Drying device for garlic processing

A drying device and garlic technology, applied in the fields of application, food processing, food science, etc., can solve the problems of not having effective turning over of garlic slices, low drying efficiency, poor drying effect, etc., so as to facilitate drying work and drying Dry evenly, convenient and no dead angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

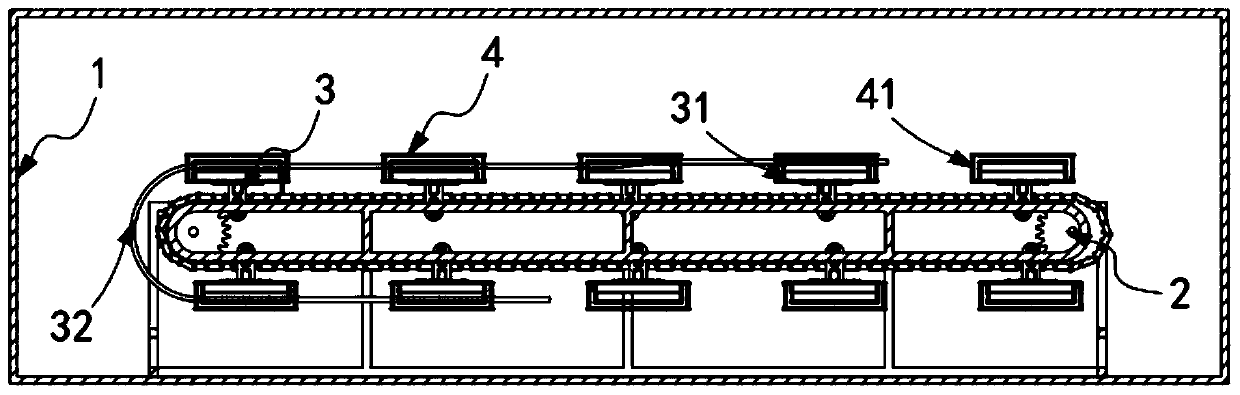

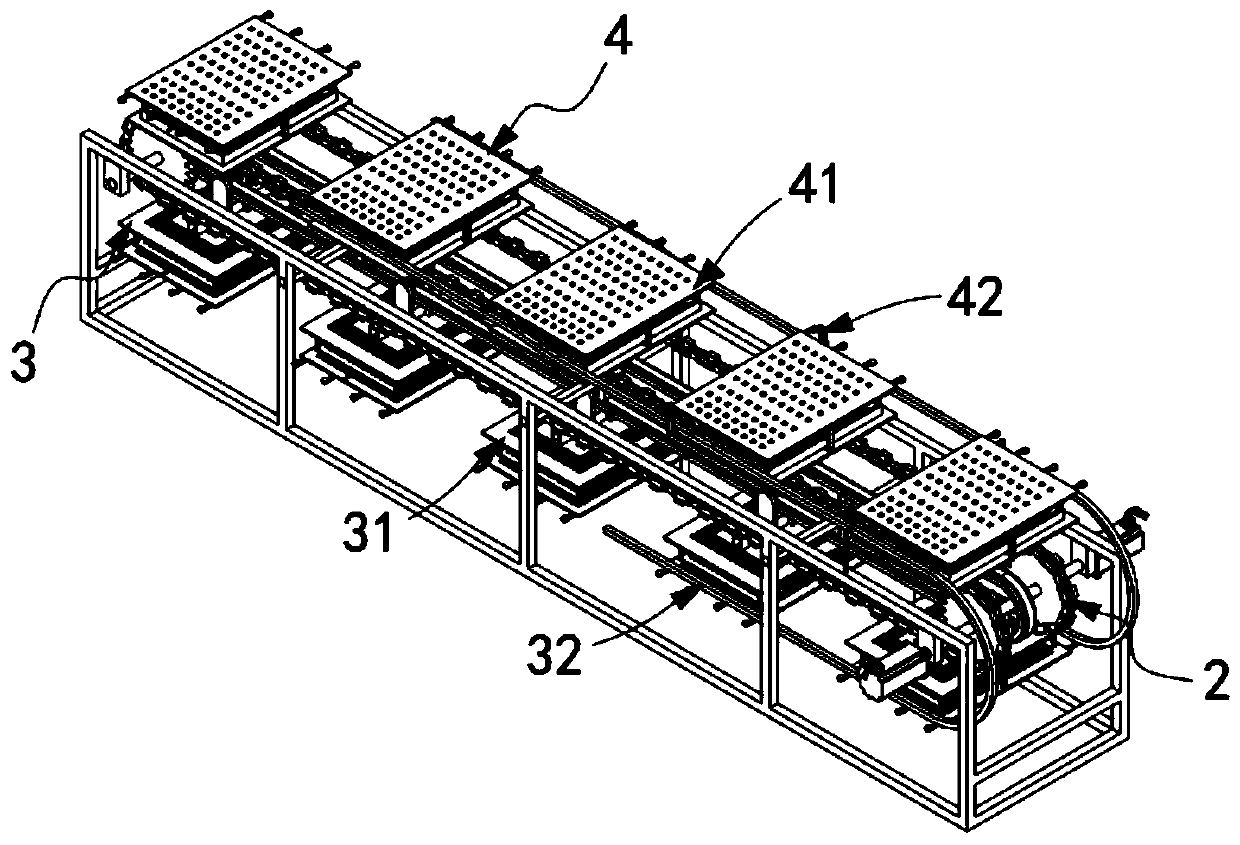

[0053] Such as figure 1 , figure 2 As shown, a drying device for garlic processing includes a drying box 1, and also includes:

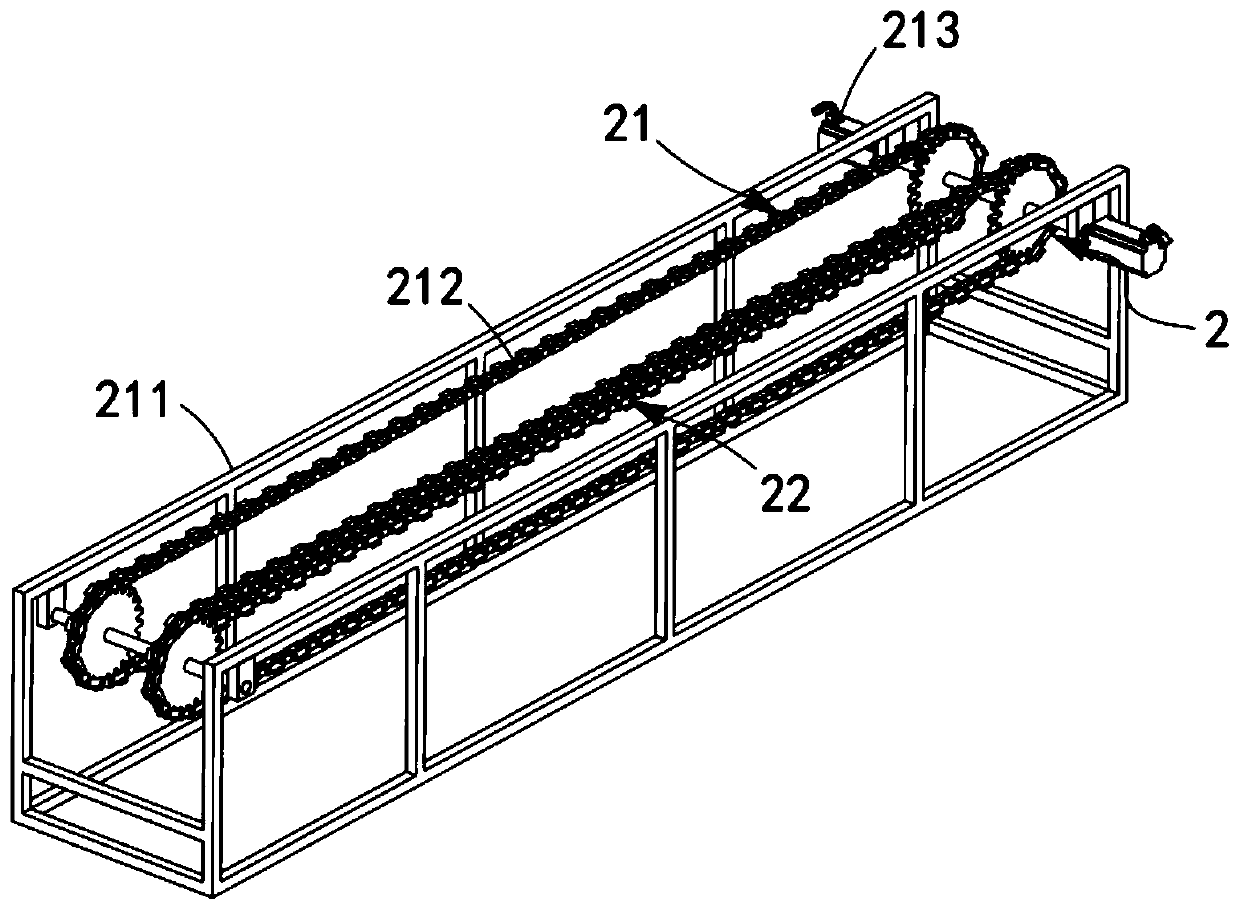

[0054] A driving mechanism 2, the driving mechanism 2 is built in the drying box 1;

[0055] The carrying mechanism 3, the carrying mechanism 3 is arranged in several groups at equal intervals along the driving direction of the driving mechanism 2, which includes a limit assembly 31 connected to the drive mechanism 2 and drives the limit assembly 31 to open and close The guide assembly 32, the sliced garlic 10 is located in the limit assembly 31; and

[0056] The dialing mechanism 4 includes a reciprocating assembly 41 connected to the limiting assembly 31 and a dialing assembly 42 installed on the driving mechanism 2 and controlling the reciprocating movement of the reciprocating assembly 41 .

[0057] In this embodiment, by setting the bearing mechanism 3 to cooperate with the driving mechanism 2, the front and back sides of the garlic slice ...

Embodiment 2

[0086] Such as Figure 12 , Figure 13 and Figure 14 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0087] further, such as Figure 12 , Figure 13 and Figure 14 As shown, the toggle assembly 42 includes a cam a421 arranged on the toggle plate 411 and a cam b422 arranged on the frame 211 , and the arc surfaces of the cam a421 and the cam b422 are matched.

[0088] In this embodiment, by setting the toggle assembly 42 to cooperate with the toggle plate 411, the compressed garlic slices 10 can be toggled, which can avoid damage to the garlic caused by collisions, and at the same time can mix garlic skins and other miscellaneous ingredients in the garlic. Screen out the waste and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com