Rapid drying device for LED shell machining material

A technology for LED housing and processing materials, which is applied in drying, drying machine, drying solid materials, etc., can solve the problems of reducing drying efficiency, inconvenient fixing of LED housing, and large difference in center temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

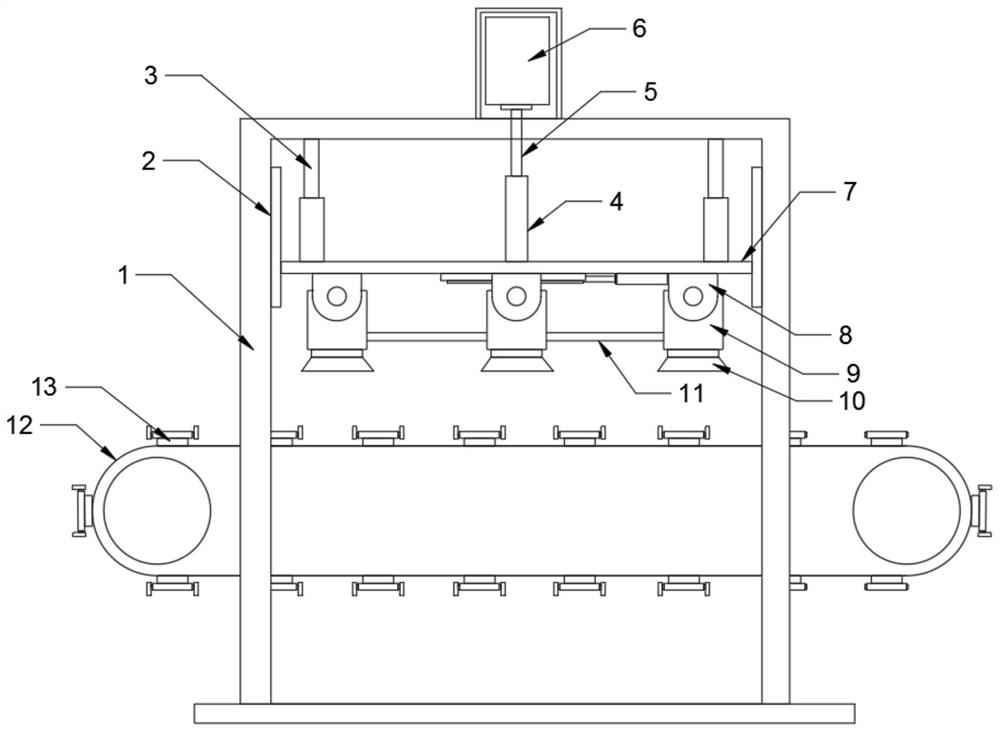

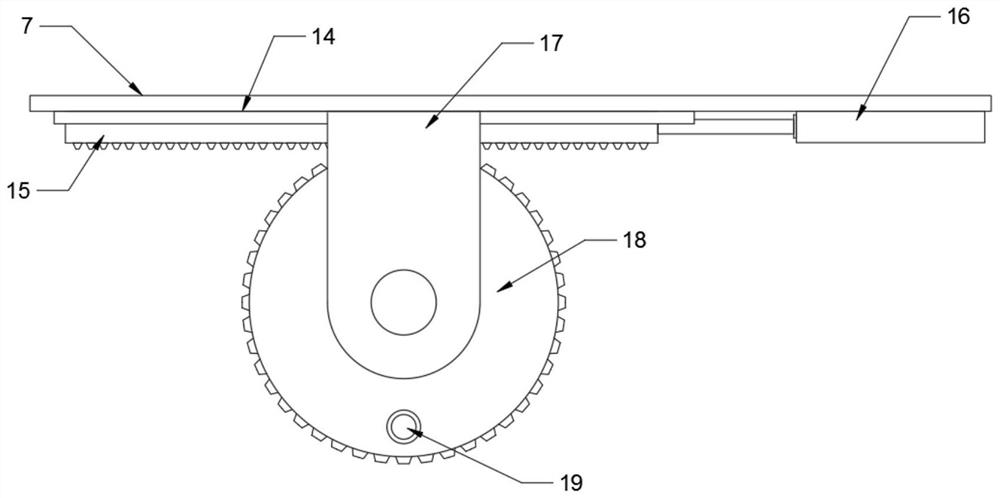

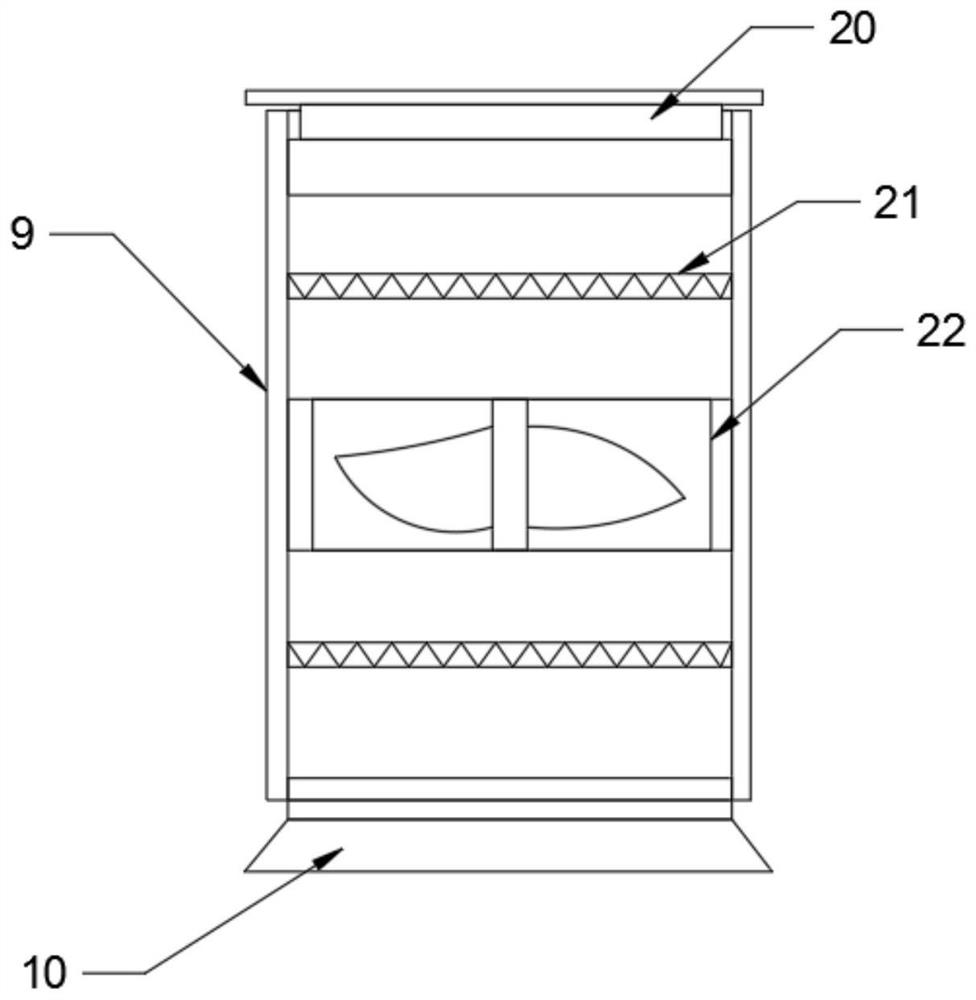

[0022]SeeFigure 1~4In the embodiment of the present invention, a rapid drying device for LED housing processing materials includes a fixing frame 1, a conveyor belt 12, and a fan 22. The fixing frame 1 is provided with slide rails 2 on the left and right sides at the upper end of the inner side. The inner side is provided with a support frame 7. The upper end of the support frame 7 is equipped with telescopic rods 3 on the left and right sides. The top of the telescopic rod 3 is connected to the top of the inner side of the fixing frame 1. The cross-sectional shape of the slide rail 2 is concave. The slide rail 2 and the support frame 7 are at the left and right ends Concave-convex connection, two telescopic rods 3 are arranged between the upper end of the support frame 7 and the inner side of the fixed frame 1; the middle of the top of the support frame 7 is installed with a fixed cylinder 4, the middle of the top of the fixed frame 1 is installed with a rotating electric machine 6...

Embodiment 2

[0026]SeeFigure 5 In the embodiment of the present invention, a rapid drying device for LED housing processing materials includes a fixing frame 1, a conveyor belt 12, and a fan 22. The fixing frame 1 is provided with slide rails 2 on the left and right sides at the upper end of