurality of spray heads, the spray heads are connectedto a water control device arranged above the machine body through a water pipe, the side face of the water control device is connected to a water tank through a water pipe, and a cleaning device comprises a cleaning table and a backflow cavity formed inside the cleaning table. According to the ultrasonic cleaning device, when in use, by arranging the cleaning device, parts needing to be cleaned can be conveniently pretreated in the using process, sludge and chippings of the parts are prevented from entering the interior of the ultrasonic cleaning device and damaging the ultrasonic cleaning device, and by arranging a control device, the whole cleaning process can be conveniently controlled to be conducted in order.

Owner:张家港三能机电设备有限公司

Safety protection textile material flushing device

ActiveCN112481854AAdjust immersion depthAdd adjustment functionTextile treatment machine arrangementsTextile treatment by spraying/projectingProcess engineeringMechanical engineering

The invention provides a safety protection textile material flushing device. The safety protection textile material flushing device comprises a flushing tank, a partition plate, a supporting frame, aguiding and conveying roller, adjusting holes, an upper locking guide conveying soaking roller structure, a filterable cleaning box structure, an adjustable flushing pipe structure, a rotatable dryingframe structure, a discharging pipe, a replacement pipe, a flushing box, a first supporting plate, a U-shaped frame, a material roller, a fixed roller, a flushing pump, a water absorption pipe and awinding device, wherein the partition plate is in bolted connection with the middle position of the left side of the inner wall of the flushing tank. Through the arrangement of the washing tank, the supporting frame, the guiding and conveying roller, the first supporting plate, the U-shaped frame, the material roller, the fixed roller and the winding device, the textile materials can be tightenedthrough power generated when the winding device works in the textile material washing process, and washing liquid can be conveniently removed in the working process; and potential safety hazards caused by corrosivity of liquid for washing textile materials are prevented, and the safety protection work of equipment is improved.

Owner:菏泽天利纺织有限公司

Tobacco water removal device

InactiveCN108991582AAvoid pollutionConvenient drying workTobacco preparationPlate pressureTobacco water

The invention relates to a tobacco water removal device. The device includes a main casing, wherein the main casing is internally provided with an electric heating chamber extending up and down, the electric heating chamber is internally provided with a heating mechanism, a front end surface of the main casing at a right side of the electric heating chamber is provided with a plate pressing grooveextending backwards, an opening of the plate pressure groove faces forwards, the plate pressure groove is internally provided with a plate pressure mechanism, a bottom end wall of the plate pressuregroove close to the left is provided with a first working chamber extending downwards, the main casing is internally provided with a second working chamber extending left and right at a bottom portionof the first working chamber, the main casing is internally provided with a funnel chamber between the first working chamber and the second working chamber, the second working chamber is internally provided with a stirring mechanism, the main casing is internally provided with a discharging groove at a bottom portion of the second working chamber, the bottom portion of the second working chamberis communicated with a top portion of the discharging groove, and a bottom portion of the discharging groove is an opening communicated with the external part.

