Textile cloth drying equipment

A technology for drying equipment and textile fabrics, applied in progressive dryers, drying chambers/containers, drying solid materials, etc., which can solve the problems of inability to absorb and recycle heat, waste time and resources, and increase the amount of manual labor. The amount of manual labor, the rapid and convenient water discharge, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

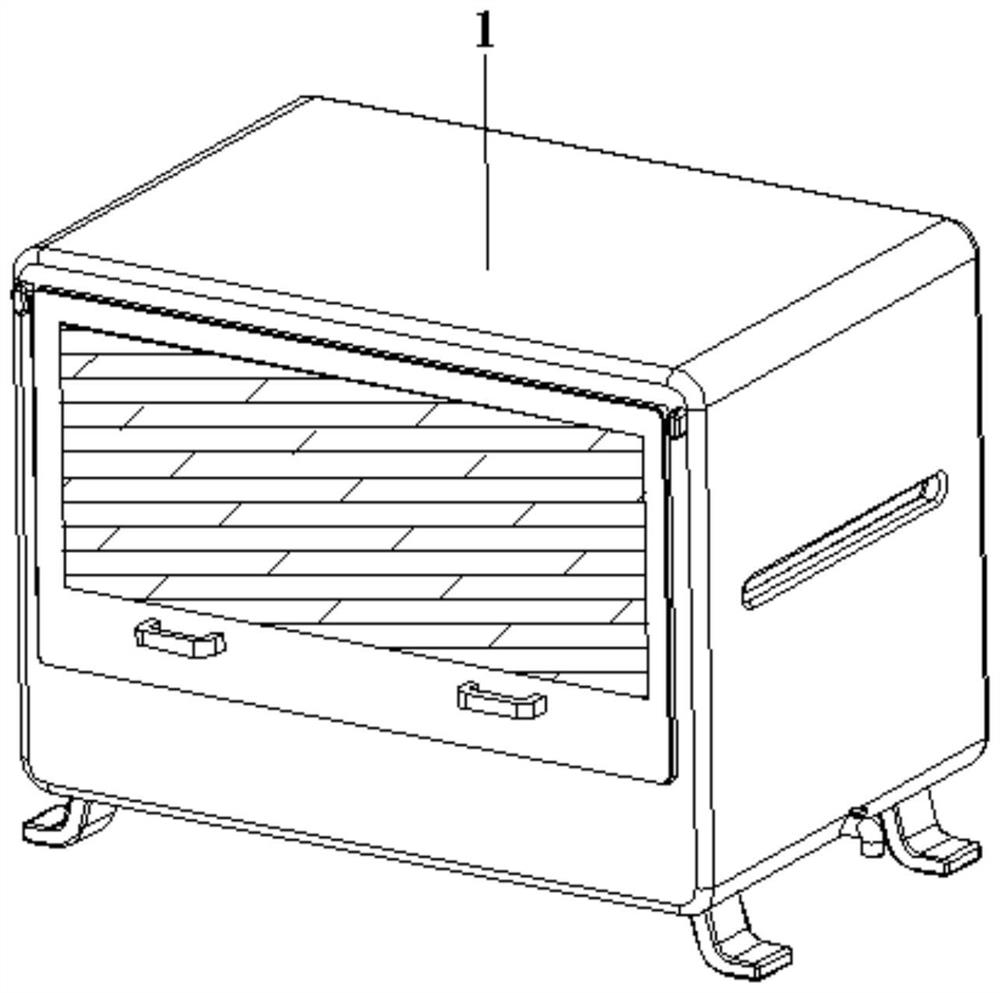

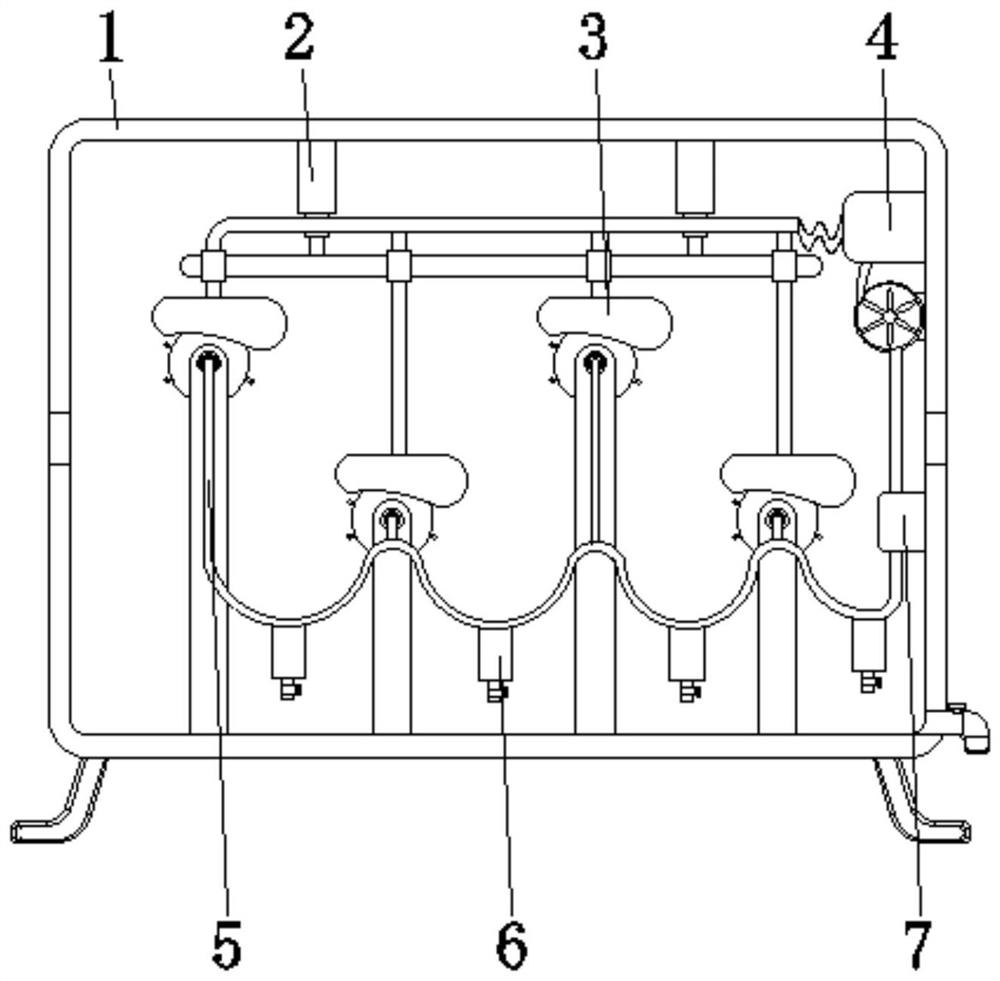

[0033] see Figure 1-7 , the present invention provides a technical solution: a textile cloth drying equipment, including a drying box 1, the interior of the drying box 1 is provided with a lifting mechanism 2, a drying device 3, a heater 4, a curved pipe 5, a water eliminator 6, a gas Dryer 7, lifting mechanism 2 is arranged at the top center of the inner wall of drying box 1, drying device 3 is arranged between the two sides corresponding to the bottom of inner wall of drying box 1 and the bottom of lifting mechanism 2, and heater 4 is fixed on the bottom of drying box 1 On one side of the inner wall and near the top, the outlet end of the heater 4 communicates with the inlet end of the drying device 3 , one end of the curved pipe 5 communicates with the air outlet end of the