Tobacco water removal device

A tobacco and equipment technology, applied in the field of tobacco dehydration equipment, can solve the problems of easy generation of dust, high heat consumption, and environmental pollution when burning coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

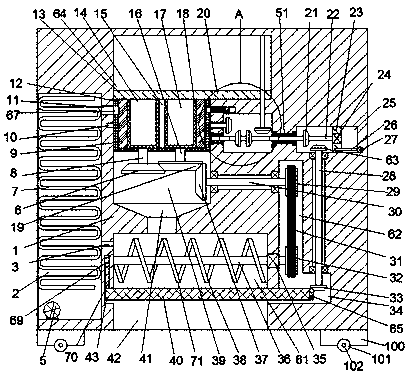

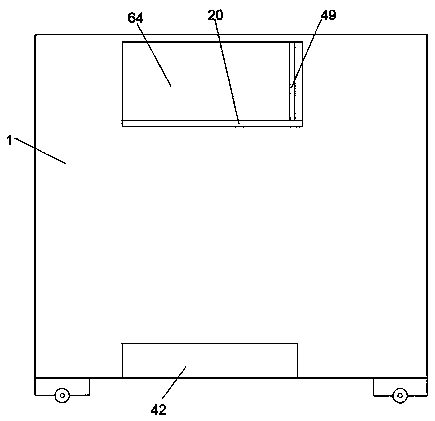

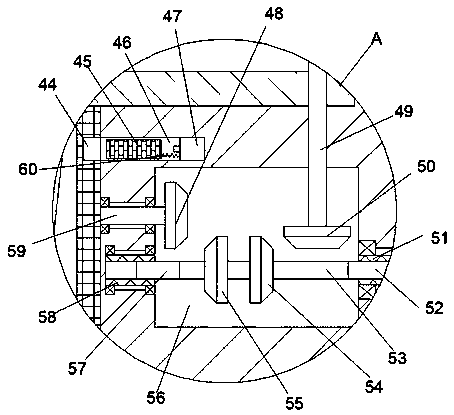

[0014] Combine below Figure 1-4 The present invention will be described in detail.

[0015] refer to Figure 1-4, a tobacco water removal device according to an embodiment of the present invention, comprising a main box body 1, an electric heating chamber 2 extending up and down is provided in the main box body 1, a heating mechanism is provided in the electric heating chamber 2, and a heating mechanism is located in the On the front end surface of the main box 1 on the right side of the electric heating chamber 2, there is a platen groove 64 extending backward. A first working cavity 39 extending downward is opened on the bottom end wall of the pressure plate groove 64 on the left side, and a first working cavity 39 extending left and right is provided in the main box 1 at the bottom of the first working cavity 39 . Two working chambers 61, the main box body 1 between the first working chamber 39 and the second working chamber 61 is provided with a funnel chamber 41, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com