Owner:张叶莎

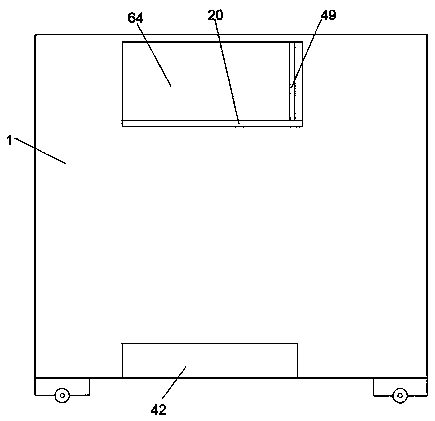

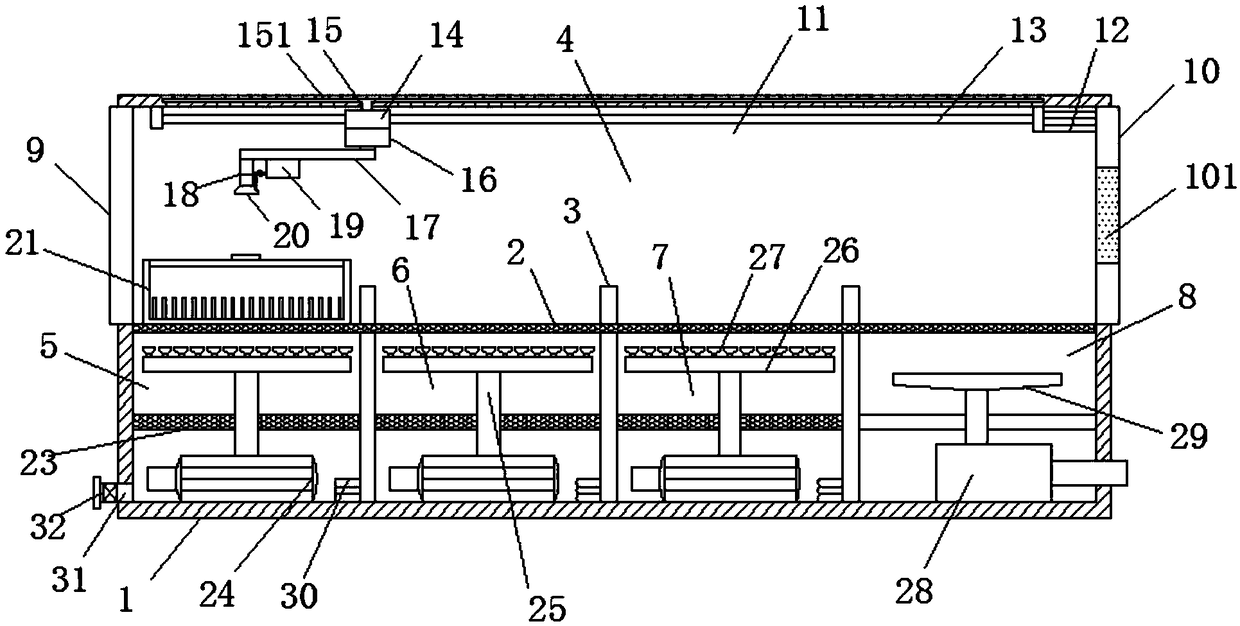

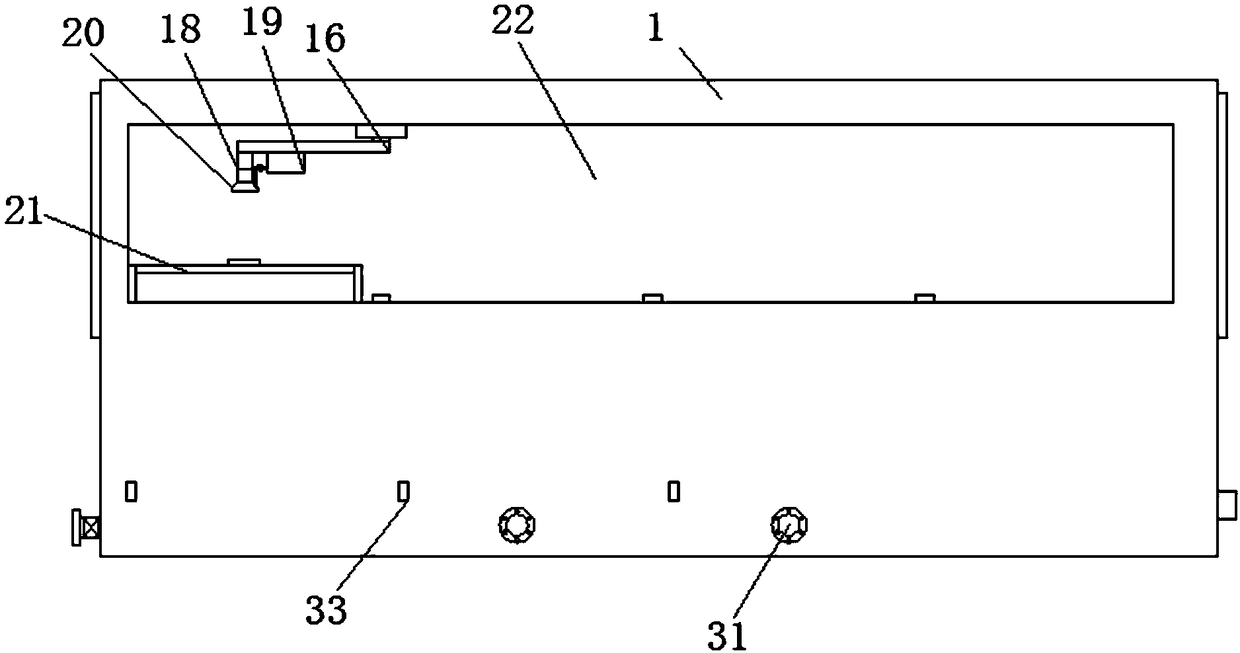

Textile cloth drying equipment

ActiveCN112944862AReduce lossDry evenlyDrying gas arrangementsDrying chambers/containersProcess engineeringMechanical engineering

The invention discloses a textile cloth drying equipment. The equipment comprises a drying box, wherein a lifting mechanism is arranged in the center of the top of the inner wall of the drying box, a drying device is arranged among the bottom of the inner wall of the drying box and two corresponding sides of the bottom of the lifting mechanism, a heater is fixed to a position, close to the top, of one side of the inner wall of the drying box, one end of a curve pipe communicates with the air outlet end of the drying device, a gas dryer is fixed to a position, close to the bottom, of one side of the inner wall of the drying box, the air inlet end of the gas dryer communicates with the end, away from the drying device, of the curve pipe, and the air outlet end of the gas dryer communicates with the air inlet end of the heater. The invention relates to the technical field of textile drying. According to the textile cloth drying equipment, purposes of heat cyclic utilization and rapid drying are achieved, moisture can be extruded out in time, auxiliary time is shortened, drying is rapid and convenient, meanwhile, heat can be recycled, heat loss is reduced, and drying efficiency and the performance are improved.