drying device 3 , and the water eliminator 6 is arranged at the bottom of the curved pipe 5 , The gas drier 7 is fixed on one side of the inner wall of the drying box 1 and near the bottom position, the...

Embodiment example 2

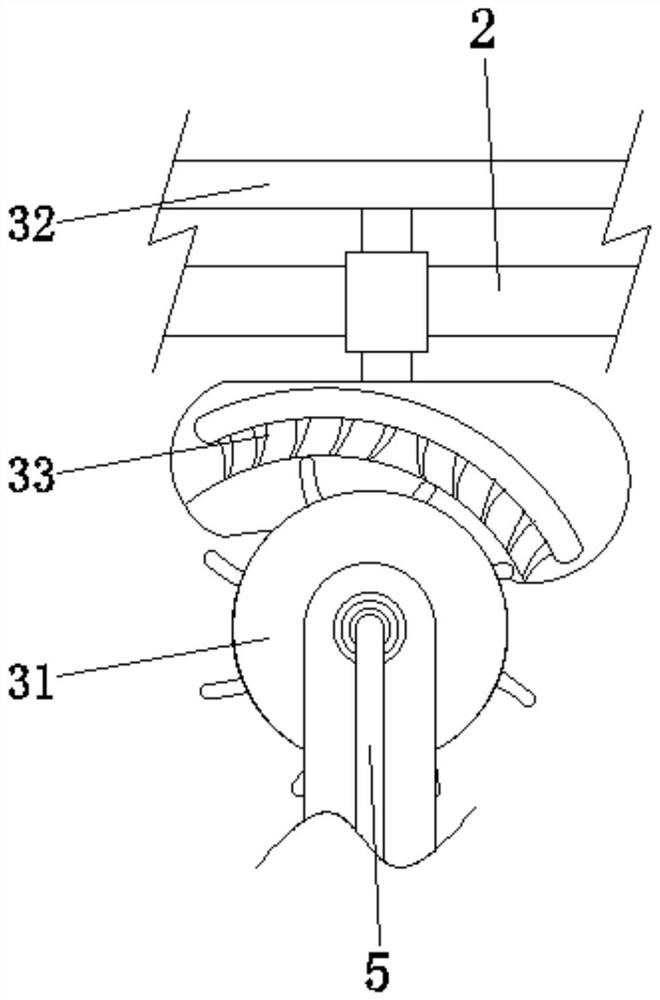

[0039] The drying head device 33 is provided with a base block 331, an arc-shaped gradual change groove 332, and a drying hole 333. The base block 331 is fixed on the bottom end of the connecting pipe 32, and the arc-shaped gradual change groove 332 is provided at the bottom of the base block 331, and the drying hole 333 Opened inside the base block 331 and located at the position of the arc-shaped gradual change groove 332 and communicated with the connecting pipe 32, when the dewatering roller device 31 is rotating, it removes water under the guidance of the arc-shaped gradual change groove 332, At the same time, the cloth will be tightly attached between the base block 331 and the dewatering roller device 31, and the water removal will be further facilitated by extrusion, and the evenly distributed drying holes 333 will output hot drying air to quickly dry the cloth.

[0040] During use, first move the drying head device 33 upwards for an appropriate distance through the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com