Tea art tea leaf drying device

A tea drying device and tea art technology, applied in the direction of tea drying, drying, drying machine, etc., can solve the problems of staining, perishability, etc., and achieve the effect of easy collection and placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

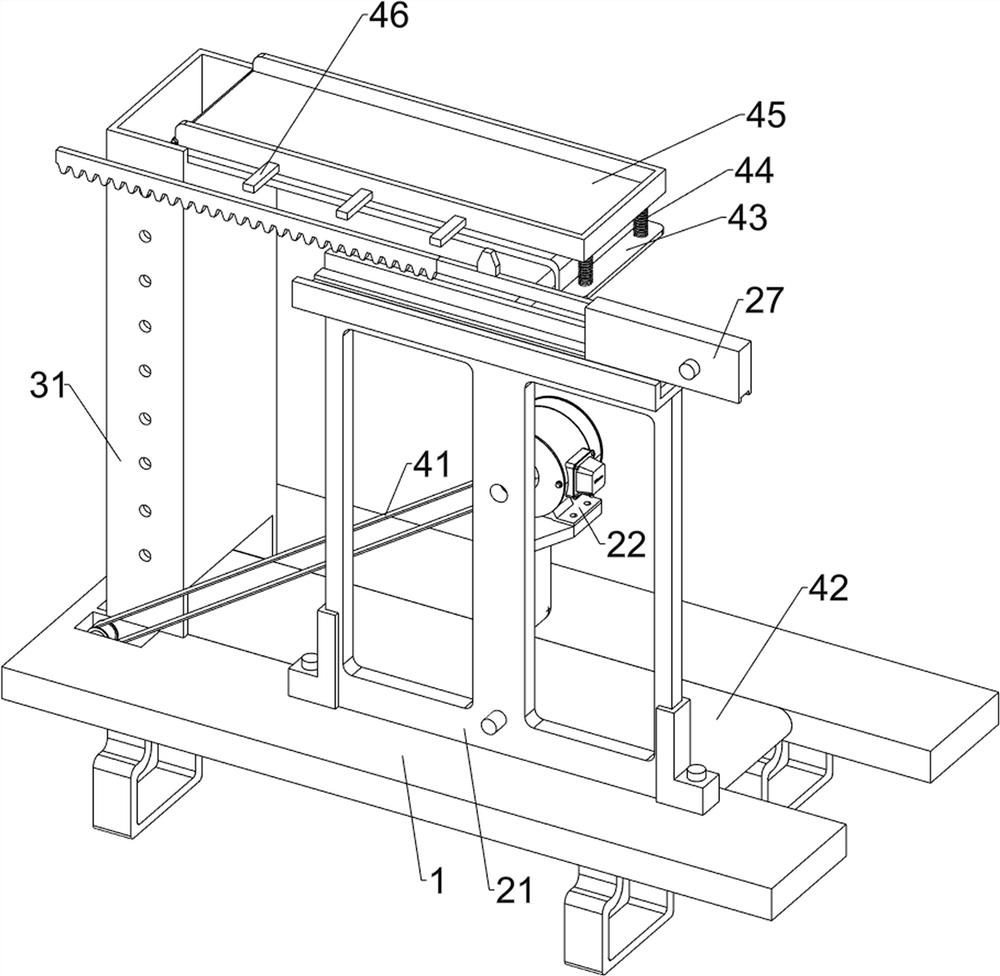

[0049] A tea art tea drying device, such as figure 1 As shown, it includes a mounting frame 1, a driving mechanism 2, a baking mechanism 3 and a blanking mechanism 4. The driving mechanism 2 is provided in the middle of the top of the mounting frame 1, and the baking mechanism 3 is provided on the left side of the top of the mounting frame 1. The baking mechanism 3 and the driving mechanism 2 are connected with a blanking mechanism 4 .