Owner:湖北新耀实业有限公司

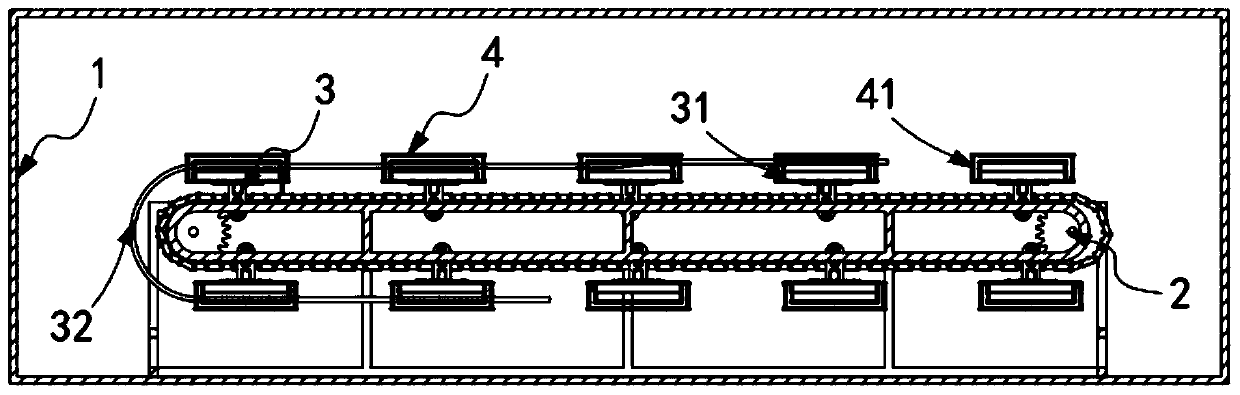

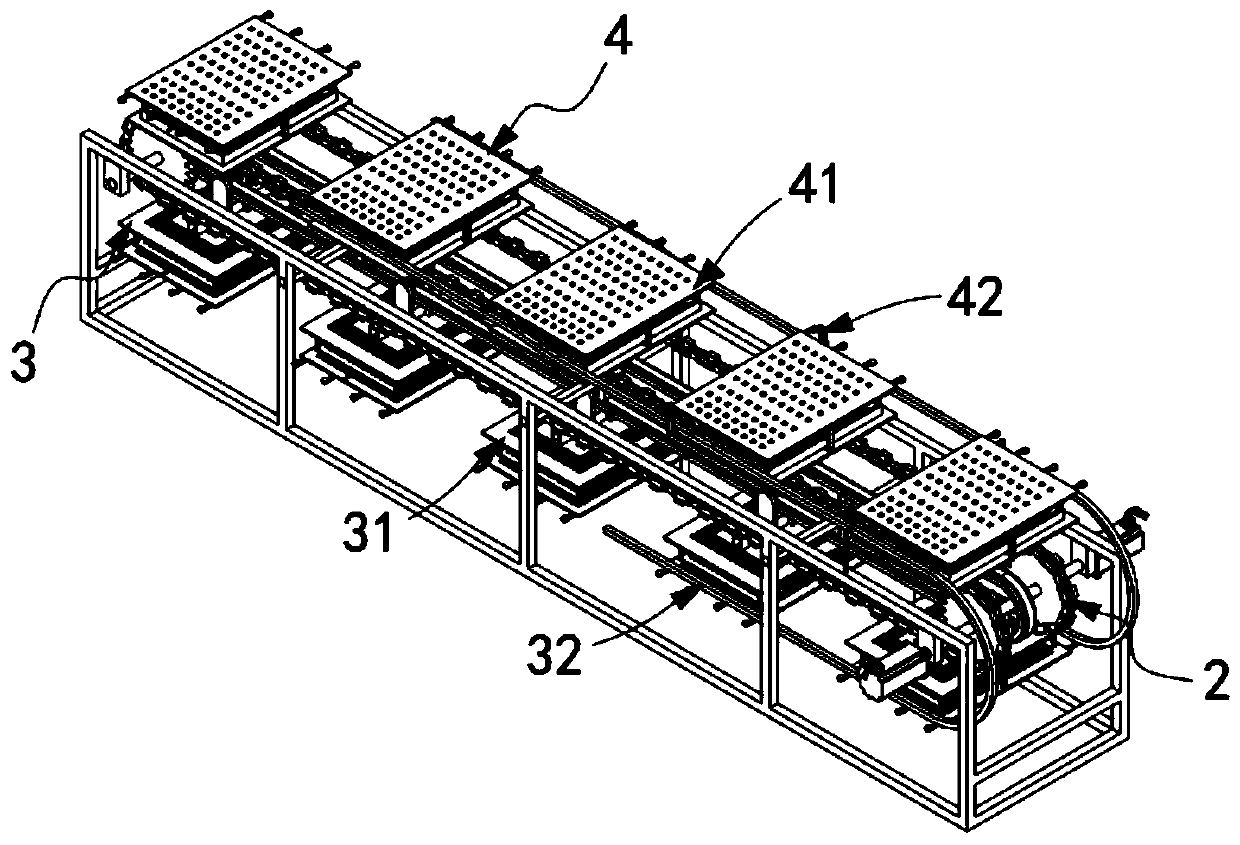

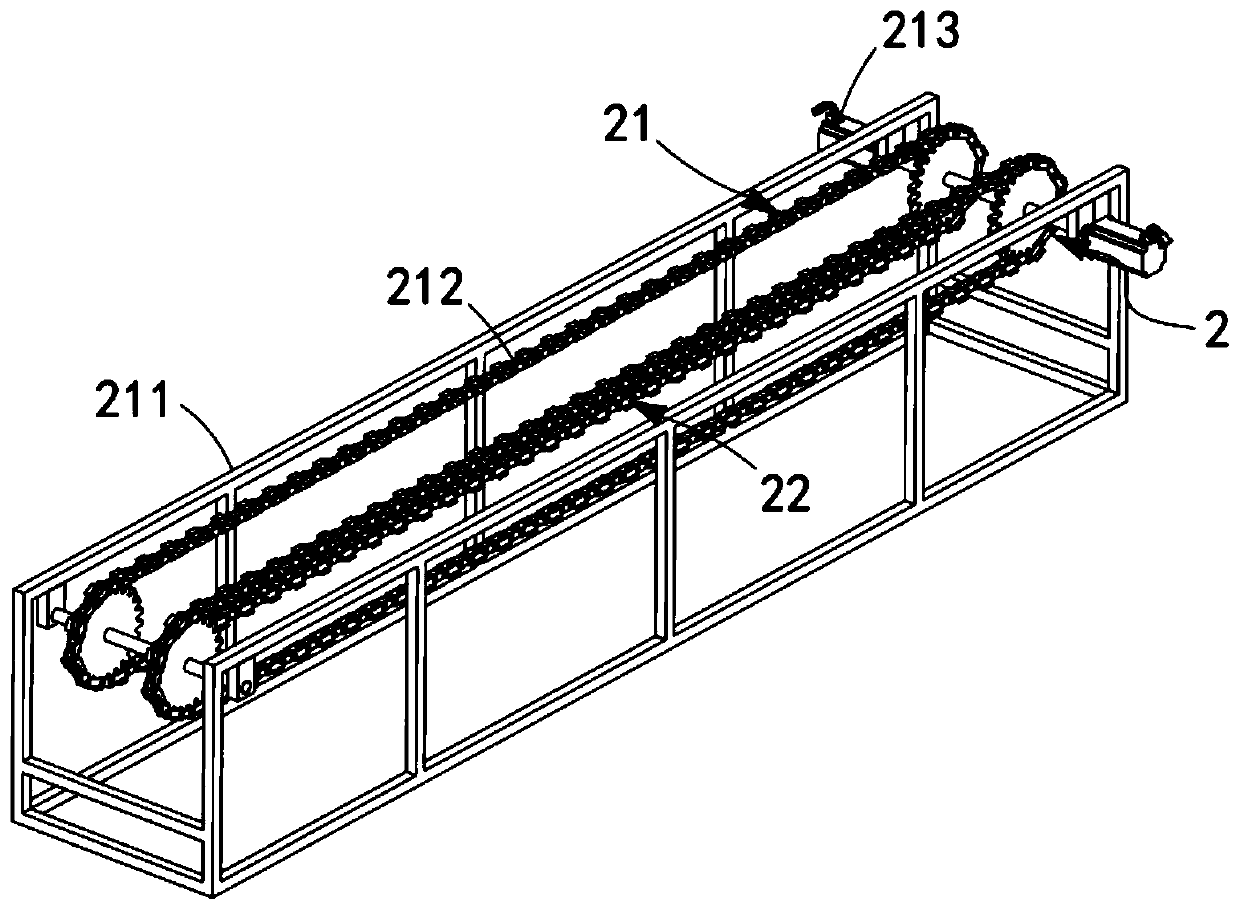

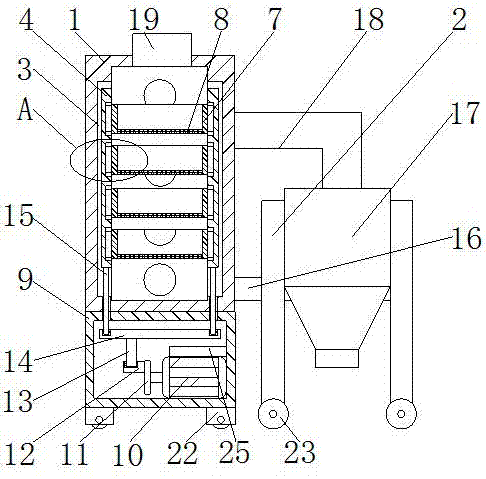

Drying device for garlic processing

ActiveCN111084397AHeat dissipation fastDry evenlyFood treatmentReciprocating motionAgricultural engineering

The invention relates to a drying device for garlic processing. The drying device includes a drying case, a driving mechanism, carrying mechanisms and material poking mechanisms; the driving mechanismis arranged in the drying case; multiple sets of the carrying mechanisms are equidistantly arranged along the transmission direction of the driving mechanism; the carrying mechanisms include limit assemblies connected to the driving mechanism and guiding assemblies for driving the limit assemblies to open and close up, and garlic is located in the limit assemblies; and the material poking mechanisms include reciprocating assemblies connected to the limit assemblies and poking assemblies installed on the driving mechanism and controlling the reciprocating movement of the reciprocating assemblies. Thus, the technical problems of poor drying effects at the connecting parts of the garlic and carriers thereof during drying can be solved.

