Drying device for plywood production

A technology of drying device and wooden splint, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of low drying efficiency and inability to meet actual needs well, so as to facilitate drying, avoid omission, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

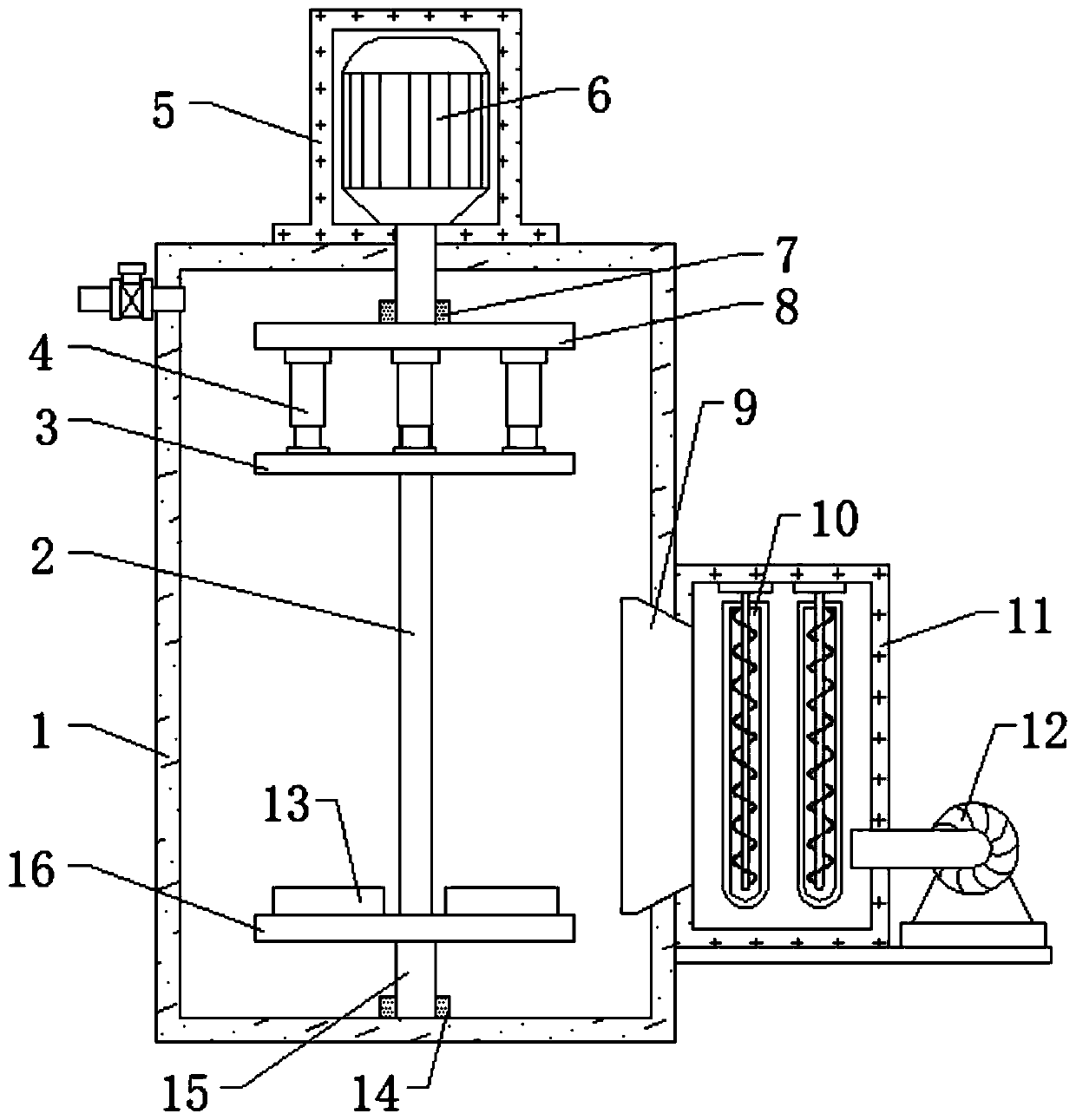

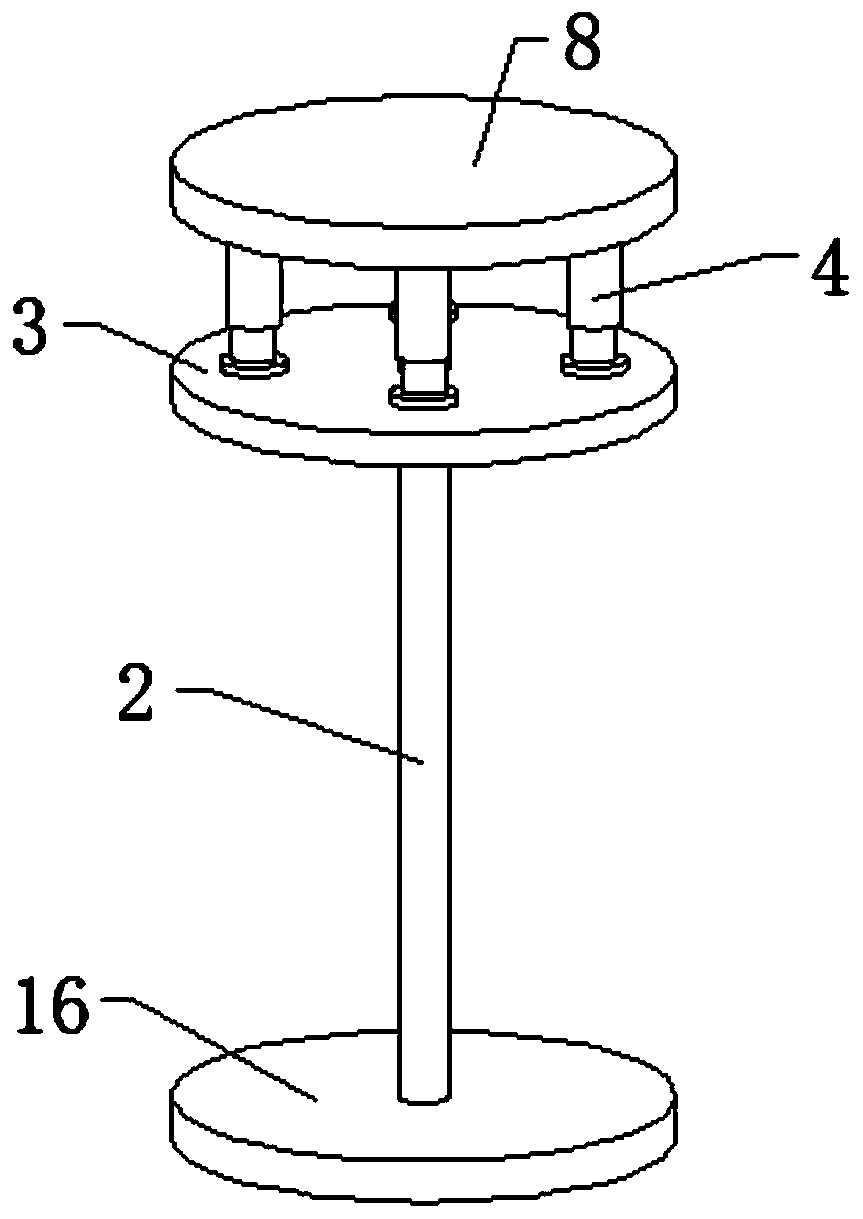

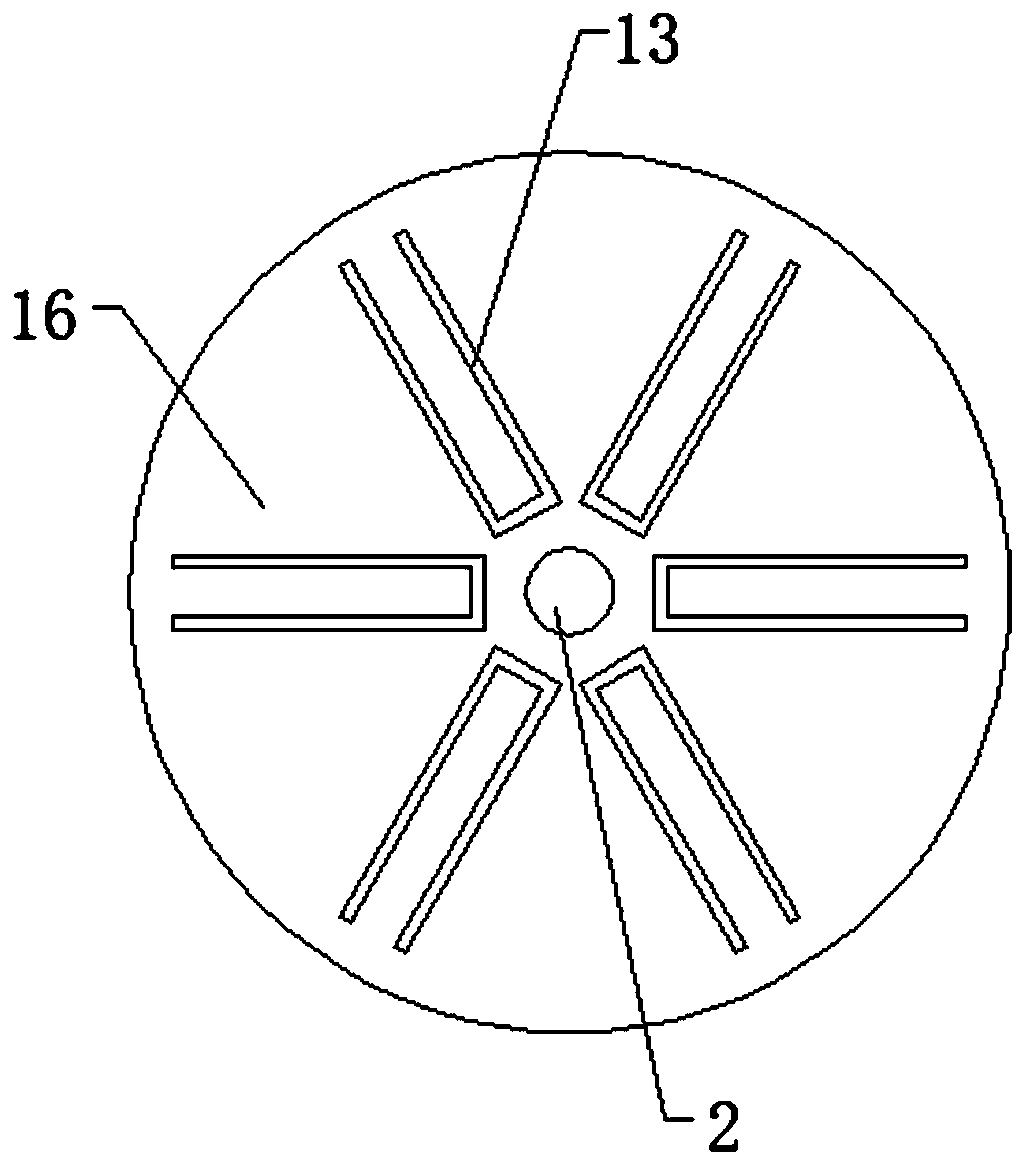

[0023] refer to Figure 1-3 , a drying device for plywood production, comprising a box body 1 and a heating and blowing mechanism, a motor box 5 is fixed to the middle of the outer wall of the top of the box body 1 by bolts, and a motor 6 is fixed to the bottom inner wall of the motor box 5 by bolts, One end of the output shaft of the motor 6 is keyed to a transmission shaft, one end of the transmission shaft is located inside the box body 1, and one end of the transmission shaft is sleeved with a first bearing 7, and the bottom end of the first bearing 7 is welded with a fixed plate 8, and the box body 1 The second bearing 14 is welded at the middle position of the inner wall of the bottom, the connecting shaft 15 is plugged into the inner peripheral wall of the second bearing 14, the top end of the connecting shaft 15 is welded with a supporting plate 16, and the opposite side of the fixing plate 8 and the supporting plate 16 The same support rod 2 is fixed on the outer wall...

Embodiment 2

[0027] refer to Figure 4 , a drying device for wood plywood production. Compared with Embodiment 1, this embodiment also includes four brake universal wheels 17, and the four brake universal wheels 17 are respectively fixed on the bottom outer wall of the box body 1 by bolts. Four corners.

[0028] Working principle: when in use, the bottom of the box body 1 is provided with a brake universal wheel 17, which makes the device move conveniently and facilitates the device to move to a suitable working place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com