the inner side. The inner side is provided with a support frame 7, the upper and left sides of the support frame 7 are equipped with telescopic rods 3, the top of the telescopic rod 3 is connected to the top of the inner side of the fixed frame 1, the middle of the top of the support frame 7 is installed with a fixed cylinder 4, and the middle of the top of the fixed frame 1 is installed with a rotation The motor 6 and the rotating motor 6 are equipped with a threaded rod 5 at the front end of the shaft, and the inner side of the fixed cylinder 4 is connected with a threaded rod 5; a first turret 8 is installed in the middle of the bottom end of the support frame 7, and a cylinder 9 is installed on the inner...

Embodiment 3

[0028]In the embodiment of the present invention, a rapid drying device for LED housing processing materials includes a fixing frame 1, a conveyor belt 12, and a fan 22. The fixing frame 1 is provided with slide rails 2 on the left and right sides at the upper end of the inner side, and the inner side of the slide rail 2 There is a support frame 7. The upper and left sides of the support frame 7 are equipped with telescopic rods 3, the top of the telescopic rod 3 is connected to the top of the inner side of the fixing frame 1, the middle of the top of the support frame 7 is installed with a fixed cylinder 4, and the middle of the top of the fixing frame 1 is installed with a rotating motor 6. The front end of the rotating motor 6 is equipped with a threaded rod 5, and the inner side of the fixed cylinder 4 is connected with a threaded rod 5; the inner bottom of the fixing frame 1 is provided with a conveyor belt 12, the surface of the conveyor belt 12 is installed with a fixing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com