Owner:临泉县金辉食品有限公司

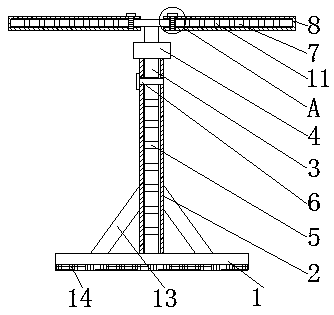

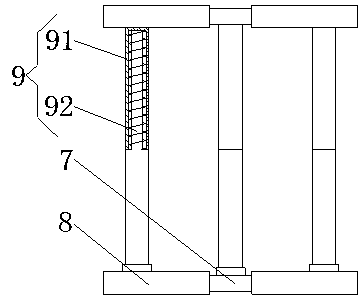

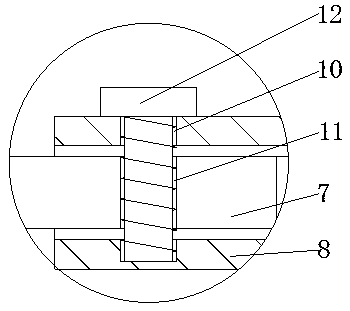

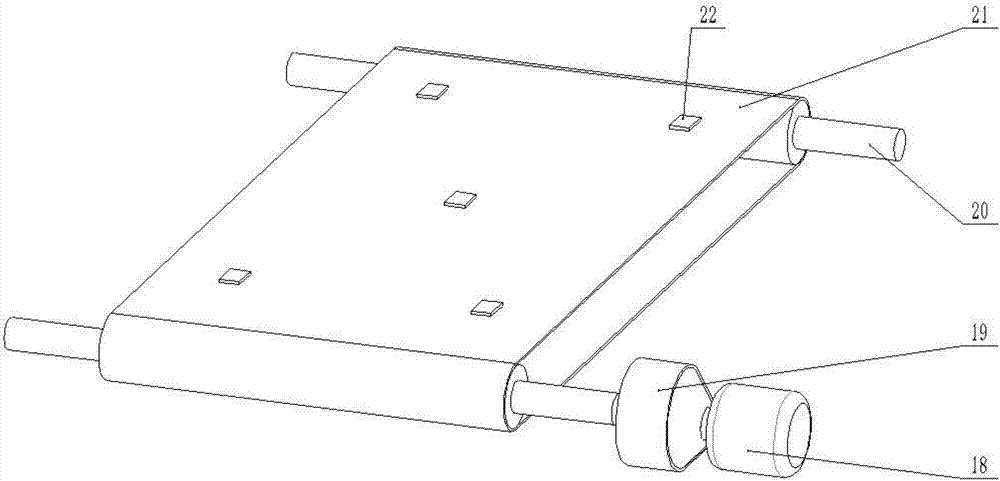

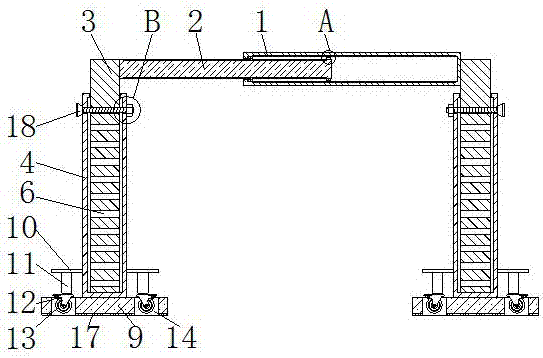

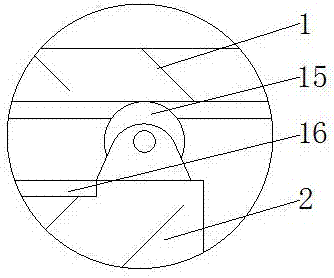

Textile fabric hanging stand

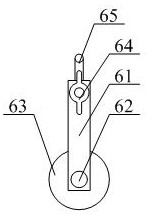

InactiveCN108007120ADrying works wellConvenient drying workDrying machines with local agitationDrying machines with materials at restArchitectural engineeringThreaded rod

The invention discloses a textile fabric hanging stand. The textile fabric hanging stand comprises a first sleeve pipe and a first sliding rod, wherein both of the right end of the first sleeve pipe and the left end of the first sliding rod are fixedly connected with second sliding rods; second sleeve pipes are arranged on the surfaces of the second sliding rods in a sleeving manner; both of firstthrough holes are formed in the top parts of the two sides of each second sleeve pipe; second through holes are formed in the second sliding rods; threaded rods are arranged in inner chambers of thesecond through holes; and the two ends of each threaded rod penetrate through the each first through hole and extends to the outer part of the each first through hole. According to the textile fabrichanging stand disclosed by the invention, through cooperative using of the first sleeve pipe, the first sliding rod, the second sliding rods, the second sleeve pipes, the first through holes, the second through holes, the threaded rods, nuts, supporting plates, electric telescopic rods, supports, roller wheels and third through holes, height and width of the hanging stand can be adjusted accordingto fabrics of different specifications, so that successful operation of an airing work can be ensured preferably, and a great convenience for the airing work is provided.

Owner:苏州聚飞纺织科技有限公司

Traditional Chinese medicinal material stir-frying device for medical care

InactiveCN107898631AStir frying is quick and efficientConvenient drying workPharmaceutical product form changeDomestic articlesWorkloadPediatrics

The invention discloses a traditional Chinese medicinal material stir-frying device for medical care. The traditional Chinese medicinal material stir-frying device for medical care comprises a bottomplate, wherein a box body is fixedly connected to the top of the bottom plate, a supporting plate is fixedly connected between two sides of the inner wall of the box body, a motor is fixedly connectedto one side of the top of the supporting plate through a connecting block, a first belt pulley sleeves the outer surface of an output shaft of the motor, a screw rod is rotationally connected betweentwo sides of the inner wall of the box body through a bearing and is located at the bottom of the supporting plate, and a second belt pulley sleeves the outer surface of one end of the screw rod. Theinvention relates to the technical field of medical facilities. According to the traditional Chinese medicinal material stir-frying device for medical care, the stir-frying effect is greatly enhanced, the abundant working time of medical staff is saved, the workload of the medical staff is alleviated, the working efficiency of the medical staff is improved, the rapid and efficient stir-frying ofthe traditional Chinese medicinal materials is realized, and thus the drying work of the traditional Chinese medicinal materials of the medical staff is greatly facilitated.