[0050] When the tea leaves need to be dried, the staff can first put the tea leaves on the 4 parts of the blanking mechanism, place a storage basket on the right side of the installation frame 1, and then start the driving mechanism 2 and the internal parts of the baking mechanism 3 to work. The driving mechanism 2 works to drive the blanking mechanism 4 and other parts of the baking mechanism 3 to work. The blanking mechanism 4 works to transport the tea to the parts of the baking mechanism 3. The baking mechanism 3 can dry the tea leaves, an...

Embodiment 2

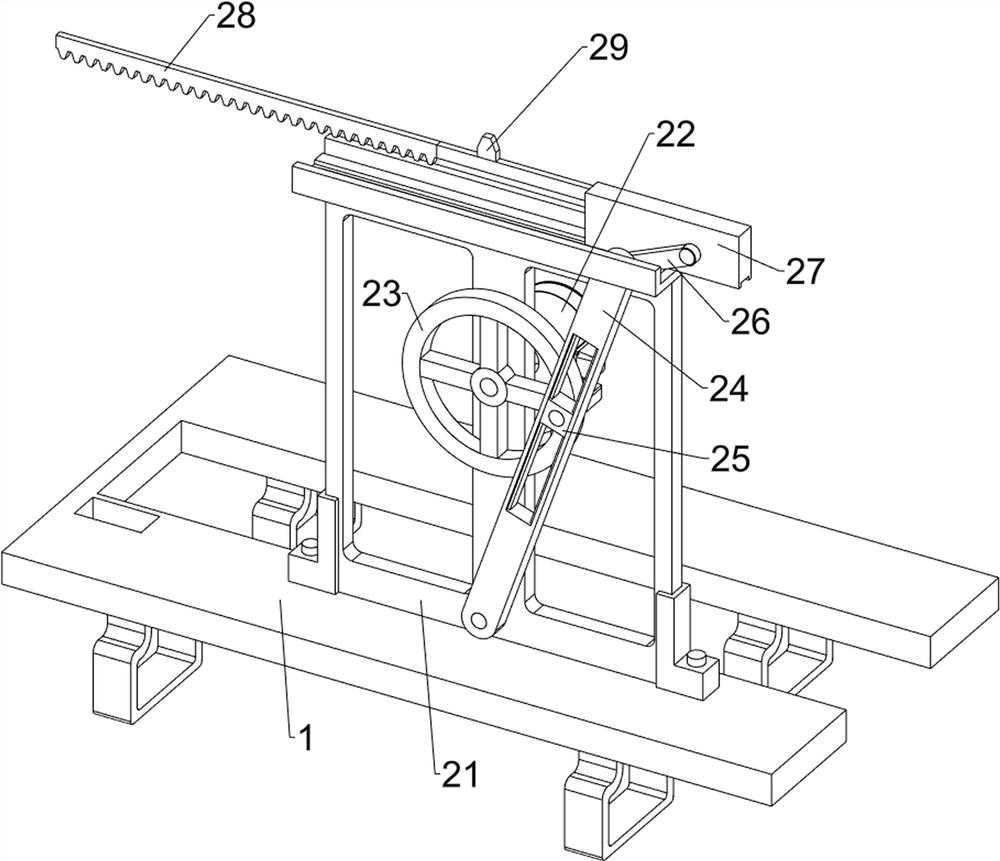

[0052] On the basis of Example 1, such as figure 2 As shown, the drive mechanism 2 includes a bracket 21, a motor 22, a turntable 23, a first connecting rod 24, a first slider 25, a second connecting rod 26, a second slider 27, a first rack 28 and a wedge 29 , the middle of the top of the mounting frame 1 is provided with a bracket 21, the middle part of the rear side of the bracket 21 is provided with a motor 22, the front end of the output shaft of the motor 22 is connected with a turntable 23, and the right side of the top of the bracket 21 is slidingly provided with a second slider 27, the second slider 27 left ends are provided with the first tooth bar 28, and the left side of the second slide block 27 top is provided with wedge block 29, and the right side of the front side of the second slide block 27 is rotated and is provided with the second connecting rod 26, and the left side of the second slide block 27 A first connecting rod 24 is rotatably connected with the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com