Owner:FOSHAN HUIZHONG SENTAI TECH CO LTD

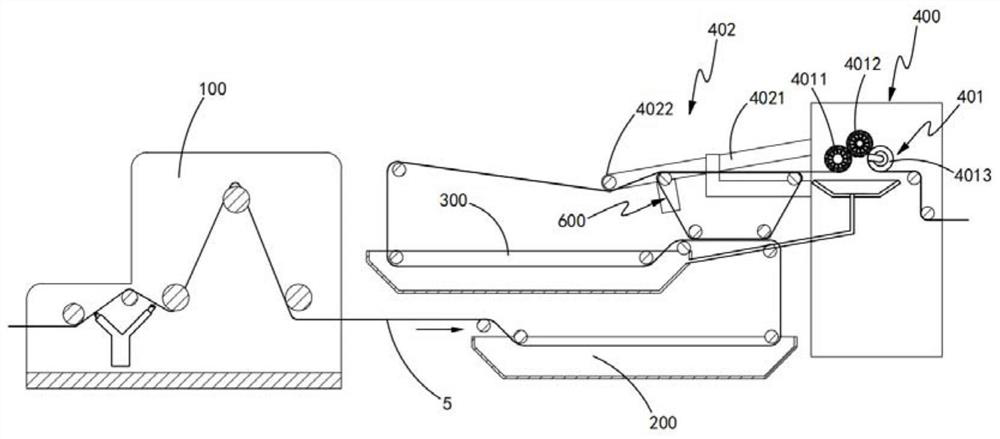

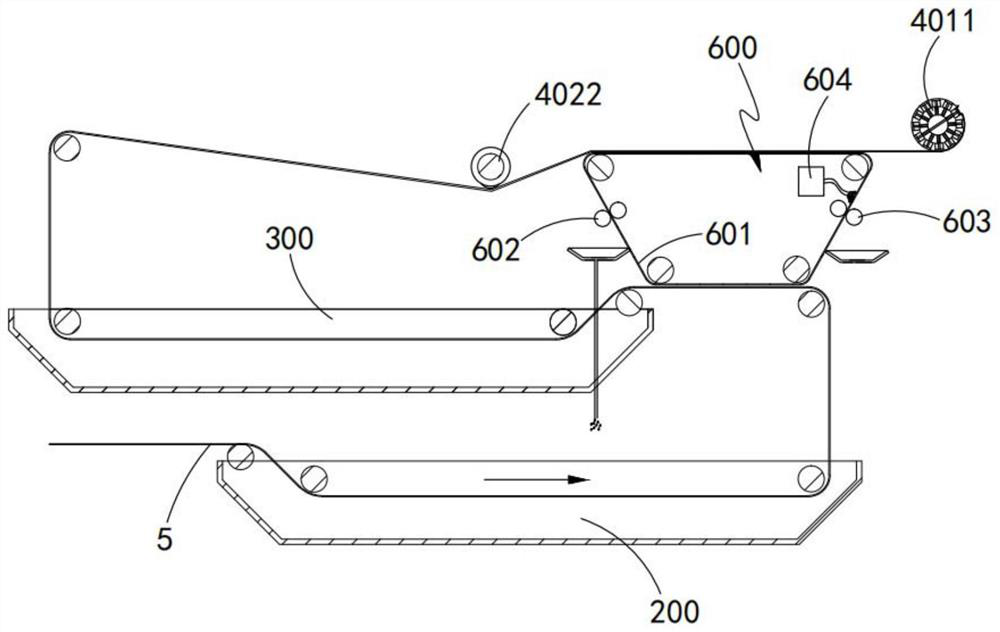

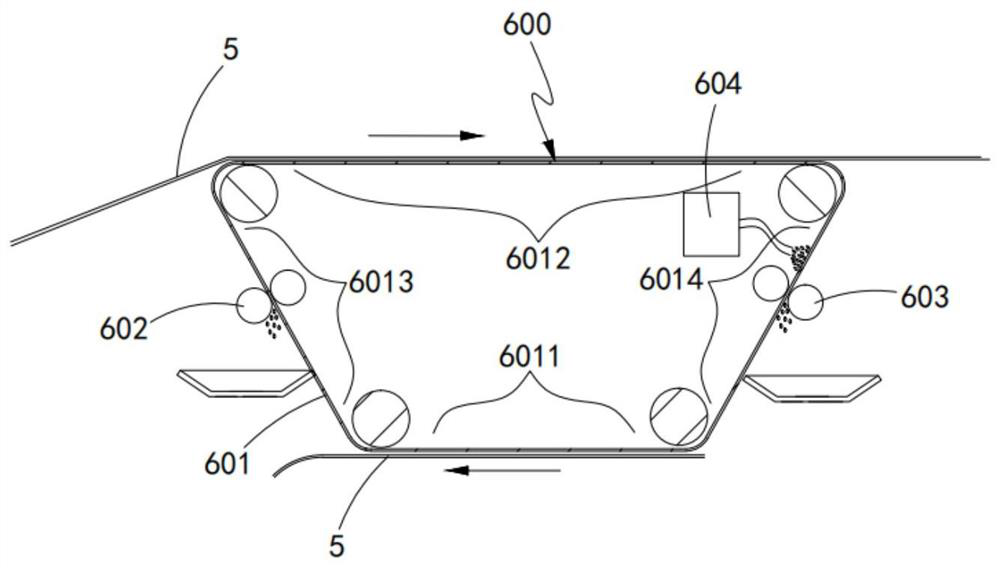

Fabric printing and dyeing production line and method

InactiveCN112609365AConvenient drying workImprove processing efficiencySingeingLiquid/gas/vapor removal by squeezing rollersPulp and paper industryManufacturing line

The invention relates to the technical field of printing and dyeing equipment, in particular to a fabric printing and dyeing production line and method. The production line comprises a singeing device, a soaking and cleaning device and a dyeing device, and further comprises a wringing device and an adsorption device; the wringing device is arranged at the outlet end of the dyeing device, a fabric is sequentially connected with the singeing device, the soaking and cleaning device, the dyeing device and the wringing device in series, and the wringing device comprises a wringing assembly and a tensioning assembly; and the adsorption device is arranged between the soaking and cleaning device and the dyeing device and is used for adsorbing liquid attached to the fabric treated by the soaking and cleaning device and the dyeing device. The method comprises automatic operation of a singeing process, a cleaning process, a dyeing process, a liquid adsorption process and a drying process. Liquid attached to the fabric after operation of the soaking and cleaning device and the dyeing device is adsorbed in time through the adsorption device, subsequent drying work on the fabric is facilitated, and the processing efficiency of the printing and dyeing process is further improved.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

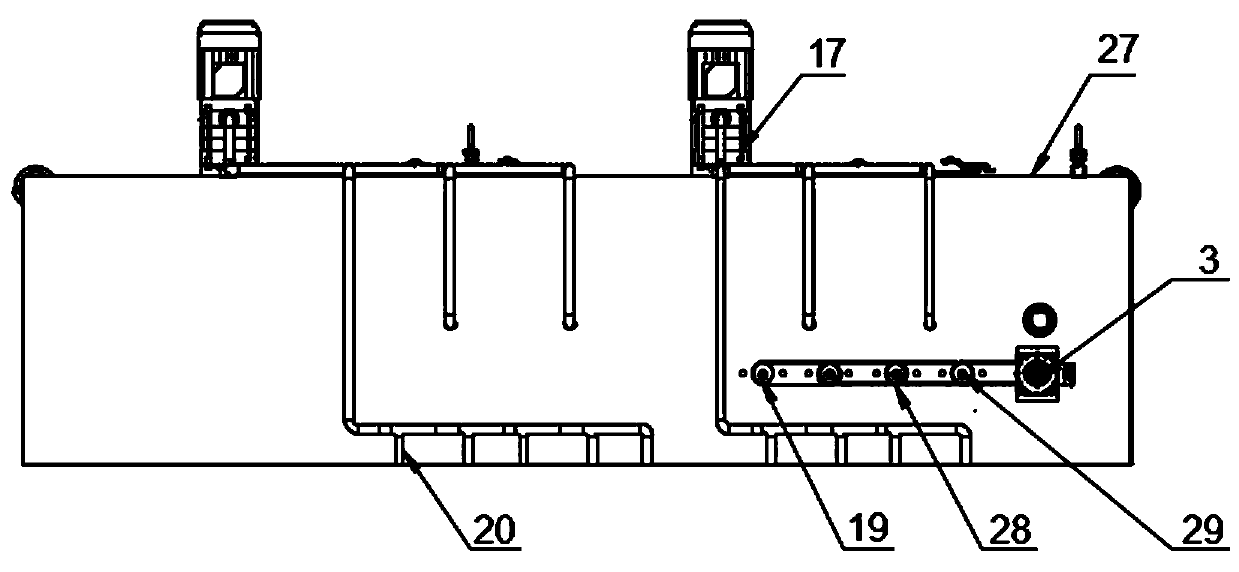

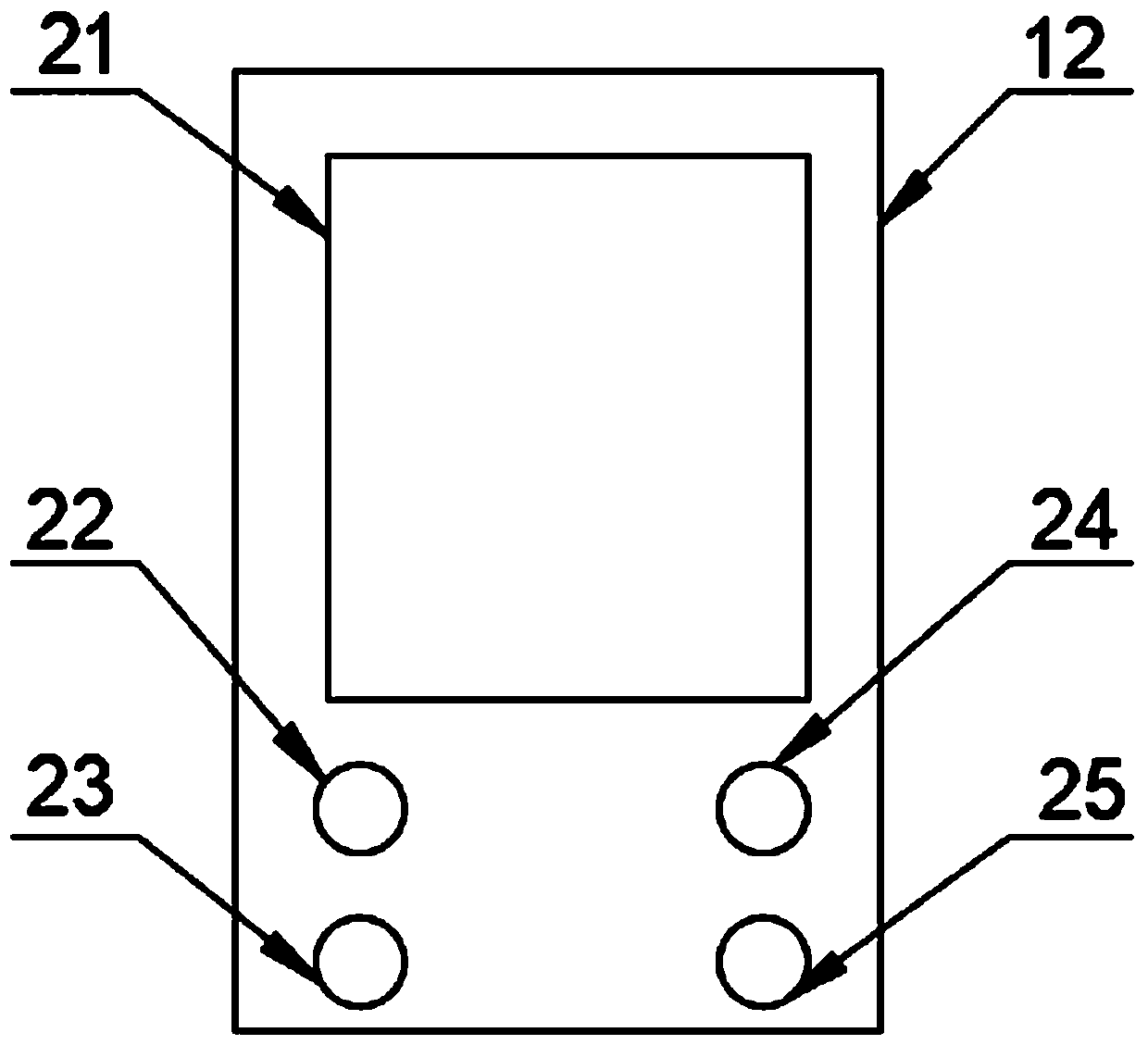

Smart kitchen dishwasher

InactiveCN108433673AGuaranteed cleaning qualityReduce usageTableware washing/rinsing machine detailsWashing processesTransfer modeSmart kitchen

The invention discloses a smart kitchen dishwasher. The dishwasher comprises a box body, and the box body is internally divided into an upper box chamber, a first cleaning chamber, a second cleaning chamber, a third cleaning chamber and a drying chamber through a transverse net plate and three vertical plates; an inlet door and an outlet door are hinged to the left and right sides of the upper boxchamber respectively, a servo driving device is transversely installed at the top of the upper box chamber, a guide bock penetrates through the servo driving device and is slidingly connected to thetop of the box body through a sliding block, a supporting rod is installed on an output shaft of a motor at the bottom of the guide block, and a downward electric push rod and a vacuum pump are installed on the supporting rod; a water pump is provided with an upward drainage pipe, and thermometers are installed at one side of the exterior of the first cleaning chamber, one side of the exterior ofthe second cleaning chamber and one side of the exterior of the third cleaning chamber. The smart kitchen dishwasher conducts the processes of pre-cleaning, main cleaning, flushing and drying separately and independently, the cleaning quality is ensured, an automatic transfer mode is adopted, and the efficiency of feeding dish racks in the cleaning process is improved.

Owner:佛山市高芯科技服务有限公司

Circulating traditional-Chinese-medicine-sea-cucumber preparing device

PendingCN110063969AGood drying and water removal abilityIncrease the gapEchinodermata material medical ingredientsCooling chamberEngineering

The invention discloses a circulating traditional-Chinese-medicine-sea-cucumber preparing device. The circulating traditional-Chinese-medicine-sea-cucumber preparing device comprises a shell, a cooking chamber, a cooling chamber, a roasting chamber, a first pipe body, a second pipe body, a third pipe body and a fourth pipe body, wherein the cooking chamber is embedded into the left side of the inner wall of the shell, the cooling chamber is connected to the right side of the top of the cooking chamber through the first pipe body, a second pipe body is arranged on the right side of the bottom of the cooling chamber, the third pipe body is arranged on the left side of the middle of the second pipe body, the roasting chamber is formed in the left side of the third pipe body, and the fourth pipe body is arranged at the top end of the left side of the roasting chamber. The whole circulating traditional-Chinese-medicine-sea-cucumber preparing device is stable in structure, fast and convenient to use and operate, few in operation step and high in production efficiency.

Owner:王孟瑶

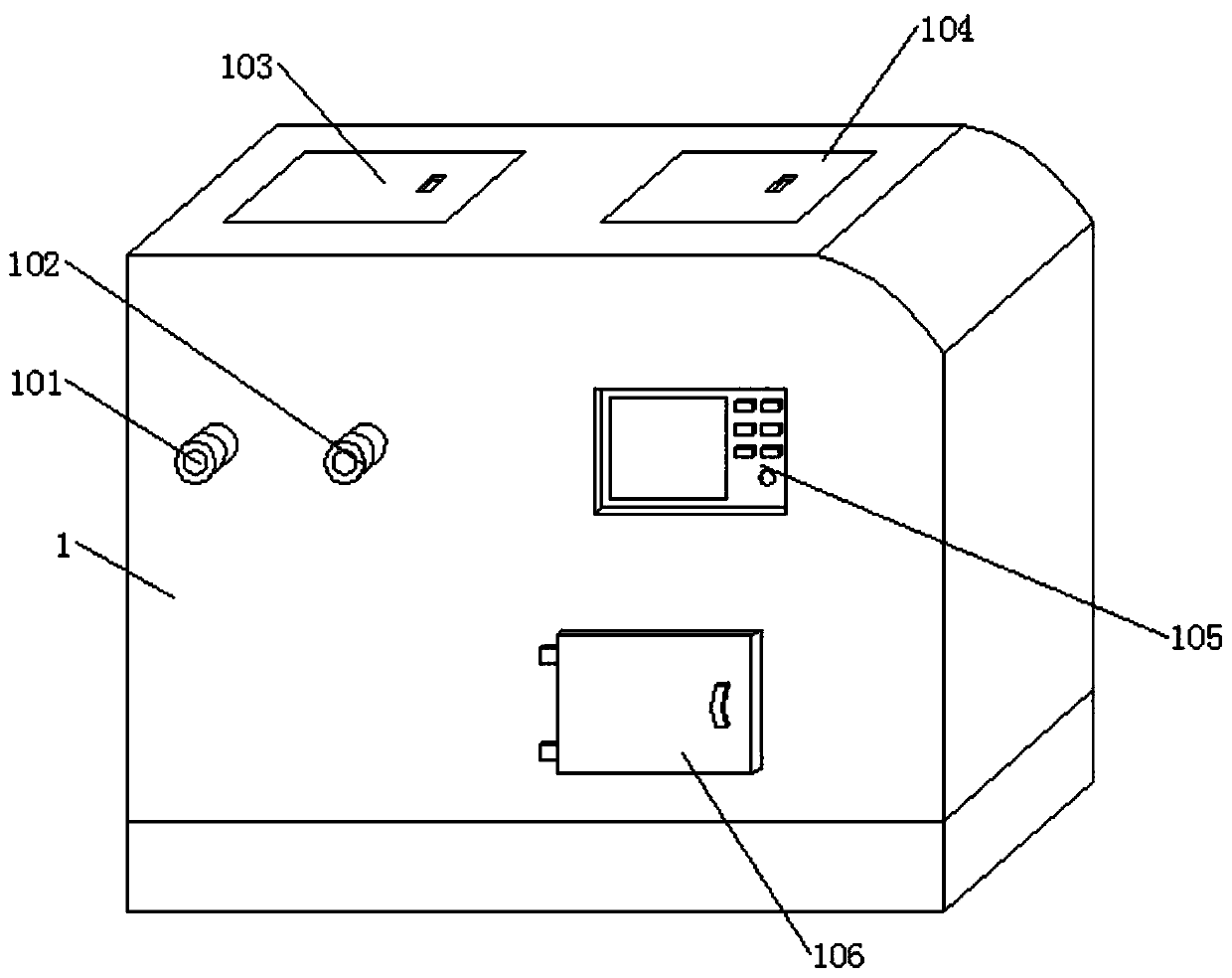

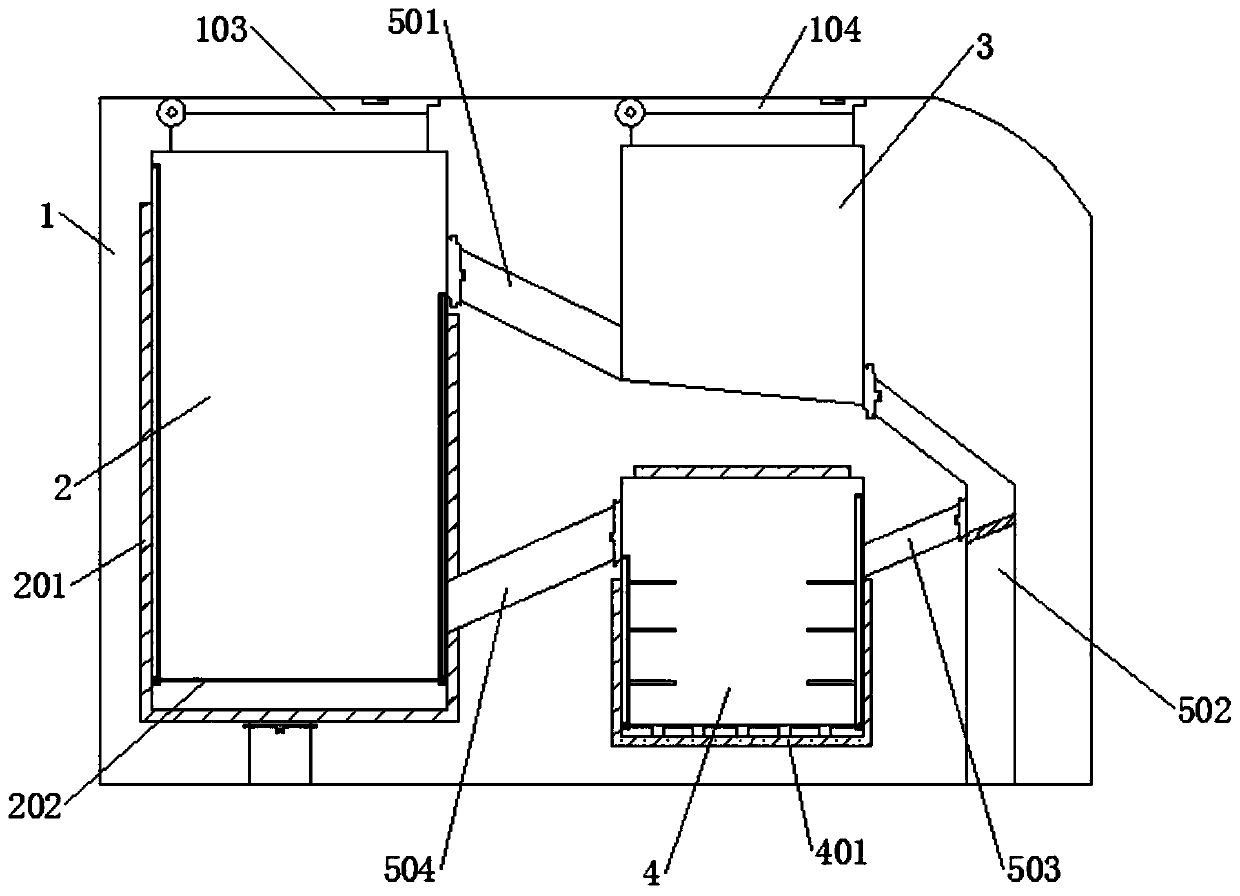

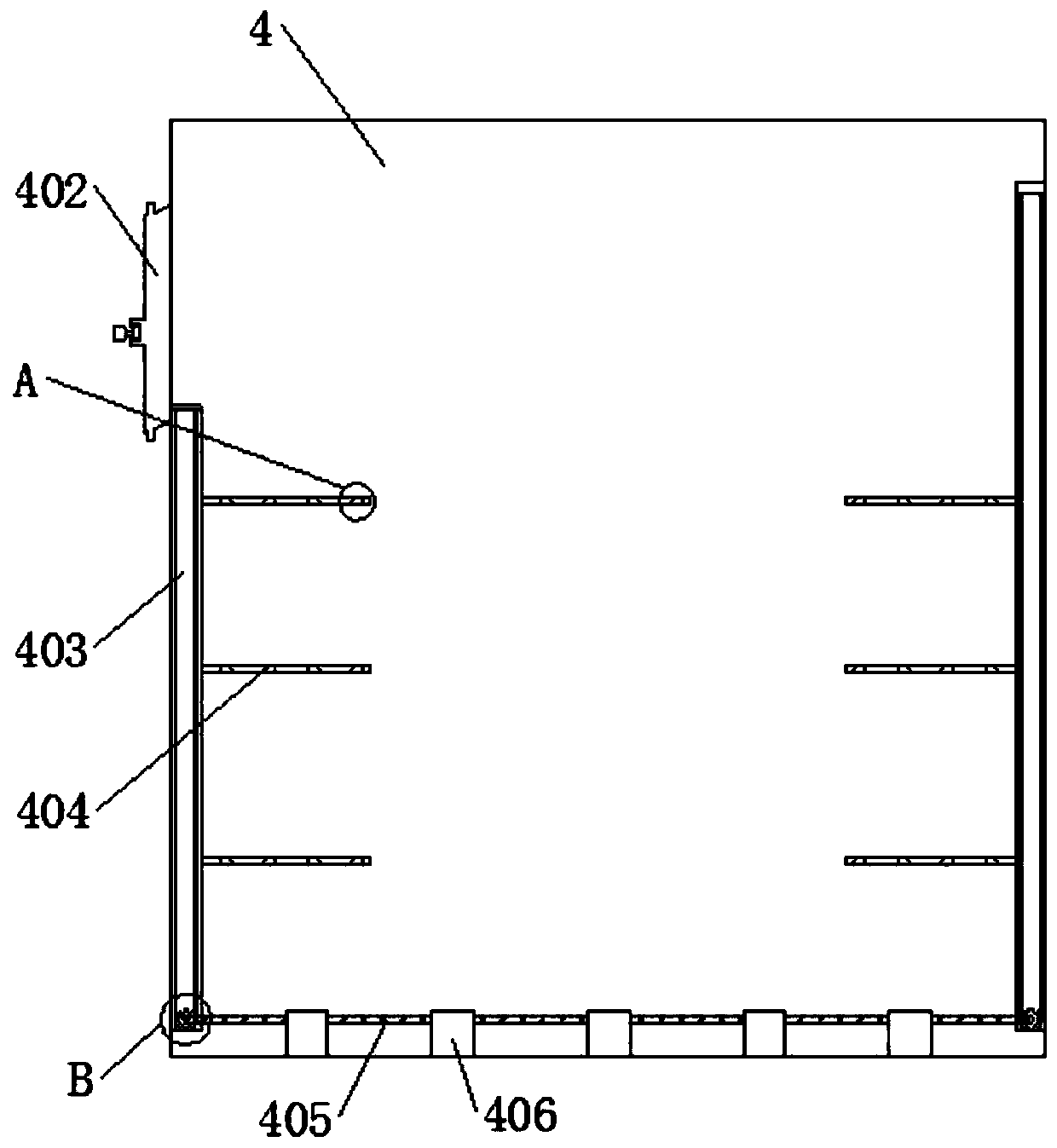

Environment-friendly intelligent washing-drying-disinfecting integrated equipment for slippers

PendingCN110547750AConvenient drying workGuaranteed automationFootwear cleanersChemicalsLiquid-crystal displayAgricultural engineering

The invention discloses an environment-friendly intelligent washing-drying-disinfecting integrated equipment for slippers. The equipment comprises a drying cabin, a spray washing cabin and an ozone disinfection box, wherein one side of the drying cabin is connected with the ozone disinfection box via a feeding wicket; mounting brackets are fixed to the lower sides of the drying cabin and the spraywashing cabin via screws; mounting side plates are welded between the mounting brackets; stand bars are in threaded connection with the lower ends of the mounting brackets; a drying cabin shell is welded to the outer end of the drying cabin; a baffle is arranged in front of the drying cabin; a control panel is arranged on one side of the baffle; a liquid crystal display is arranged at the upper part of the control panel; a working display lamp and a water pump switch are electrically connected with the lower side of the liquid crystal display; a heating switch and a switch are electrically connected with the lower sides of the working display lamp and the water pump switch; the inner side of the baffle is meshed with a rotation shaft via a chain; slipper rack heating pipes are fixed on the chain; heating pipes are installed on the inner side of the upper end face of the drying cabin shell; and a plurality of hot air outlets are formed between the heating pipes. The equipment achievesthe integrated design of washing, drying and disinfecting, and is efficient and intelligent.

Owner:杭州杜尚美环保科技有限公司

Sweet potato slice drying device

The invention discloses a drying device for sweet potato slices, which comprises a drying box and a support frame. Both sides of the inner cavity of the drying box are provided with first chute, and the inner cavity of the first chute is slidably connected with The first slider, the side of the first slider away from the first chute is provided with a second chute, the inner cavity of the second chute is slidably connected with a second slider, and the second slider is far away from the first chute. One side of the second chute is fixedly connected with a screen frame. The present invention passes through the first chute, the first slider, the second chute, the second slider, the screen frame, the screen, the motor, the wheel, the first support rod, the second support rod, the third support rod and With the use of the transmission rod, it is better to turn over the sweet potato slices to dry the sweet potato slices thoroughly. Through the combined use of the dryer, the first conveying pipe and the second conveying pipe, the sweet potato slices can be dried quickly. It saves a lot of time and manpower, greatly improves the efficiency and reduces the labor intensity of the staff.

Owner:耒阳市耒兴薯业发展有限公司

Tea art tea leaf drying device

PendingCN112344719AConvenient drying workEasy to collect and placePre-extraction tea treatmentTea dryingHorticultureChemistry

The invention relates to a drying device, in particular to a tea art tea leaf drying device, and provides a tea art tea leaf drying device without manually turning over tea leaves when the tea leavesare dried. The tea art tea leaf drying device comprises a mounting frame, a baking mechanism and a discharging mechanism, wherein a driving mechanism is arranged in the middle of the top of the mounting frame; the baking mechanism is arranged on one side of the top of the mounting frame; and the discharging mechanism is connected between the baking mechanism and the driving mechanism. By arrangingthe discharging mechanism, the tea leaves intermittently fall into a baking oven, and the amount of the tea leaves falling into the baking oven every time is small, so that tea leaf drying is facilitated; and by arranging the baking mechanism, the tea leaves being baked do not need to be turned over manually.

Owner:许勤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com